Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Ethyl tert-butyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl tert-butyl ether (ETBE) is commonly used as an oxygenate gasoline additive in the production of gasoline from crude oil. ETBE offers equal or greater air quality benefits than ethanol, while being technically and logistically less challenging. Unlike ethanol, ETBE does not induce evaporation of gasoline, which is one of the causes of smog, and does not absorb moisture from the atmosphere.

Process for dewatering ethanol

InactiveUS7399892B2Avoid disadvantagesSemi-permeable membranesMembranesEthyl tert-butyl etherWater content

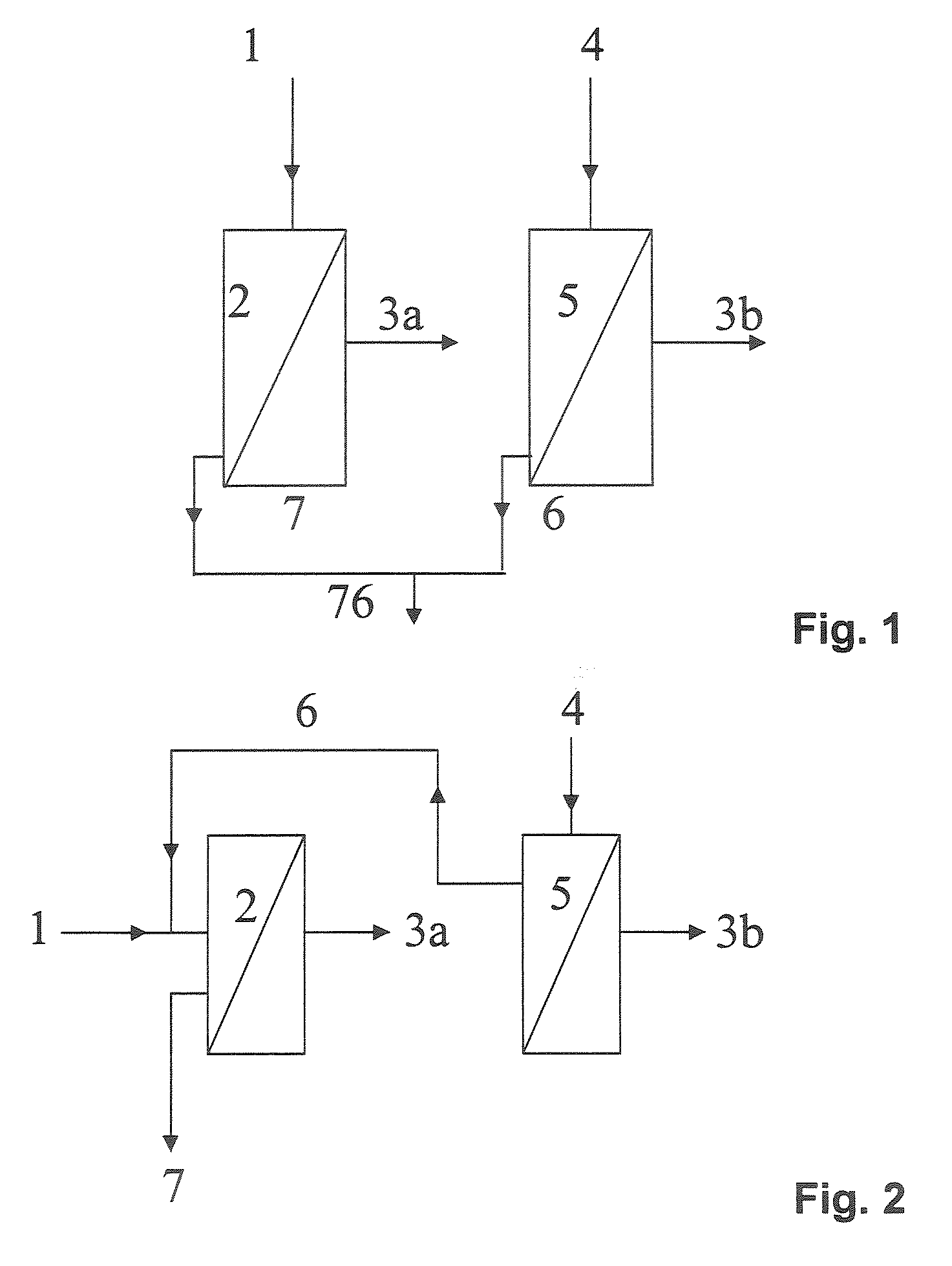

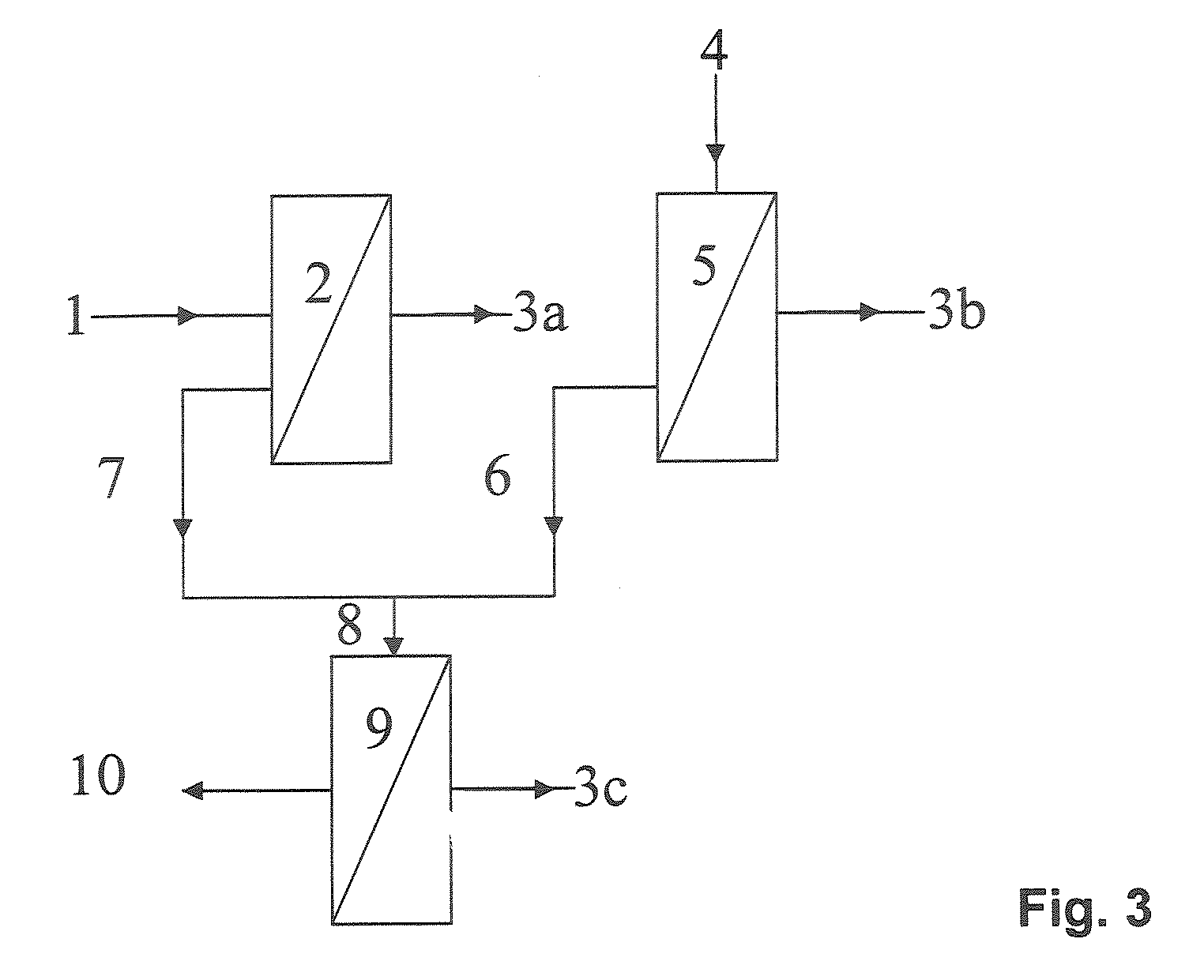

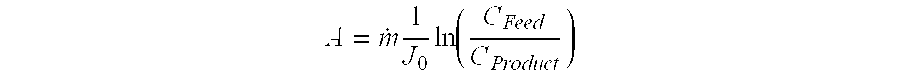

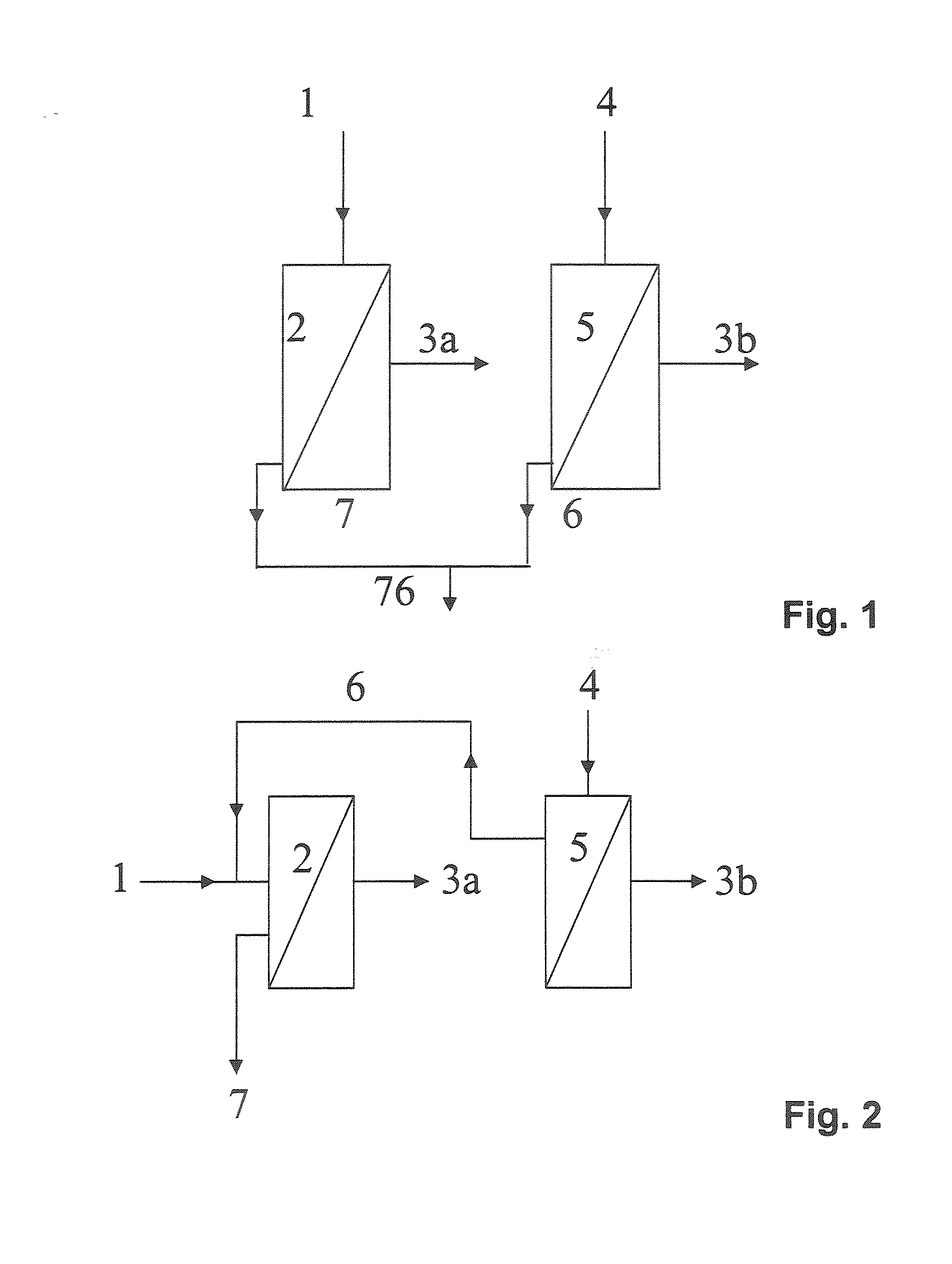

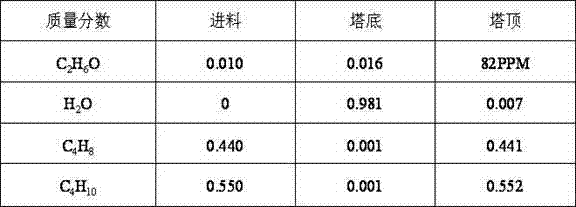

A process for preparing low-water ethanol from at least two streams of relatively water-rich ethanol that have a different water content by dewatering at membranes. The low-water ethanol can be used to prepare ethyl tert-butyl ether (ETBE).

Owner:EVONIK OXENO GMBH (DE)

Process for dewatering ethanol

InactiveUS20070173670A1Avoid disadvantagesSemi-permeable membranesMembranesEthyl tert-butyl etherWater content

A process for preparing low-water ethanol from at least two streams of relatively water-rich ethanol that have a different water content by dewatering at membranes. The low-water ethanol can be used to prepare ethyl tert-butyl ether (ETBE).

Owner:EVONIK OXENO GMBH (DE)

