Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Coir fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent material including coir fibres and/or coir dust

PCT No. PCT / AU97 / 00535 Sec. 371 Date May 24, 1999 Sec. 102(e) Date May 24, 1999 PCT Filed Aug. 21, 1997 PCT Pub. No. WO98 / 07804 PCT Pub. Date Feb. 26, 1998A fire retardant absorbent material including coir fibres and / or coir dust, an effective quantity of a fire retardant material in the form of small particles, the particle size of the fire retardant material being of the order of less than 1 micron to ensure that the fire retardant material substantially penetrates or substantially coats at least a substantial proportion of the coir fibres present in the absorbent material.

Owner:WOOLCOTT TRADING +1

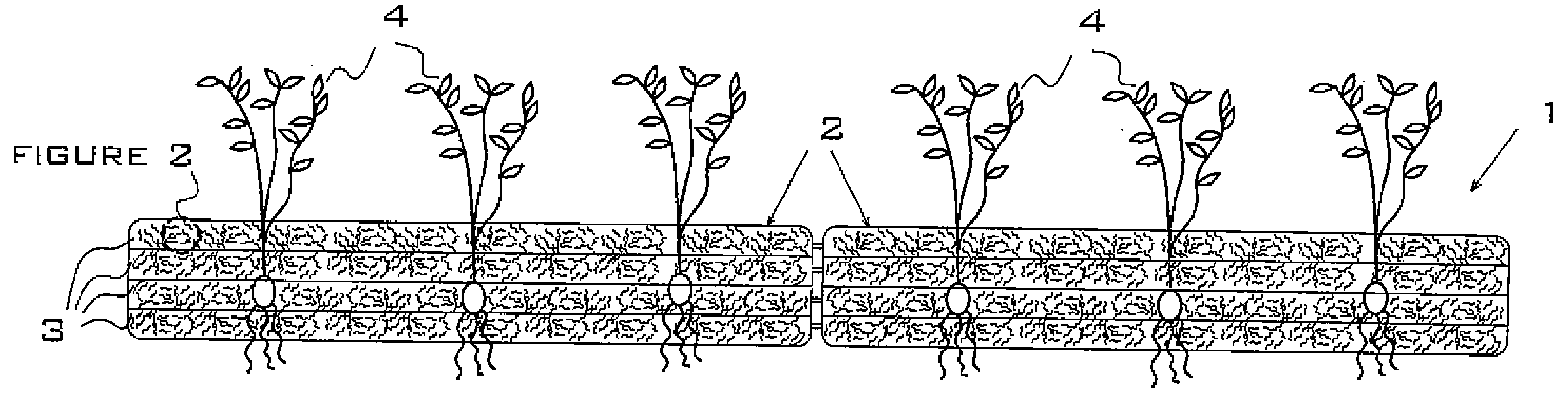

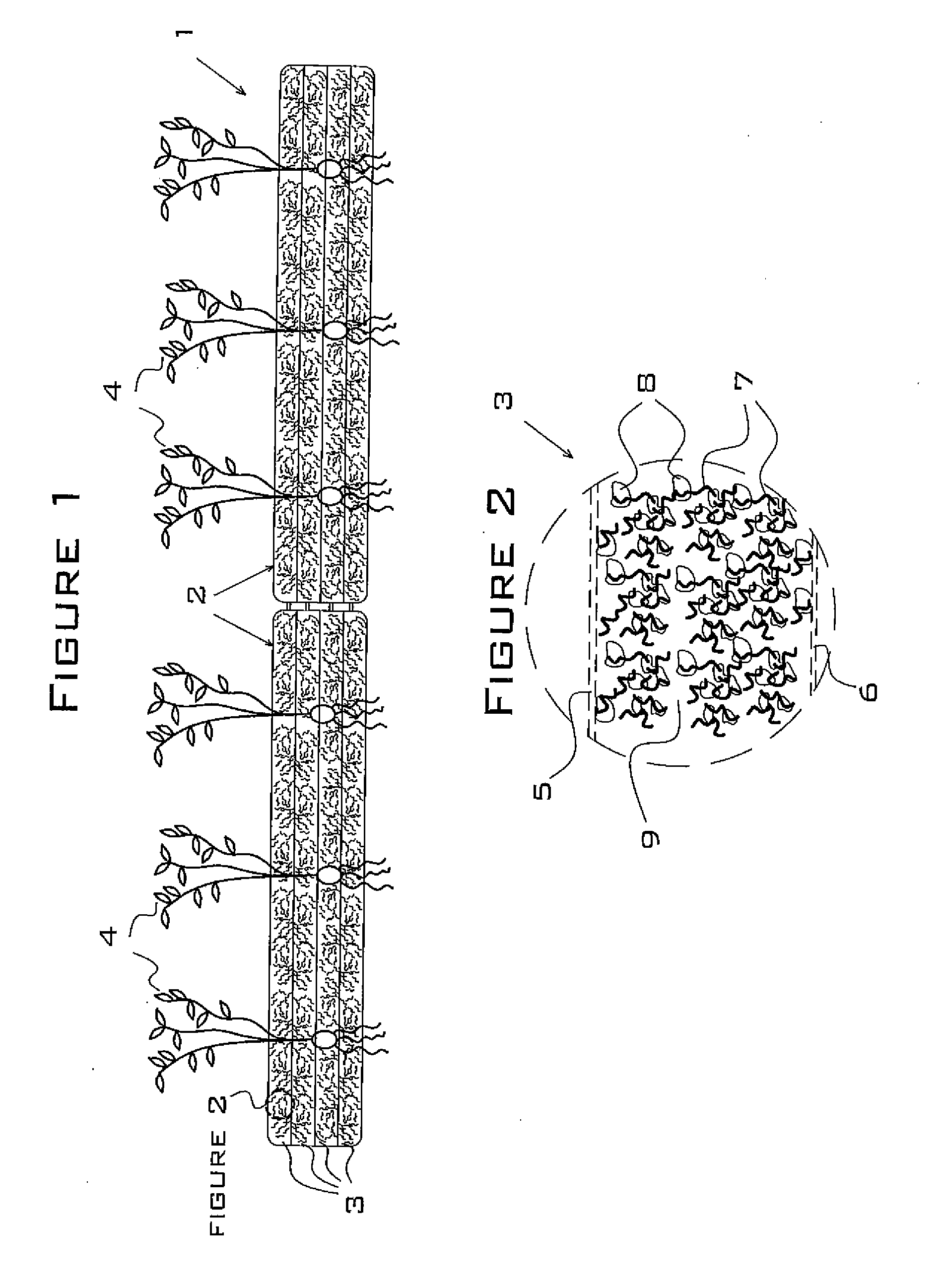

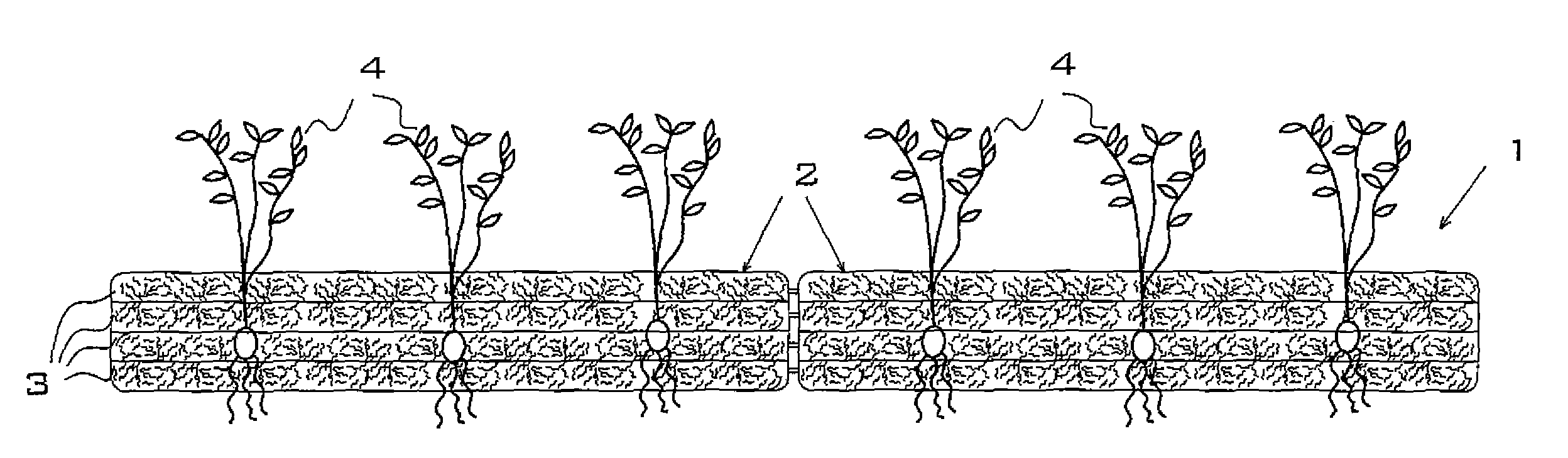

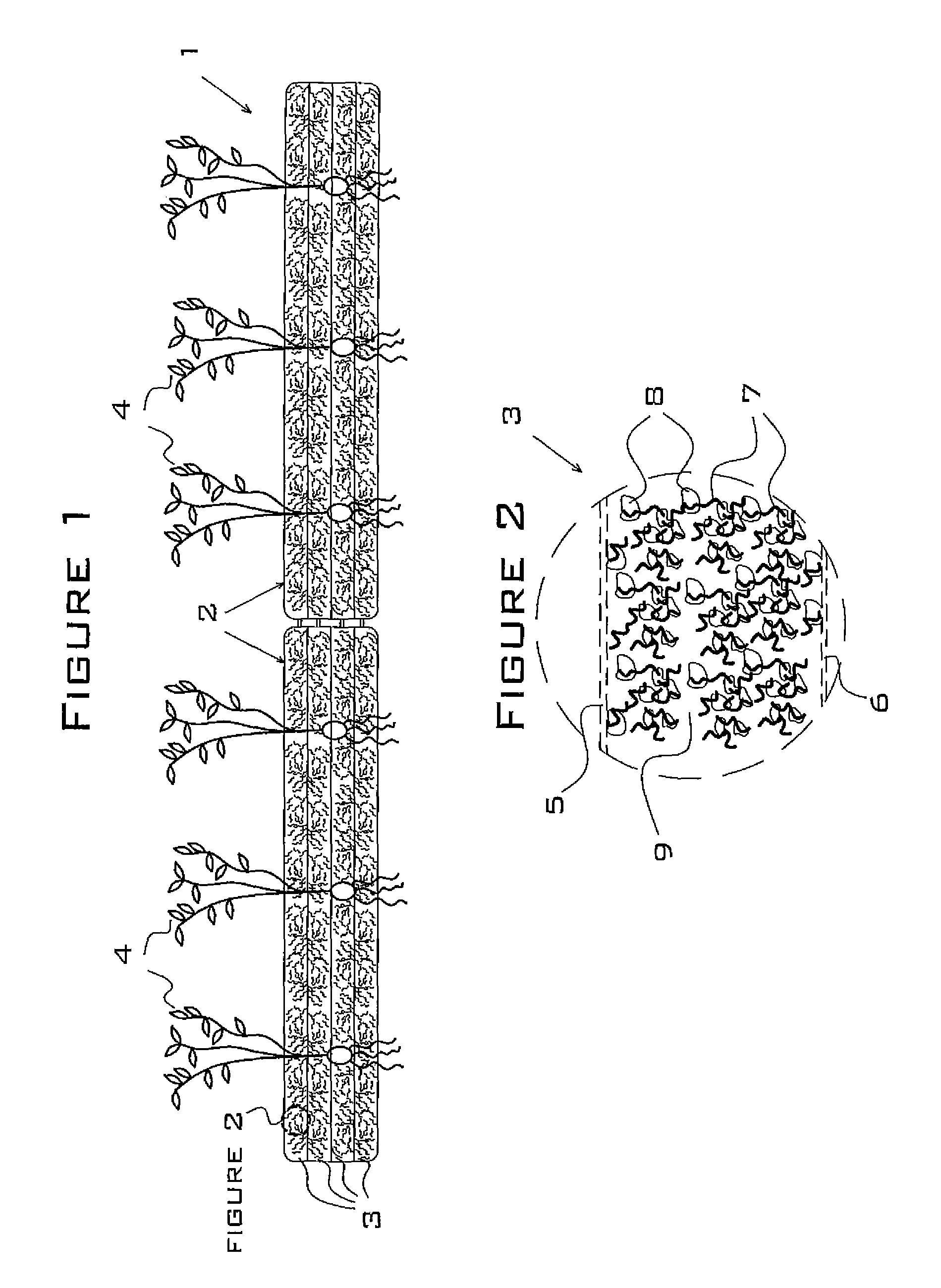

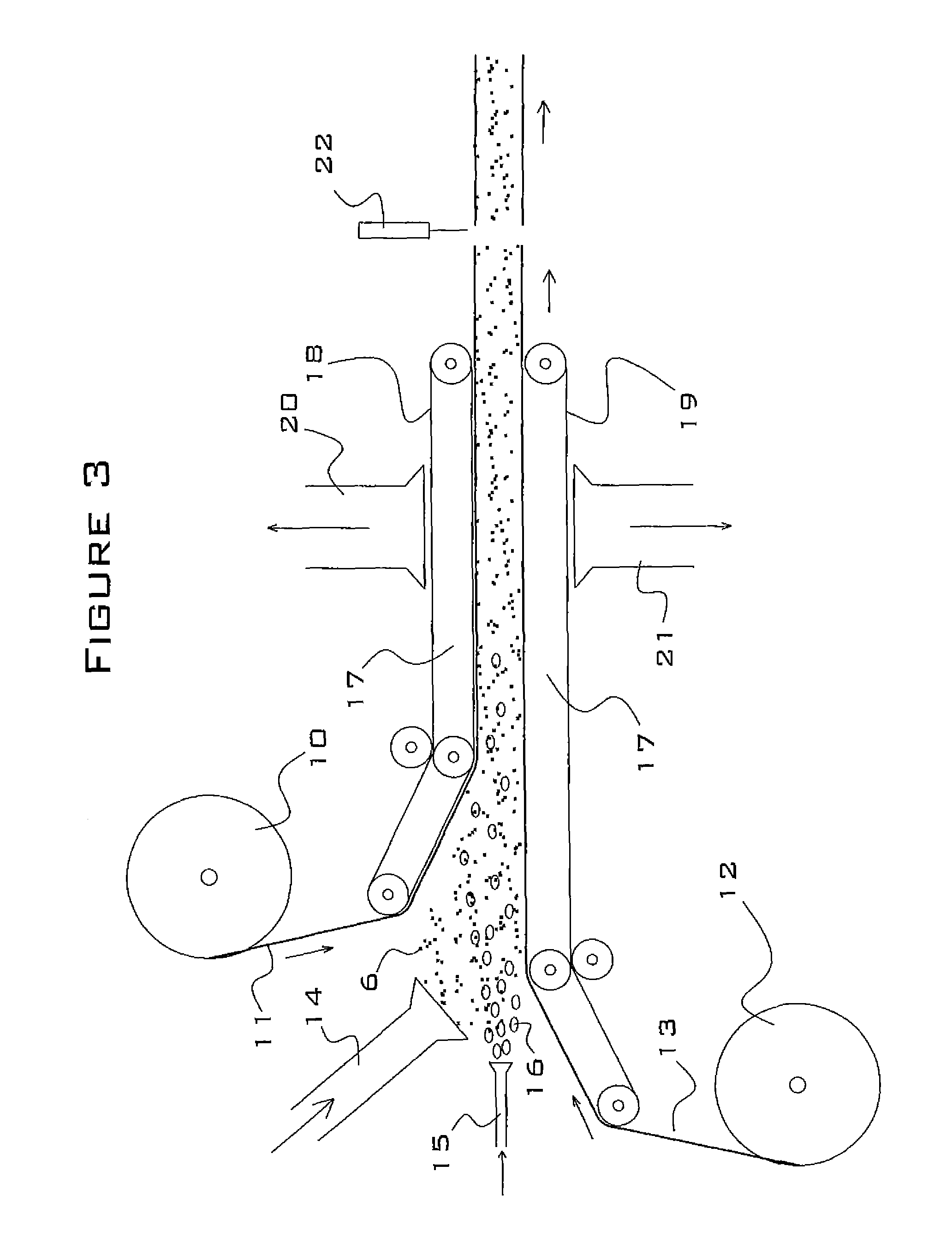

Floating island module comprised of post-consumer carpet fiber matrix and method of manufacturing same

A floating island comprising one or more modules each comprised of one or more layers of permeable and porous matrix comprised of post-consumer carpet fibers and a top covering and a bottom covering around each layer. Alternate embodiments include layers comprised of polyethylene terephthalate bottle-fiber matrix and / or jute or coir fibers. A method of manufacturing the floating island module described above.

