Device and method for coproduction of 1,3-butadiene and ethyl tert butyl ether from methanol to olefin (DMTO) byproduct coal-based mixing C4

A technology of ethyl tert-butyl ether and mixed carbon four, which is applied in chemical instruments and methods, preparation of ether by addition of unsaturated compounds, preparation of ether, etc., can solve the problem of low utilization rate and achieve the effect of improving comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

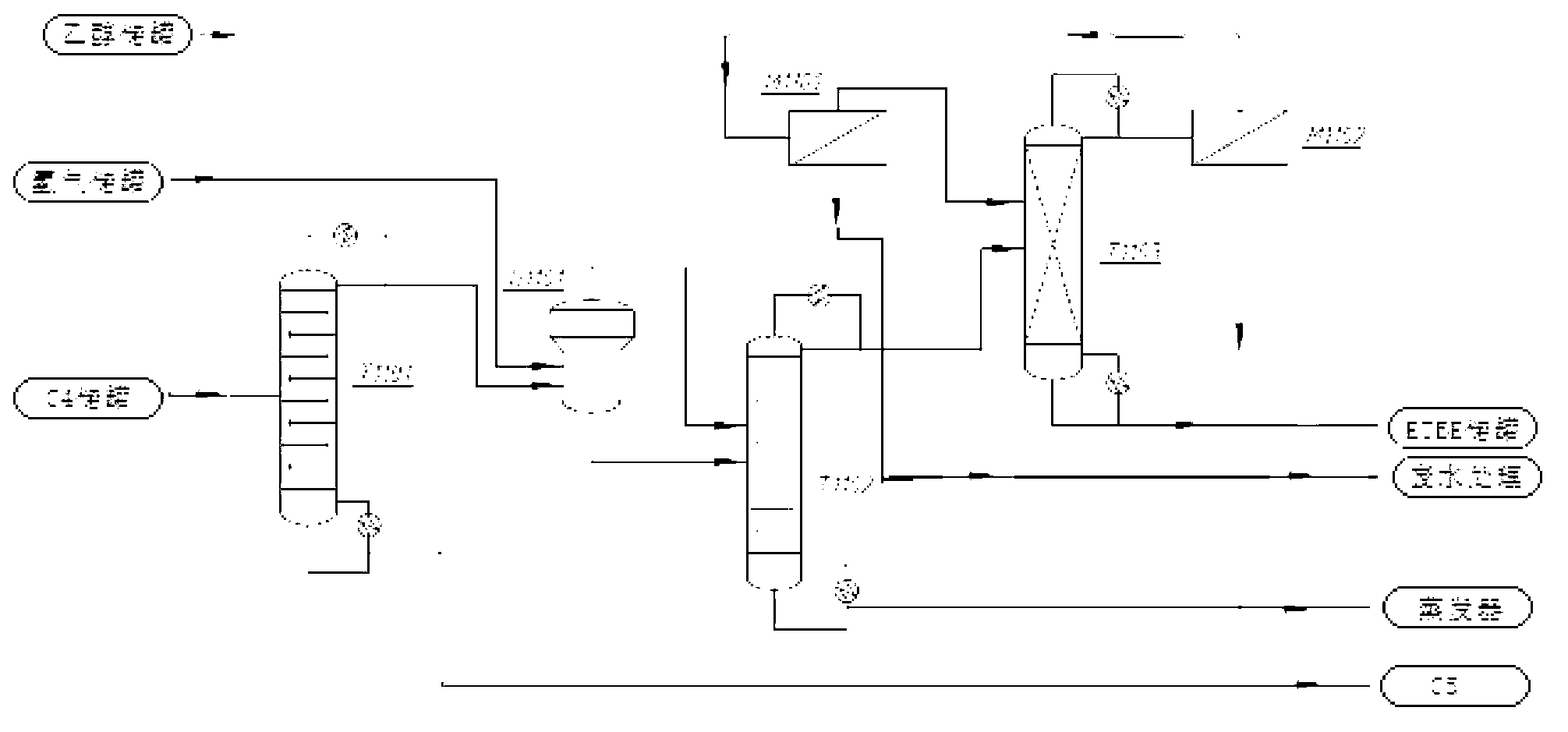

[0051] With reference to the accompanying drawings, a method for co-producing 1,3-butadiene and ethyl tert-butyl ether with DMTO by-product coal-based mixed C4 as raw material provided by the present invention comprises the following three sections in turn: 1. Coal 2. Butene oxidative dehydrogenation section; 3. Butadiene refining section.

[0052] 1. Coal-based mixed carbon four pretreatment and etherification section includes coal-based mixed carbon four pretreatment steps and etherification steps; coal-based mixed carbon four pretreatment steps include:

[0053] (1) To remove carbon five components, pump the carbon four in the coal-based mixed carbon four storage tank into the five decarbonization tower. The operating pressure of the tower is 4atm, the temperature at the top of the tower is maintained at 41.8°C, and the temperature at the bottom of the tower is 84.6°C;

[0054] (2) Hydroisomerization reaction, enter the hydroisomerization reactor from the output of step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com