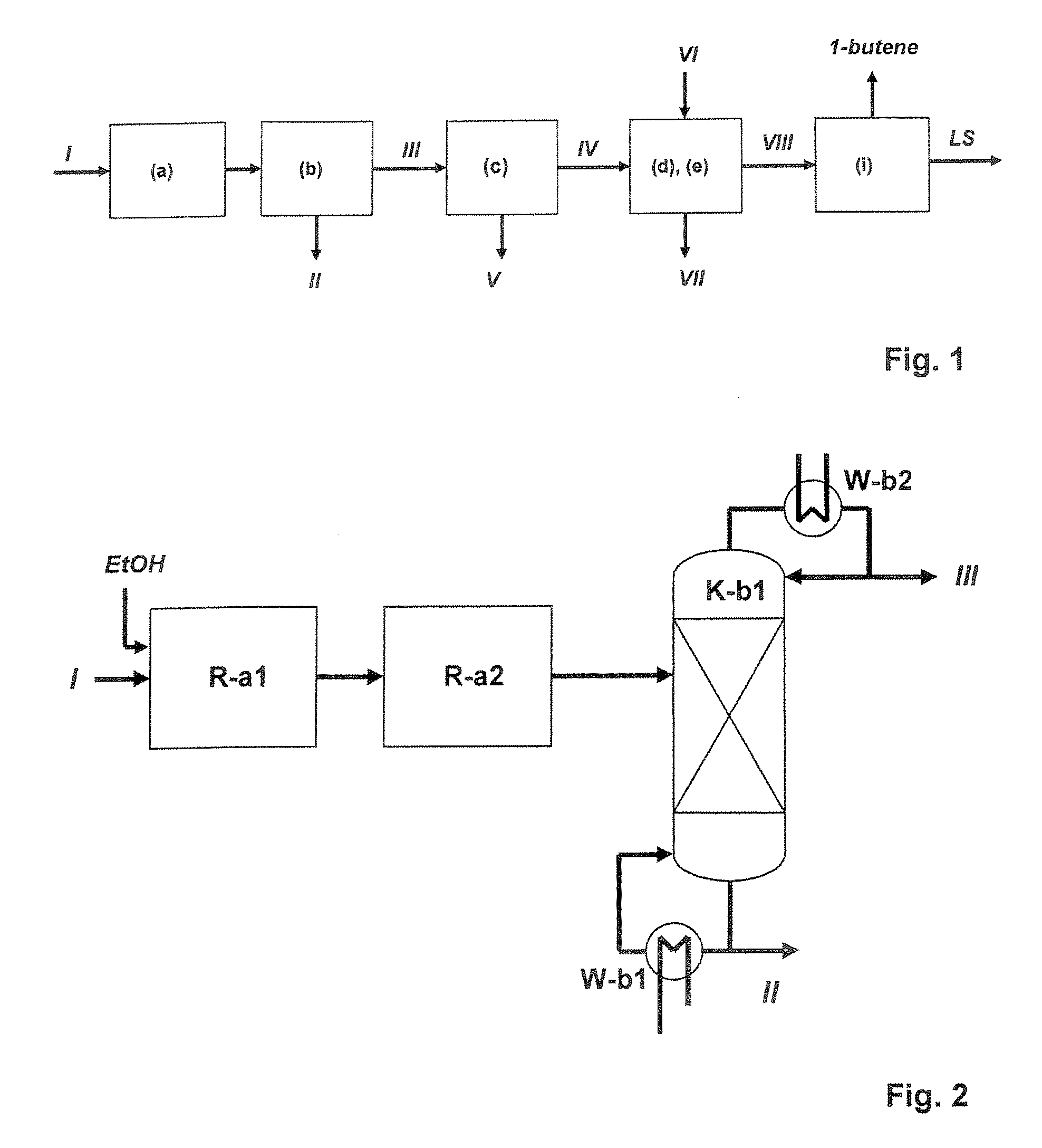

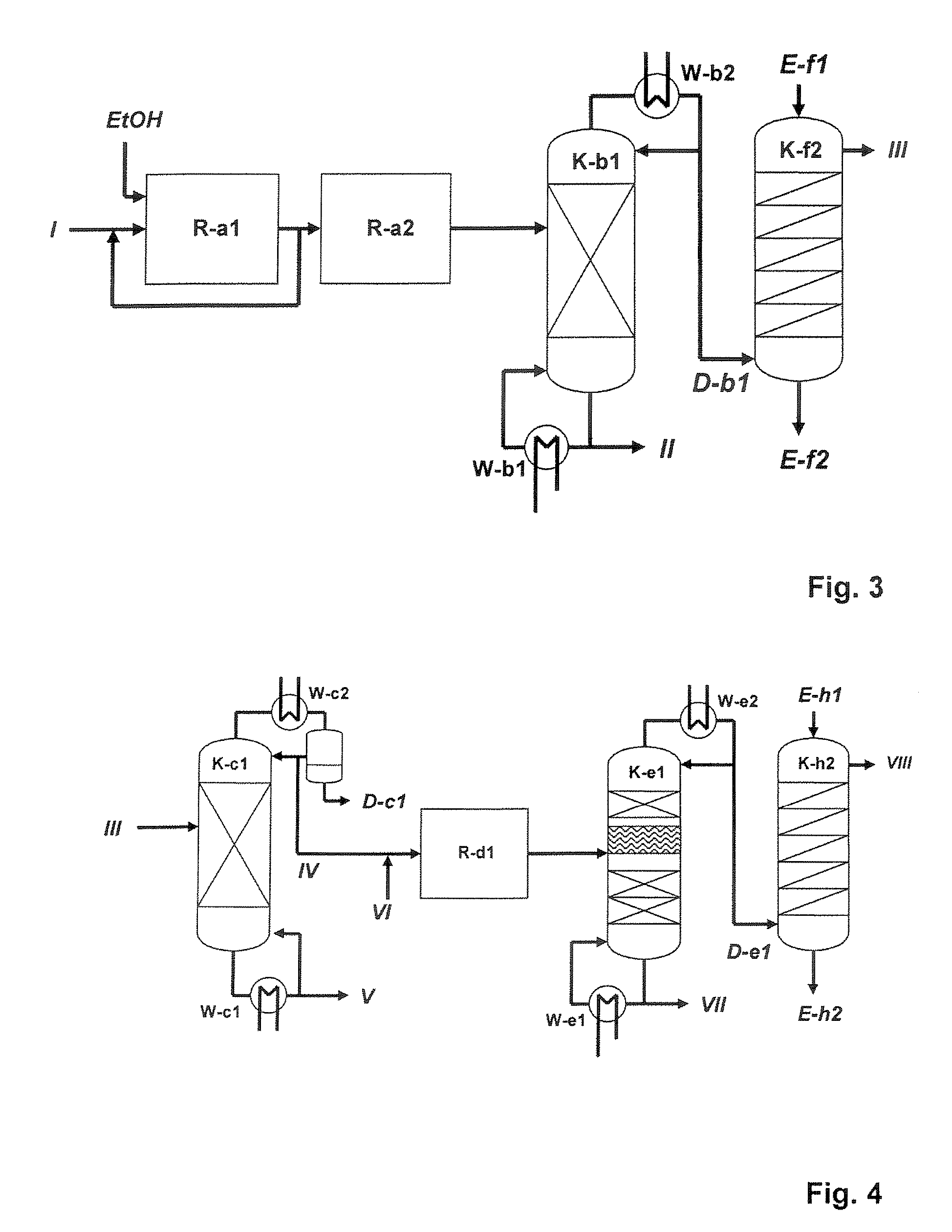

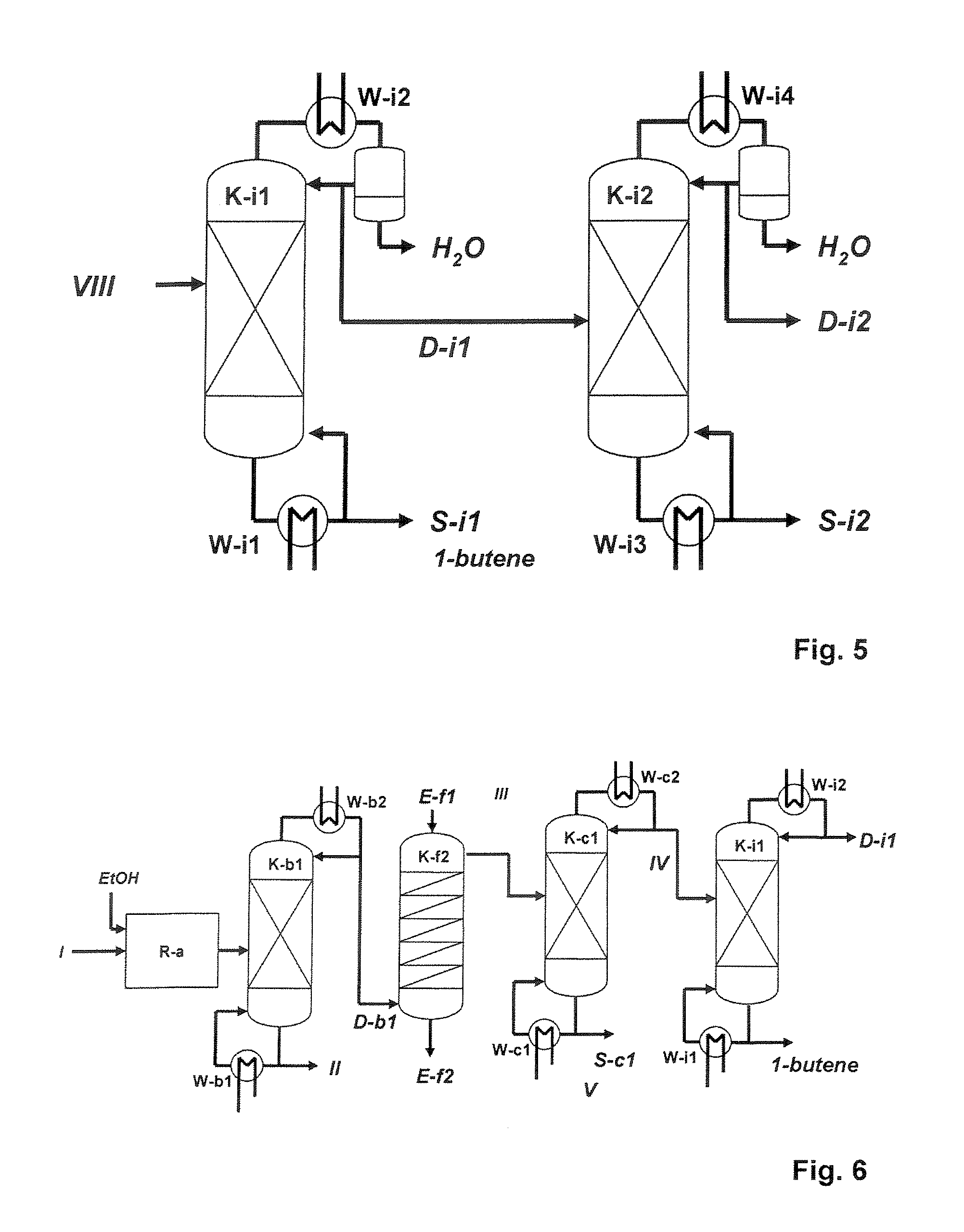

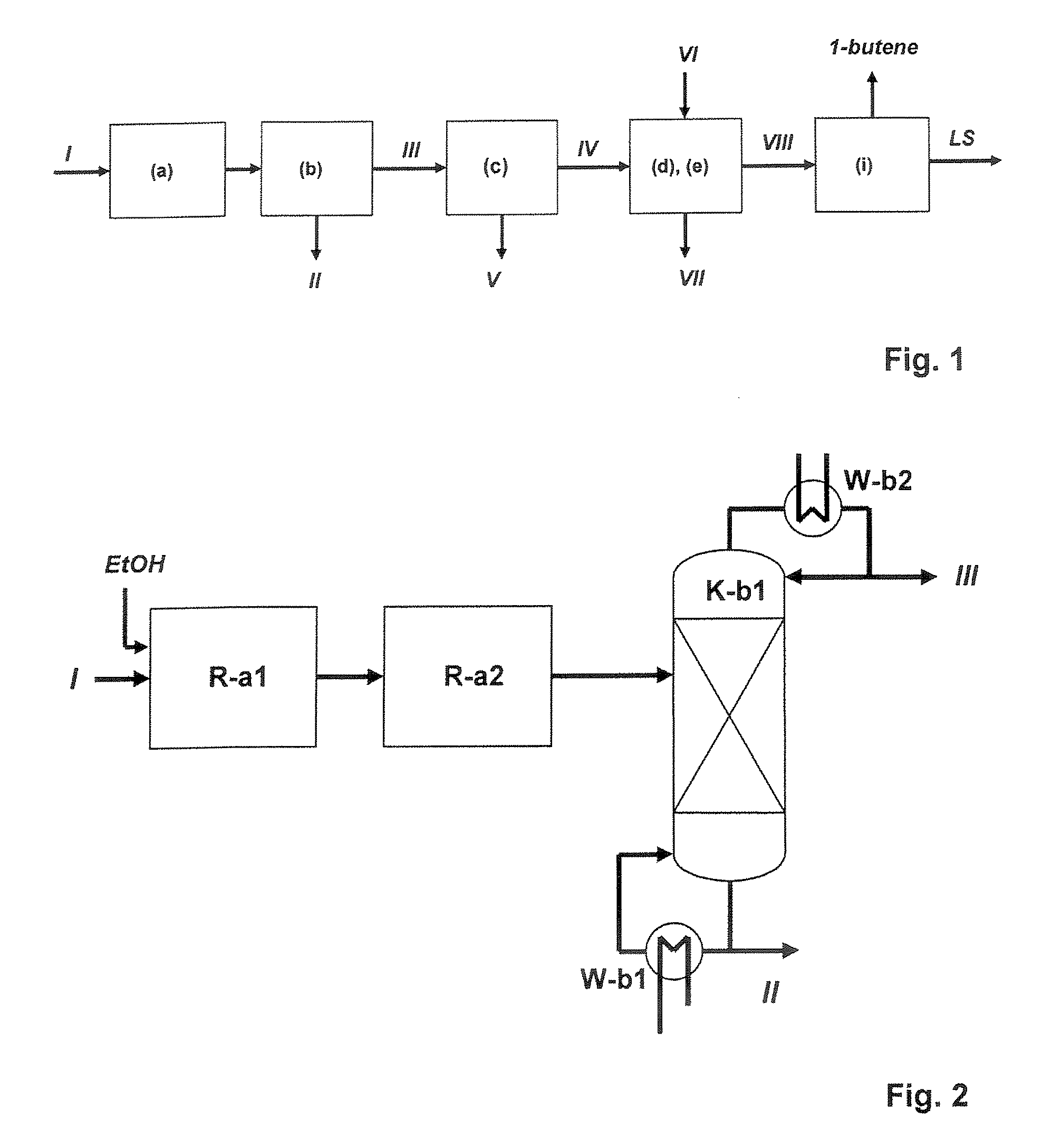

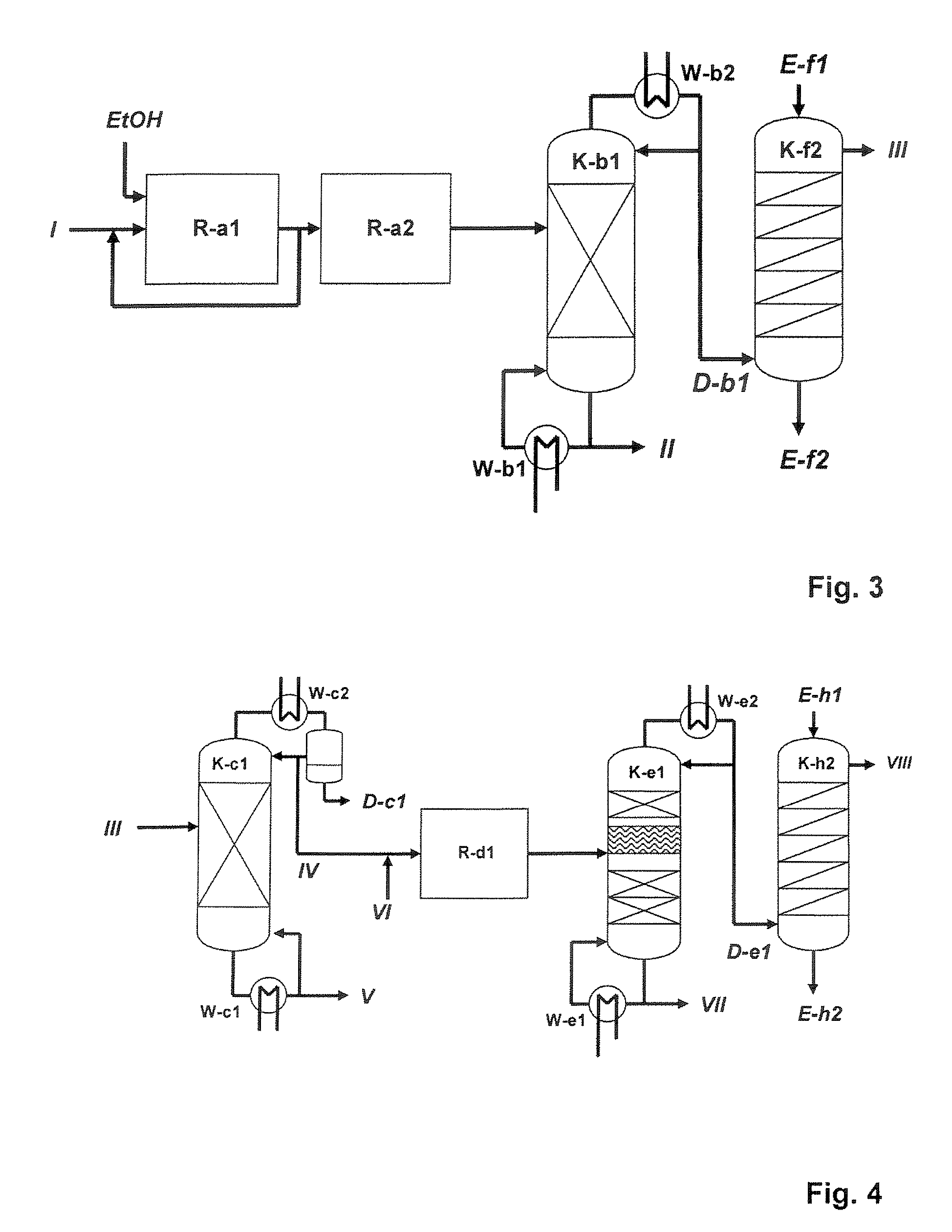

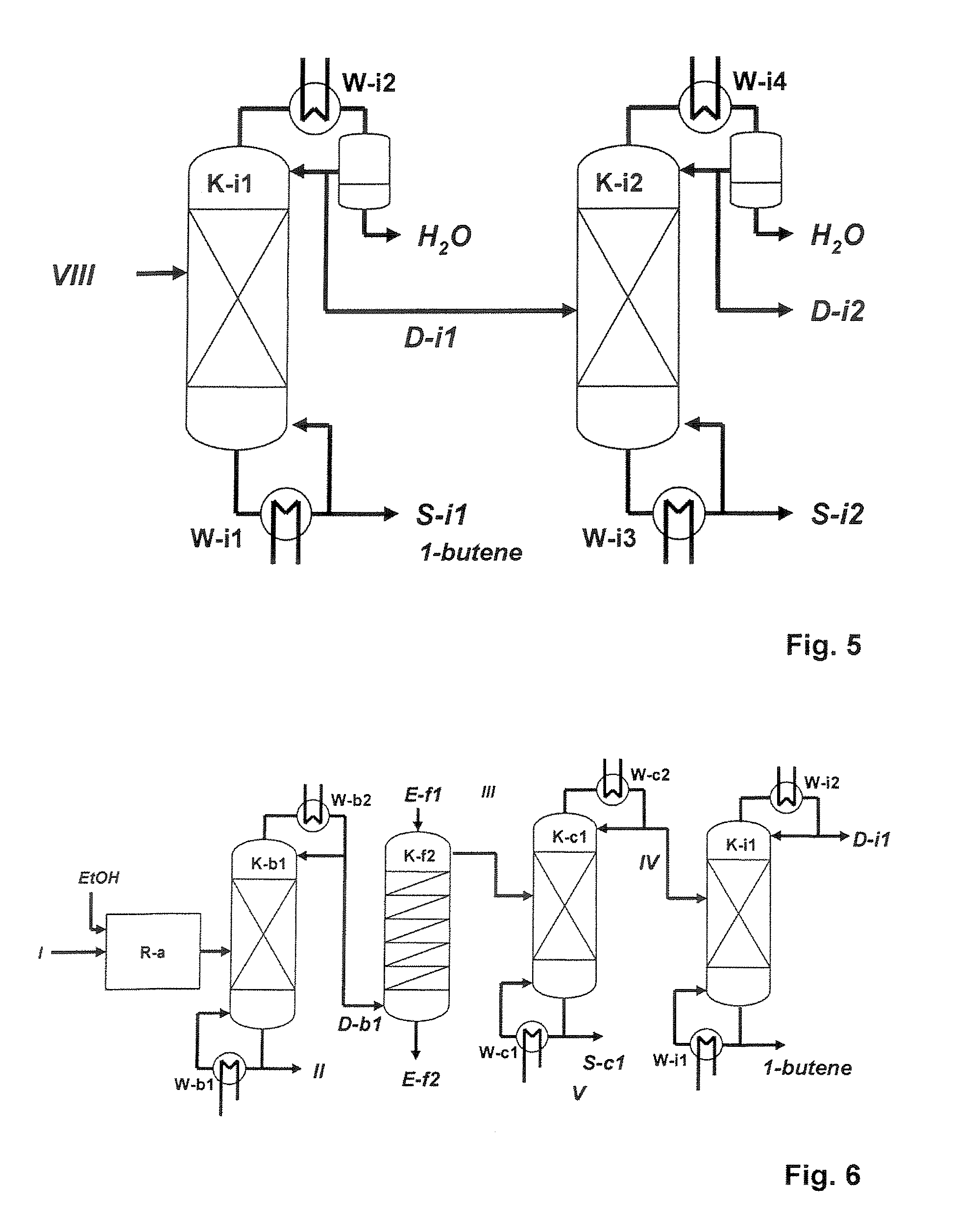

Process for preparing ethyl tert-butyl ether from technical mixtures of c4 hydrocarbons

InactiveUS20070203369A1Speed up the processReduce formationEther separation/purificationOrganic compound preparationButene2-Butene

The invention relates to a process for preparing ETBE from technical mixtures which comprise at least 1-butene, isobutene, n-butane