Owner:FOUNTAINHEAD

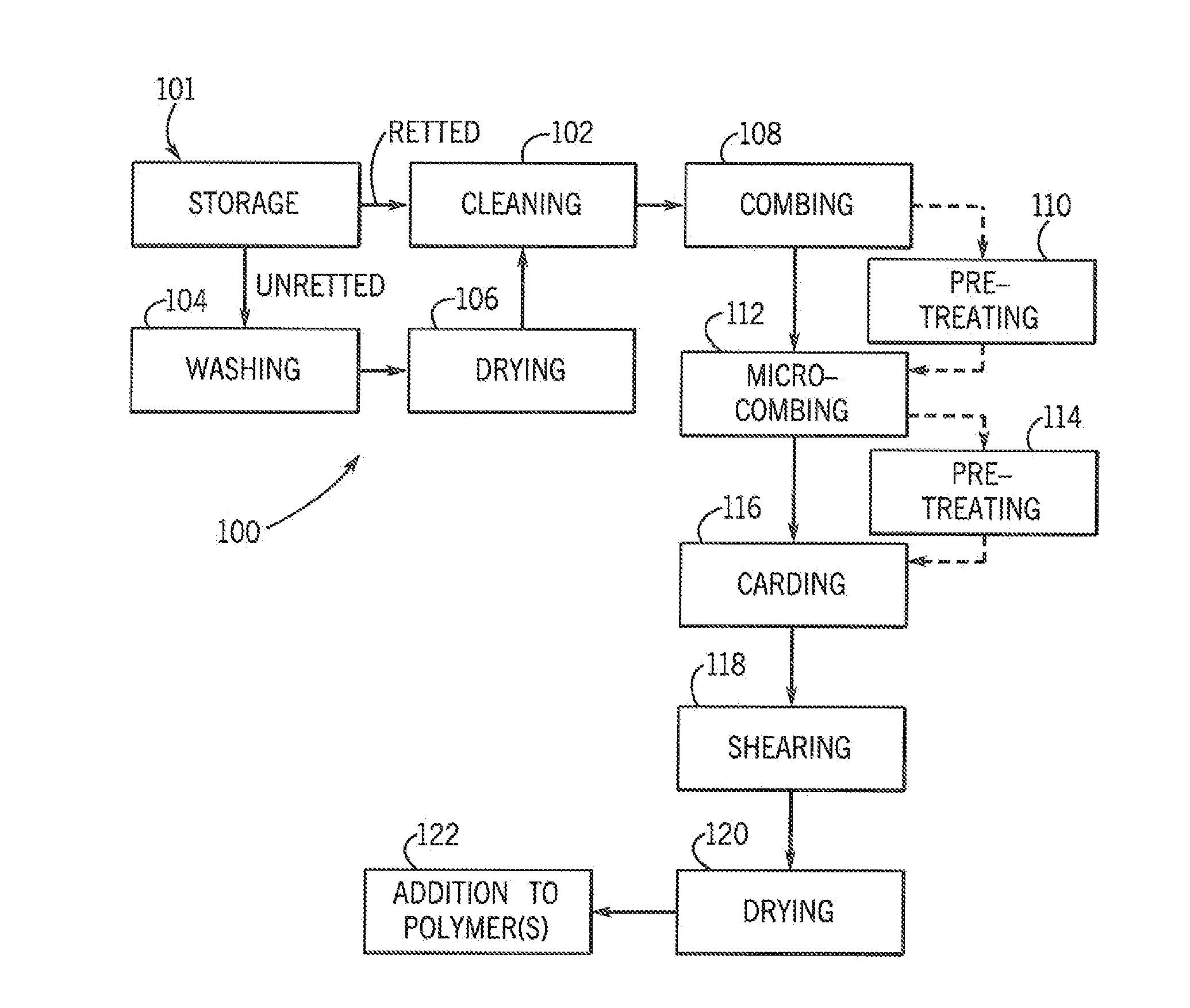

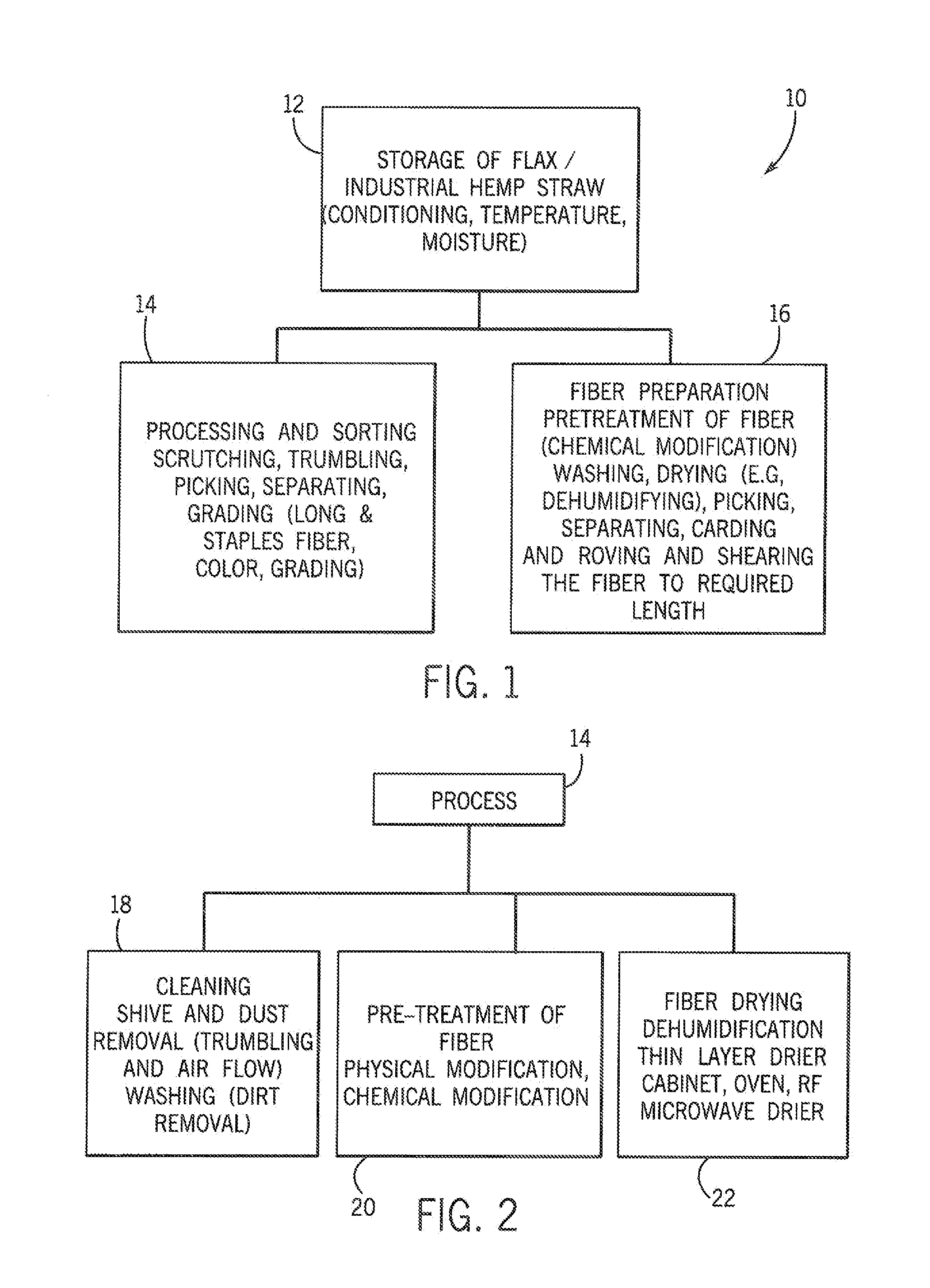

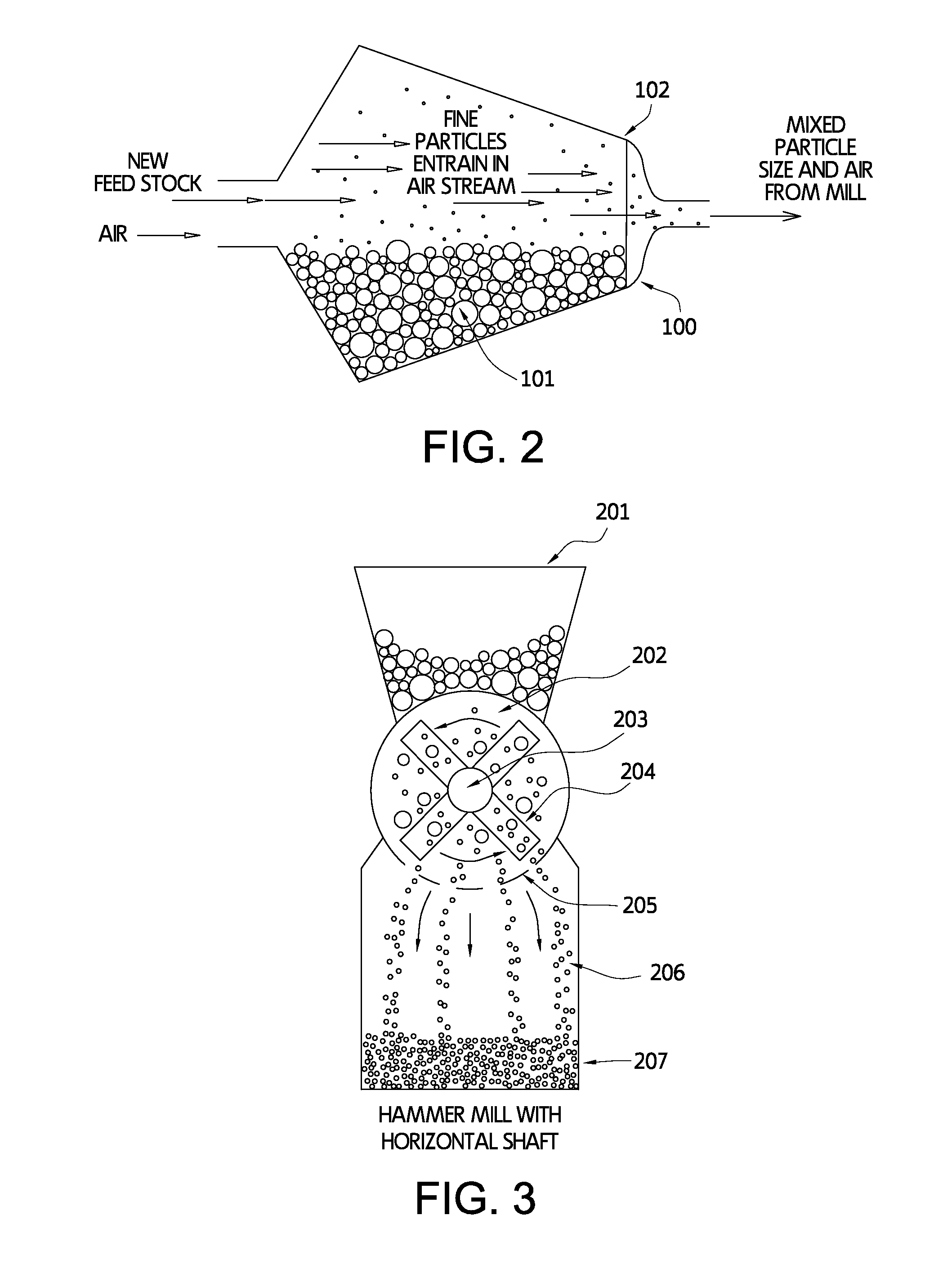

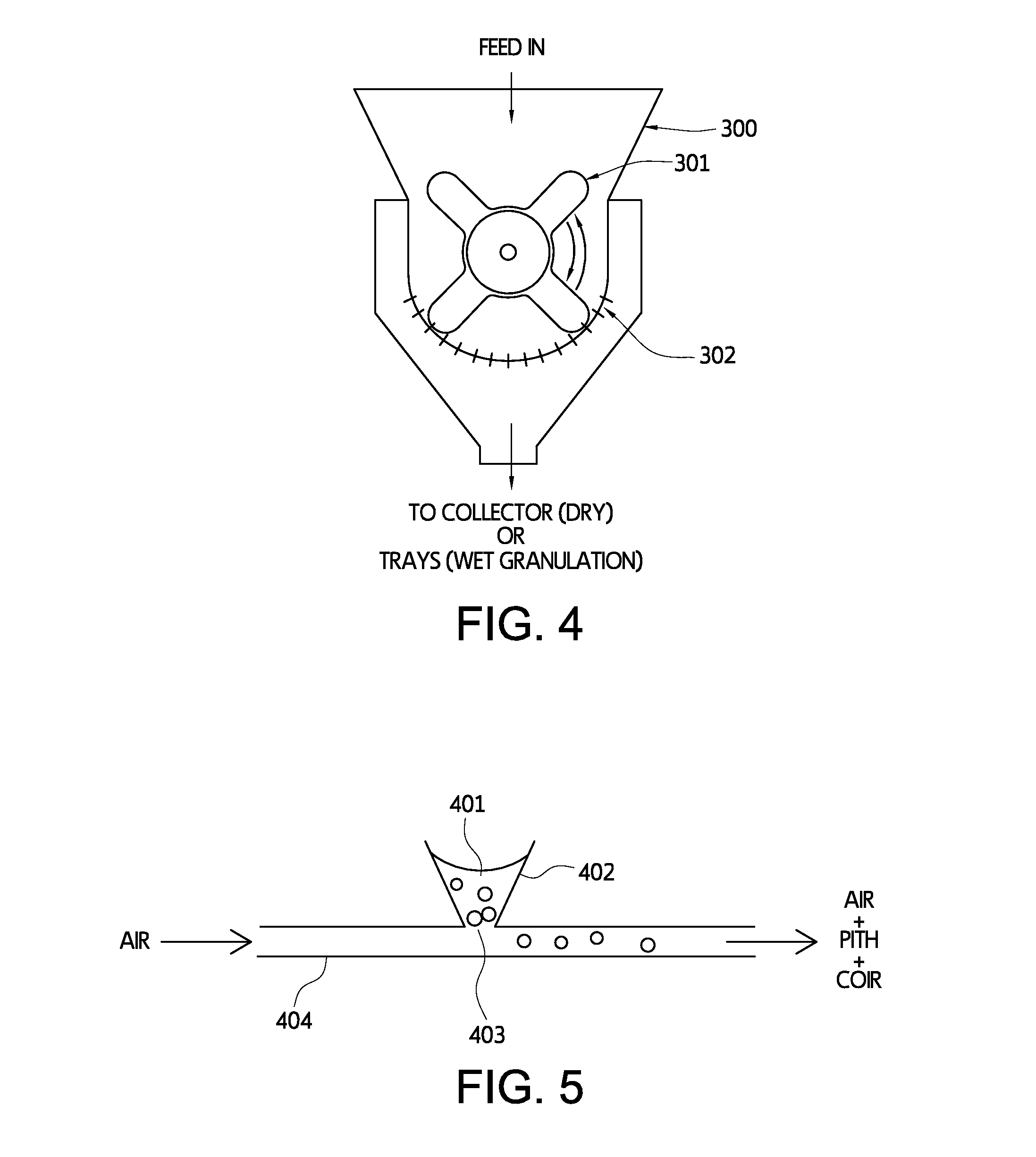

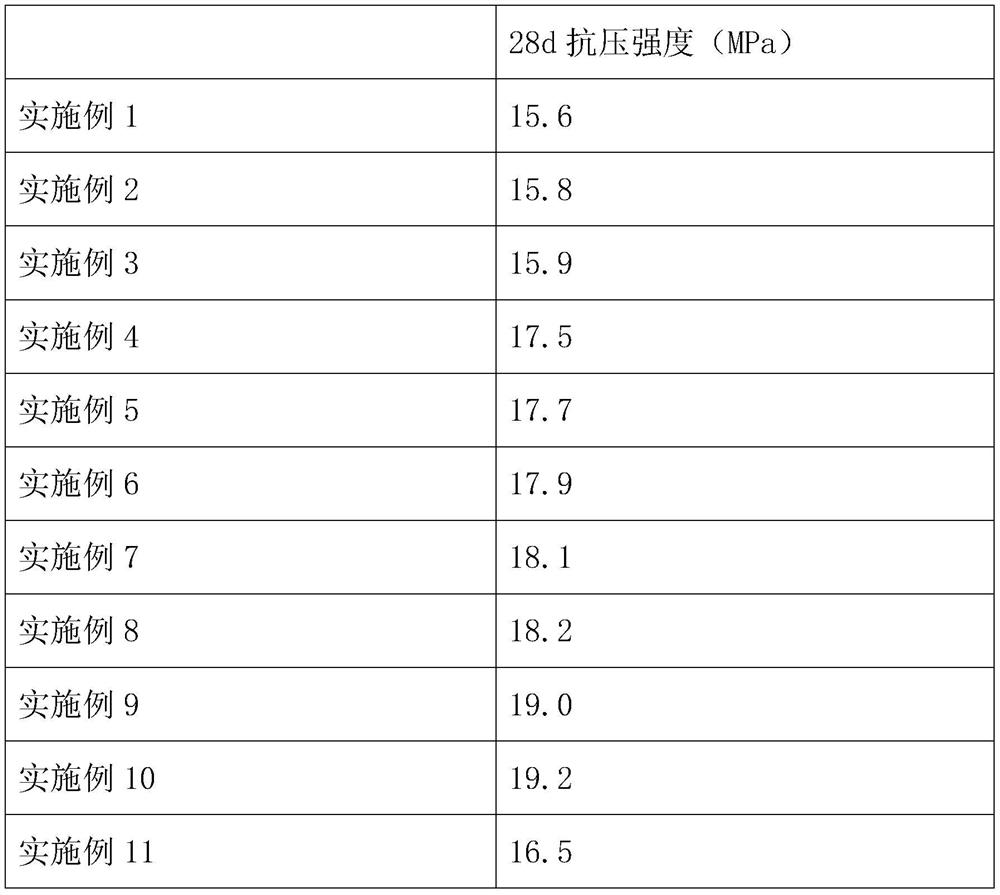

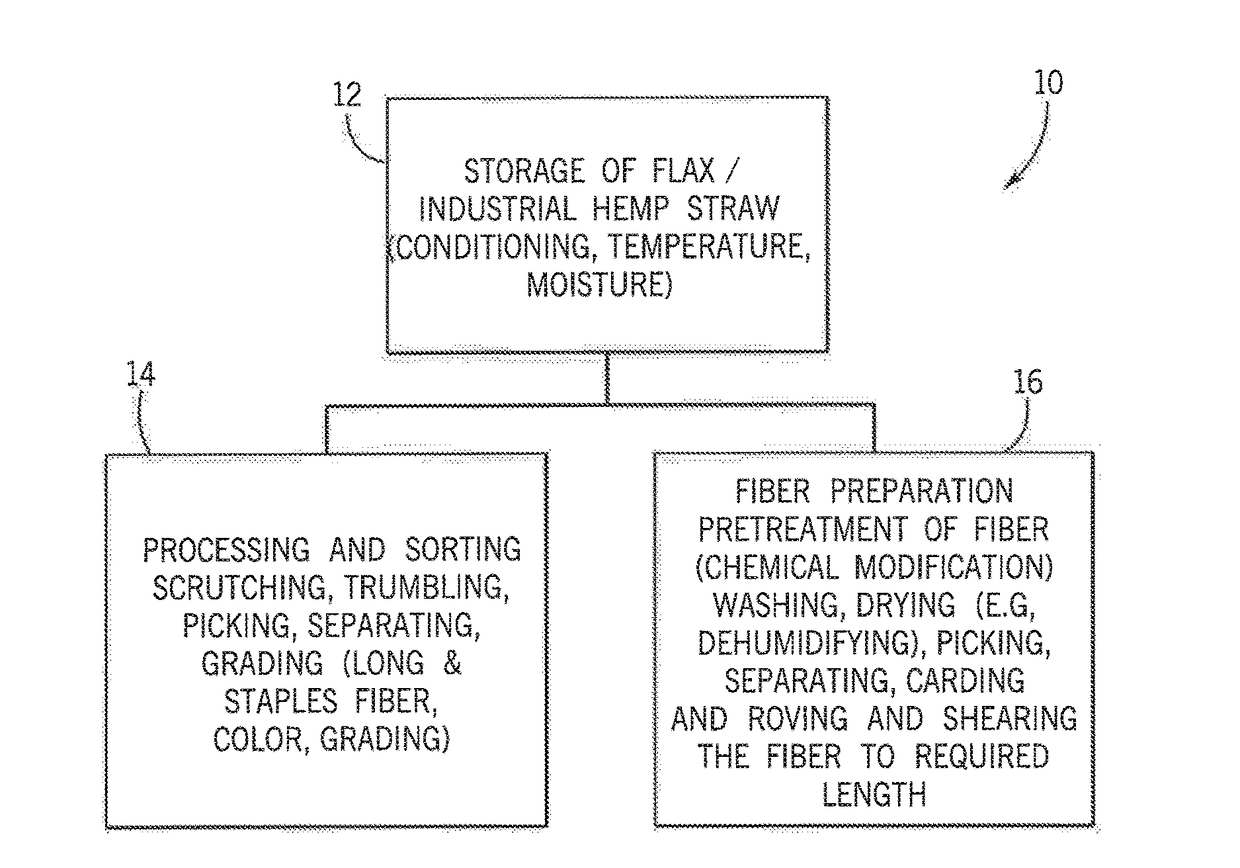

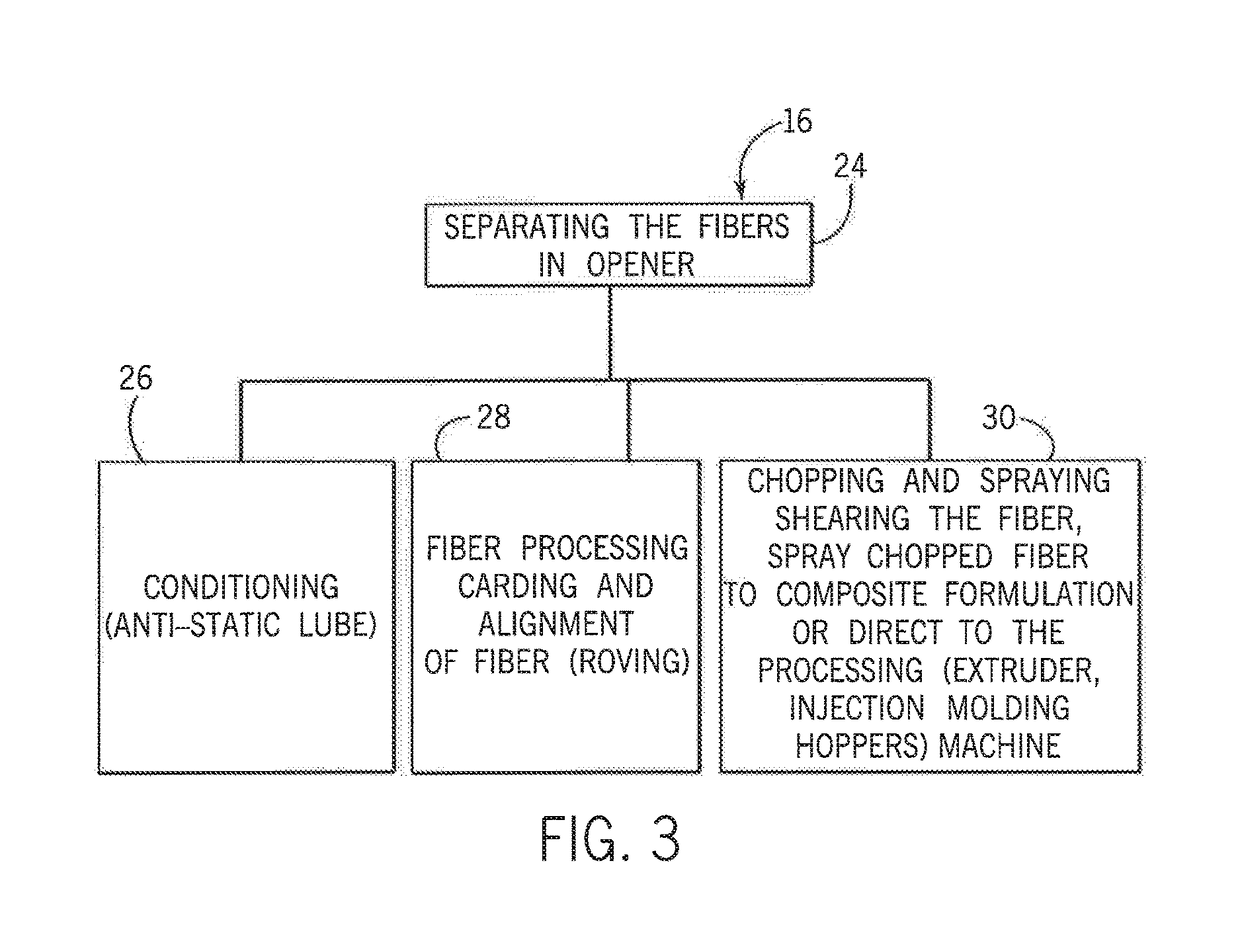

Method To Process Oilseed Flax Fiber For Use In Biocomposite Materials

ActiveUS20150166745A1Retention strengthOptimizationMechanical impurity removalFibre cleaning/opening by air draught arrangementsFlax fiberSISAL

A method and system for the production of fibers for use in biocomposites is provided that includes the ability to use both retted and unretted straw, that keeps the molecular structure of the fibers intact by subjecting the fibers to minimal stress, that maximizes the fiber's aspect ratio, that maximizes the strength of the fibers, and that minimizes time and energy inputs, along with maintaining the fibers in good condition for bonding to the polymer(s) used with the fibers to form the biocomposite material. This consequently increases the functionality of the biocomposites produced (i.e. reinforcement, sound absorption, light weight, heat capacity, etc.), increasing their marketability. Additionally, as the disclosed method does not damage the fibers, oilseed flax straw, as well as all types of fibrous materials (i.e. fiber flax, banana, jute, industrial hemp, sisal, coir) etc., can be processed in bio composite materials.

