Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Fiber tract" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

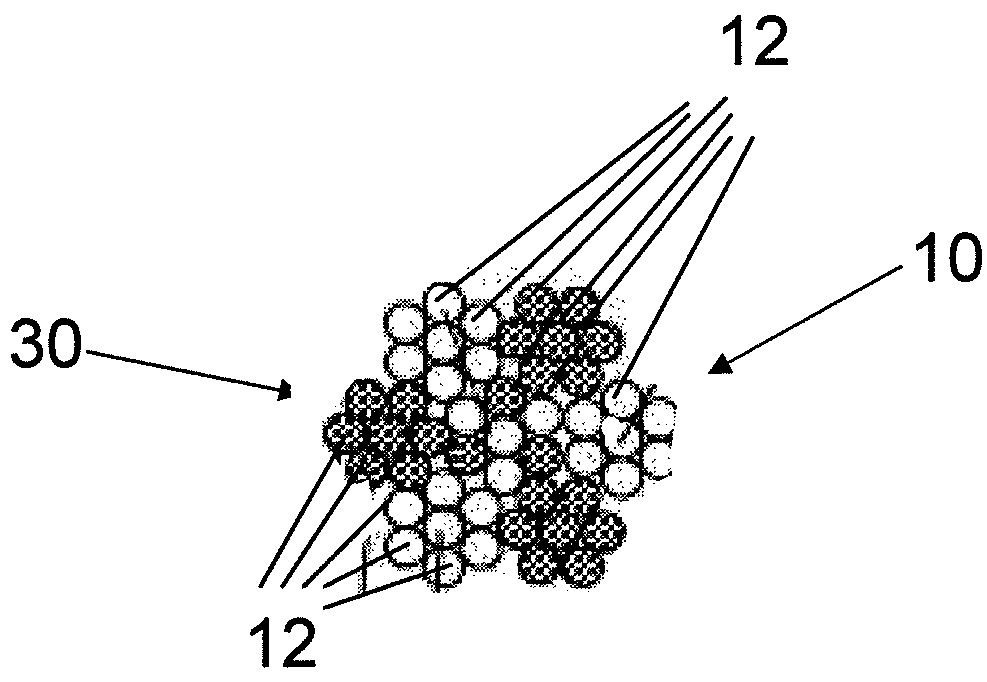

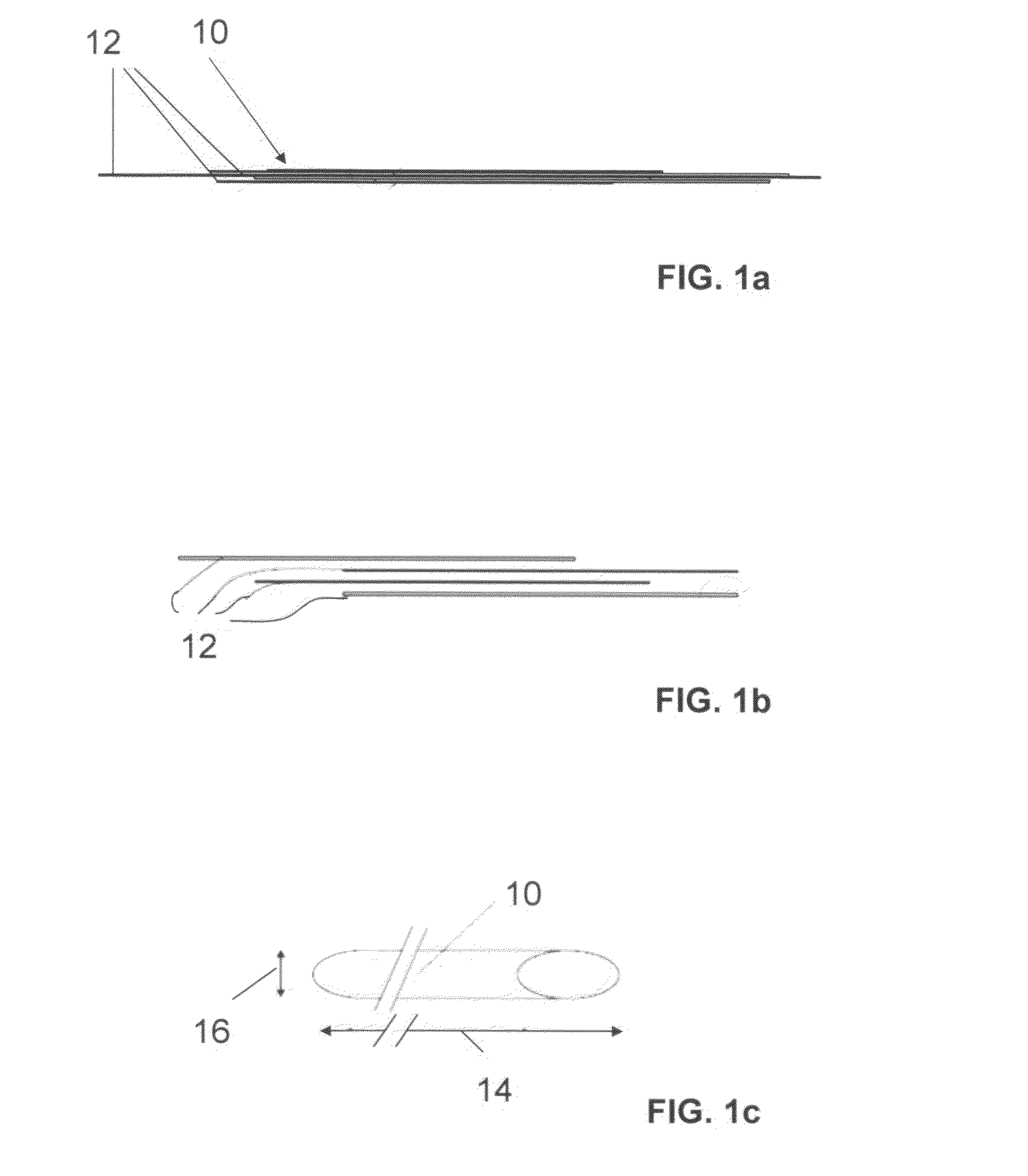

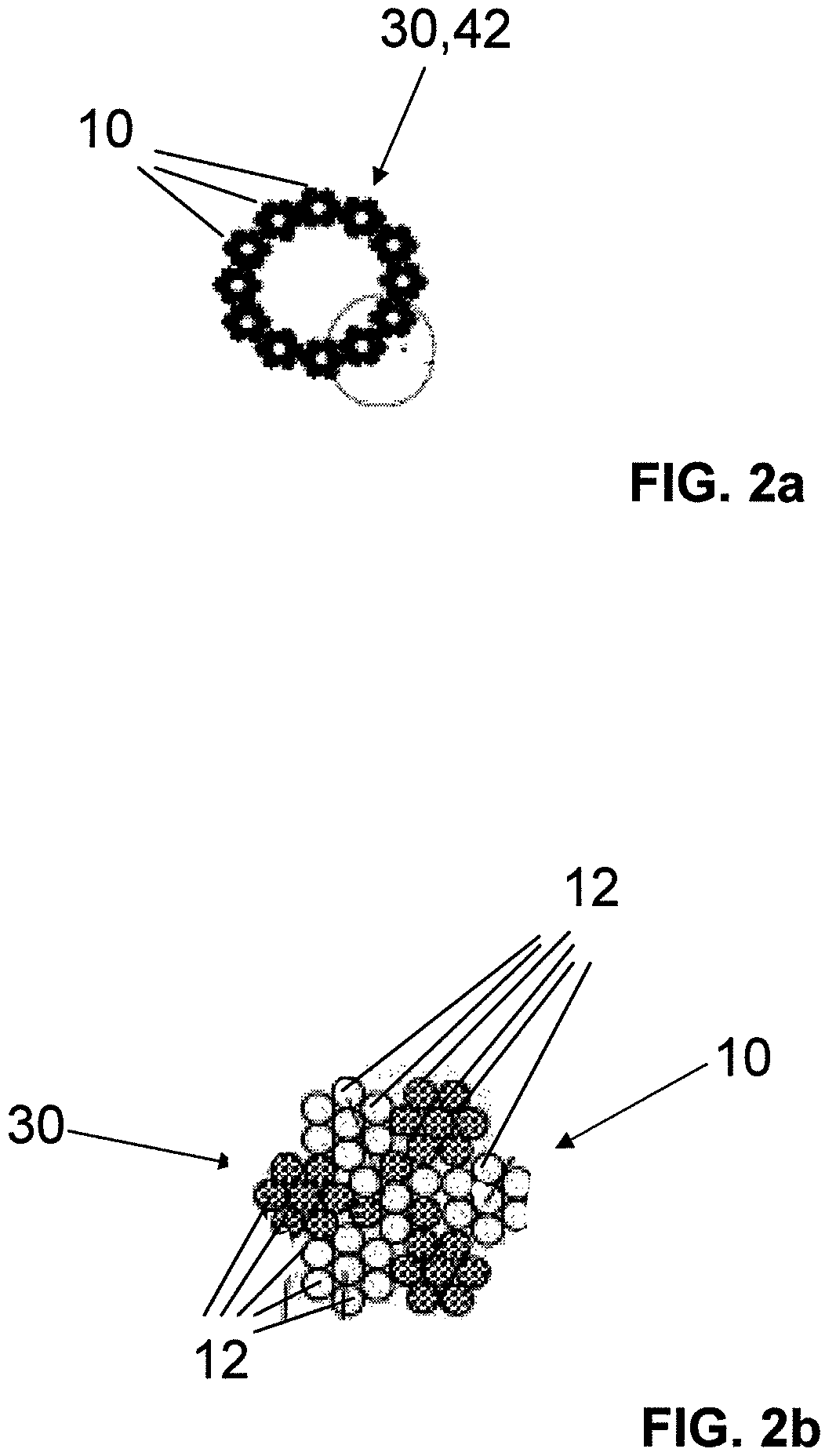

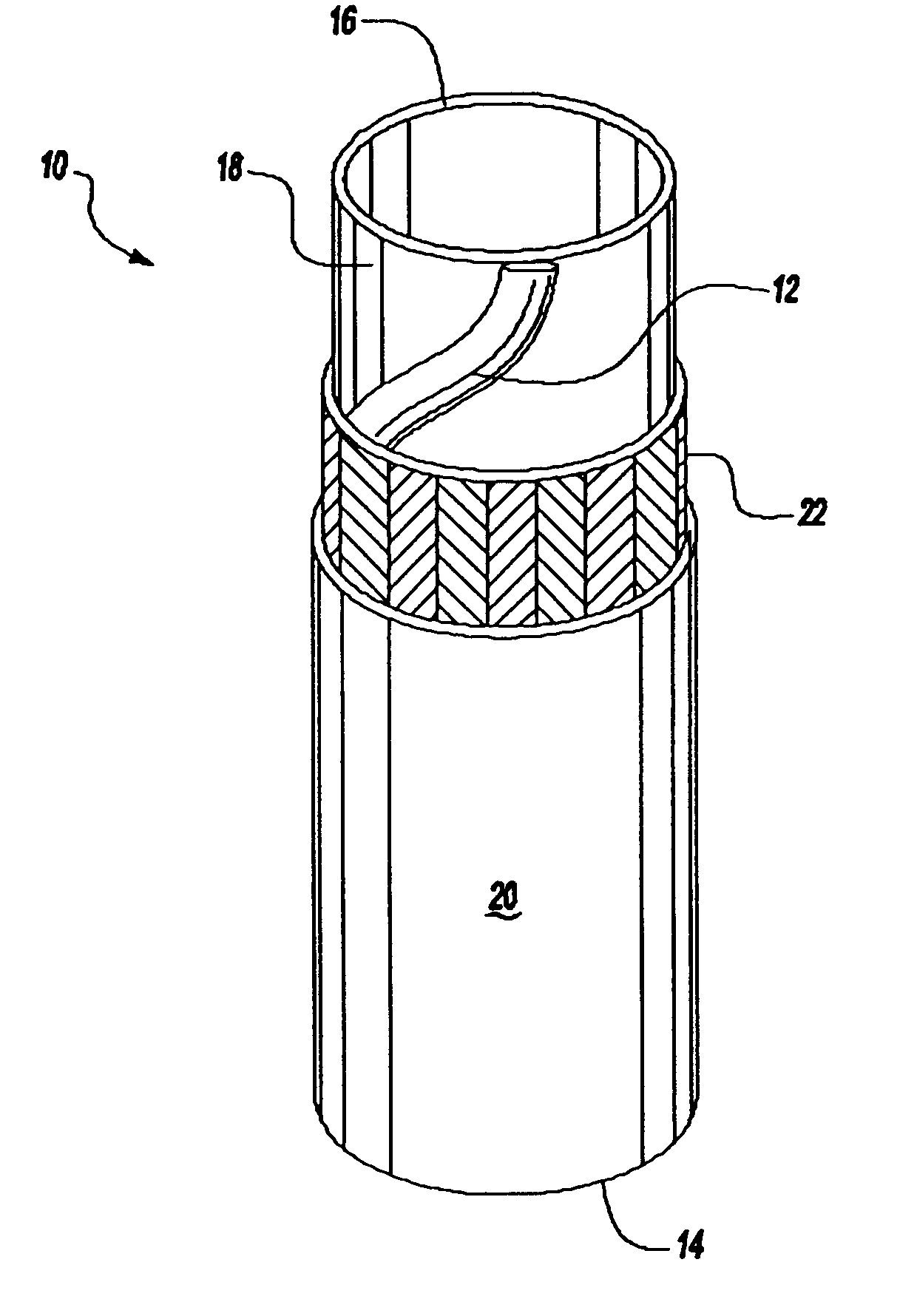

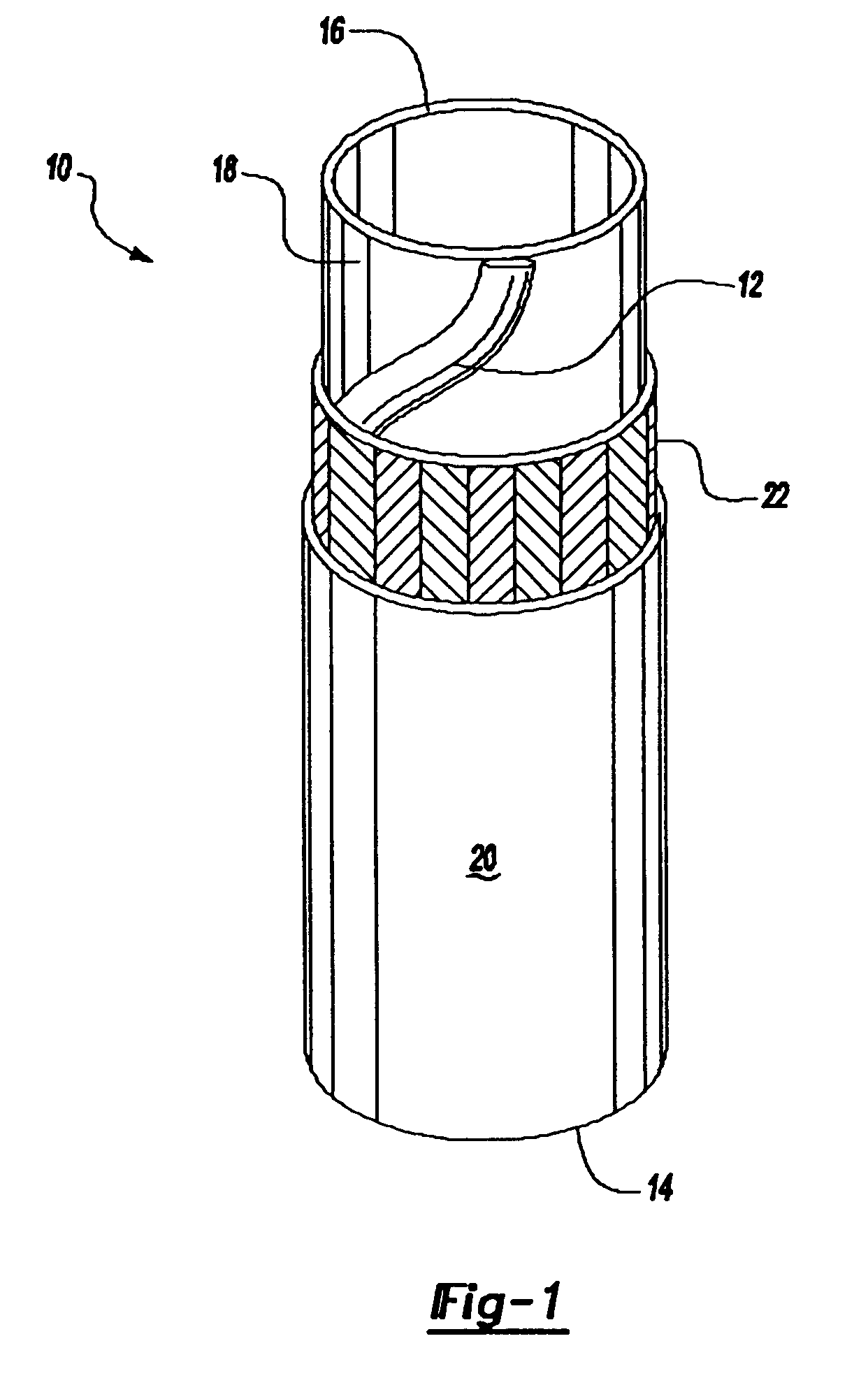

Fiber strand and implantable supporting body having a fiber strand

InactiveUS7997054B2Desired mechanical properties can be adjusted especially easilySignificant positive effectPowder deliveryStentsFiberBiomedical engineering

The invention relates to a fiber strand (10) for an implantable supporting body (100) comprising at least two individual fibers (12). The at least two individual fibers (12) are each shorter in their longitudinal extent than the longitudinal extent (14) of the fiber strand, and in their transverse extent they are each thinner than the transverse extent (16) of the fiber strand.