and 2-butenes, by reacting the isobutene present, distillatively removing a fraction comprising 1-butene and isobutene and again reacting the isobutene present therein to give ETBE.

Owner:EVONIK DEGUSSA GMBH

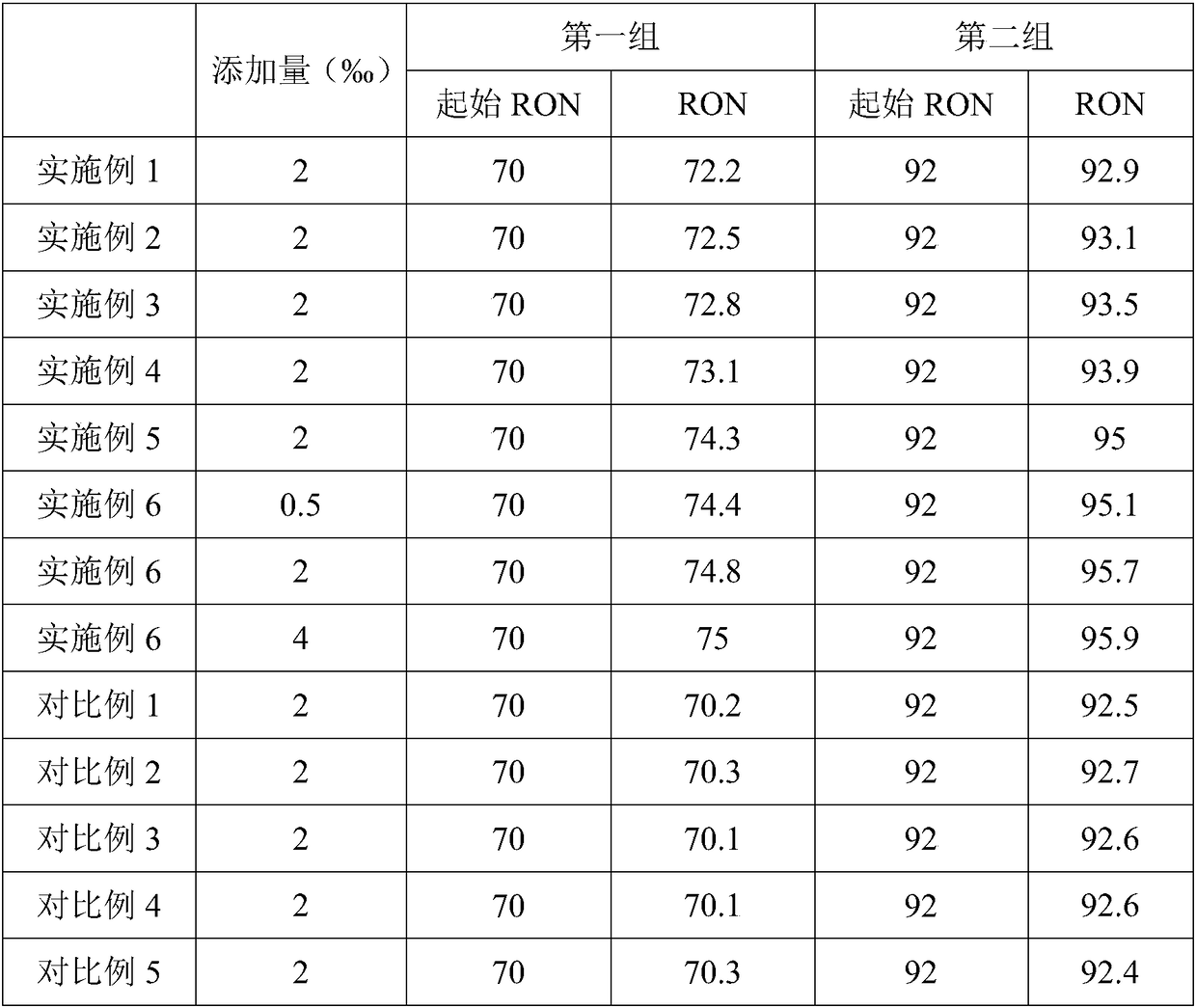

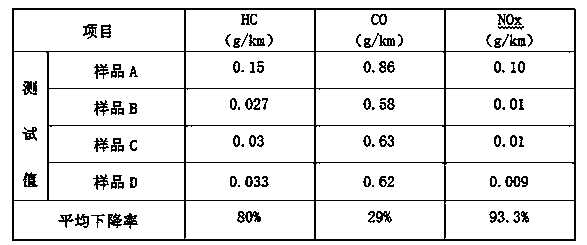

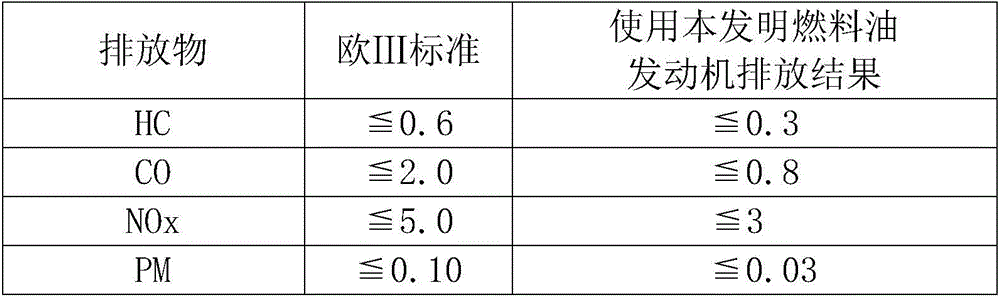

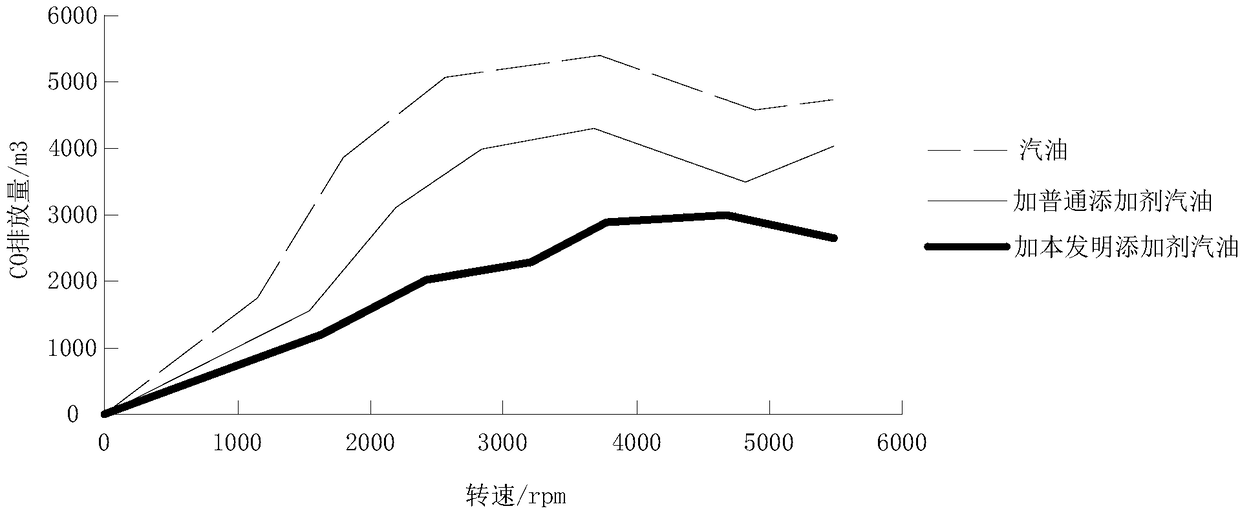

Environmentally-friendly energy-saving emission reduction gasoline additive and preparation method thereof

The invention relates to the field of gasoline additives, in particular to an environmentally-friendly energy-saving emission reduction gasoline additive and a preparation method thereof. The environmentally-friendly energy-saving emission reduction gasoline additive is prepared from the following ingredients in parts by weight: 4-9 parts of ethyl tert butyl ether, 2-5 parts of dimethyl carbonate,1-3 parts of 3-phenyl-1-(2-amino-3,4,5-triethoxy-phenyl)acrylketone, 2-6 parts of 3,4,5-trihydroxy benzene formamide, 3-9 parts of 1-(4-hydroxy phenyl)-5-sulfydryl-tetrazole, 1-5 parts of benzotriazole, 4-8 parts of ethyl acetate, 2-5 parts of triethanolamine, 11-15 parts of isopentyldiol and 14-30 parts of solvent.