Owner:CNH IND CANADA

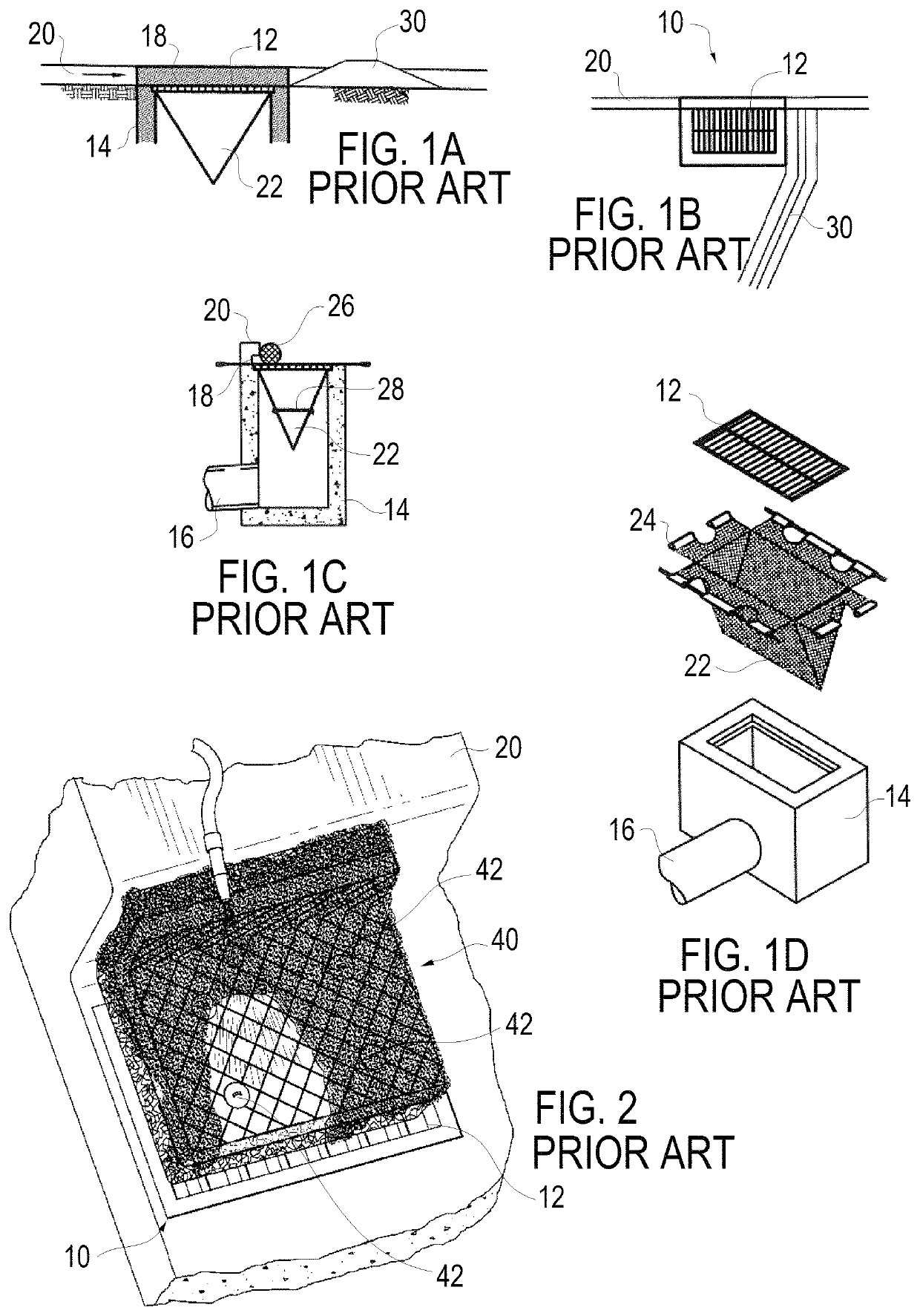

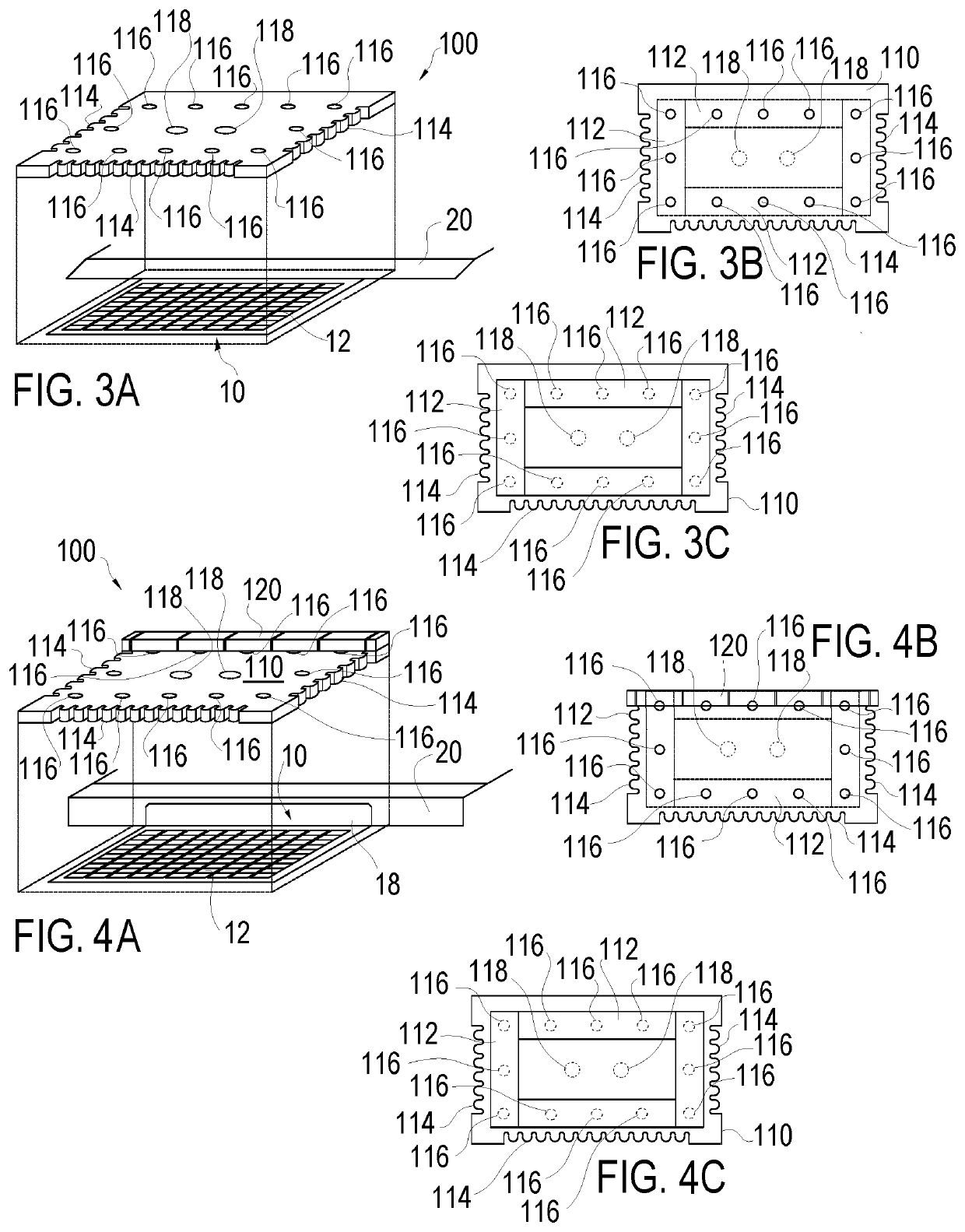

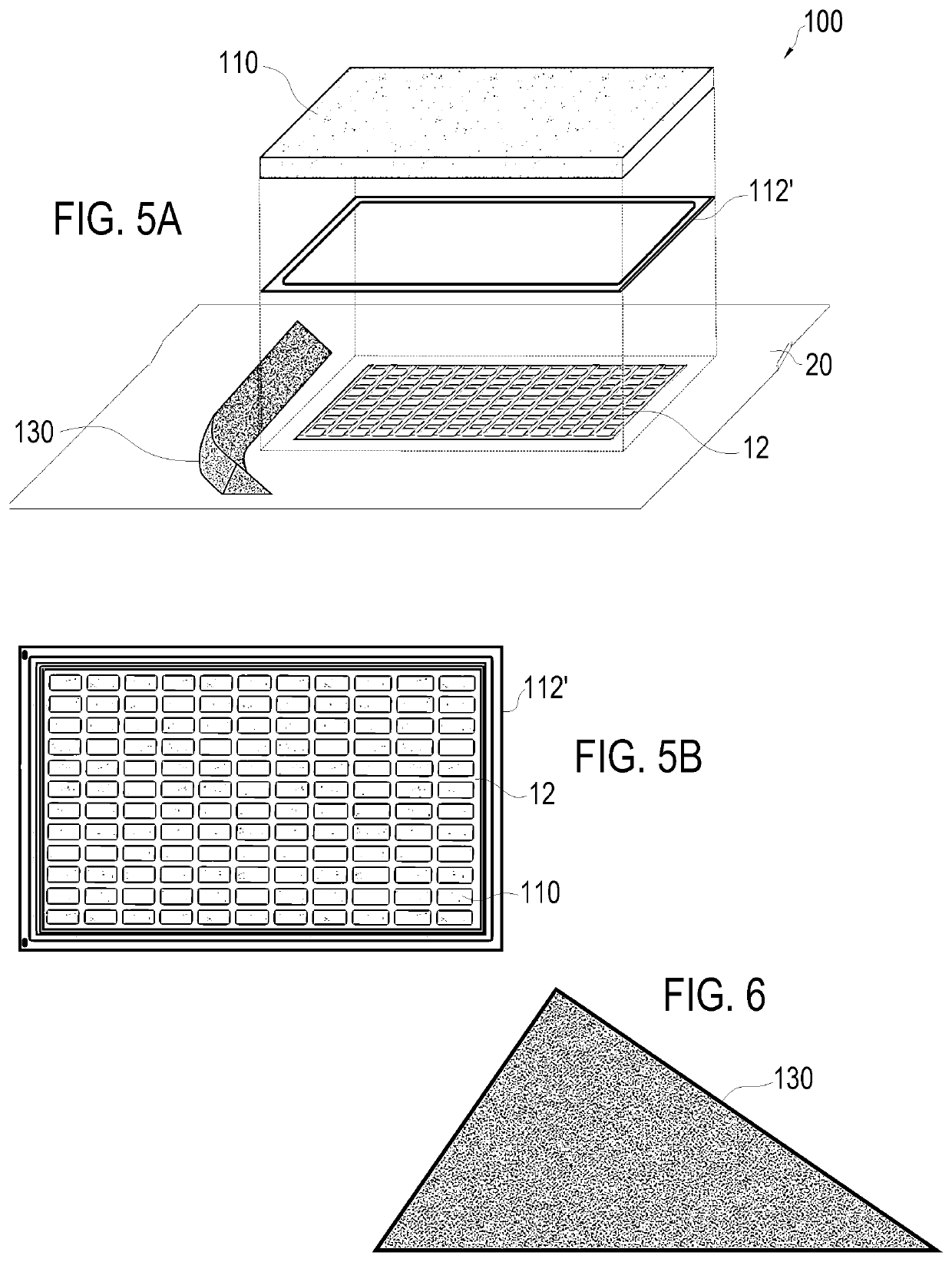

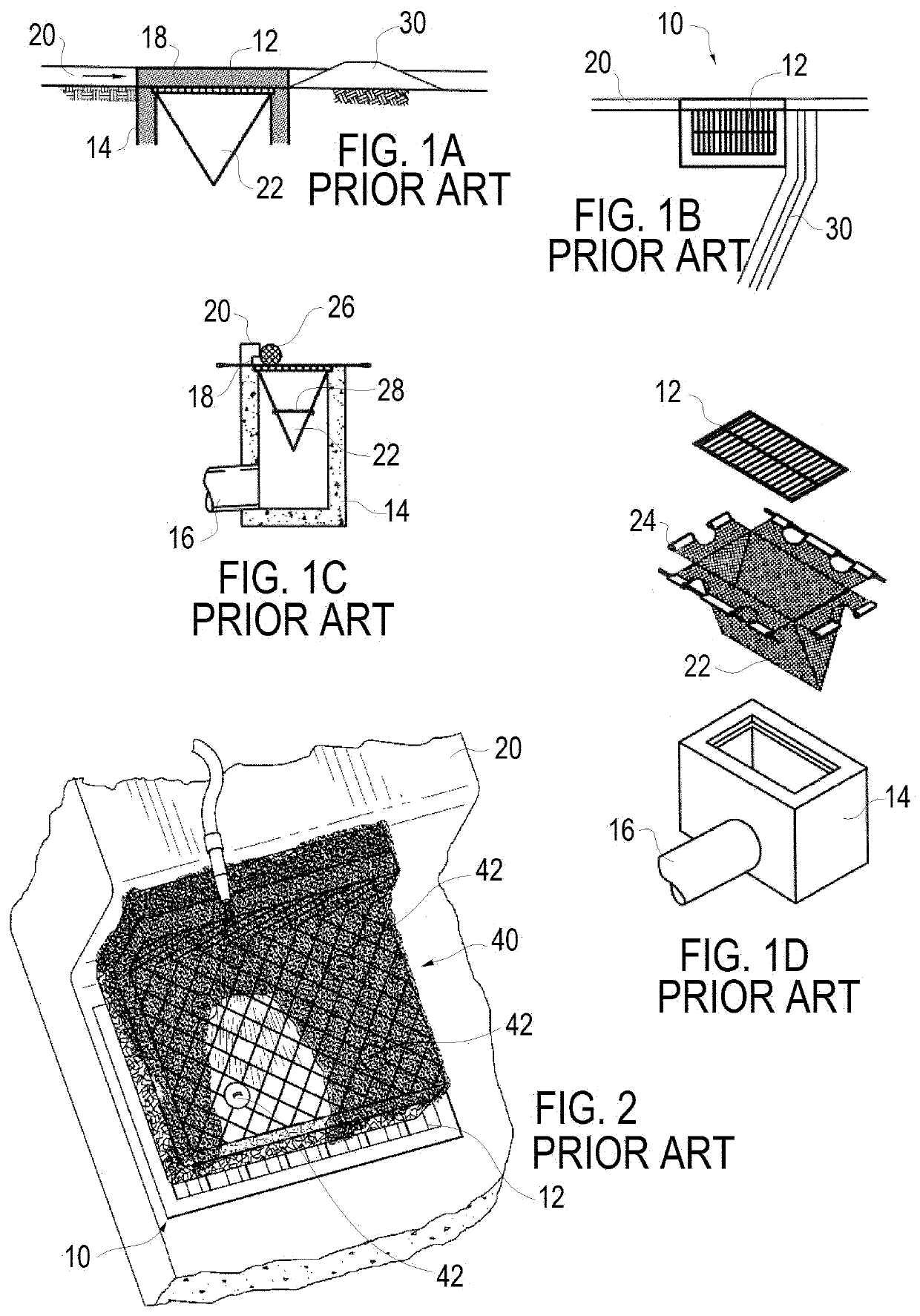

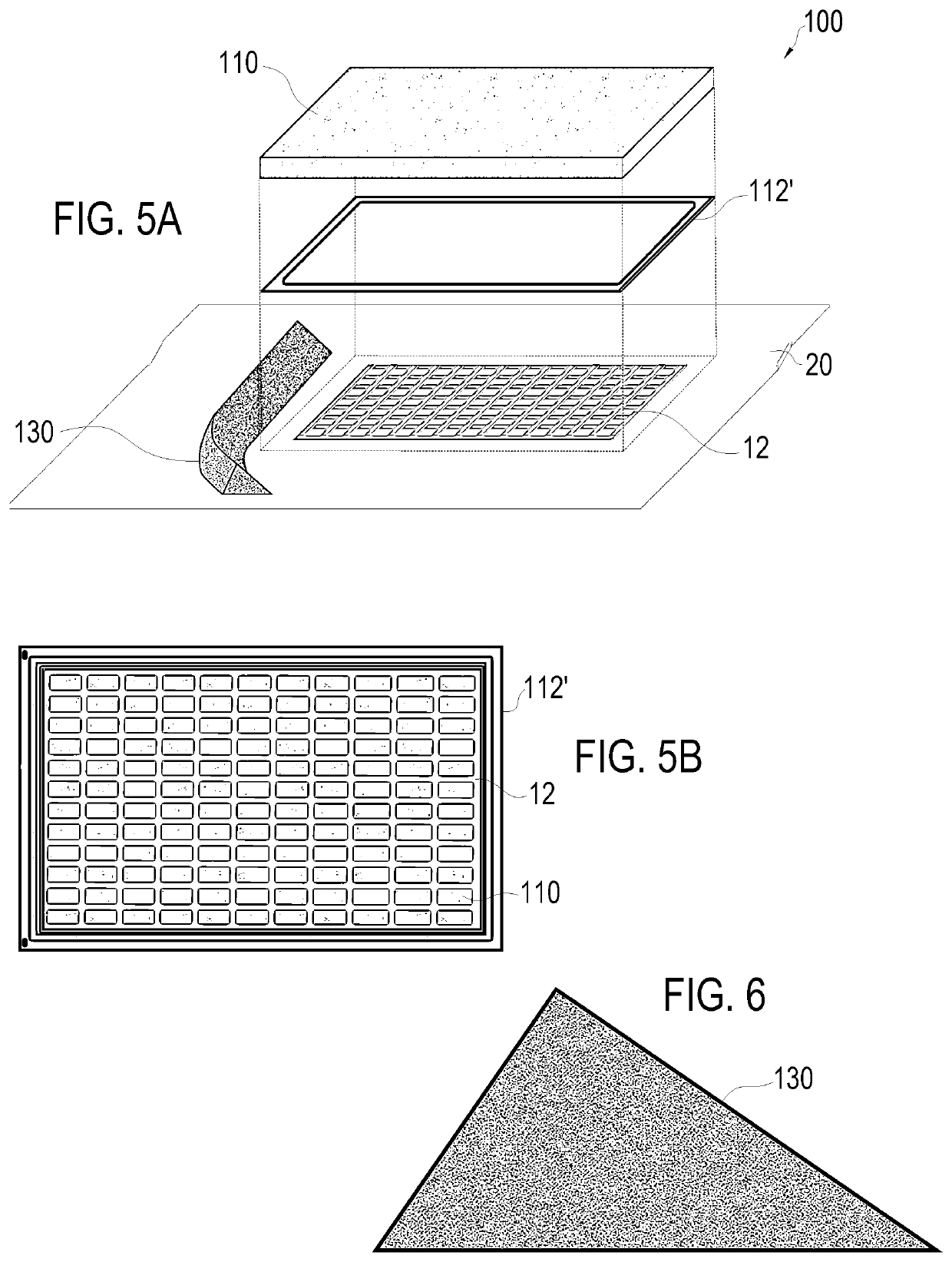

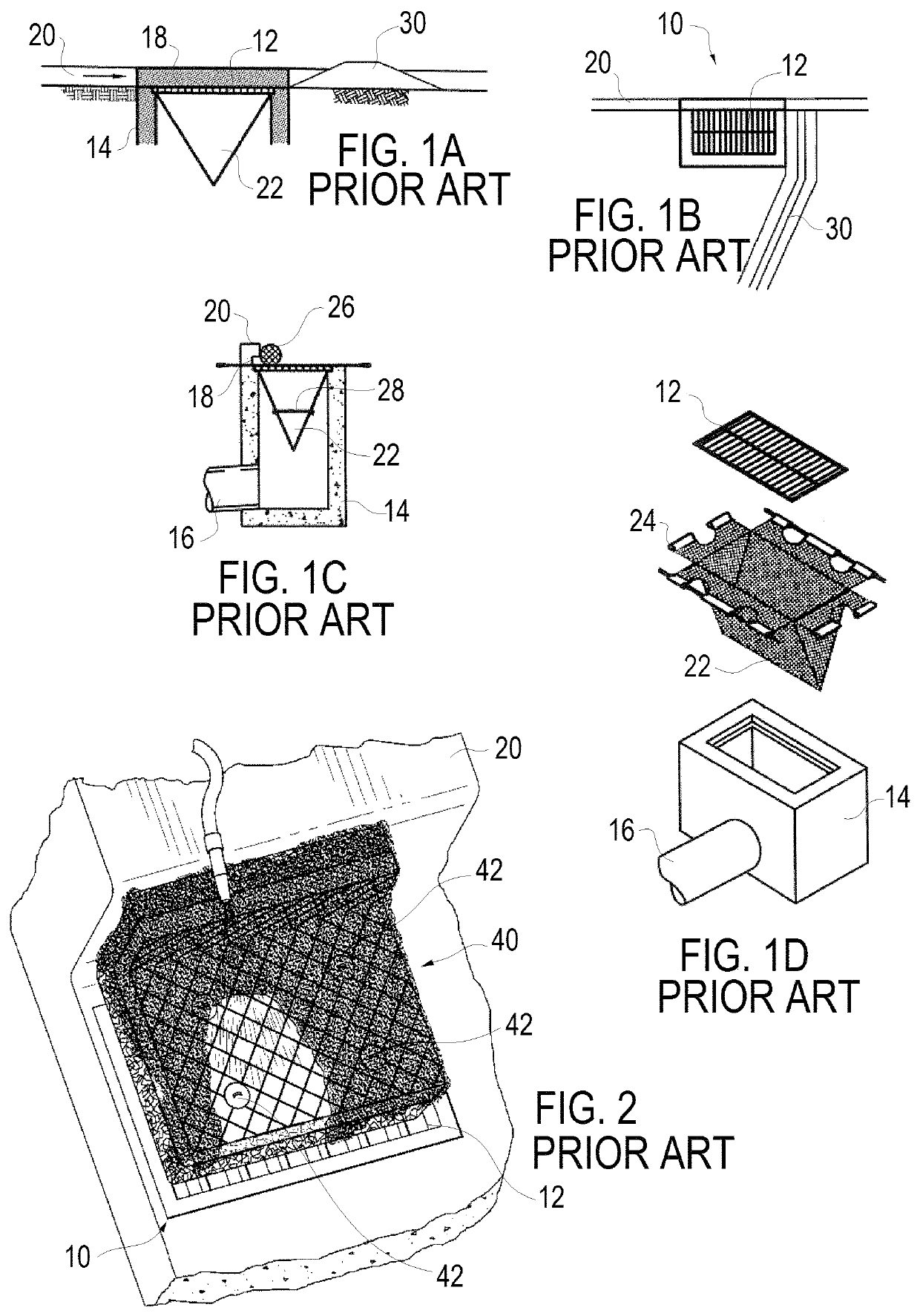

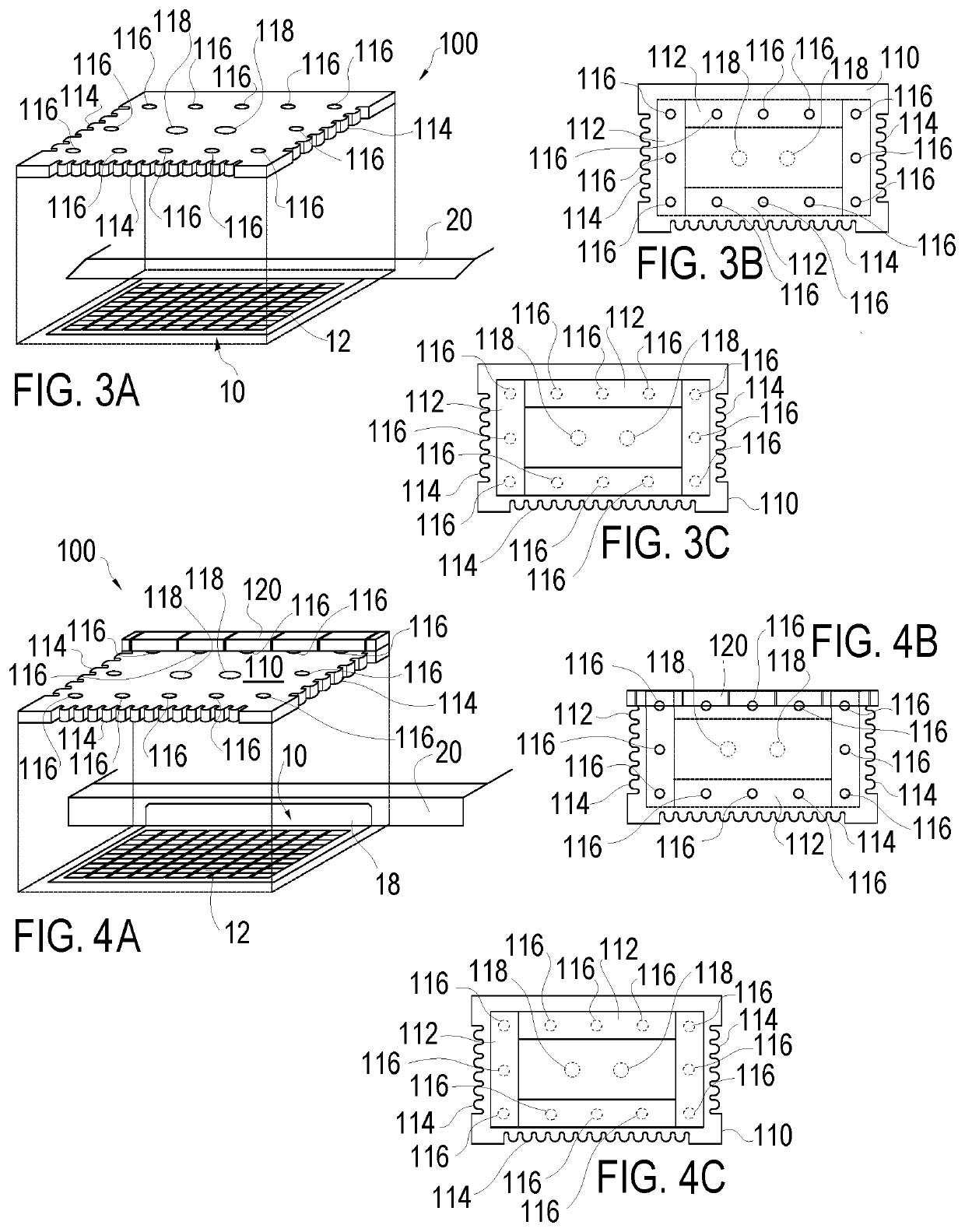

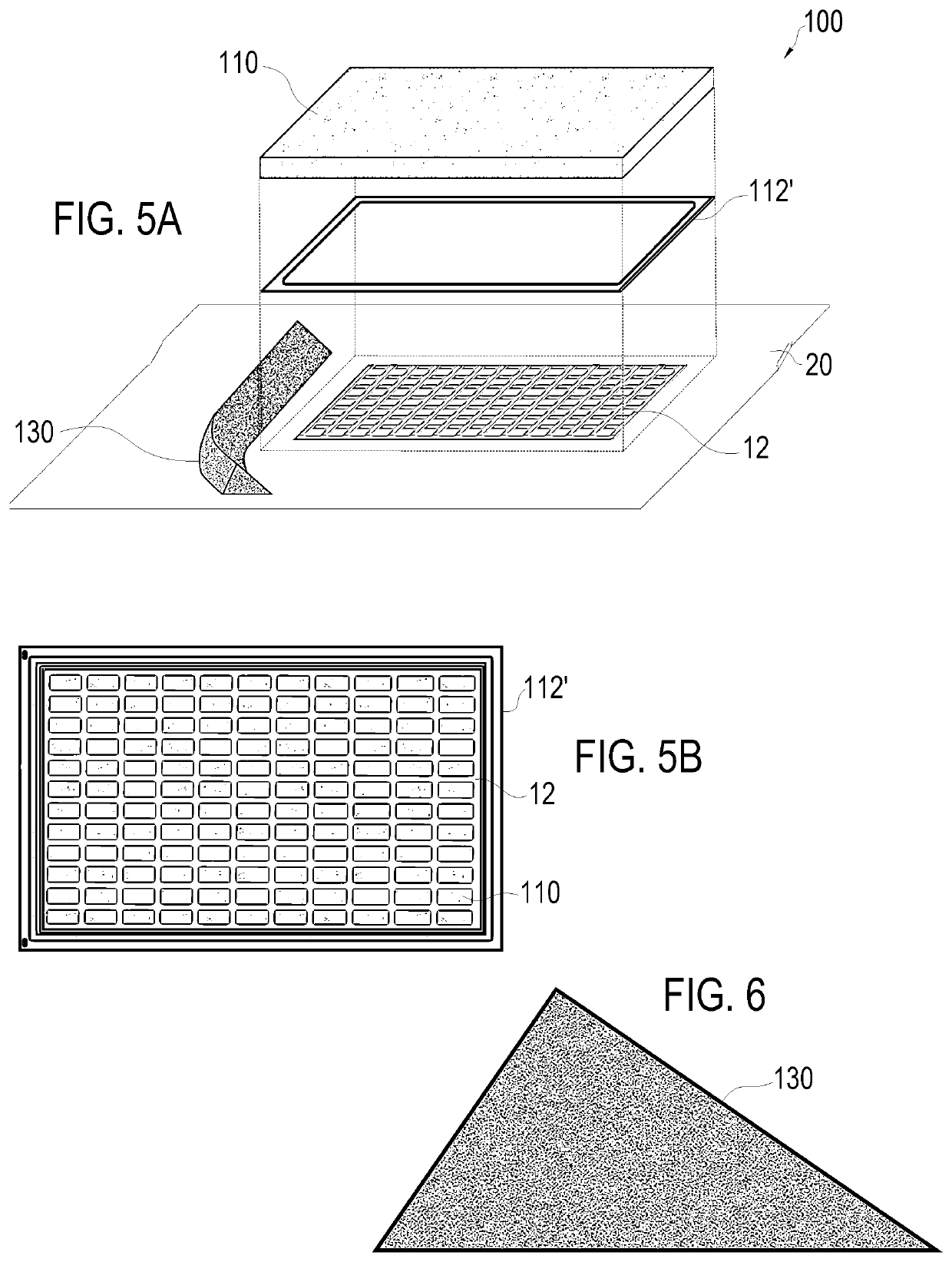

Erosion and sediment control above grate based inlet filter system

An above grate based inlet filter system for erosion and sediment control comprises a filter mat configured to extend beyond the perimeter of the grate and a securing mechanism, such as magnets, configured to securing the filter mat around the perimeter of the grate. The system may include a filter berm secured in vicinity to the mat, and a rectangular array of magnets coupling the filter mat to the grate. The natural fiber filter mat may effectively be formed of vertically aligned coir fibers or alternatively of reticulated foam. Multiple side edges of the mat are undulating having a pattern of repeating