Owner:BIOTRONIK AG

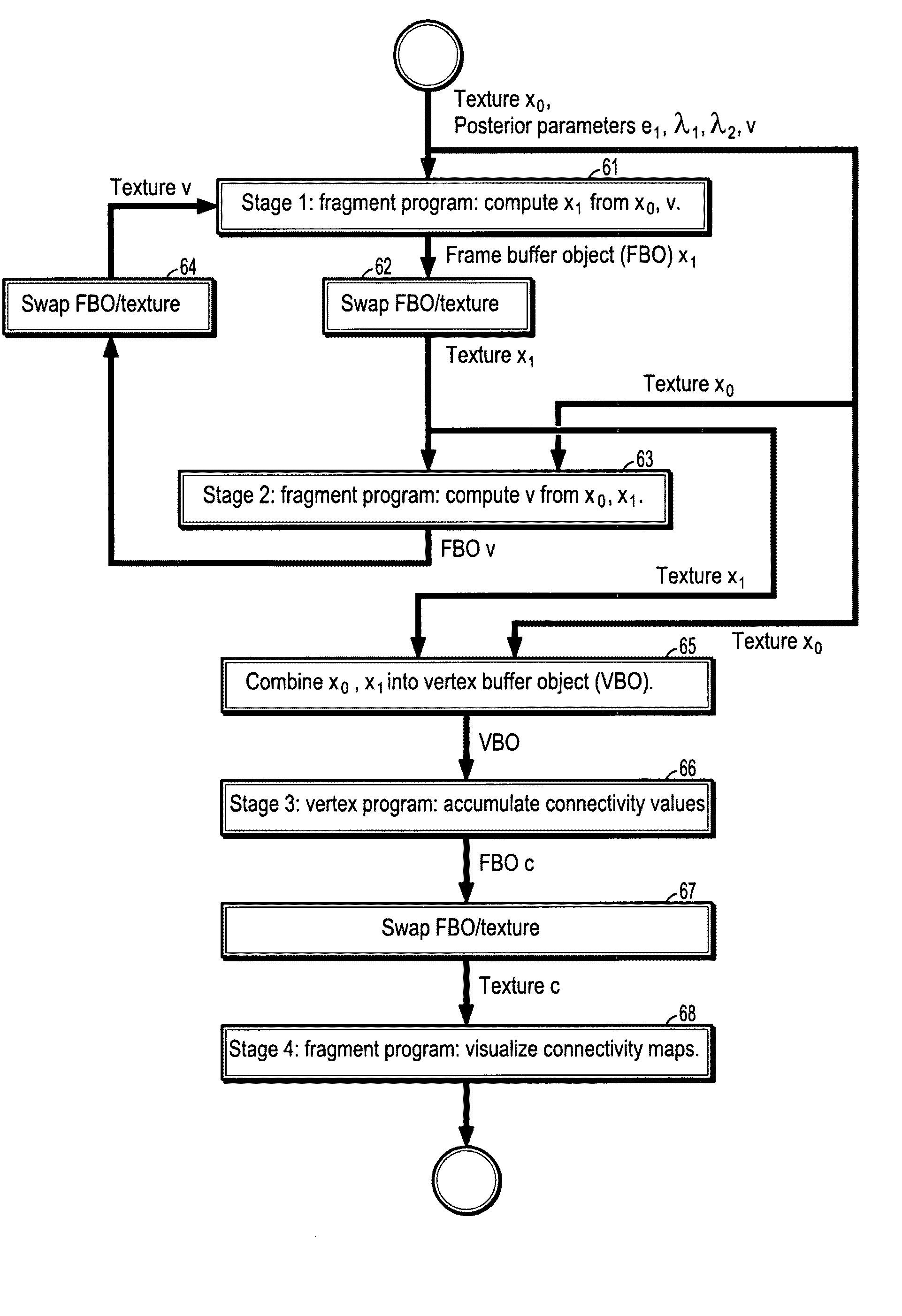

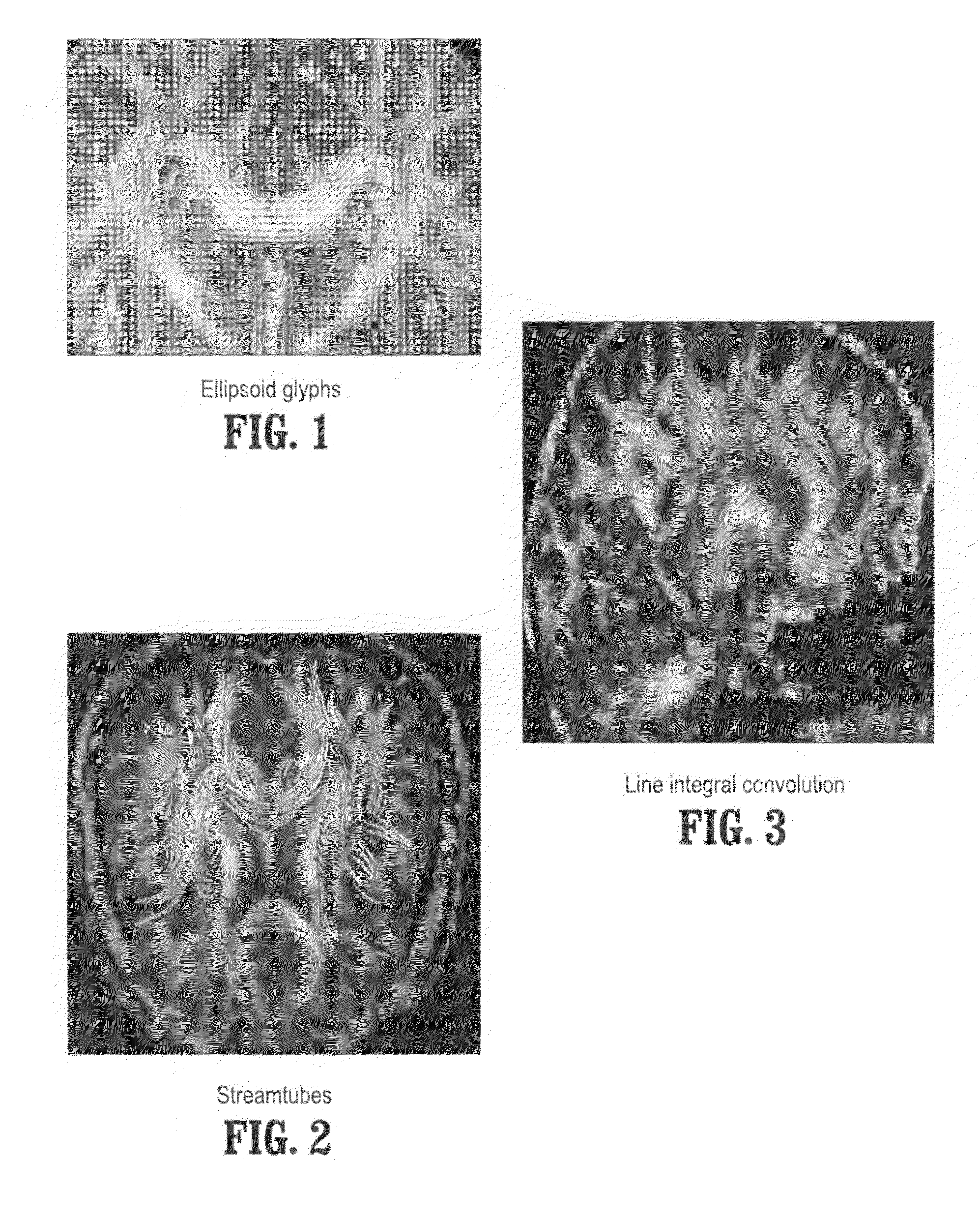

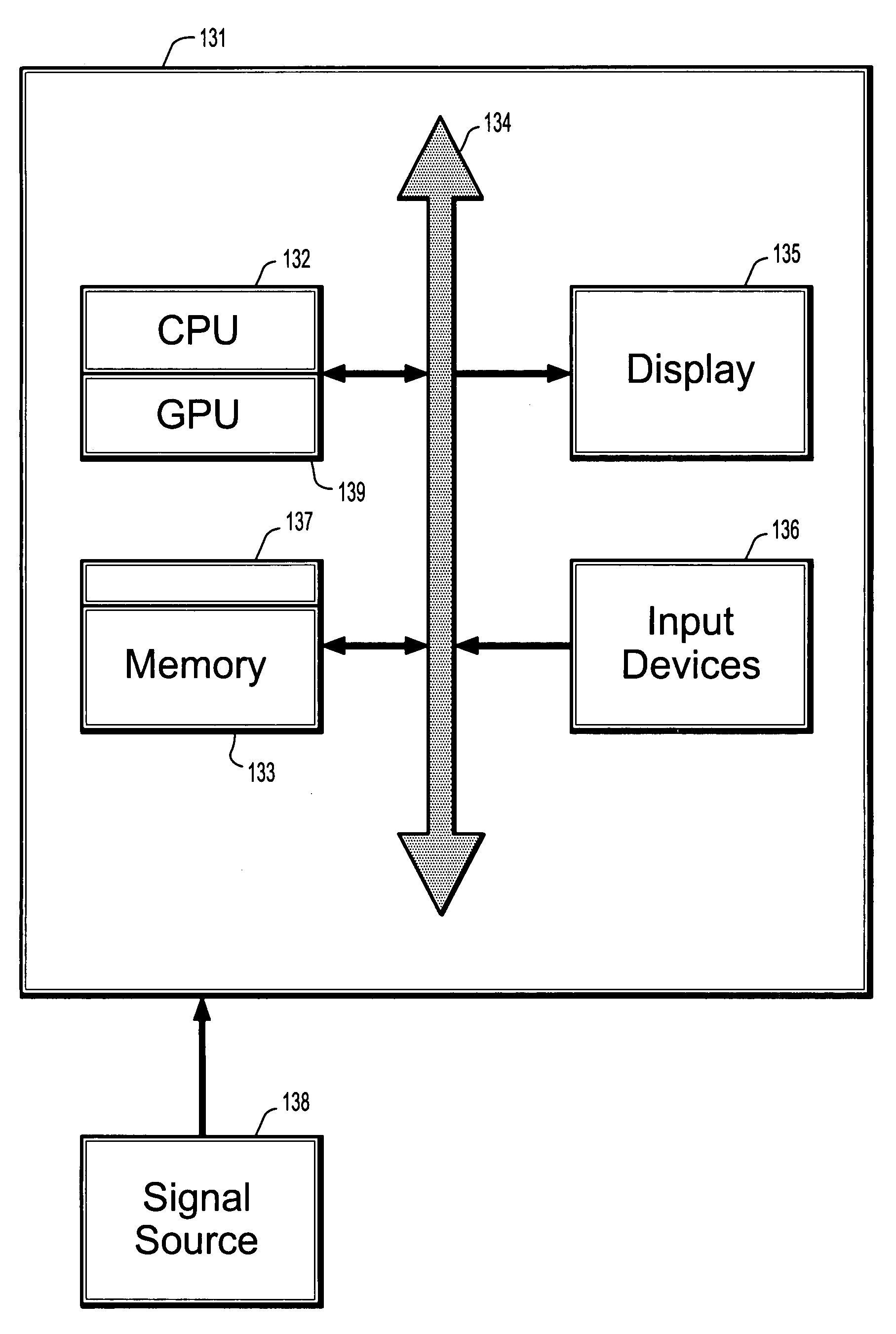

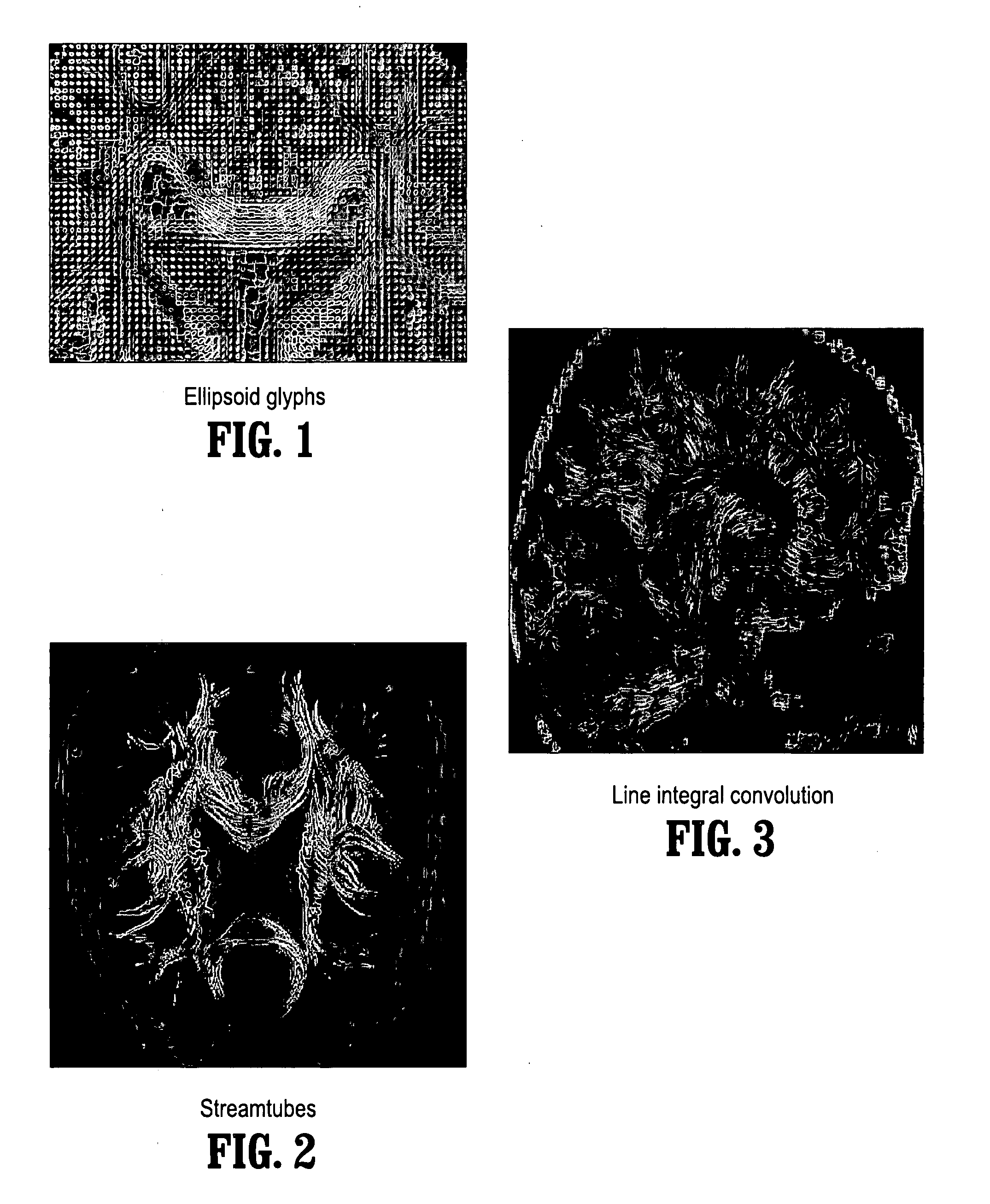

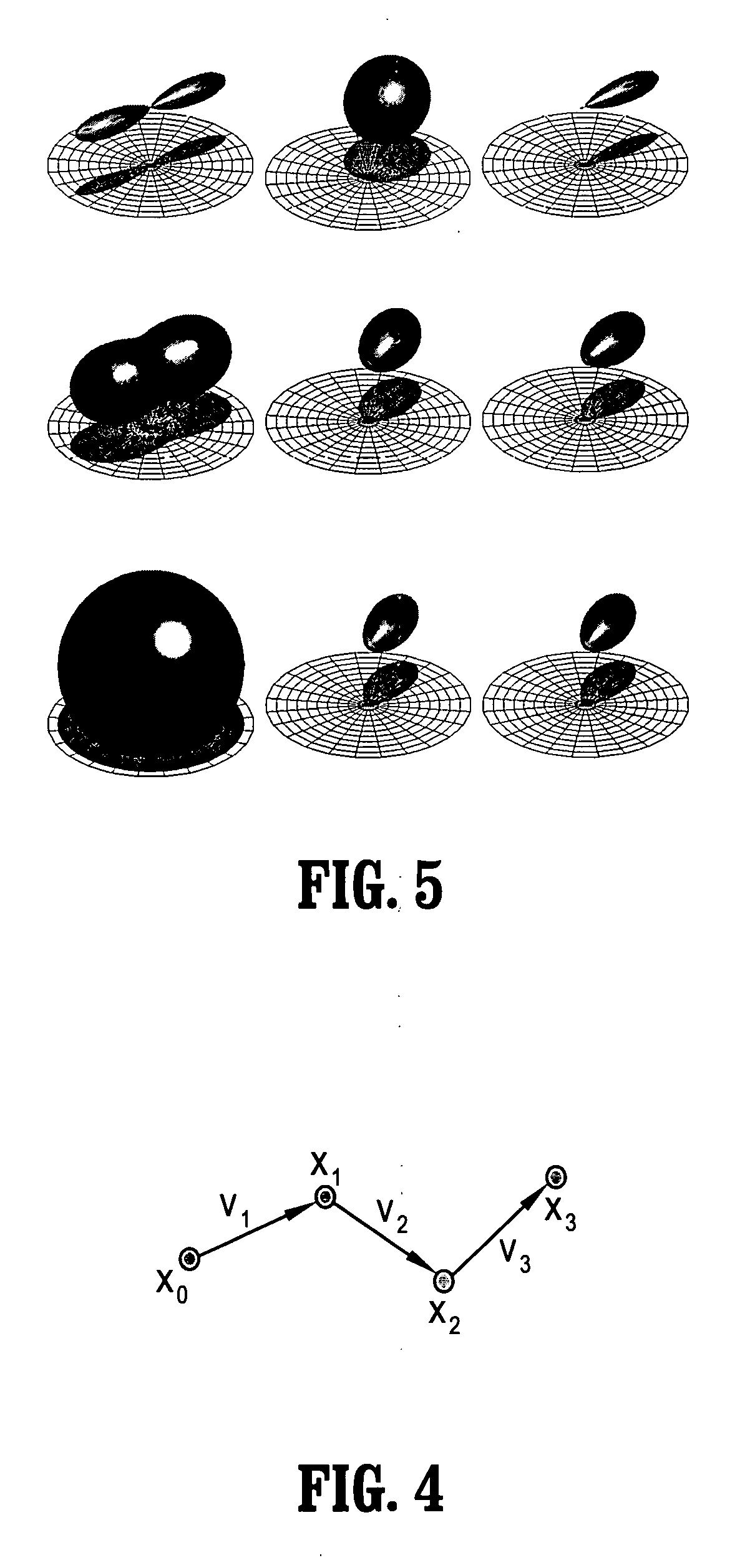

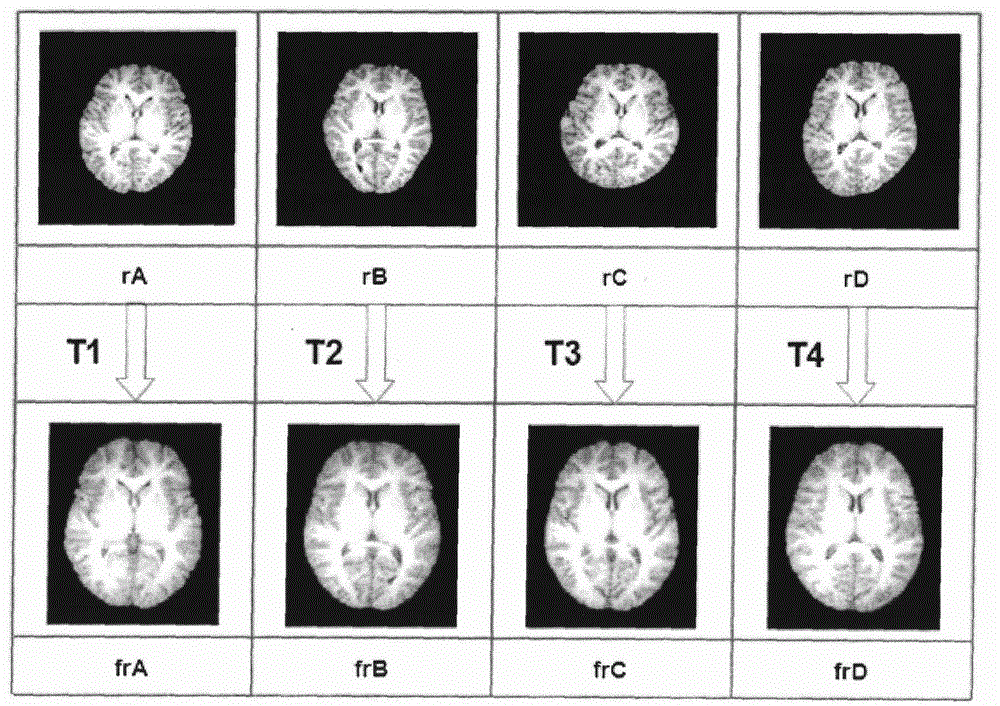

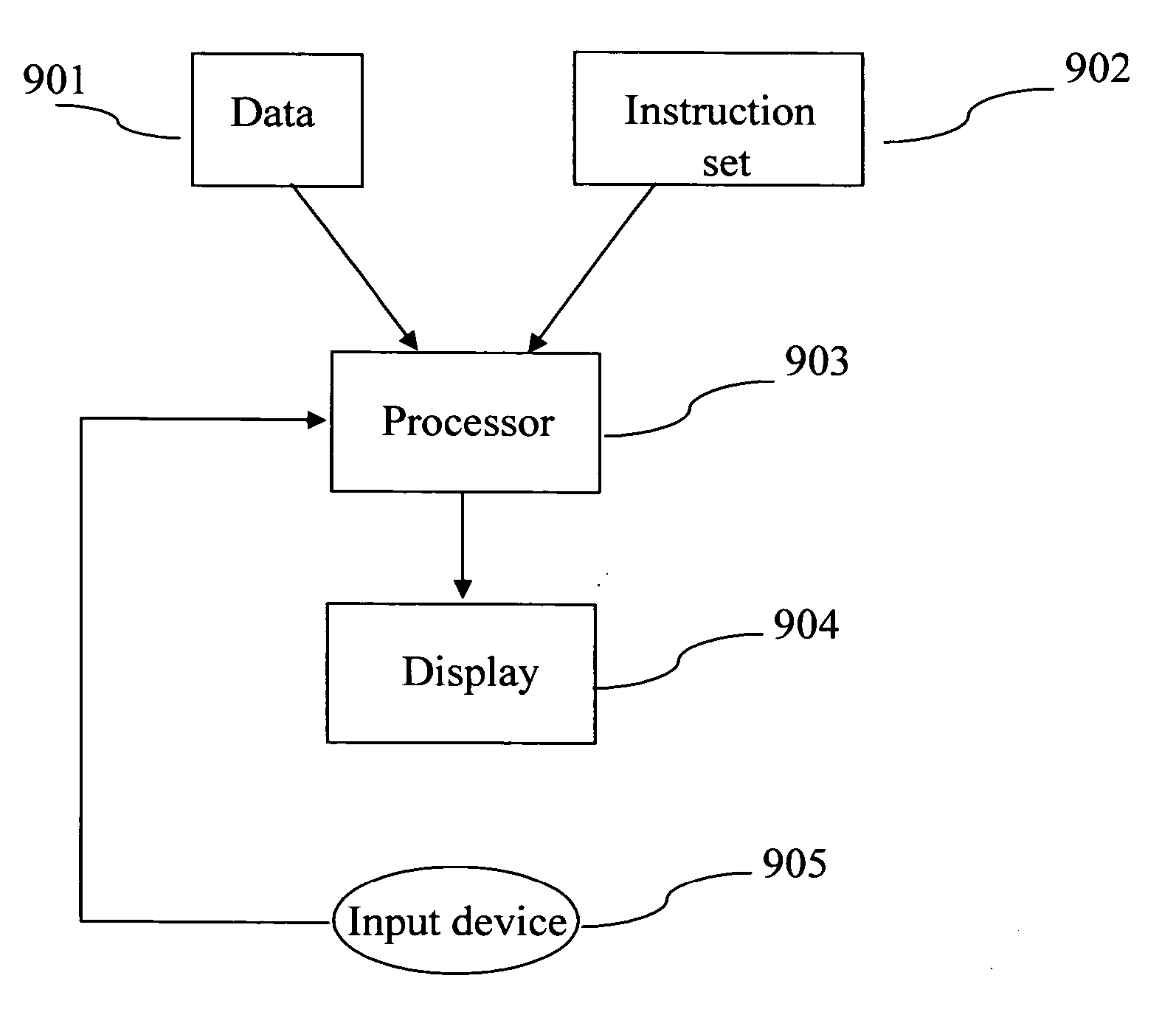

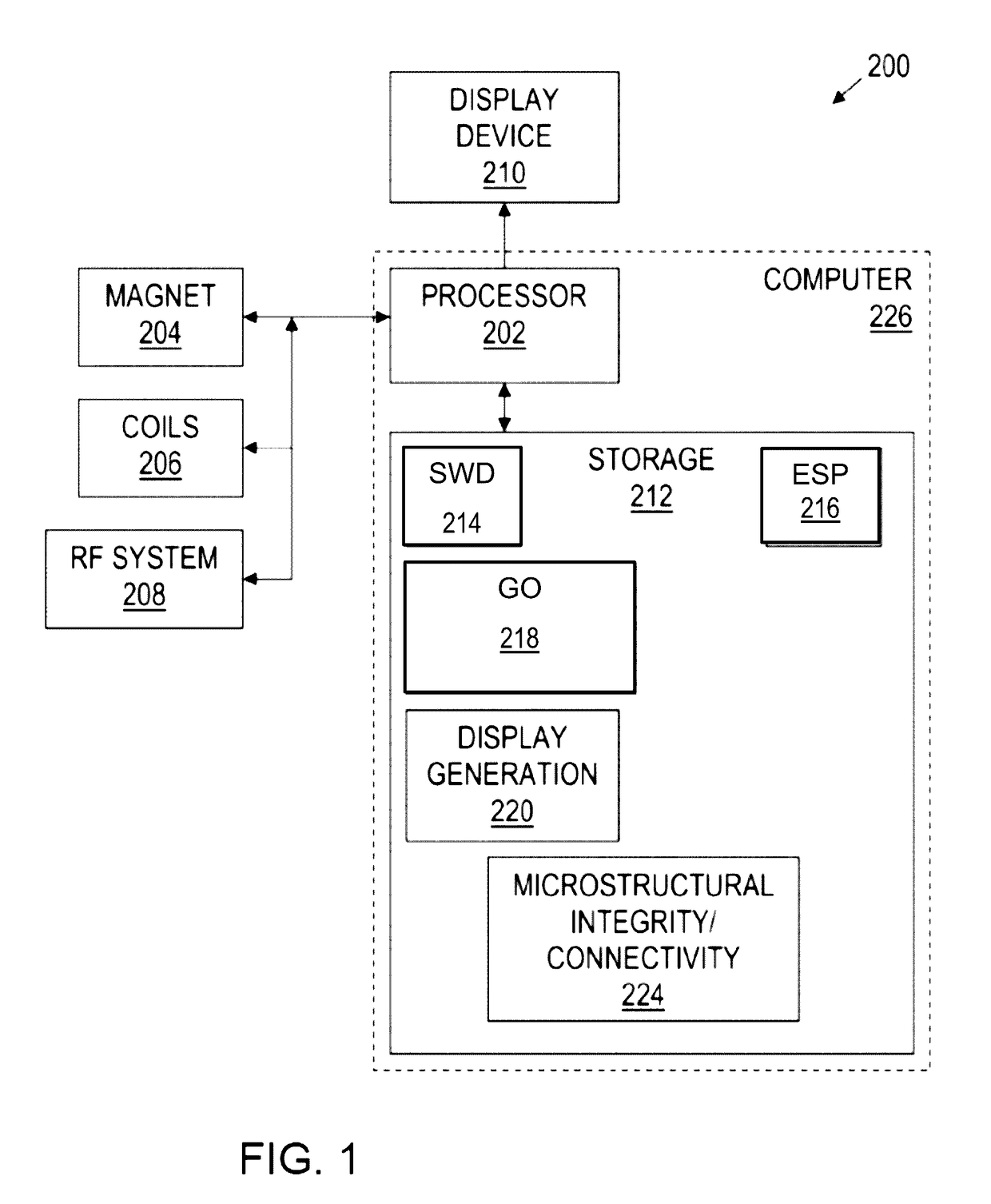

System and method for stochastic DT-MRI connectivity mapping on the GPU

InactiveUS7672790B2Highly parallelizableDrawing from basic elementsMagnetic measurementsGraphicsDiffusion

A graphics processing unit implemented method for fiber tract mapping from diffusion tensor magnetic resonance imaging data includes providing a diffusion tensor magnetic resonance brain image volume, initializing a set of fiber positions in a 3D set of points, fiber displacements, and a posterior distribution for an updated fiber displacement in terms of the initial displacements and diffusion tensors, randomly sampling a set of updated fiber displacements from said posterior distribution, computing a new set of fiber positions from said initial fiber positions and said updated fiber displacements, wherein a fiber path comprises a set of fiber points connected by successive fiber displacements, accumulating connectivity values in each point of said 3D set of points by additive alpha-blending a scaled value if a fiber path has passed through a point and adding zero if not, and rendering said connectivity values.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

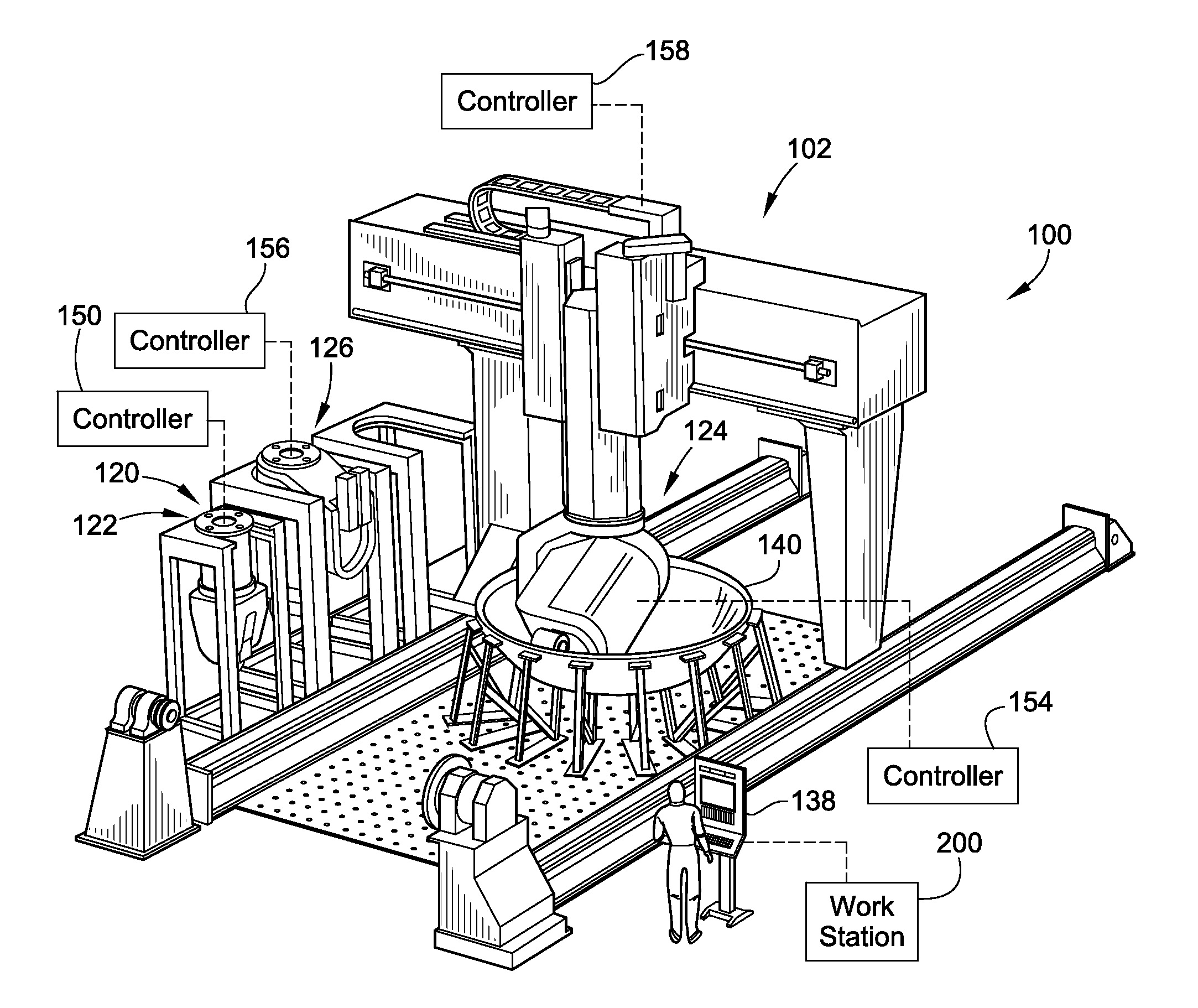

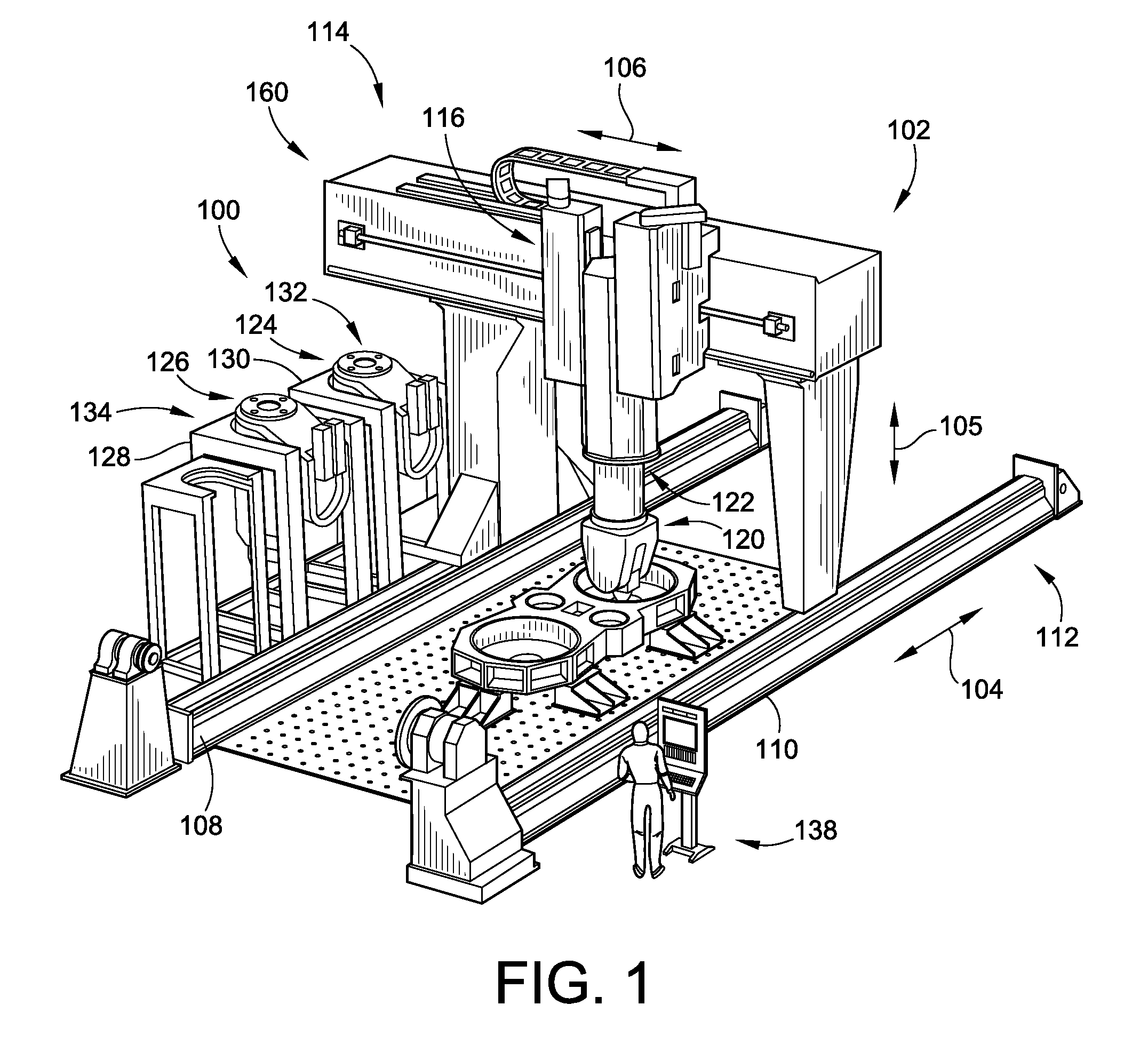

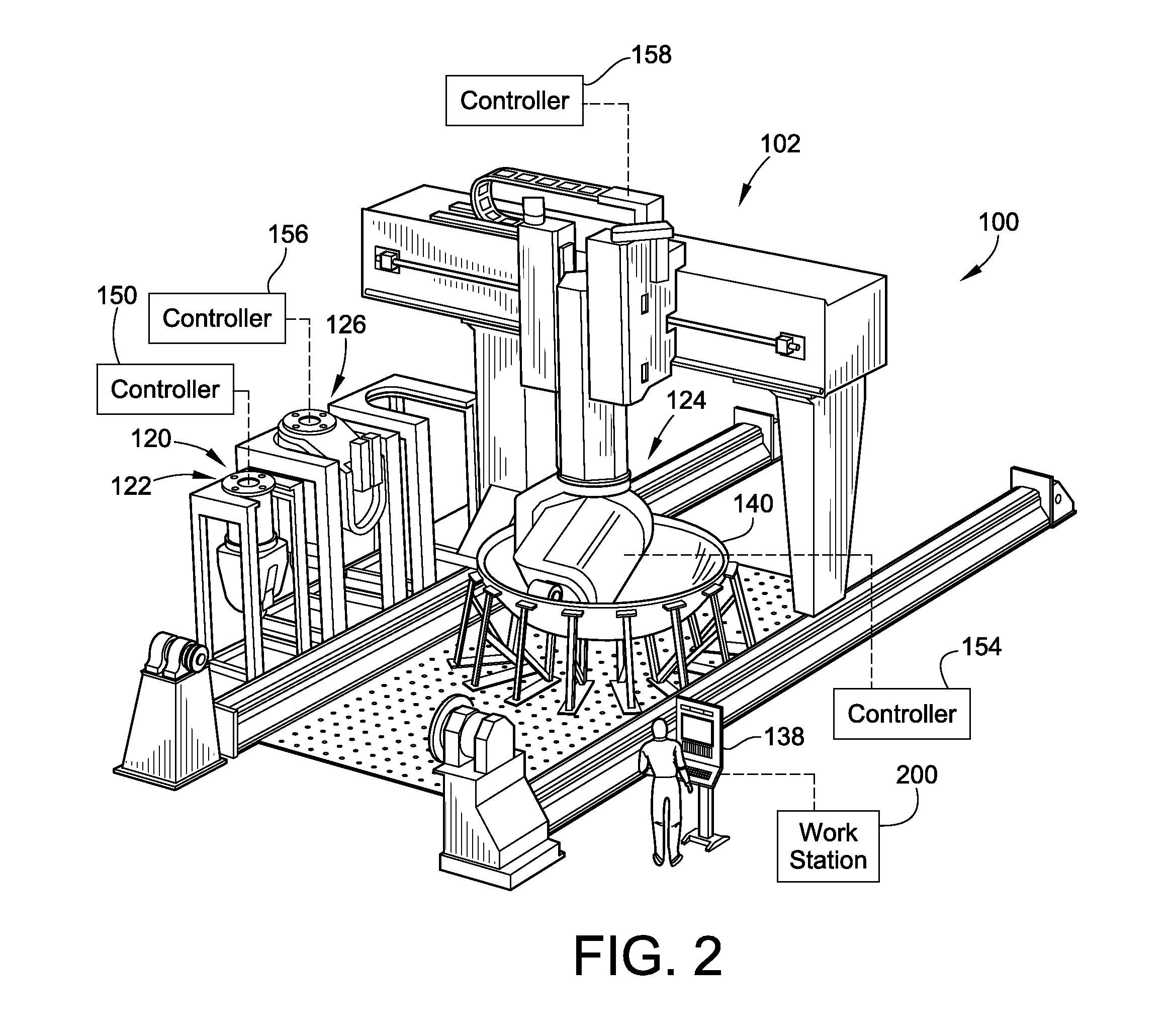

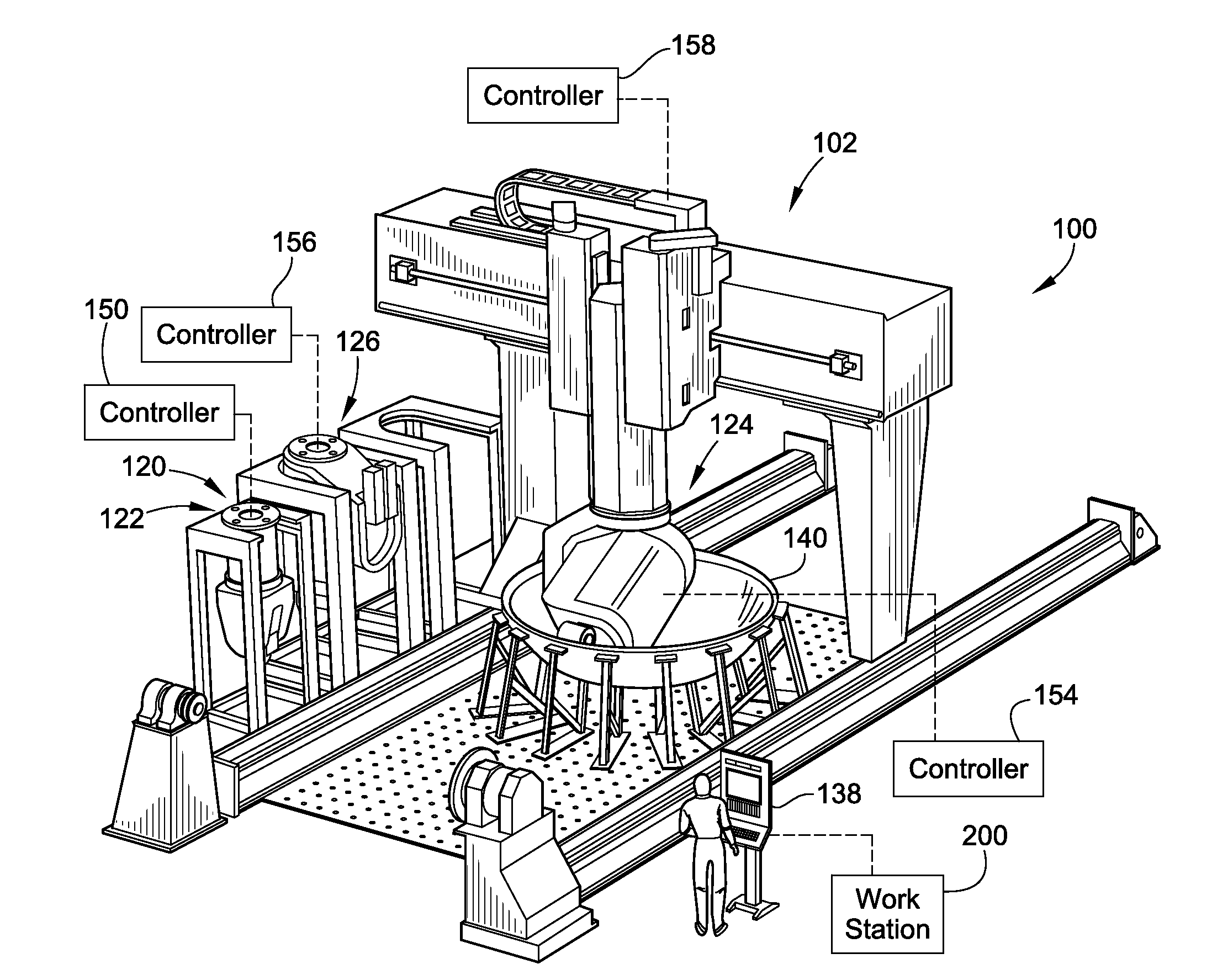

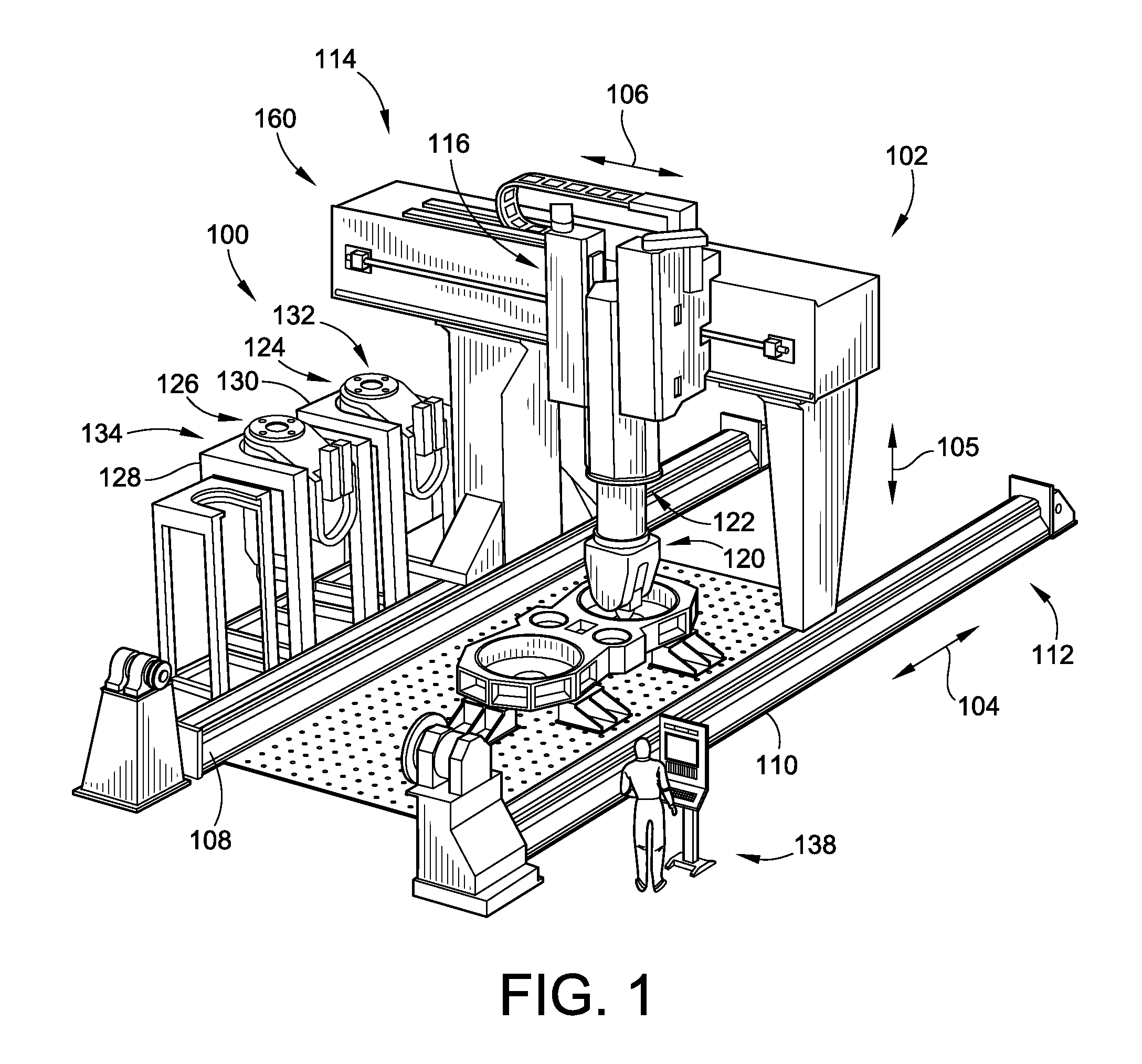

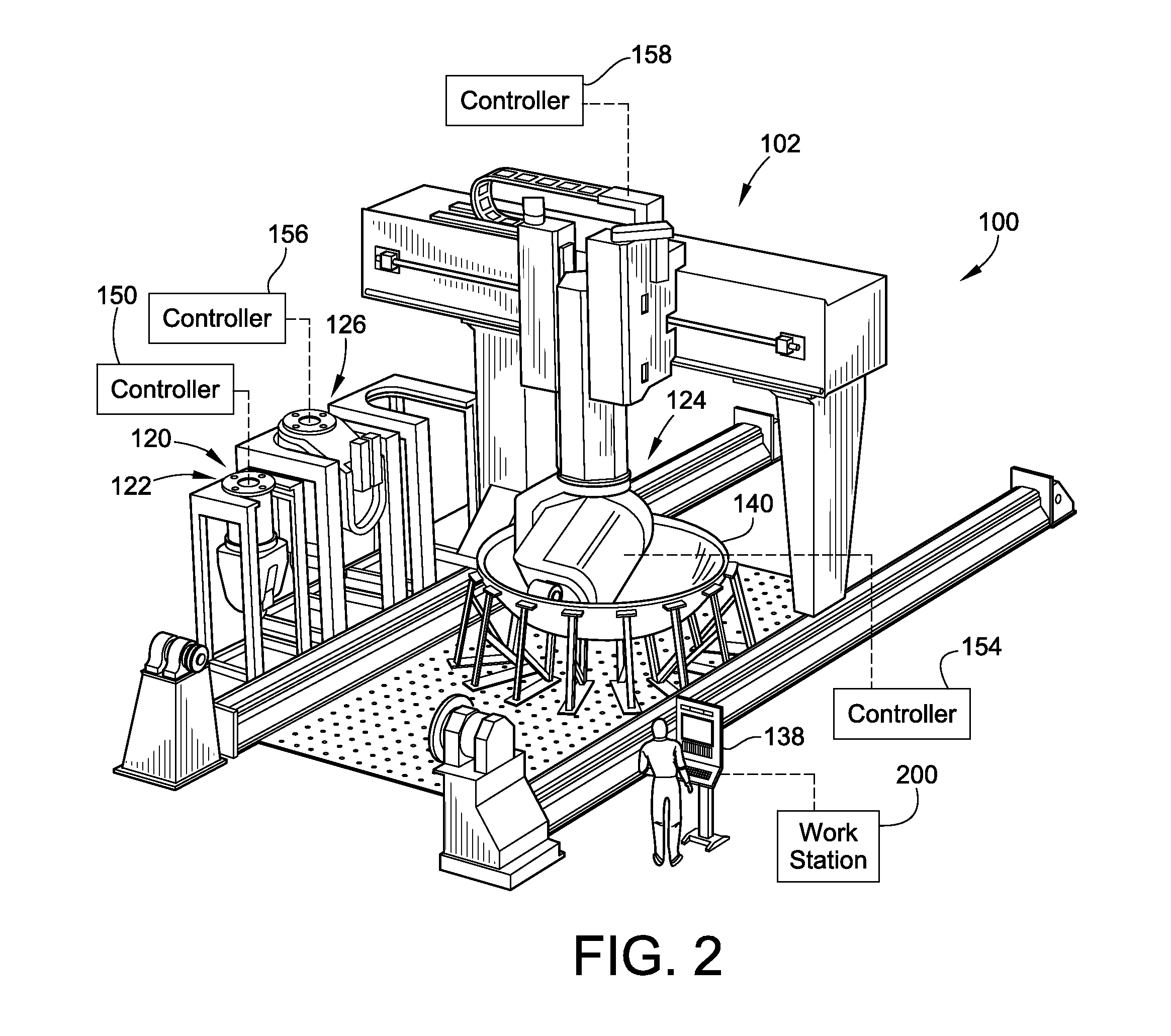

Manufacturing process and apparatus having an interchangeable machine tool head with integrated control

ActiveUS8954180B2Efficient transferAutomatic control devicesTool changing apparatusFiberDegrees of freedom

A modular manufacturing system and methods of using are provided. The modular manufacturing system includes a plurality of manufacturing heads that perform different manufacturing processes. These heads may include multi-axial machining heads, fiber placement heads including fiber tow and fiber tape lay-up heads. The heads are fixably attachable to a single positioning system that can manipulate the various heads along a plurality of different degrees of freedom relative to a tool or material blank.

