Laser evaporation coating device

A coating device and laser evaporation technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of low heating melting point, pollution of vacuum cavity, and inability to heat high melting point metal materials, etc., to achieve Effects of reduced pollution, high evaporation rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

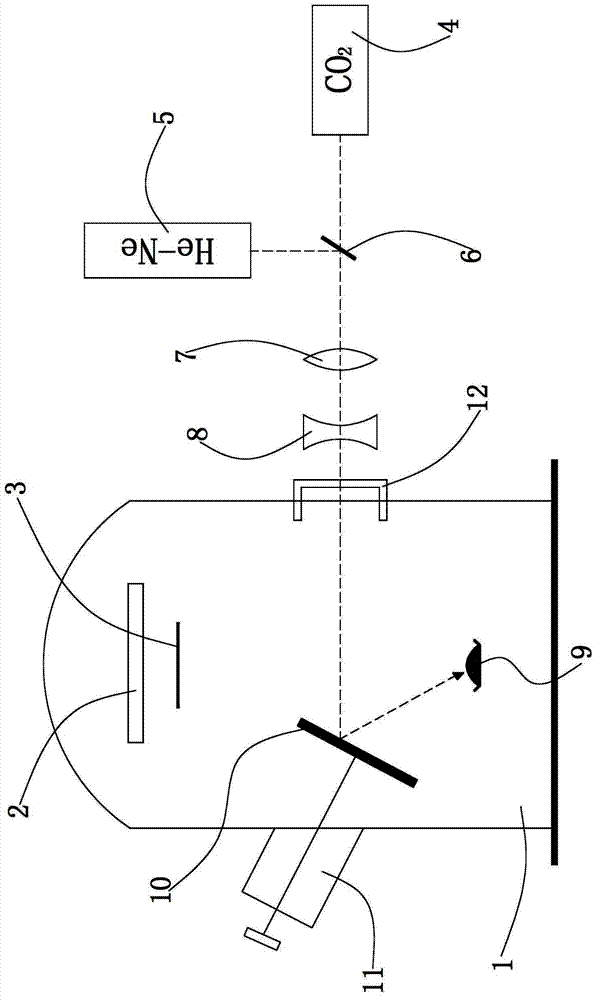

[0023] Such as figure 1 As shown, a laser evaporation coating device includes a vacuum reaction chamber 1, a substrate frame 2, an adjustable baffle 3, a CO 2 Laser 4 , a He-Ne laser 5 , a beam splitter 6 , a focusing convex lens 7 , a defocusing concave lens 8 , a pincer 9 , a mirror 10 , and a mirror adjustment device 11 .

[0024] The side wall of the vacuum reaction chamber 1 is sealed with a window 12 made of Ge or ZnSe material.

[0025] The substrate frame 2 is arranged in the vacuum reaction chamber 1 for placing the substrate or substrate to be coated.

[0026] The CO 2 The laser 4 is located outside the vacuum reaction chamber 1 and arranged horizontally, and its laser emits laterally and is opposite to the window 12 .

[0027] The He-Ne laser 5 is located outside the vacuum reaction chamber 1 and arranged vertically, and emits laser light longitudinally.

[0028] The beam splitter 6 is located outside the vacuum reaction chamber 1 and is located in the CO at an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com