Spinning device

A fiber and hollow technology, which is applied in the field of spinning devices, can solve the problems of poor spinning performance, insufficient spinning strength, and high fiber loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An example of the present invention will be described below, but it is not limited to this example unless the gist of the present invention is exceeded.

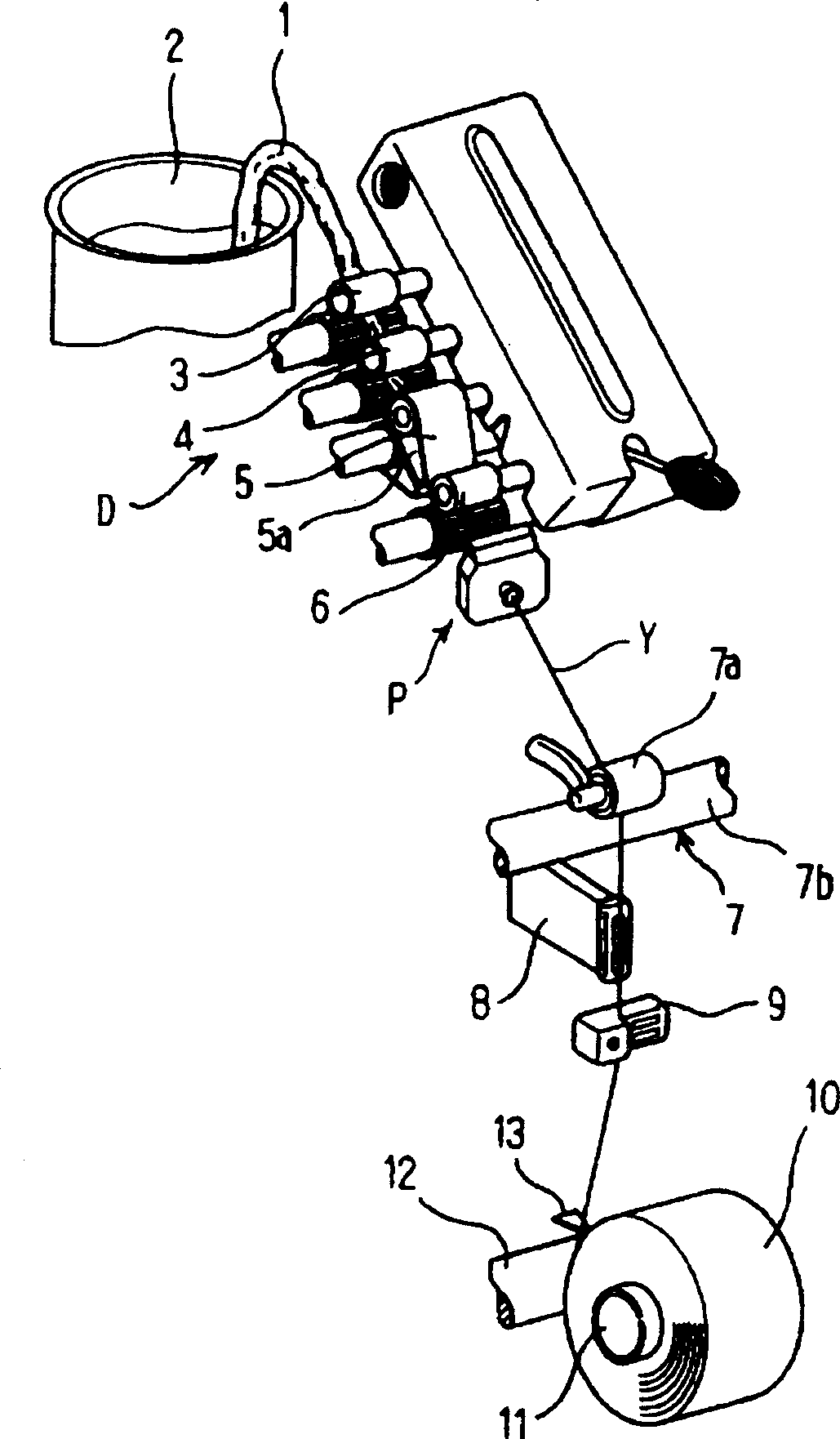