Owner:INGERSOLL MACHINE TOOLS

Antigen-free collagen aggregate and preparation method thereof

The invention discloses an antigen-free collagen aggregate and a preparation method thereof. The preparation method is characterized by comprising the following steps: with traceable animal skin or tendo calcaneus as a raw material, performing operations by the process such as fleshing, stripping fascia, degreasing, removing foreign protein and decellularizing; performing fine purification on the animal skin or tendo calcaneus, and then carrying out separation and purification on the collagen aggregate by the methods of acid fluffing, homogenizing, salting out for a plurality of times, centrifuging for a plurality of times and the like, thereby finally obtaining the antigen-free collagen aggregate. The collagen aggregate is a mixture of a collagen fiber and a collagen bundle, and has a periodic light and shade horizontal grain structure; and the space between the horizontal grains is about 67nm. The material has good biocompatibility, biodegradability, mechanical property and hemostatic performance, also has the characteristics of low antigenicity, biological activity and the like, and can be widely applied to preparation of biomedical materials such as a hemostatic material, a tissue engineering material, a biological dressing, a biodegradable medical suture and a plastic material.

Owner:SICHUAN UNIV

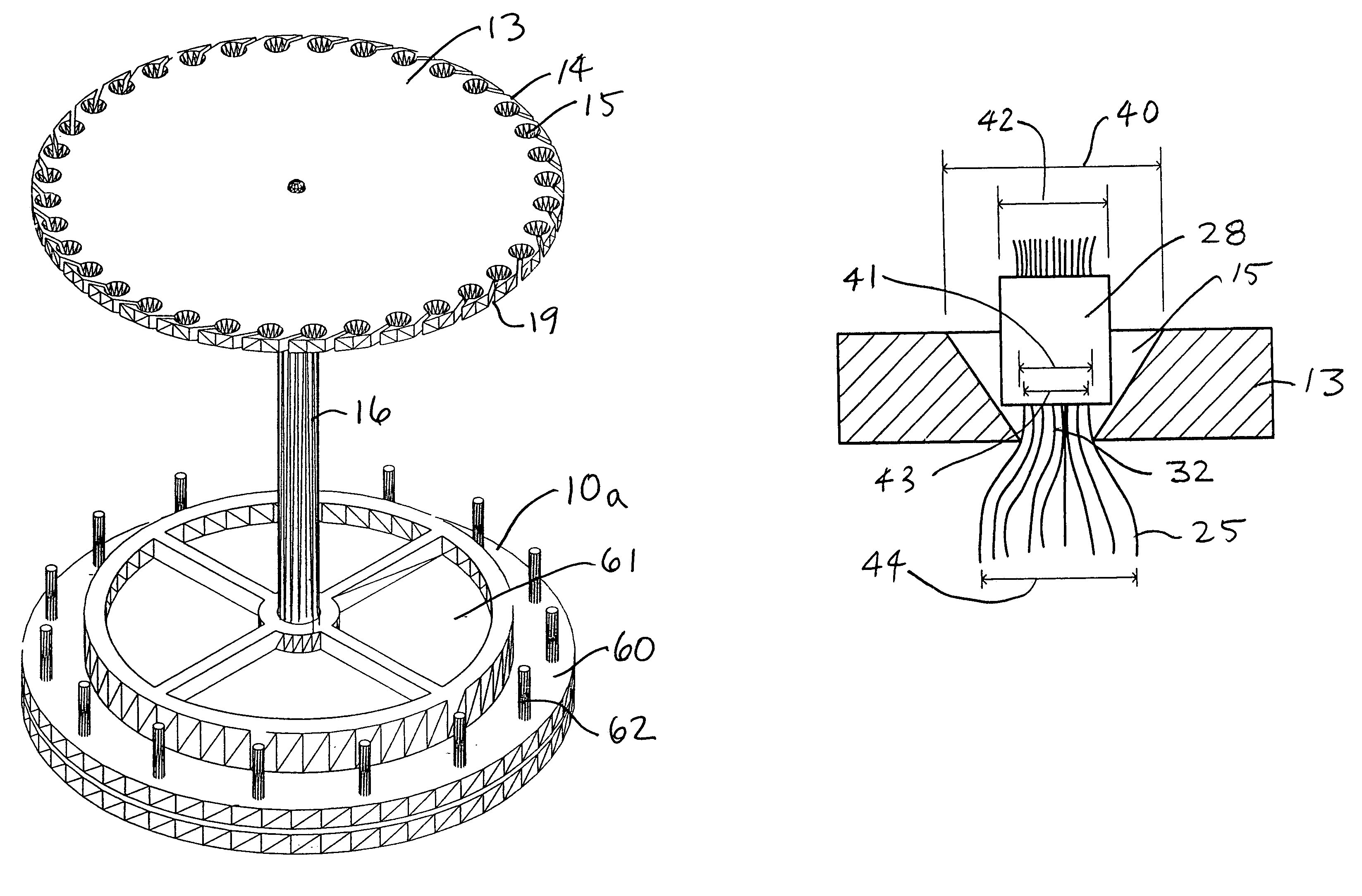

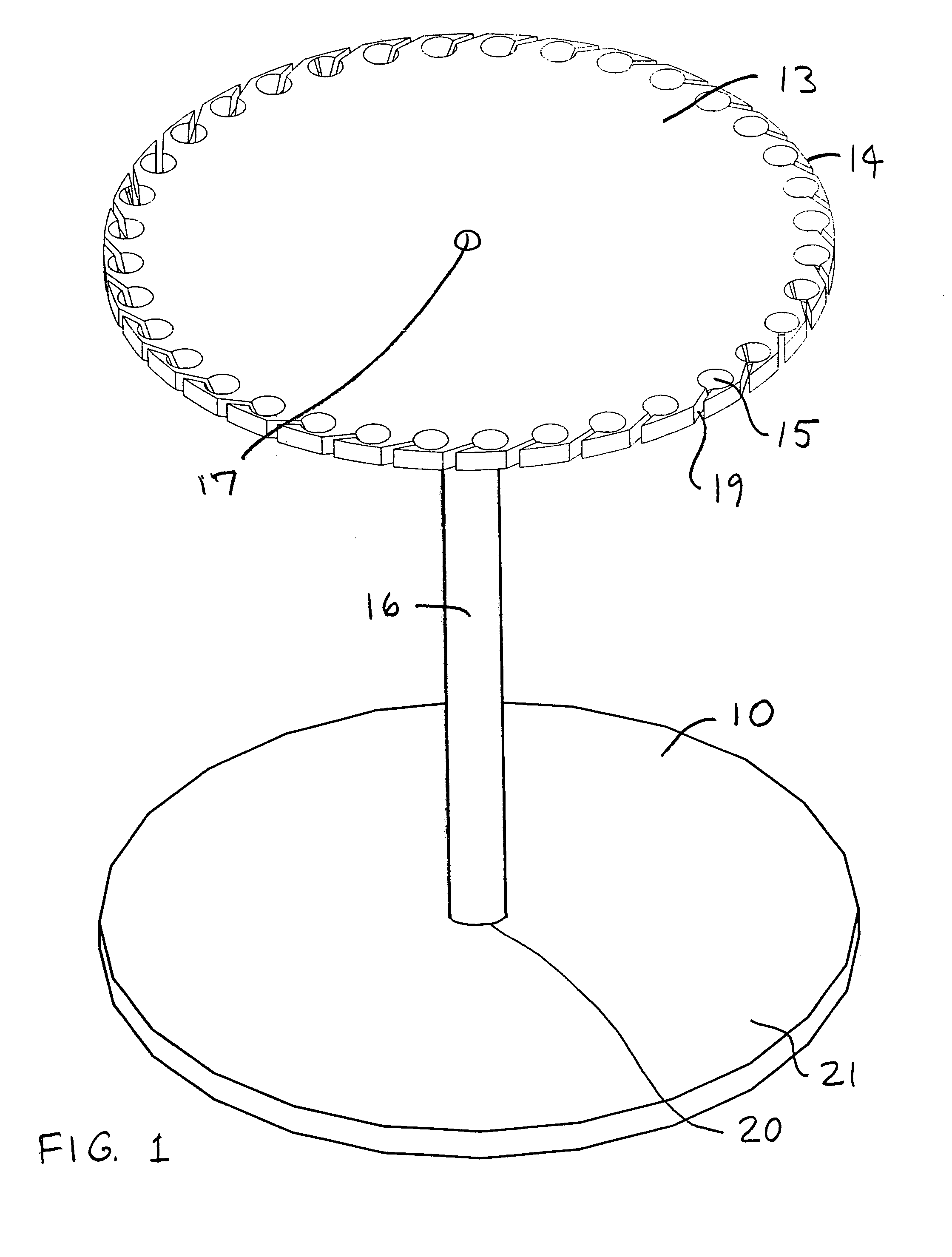

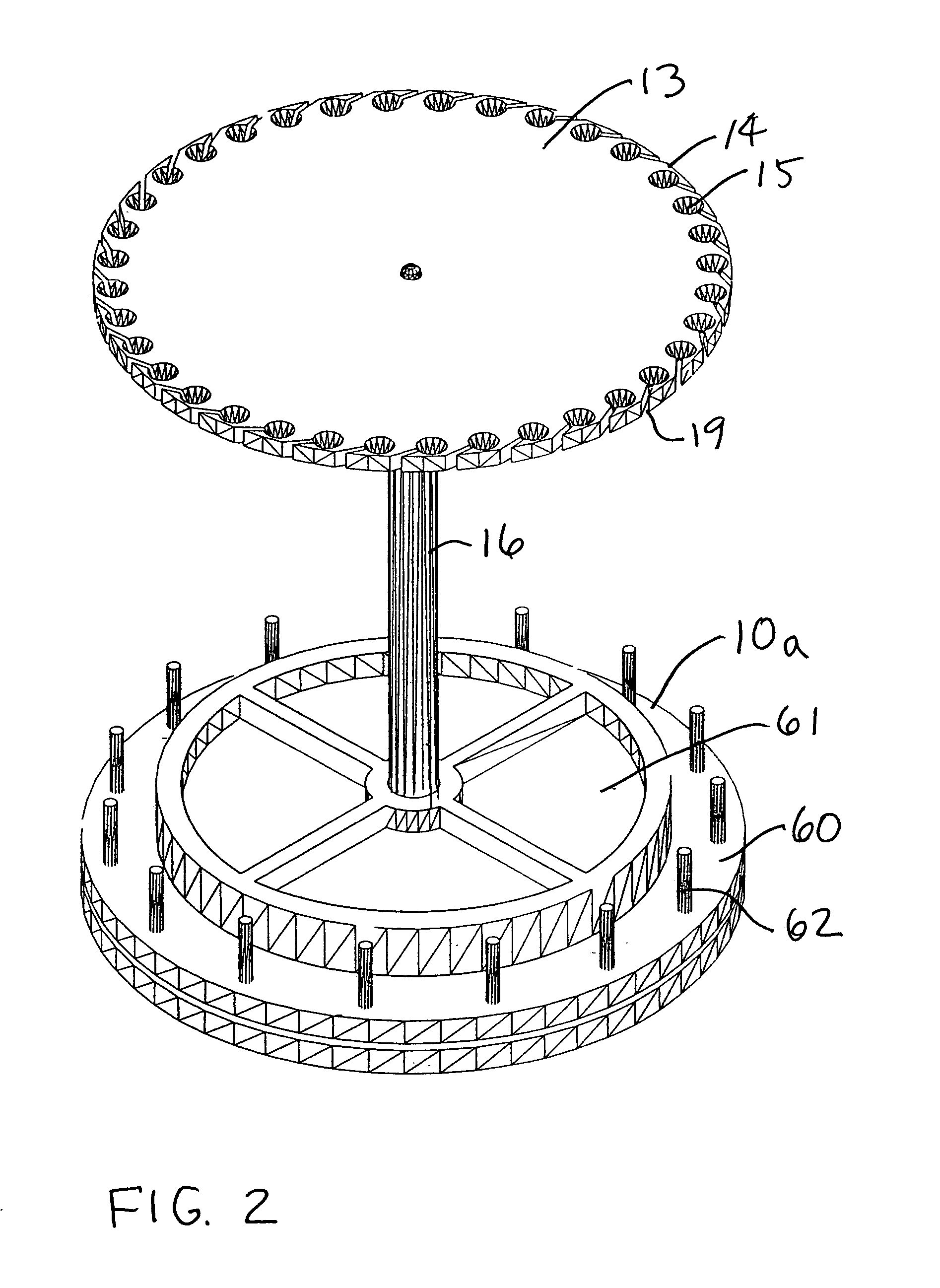

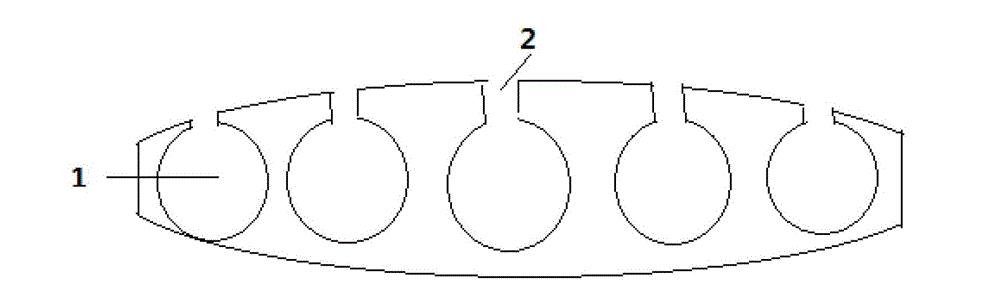

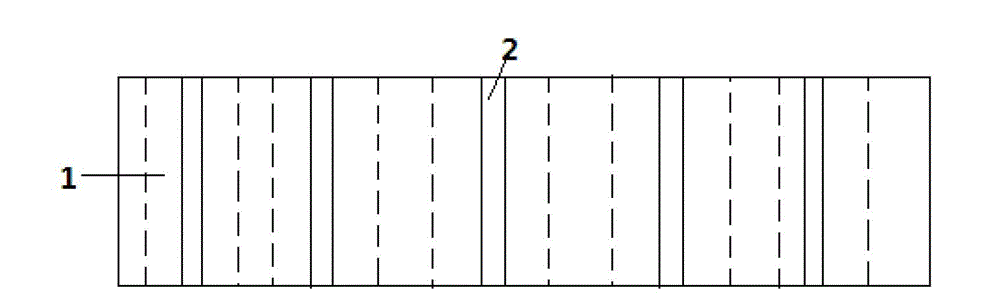

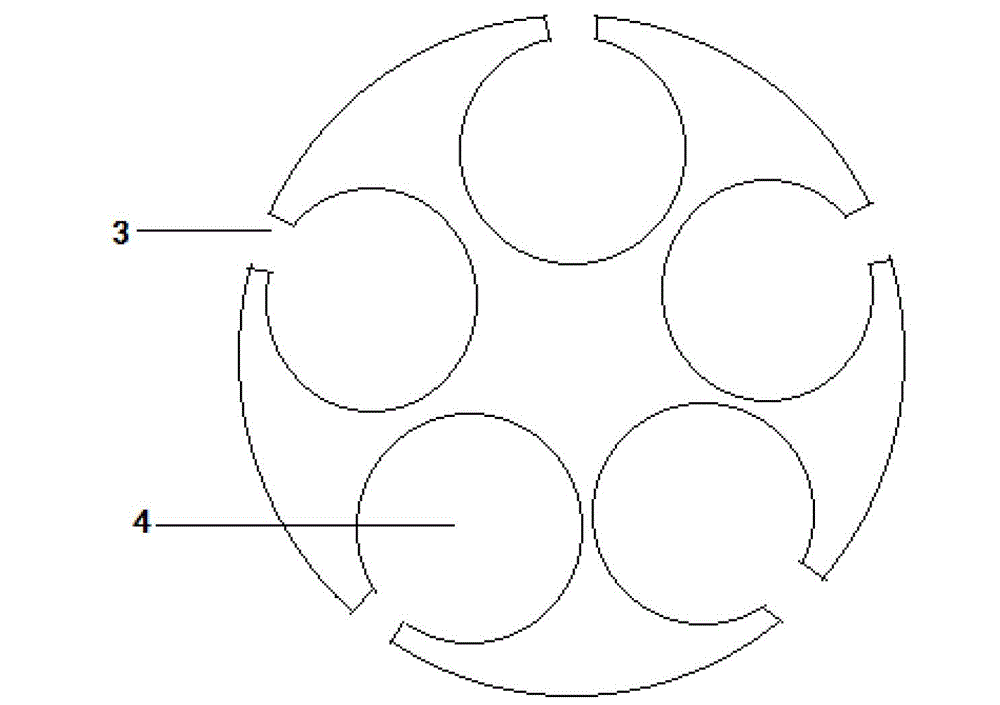

Fiber holder

InactiveUS6938766B1Easy maintenanceEasy to operateFilament handlingOther accessoriesFiberCircular cone

The invention is a suspension plate system for providing access to hanks of fiber. The system may include a circular, transparent, plastic disc having a plurality of truncated conic circular bores located equidistant from the center of the disc and being substantially equidistant from each other. Each bore has a larger diameter opening on the top of the disc and a smaller diameter opening on the bottom of the disc. A plurality of generally radial slots equal in number to the number of bores are located on the disc to communicate between each bore and the outer edge of the disc. Each bore provides a device wherein a hank of fiber, cut into substantially equal lengths to other hanks and divided by color and / or nature can be presented for display and use. The hank of fiber of like color and / or nature is bound by a knob-like binder that can be captured in one of the bores, with the hank of fiber suspended down from the disc, thus locking the hank of fiber in place relative to other hanks and to the disc. The binder is captured because its effective diameter is between the diameters of the upper and lower openings of the bore. The slot allows the hank of fiber to be axially placed within the bore without the hank having to be threaded longitudinally into the bore.

Owner:LEE THOMAS M

Manufacturing process and apparatus having an interchangeable machine tool head with integrated control

ActiveUS20120035754A1Efficient transferAutomatic control devicesTool changing apparatusFiberDegrees of freedom

A modular manufacturing system and methods of using are provided. The modular manufacturing system includes a plurality of manufacturing heads that perform different manufacturing processes. These heads may include multi-axial machining heads, fiber placement heads including fiber tow and fiber tape lay-up heads. The heads are fixably attachable to a single positioning system that can manipulate the various heads along a plurality of different degrees of freedom relative to a tool or material blank.

Owner:INGERSOLL MACHINE TOOLS

System and method for stochastic dt-mri connectivity mapping on the GPU

InactiveUS20080109171A1Highly parallelizableDrawing from basic elementsMagnetic measurementsFiberDiffusion

A graphics processing unit implemented method for fiber tract mapping from diffusion tensor magnetic resonance imaging data includes providing a diffusion tensor magnetic resonance brain image volume, initializing a set of fiber positions in a 3D set of points, fiber displacements, and a posterior distribution for an updated fiber displacement in terms of the initial displacements and diffusion tensors, randomly sampling a set of updated fiber displacements from said posterior distribution, computing a new set of fiber positions from said initial fiber positions and said updated fiber displacements, wherein a fiber path comprises a set of fiber points connected by successive fiber displacements, accumulating connectivity values in each point of said 3D set of points by additive alpha-blending a scaled value if a fiber path has passed through a point and adding zero if not, and rendering said connectivity values.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

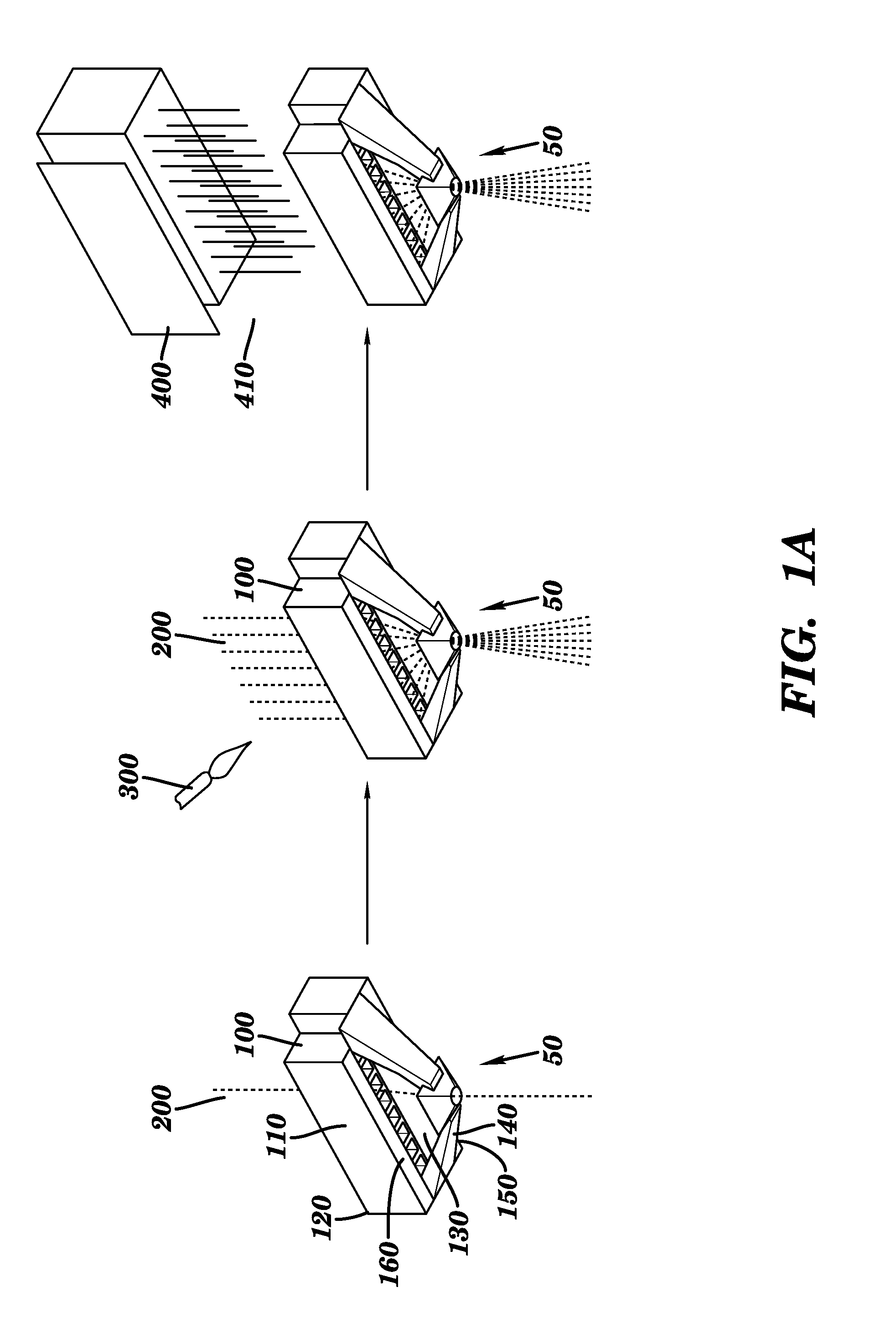

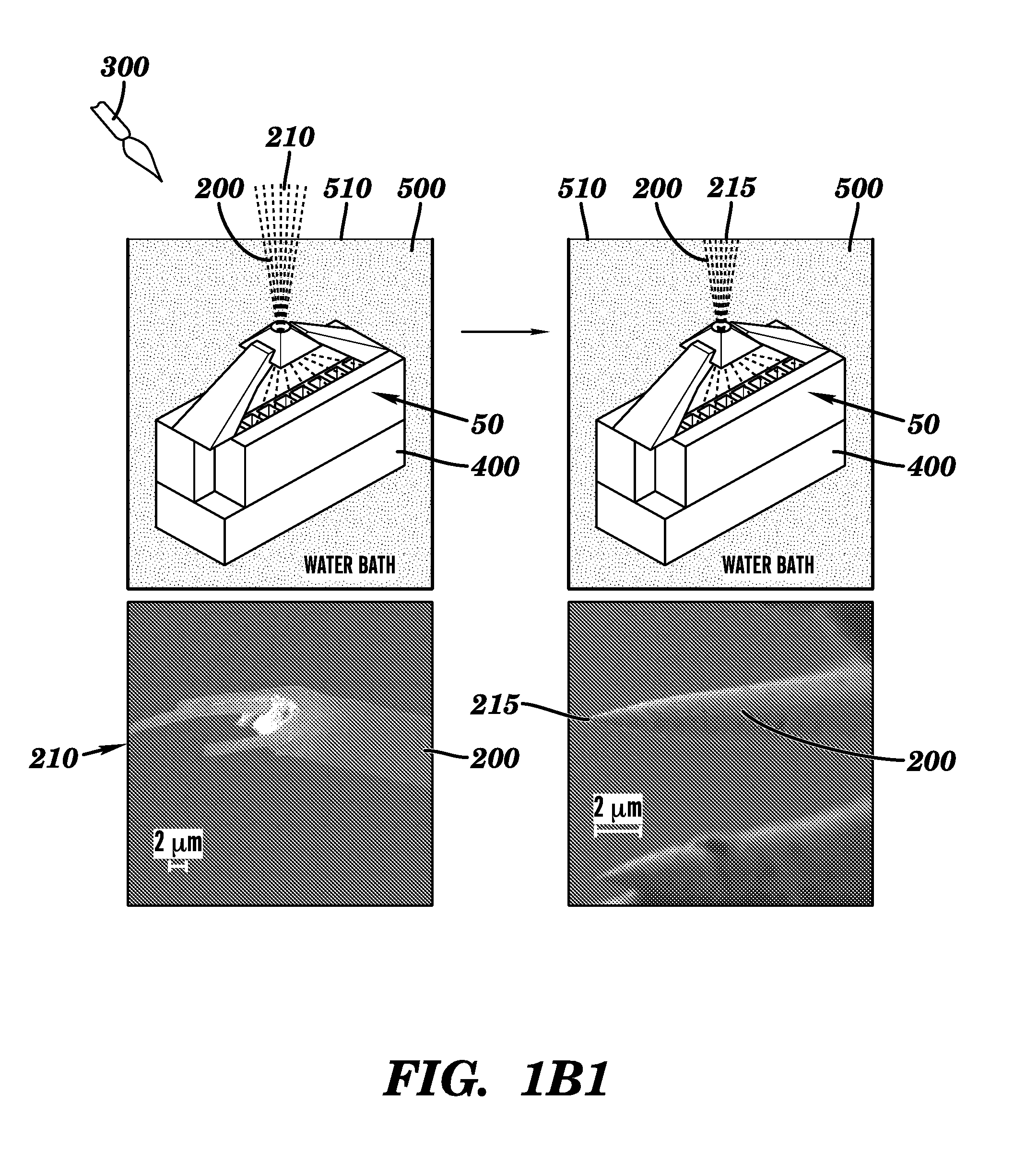

Minimally invasive splaying microfiber electrode array and methods of fabricating and implanting the same

InactiveUS20170007824A1Minimum driftMaximum countSpinal electrodesHead electrodesSurface mountingElectrical connection

An electrode array having a splayable bundle of fibers having heat-sharpened tips. A method of manufacturing an electrode array including heat-sharpening a tip of each of a plurality of fibers; and bundling the plurality of fibers. A method of implanting an electrode array into a subject, the electrode array having a bundle of fibers, the method including exposing a target in the subject for the electrode array; and inserting the bundle of fibers into the target, where forces holding the bundle of fibers together are released during the insertion thus resulting in splaying of the fibers. An electrical connection with the fibers can be formed by a conductive material, or in high-channel count designs formed by surface mounting two-dimensional amplifier arrays to a base of a fiber array.

Owner:TRUSTEES OF BOSTON UNIV

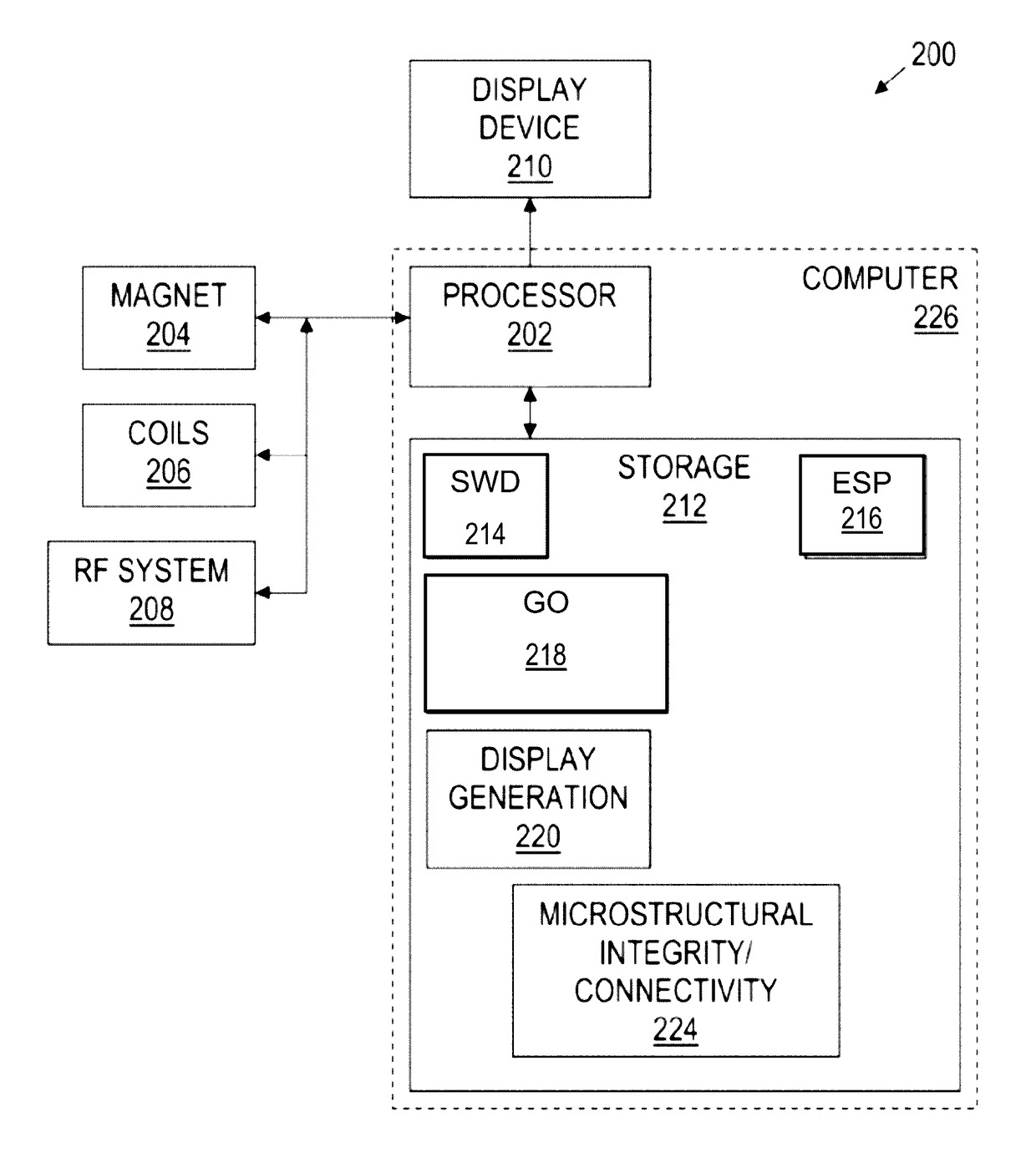

Fiber tractography using entropy spectrum pathways

A method for fiber tractography processes multi-shell diffusion weighted MRI data to identify fiber tracts by calculating intravoxel diffusion characteristics from the MRI data. A transition probability is calculated for each possible path on the lattice, with the transition probability weighted according the intravoxel characteristics. Entropy is calculated for each path and the paths are ranked according to entropy. A geometrical optics algorithm is applied to the entropy data to define pathways, which are ranked according to their significance to generate a map of the pathways.