Owner:深圳市亮秦科技有限公司

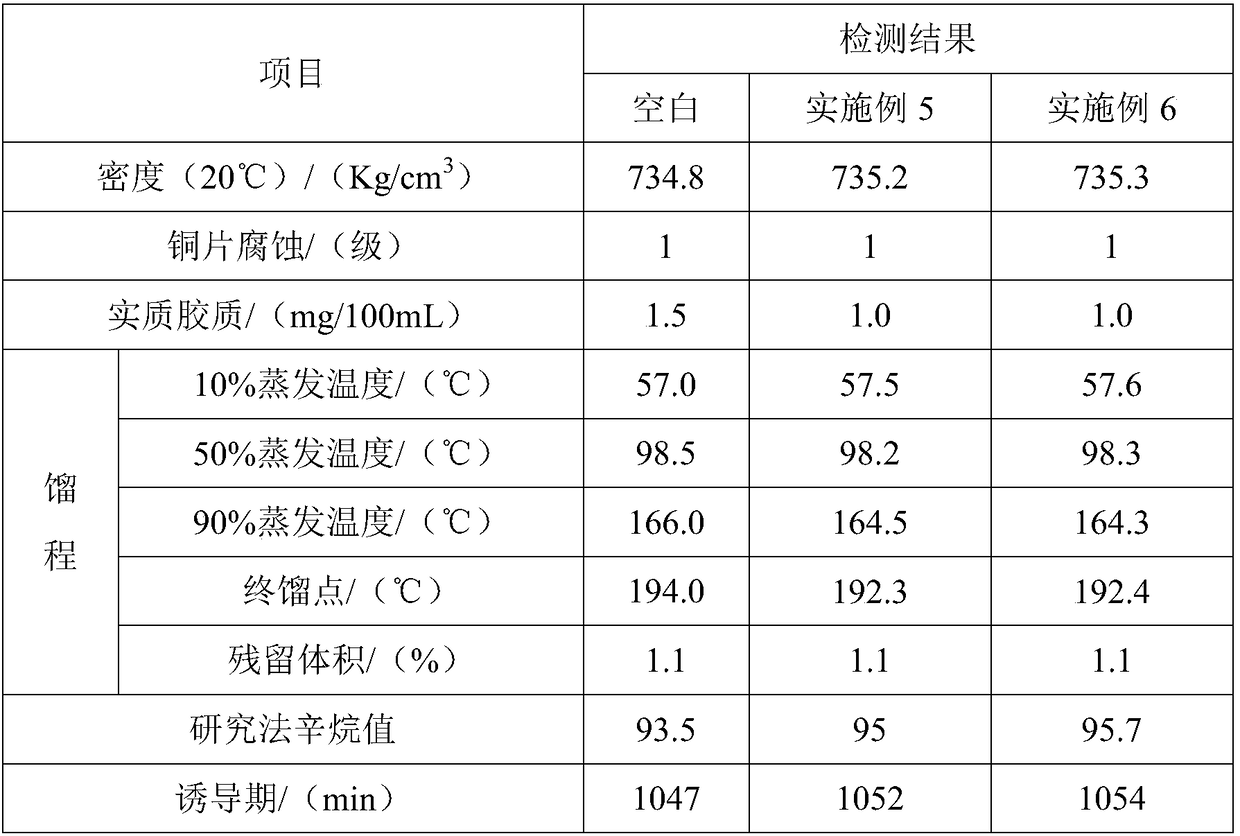

98# vehicular gasoline and preparation method thereof

ActiveCN101875871AReduce sulfur contentReduce olefin contentLiquid carbonaceous fuelsNational standardFuel oil

The invention relates to the technical field of processing fuel oil, in particular to 98# vehicular gasoline and a preparation method thereof. The invention discloses the high-grade 98# vehicular gasoline prepared by adopting catalytic gasoline and additives such as ethyl tert-butyl ether (ETBE), dimethylbenzene, aromatic hydrocarbon, an octane number improver and the like, and the preparation method thereof. The octane number of the clear gasoline prepared by the method reaches the standard requirement of the 98# vehicular unleaded gasoline, and part of indexes is superior to the national standard requirement; and the product is safe and environmental-friendly, fully utilizes the catalytic gasoline, improves the industrial added value of the catalytic gasoline product, and has simple process and convenient and feasible operation.

Owner:SHANDONG TAIDE NEW ENERGY

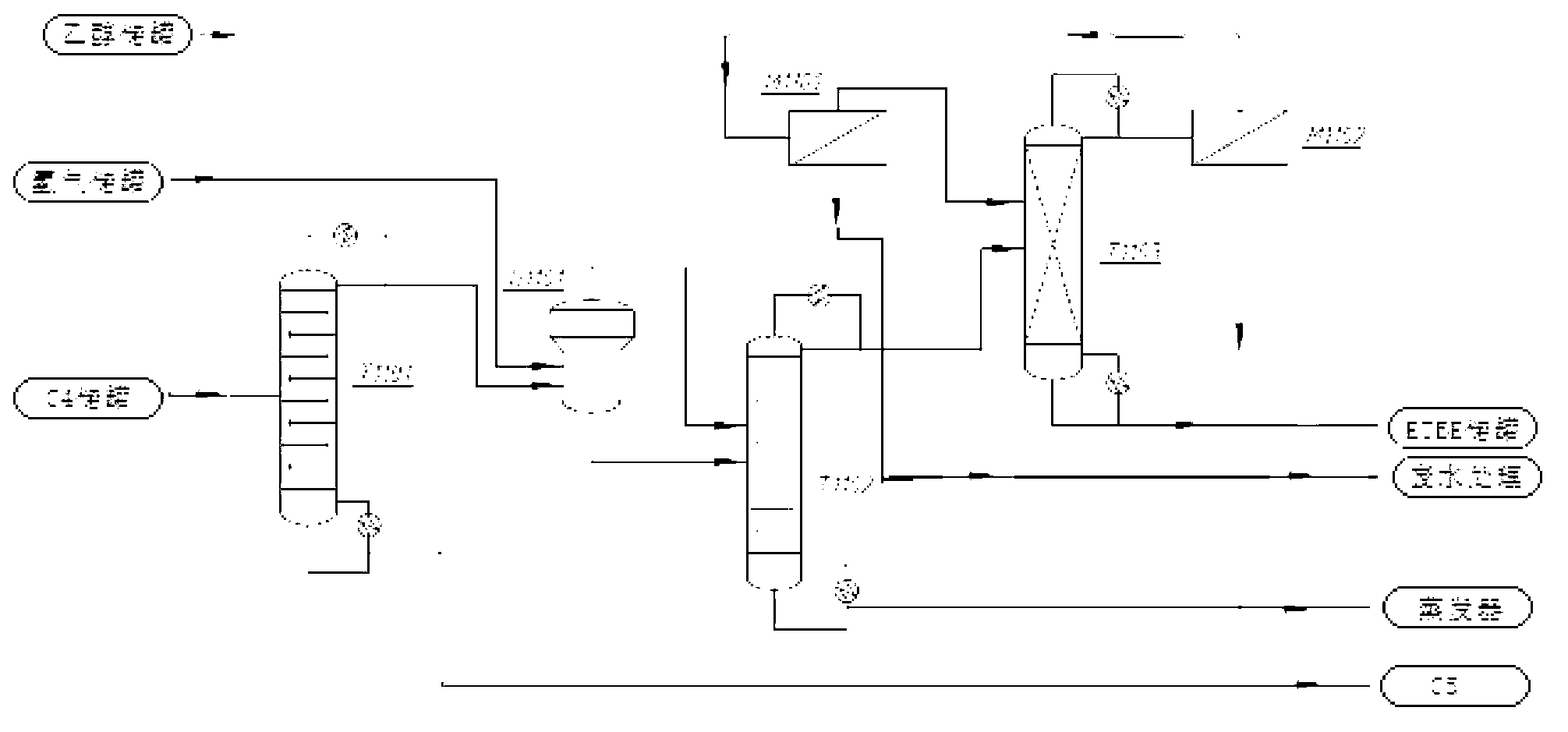

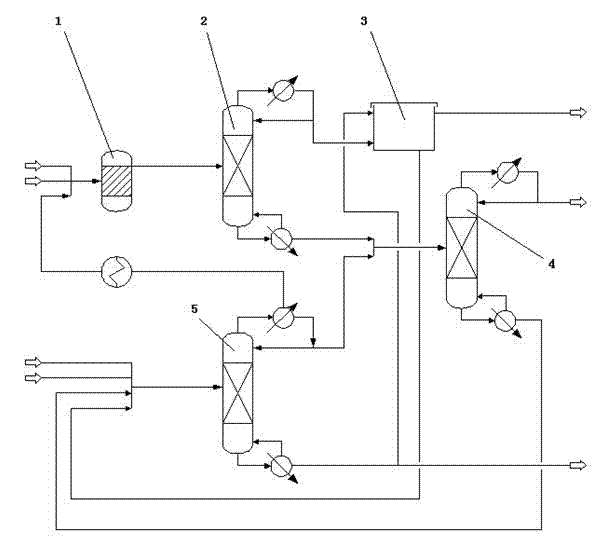

Device and method for coproduction of 1,3-butadiene and ethyl tert butyl ether from methanol to olefin (DMTO) byproduct coal-based mixing C4

InactiveCN103193581AImprove balance conversionReduce adverse effectsHydrocarbonsEther preparation by compound additionButeneButadiene Dioxide

The invention discloses a method for coproduction of 1,3-butadiene and ethyl tert butyl ether from methanol to olefin (DMTO) byproduct coal-based mixing C4. The method sequentially comprises the following three working sections: coal-based mixing C4 pretreatment and etherification working section, butene oxidative dehydrogenation working section and butadiene refining working section, wherein the coal-based mixing C4 pretreatment working section sequentially comprises the following steps: (1) removing a C5 component; (2) implementing hydroisomerization; and (3) condensing isobutene; and in the etherification step, isobutene obtained from the top of an isobutene condensation tower is pumped into an etherification tower together with ethanol for an etherification reaction. Furthermore, the invention discloses a combination device for coproduction of 1,3-butadiene and ethyl tert butyl ether from methanol to olefin (DMTO) byproduct coal-based mixing C4. The method can be used for realizing the effective and comprehensive utilization of 1-butene, isobutene, 2-butene and 1,3-butadiene in the coal-based mixing C4 as well as few C5 component, so that the comprehensive utilization rate is improved, and the method is a new trend of comprehensive utilization of the coal-based mixing C4.

