Coating method for plasma deposition after laser evaporation

A technology of plasma deposition and laser evaporation, which is applied in the direction of fusion spraying, metal material coating process, coating, etc., can solve the problems of long time consumption, high cost, overheating of parts, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention provides a coating method for plasma deposition after laser evaporation, comprising the following steps:

[0029] S1, using a plasma accelerator directed to the surface of the part to be sprayed, the plasma accelerator generating a plasma flow, and providing laser radiation perpendicular to the plasma flow;

[0030] S2, generating vapor by focusing the evaporation target with laser radiation;

[0031] S3, depositing the vapor generated in step S2 on the surface of the part to be sprayed by indirect plasma jet, finally forming a thin film coating.

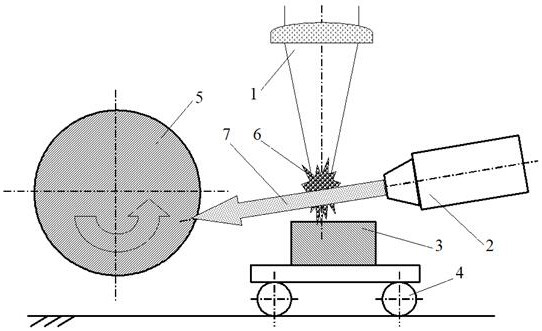

[0032] Specifically, such as figure 1 as shown, figure 1 Indicates the principle of plasma deposition after laser evaporation. Laser radiation 1 is focused by a plasma jet generated by a plasma accelerator 2 onto the surface of a target 3 made of the metal to be sprayed. The target is placed on the movable platform 4 to ensure that it has continuous movement, a stable evaporation process and prevent local ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser intensity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com