Owner:RGT UNIV OF CALIFORNIA +1

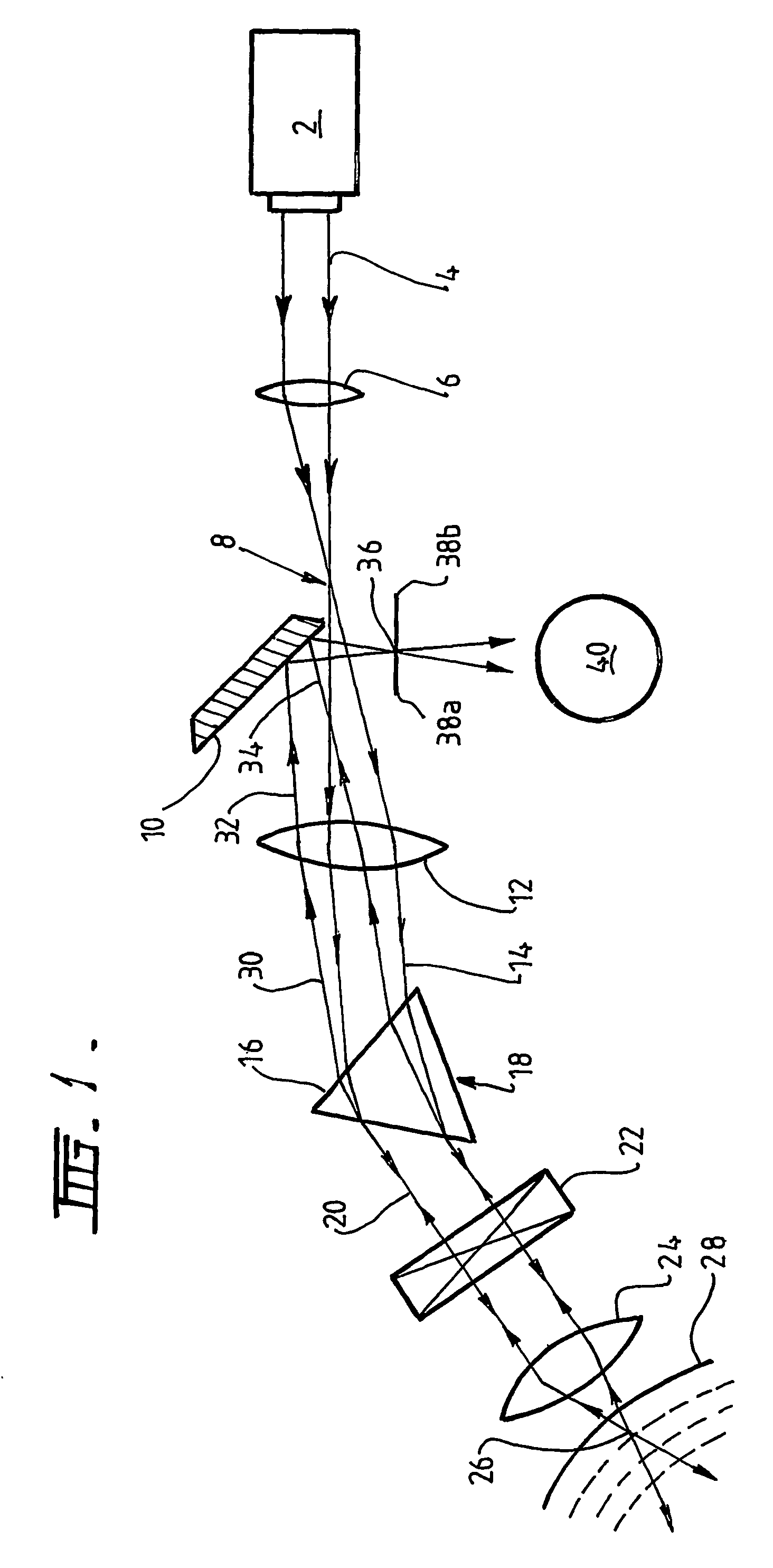

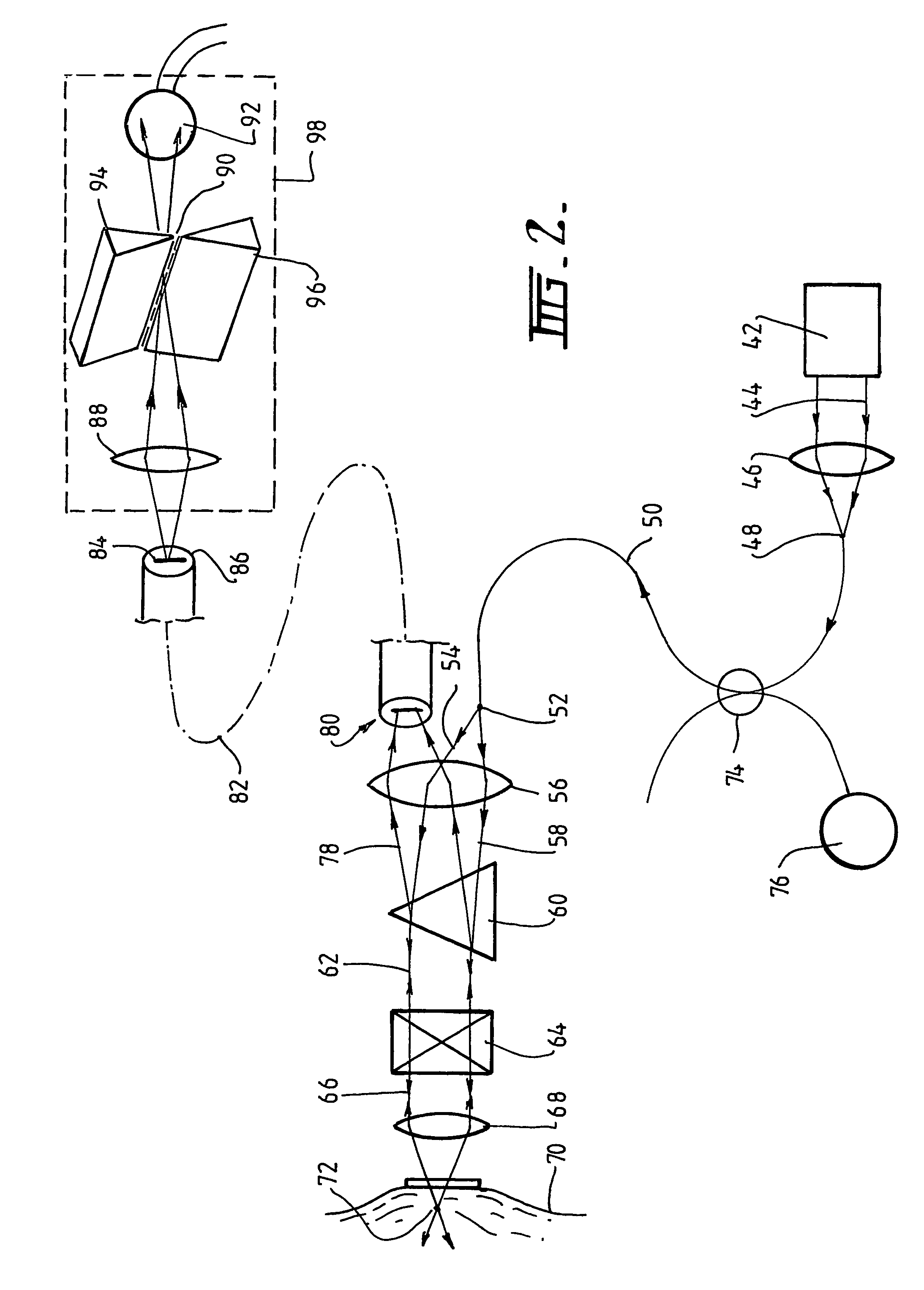

Laser scanning confocal microscope with fibre bundle return

ActiveUS7330305B2Good flexibilityImprove isolationRadiation pyrometrySpectrum investigationFiberFluorescence

The invention provides a confocal microscope or endoscope, having a source of coherent light for illuminating a sample, and an imaging optical fibre bundle (82) for receiving return light, whereby the fibre bundle (82) provides a return channel for fluorescent return light (78). The optical fibre bundle (82) preferably preserves, between entry and exit ends of the bundle, the relative spatial coordinates of the cores of individual fibres constituting the bundle.

Owner:OPTISCAN

Hose with conductive fiber

A composite hose includes a conductive fiber media extending contiguously from one end of the hose to the other. The conductive fiber media is covered by silver plating, and in one described embodiment comprises a silver-plated nylon fiber. The nylon fiber provides a flexible medium not readily prone to breakage, while the silver plating provides relatively low electrical resistance, due to its relatively high electrical conductivity, for avoiding potentially lethal effects of static electricity. In one described embodiment, the hose includes an inner layer of an insulation material, such as rubber. An electrically conductive fiber strand is applied over the inner layer in a spiral pattern, and an outer cover material is an extruded over the inner layer of the hose and the fiber strand. In another embodiment, the hose includes a textile braided yam layer positioned directly above the strand over the inner layer, immediately beneath the outer cover.

Owner:DANA CORP

White matter fiber tract reconstruction method based on deep learning

InactiveCN106971410AReduce the impact of noiseImprove accuracyImage enhancementReconstruction from projectionFiberReconstruction method

The invention discloses a white matter fiber tract reconstruction method based on deep learning, which mainly aims at white matter fiber tract reconstruction. The method comprises the following steps: extracting signal sparsity features of a digital image in a training sample set; importing the signal sparsity features to a convolutional neural network for training, forwardly propagating the classification result, using a back propagation algorithm for the classification error, and getting a best network model; inputting extracted signal sparsity features of an image in a test sample set to a trained network model to get a final prediction result; and finally, describing the result into the orientation and distribution of white matter fibers through continuous curve fitting, and reconstructing a three-dimensional white matter fiber tract. Cross and forked white matter fiber tracts can be constructed accurately to provide help for the clinical research and physiological and pathological mechanisms of white matter fiber tracts.

Owner:SOUTH CHINA UNIV OF TECH

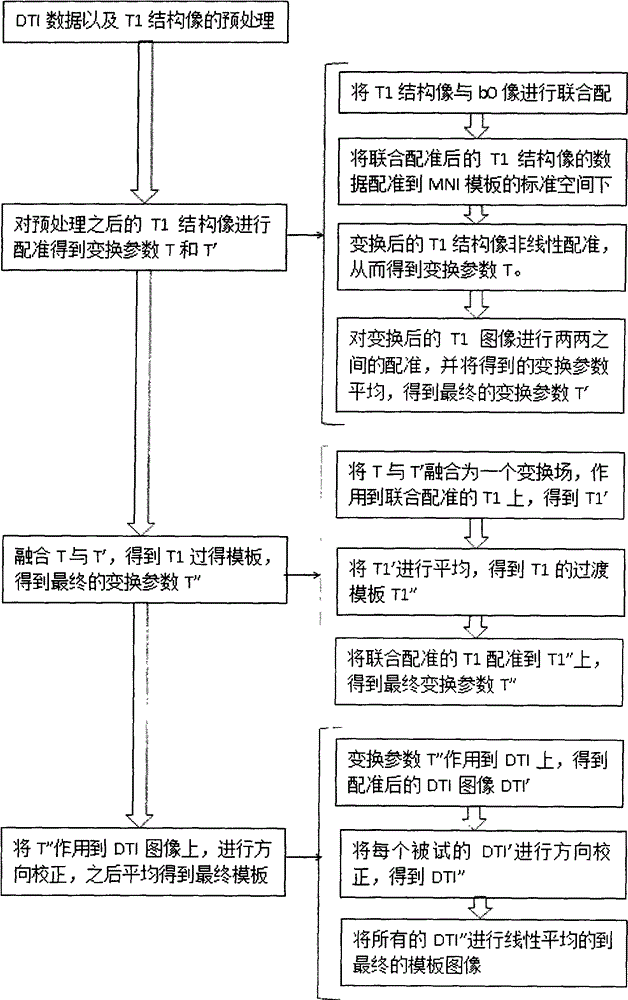

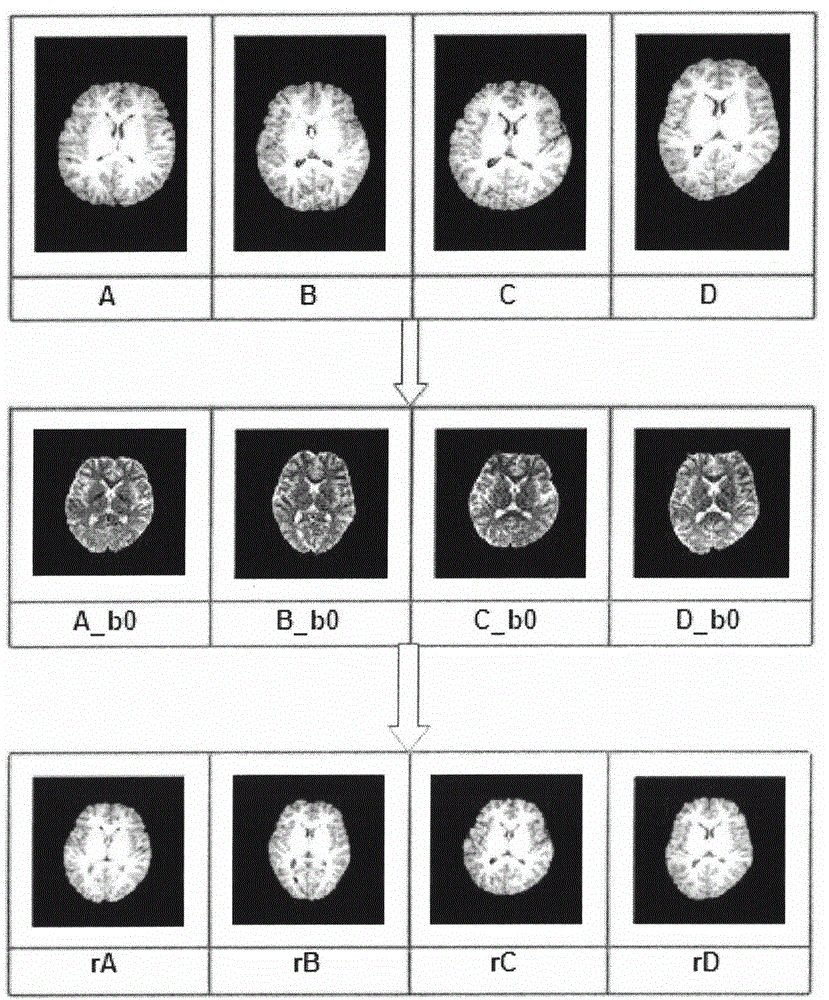

Construction method for health people white matter fiber tract atlas

InactiveCN104523275AImprove Spatial ConsistencyClear structural informationImage analysisDiagnostic recording/measuringAnatomical structuresData set

The invention relates to a construction method for a health people white matter fiber tract atlas. The method comprises the steps that through seeking the corresponding relationship between individual gray matter structure space and DTI space, the information of the tensor image average space of group people is calculated, and the DTI data of individuals are transformed into the average space; parameters jointly registered by a magnetic resonance anatomical structure image and an MNI standard form are integrated with registration parameters in the group by using related integration means and applied in an individual T1 dataset, and a group transition tensor image template is established; the individual T1 data are registered into the transition template through non-linear registration, and transformation parameters of a T1 structure image registered to the transition template are obtained; the transformation parameters are used in the individual T1 data, the correction for direction of a tensor field on each voxel point is carried out by using methods of keeping the main characteristic direction, the linear average of the voxel point one by one is carried out on the corrected tensor, and finally the diffusion tensor atlas of the specific health people group is obtained.

Owner:XIDIAN UNIV

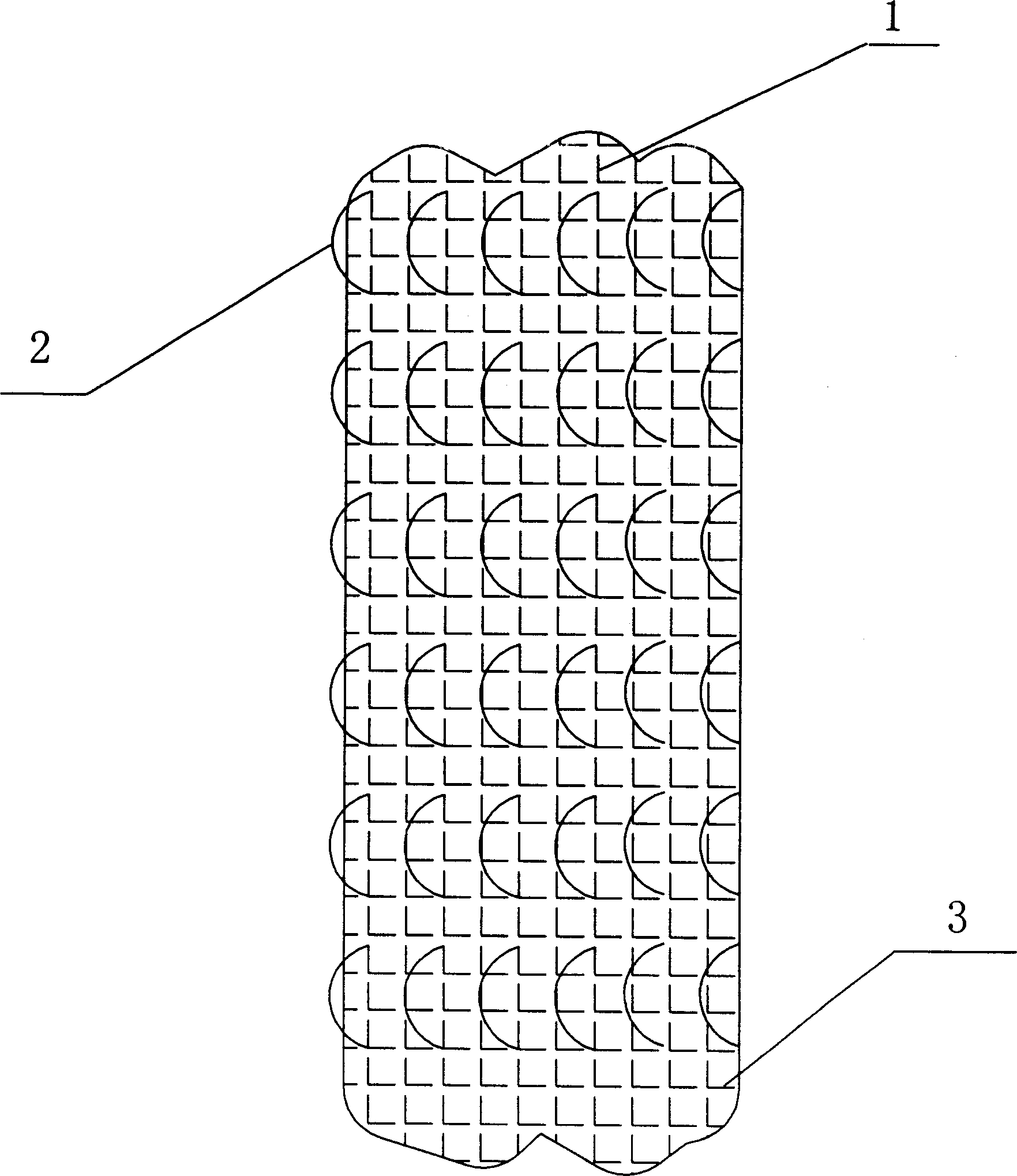

Method for weaving fabric with Z-direction loop

The Z-loop weaving method for fabric comprises the warping pretreatment, beaming, preparing for weave, weaving, splining, and shaping, and is characteristic in: 1) selecting one of the carbon fiber, pre-oxygen fiber, aramid fiber and glass fiber; 2) pretreating the fiber before the weave; 3)forming the fabric structure with two system warpthreads and one system weft yarn; 4) storing said warpthread on two warping axis with quantity determined by fabric length, width and Z-loop height. This invention improves fabric interlayer connection strength greatly to let the precast have integral reinforced structure with low cost.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

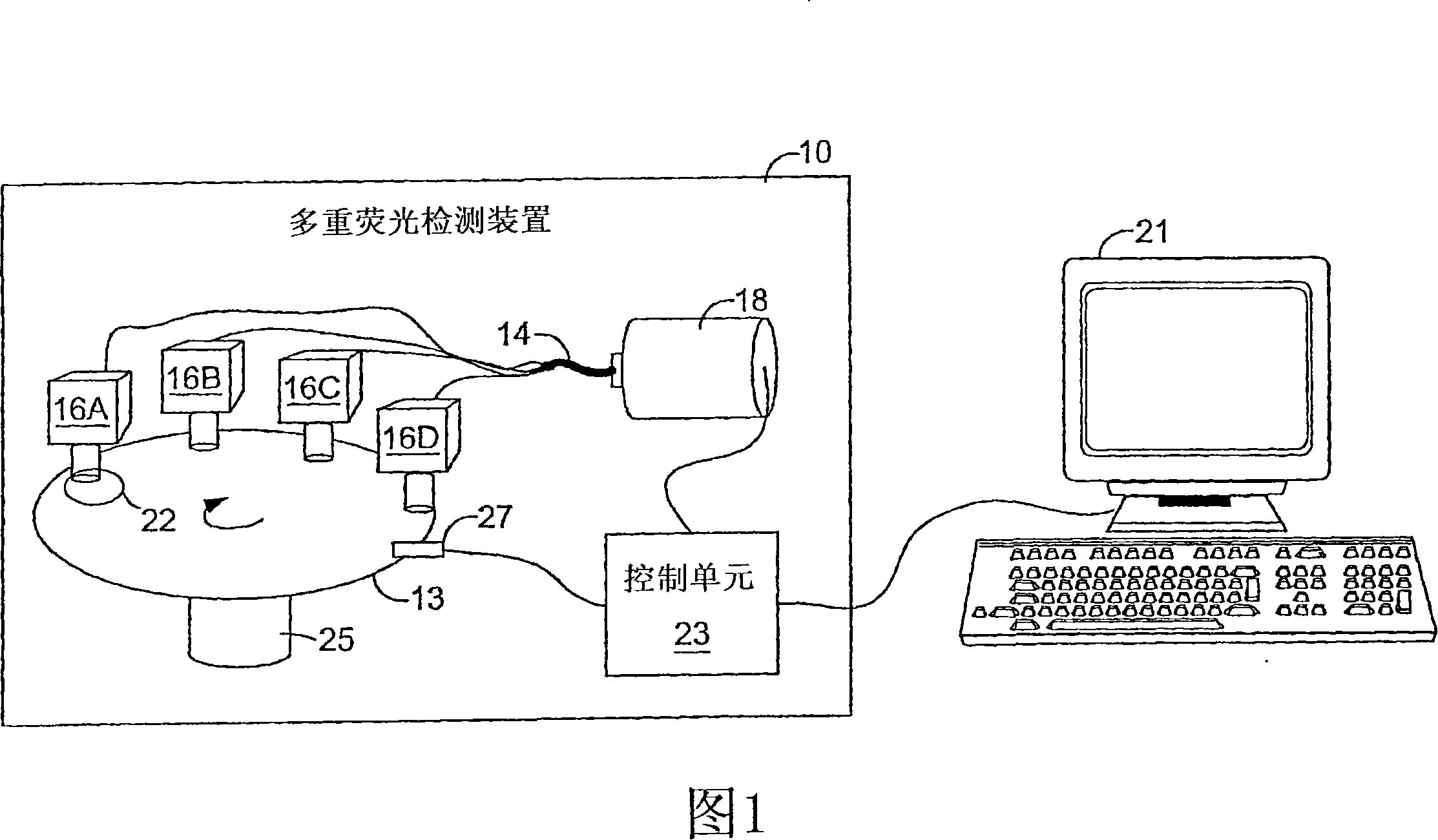

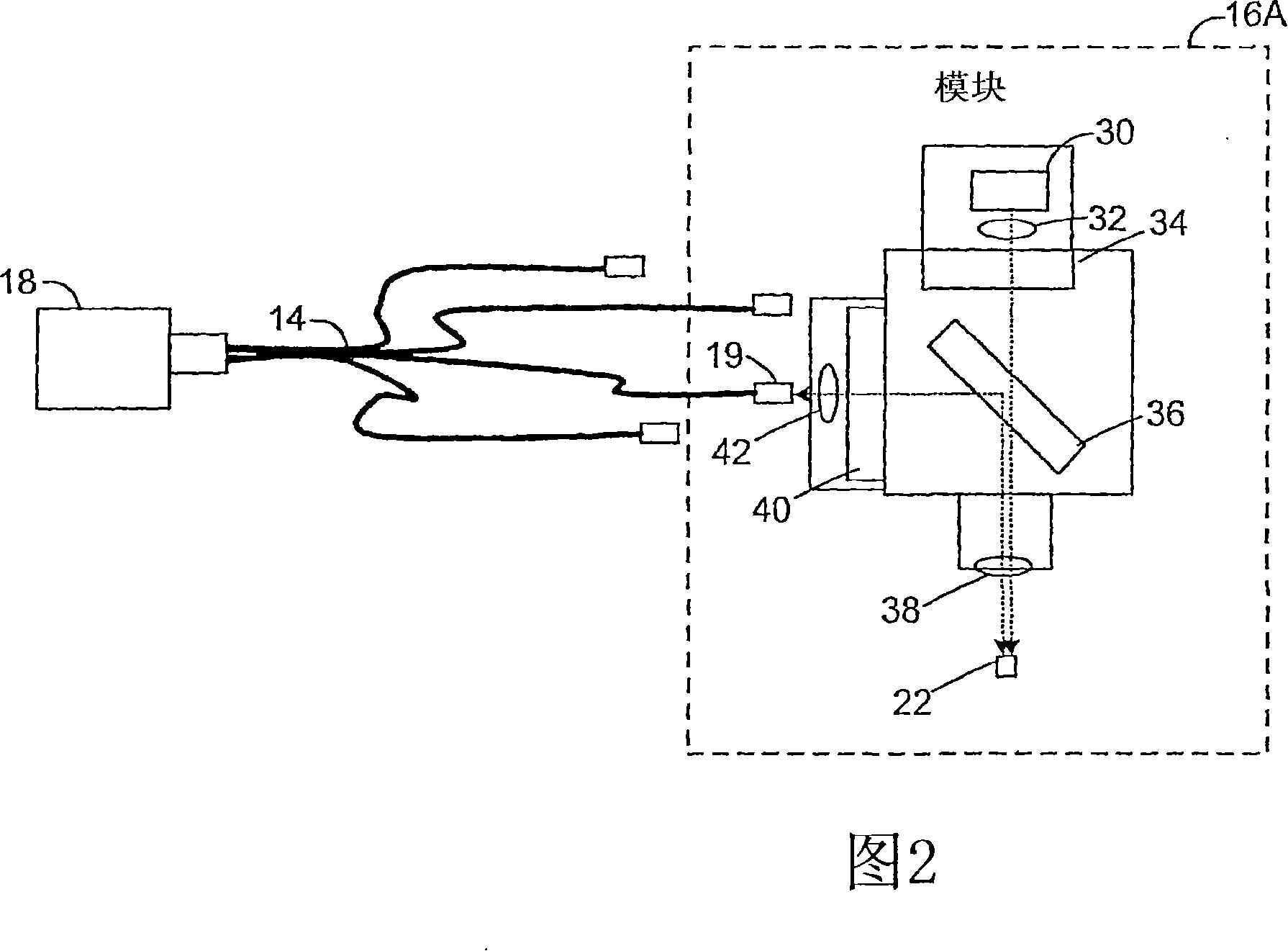

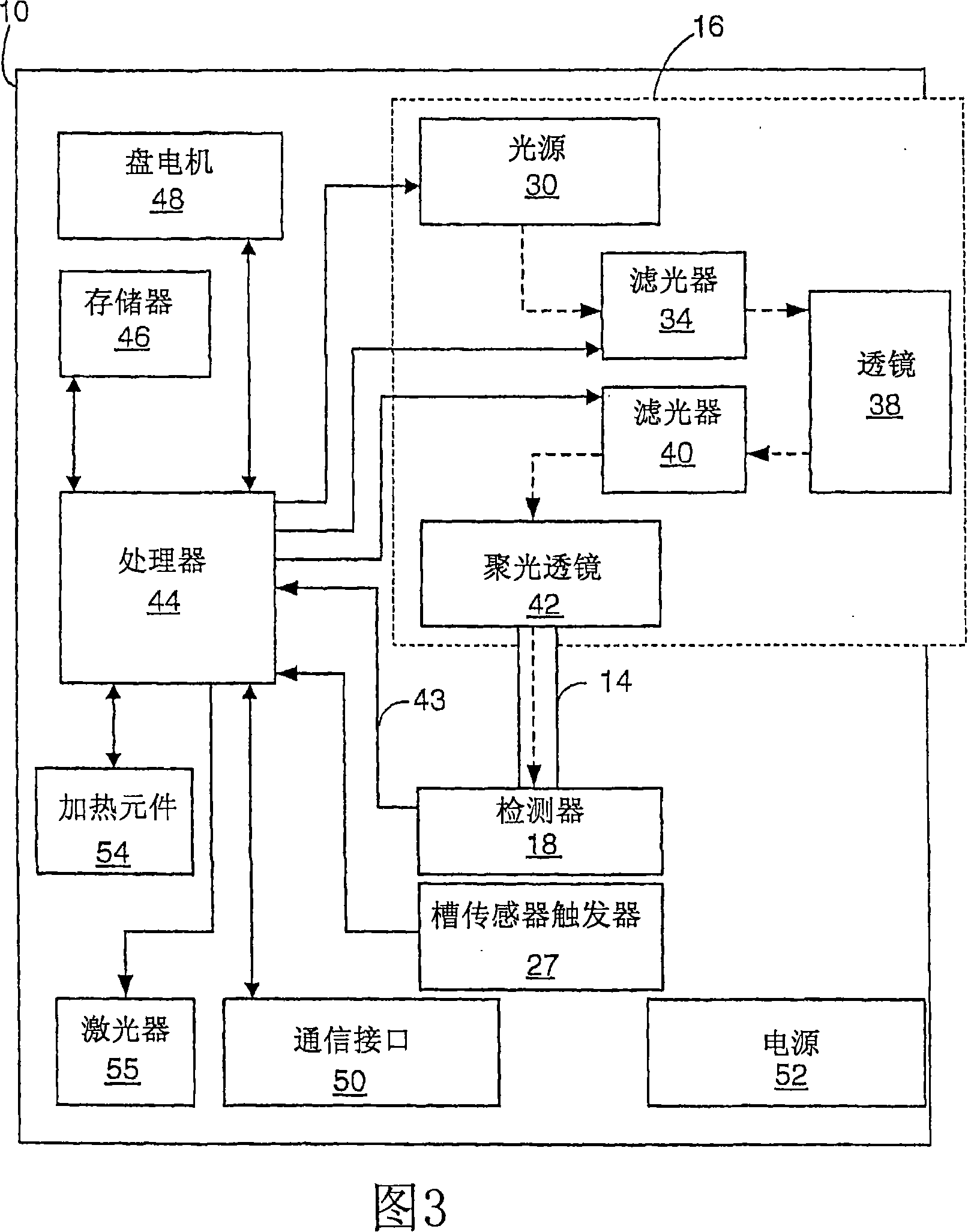

Multiplex fluorescence detection device having removable optical modules

Techniques are described for the detection of multiple target species in real-time PCR (polymerase chain reaction). For example, a system is described that includes a data acquisition device and a detection device coupled to the data acquisition device. The detection device includes a rotating disk having a plurality of process chambers having a plurality of species that emit fluorescent light at different wavelengths. The device further includes a plurality of optical modules. Each of the optical modules is optically configured to excite the species and capture fluorescent light emitted by the species at different wavelengths. A fiber optic bundle coupled to the plurality of optical modules conveys the fluorescent light from the multiple optical modules to a single detector.