Owner:EAST CHINA UNIV OF SCI & TECH

Process method for preparing ethyl tert-butyl ether

ActiveCN103044213ARegulate acidityRegulatory activityOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound additionPhosphomolybdic acidHeteropoly acid

The invention provides a process method for preparing ethyl tert-butyl ether. The process method comprises the following steps of: taking isobutene and ethanol as raw materials, and using a heteropoly acid / aluminum-based complex oxide catalyst, wherein the heteropoly acid / aluminum-based complex oxide catalyst takes a complex oxide as a carrier and takes heteropoly acid as an active component, the complex oxide is one or more of aluminum-based complex oxides in MgO-Al2O3, TiO2-Al2O3 and ZrO2-Al2O3, and the heteropoly acid is one or more of phosphotungstic acid, silicotungstic acid, arsenotungstic acid, germanotungtic acid, phosphomolybdic acid, silicomolybdic acid, arsenomolybdic acid, germanomolybdic acid and the like. According to the process method provided by the invention, the catalyst adopting the aluminum-based complex oxide to load the heteropoly acid is adopted, so that the shortcomings of inactivation of the catalyst and reduced conversion rate, which are caused by easiness in damaging the Keggin structure of the heteropoly acid of the heteropoly acid catalyst, easiness in loss of acid amount and difficulty in separation, can be overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

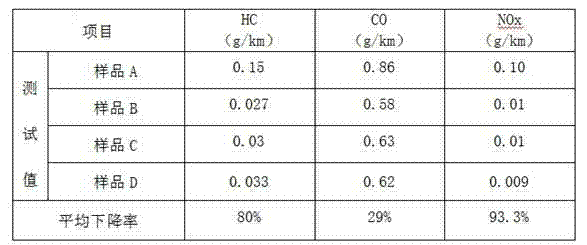

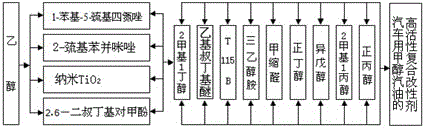

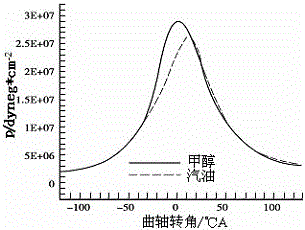

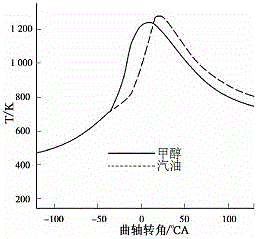

High-activity compound modified additive of methanol gasoline for automobile and preparation process thereof

InactiveCN104745252AMeet the output powerFrequent replacementLiquid carbonaceous fuelsAntioxidantSolvent

The invention relates to a high-activity compound modified additive of methanol gasoline for an automobile. The additive is prepared from the following components in percentage by weight: 12% of ethanol as a solvent, 0.1% of 2-methyl-1-butanol as an antidetonant, 0.5% of sulfurized calcium alkyl as an adjustor, 1.5% of triethanolamine as an engine carbon deposition preventer and an anticorrosive agent, 2.5% of methylal as a combustion improver, 59% of normal butanol as an active mutual solvent, 0.1% of 3-methyl-1-butanol as a synthetic solvent, 10% of 2-methyl-1-propanol as a synthetic solvent, 10% of normal propyl alcohol as a synthetic solvent, 0.1% of ethyl tert butyl ether as an antidetonant, 2% of 1-phenyl-5-mercapto-tetrazole as a corrosion inhibitor, 1% of 2-mercapto benzimidazole as a corrosion inhibitor, 20.6% of nano TiO as a protective coating and 0.6% of 2, 6-ditert-butyl p-cresol as an antioxidant. The additive can be widely applied to additives of methanol and methanol motor gasoline.

Owner:王军

Low-emission vehicle fuel

InactiveCN106753597AEmission reductionAvoid replacementLiquid carbonaceous fuelsFuel additivesExhaust gas emissionsEthyl tert-butyl ether

The invention relates to the technical field of fuels, and particularly relates to low-emission vehicle fuel. The low-emission vehicle fuel is prepared though the following raw materials in parts by weight: 25-50 parts of monohydric alcohol, 20-35 parts of normal octane, 10-20 parts of ethyl levulinate, 2-8 parts of 1-trityl-1H-imidazole, 1-3 parts of a clearing agent, and 0.5-2.3 parts of an combustion improver, wherein the monohydric alcohol is one or two of methyl alcohol, amyl alcohol and isobutyl alcohol; the clearing agent is the mixture of 2-methylimidazole and butyl cellosolve; the combustion improver is the mixture of dimethyl carbonate and ethyl tert butyl ether. The low-emission vehicle fuel is high in exhaust gas emission and can directly replace gasoline on the premise that an engine remains and low exhaust gas emission is ensured.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Preparation method of ethyl tert butyl ether

ActiveCN103044214AHigh activityImprove stabilityPhysical/chemical process catalystsEther preparation by compound additionFixed bedReaction temperature

The invention provides a preparation method of ethyl tert butyl ether. With isobutylene and ethanol as reaction raw materials and supported caesium phosphotungstate acidic salt as a catalyst, the ethyl tert butyl ether is prepared under the reaction conditions that liquid hourly volume space velocity of isobutylene is 0.5-5.0 / h, mole ratio of the ethanol to the isobutylene is (1.0-10.0):1, reaction temperature is 90-200 DEG C and reaction pressure is 2.0-6.0MPa. The preparation method provided by the invention adopts the supported caesium phosphotungstate acidic salt as the catalyst, the defect that the typical heteropolyacid phosphotungstic acid and caesium phosphotungstate acidic salt thereof are easy to run away in a using process, are difficult to separate as particles are too small and are difficult to be used on a fixed bed reactor is overcome, continuous production by virtue of a fixed bed is realized, reaction activity is high, the supported caesium phosphotungstate acidic salt is easy to recycle and can be repeatedly used, and a reaction process operation is easy, so that the preparation method provided by the invention is a new environment-friendly process.

Owner:CHINA PETROLEUM & CHEM CORP +1

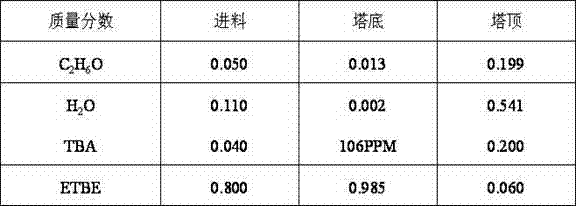

Method for coproducing isobutene and ETBE from tert-Butanol mixture

InactiveUS9169183B1Easy to transportFacilitate tradeEther separation/purificationChemical industryCatalytic distillationEthyl tert-butyl ether

This invention describes a method for co-producing isobutene and ethyl tert-butyl ether from tert-butanol mixture in a catalytic distillation column, wherein catalyzing the tert-butanol mixture with the ethanol undergoes dehydration and etherification. The tert-butanol mixture contains absolute ethanol or aqueous ethanol as the antifreeze agent. The isobutene and the ethyl tert-butyl ether withdrawn from the column top are further separated, thus high purity isobutene and ethyl tert-butyl ether for fuel-additive are obtained.

Owner:CPC CORPORATION

Strong acid type cationic resin catalyst, and catalytic preparation and application of ethyl tert-butyl ether of strong acid type cationic resin catalyst

InactiveCN108126750AThe preparation method is safeEasy to prepareOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound additionStrong acidsAlkylphenol

The invention provides a strong acid type cationic resin catalyst, and catalytic preparation and application of ethyl tert-butyl ether of the strong acid type cationic resin catalyst. The strong acidtype cationic resin catalyst is obtained by performing suspension copolymerization on tert-butyl styrene and a divinyl benzene monomer under the action of a pore-foaming agent and a surfactant comprising sorbitan ester, alkylphenol ethoxylates, paralkyl sodium sulfonate and sodium hexadecyl benzene sulfonate to obtain a copolymer white ball and then performing pore purification and sulfonation. The invention further provides the catalytic preparation and application of ethyl tert-butyl ether of the strong acid type cationic resin catalyst. According to the technical scheme, a preparation method of the catalyst is safe, simple and convenient; practice also proves that the catalyst is applied to the ethyl ether tert-butyl ether catalytic etherification process to show higher activity and stability, the molar ratio of alcohol to alkene is reduced, the iso-butene conversion rate is 95 percent or higher, and the selectivity of the ethyl ether tert-butyl ether is higher than 99 percent.

Owner:丹东明珠特种树脂有限公司

Synthetic method and device of ethyl tert butyl ether

InactiveCN103044216AAvoid smallGuarantee normal productionEther preparation by compound additionEther preparation by compound dehydrationEthyl tert-butyl etherPetroleum

The invention discloses a synthetic method and device of ethyl tert butyl ether. The ethyl tert butyl ether is prepared from isobutene, ethanol, tertiary butanol and ethanol in combination; the isobutene and the ethanol react in a first reaction system; the tertiary butanol and the ethanol react in a second reaction system; tertiary butanol generated in the first reaction system enters the second reaction system to be recycled; and isobutene generated in the second reaction system enters the first reaction system to be recycled as a reactant. The concentration of the ethanol is lower than that of enol which is directly added for preparing the ethyl tert butyl ether, so that the material adaptability is improved, and the material cost is reduced; the source of the isobutene is restricted by petroleum, and the amount of the tertiary butanol increases, so that the production of the ethyl tert butyl ether can be ensured, and the adaptability of the devices is enhanced; by-products generated by reaction can be recycled between the systems, so that the conversion ratio of the reactants is enhanced; and the tertiary butanol is a by-product from production of epoxypropane, and thus the reactant is easily available.

Owner:SUN YAT SEN UNIV

Gasoline additive

InactiveCN102977947AImprove solubilityHigh calorific valueLiquid carbonaceous fuelsSolubilityGasoline

The invention relates to a gasoline additive, which is characterized by comprising the following raw materials in percentage by weight: 20-30% of ethyl tert butyl ether, 10-20% of dimethyl carbonate, 15-25% of cyclohexane, 12-20% of neopentyl glycol, 18-25% of methanol, and 25-35% of alkylbenzene; the gasoline additive can be directly used after being added in gasoline without changing any structures of a vehicle, and has excellent solubility, high heat value, excellent performance, excellent stability and high activity.

Owner:青州市天源化工有限公司

Gasoline quality improver applicable to national IV-level gasoline

ActiveCN104004553AGood \"miscibility\"Improve anti-corrosion performanceLiquid carbonaceous fuelsAlkylphenolGasoline

The invention relates to a gasoline quality improver applicable to national IV-level gasoline. The gasoline quality improver comprises the following compounds in parts by weight: 22-25 parts of polyisobutene amine, 15-18 parts of alkylphenol, 7-10 parts of polyether amine, 10-13 parts of nitromethane, 10-15 parts of dimethyl carbonate, 5-10 parts of ethyl tert-butyl ether and 18-22 parts of solvent soil. Compared with the prior art, the gasoline quality improver applicable to national IV-level gasoline is capable of reducing fuel consumption, prolonging the service life of an engine and reducing emission of gaseous pollutants; meanwhile, the gasoline quality improver has the important practical value.