recesses. The mat includes a plurality of high flow holes extending into the mat and which are closed at a bottom surface thereof. The mat includes at least one removable dewatering plug configured to allow for selective mat bypass.

Owner:MKB CO LLC

Floating island module comprised of post-consumer carpet fiber matrix and method of manufacturing same

A floating island comprising one or more modules each comprised of one or more layers of permeable and porous matrix comprised of post-consumer carpet fibers and a top covering and a bottom covering around each layer. Alternate embodiments include layers comprised of polyethylene terephthalate bottle-fiber matrix and / or jute or coir fibers. A method of manufacturing the floating island module described above.

Owner:FOUNTAINHEAD

Multifunctional non-woven fabric

ActiveCN105908365ANormal productionImprove filtering effectPhysical treatmentNon-woven fabricsPyrophylliteNonwoven fabric

The invention relates to a multifunctional non-woven fabric. The multifunctional non-woven fabric comprises a middle layer, an upper surface layer and a lower surface layer, wherein the upper surface layer and the lower surface layer are located on the two sides of the middle layer respectively. The middle layer is prepared from, by weight, 35-55 parts of modified bamboo charcoal fibers, 15-20 parts of jute fibers, 10-15 parts of coconut fibers, 3-5 parts of modified nano-pyrophyllite, 15-25 parts of algae extract and 3-5 parts of chitin fibers. The composite non-woven fabric can be normally produced completely according to an original production technology; the non-woven fabric is environmentally friendly, degradable, good in filtering performance, spinnability, coloring performance and softness, free of size dripping, uniform in lapping, normal in gram weight and high in tensile strength; the anti-bacterial, flame-retardant and waterproof effects are good; toxicity and irritation are avoided, strength is non-directional, and the longitudinal strength and the transverse strength are approximate.