Owner:索灵意大利股份公司

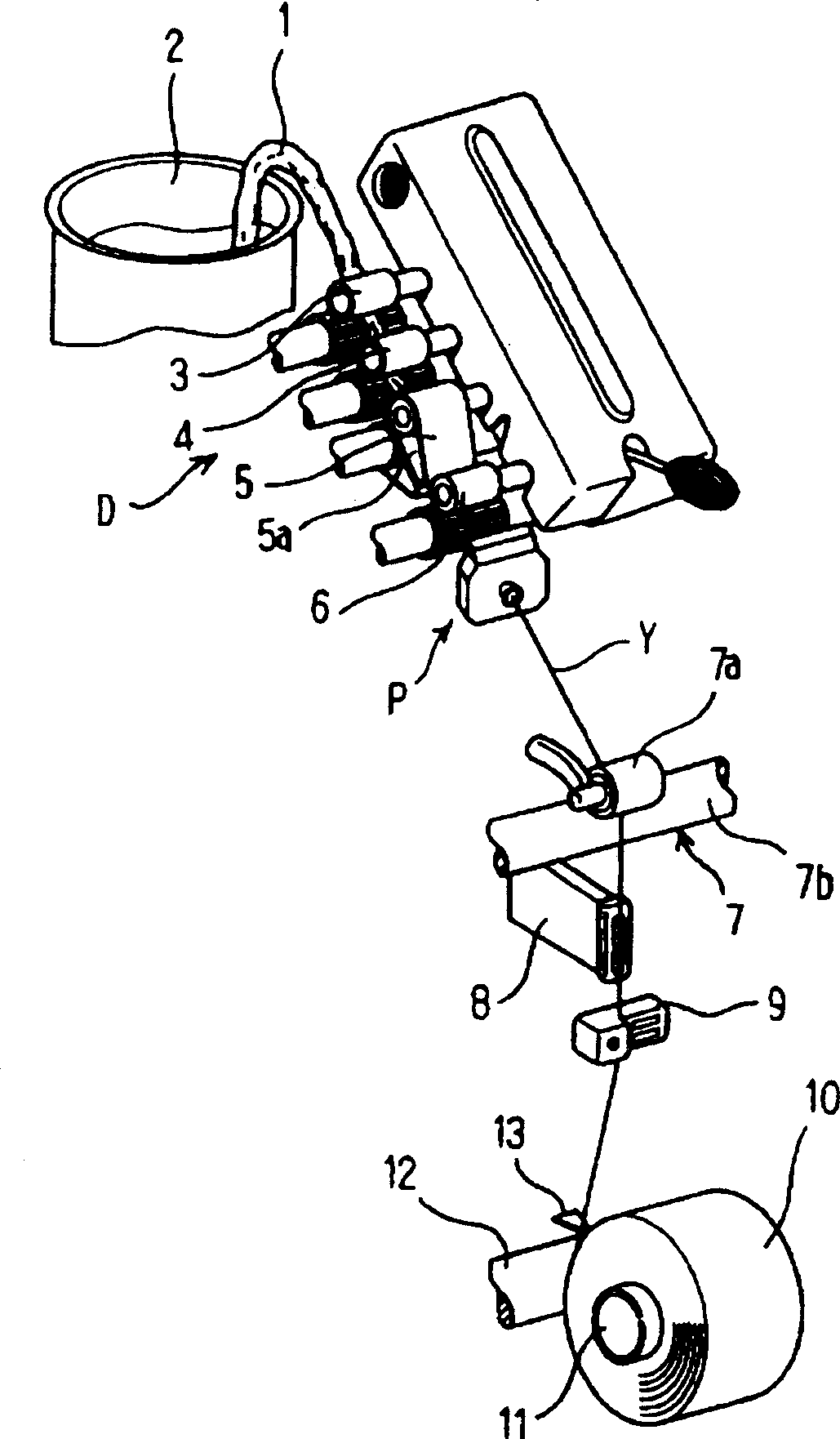

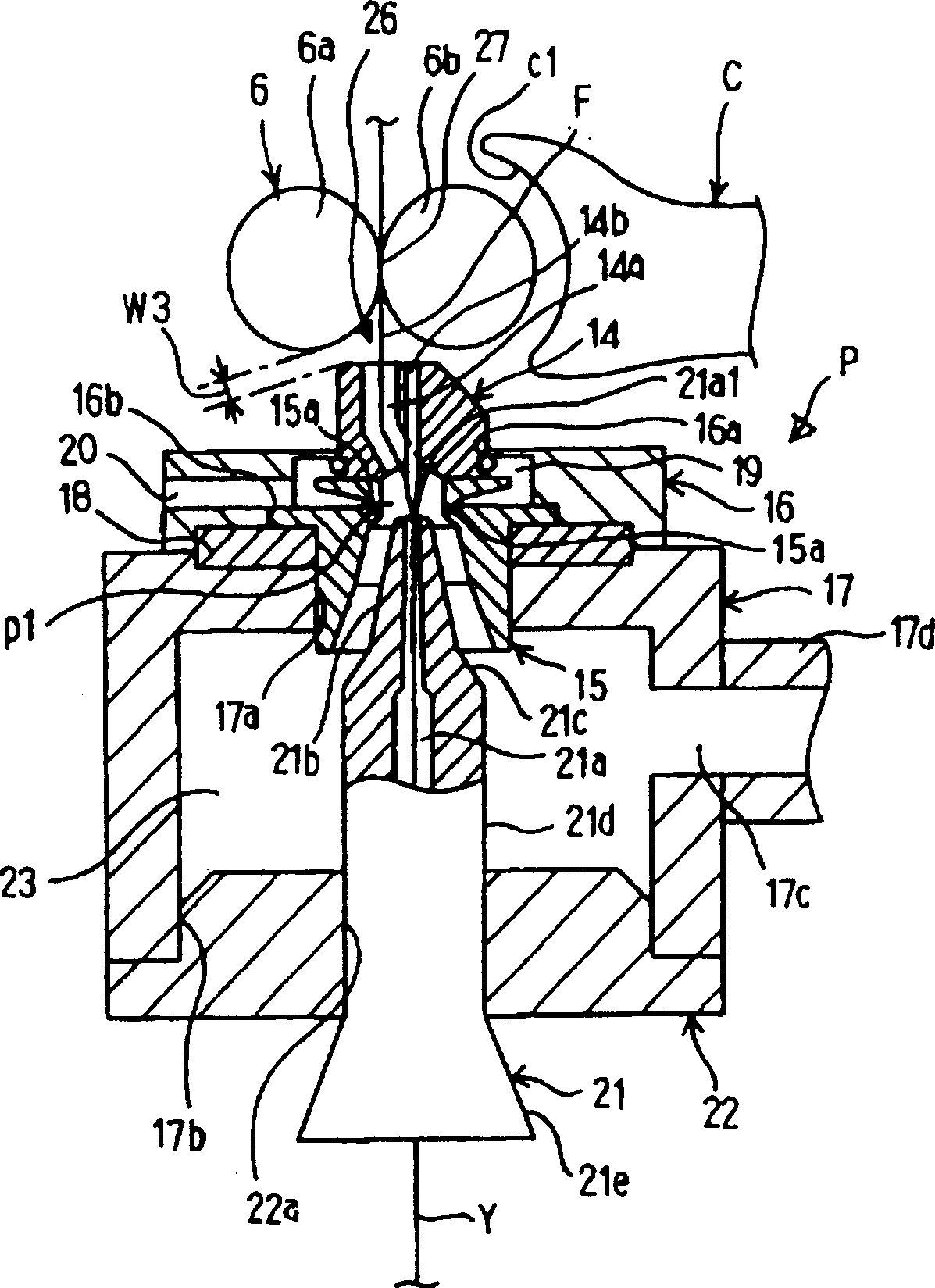

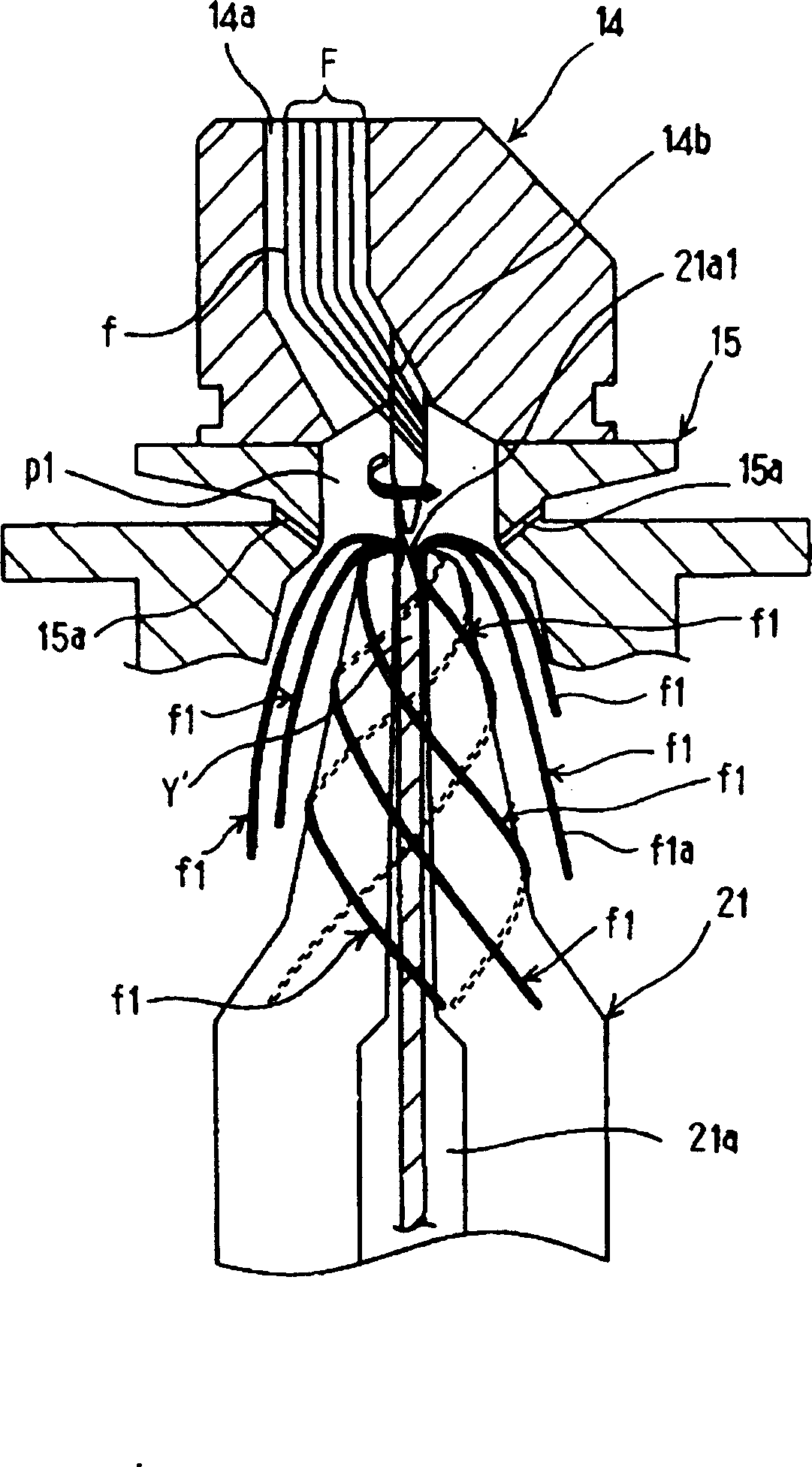

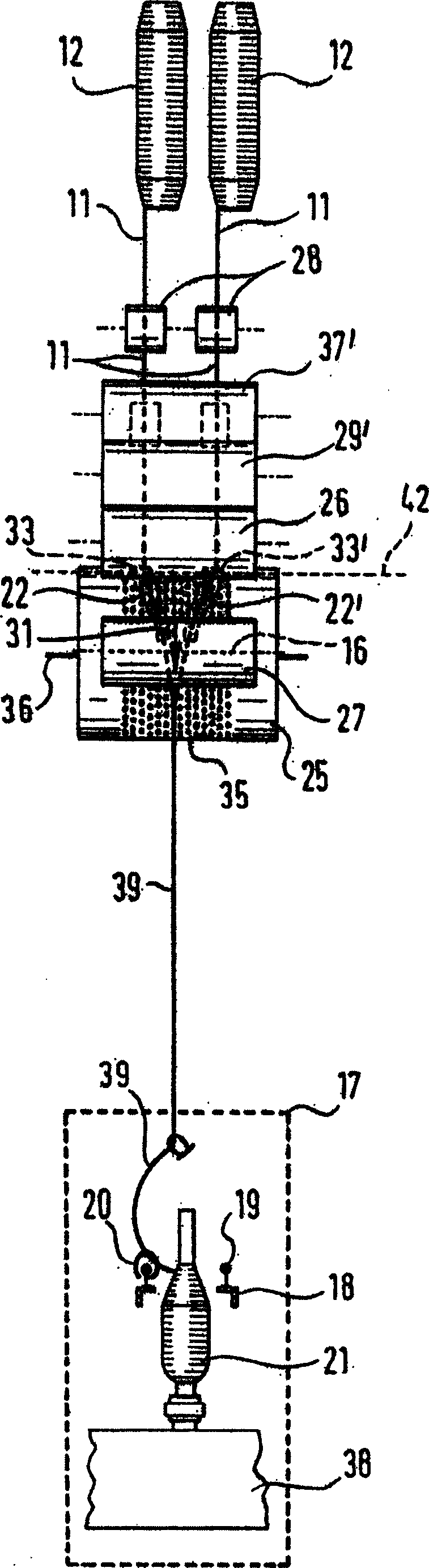

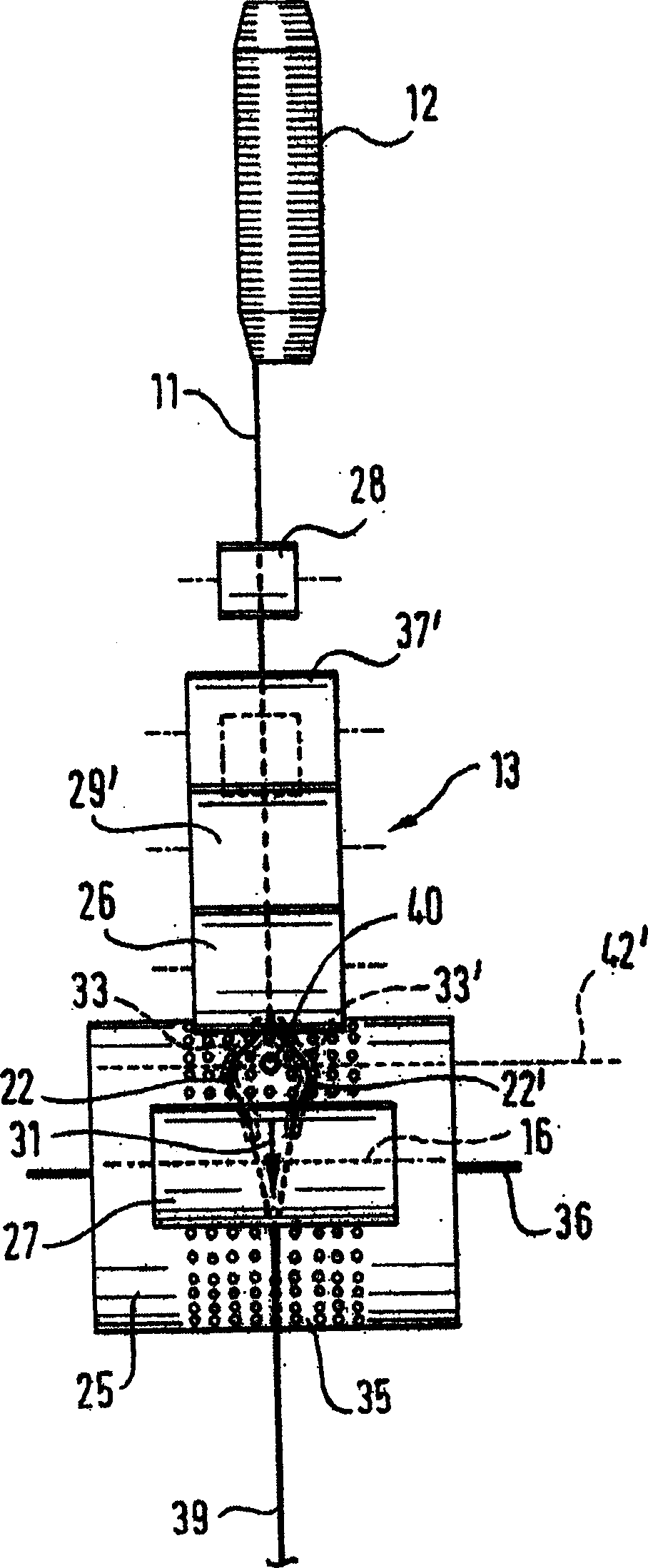

Spinning device

The objective of the invention is to improve intensity and apparentness of spinning. The spinning device has hollow guide shaft body and spinning nozzle, setting a shrinking part between middle of nozzle holder and the hollow guide shaft body, and selecting properly position relationship of the shrinking part and the hollow guide shaft body, forming a cylinder part and a horn part on inner wall of the nozzle holder, the cylinder part with proper lenght makes flow rate of injecting air most properly. And, selecting a proper gap between the front roller and fiber introduing part. Thereby, fiber beam is hard to noil and affect by accompany airflow, can generate yarn with physical characteristica of applicable breaking strength.

Owner:MURATA MASCH LTD

Process for producing sheath-core staple fibre with a three-dimensional crimp, and corresponding sheath-core staple fibre

InactiveCN101305118AFavorable thermal bondingAvoid structural changesHollow filament manufactureFilament/thread formingFiberAir velocity

The invention relates to a process for producing sheath-core staple fibre with a three-dimensional crimp, and to corresponding sheath-core staple fibre. In this process the fibre, with a symmetrical sheath-core arrangement, is extruded from two different polymer melts, with one polymer component, A, for the core and one polymer component, B, for the sheath. In order to maximize the intensity of the three-dimensional crimping in the fibre, the fibre is cooled with a sharp stream of cooling air, with a quench air velocity of at least 3 m / sec, and, after the fibres have been bundled to a tow, the multi-stage treatment takes place in a fibre line at a maximum temperature load which is below the glass transition temperature of the polymer component B in the sheath of the fibre.; In this way it is possible, after the multi-stage treatment and before the cutting of the fibre, to achieve a high degree of three-dimensional crimp.

Owner:OERLIKON TEXTILE GMBH & CO KG

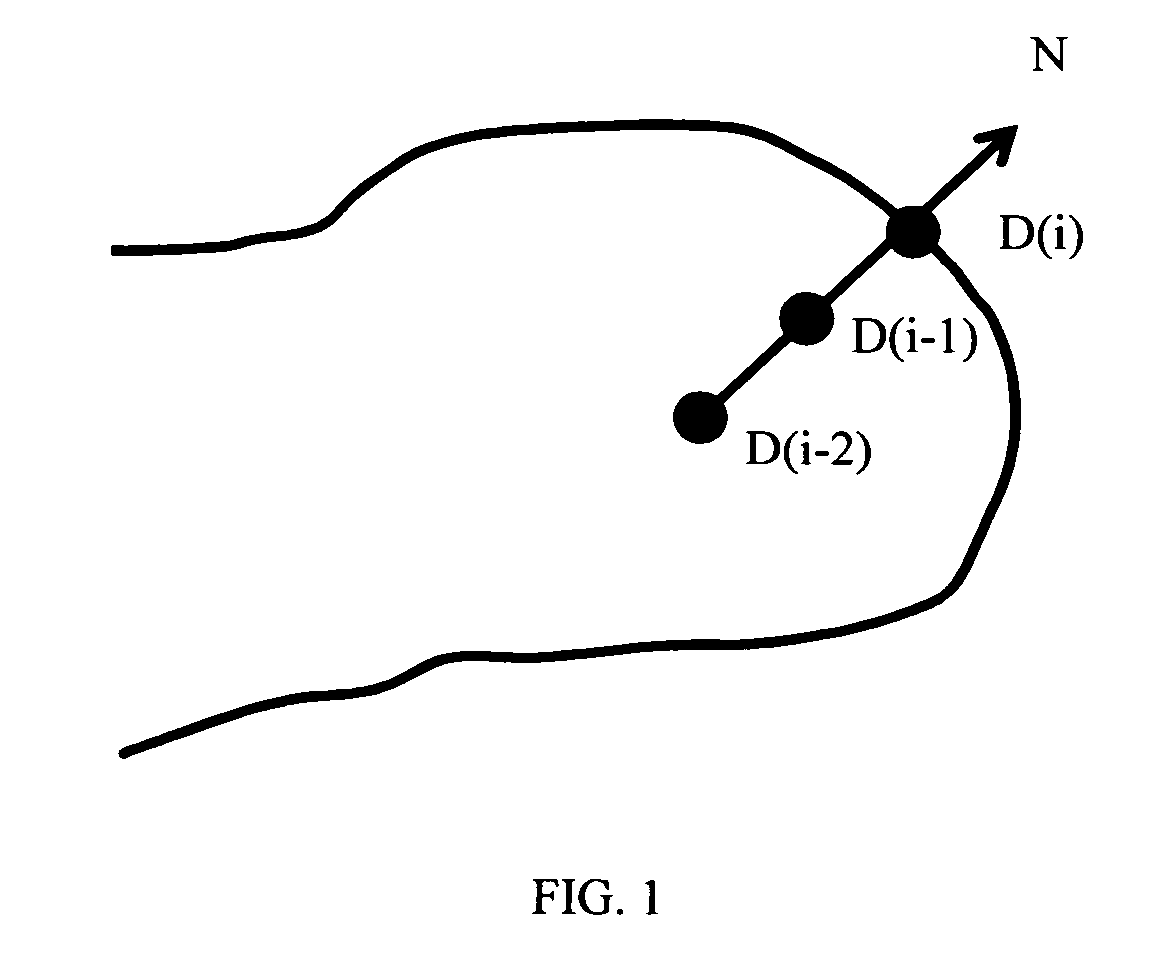

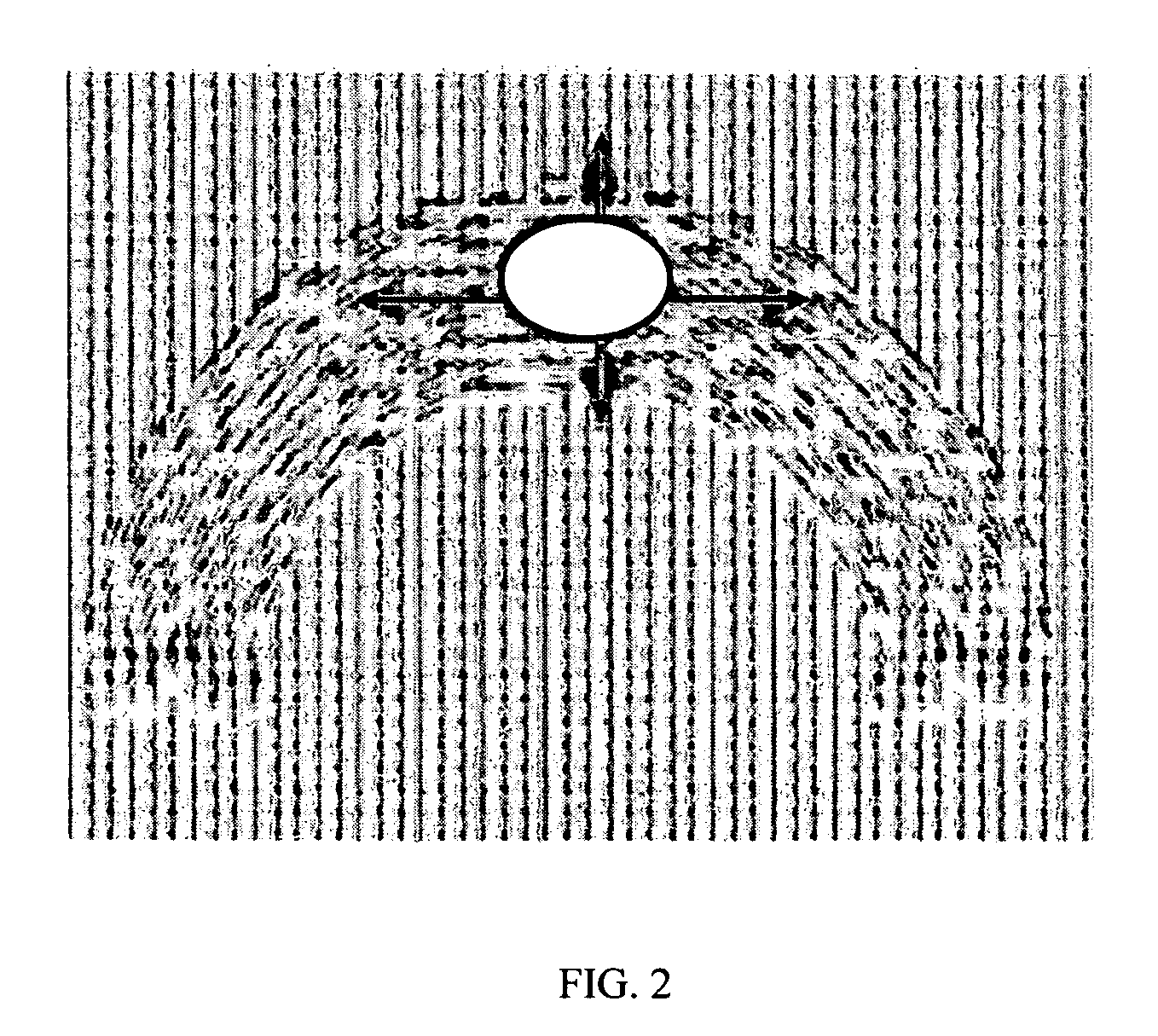

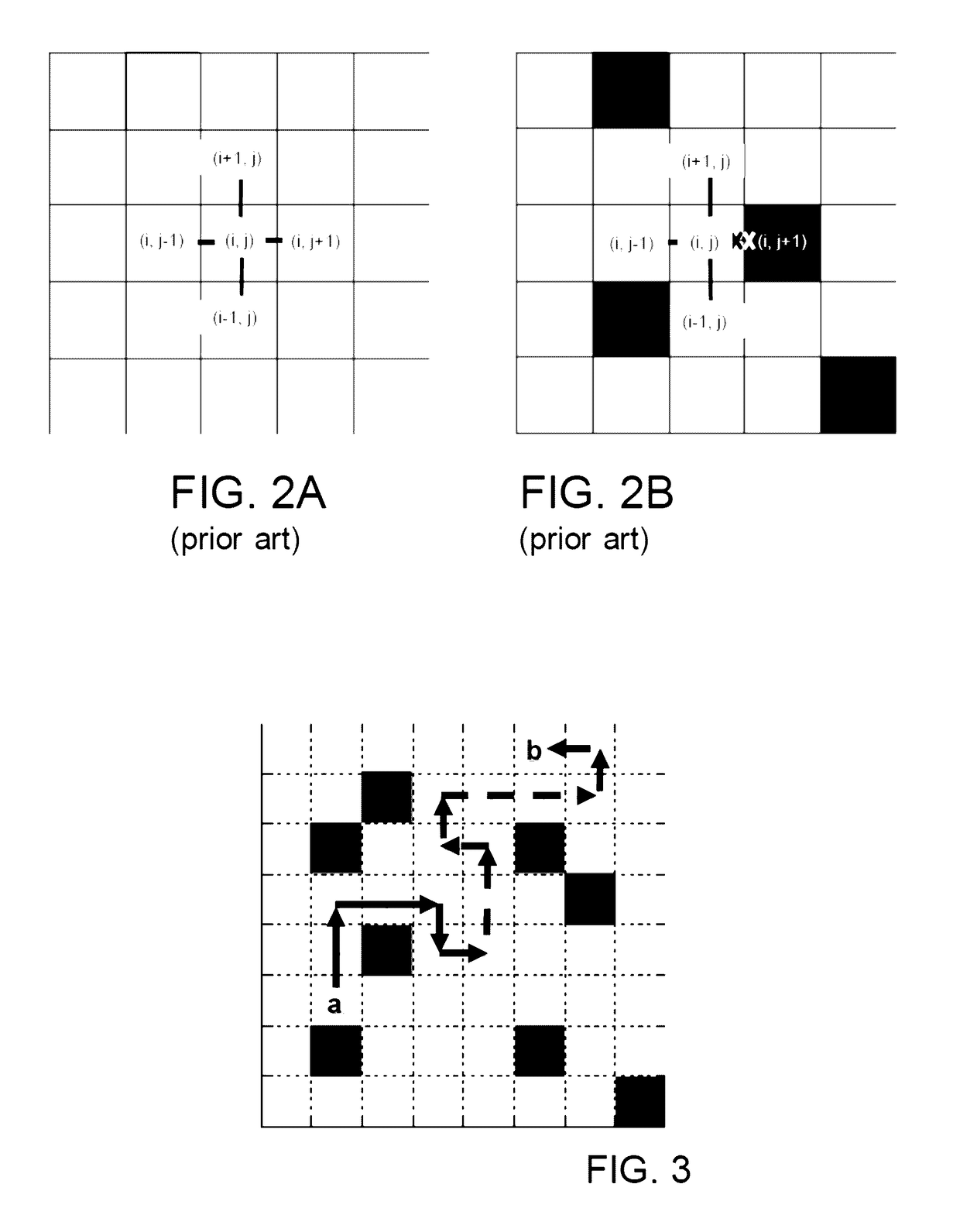

Fast geometric flows based white matter fiber tract segmentation in DT-MRI

InactiveUS20070092120A1Increase surface evolution velocityHigh speedImage enhancementImage analysisAlgorithmTensor field

Segmentation of White Matter Fiber Tract in DT-MRI images is achieved by using level sets methods including a method which will increase the speed and quality of the surface evolvement. A method system representing a measure of coincidence of the tensor field with the normal of the surface front to increase the speed and quality of a level set method in DT-MRI is disclosed.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Dyeing process and dyeing apparatus for collagen fiber regenerated leather

ActiveCN103255653AEffective penetrationUniform dyeing effectTextile treatment machine partsDyeing processFiberHigh concentration

The invention relates to a dyeing process for collagen fiber regenerated leather. The process successively comprises at least two dyeing treatment, at least one fixation treatment, at least one handfeel modification and drying treatment, wherein dyeing, fixation and handfeel modification are all carried out in an supersonic sound field, so a coloring agent, a fixing agent and a handfeel modifier can effectively penetrate into collagen fiber bundles so as to obtain a more uniform dyeing effect. The concentration of the coloring agent in sequentially used bath liquids increasingly decreases, temperatures of the bath liquids gradually increase, the power of the supersonic sound field increasingly decreases, so bath liquids with high concentration can infiltrate into a leather blank at first, and flooding which is serious in the process of filtration can be eliminated in subsequent dipping in liquids with low concentration; thus, flooding generated in subsequent procedures increasingly decreases, and uniform dyeing of the leather blank is realized. Moreover, surface flooding is eliminated in virtue of a brush of a brush roller in the invention. The invention also relates to a dyeing apparatus capable of realizing continuous uniform dyeing of cloth and leather.