Owner:SHANDONG JILIDA ENERGY SCI & TECH CO LTD

Power additive used for automobile, and preparation method thereof

InactiveCN108251171AMake up for the problem of insufficient calorific valueIncrease motivationLiquid carbonaceous fuelsFuel additivesP-NitroanilineEthyl tert-butyl ether

The invention discloses a power additive used for an automobile, and a preparation method thereof. The power additive is prepared from the following ingredients: methyl alcohol, C12, xylene, ethyl tert butyl ether, an emulgator OP-10, n-octyl alcohol, paranitroaniline, imidazoline petroleum barium sulfonate, laurinol, propargyl alcohol and dioctyl phthalate. The additive is hydrogen-rich carbon-containing combustible liquid, the additive is added into gasoline at the volume fraction of 30-40%, the additive can partially replace the gasoline as fuel, the quality of the gasoline can be improved,the quality of the gasoline is improved, the cost of the gasoline is lowered, the octane value of the gasoline is improved, and dynamic performance is enhanced. The ingredients of the additive are abundant and are completely combustible, in addition, an ignition point is low, carbon deposition and series problems caused by carbon deposition can be avoided, the corrosion of the methyl alcohol forautomobile metal components can be prolonged, and the swelling function of the methyl alcohol for automobile rubber components is lowered. The additive is safe and environmentally friendly, tail gas emissions are reduced by 60% than the gasoline, and each index is superior to the index of common gasoline.

Owner:曹玉会

Process for preparing ethyl tert-butyl ether from technical mixtures of C4 hydrocarbons

InactiveUS8269050B2Reduce formationAvoid problemsEther separation/purificationOrganic compound preparationButene2-Butene

The invention relates to a process for preparing ETBE from technical mixtures which comprise at least 1-butene, isobutene, n-butane and 2-butenes, by reacting the isobutene present, distillatively removing a fraction comprising 1-butene and isobutene and again reacting the isobutene present therein to give ETBE.

Owner:EVONIK DEGUSSA GMBH

Methanol fuel

InactiveCN106221821AGood miscibilityNo deteriorationLiquid carbonaceous fuelsFuel additivesExhaust gas emissionsEthyl tert-butyl ether

The invention belongs to the technical field of fuel, and particularly relates to a methanol fuel. The methanol fuel is prepared from, by weight, 80-100 parts of methanol, 10-30 parts of gasoline, 1-5 parts of 2-methylimidazole, 0.1-0.6 part of ethyl tert butyl ether, 0.02-0.08 part of dodecylbenzene sulfonic acid, 0.2-1.2 parts of 1-decanol, 0.02-0.08 part of 1-hydroxyethylidene-1,1-diphosphonic acid, 0.3-0.9 part of tributyl phosphate and 0.2-1.2 parts of antiknock agent. The methanol fuel is good in intersolubility and swelling property, good in corrosion resistance and high in calorific value and octane number, and remarkably reduces exhaust gas emission.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Improved multi-functional fuel oil additive

InactiveCN104327893AImprove low temperature resistanceAnti-corrosionLiquid carbonaceous fuelsFuel additivesPhosphorous acidCarbamate

The invention relates to an improved multi-functional fuel oil additive. The improved multi-functional fuel oil additive is prepared from the following raw materials in parts by weight: 5-9 parts of lauroyl diethanolamide, 3-6 parts of carboxylic ester, 5-7 parts of polyether acetate, 4-8 parts of non-ionic surface active agent, 6-8 parts of petroleum solvent, 6-10 parts of glycerol monostearate, 3-9 parts of petroleum calcium sulfonate, 1-5 parts of ethyl tert butyl ether, 1-4 parts of combustion improver, 4-9 parts of boronized succinimide, 2-7 parts of cupric isooctoxylborate, 3-8 parts of polyisobutene carbamate, 5-8 parts of dibutyl phosphite and 1-3 parts of viscosity index improver. The improved multi-functional fuel oil additive can improve the low temperature resistance of fuel oil, has corrosion-resistant and lubricating functions and can protect the engine.

Owner:QINGDAO TOPLINK INFORMATION TECH

High-cleanness ether-base fuel

InactiveCN106753600AIncrease oxygen contentEmission reductionLiquid carbonaceous fuelsFuel additivesHazardous substanceFuel tank

The invention discloses high-cleanness ether-base fuel, which is characterized by being prepared from the following components in parts by weight: 76 to 84 parts of low-carbon mixed alcohol, 8 to 12 parts of coal-based dimethyl ether, and 8 to 12 parts of additive, wherein the additive is prepared from the following components in parts by weight: 0.05 part of clean dispersing agent, 0.05 part of metal deactivator, 0.1 to 0.5 part of antioxygen, 0.1 part of rubber swelling inhibitor, 5 to 8 parts of ethyl tert butyl ether, and 2.3 to 3.7 parts of solvent. The high-cleanness ether-base fuel provided by the invention can be burned more sufficiently, so that the emission of hazardous substances in the tail gas can be reduced; the precipitation and the condensation of impurities in an oil tank and an oil circuit system can be effectively eliminated, and the high-cleanness ether-base fuel has a favorable oil circuit dredging function, a good anti-knock property, low energy consumption and good dynamic property, and is low in production cost and remarkable in effect.

Owner:戴丽莉

Environment-friendly gasoline additive and preparation method thereof

The invention discloses an environment-friendly gasoline additive. The environment-friendly gasoline additive is prepared from the following raw materials in parts by weight: 1-5 parts of short chainalcohol, 3-7 parts of core shell structure cerium oxide / silica particles, 2.5-7.5 parts of polyhedral oligomeric silsesquioxane, 0.5-3 parts of perfluoropolyether, 10-30 parts of ethyl tert butyl ether, 5-10 parts of diethylene glycol monomethyl amyl ether, 1-6 parts of butyl acetyl ricinoleate, and 2-8 parts of a fluorinated diamine compound. According to the environment-friendly gasoline additive, the problems such as environmental pollution, engine carbon deposition and fuel oil standing stratification generated after gasoline combustion are solved, power, anti-corrosion, anti-rust and lubrication properties of an engine are also improved, so that engine wear is reduced, the service life of the engine is prolonged, and large-scale promotion and application are more advantageous. The invention further discloses a preparation method of the environment-friendly gasoline additive.

