Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Ethyl nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl nitrate is the ethyl ester of nitric acid and has the chemical formula C₂H₅NO₃. It is a colourless, volatile, highly flammable liquid. It is used in organic synthesis and as an intermediate in the preparation of some drugs, dyes, and perfumes.

Biofuel oil and preparation thereof

InactiveCN101280231ABoost octaneIncrease cetane numberLiquid carbonaceous fuelsResource savingFuel oil

The invention relates to a method of preparing biological fuel oil based on the compositions of ethanol, methanol, toluene, isopropyl alcohol, surface active agent, ethyl nitrate and ferrocene and the prepared product; the biological fuel oil in the invention has high octane number, high cetane number and low corrosiveness.; the engine which uses the product prepared by the method in the invention has high power and low environmental pollution so that the fuel oil product prepared by the method is the fuel oil which is environmental-friendly and resource saving.

Owner:柏绿山

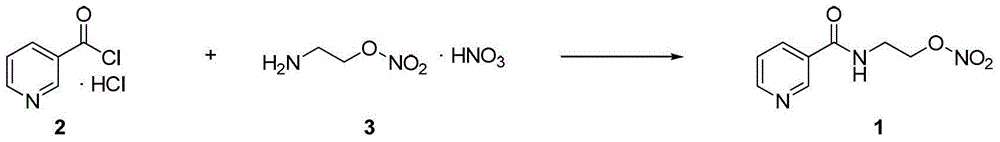

Process for the manufacture of nicorandil

Disclosed is a process for the synthesis of Nicorandil (1), 2-(nicotinamide)ethyl nitrate, starting from N-(2-hydroxyethyl)nicotinamide (15), using nitration with nitric acid in the presence of acetic anhydride Said synthesis method is particularly advantageous because it solves the safety problems involved in the use of nitric acid as nitrating agent, and allows a product with excellent yields and quality to be isolated.

Owner:PROCOS

Methanol diesel oil fuel and preparation method thereof

InactiveCN101235325ASolve layeringImprove performanceLiquid carbonaceous fuelsAcetic acidIsobutyl alcohol

The invention relates to novel vehicular energy-saving environment-friendly methanol diesel oil and a manufacturing method, the proportion of each component of methanol diesel oil fuel according to weight by parts is that diesel oil 23-50, methanol 35-70 and combined addition agent 5-13, wherein the components and contents of the combined addition agent are that ethyl nitrate 0-3, cyclopean ferrocene 0-0.008, carbon dodecanol 0-2.5, isobutyl alcohol 0-3, diethyl carbonate 0-4, acetic ether 0-2.5, benzyl alcohol 0-0.5 and butanol 0-3. The process for preparation comprises getting dissel oil, methanol and combined addition agent according formula ratio under the condition of normal temperature and normal pressure, firstly, adding combined addition agent in methanol, preparing denatured methanol after completely dissolving, secondly, adding the above denatured methanol in diesel oil, finally completely evenly stirring for 10-20 minutes to get products. The products have excellent property and environmental protection.

Owner:浙江赛孚能源科技有限公司

Clean environment-friendly dimethyl carbonate diesel and preparation method thereof

The invention discloses a preparation method of environment-friendly dimethyl carbonate diesel for an automobile. The environment-friendly dimethyl carbonate diesel comprises the following components by weight percent: 50-300ppm of 2,6-tertiary butyl p-cresol, 10-200ppm of tris(2,4-ditert-butyl phenyl) phosphite, 10-200ppm of thiadiazole or benzotriazole, 10-500ppm of isooctyl nitrate or ethyl nitrate, 100-500ppm of lubricity improver, 9.982-29.83% of dimethyl carbonate and 70-90% of diesel. The preparation method comprises the following steps of: adding various additives into dimethyl carbonate and then mixing to obtain a dimethyl carbonate solution I; and then mixing the dimethyl carbonate solution I and dimethyl carbonate with the diesel to obtain the dimethyl carbonate diesel. The dimethyl carbonate diesel disclosed by the invention has the advantages of good stability, corrosion resistance and environmental protection performance, can be intersoluble with the diesel in any proportion, and is simple to prepare, low in cost and strong in competitive power.

Owner:HENAN COAL CHEM IND GROUP INST

Condensed emulsified diesel and its preparation method and application

InactiveCN1632066ASame colorIndistinguishable transparencyRefining by water treatmentOil additivePotassium hydroxide

Disclosed is a condensed emulsive diesel oil, comprising of the following ones: diesel oil 30-81, alkylnaphthalene 1-8, water 5-35, ethanolamine 0.3-11, oleic acid 4-35, or ethyl nitrate 0.05-0.6, potassium hydroxide or sodium hydroxide,The invention has log guarantee period which can be more than three years, good stability, no delamination of oil and water after being placed for a long period, low content of sulpher, can be used directly as well as being mixed with pure diesel oil; and it has low productive cost, simple preparing technique, low degree of corrosion; by using the invention, the service life of motor can be prolonged, with high of efficiency. It can be applied in industrial burning, equipments in auto, ship and generating set, with high ratio of performance and price, as diesel oil additive, it can decrease the drainage of harmful gas, make the oil-saving rate to be 20%, has bright future in market.

Owner:刘少君

Methanol diesel

InactiveCN104498110AImprove stabilitySolve the difficulty of starting at low temperatureLiquid carbonaceous fuelsIsobutanolKetone

The invention relates to a methanol diesel. The methanol diesel is characterized by comprising the following components in percentage by weight: 60-80% of diesel, 15-25% of methanol and 5-15% of additives, wherein the additives are composed of the following components in percentage by weight: 0.1-7% of cyclopentyl ferrocene, 2-30% of isopropyl-ketone, 0.2-16% of dimethyl carbonate, 0.1-18% of isobutanol, 0.2-10% of methylbenzene, 0.5-15% of n-butyl alcohol, 6-20% of methyl tertiary-butyl ether, 3-15% of octane, 15% of methyl cyclopentane, 0.2-10% of oleic acid, 0.05-15% of ethyl nitrate, 0.05-10% of 12 carbons, 0.02-1% of castor oil, 2-20% of petroleum ether, 0.5-15% of ethyl acetate, 0.1-20% of n-octyl alcohol, 0.3-30% of isoamyl alcohol, 5-10% of fatty acid, 2-15% of ethanol amine, 1-9% of butanediamide, 0.05-0.4% of benzotriazole, 0.05-1% of Twain and 0.03-2% of span 80. The methanol diesel provided by the invention can be widely used in a vehicle fuel.

Owner:崔天豪

Polypropylene tow forming adhesive for cigarette

InactiveCN1594482AImprove adsorption capacityGreat tasteTobacco smoke filtersAdhesivesPolymer scienceAdhesive

The invention discloses a polypropylene tow forming adhesive for cigarette wherein the adhesive is charged by, auxiliary solvent comprising the mixture of one or more from 0.1-2% of ethanol, propanol, butanol, 0.5-3% of emulsifying agent, which is the mixture of one or more from propanetriol, propylene glycol, ethylene glycol, the mixture of one or more from trishydroxymethylaminomethane, 2-amido-2-hydroxyl-1, 3-propylene glycol, 5,5-dimethyl-hydantoin, dehydration sorbic alcohol fatty acid ester, polyoxyethylene dehydration sorbic alcohol fatty acid ester, octadecanamide ethyl dimethyl-beta-hydroxyl ethyl nitrate.