Owner:JIANGYIN JUNHUA TEXTILE TECH

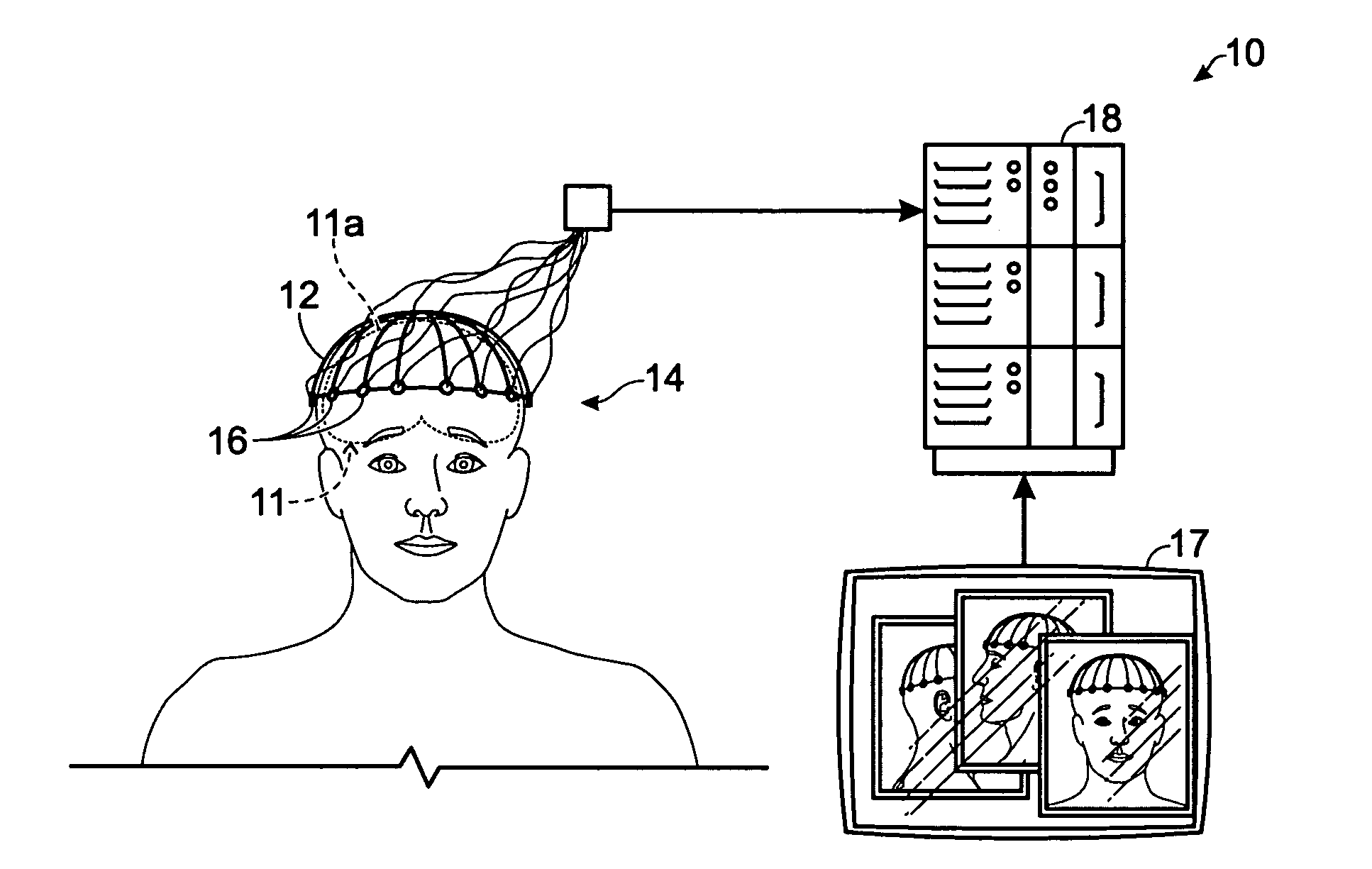

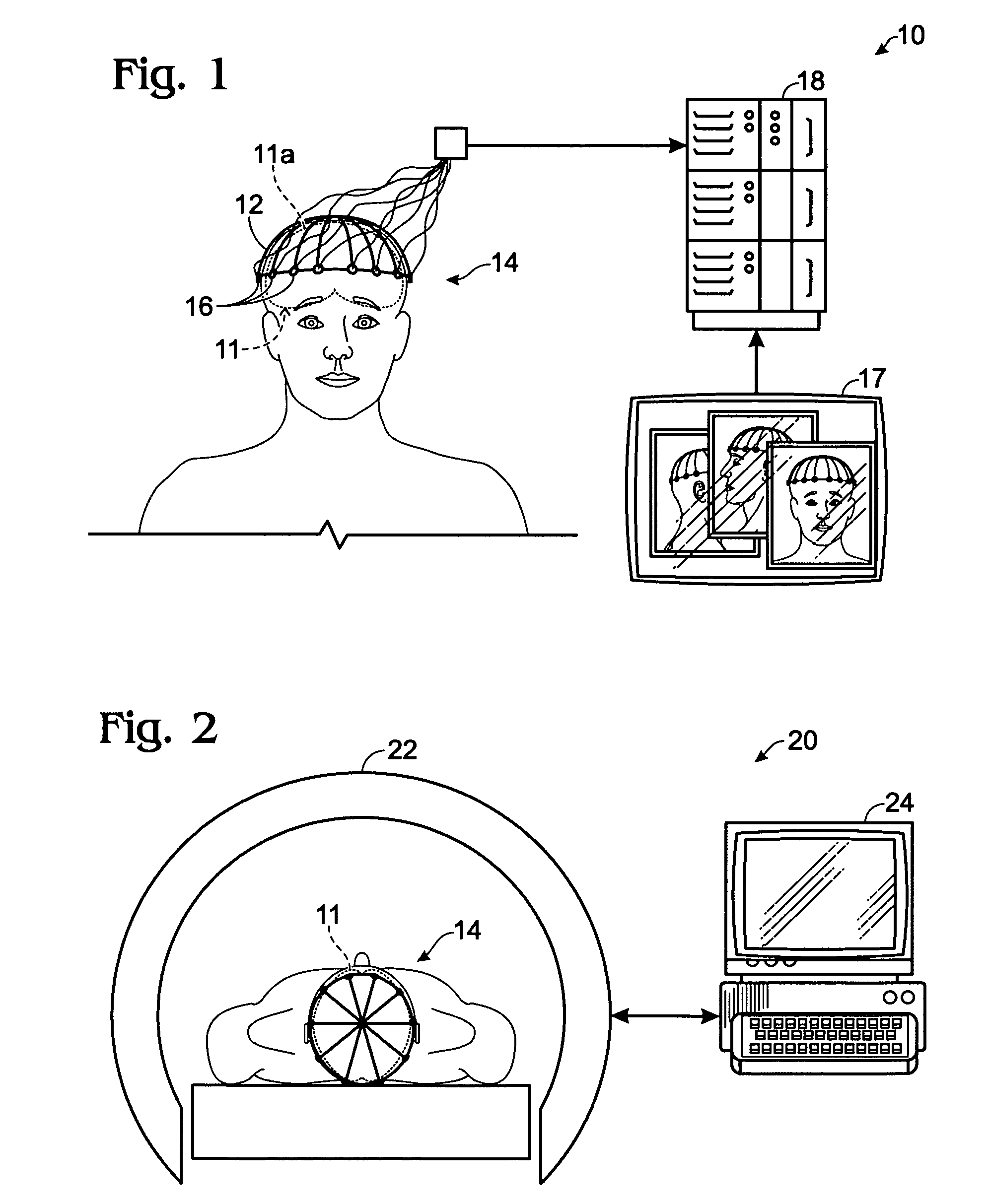

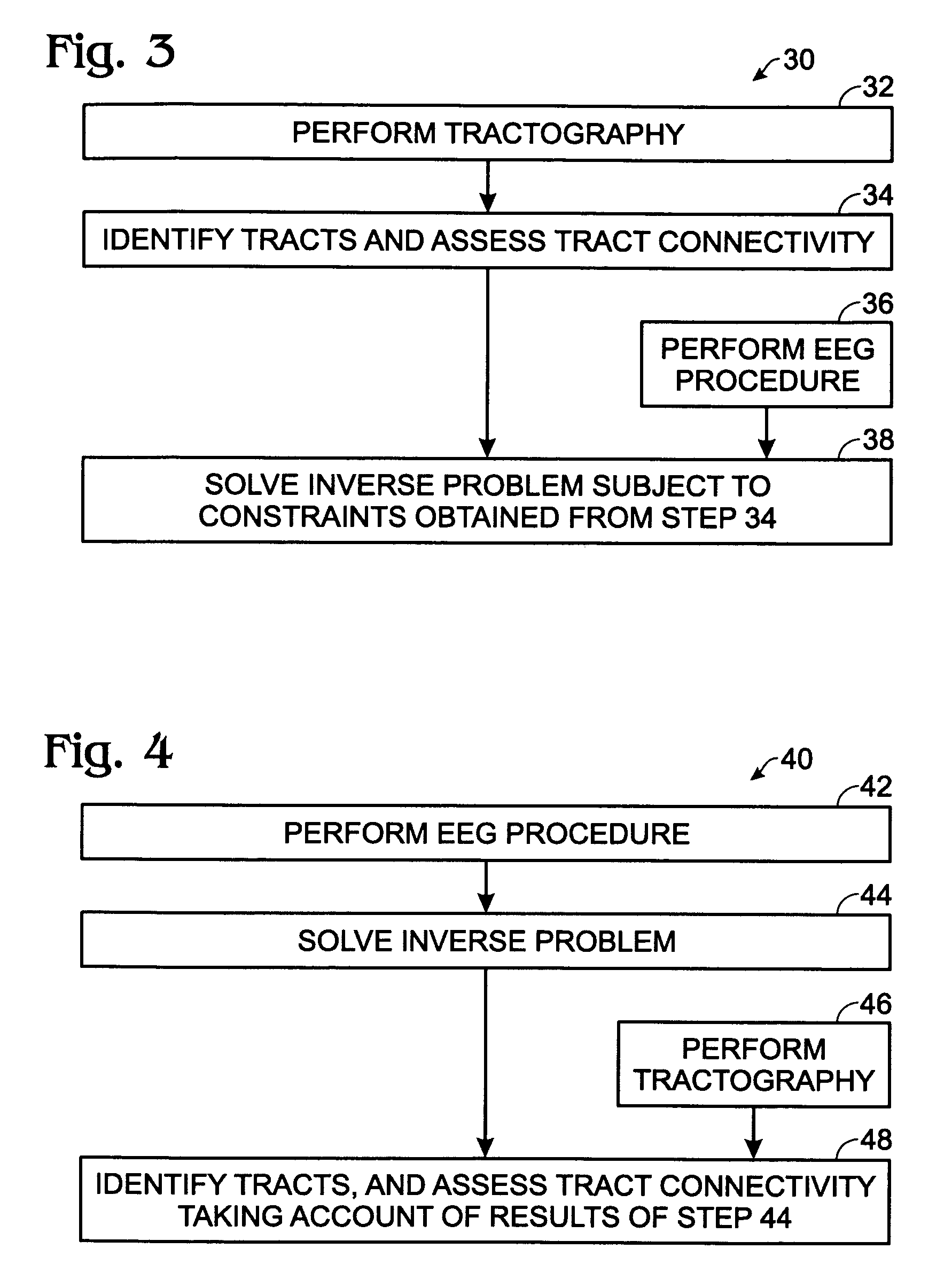

Method for locating tracts of electrical brain activity

InactiveUS20090306532A1Easy to understandElectroencephalographyMagnetic measurementsFiber tractographyComputer science

A method and apparatus for locating tracts of electrical brain activity. A source localization procedure may be performed including solving the inverse problem subject to one or more constraints resulting from a tractographic procedure, and a tractographic procedure may be performed that includes obtaining a probabilistic assessment of tract connectivity that takes account of the results of a source localization procedure.

Owner:ELECTRICAL GEODESICS

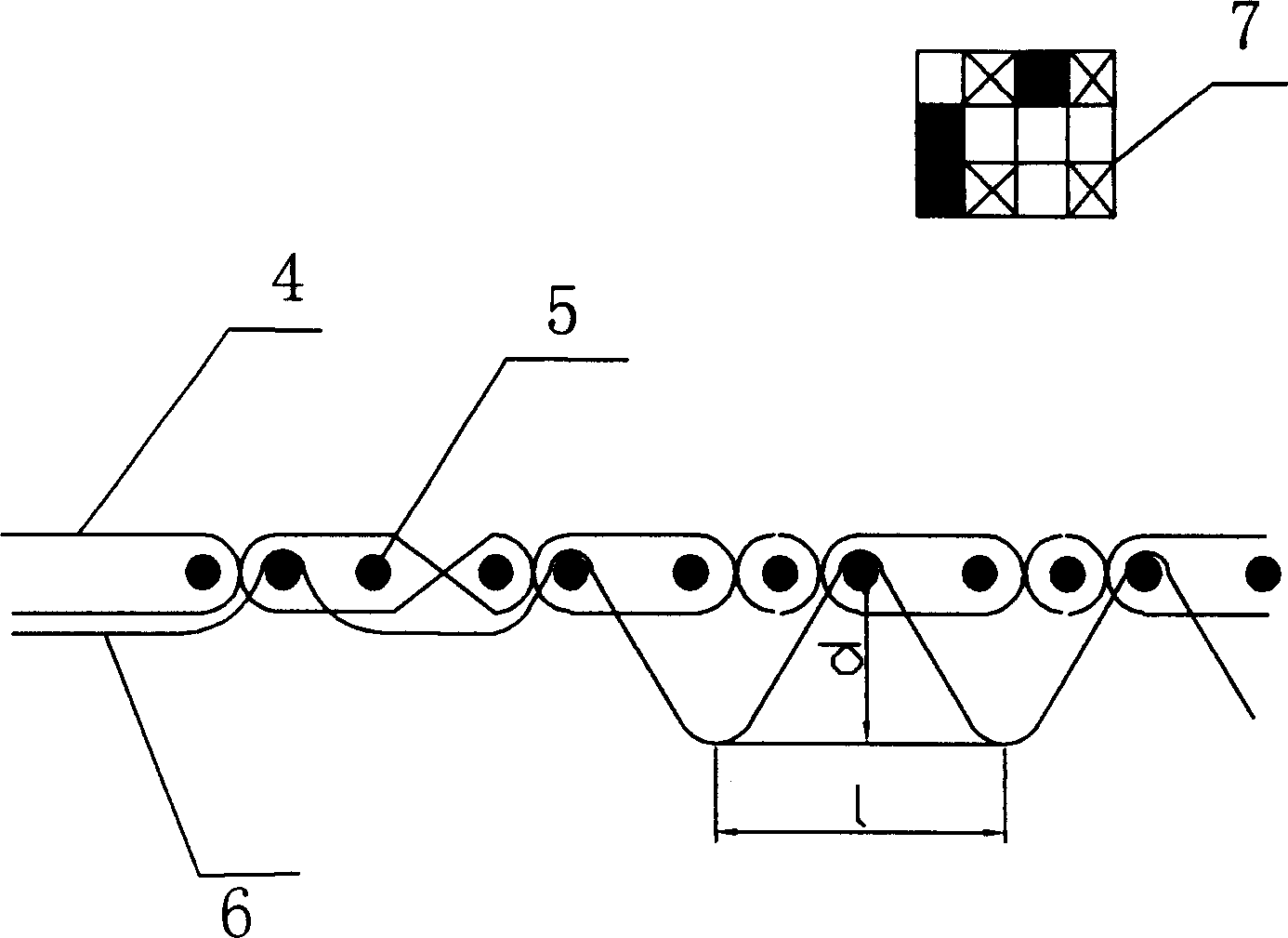

Spinning frame having multi-stage condensation draft unit

InactiveCN1483870AFull spinning twistHigh strengthDrafting machinesContinuous wound-up machinesFiberMaterial Perforation

The frame is equipped with a suction device 25 equipped with a perforation range 35 on a pair of exit rollers of a multi step drafting machine 13, and the suction device 25 provides a guiding plane for sliver to form a condensing step, set to form compact fiber strands by condensing the slivers in the condensing step, and a revolution changing device 52d is equipped on a drafting device 13 or a driving mechanism for drafting device, and revolutions of the individual roller pairs 29 become free from each other in relation to time that induces the compact fiber strands 22, 22' to receive a variable draft in time.

Owner:MASCHINENFABRIK RIETER AG

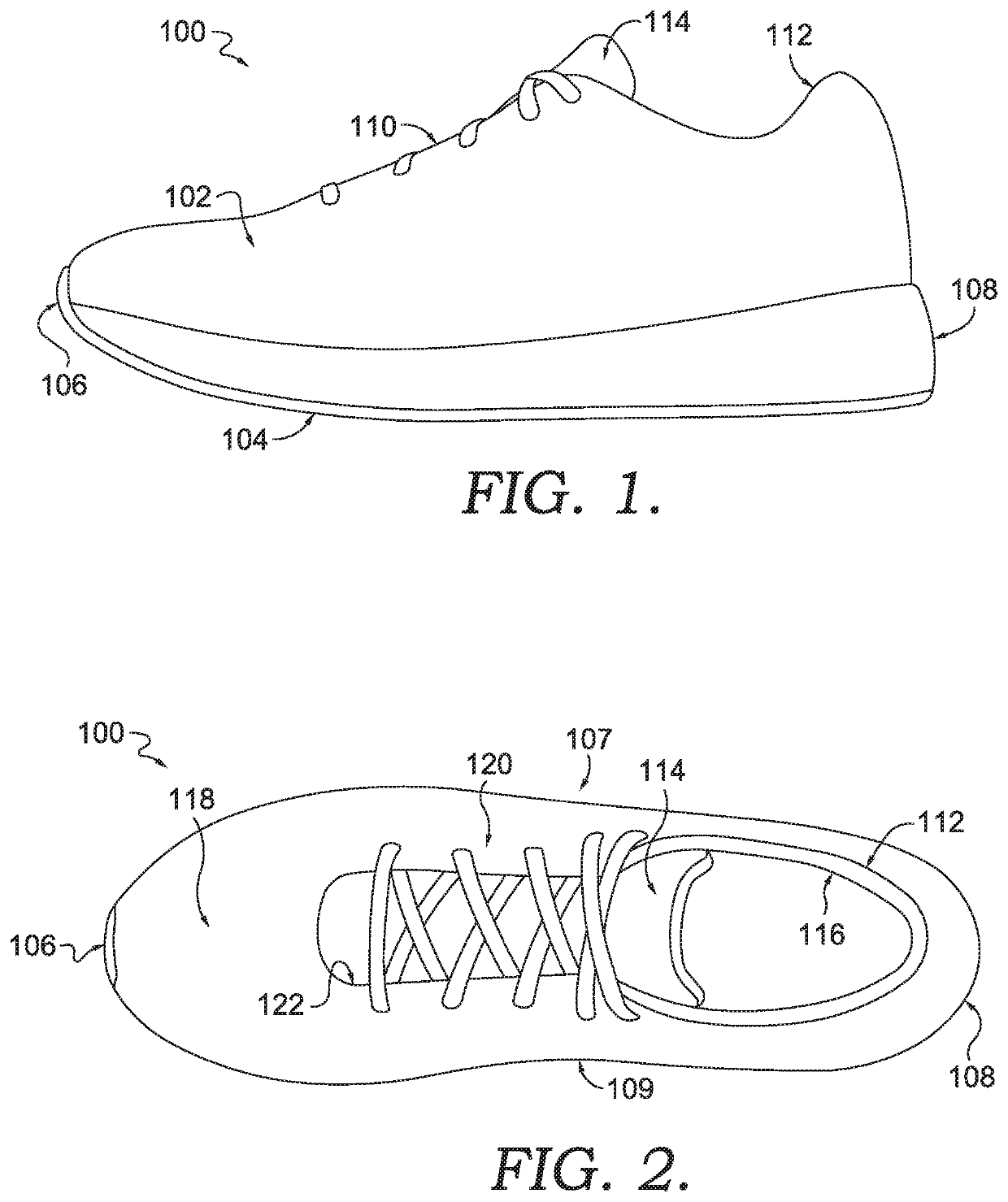

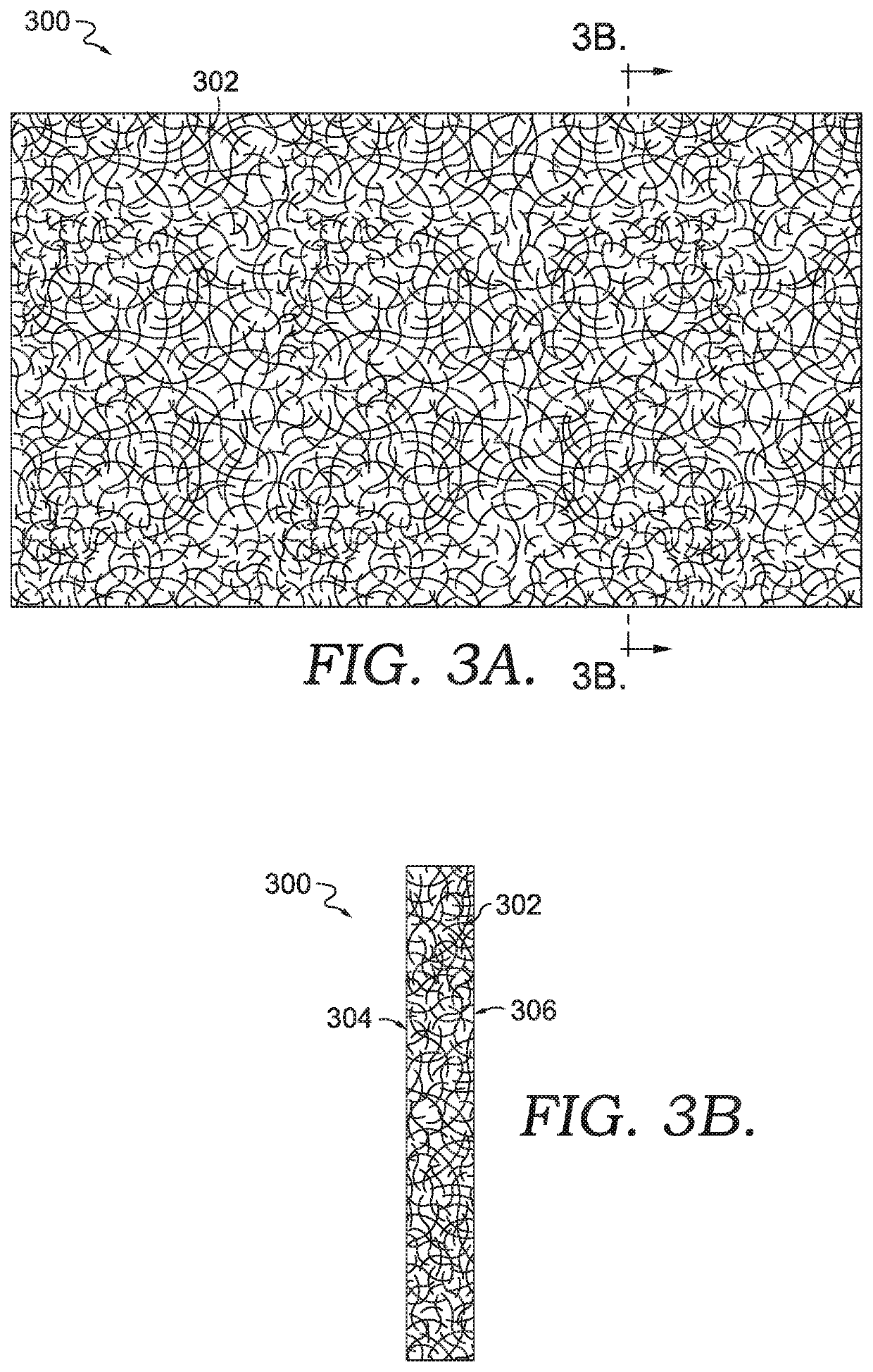

Fiber-Bound Engineered Materials Formed Using Zonal Scrims

A fiber bound engineered material is provided that imparts an intended characteristic at an intended relative location. A fiber layer is entangled with additional fibers in a manner to create a non-uniform engineered material. The lack of uniformity of a fiber bound engineered material may be accomplished through manipulation of the fibers and / or through fiber binding a scrim. The fiber layer binds with additional fibers through entanglement such that a mechanical connection between the entangled fibers is provided. This entanglement allows the fibers to bind without supplemental adhesives, interlacing, or connections. Variations in the fibers and / or inclusion of scrim materials prior to entanglement allows for an intended characteristic (e.g., a functional characteristic) at an intended relative location (e.g., a position determined by an article to be formed therefrom).

Owner:NIKE INC

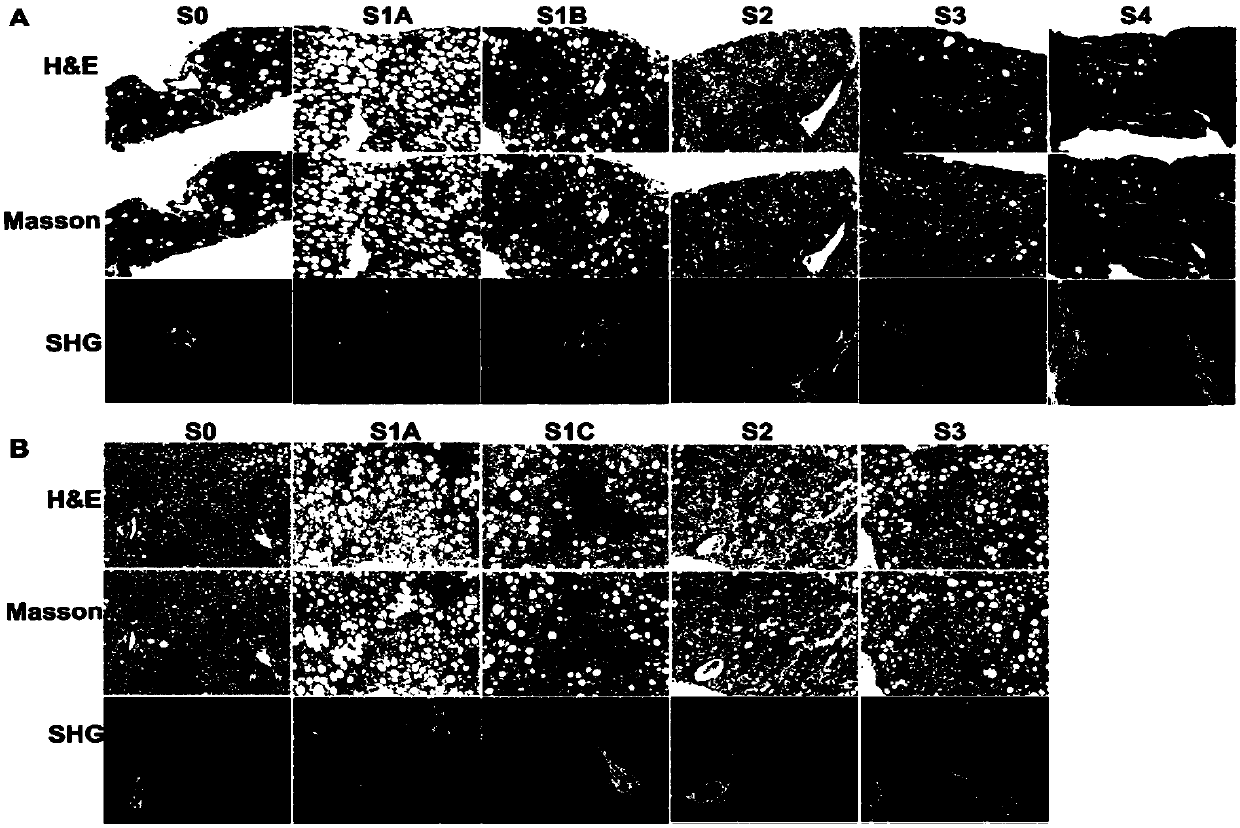

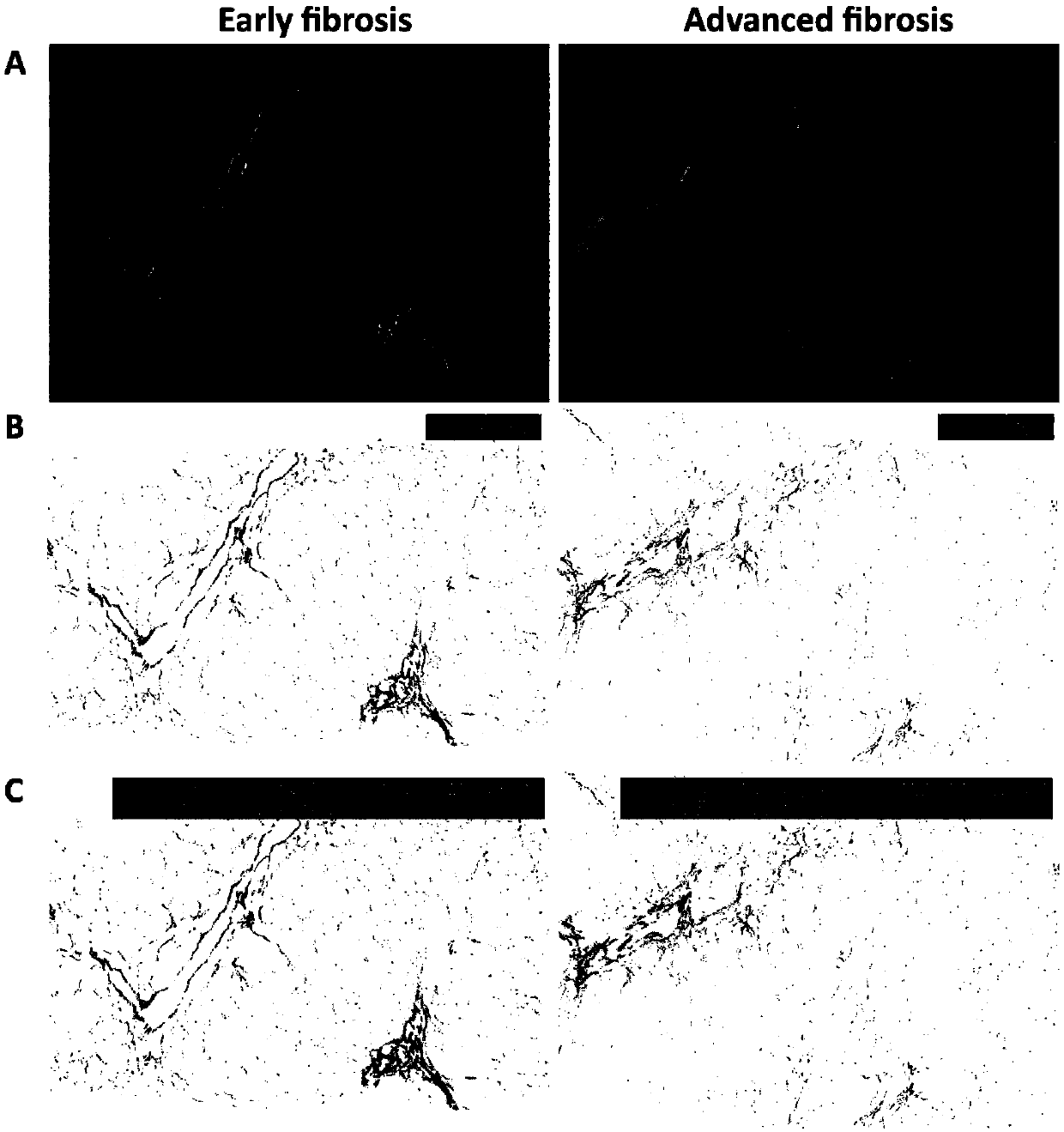

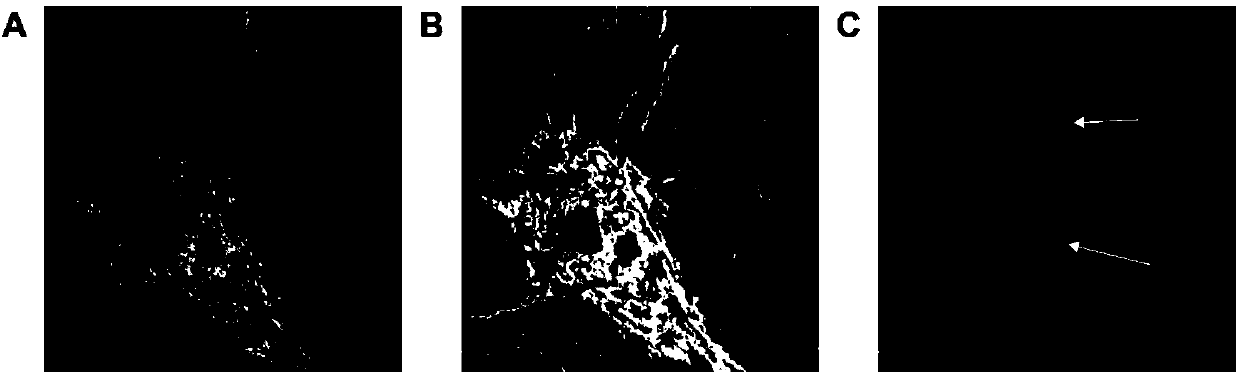

Application of parameters in SHG/TPEF images as hepatic fibrosis staging characteristic parameters of adults or children

InactiveCN107895368AEffective resolutionEffective resolution of stagingImage enhancementImage analysisFiberVein

The invention relates to the field of photo-electrochemical detection, and especially relates to an application of parameters in SHG / TPEF images as hepatic fibrosis staging characteristic parameters of adults or children. Images of nonchromosomal tissues obtained from liver puncture of adults and children are formed by means of an SHG / TPEF technology, and fibrosis characteristic parameters of a central vein area / portal area / perisinusoidal area are extracted by means of a digital image processing technology. Whether a sample is an adult or child is distinguished by means of four parameters (thenumber of crosslinking points in the portal area, the percentage of accumulative collagen in the portal area, the number of accumulative long tracts in the central vein area or the number of discretethick tracts in the central vein area). Fibrosis evaluation is carried out by means of six fibrosis characteristic parameters (the fiber tract length, the fiber tract width, the fiber tract eccentricity, the fiber tract toughness, the number of fiber tracts in the portal area and the number of short fiber tracts in the portal area), and the NASH CRN stages of adults and children can be effectively distinguished.