Owner:浙江中宇节能科技有限公司

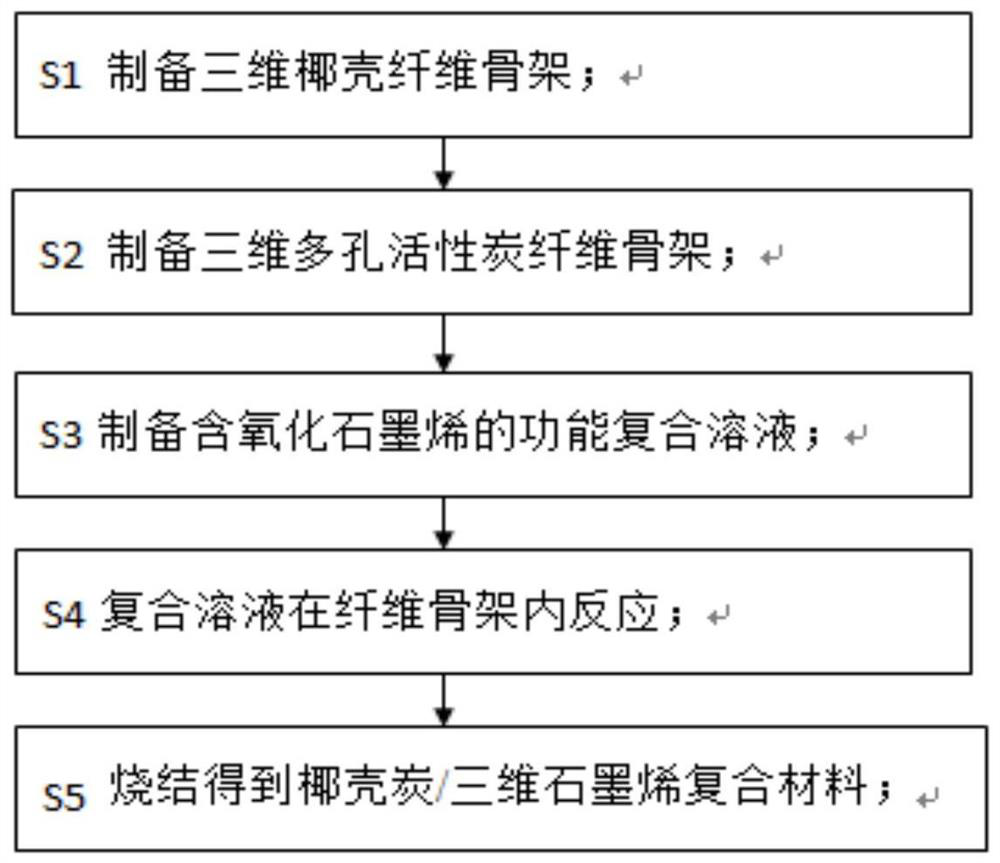

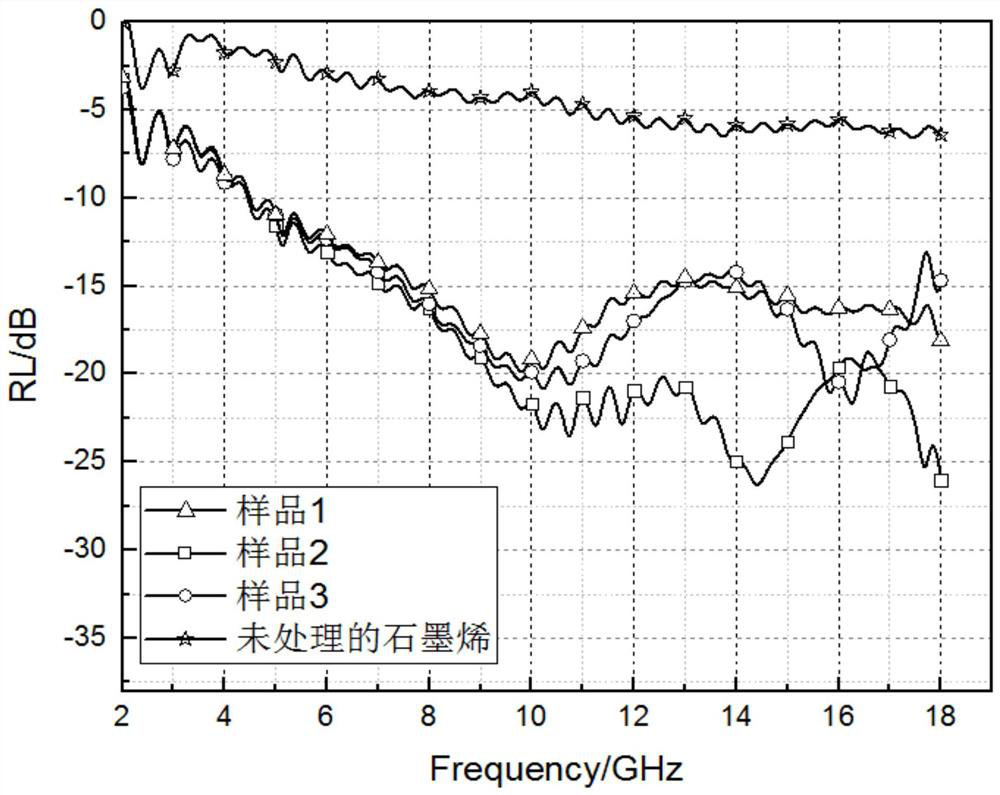

Preparation method and application of coconut shell charcoal/three-dimensional graphene composite material

PendingCN111847450AImprove mechanical propertiesPromote absorptionMagnetic/electric field screeningGrapheneActivated carbonGraphite oxide

The invention provides a preparation method of a coconut shell charcoal / three-dimensional graphene composite material. The preparation method comprises the following steps: S1, pretreating coconut shells to obtain a three-dimensional coconut shell fiber skeleton; S2, carbonizing the three-dimensional coconut fiber skeleton in an inert atmosphere, and then performing broaching and activating treatment to obtain a three-dimensional porous activated carbon fiber skeleton; S3, preparing a graphene oxide dispersion liquid, and adding functional components into the graphene oxide dispersion liquid to obtain a composite solution; S4, reacting the activated carbon fiber skeleton with the composite solution at high temperature and high pressure for 0.5-24 hours, and cleaning and drying after the reaction is finished; and S5, sintering the sample obtained in the step S4 in an inert atmosphere to obtain the coconut shell charcoal / three-dimensional graphene composite material. According to the preparation method of the coconut shell charcoal / three-dimensional graphene composite material, the problem that three-dimensional graphene is easy to crack in the preparation process is solved, and theobtained coconut shell charcoal / three-dimensional graphene composite material has better mechanical properties and electromagnetic wave absorption performance.

Owner:SHENZHEN KUANG CHI GANG DA INNOVATIVE TECH LTD +1

Method for extracting coconut fiber

ActiveCN109162132AReduce hydroxylRealize the second degreasingCellulose treatment using microorganisms/enzymesRaw material divisionChlorine dioxideThermal water

The invention discloses a method for extracting coconut fiber. The method comprises the following steps: crushing coconut shell; adding deionized water and lipase into a cylinder, conducting uniform mixing, heating the mixture to 45 DEG C, and soaking the coconut shell into a cylinder for 2-3 h after soaking; adding sodium hydroxide solution in a cooking tank, putting the filtered coconut shell into the cooking tank, heating and pressurizing the mixture, cooking the mixture for 1-1.5 h, taking out the cooked coconut shell, and rinsing off the cooked coconut shell with water for 10-15 min; dissecting the rinsed coconut shell in the step (3) into crude fiber by a filament forming machine, and then rinsing the fiber with water for 10-15 minutes; mixing the deionized water with chlorine dioxide and sodium carbonate uniformly, and then the rinsed crude fiber in the step (4); conducting soaking for 30 to 40 minutes, taking out the fiber, and rinsing the fiber with hot water for 15 to 20 minutes; and dehydrating the dried fiber in the step (5), and then loosening the fiber with a carding machine to obtain the coconut fiber. The coconut shell fiber extracted by the method for extracting the coconut fiber of the invention has uniformity, less impurities, low residual fat ratio, and guaranteed quality.

Owner:安徽九天印务有限公司

Composite boards and a method of making the same

InactiveUS8586655B2Reduce the possibilityImprove scratch resistanceFibreboardConfectioneryPolymer sciencePolyolefin

A composite board is manufactured from hydrophobic coconut coir fibers which have been treated to remove at least a portion of coconut pith therefrom; and a hydrophobic vinyl polymer, such as a polyolefin. The composite board is manufactured without any step of chemically modifying coconut coir fibers. The composite board is manufactured by removing at least a portion of coconut pith from coconut coir fibers using a cyclonic separator; combining coconut coir fibers with a hydrophobic polymer to form a mixture; and extruding the mixture to form a composite board.

Owner:ADMIRAL COMPOSITE TECH

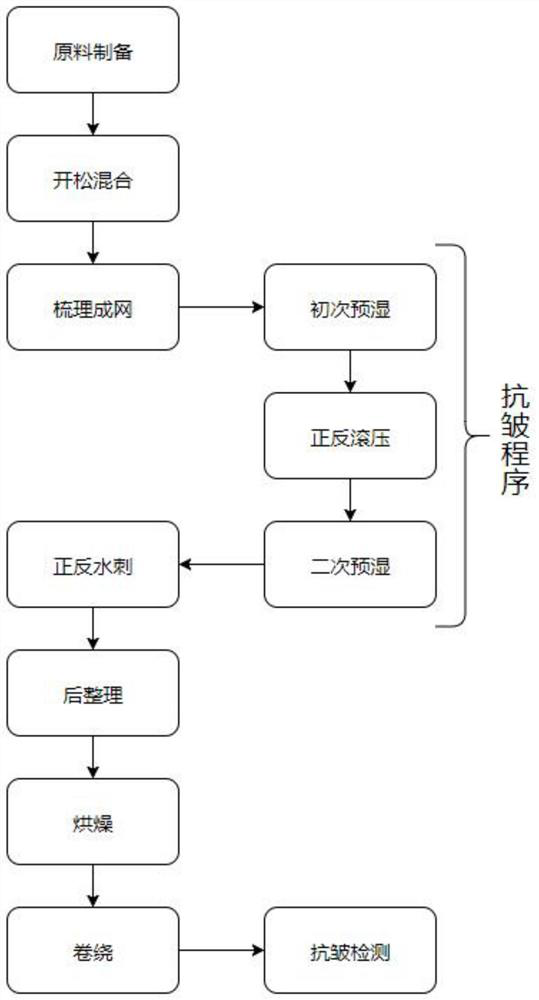

Production process of environment-friendly colored non-woven fabric

InactiveCN113352711AImprove flexural and flexural strengthIncrease softnessLamination ancillary operationsSynthetic resin layered productsPolymer scienceKapok fiber

The invention discloses a production process of environment-friendly colored non-woven fabric, and relates to the technical field of non-woven fabric production. The preparation method comprises the following steps of: preparing raw materials, specifically, preparing 20-25 parts by weight of polypropylene, 2-3 parts by weight of bamboo fiber, 1-3 parts by weight of flax, 2-5 parts by weight of coconut fiber, 1-2 parts by weight of kapok fiber, 5-7 parts by weight of sisal hemp, 3-4 parts by weight of sawdust and 1.5-3 parts by weight of silk; performing scutching and mixing, bisecting the polypropylene, respectively mixing and scutching the bisected polypropylene and the other raw materials in the step 1; performing carding to form a screen, carding all the raw materials except the polypropylene into a base layer, then carding the bisected polypropyleneinto covering layers respectively; and adhering the two covering layers to the upper surface and the lower surface of the base layer respectively by using an adhesive to form a fiber screen. The soft degree of the outer layer of the non-woven fabric can be improved, and the comfort level can be improved conveniently; the toughness of the base layer in the non-woven fabric can be improved, and the overall bending strength and breaking strength of the non-woven fabric can be improved.

Owner:揭阳市少记科技有限公司

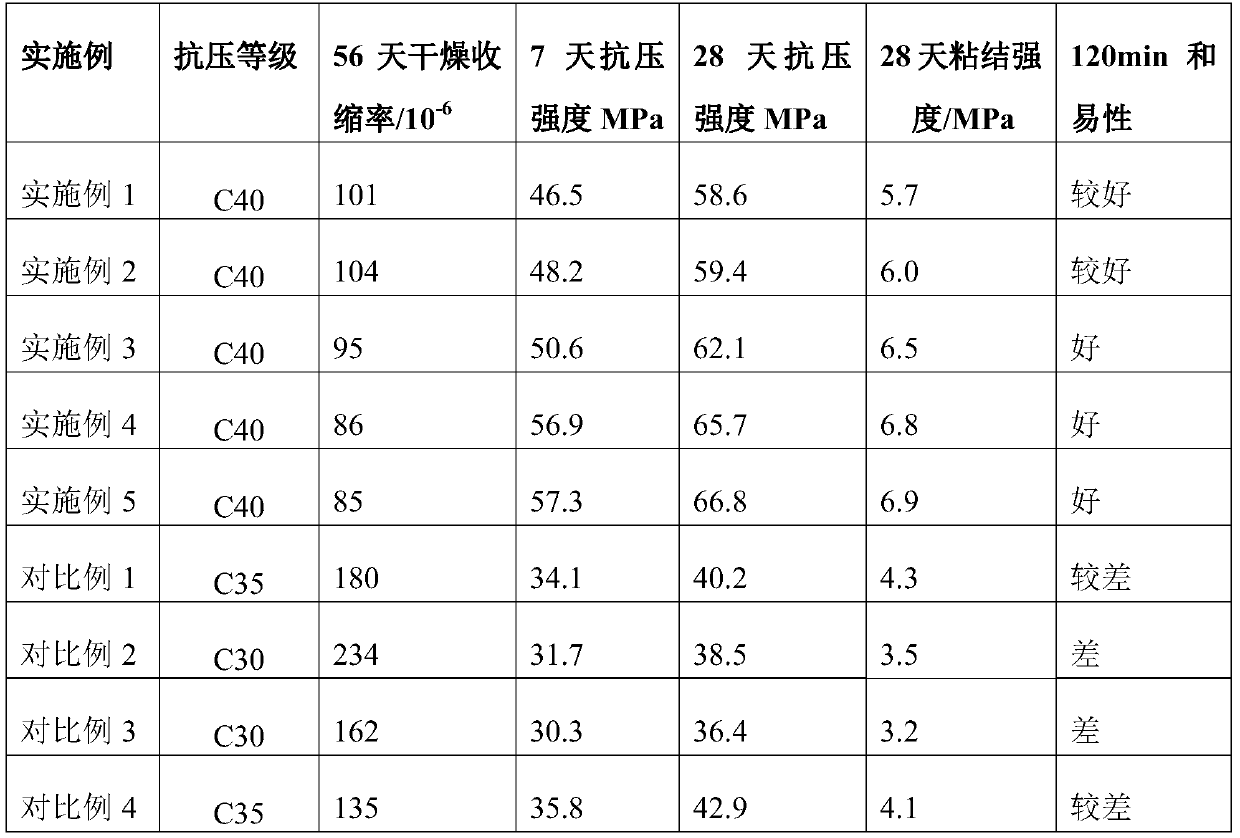

Method for producing C40 concrete

The invention provides a method for producing C40 concrete. The method comprises the following steps: (1) preparing the following raw materials in parts by weight for each cubic meter of concrete: 230-240Kg of cement, 95-105g of coal ash, 160-170kg of water, 830-840kg of sand, 935-955kg of bluestone, 120-130kg of mineral powder, 8-10kg of a composite water reducing agent and 12-18kg of a mixed fiber, wherein the composite water reducing agent comprises a polycarboxylate superplasticizer, an aliphatic water reducing agent, a reinforcing agent, an expanding agent, an anti-sinking agent, a defoaming agent and water; the mixed fiber is a mixture of aluminum oxide fine powder, short carbon fiber, polyethylene long fiber and coconut shell fiber, and the bluestone is crushed for certain size grading; (2) preparing the composite water reducing agent; and (3) adding the coal ash and the mineral powder into an upright stirrer, performing stirring, adding bluestone, sand and cement, performing stirring at a speed of 90-105r / min, adding the mixed fiber, performing stirring at a speed of 230-260r / min, adding the composite water reducing agent and water, performing stirring at a speed of 130-150r / min firstly, and further performing stirring at a speed of 160-180r / min, so as to obtain the C40 concrete. The C40 self-compacted concrete produced by using the production method which is provided by the invention and is used for producing the C40 concrete takes both good compensation shrinkage and peaceability into account.