Owner:常德市中耀应用技术研究所

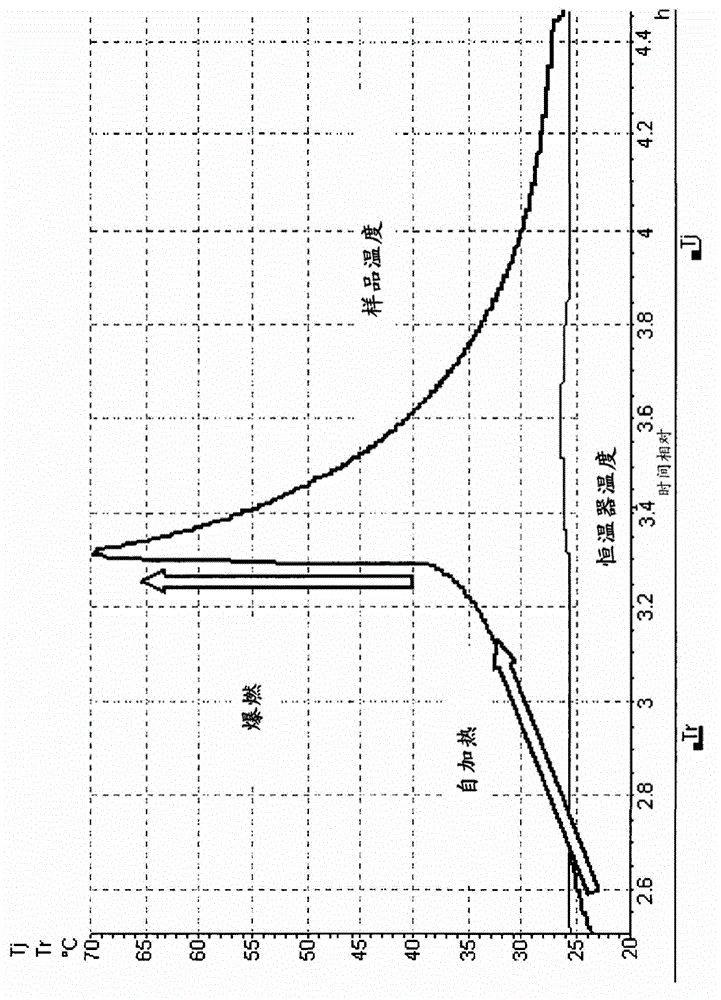

Gas generator composition and preparation thereof

ActiveCN101468934AImprove gas production efficiencyBurn fasterNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsCombustionSolvent

The invention relates to a gas production composition and a preparation method thereof. The gas production composition provided by the invention contains solute and solvent, wherein the gas production composition also contains cosolvent, and the solute is ethyl nitrate, nitrification diethanolamine or polyurethane. The method for preparing the gas production composition, which is provided by the invention, comprises the steps of well mixing the solute, the solvent and the cosolvent at a temperature between 0 and 65 DEG C and obtaining the gas production composition, wherein the solute is ethyl nitrate, nitrification diethanolamine or polyurethane. The gas production composition provided by the invention has the characteristics of innocuity, high gas production efficiency, fast combustion, no residue after combustion, low combustion temperature and suitability for large-scale application.

Owner:BYD CO LTD

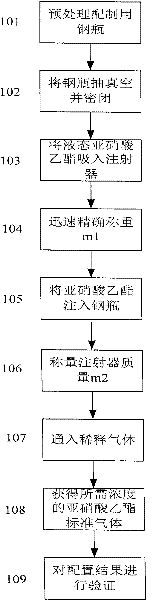

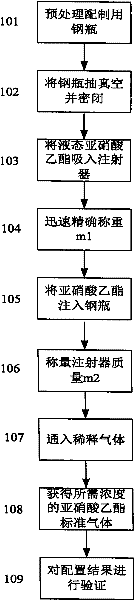

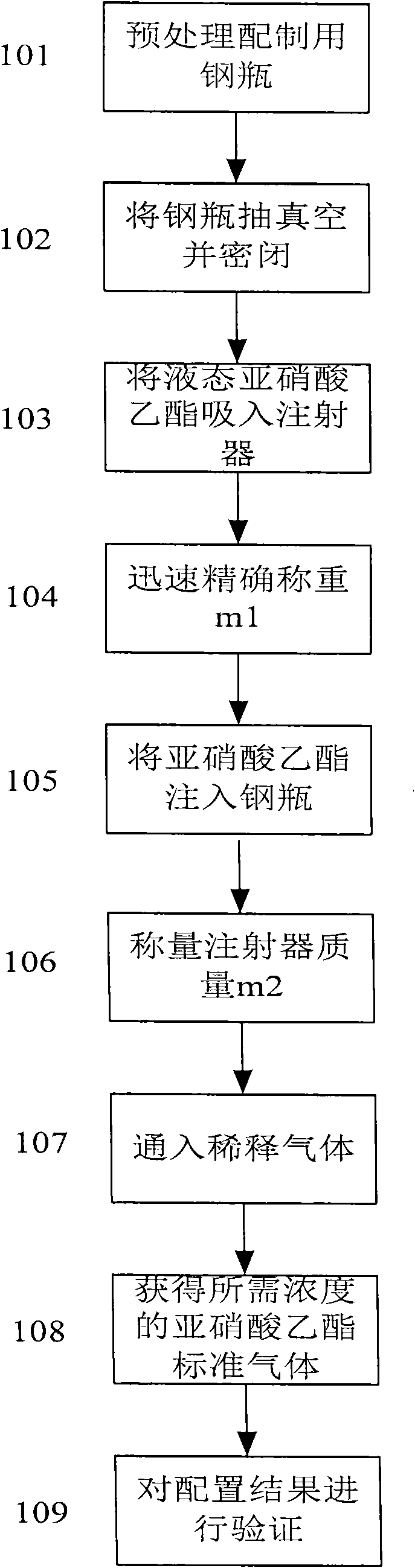

Preparation method for ethyl nitrite standard gas

ActiveCN102539202AAccurate and reliable gas concentrationEasy to preparePreparing sample for investigationLiquid stateDiluent

The invention provides a preparation method for ethyl nitrite standard gas. The method comprises the following steps of: a1, pre-treating a container used in the preparation method; a2, vacuating the container and sealing; a3, absorbing liquid ethyl nitrite into a syringe, and weighing the total mass m1 of the syringe and the liquid ethyl nitrite; a4, weighing mass m2 of the syringe; and a5, introducing diluents into the container to obtain the ethyl nitrite standard gas. The ethyl nitrite standard gas prepared by the preparation method is accurate and reliable in gas concentration. Industrial ethyl nitrite standard gas can be prepared easily and quickly by the method, the standard gas is provided for detecting ethyl nitrite, and the method has industrial application significance.