Owner:PEOPLES HOSPITAL PEKING UNIV +1

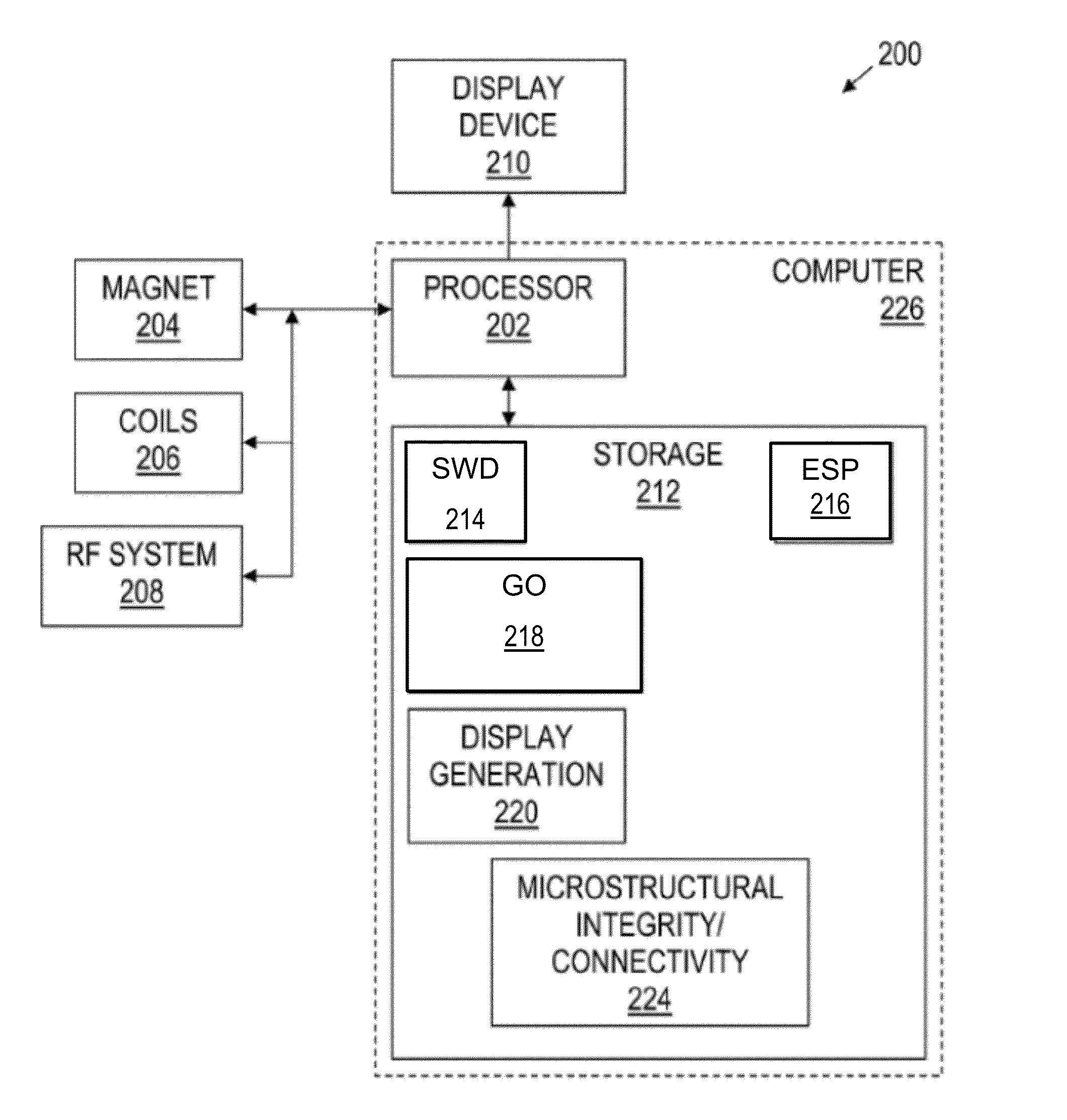

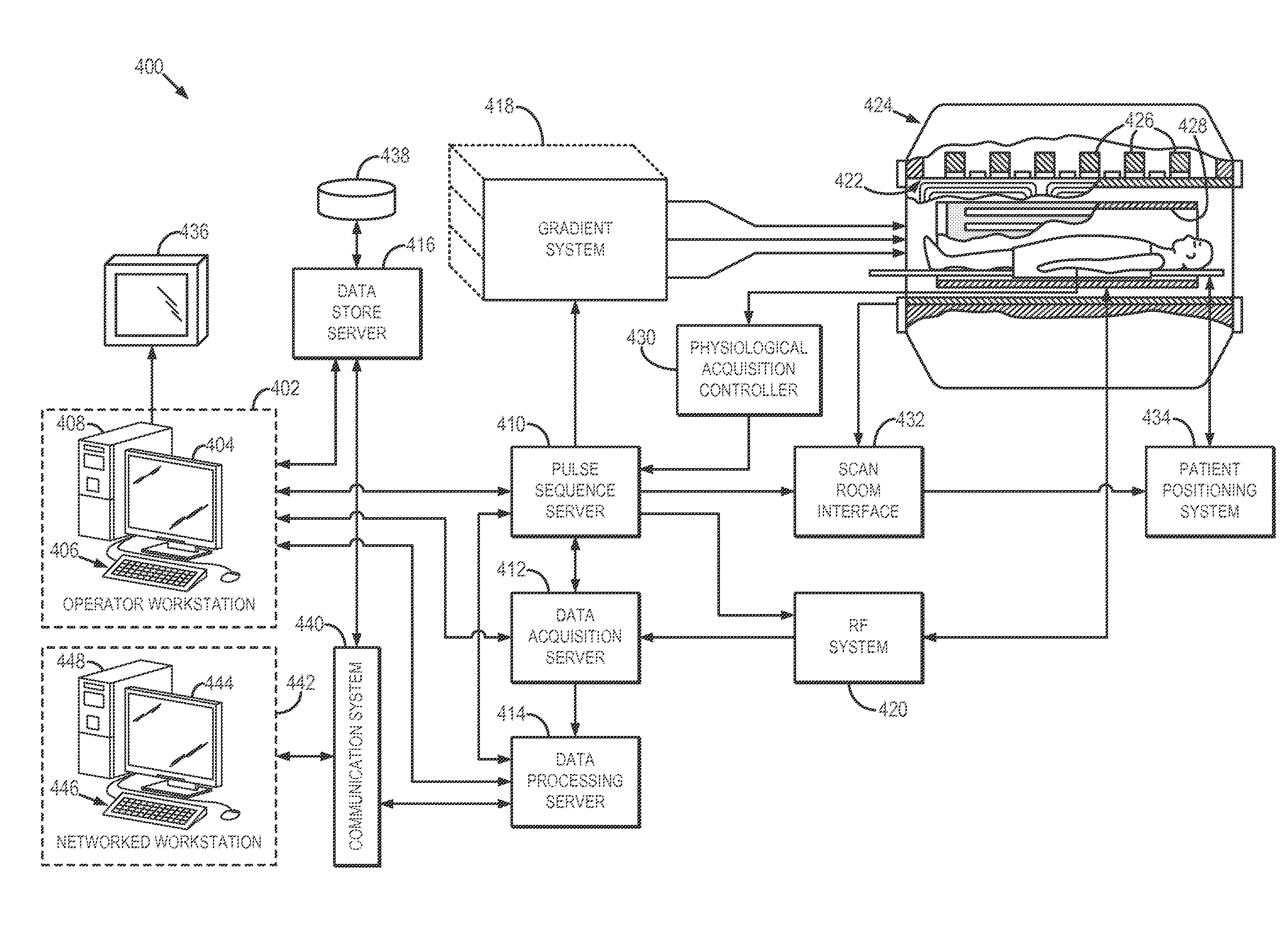

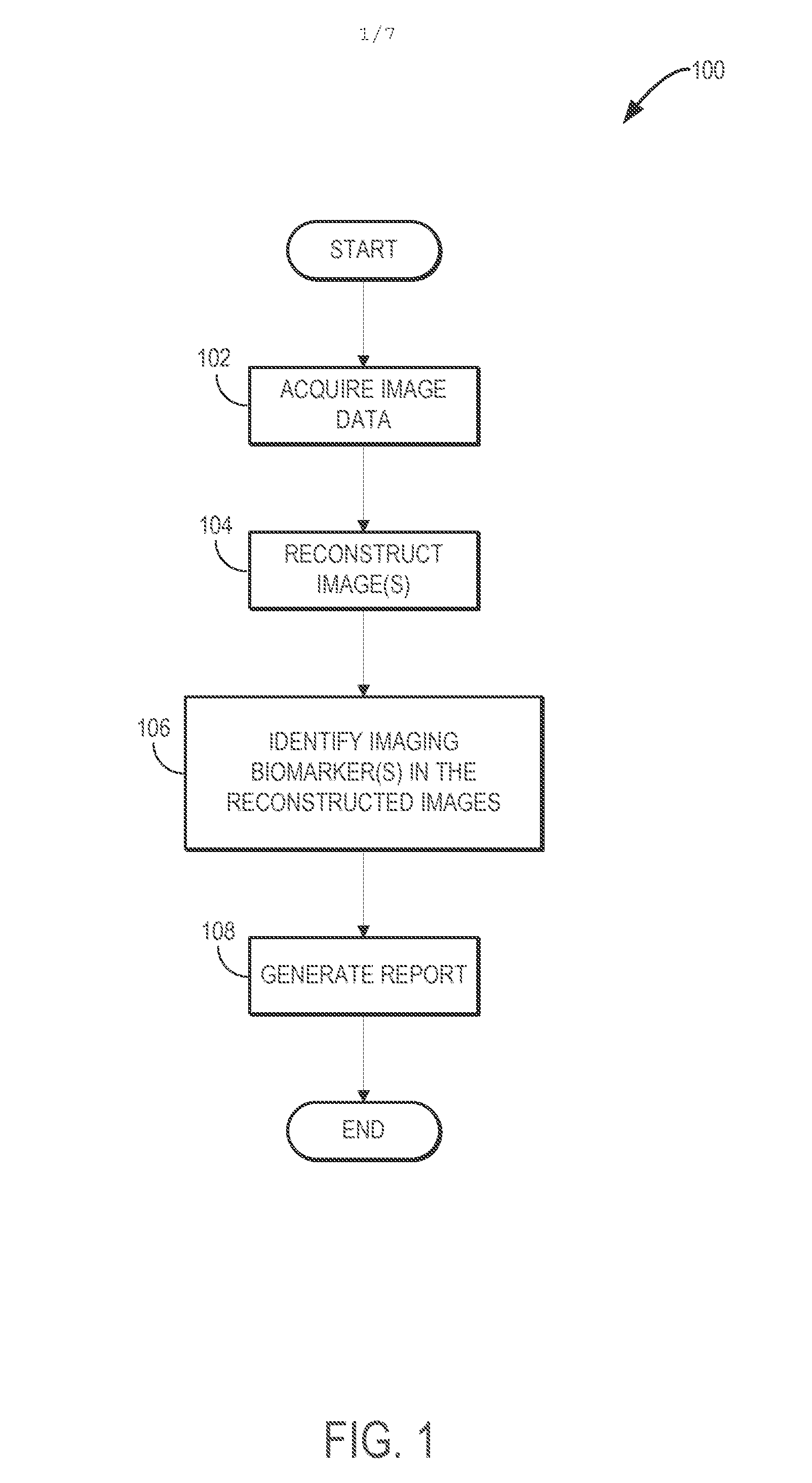

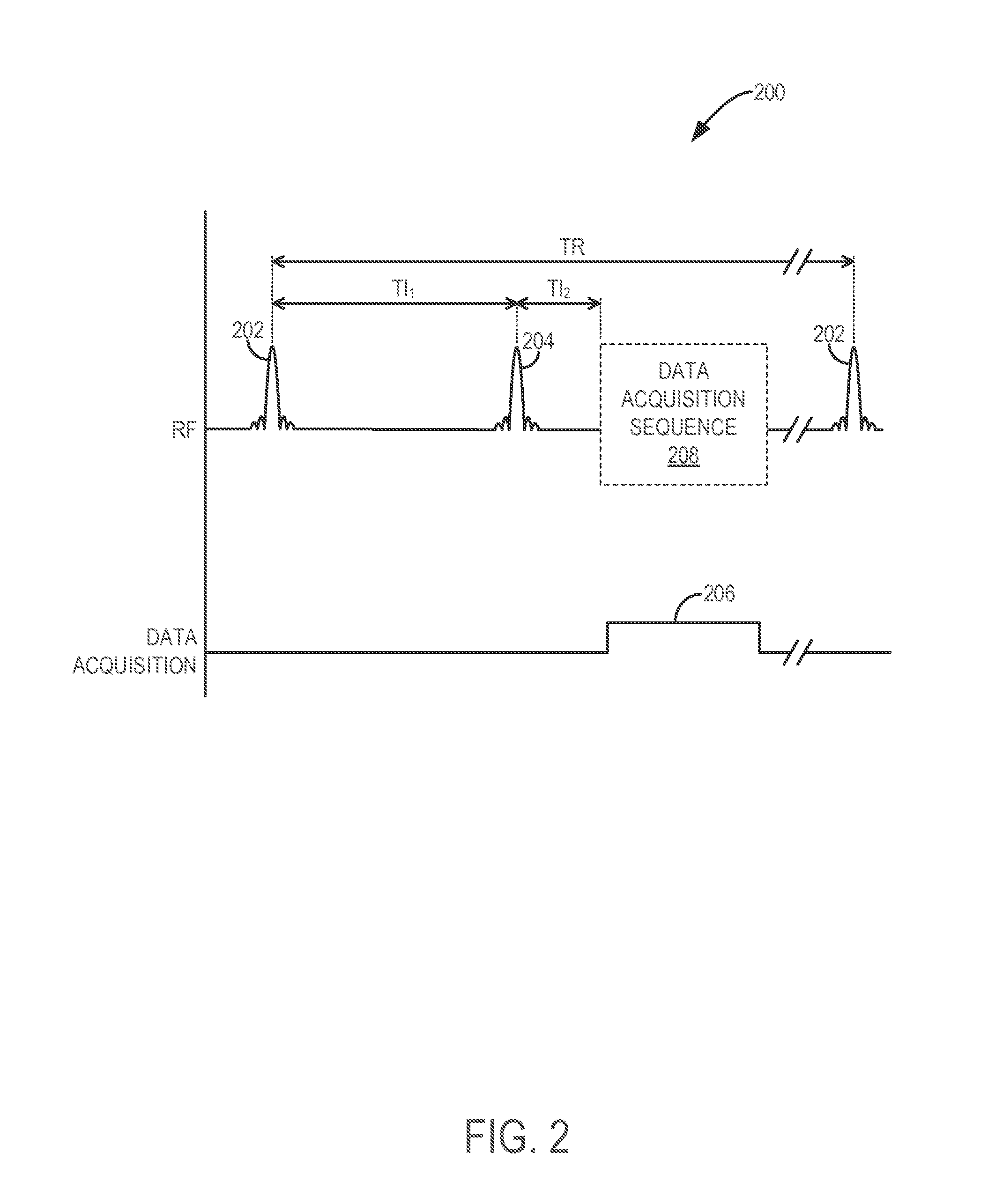

Systems and methods for producing imaging biomarkers indicative of a neurological disease state using gray matter suppressions via double inversion-recovery magnetic resonance imaging

ActiveUS20160220168A1Medical imagingMeasurements using NMR imaging systemsInversion recoveryPulse sequence

Systems and methods related to imaging biomarkers for determining neurological disease states of a subject are provided. In one embodiment, a method for producing an image indicative of a neurological disease using a magnetic resonance imaging (“MRI”) system is provided. The method includes directing the MRI system to perform a double inversion-recovery (“DIR”) pulse sequence to generate data where signals from gray matter and cerebral spinal fluid are substantially suppressed. The method also includes analyzing the DIR images, reconstructed from the acquired data, to identify cortical and white matter lesions. This includes identifying imaging biomarkers based on visual signatures of brain tissue, including white matter tissue. In some aspects, diffusion-weighted data may also be obtained using the MRI system. Diffusion-weighted data may be used in a tractography process to determine connectivities, or connectivity patterns between the identified lesions, including cortical lesions, to determine neurological disease states of the subject.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

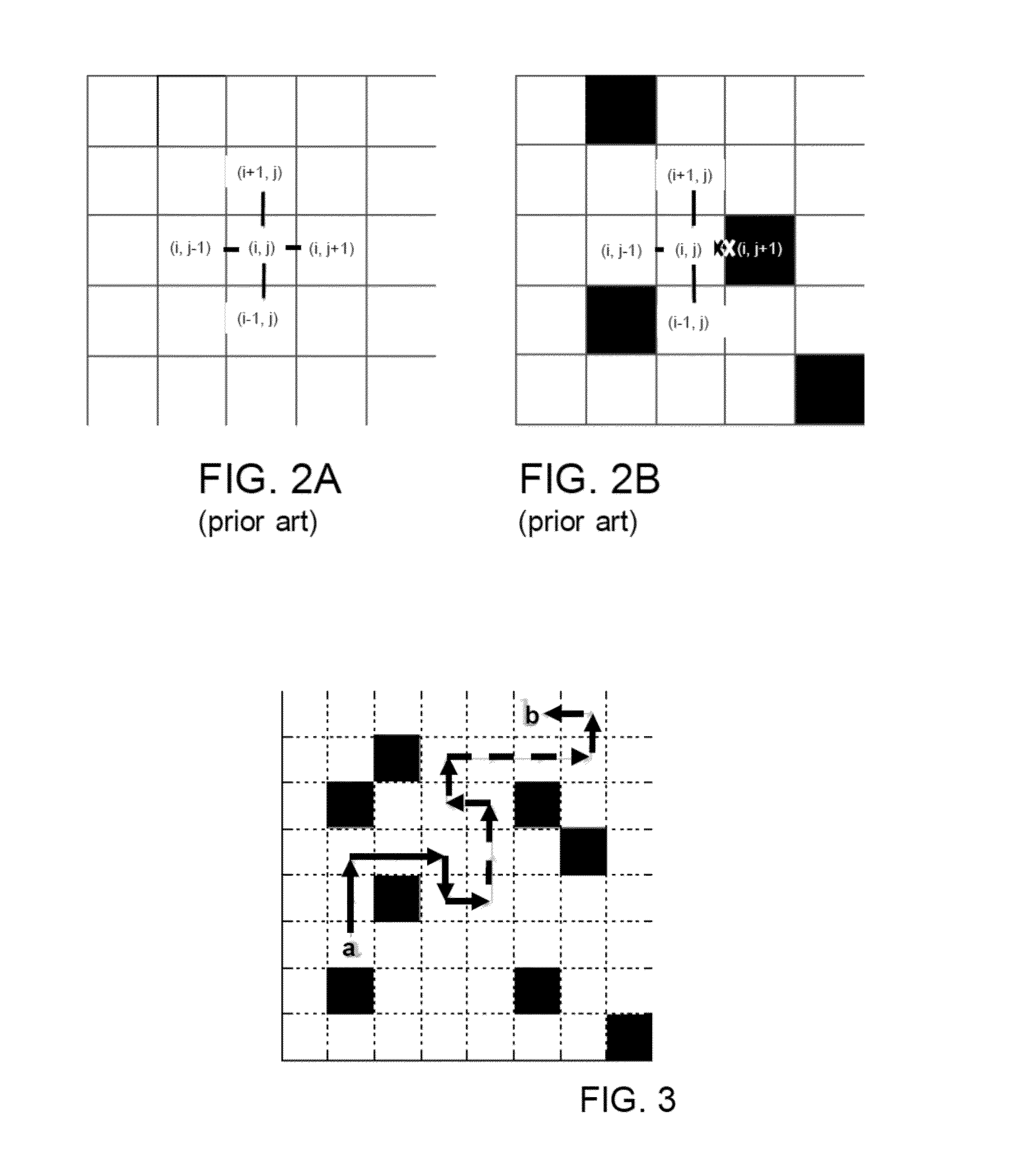

Fiber tractography using entropy spectrum pathways

ActiveUS9645212B2Simple methodAccurate informationImage enhancementMedical imagingFiberFiber tractography

A method for fiber tractography processes multi-shell diffusion weighted MRI data to identify fiber tracts by calculating intravoxel diffusion characteristics from the MRI data. A transition probability is calculated for each possible path on the lattice, with the transition probability weighted according the intravoxel characteristics. Entropy is calculated for each path and the paths are ranked according to entropy. A geometrical optics algorithm is applied to the entropy data to define pathways, which are ranked according to their significance to generate a map of the pathways.

Owner:RGT UNIV OF CALIFORNIA +1

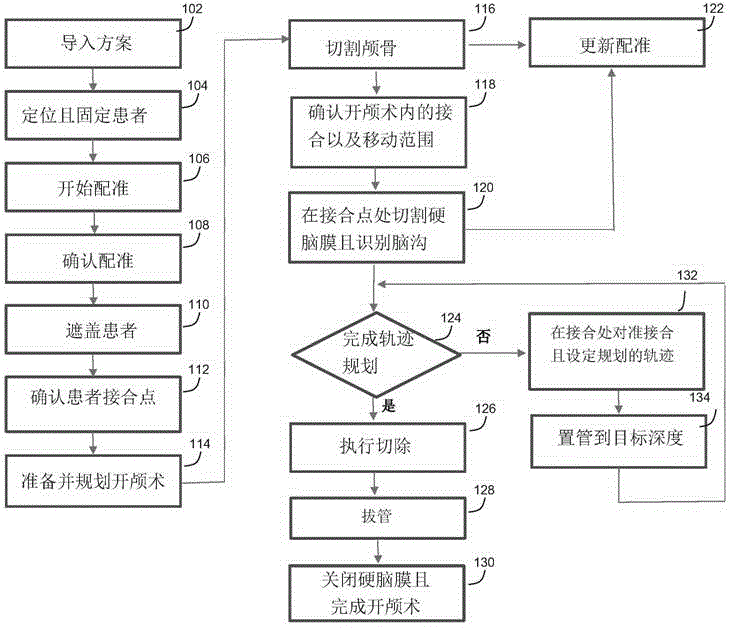

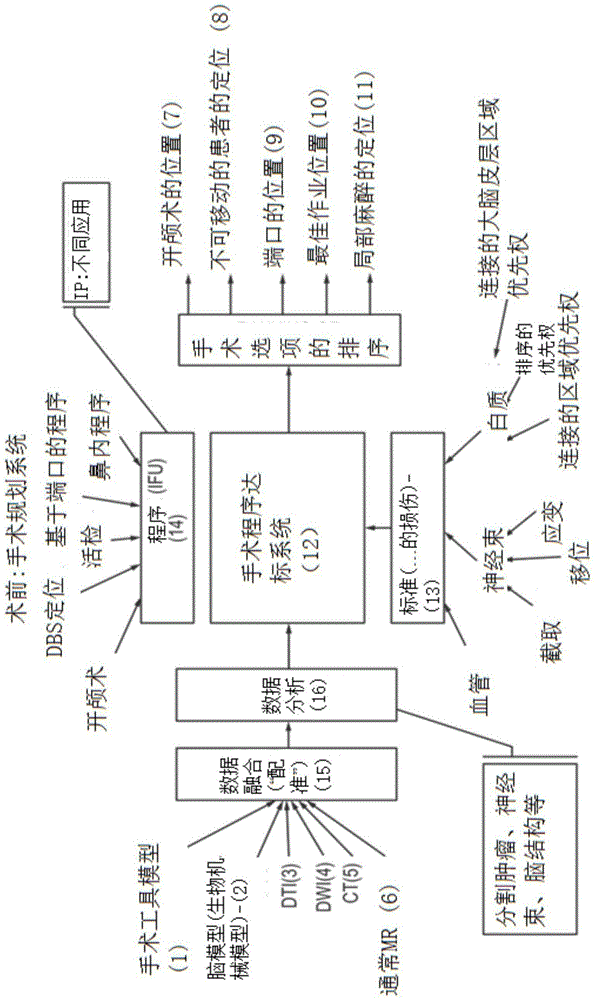

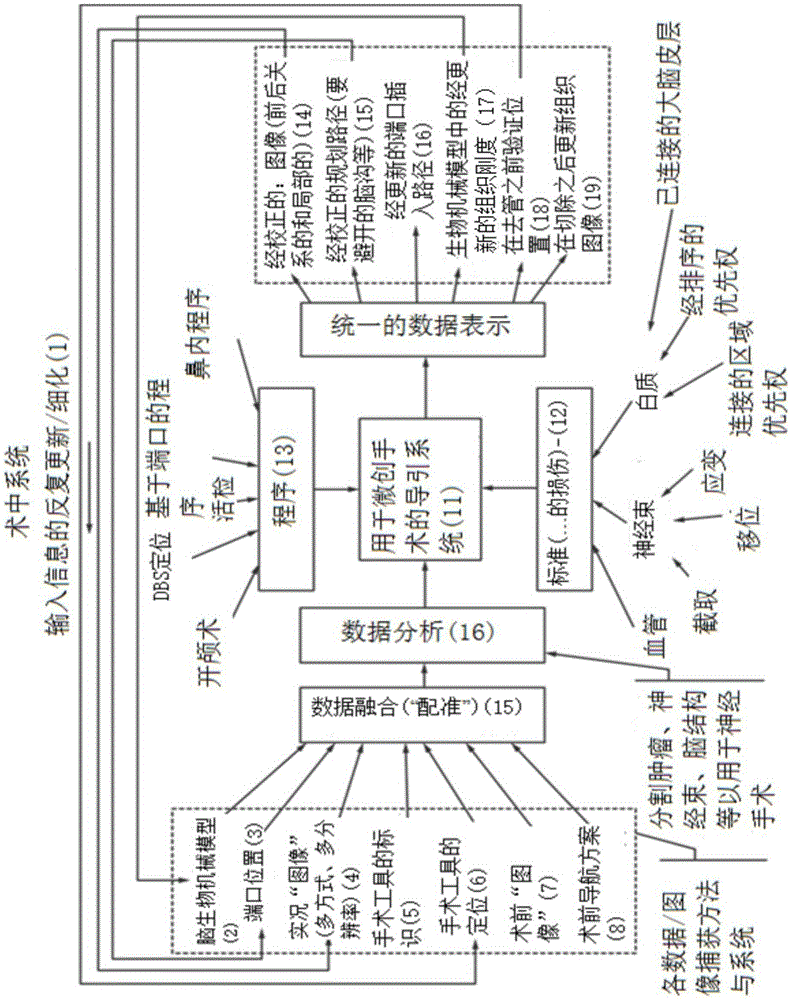

System and method for detecting tissue and fiber tract deformation

Disclosed herein is a method for producing an evolvable tissue model of a patient and, using this model, modelling physical transformations of the tissue (e.g. deformation) of the tissue model by interacting the tissue model with influence models which model interactions with the tissue such as surgical instruments, pressure, swelling, temperature changes etc. The model is produced from a set of input data of the tissue which includes directional information of the tissue. The directional information is used to produce an oriented tissue map. A tissue model is then produced from the oriented tissue map such that the tissue model reflects the directionality of the tissue component. When the tissue model is subjected to an influence that causes tissue deformation over a period of time, the tissue model directionally deforms over the period of time in a manner which reflects a trajectory of the influence interacting with the directionality of the tissue component.