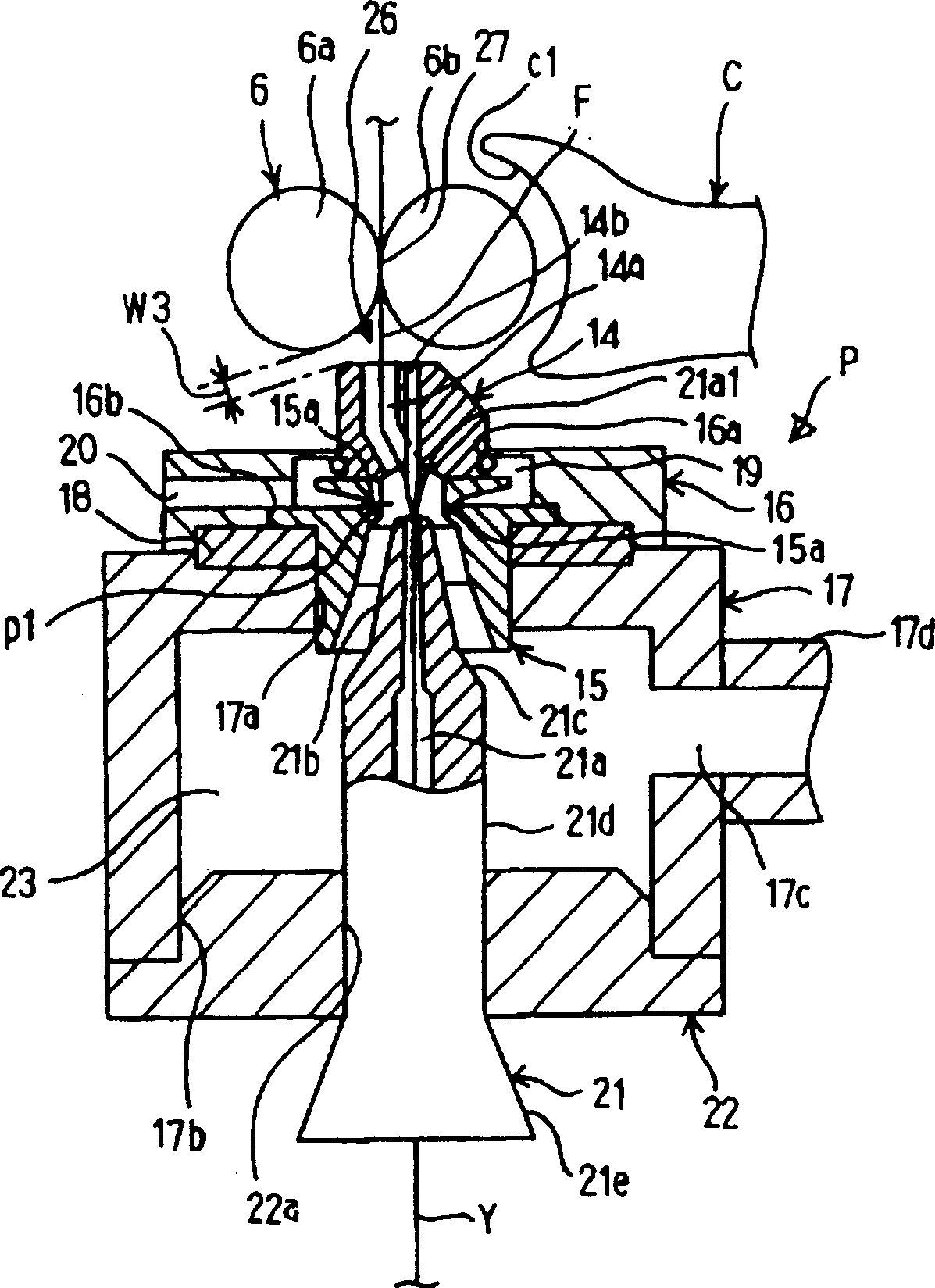

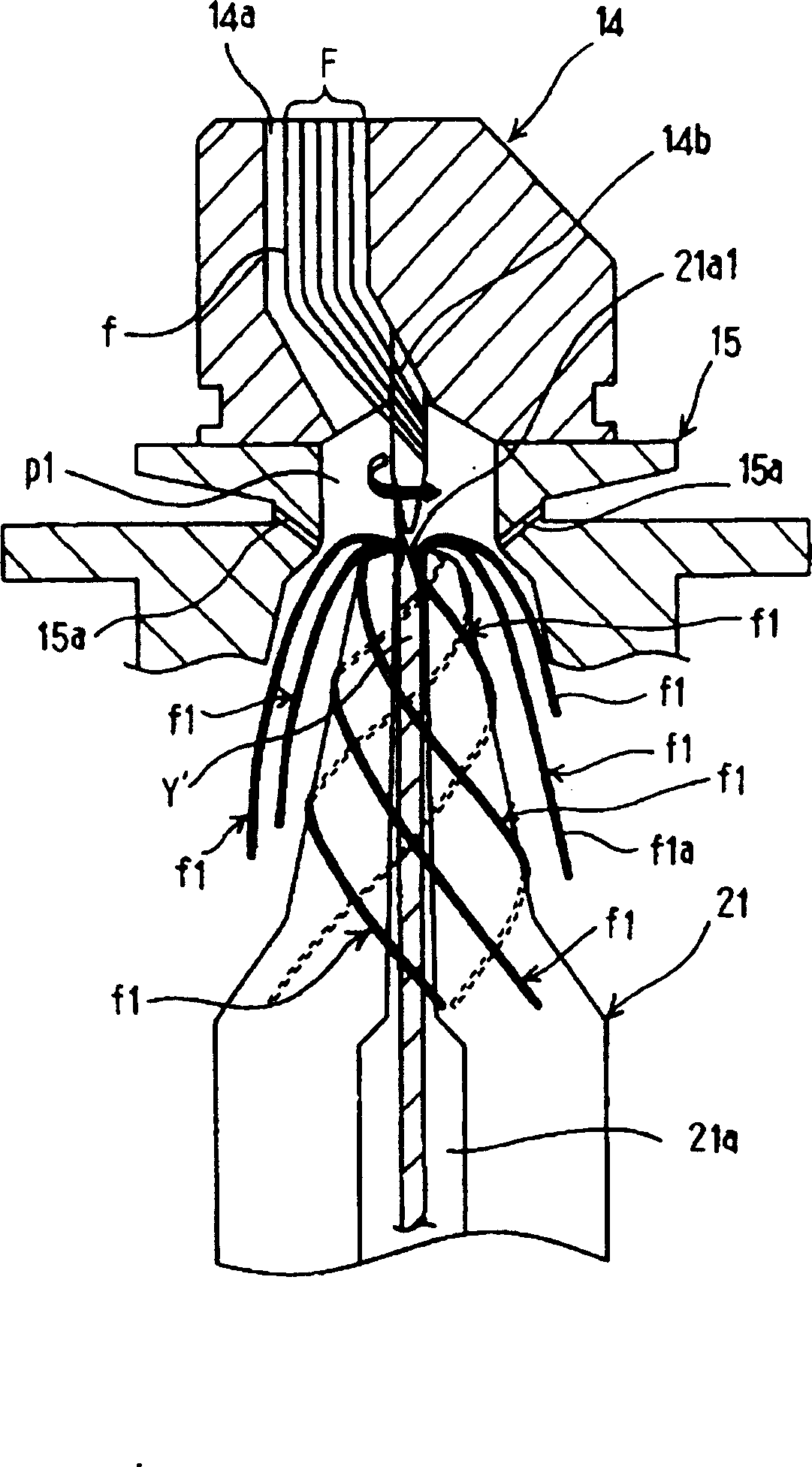

[0023] First, use figure 1 The overall configuration of a spinning device as an example will be described.

[0024] 1 is the fiber bundle before being stretched in the can 2, and D is a 4-line stretching device as an example. The second roller 5 and the front roller 6 are composed. P is a spinning section described later, 7 is a yarn feeding member composed of a nip roller 7a and a delivery roller 7b, and 8 is a device for temporarily storing the yarn discharged from the spinning section P that restarts spinning during the piecing operation. Slack bobbin, 9 is a yarn cleaner. 10 is a package formed on a bobbin 11 supported by a bobbin holder not shown in the figure, and the package 10 is configured such that its surface abuts against a rubbing roller 12 to rotate. 13 is the oscillating yarn guide of the oscillatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com