Owner:JIANGSU WAN QI BIOLOGICAL TECH

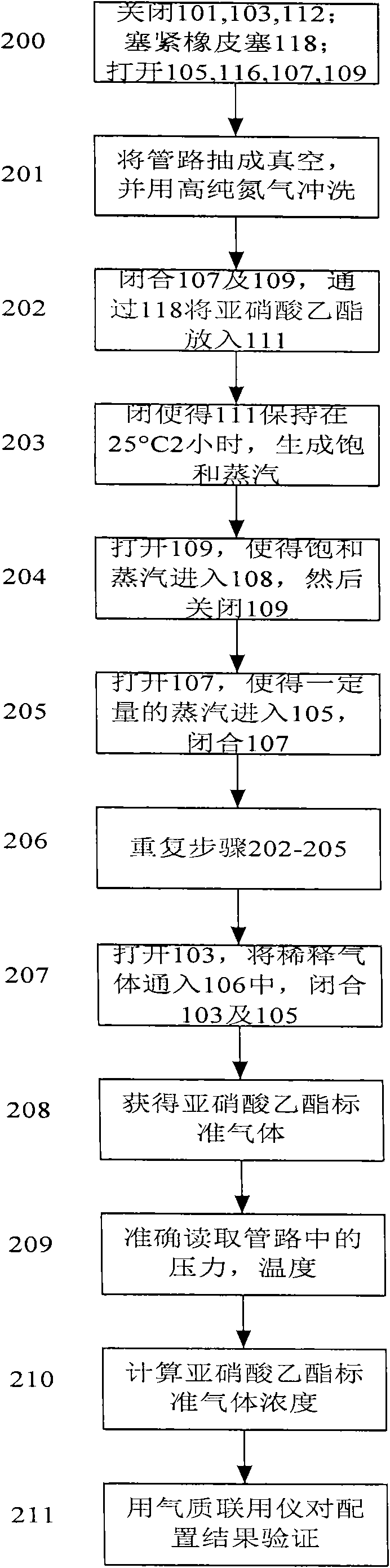

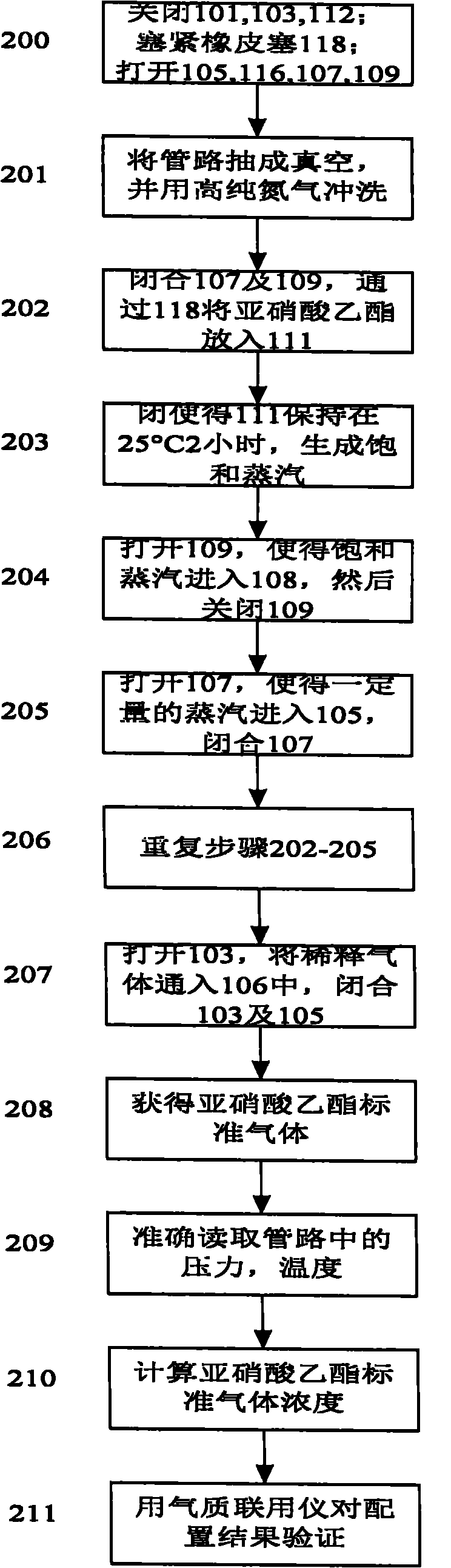

Preparation method for ethyl nitrite standard gas

ActiveCN102564833AAccurate and reliable gas concentrationEasy to preparePreparing sample for investigationMixer accessoriesGas cylinderEthyl ester

The invention provides a preparation method for ethyl nitrite standard gas. The method includes the following steps: (a1) ethyl nitrite solution is filled into a vacuum constant-temperature reaction kettle and kept for 2 hours, wherein the temperature in the vacuum constant-temperature reaction kettle is kept at 25 DEG C until the ethyl nitrite solution becomes saturated vapor; (a2) the saturated ethyl nitrite vapor is quantitatively transferred into a sample loop; (a3) the saturated ethyl nitrite vapor in the sample loop is put into a standard gas bottle; (a4) steps a1 to a3 are repeated in order to regulate the volume of the saturated ethyl nitrite vapor entering the standard gas bottle; (a5) inert gas used as diluting gas is filled into the standard gas bottle; (a6) the ethyl nitrite standard gas is obtained. The concentration of the ethyl nitrite standard gas prepared by the preparation method is accurate and reliable. The usage of the method can easily and conveniently prepare the industrial ethyl nitrite standard gas, provides standard gas for the industrial test of ethyl nitrite, and is highly significant in industrial application.

Owner:JIANGSU WAN QI BIOLOGICAL TECH

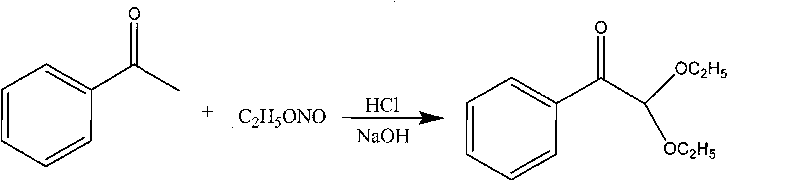

Synthetic method of 2,2-diethoxy acetophenone photoinitiator

InactiveCN101735031AAvoid decompositionEase of industrial productionOrganic compound preparationCarbonyl compound preparationAcetophenoneSodium nitrite

The invention relates to a synthetic method of a 2,2-diethoxy acetophenone photoinitiator, which comprises the following steps: a, synthesizing ethyl nitrite, namely mixing ethanol with 28 percent of aqueous solution of sodium nitrite in a reaction kettle with mechanical stirring and a gas ingress pipe, dripping 20 percent dilute sulphuric acid into the mixture at the temperature of between 20 and 30 DEG C to generate ethyl nitrite gas, and directing introducing the generate ethyl nitrite gas into the step b for reaction, wherein the molar ratio of the ethanol to the sodium nitrite to the dilute sulphuric acid is 1.00:1.09 to 1.68:1.10 to 1.18; and b, synthesizing 2,2-diethoxy acetophenone, namely introducing the ethyl nitrite gas generated by the step a into acetophenone and 36 percent hydrogen chloride ethanol solution, and neutralizing the mixture by using sodium hydroxide solution after a reaction ends to prepare finished products, wherein the molar ratio of the acetophenone to the hydrogen chloride ethanol solution is 1:1. The synthetic method is simple and convenient in process and high in product yield and is suitable for industrial production.

Owner:NANKAI UNIV +1

High efficient diesel oil additive

InactiveCN104974802AImprove performanceImprove combustion efficiencyLiquid carbonaceous fuelsOil additiveGlycerol

A high efficient diesel oil additive is composed of the following raw materials in parts by weight: 6 to 14 parts of tween, 7 to 9 parts of magnesium nitrate, 6 to 13 parts of N,N-dimethyl myristyl tert-alcohol, 8 to 12 parts of dimethoxy propane, 4 to 7 parts of ethyl nitrate, 3 to 6 parts of petroleum ether, 4 to 9 parts of dimethyl carbonate, 2 to 4 parts of isoamyl alcohol, 1.5 to 6 parts of triethanolamine, 7 to 8 parts of ferrocene, 3 to 7 parts of DMC, 11 to 13.5 parts of glycerol, 8 to 11 parts of 4-trifluoromethoxy benzyl alcohol, 7 to 9 parts of polyisobutylene amine, 1.2 to 4 parts of O,O-dibutyl zinc dithiophosphate, and 8 to 12 parts of tert-butyl alcohol. The provided diesel oil additive can save the energy, is efficient, is capable of improving the diesel oil performances and promoting the burning efficiency of diesel oil, and can reduce the accumulated carbon at the same time.

