Low-emission vehicle fuel

A vehicle fuel and emission technology, applied in the direction of fuel, fuel additives, liquid carbon-containing fuel, etc., can solve problems such as unstable performance, affecting the service life of the combustion nozzle, and volatile, so as to reduce exhaust emissions and protect the engine Equipment, effect of preventing knocking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

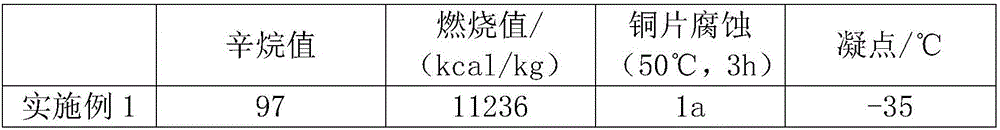

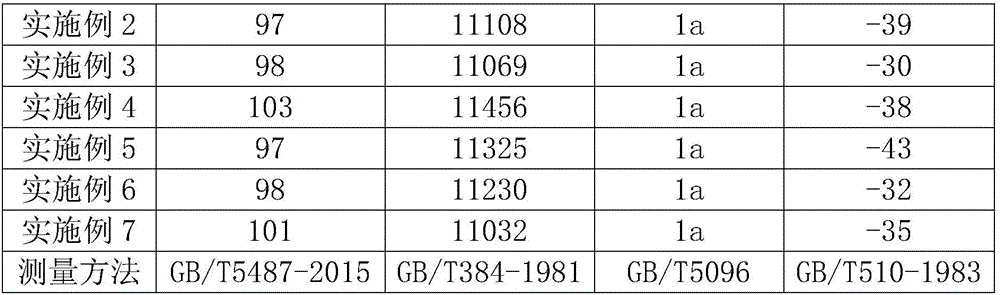

Examples

Embodiment 1

[0028] A low-emission vehicle fuel made from the following raw materials in parts by weight: 15 parts of amyl alcohol, 10 parts of isobutanol, 35 parts of n-octane, 10 parts of ethyl levulinate, and 8 parts of 1-trityl imidazole part, 1 part of detergent, 0.5 part of combustion aid; said detergent is a mixture of 30 parts by weight of 2-methylimidazole and 3 parts by weight of ethylene glycol butyl ether; said combustion aid is 28 parts by weight of dimethyl carbonate A mixture of esters and 1 part by weight of ethyl tert-butyl ether.

[0029] The preparation method of the above-mentioned low-emission vehicle fuel is: mix amyl alcohol, isobutanol, n-octane, ethyl levulinate and 1-trityl imidazole, stir for 55 minutes, and then add detergent and combustion aid, continue to stir for 30 minutes, vacuumize, and let it stand for 15 hours.

Embodiment 2

[0031] The low-emission vehicle fuel is made of the following raw materials in parts by weight: 20 parts of methanol, 10 parts of amyl alcohol, 32 parts of n-octane, 12 parts of ethyl levulinate, 7 parts of 1-trityl imidazole, 1.2 parts of cleaning agent, 0.8 part of combustion aid; Described detergent is the mixture of 28 parts by weight 2-methylimidazole and 4 parts by weight of ethylene glycol butyl ether; Described combustion aid is 25 parts by weight of dimethyl carbonate and A mixture of 2 parts by weight of ethyl tert-butyl ether.

[0032] The preparation method of the above-mentioned low-emission vehicle fuel is as follows: methanol, amyl alcohol, n-octane, ethyl levulinate and 1-trityl imidazole are mixed uniformly, stirred for 50 minutes, and then adding detergent and combustion-supporting agent, continue to stir for 35 minutes, vacuumize, and let it stand for 17 hours.

Embodiment 3

[0034] A low-emission vehicle fuel made of the following raw materials in parts by weight: 35 parts of amyl alcohol, 30 parts of n-octane, 14 parts of ethyl levulinate, 6 parts of 1-trityl imidazole, and 1.7 parts of detergent , 1.1 parts of a combustion aid; the detergent is a mixture of 25 parts by weight of 2-methylimidazole and 5 parts by weight of ethylene glycol butyl ether; the combustion aid is 22 parts by weight of dimethyl carbonate and 3 parts by weight of ethylene glycol A mixture of tert-butyl ethers.

[0035] The preparation method of the above-mentioned low-emission vehicle fuel is: mixing amyl alcohol, n-octane, ethyl levulinate and 1-trityl imidazole, stirring for 45min, and then adding detergent and combustion improver, Continue to stir for 40 minutes, vacuumize, and let it stand for 15 to 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com