Methanol fuel

A methanol fuel and methanol technology, which is applied to fuels, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of poor swelling, high manufacturing cost, poor mutual solubility, etc., and achieve good anti-knock, good frost resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

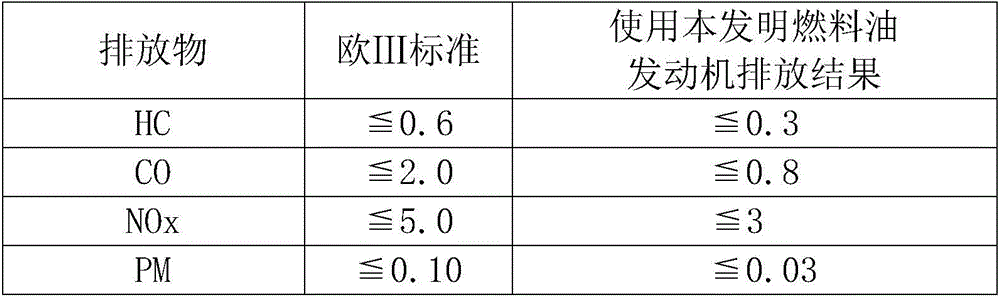

Image

Examples

Embodiment 1

[0021] A methanol fuel, made from the following raw materials in parts by weight (under normal temperature, just mix uniformly): 80 parts of methanol, 30 parts of gasoline, 1 part of 2-methylimidazole, 0.6 part of ethyl tert-butyl ether, 12 parts 0.02 part of alkylbenzenesulfonic acid, 0.2 part of n-decyl alcohol, 0.02 part of hydroxyethylidene diphosphonic acid, 0.9 part of tributyl phosphate, and 0.2 part of antiknock agent.

[0022] The above-mentioned antiknock agent is a mixture of 6 parts of o-acetamido-p-cresol, 12 parts of o-propylphenol and 5 parts of diisobutylamine.

Embodiment 2

[0024] A methanol fuel, made from the following raw materials in parts by weight (under normal temperature, just mix uniformly): 85 parts of methanol, 25 parts of gasoline, 2 parts of 2-methylimidazole, 0.5 part of ethyl tert-butyl ether, 12 parts 0.04 part of alkylbenzenesulfonic acid, 0.9 part of n-decyl alcohol, 0.03 part of hydroxyethylidene diphosphonic acid, 0.8 part of tributyl phosphate, and 0.5 part of antiknock agent.

[0025] The above-mentioned antiknock agent is a mixture of 8 parts of o-acetamido-p-cresol, 10 parts of o-propylphenol and 2 parts of diisobutylamine.

Embodiment 3

[0027] A methanol fuel, made from the following raw materials in parts by weight (at normal temperature, just mix uniformly): 90 parts of methanol, 20 parts of gasoline, 3 parts of 2-methylimidazole, 0.4 part of ethyl tert-butyl ether, 12 parts 0.05 part of alkylbenzenesulfonic acid, 0.7 part of n-decyl alcohol, 0.05 part of hydroxyethylidene diphosphonic acid, 0.6 part of tributyl phosphate, and 0.7 part of antiknock agent.

[0028] The above-mentioned antiknock agent is a mixture of 11 parts of o-acetamido-p-cresol, 8 parts of o-propylphenol and 3 parts of diisobutylamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com