Owner:张宇

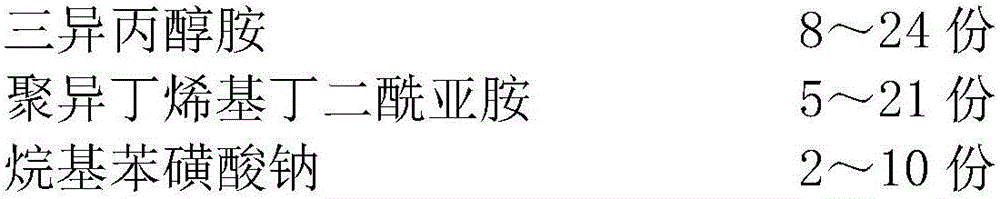

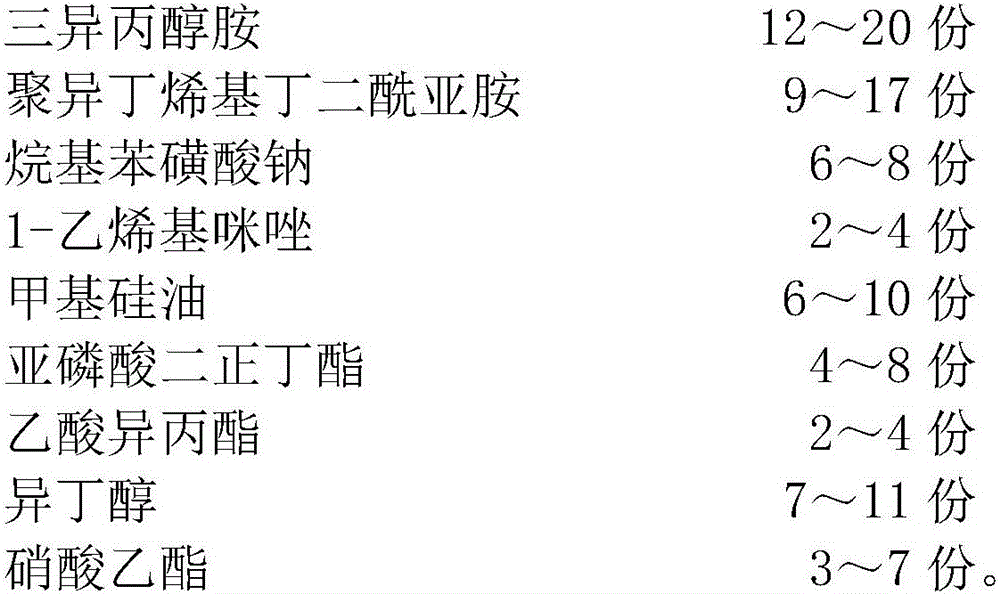

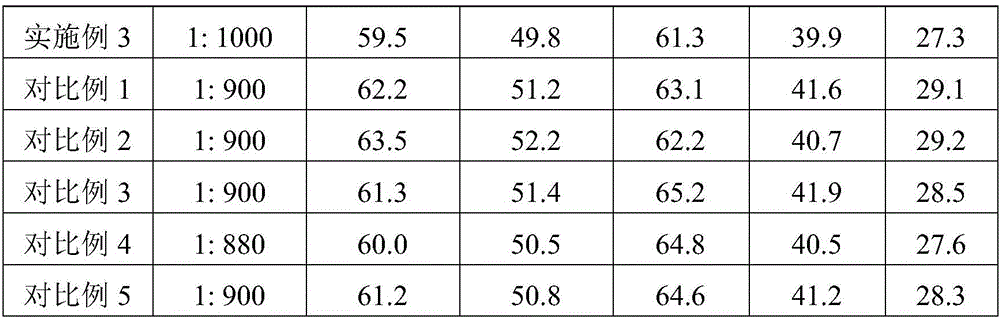

Diesel oil fuel combustion enhancing additive

InactiveCN106221835APrevent Storage StratificationImprove low temperature performanceLiquid carbonaceous fuelsFuel additivesAcetic acidCombustion

The invention relates to the technical field of fuel additives, in particular to a diesel oil fuel combustion enhancing additive. The diesel oil fuel combustion enhancing additive is prepared from, by weight, 8-24 parts of triisopropanolamine, 5-21 parts of polyisobutylene keating diimide, 2-10 parts of sodium alkyl benzene sulfonate, 1-5 parts of vinylimidazole, 1-7 parts of methylsilicone oil, 2-10 parts of dibutyl phosphite, 1-5 parts of acetic acid isopropyl ester, 4-14 parts of isobutyl alcohol and 1-9 parts of ethyl nitrate. The diesel oil fuel combustion enhancing additive can improve the combustion performance and the combustion efficiency of diesel oil fuel, diesel oil is effectively saved, exhaust gas emission is reduced, and the diesel oil fuel combustion enhancing additive has good cleaning purification and preservation effects.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

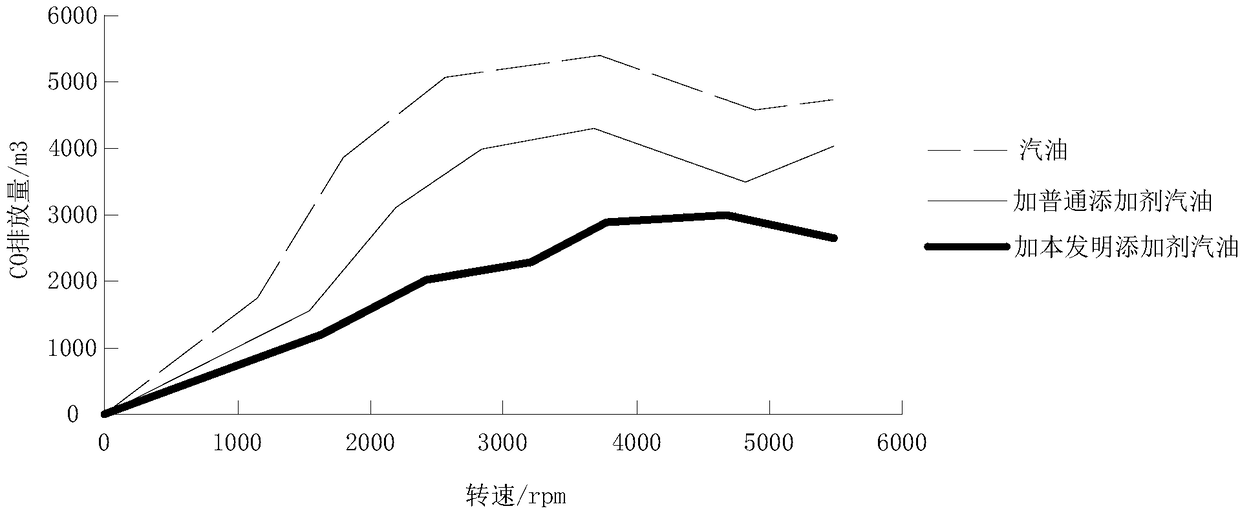

Adjuvant capable of reducing automobile exhaust emission

InactiveCN106350133AEmission reductionIncrease surface activation energyLiquid carbonaceous fuelsAutomotive emissionsCerium oxide

