Method for weaving fabric with Z-direction loop

A technology of looping fabrics and fabrics, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of weaving looped fabrics, etc., and achieve the effect of low cost, adjustable fabric density, uniformity, and high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

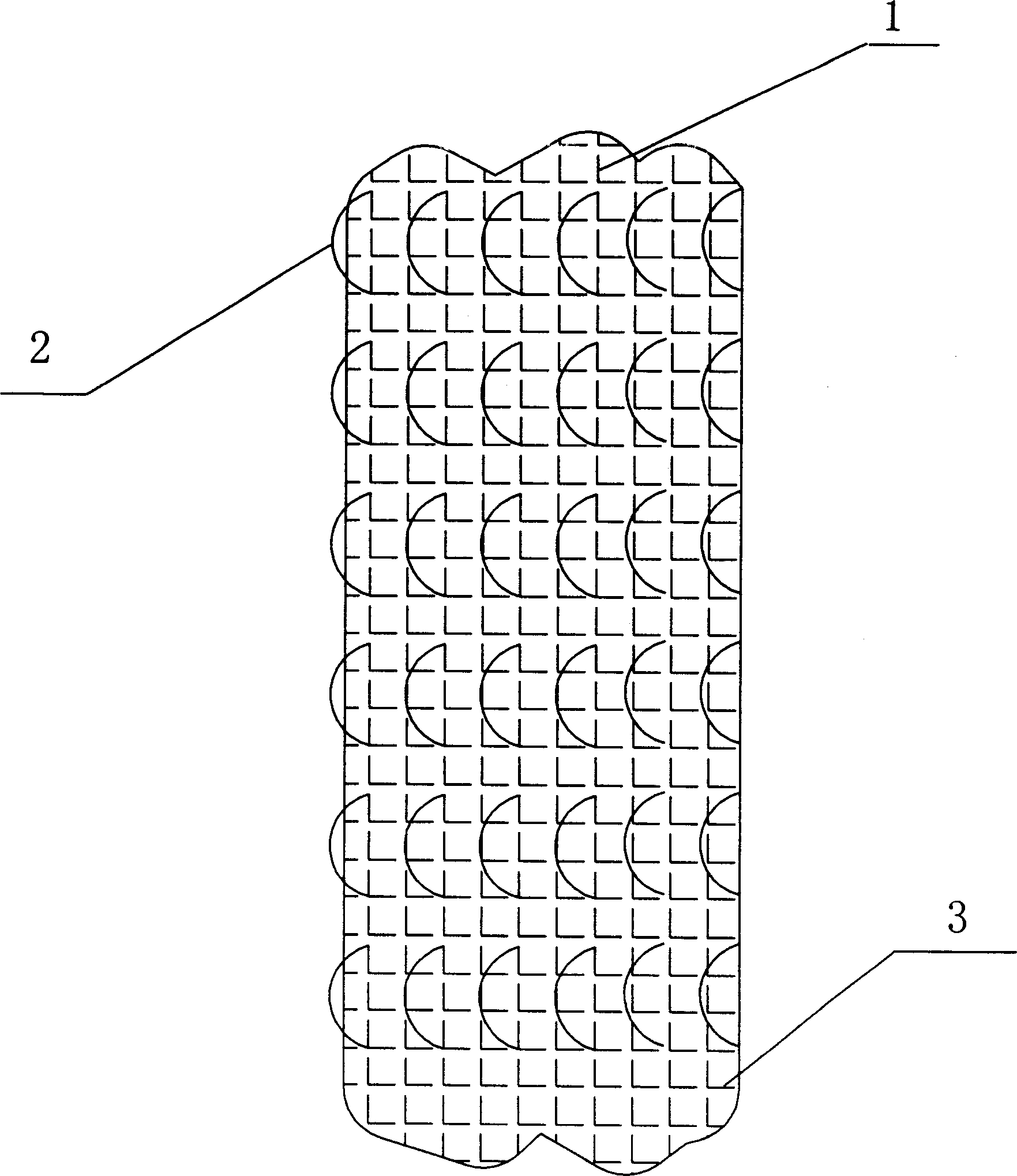

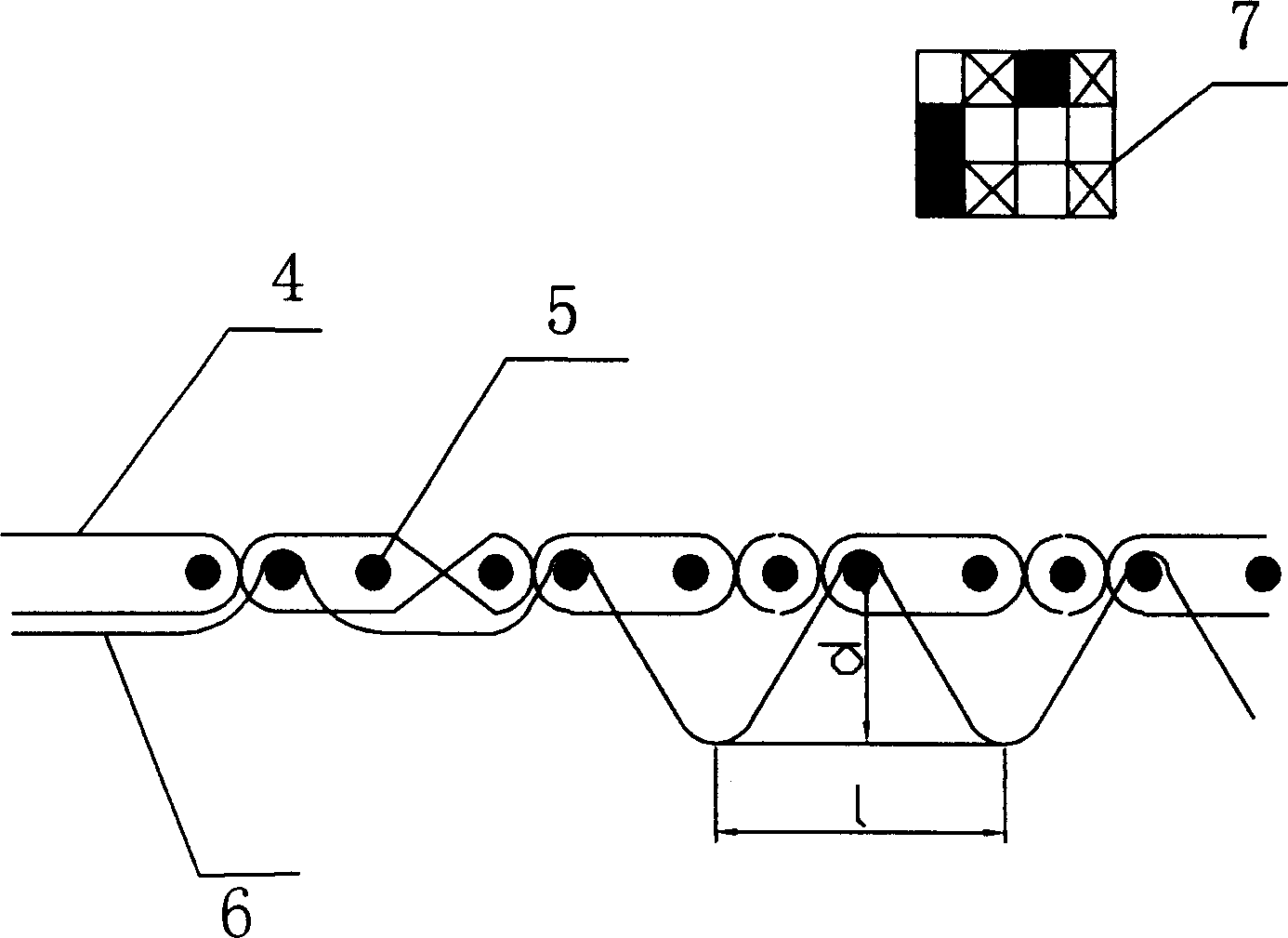

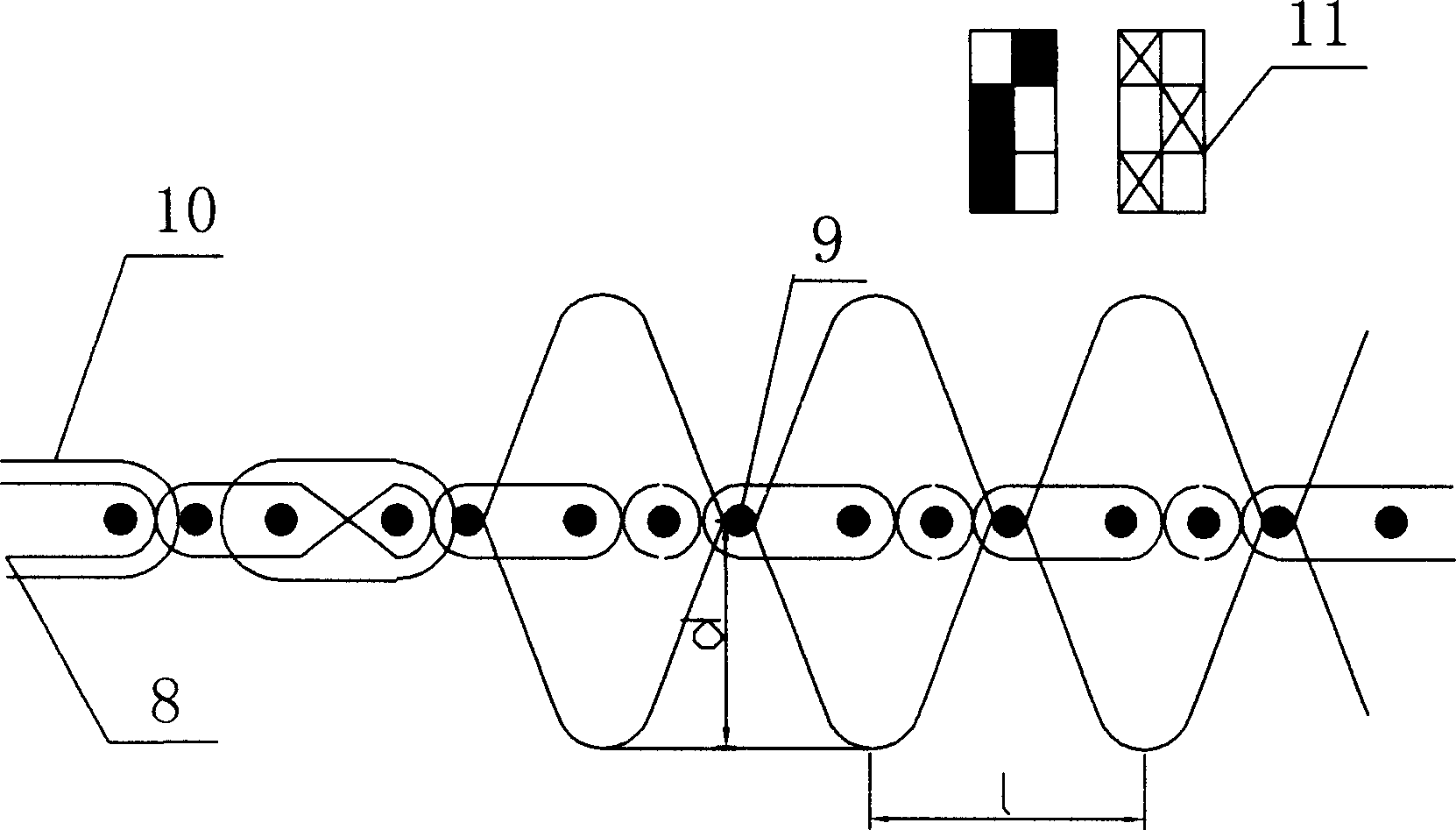

[0032] The present invention adopts the fabric (as figure 1 Shown), according to the way of looping can be divided into: single-sided looping (such as figure 2 shown) and double-sided looping (such as image 3 Shown), its weaving process is:

[0033] Warp pretreatment→warping→preparation before weaving→weaving→sampling and shaping

[0034] Component name

Carbon Fiber (3K)

Carbon Fiber (6K)

Pre-oxidized silk fiber (3K)

Polyacrylate resin content (%)

2.0

3.0

2.2

Triacetamide oleic acid soap content (%)

6.0

6.0

6.0

water(%)

92

91

91.8

[0035] Weigh the polyacrylate resin and triacetamine oleic acid soap according to the actual amount, dilute the polyacrylate resin with a small amount of water, dissolve the triacetamide oleic acid soap with 50°C hot water, mix and stir the two after cooling for a while, Finally, dilute to the total volume with water and mix well before use....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com