Diamond/silicon carbide composite material and preparing method thereof

A technology of composite materials and silicon carbide, which is applied in the field of diamond/silicon carbide composite materials and its preparation, can solve the problems of easy deformation of composite materials, uneven microstructure, incomplete siliconization reaction, etc., and achieve active chemical properties and microstructure The effect of uniform structure and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

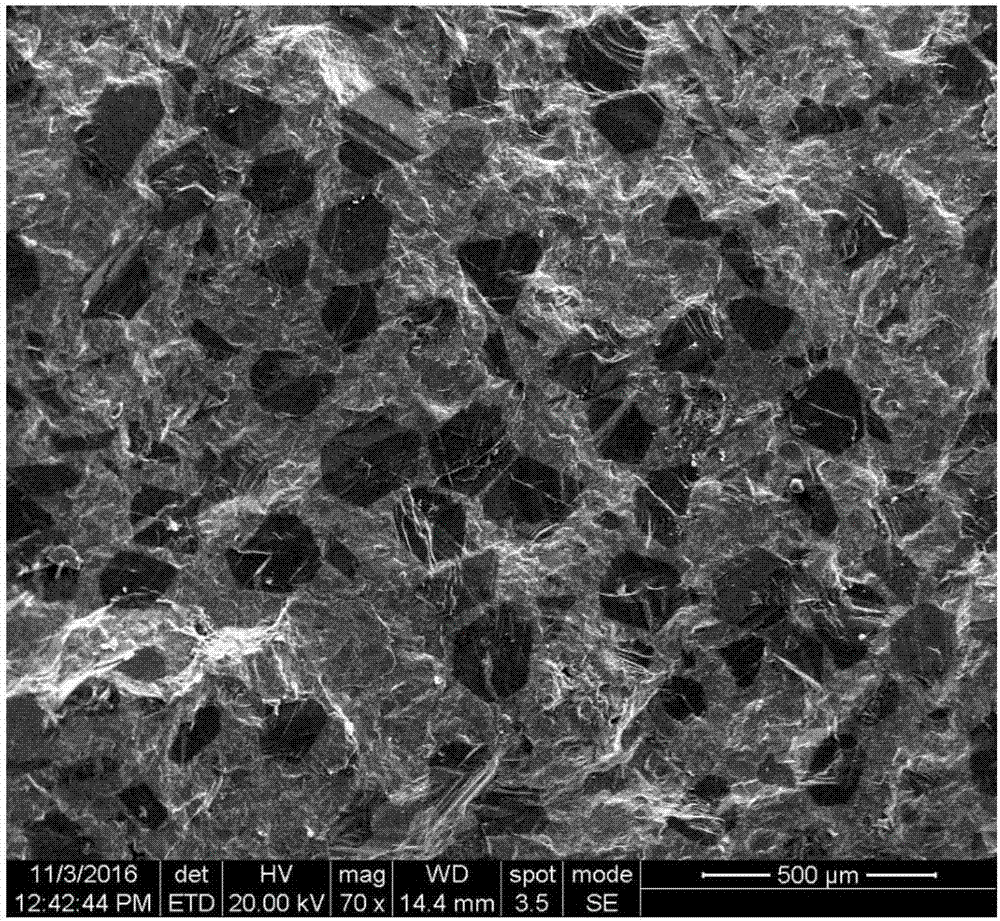

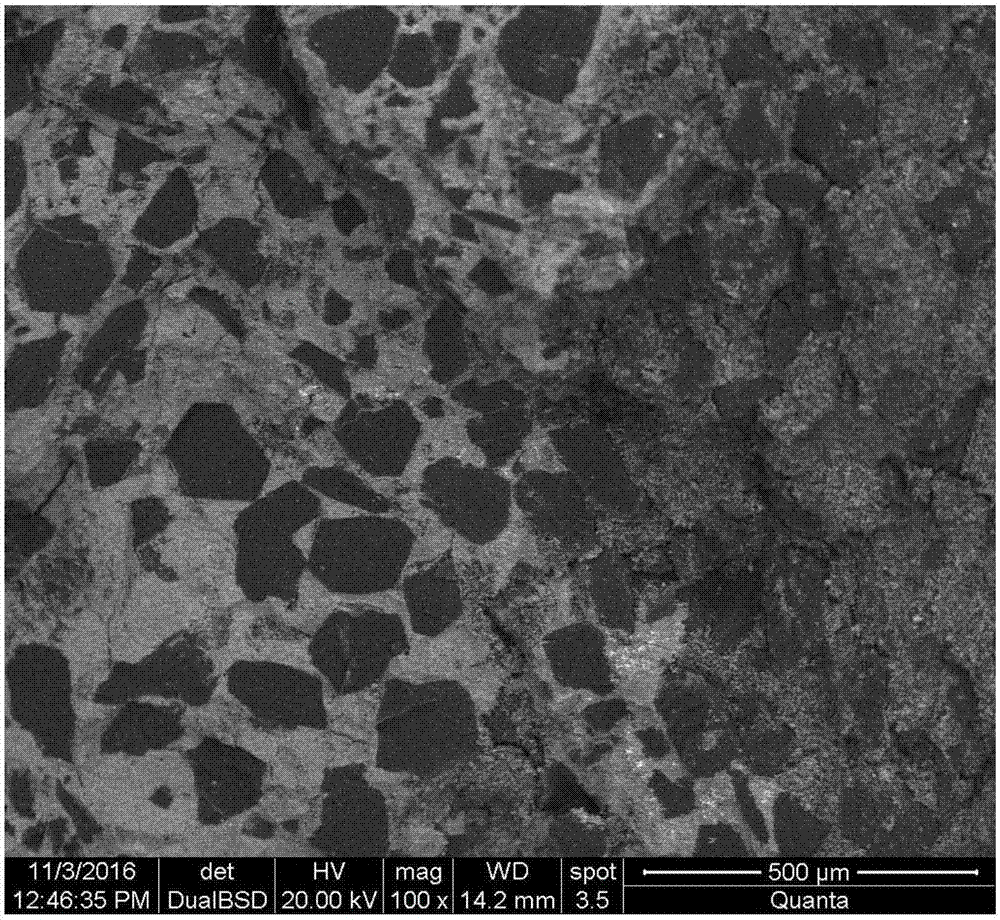

Image

Examples

Embodiment 1

[0026] Raw materials: 10g of phenolic resin, 15g of carbon black, 15g of silicon carbide, and 60g of 50-mesh diamond.

[0027] Preparation method: at room temperature, firstly add carbon powder and phenolic resin to the ball mill and mix them with alcohol, then put them on the ball mill for 4 hours, then add silicon carbide ball mill for 4 hours, and finally add diamond ball mill for 1 hour; after drying, dry, crush and sieve to obtain Composite material; at room temperature, the composite material was press molded at 150 MPa to obtain a green body; then placed in a cracking furnace for 3 hours under the protection of 1100° C. argon to crack to obtain a porous green body.

[0028] Put the porous green compact in a siliconizing furnace at 1700°C for 1 hour to obtain a diamond / silicon carbide ceramic matrix composite material.

Embodiment 2

[0030] Raw materials: 10g of phenolic resin, 10g of carbon black, 30g of silicon carbide, 50g of 50 mesh diamond.

[0031] At normal temperature, the above raw materials are mixed with alcohol and placed on a ball mill for 8 hours to disperse, dried in the air, crushed, sieved, molded at normal temperature, and then placed in a cracking furnace under the protection of argon at 1000°C for cracking. Finally, it is placed in a siliconizing furnace at 1600°C for siliconizing, and finally a dense high-performance diamond / silicon carbide ceramic matrix composite material is obtained.

Embodiment 3

[0033] Mix 10g of phenolic resin, 10g of carbon black, 20g of silicon carbide, and 60g of 50-mesh diamond. At room temperature, mix them with alcohol and put them on a ball mill for 8 hours to disperse. After drying, dry, pulverize, sieve, and use Molded at room temperature, and then placed in a cracking furnace for cracking under the protection of argon at 1000°C. Finally, it is placed in a siliconizing furnace at 1650°C for siliconizing, and finally a dense high-performance diamond / silicon carbide ceramic matrix composite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com