Owner:SYNAPTIVE MEDICAL (BARBADOS) INC

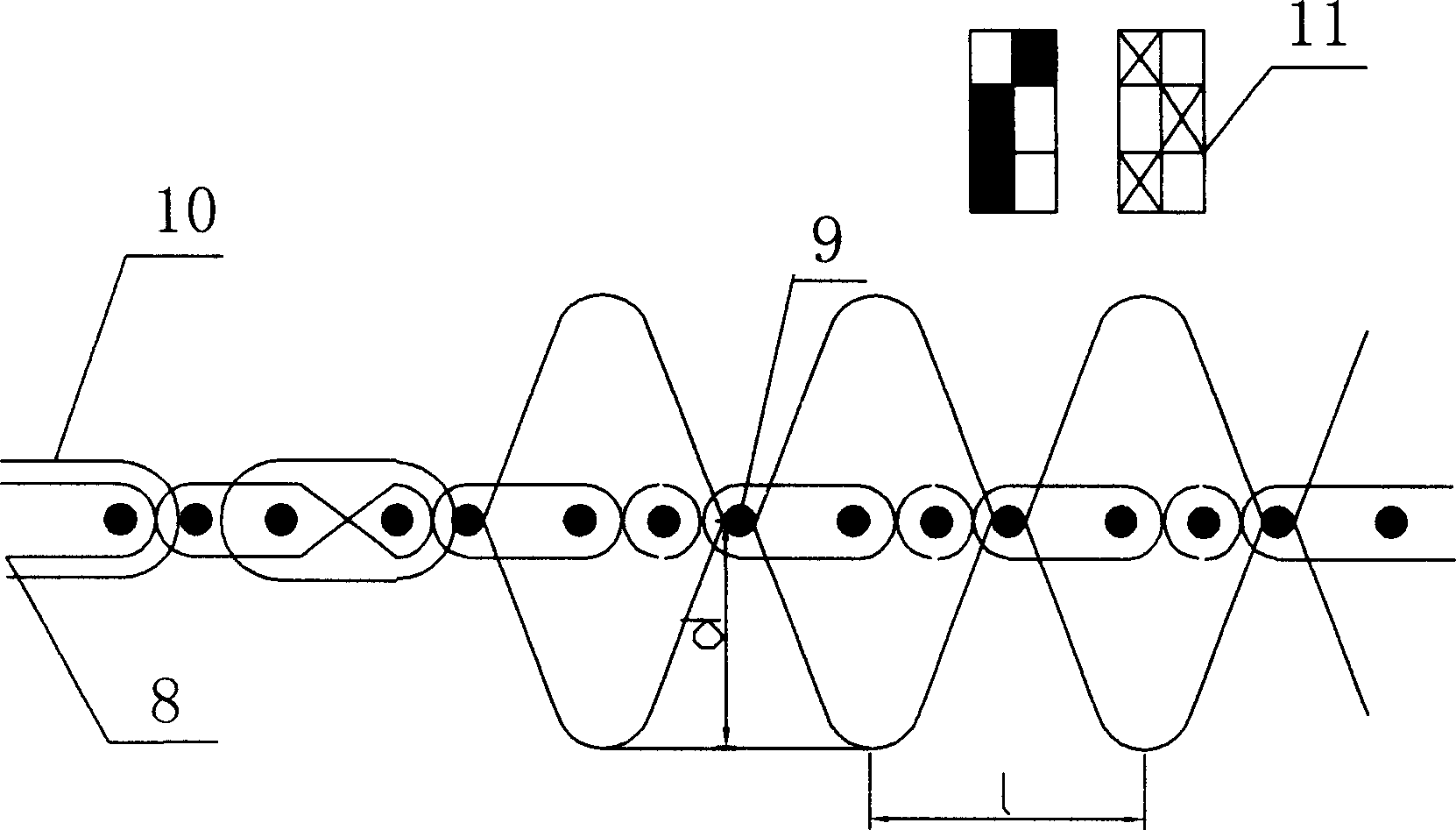

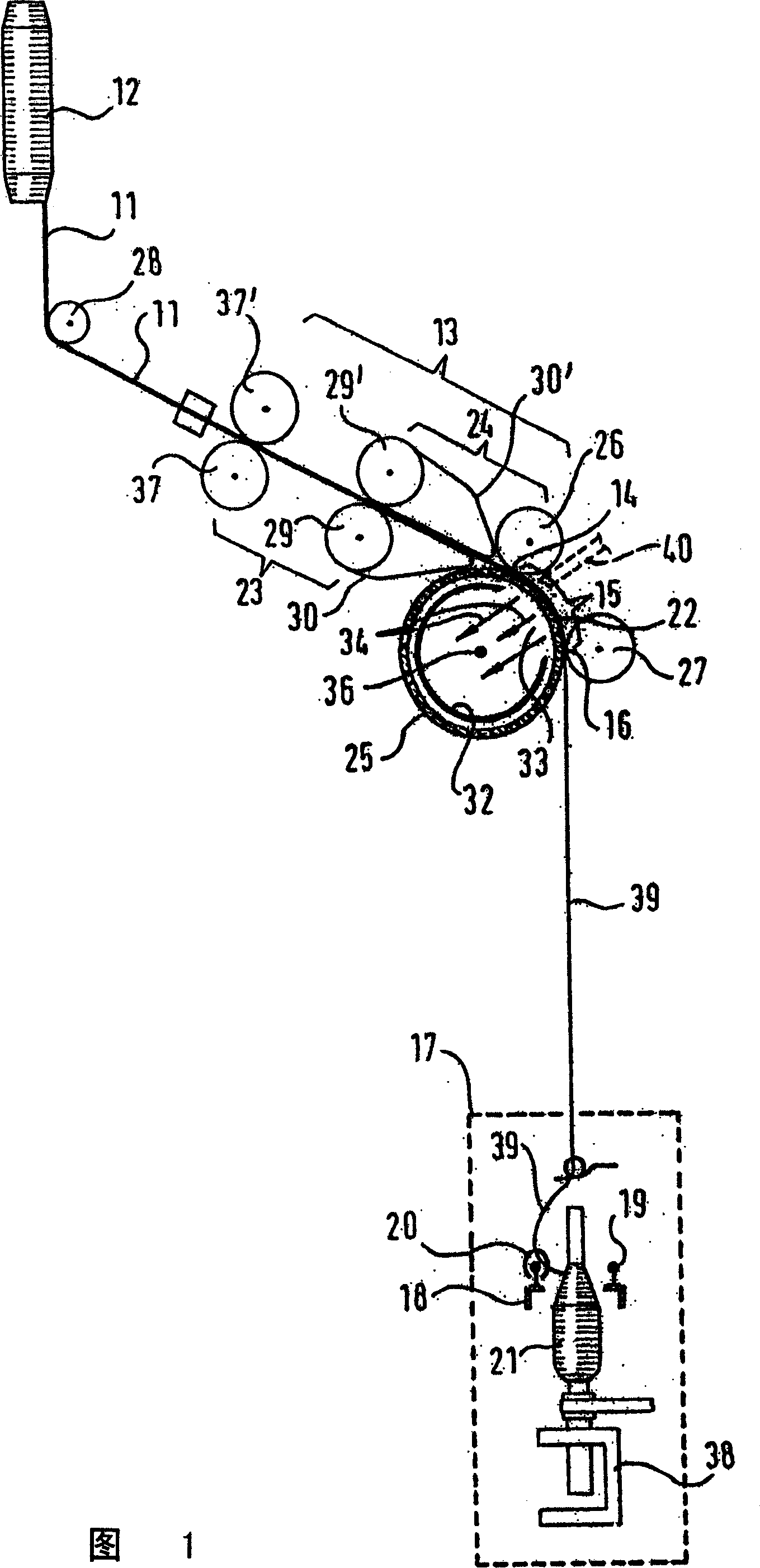

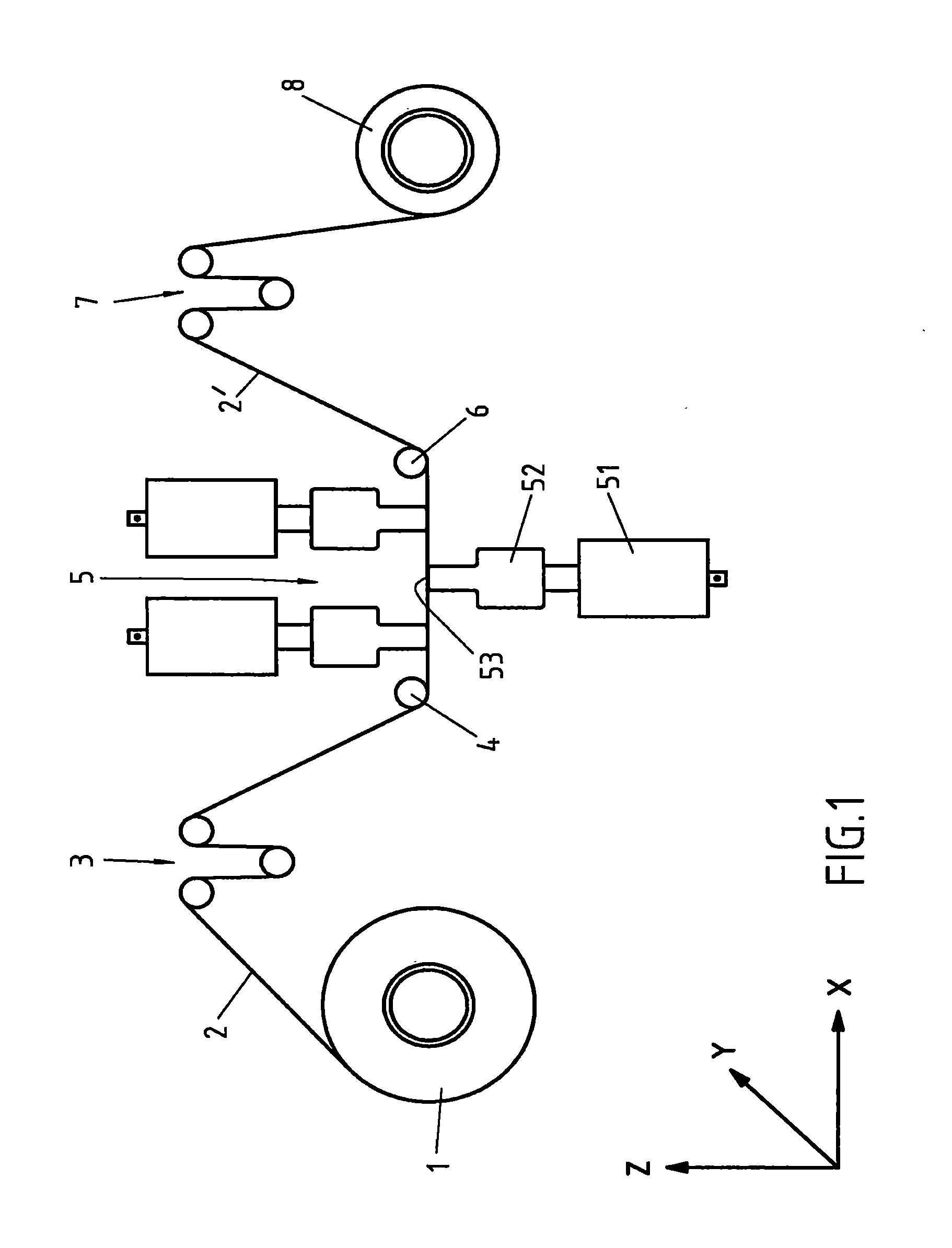

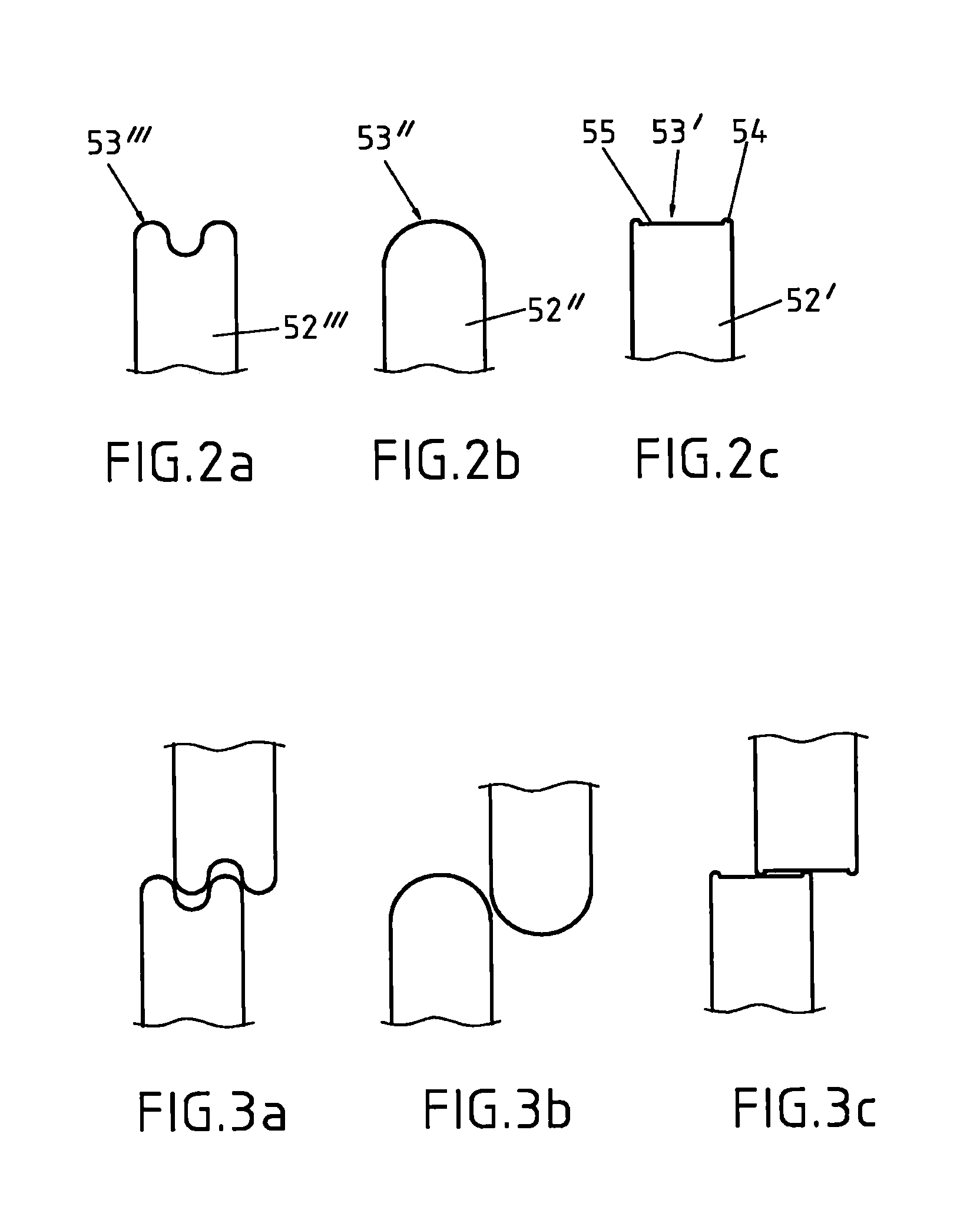

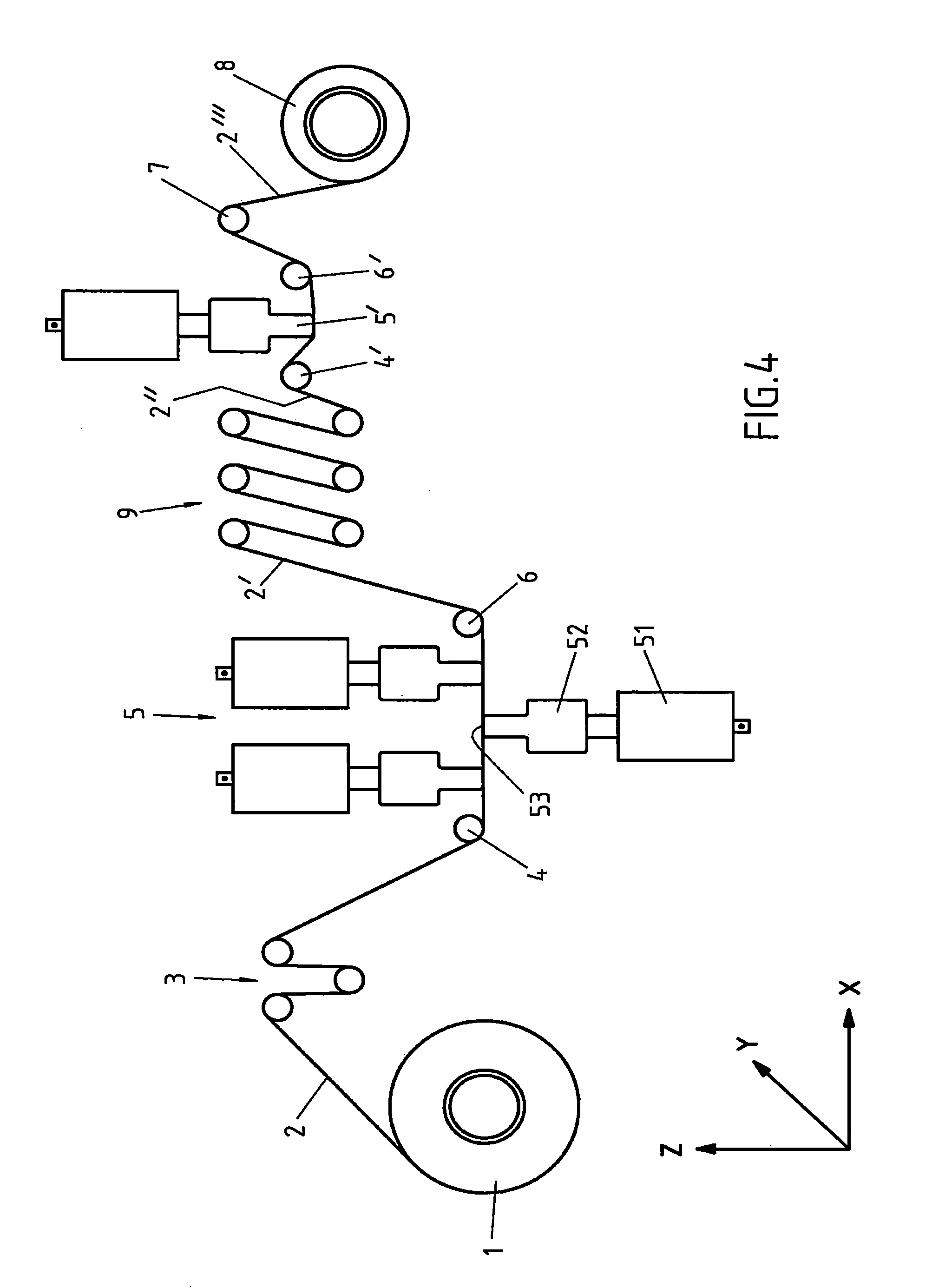

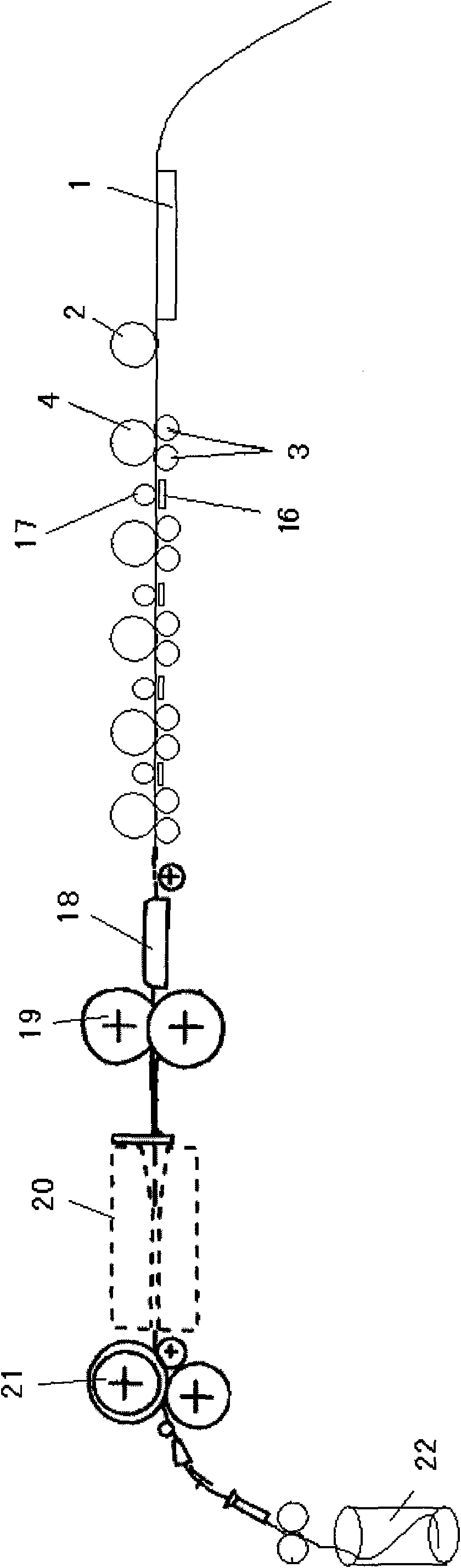

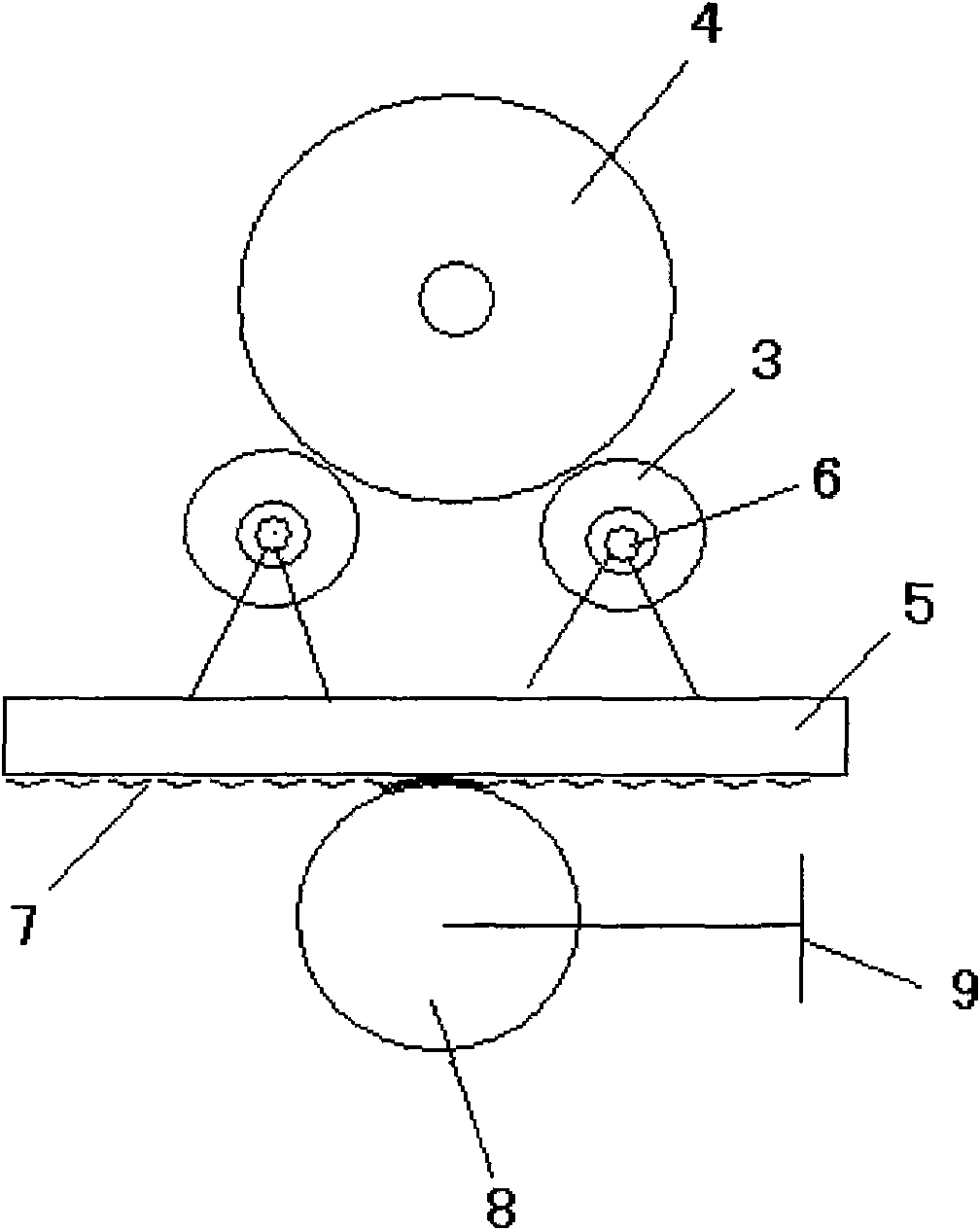

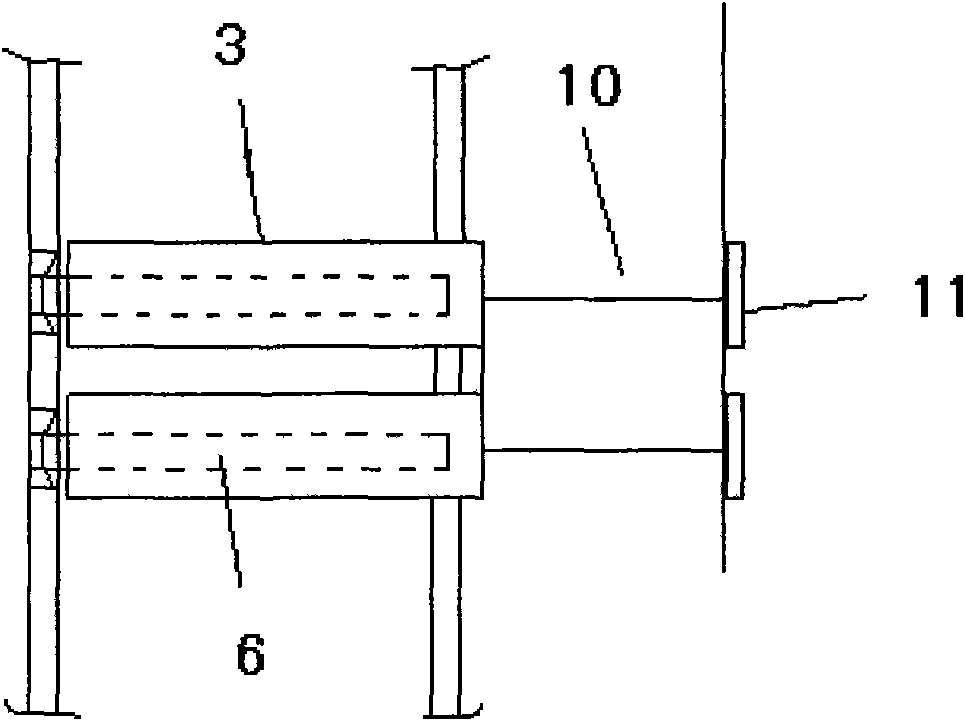

Method and device for spreading fiber strands

A method and a device for spreading a fiber strand to provide a strip-type fiber strand. In particular, the initial fiber strand is provided with an initial width and thickness, and is then spread to form the strip-type fiber strand having a greater final width and a smaller final thickness as compared to the initial width and thickness. The fiber strand consists of continuous multifilament fibers.

Owner:C CRAMER WEBEREI HEEK NIENBORG

Processing method and processing device capable of mixing two fibers in spinning process

The invention relates to a processing method and a processing device capable of mixing two fibers in a spinning process. The processing device comprises a front roller, a middle roller, a back roller, output rollers, five-mouth parallel horn mouths, a five-mouth annular horn mouth and a nozzle, wherein a pair of output rollers is arranged at the front of the front roller, a space capable of independently twisting through two yarns is formed; two five-mouth parallel horn mouths are arranged at the back of the front roller and are used for uniformly separating a fiber bundle; one five-mouth annular horn mouth is arranged at the backs of two five-mouth parallel horn mouths, and is divided into a small bundle of different fiber combinations; one nozzle is arranged between the output rollers and the five-mouth annular horn mouth, so that the yarns are twisted. According to the invention, the yarns made of two raw materials are uniformly mixed in the spinning process, and are twisted to form yarns, so that a process of drawing is shortened, the cost is saved, and the efficiency is improved.

Owner:DONGHUA UNIV +1

Stretch breaking carding method and device for phloem fiber

ActiveCN101824683AIncrease profitIncrease the degree of splittingDrafting machinesEngineeringTraction unit

The invention relates to a stretch breaking carding method and a device for phloem fiber. The method of the invention comprises the following steps: (1) uniformly and flatly paving phloem fiber beams after unglued health preservation on a hemp feeding plate of a stretch breaking mechanism, and forwards conveying the phloem fiber beams through a feeding roller; (2) installing a plurality of traction units at intervals in the forward direction of the output end of the feeding roller, wherein each traction unit is provided with two synchronously rotating support rollers, in addition, the rotating speed of the support rollers of the front traction units is higher than that of the support rollers of the back traction units, at the same time, a pressurizing roller driven by the two support rollers through friction force is arranged on the top of the two support rollers so that the fiber is milled and stretched when passing each traction unit until the traction unit of the one side near the output end has the tensile failure; (3) inputting the fiber into a beam collection device for beam gathering and collection; (4) sending the fiber into a row of carding boxes provided with needle strips to be carded; and (5) merging the fiber into strips and dripping the strips into a strip forming tube. The invention can be widely used in the processing process of various kinds of phloem fiber, gramineae fiber and leaf fiber.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

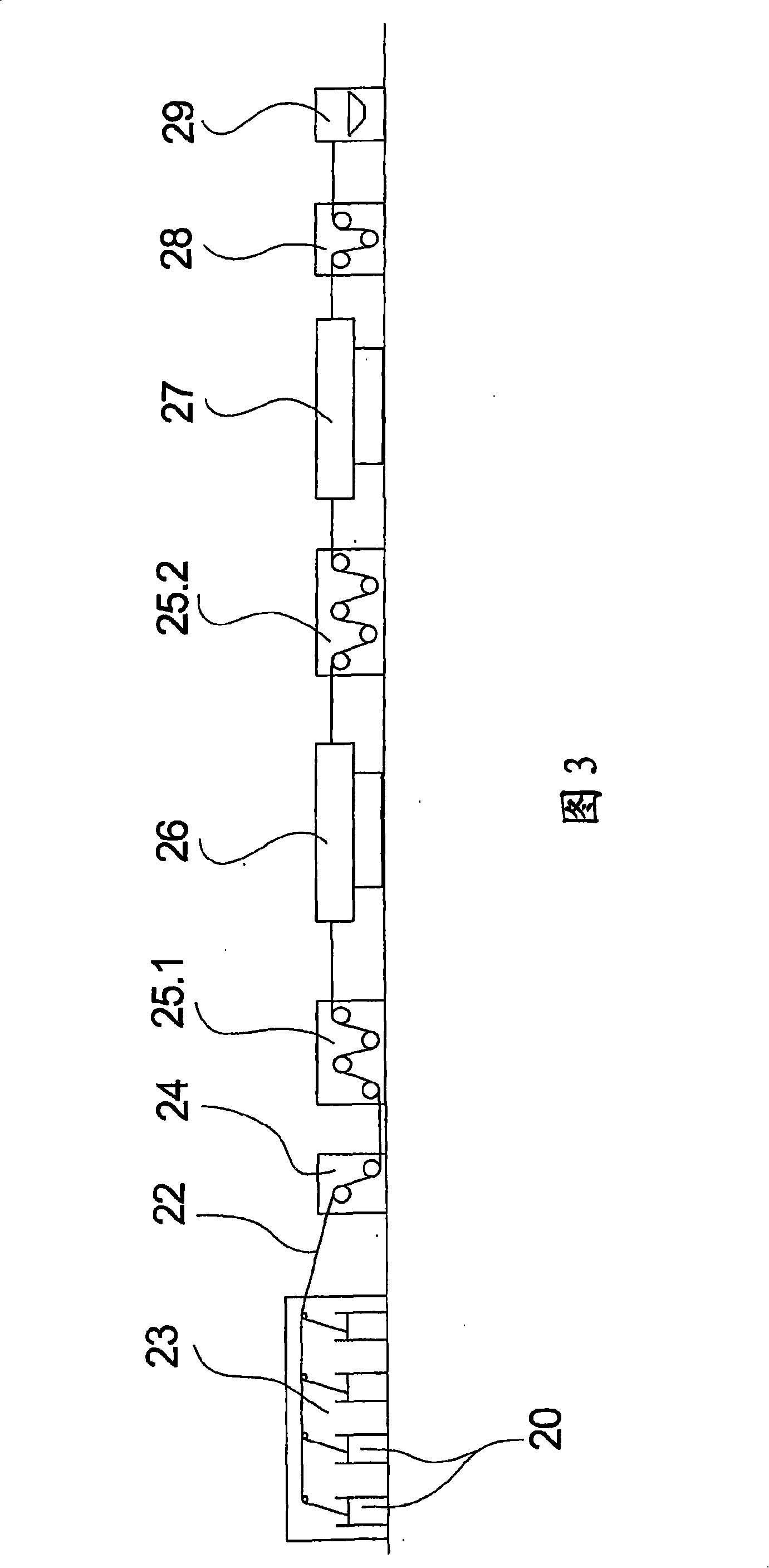

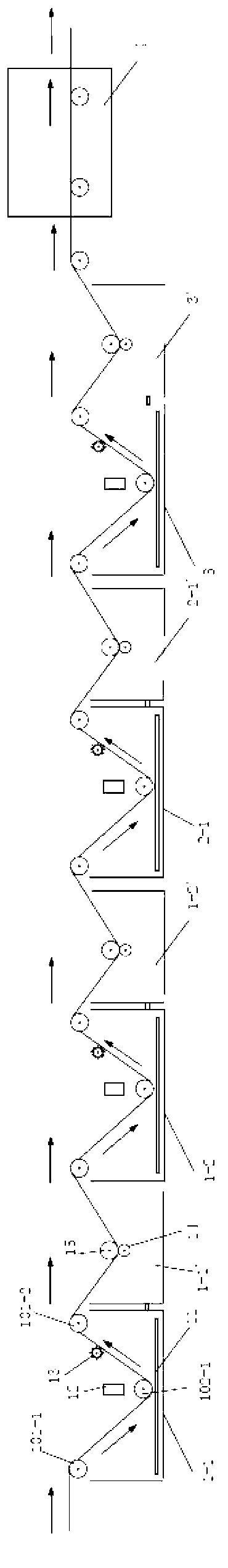

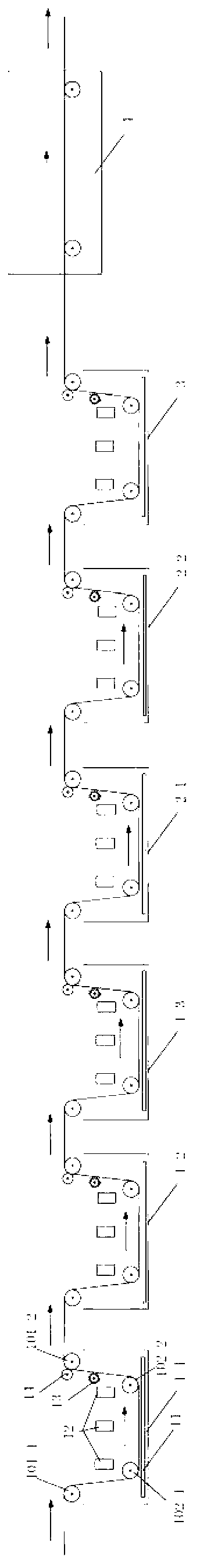

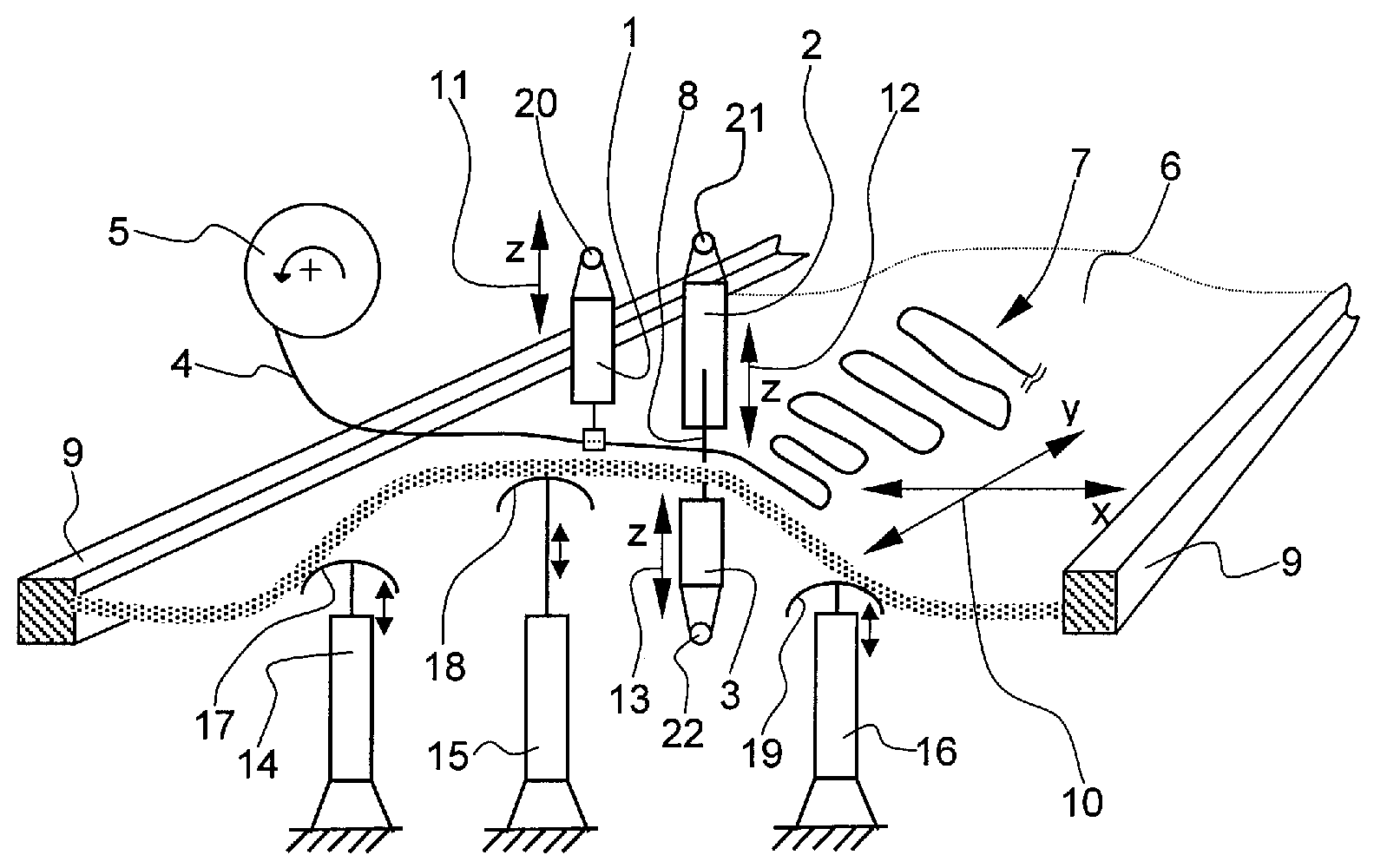

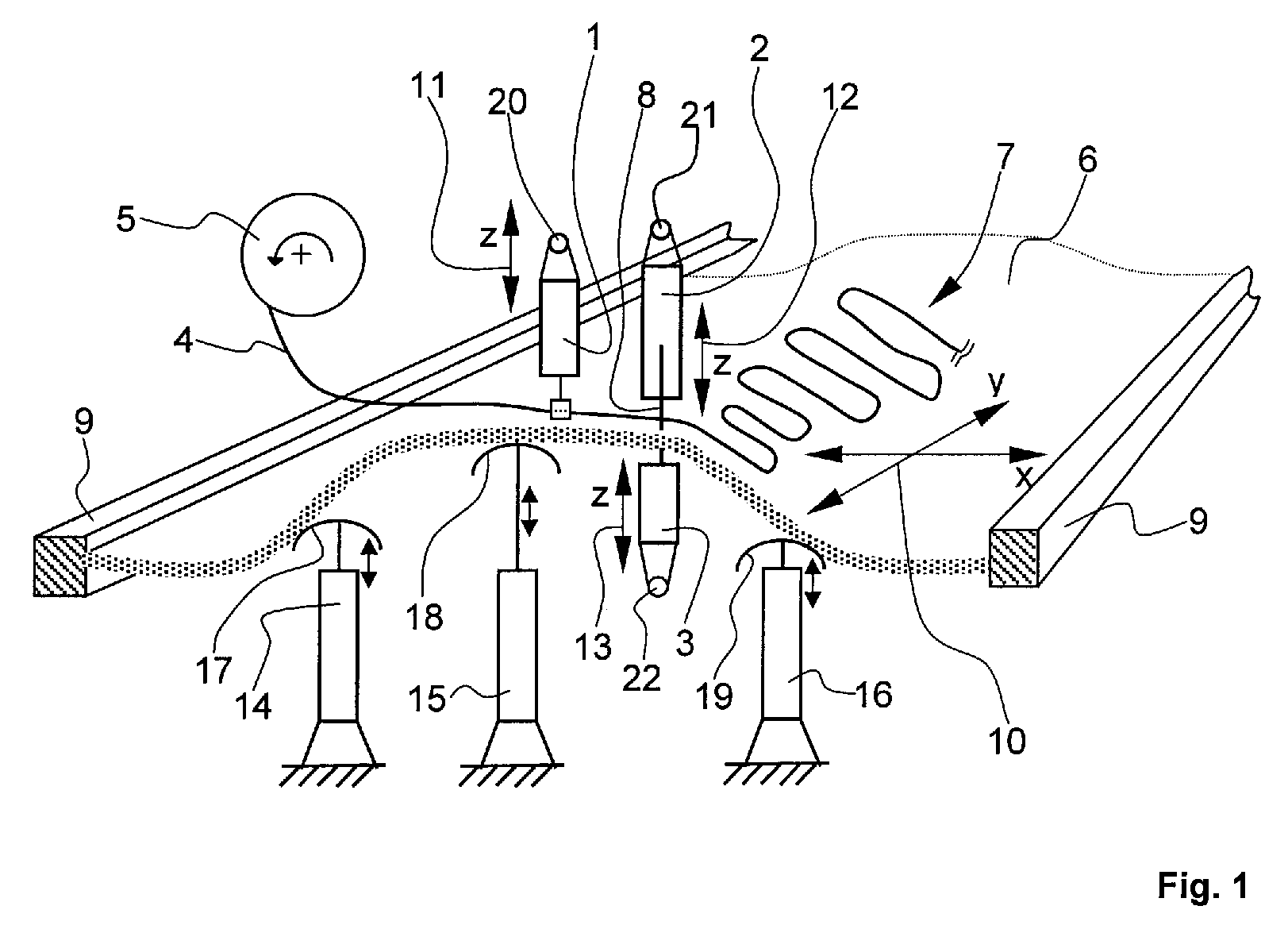

Device for producing a fiber preform with virtually any desired surface geometry by the TFP process

InactiveUS7954440B2Simple actionEasy constructionDomestic articlesAutomatic machinesFiberEngineering

Device for producing a fiber preform with virtually any desired surface geometry by a TFP process. A guiding device lays a fiber strand along virtually any desired path curve on a backing layer and a sewing head attaches the fiber strand on the backing layer by at least one fixing thread. The backing layer can be positioned in an xy direction in relation to the guiding device and the sewing head, wherein the sewing head and / or the guiding device can be positioned in a z direction. The separation of the positioning capabilities of the backing layer (xy direction) and the guiding device, the sewing head and the lower thread guide (z direction) provides a relatively simple device construction. Example devices can produce fiber preforms for dome-shaped composite components for use inter alia as pressure bulkheads for cabins in aircraft with virtually optimum properties.

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com