The invention discloses an adjuvant capable of reducing automobile exhaust emission, which is prepared from the following components in parts by weight: 2-5 parts of acetone, 1-3 parts of isoamylol, 2-4 parts of tertiary butanol, 1-3 parts of n-hexanol, 2-4 parts of n-octane, 3-5 parts of vinyl acetate, 4-6 parts of petroleum ether, 1-3 parts of dimethyl ether, 2-5 parts of dimethyl carbonate, 1-4 parts of ethyl nitrate, 10-15 parts of dimethylformamide, 1-3 parts of stearic acid, 0.6-0.8 part of dioctyl phthalate, 1-3 parts of strontium peroxide, 0.2-0.6 part of nonylphenol polyoxyethylene ether, 0.3-0.7 part of fluorocarbon surfactant, 1-4 parts of polytetrafluoroethylene, 0.6-0.9 part of catalyst, 0.3-0.5 part of bentonite powder, 0.2-0.4 part of nano cerium oxide and 0.3-0.6 part of nano magnesium powder.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Diesel oil smoke-eliminating and oil-saving additive

InactiveCN101768486AReduce the amount requiredImprove solubilityLiquid carbonaceous fuelsFuel additivesCombustionTetramine

The invention relates to a diesel oil smoke-eliminating and oil-saving additive. An engine using diesel oil wastes energy sources due to insufficient combustion of diesel oil, and the discharged tail gas has heavy pollution to the environment. Some diesel oil additives exist in the current market, but the oil-saving effect is not quite obvious. The diesel oil smoke-eliminating and oil-saving additive comprises the following components in percentage by weight: 85 percent of diesel oil, 5 percent of ferrocene, 3 percent of cyclopentadiene hydroxymanganese, 4 percent of ethyl nitrate and 3 percent of triethylene tetramine. The components are just mixed, stirred and filtered. The invention provides the additive for the diesel oil as fuel.

Owner:迟凤文

Emulsified diesel oil for automobile

The invention discloses emulsified diesel oil for vehicle. According to volume portion, the composition formulation comprises 40 to 70 portions of diesel oil, 10 to 30 portions of methanol, 10 to 20 portions of water, 0.5 to 1.5 portions of ethyl nitrate, 0.8 to 1.8 portions of polyoxyethylene nonyl phenyl ether, 0.2 to 0.7 portions of cyclopentyl ferrocene, 1.0 to 2.0 portions of acetone, 0.0 to 0.7 portions of petroleum sodium sulfonate, 1.0 to 1.5 portions of isoamyl alcohol and 1.3 to 1.8 portions of normal hexane. The viscosity, condensation point, flash point and cetane value of the emulsified diesel oil are all accorded with the index requirements of diesel oil for vehicle, and the source of the required raw materials and auxiliary materials is wide, the price is low and the exhaust emission is accorded with the requirements of the 3# European standard; by using the emulsified diesel oil, the fuel saving rate can reach 28%, the wearing of the cylinder jacket and the piston ring of the diesel engine is reduced by 25% for running 3,500 hours comparing with using pure diesel oil; the implementation of the invention has important economic value and social significance.

Owner:上海龙津石油有限公司

Nanometer emulsified diesel oil and preparation method thereof

The invention relates to a nanometer emulsified diesel oil and a preparation method thereof and relates to the manufacturing technique of motor vehicle fuel. The invention solves the shortcomings of the other diesel oil. The diesel oil is made from n-nonyl alconyl, methyl alcohol, diesel oil, emulsifier, methyl tert-butyl ether, ferrocene, ethyl nitrate, toluene and acetone. The method comprises the steps of: adding the materials into a container and stirring for 20 minutes. Through the technical solution, the invention saves energy resource, lowers the cost to 30% of common diesel oil and stabilizes the property. In a storage pot at 90 DEG C, the diesel oil can be stored for 100 days. Under normal temperature, the diesel oil can be stored for more than 3 years, without demulsification and delamination.

Owner:马增杰

Concentrated emulsified diesel fuel

InactiveCN103254954AEasy to useBurn fullyLiquid carbonaceous fuelsOleic Acid TriglycerideSodium hydroxide

The invention discloses a concentrated emulsified diesel fuel. The concentrated emulsified diesel fuel is prepared by the following raw materials in parts by weight: 25-45 parts of diesel fuel, 15-30 parts of alkyl naphthalene, 3-8 parts of mono ethanol amine, 12-25 parts of oleic acid, 2-5 parts of sodium hydroxide, 0.1-0.5 part of ethyl nitrate, 1.5-4 parts of cyclohexylamine, 1-5 parts of acetone and 0.2-1 part of an emulsifying agent. The diesel fuel has a good use effect, is sufficient to burn, high in fuel saving ratio and suitable for diesel cars as a fuel, and the exhaust emission is greatly reduced.

Owner:WUJIANG DEZUO DAILY CHEM PROD

Reverse magnetic field boiling fuel oil

InactiveCN1900239AImprove liquidityIncrease combustionLiquid carbonaceous fuelsDetonatorReaction temperature

The present invention is the production process and usage of reverse magnetic field boiling fuel oil. The reverse magnetic field boiling fuel oil is prepared with stalk ethanol, biological gasoline and diesel oil, water, stabilizer A, stabilizer B, combustion promoter toluene and methanol, and detonator ethyl nitrate and pental nitrate, and through reaction at certain temperature in some specific chemical apparatus. The reverse magnetic field boiling fuel oil has low cost, no corrosion to metal, no swelling to rubber, and no pollution to atmosphere, soil and water, and may be used in oil burning boiler, internal combustion engine, etc.

