Synthetic method and device of ethyl tert butyl ether

A technology of ethyl tertiary butyl ether and a synthesis method, which is applied in the directions of ether preparation, dehydration of hydroxyl-containing compounds to prepare ether, and addition of unsaturated compounds to prepare ether, etc., to achieve the effects of enhanced adaptability, increased conversion rate and convenient source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

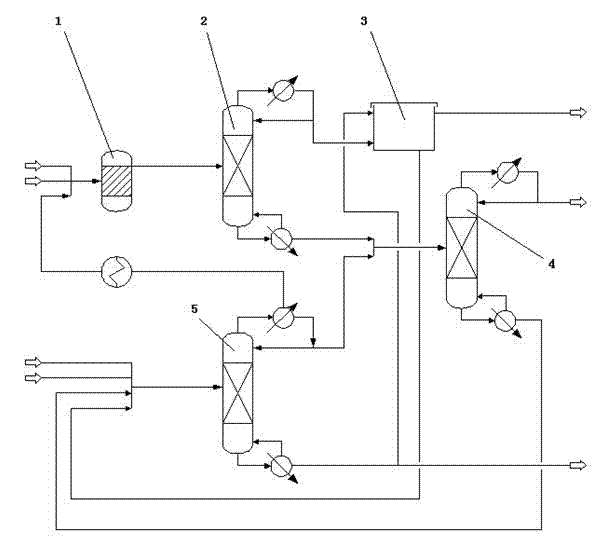

[0023] Such as figure 1 Shown, a kind of synthesis equipment of ethyl tert-butyl ether comprises the first reaction system, the second reaction system, the washing tower and the separation system; the first reaction system comprises the reactor 1 and the first reactive distillation column 2, and the raw material The feed line is connected to the feed port of reactor 1, the outlet of reactor 1 is connected to the feed port of the first reactive distillation tower 2, and the top outlet of the first reactive distillation tower 2 is connected to the lower feed port of the water washing tower 3 , the outlet at the bottom of the tower is connected with the vacuum rectification tower 4 feed ports of the separation system; the second reaction system includes the second reactive distillation tower 5, and the raw material feed line is connected with the second reactive distillation tower 5 feed ports , the second reactive distillation tower 5 feed inlets are also connected to the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com