Active coupling agent for contact reaction of graphite and stainless steel and brazing method thereof

A technology of active connection and contact reaction, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as cracks, welding failures, large differences in thermal expansion coefficients, etc., to ensure mechanical properties and reduce welding. Thermal stress, the effect of improving the degree of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

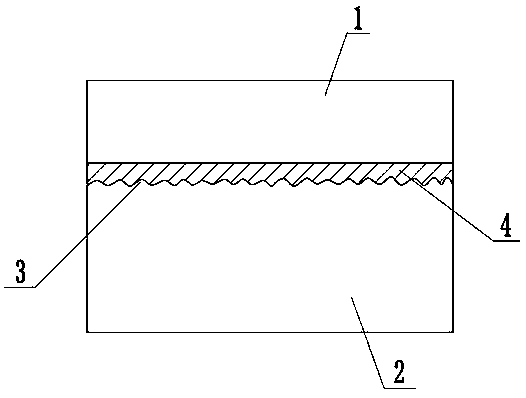

Image

Examples

Embodiment 1

[0023] A kind of active connecting agent for the contact reaction of graphite and stainless steel, comprising pure Cu powder, Ti powder, CuLi10 alloy powder and binding agent, the preparation method of active connecting agent is as follows: by mass fraction, get Ti powder 10%, CuLi10 powder 10% %, 10% binder, 70% Cu powder, and stir evenly to prepare a paste-like active linking agent.

[0024] Further, the particle size of the pure Cu powder is 100-200um, and the purity is greater than 99.99%; the particle size of the CuLi10 alloy powder is 250-350um.

[0025] Further, the binder is sodium silicate.

[0026] In the present invention, Li is used as an active agent and is added in the form of CuLi10 alloy powder. Its chemical properties are more lively, and it is a strong deoxidizer and degasser. At high temperatures, Li+O 2 = LiO 2 , LiO 2 Can form low-melting composite compounds with many oxides, such as Li 2 CrO 4 The melting point is 517°C, and LiO 2 It has a great aff...

Embodiment 2

[0037] A kind of active connecting agent for the contact reaction of graphite and stainless steel, comprising pure Cu powder, Ti powder, CuLi10 alloy powder and binding agent, the preparation method of active connecting agent is as follows: by mass fraction, get Ti powder 15%, CuLi10 powder 40 %, 10% binder, 35% Cu powder, and stir evenly to prepare a paste-like active linker.

[0038] Further, the particle size of the pure Cu powder is 100-200um, and the purity is greater than 99.99%; the particle size of the CuLi10 alloy powder is 150-250um.

[0039] Further, the binder is sodium silicate.

[0040] In the present invention, Li is used as an active agent and is added in the form of CuLi10 alloy powder. Its chemical properties are more lively, and it is a strong deoxidizer and degasser. At high temperatures, Li+O 2 = LiO 2 , LiO 2 Can form low-melting composite compounds with many oxides, such as Li 2 CrO 4 The melting point is 517°C, and LiO 2 It has a great affinity fo...

Embodiment 3

[0051] A kind of active connecting agent for the contact reaction of graphite and stainless steel, comprising pure Cu powder, Ti powder, CuLi10 alloy powder and binding agent, the preparation method of active connecting agent is as follows: by mass fraction, get Ti powder 20%, CuLi10 powder 60% %, binder 10%, Cu powder 10%, stir well and prepare active linking agent into paste.

[0052] Further, the particle size of the pure Cu powder is 75-100um, and the purity is greater than 99.99%; the particle size of the CuLi10 alloy powder is 150-250um.

[0053] Further, the binder is sodium silicate.

[0054] In the present invention, Li is used as an active agent and is added in the form of CuLi10 alloy powder. Its chemical properties are more lively, and it is a strong deoxidizer and degasser. At high temperatures, Li+O 2 = LiO 2 , LiO 2 Can form low-melting composite compounds with many oxides, such as Li 2 CrO 4 The melting point is 517°C, and LiO 2 It has a great affinity fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com