Owner:杜鹏

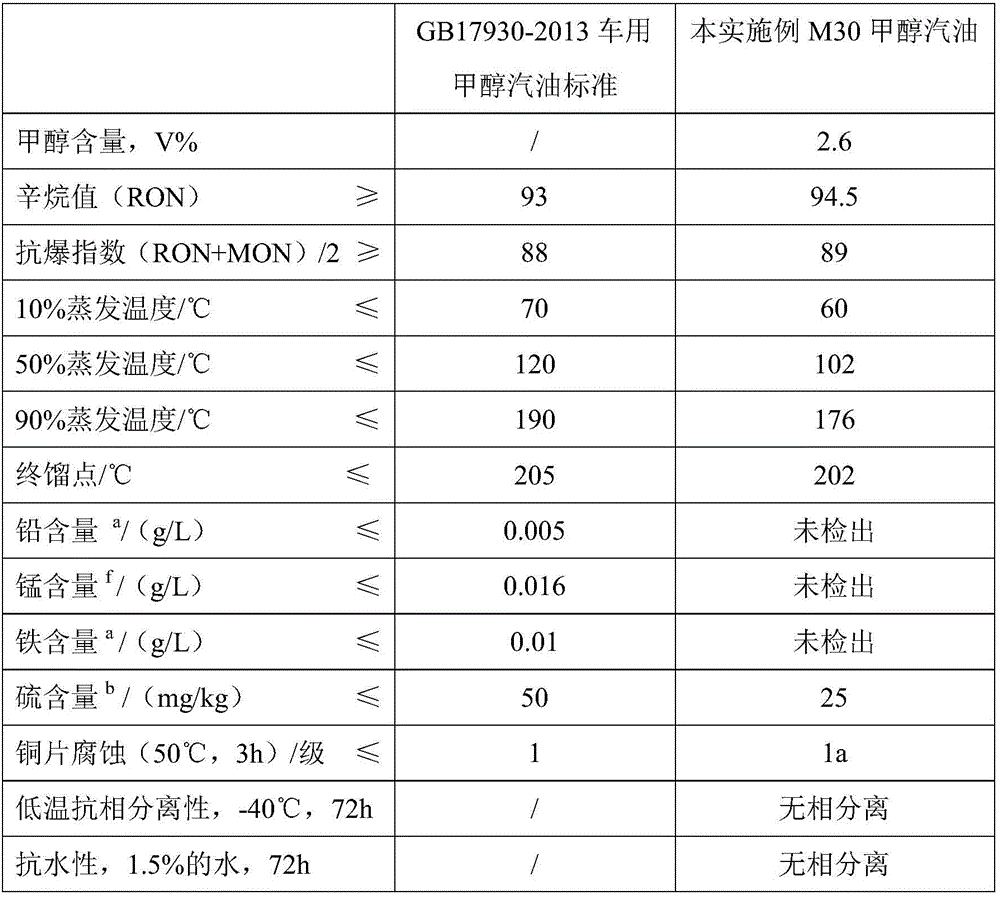

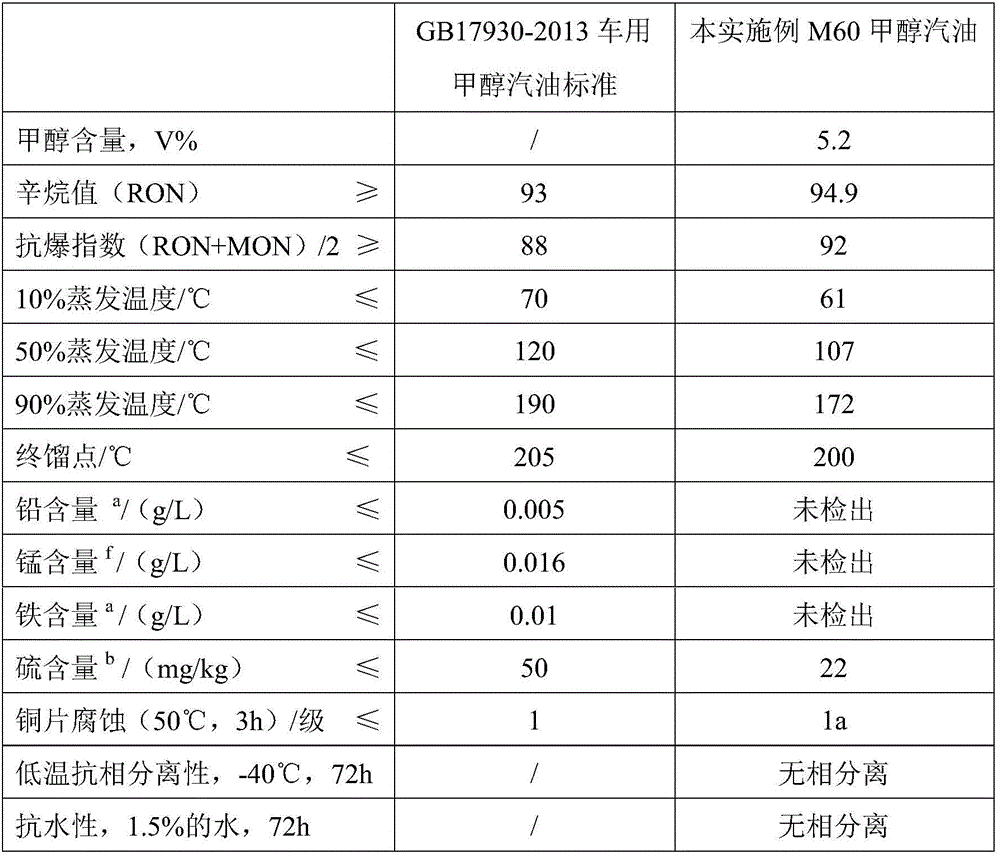

Methanol gasoline composite additive, and preparation method and application thereof

InactiveCN106566584AExtended service lifeBoost octaneLiquid carbonaceous fuelsFuel additivesPotassium hydroxideAlkylbenzenes

The invention relates to a methanol gasoline composite additive, and a preparation method and application thereof. The methanol gasoline composite additive is prepared from the following raw materials in percentage by weight: 68 to 72 percent of animal oil, 0.5 to 1.0 percent of plant oil, 0.2 to 0.5 percent of alkylbenzene, 0.1 to 0.7 percent of monoethanolamine, 0.1 to 0.7 percent of diethanolameine, 0.1 to 0.6 percent of triethanolamine, 1.0 to 2.1 percent of isooctyl nitrate, 1.0 to 2.1 percent of isopropyl nitrate, 1.0 to 2.1 percent of ethyl nitrate, 1.0 to 2.1 percent of sodium hydroxide, 1.0 to 2.1 percent of potassium hydroxide and 18 to 22 percent of water. According to the preparation method, the raw materials are sequentially put into a mixing container according to the proportion, and are stirred at the same time; then, the mixing container is put into ultrasonic waves, and agitation is performed for 15 to 25 min; and the composite additive is obtained. The composite additive provided by the invention can be applied to M25 to M60; the corrosion of methanol gasoline on an automobile can be reduced; and the octane value, the blasting point, the combustion heat value, the oil product quality and the power of the methanol gasoline can be improved.

Owner:XUZHOU LANHAI ENERGY TECH CO LTD

Process for the manufacture of nicorandil

Disclosed is a process for the synthesis of Nicorandil (1), 2-(nicotinamide)ethyl nitrate, starting from N-(2-hydroxyethyl)nicotinamide (15), using nitration with nitric acid in the presence of acetic anhydride Said synthesis method is particularly advantageous because it solves the safety problems involved in the use of nitric acid as nitrating agent, and allows a product with excellent yields and quality to be isolated.