Owner:交城县万里通加油站

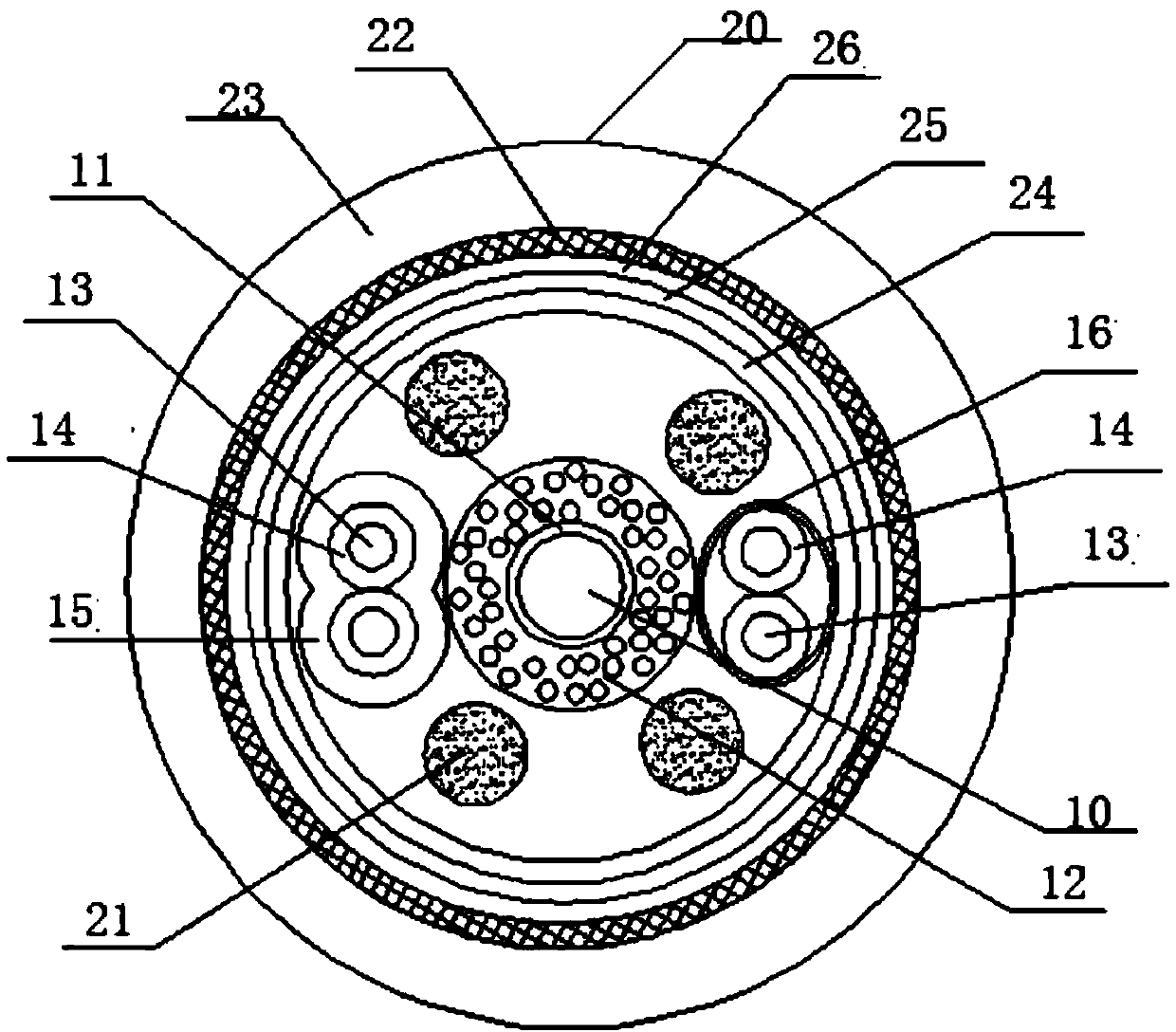

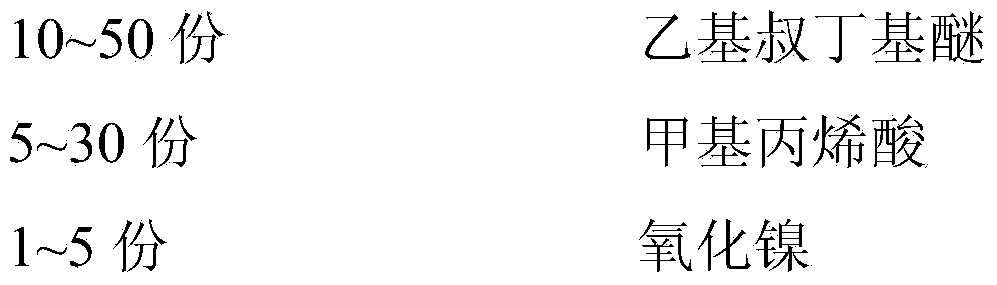

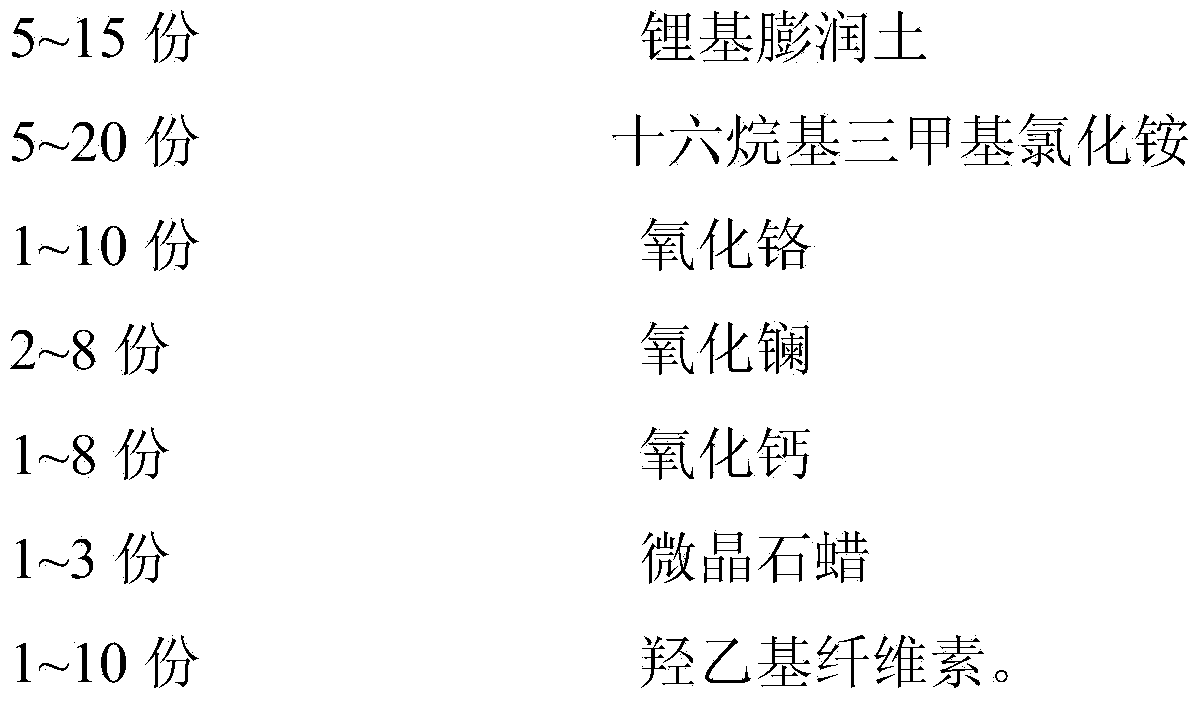

High-strength control cable

ActiveCN104051066AHigh strengthExtended service lifeInsulated cablesOrganic insulatorsLithiumMolecular materials

The invention discloses a high-strength control cable. A middle wire core of the cable is formed by a first wire core, a conducting layer arranged on the outer surface of the first wire core and a first insulating layer wrapped outside the conducting layer. A separating layer is arranged outside the middle wire core. Left wire cores are arranged between the middle wire core and the separating layer, wherein each left wire core is formed by two mutually wound second wire cores. The outer surfaces of the two second wire cores are provided with wire core separating layers respectively. The outer surface of the two mutually wound second wire cores is provided with the first insulating layer, wherein the two mutually wound second wire cores wrapped by the first insulating layer form a structure shaped like an Arabic number eight. According to the high-strength control cable, the cable is made to have good mechanical performance through addition of ceramic components, intensity of the cable is improved, mechanical damage is effectively reduced, and service life of the cable is prolonged; nickel oxide and lithium base bentonite interact with each other, so that anti-aging performance of ethyl tert butyl ether and methacrylic acid which are of high molecular material components is improved effectively, and the service life of the cable is further prolonged.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Process method for preparing ethyl tert-butyl ether

ActiveCN103044212ARegulate acidityRegulatory activityOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound additionPhosphomolybdic acidHeteropoly acid

The invention provides a process method for preparing ethyl tert-butyl ether. The process method comprises the following steps of: taking isobutene and ethanol as raw materials, and using a heteropoly acid / titanium-based complex oxide catalyst to prepare the ethyl tert-butyl ether, wherein the heteropoly acid / titanium-based complex oxide catalyst takes a complex oxide as a carrier and takes heteropoly acid as an active component, the complex oxide is one or more of titanium-based complex oxides in TiO2-SiO2 or TiO2-ZrO2, and the heteropoly acid is one or more of phosphotungstic acid, silicotungstic acid, arsenotungstic acid, germanotungtic acid, phosphomolybdic acid, silicomolybdic acid, arsenomolybdic acid and germanomolybdic acid. According to the process method provided by the invention, the catalyst adopting the titanium-based complex oxide to load the heteropoly acid is adopted, so that the shortcomings of inactivation of the catalyst and reduced conversion rate, which are caused by easiness in damaging the Keggin structure of the heteropoly acid of the loaded heteropoly acid catalyst, easiness in loss of acid amount and difficulty in separation, can be overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing ETBE (Ethyl Tert Butyl Ether) by using C4 fraction in etherified liquefied gas

InactiveCN103739453APromote generationEther preparation by compound additionPtru catalystEthyl group

The invention relates to the technical field of chemical engineering, and particularly relates to a process for preparing ETBE (Ethyl Tert Butyl Ether) by using a C4 fraction in an etherified liquefied gas as a raw material. A process for preparing the ETBE by using the C4 fraction in the etherified liquefied gas is characterized in that in a synthesis device of ETBE, the raw material C4 and alcohol enter a reactor, isobutene in the C4 and the alcohol generate an etherification reaction under the action of a catalyst to generate ETBE, the reaction materials including redundant alcohol, etherified C4, product ETBE, byproduct dimethyl ether and C8 tertiary butanol are sent to an azeotrope tower so as to be separated, and an ETBE crude product flows out from the bottom of the azeotrope tower. By adoption of a process for producing the ETBE by using the C4 fraction in the etherified liquefied gas as the raw material according to the method provided by the invention, the yield of the ETBE can reach 96 percent.

Owner:YUHUA CHEM PLANT BINZHOUSNDONG PROV

Energy-saving emission-reducing gasoline additive and preparation method and application thereof

InactiveCN108795519ASmall air resistanceBoost octaneLiquid carbonaceous fuelsFuel additivesFuel oilSorbitan

The invention discloses an energy-saving emission-reducing gasoline additive and a preparation method and application thereof, and belongs to the technical field of fuels. The energy-saving emission-reducing gasoline additive is prepared from denatured fuel ethanol, 2-ethyl hexanol, isopropyl alcohol, methylbenzene, ethyl tert butyl ether, paraffin hydrocarbon solution, a nonionic surfactant, bis-(3-triethoxysilylpropyl)-tetrasulfide, polyoxyethylene sorbitan fatty acid ester, ethyl nitrate and isooctyl nitrate; the energy-saving emission-reducing gasoline additive is applicable to fuel oils,has low addition quantity, high combustion efficiency, low gasoline consumption and good cleaning effect, emission of pollutants is decreased, and environmental pollution is relieved.

Owner:胡张艳

Gasoline quality improver applicable to national IV-level gasoline

ActiveCN104004553BImprove anti-corrosion performanceImprove ignition performanceLiquid carbonaceous fuelsGasolineAlkylphenol

Owner:SHANDONG JILIDA ENERGY SCI & TECH CO LTD

Sole material emulsifier and preparation method thereof

The invention discloses a sole material emulsifier which comprises the following raw materials by weight: 5-10 parts of Artemisia stelleriana extract, 2-9 parts of a nonionic emulsifier, 3-10 parts of a non-ionic emulsifier, 5-7 parts of polyamide, 3-7 parts of polyethylene polyamine, 2-10 parts of methyl tert butyl ether, 3-8 parts of ethyl tert butyl ether, 0.5-3.5 parts of a stabilizer and 3.5-6.5 parts of a defoaming agent. The invention provides the sole material emulsifier and a preparation method thereof. The sole material emulsifier is simple in composition, good in emulsification effect, simple in preparation method, and used as an additive for sole production process, and can improve sole toughness and wear resistance, the ionic emulsifier and the non-ionic emulsifier in the raw materials can reduce interfacial tension and reduce energy needed for formation of emulsion from a sole material, and strength and elasticity and other physical performances of the sole material can be improved.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Process method for preparing ethyl tert-butyl ether

ActiveCN103044212BImprove conversion rateImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound additionPhosphomolybdic acidHeteropoly acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Highly active composite modified additive for methanol gasoline for automobiles and its preparation process

InactiveCN104745252BMeet the output powerFrequent replacementLiquid carbonaceous fuelsTetrazoleAntioxidant

The invention relates to a high-activity compound modified additive of methanol gasoline for an automobile. The additive is prepared from the following components in percentage by weight: 12% of ethanol as a solvent, 0.1% of 2-methyl-1-butanol as an antidetonant, 0.5% of sulfurized calcium alkyl as an adjustor, 1.5% of triethanolamine as an engine carbon deposition preventer and an anticorrosive agent, 2.5% of methylal as a combustion improver, 59% of normal butanol as an active mutual solvent, 0.1% of 3-methyl-1-butanol as a synthetic solvent, 10% of 2-methyl-1-propanol as a synthetic solvent, 10% of normal propyl alcohol as a synthetic solvent, 0.1% of ethyl tert butyl ether as an antidetonant, 2% of 1-phenyl-5-mercapto-tetrazole as a corrosion inhibitor, 1% of 2-mercapto benzimidazole as a corrosion inhibitor, 20.6% of nano TiO as a protective coating and 0.6% of 2, 6-ditert-butyl p-cresol as an antioxidant. The additive can be widely applied to additives of methanol and methanol motor gasoline.

Owner:王军

Preparation method of ethyl tert butyl ether

ActiveCN103044214BHigh activityImprove stabilityPhysical/chemical process catalystsEther preparation by compound additionFixed bedReaction temperature

The invention provides a preparation method of ethyl tert butyl ether. With isobutylene and ethanol as reaction raw materials and supported caesium phosphotungstate acidic salt as a catalyst, the ethyl tert butyl ether is prepared under the reaction conditions that liquid hourly volume space velocity of isobutylene is 0.5-5.0 / h, mole ratio of the ethanol to the isobutylene is (1.0-10.0):1, reaction temperature is 90-200 DEG C and reaction pressure is 2.0-6.0MPa. The preparation method provided by the invention adopts the supported caesium phosphotungstate acidic salt as the catalyst, the defect that the typical heteropolyacid phosphotungstic acid and caesium phosphotungstate acidic salt thereof are easy to run away in a using process, are difficult to separate as particles are too small and are difficult to be used on a fixed bed reactor is overcome, continuous production by virtue of a fixed bed is realized, reaction activity is high, the supported caesium phosphotungstate acidic salt is easy to recycle and can be repeatedly used, and a reaction process operation is easy, so that the preparation method provided by the invention is a new environment-friendly process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com