Owner:PROCOS SPA

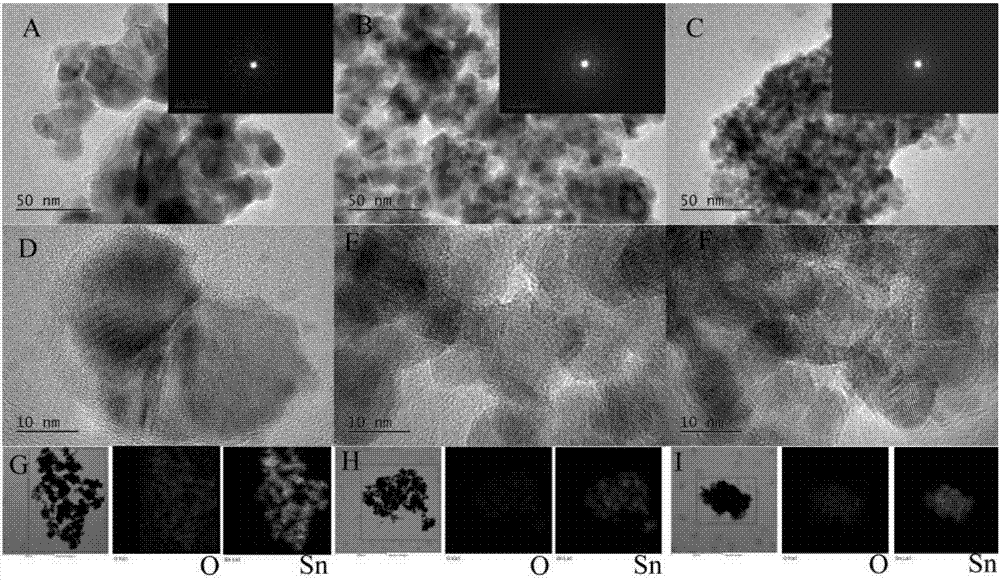

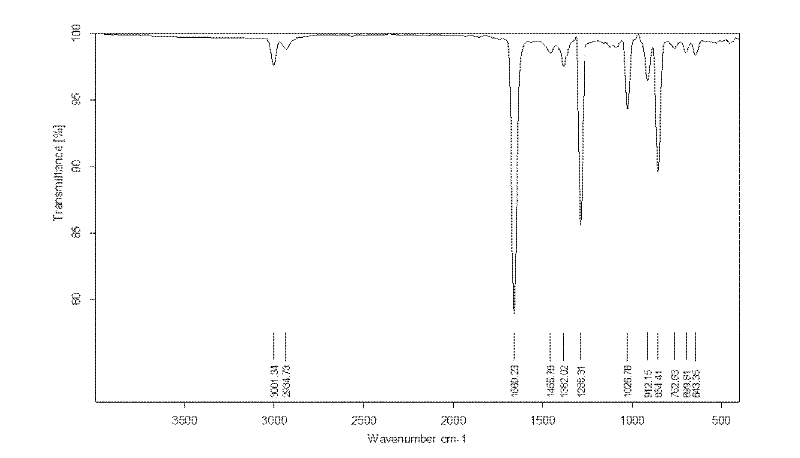

Preparation method of particle size controllable tin dioxide nano-powder

ActiveCN106865600AUniform particle size distributionSimple processTin oxidesTin dioxideCrystallinity

The invention discloses a preparation method of a particle size controllable tin dioxide nano-powder, and in particular relates to a preparation method of a high dispersibility and high crystallinity tin oxide nano-powder with a particle size of 10-18nm, i.e. ethyl nitrate assisted precipitation method. The method utilizes the auxiliary effect of ethyl nitrate formed by nitric acid and ethanol and precipitation technique to prepare tin oxide nano-powder. The tin oxide nano-powder prepared by the method has adjustable particle size, uniform particle size distribution, and good dispersion and crystallization properties, also has no need for changing the calcination temperature and heat treatment time, and has the advantages of simple process, low cost, and short preparation cycle, etc.

Owner:DALIAN JIAOTONG UNIVERSITY

Novel compression-resistant gear oil

InactiveCN103602410AReduce noiseReduce body temperatureLubricant compositionOil and greaseGear wheel

The invention discloses a novel compression-resistant gear oil, which is made by the following raw materials in parts by weight: 25-33 parts of an animal mixed grease, 8-17 parts of dicumyl peroxide, 2.3-4.1 parts of ethyl nitrate, 1.7-4.4 parts of acetone dimer acid, 3.5-6.3 parts of pentaerythritol ammonium oleate and 1.2-3.6 parts of alkyl phenol-formaldehyde resin. Compared with the existing gear oil, the excellent base oil is compounded with the novel environmental-protection gear oil additive, the special extreme pressure anti-wear agent is also used, so as to greatly improve the bearing capacity of the gear oil, more prevent the traditional lead-containing formula from affecting the health of operators and effectively prevent the surfaces of the steel and copper parts from being worn. The gear oil has proper adhesive capacity and extremely low coefficient of friction, the noise which is generated when a gear operates and the machine temperature are effectively reduced, the energy consumption is reduced, and the service life of the gear is prolonged.

Owner:QINGDAO HIBOUND CHENGYUAN PLASTIC

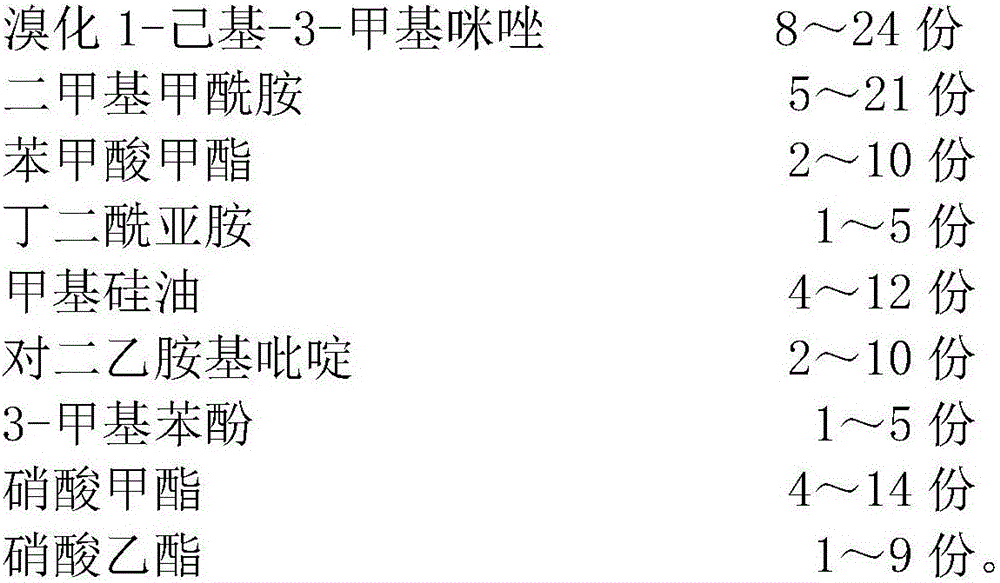

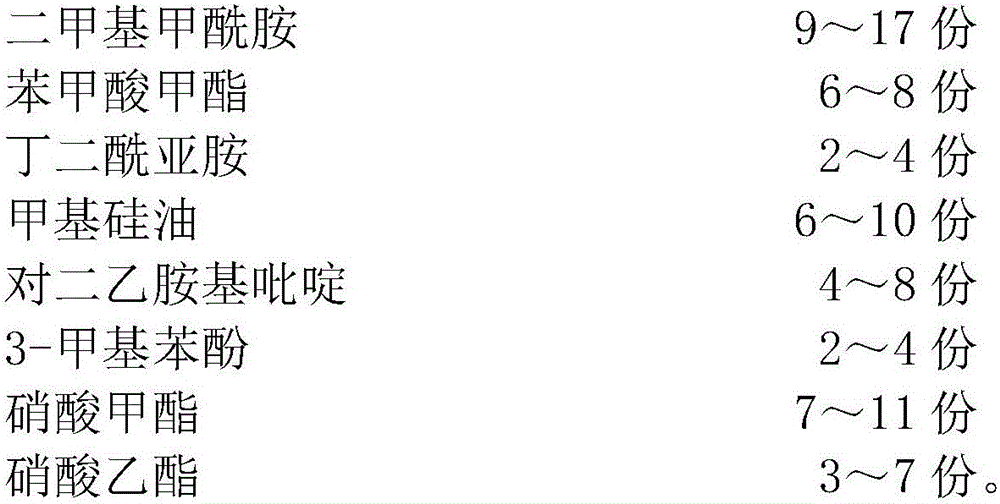

Diesel oil efficiency-increase and emission-reduction additive

InactiveCN106244265APrevent Storage StratificationImprove low temperature performanceLiquid carbonaceous fuelsFuel additivesParticulatesExhaust gas emissions

The invention relates to the technical field of fuel additives, and in particular, relates to a diesel oil efficiency-increase and emission-reduction additive prepared from the following raw materials in parts by weight: 8-24 parts of 1-hexyl-3-methylimidazolium bromide, 5-21 parts of dimethylformamide, 2-10 parts of methyl benzoate, 1-5 parts of succimide, 1-7 parts of methyl silicone oil, 2-10 parts of 2-diethylaminopyridine, 1-5 parts of 3-methylphenol, 4-14 parts of methyl nitrate, and 1-9 parts of ethyl nitrate. The diesel oil efficiency-increase and emission-reduction additive has the advantages of good cleaning purification and anti-corrosion effects, effectively saves diesel oil, reduces exhaust gas emission, and significantly reduces emissions of black smoke and particulate matters.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Method for preparing ethyl nitrate by continuously nitrifying nitric acid steam

The invention discloses a method for preparing ethyl nitrate by continuously nitrifying nitric acid steam, which belongs to the field of energetic materials. The method comprises the steps of preparing a nitrifying agent, heating the nitrifying agent to 40-60 DEG C, adding dropwise ethanol and nitric acid, and separating liquid after the addition, wherein ethyl nitrate is positioned in the lower layer; and finally washing, drying and rectifying the ethyl nitrate to obtain pure ethyl nitrate. The method changes the traditional nitrifying method for preparing the ethyl nitrate, effectively uses the steam produced by nitrifying under the protection of carbonyl groups, enables products to be moved out fast, controls the feeding speed and the product production in order, shortens the residence time of nitrate in a heating environment, slows the production of nitrous acid products, and improves the safety of production and preparation processes.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Alcohol-based fuel oil and preparation method thereof

InactiveCN103087787AEasy to prepareSolve the dosageLiquid carbonaceous fuelsResource utilizationFuel oil

Te invention relates to alcohol-based fuel oil and a preparation method thereof. The alcohol-based fuel oil comprises the following components in percentage by weight: 57.5%-67.5% of fuel oil, 10%-20% of fatty acid, 10%-20% of crude carbinol, 0.5%-1.5% of diethanol amine and 0.1%-1% of ethyl nitrate. The preparation method for the alcohol-based fuel oil comprises the following steps of: adding the 10%-20% of crude carbinol when the fuel oil, the fatty acid, the diethanol amine and the ethyl nitrate are mixed and heated up to 40 DEG C; and forming the clear fuel oil by high-speed shearing and stirring. The fuel oil is high in stability; the preparation method is simple; the fatty acid is utilized as an emulsifier, and the crude carbinol can be uses as a combustion improver and pour point reducer by virtue of the water-containing characteristics of the crude carbinol, so that the dosage of the dear additive is reduced and the production cost is reduced; moreover, the fatty acid is formed and processed by utilizing recycled cooking oil as well as waste acidifying plant oil as materials, so that the waste is recycled, and the resource utilization rate is high.

Owner:张学纯

Energy-saving emission-reducing gasoline additive and preparation method and application thereof

InactiveCN108795519ASmall air resistanceBoost octaneLiquid carbonaceous fuelsFuel additivesFuel oilSorbitan

The invention discloses an energy-saving emission-reducing gasoline additive and a preparation method and application thereof, and belongs to the technical field of fuels. The energy-saving emission-reducing gasoline additive is prepared from denatured fuel ethanol, 2-ethyl hexanol, isopropyl alcohol, methylbenzene, ethyl tert butyl ether, paraffin hydrocarbon solution, a nonionic surfactant, bis-(3-triethoxysilylpropyl)-tetrasulfide, polyoxyethylene sorbitan fatty acid ester, ethyl nitrate and isooctyl nitrate; the energy-saving emission-reducing gasoline additive is applicable to fuel oils,has low addition quantity, high combustion efficiency, low gasoline consumption and good cleaning effect, emission of pollutants is decreased, and environmental pollution is relieved.

Owner:胡张艳

Preparation method for ethyl nitrite standard gas

ActiveCN102539202BAccurate and reliable gas concentrationEasy to preparePreparing sample for investigationLiquid stateDiluent

The invention provides a preparation method for ethyl nitrite standard gas. The method comprises the following steps of: a1, pre-treating a container used in the preparation method; a2, vacuating the container and sealing; a3, absorbing liquid ethyl nitrite into a syringe, and weighing the total mass m1 of the syringe and the liquid ethyl nitrite; a4, weighing mass m2 of the syringe; and a5, introducing diluents into the container to obtain the ethyl nitrite standard gas. The ethyl nitrite standard gas prepared by the preparation method is accurate and reliable in gas concentration. Industrial ethyl nitrite standard gas can be prepared easily and quickly by the method, the standard gas is provided for detecting ethyl nitrite, and the method has industrial application significance.

Owner:JIANGSU WAN QI BIOLOGICAL TECH

Environmental protection energy-saving water-adding blended diesel oil additive

InactiveCN1169607CLong stable periodHigh water mixing rateTransportation and packagingRefining by water treatmentOil additiveAmmonium hydroxide

An environmental protection type energy-saving additive for adding water to diesel oil is prepared from anhydrosorbitol monooleate, naphthenic acid, tetrahydrofuran, fatty acid, C12, polyvinylpolyamine, ammonium hydroxide, and ethyl nitrate. It can make the percentage of water in diesel reach 15-30%.

Owner:李宇翔

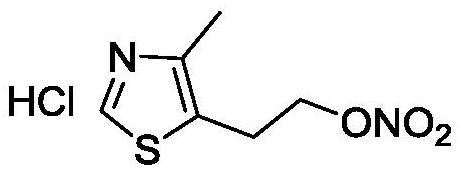

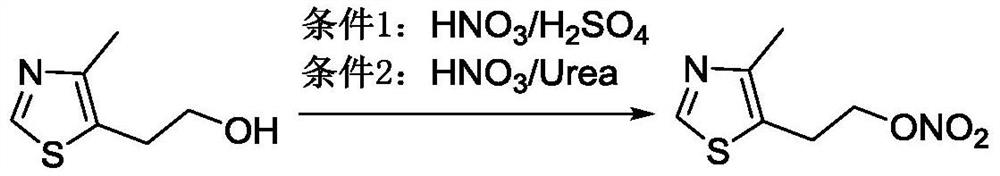

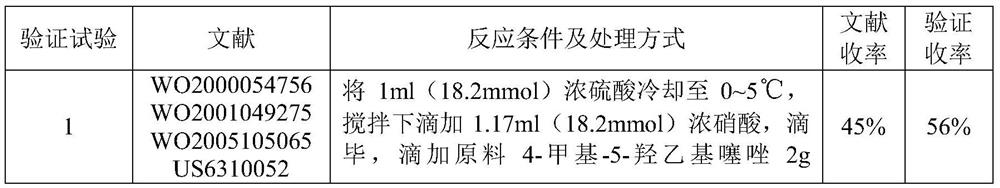

The preparation method of 2-(4-methylthiazol-5-yl) ethyl nitrate hydrochloride

The invention provides a kind of preparation method of 2-(4-methylthiazol-5-yl) ethyl nitrate hydrochloride, which is characterized in that it comprises the following steps: (1) using 4-methyl-5-(2-hydroxy Ethyl) thiazole is that starting material obtains nitrate 2-(4-methylthiazole-5-yl) ethyl ester through nitration reaction; (2) nitrate 2-(4-methylthiazole-5-yl) ethyl ester in solvent React with hydrochloric acid to make nitrate 2-(4-methylthiazole-5-yl) ethyl ester hydrochloride crude product; (3) to nitrate 2-(4-methylthiazole-5-yl) ethyl ester hydrochloride The crude product was recrystallized to obtain a qualified product. The method has the advantages of simple operation, mild reaction conditions, high yield and good product purity, and is suitable for large-scale industrial production.

Owner:INST OF MATERIA MEDICA CHINESE ACAD OF MEDICAL SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com