Owner:海南华盛混凝土有限公司

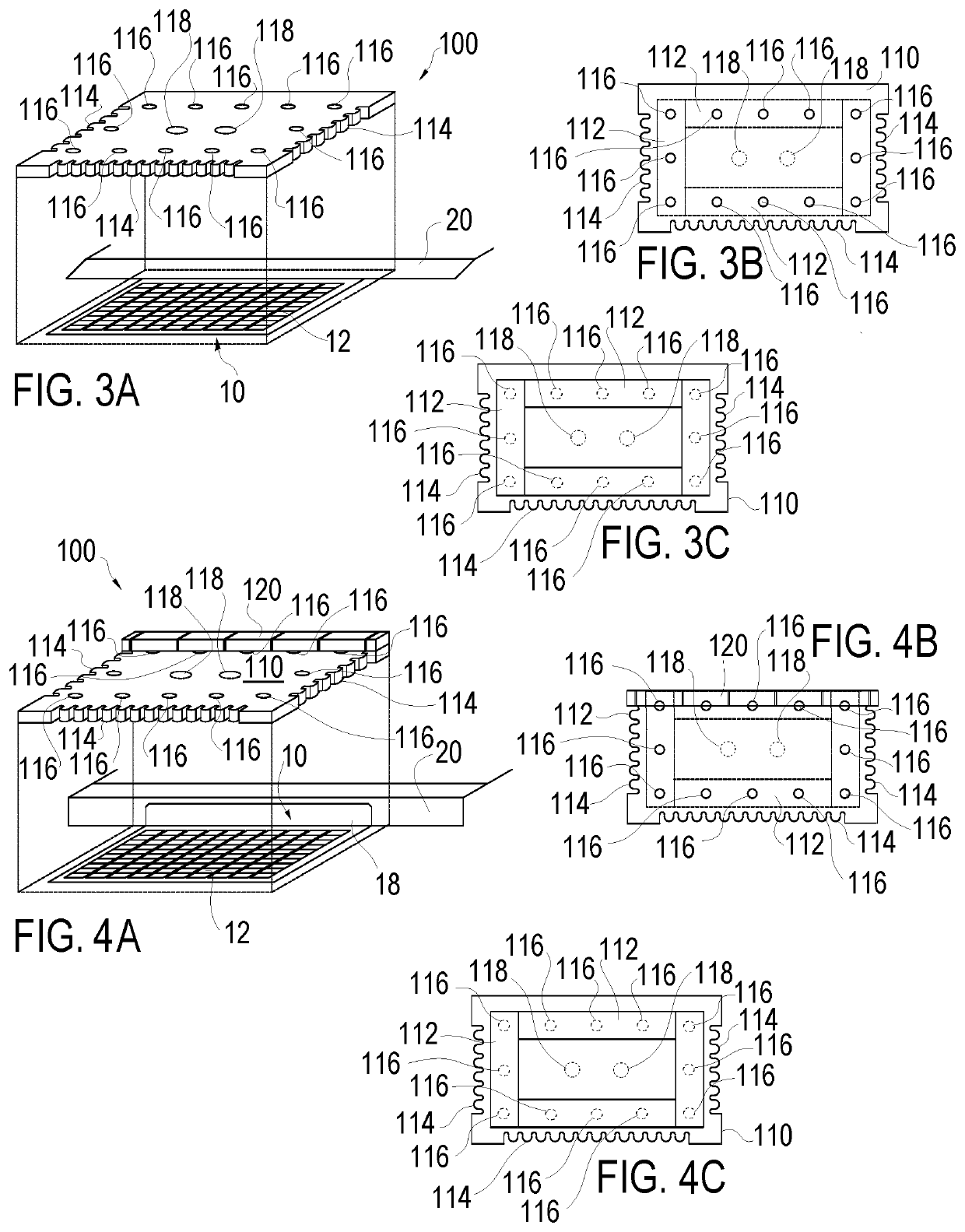

Erosion and sediment control above grate based inlet filter system including high traffic embodiments

ActiveUS20200109548A1Fatty/oily/floating substances removal devicesSewerage structuresReticulated foamFilter system

An above grate based inlet filter system for erosion and sediment control comprises a filter mat configured to extend beyond the perimeter of the grate and a securing mechanism, such as magnets, configured to securing the filter mat around the perimeter of the grate. The system may include a filter berm secured in vicinity to the mat, and a rectangular array of magnets coupling the filter mat to the grate. The natural fiber filter mat may effectively be formed of vertically aligned coir fibers or alternatively of reticulated foam. Multiple side edges of the mat are undulating having a pattern of repeating recesses. The mat includes a plurality of high flow holes extending into the mat and which are closed at a bottom surface thereof. The mat includes at least one removable dewatering plug configured to allow for selective mat bypass

Owner:MKB CO LLC

Luggage shell material

InactiveCN112060713ALight in massImprove stress resistanceSynthetic resin layered productsBagsPolymer sciencePoly(butylene succinate)

The invention discloses a luggage shell material which comprises an outer side layer, an inner side layer and a middle layer located between the outer side layer and the inner side layer, the outer side layer is made of a biodegradable antifouling material, the middle layer is made of a coconut shell fiber / polybutylene succinate composite material, the inner side layer is made of an inorganic fiber reinforced material, the coconut fiber / polybutylene succinate composite material and the inorganic fiber reinforced material are compounded into a plate through heating and pressurizing, and the biodegradable anti-fouling material is uniformly attached to the surface of the coconut fiber / polybutylene succinate composite material through spraying. The invention belongs to the technical field of high polymer materials, and particularly relates to the luggage shell material which is good in drawing depth, high in bending strength, high in impact strength and capable of being biodegraded.

Owner:湖南省亚玛图工贸有限公司

High elastic coconut fiber mat

InactiveCN111020867AIncrease the amount addedHeating/cooling textile fabricsNon-woven fabricsPolyesterPolymer science

The invention discloses a high elastic coconut fiber mat. The high elastic coconut fiber mat includes the components in parts by weight: 60-80 parts of coconut fibers, 20-40 parts of high elastic short polyester fibers and 15-30 parts of low-melting-point polyester fibers. The fibers are formed into finished products through cutting after opening, mixing, carding, lapping, needling, baking, bonding, cooling and shaping. According to the abovementioned mode, the high elastic coconut fiber mat partially with the performance of a coconut fiber mat adhered by latex, the production process is moreenvironmentally friendly and odorless, and the product has both high permeability and high elasticity.

Owner:苏州椰为媒纤维制品科技有限公司

Slow-rebounding coconut fiber mattress and production process thereof

InactiveCN111621924AStrong supportImprove protectionStuffed mattressesSpring mattressesPolyesterMoisture absorption

The invention discloses a slow-rebounding coconut fiber mattress. The slow-rebounding coconut fiber mattress is prepared from following components by mass: 30-50 parts of coconut fibers, 20-40 parts of three-dimensional hollow polyester fibers and 10-20 parts of low-melting-point polyester fibers. After the raw materials are mixed, opened, webbed, needled, baked, cooled and shaped and the like, the finished slow-rebounding coconut fiber mattress is manufactured. In this way, the slow-rebounding coconut fiber mattress has the beneficial effects of a common slow-rebounding mattress and a coconutfiber mattress, and is refreshing, transparent and free of moisture absorption while achieving a good protection effect on vertebrae of the human body, and bacterium breeding is not easily caused.

Owner:苏州椰为媒纤维制品科技有限公司

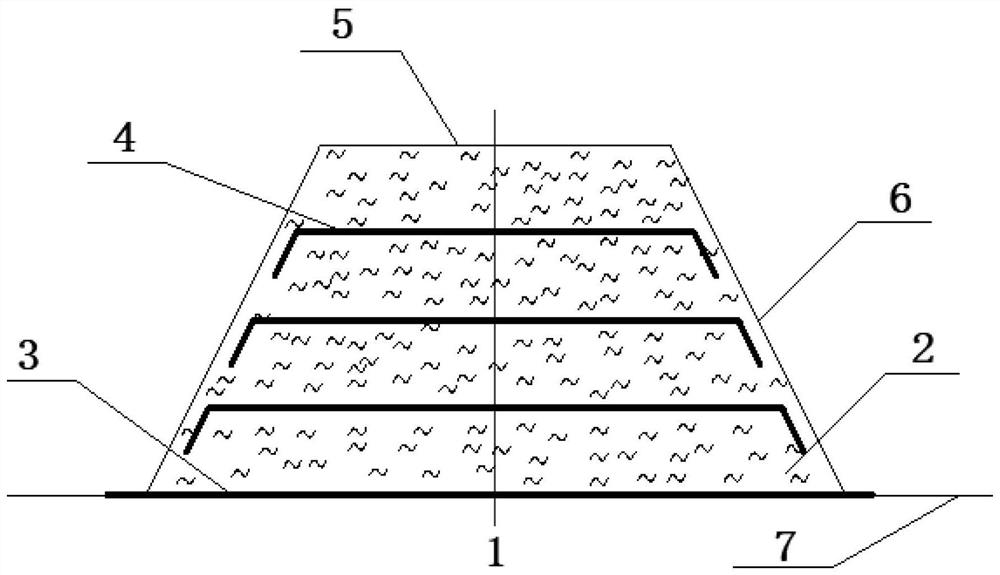

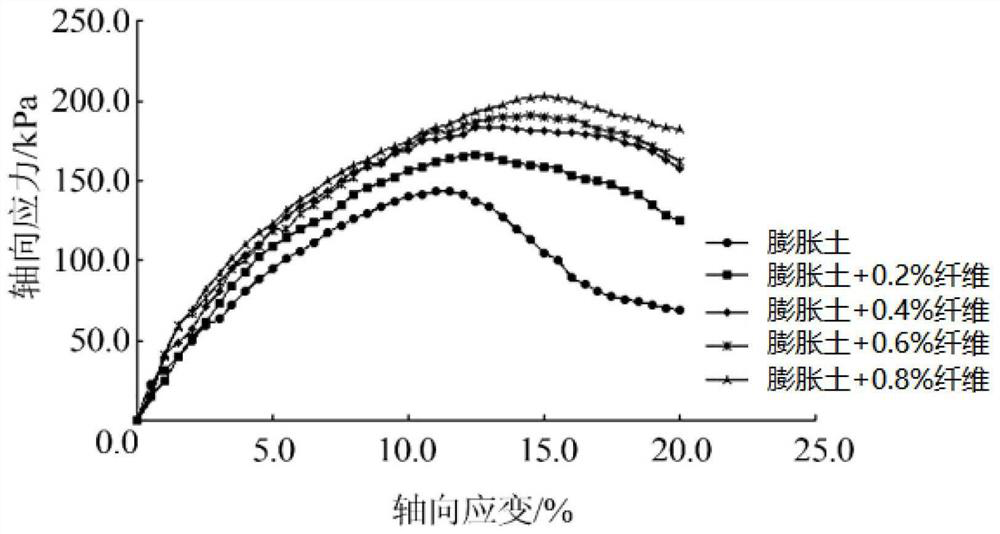

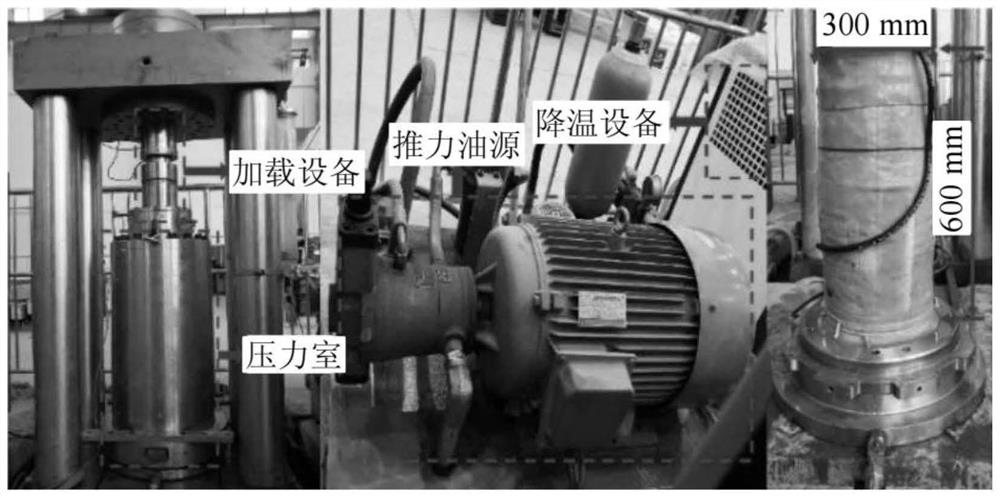

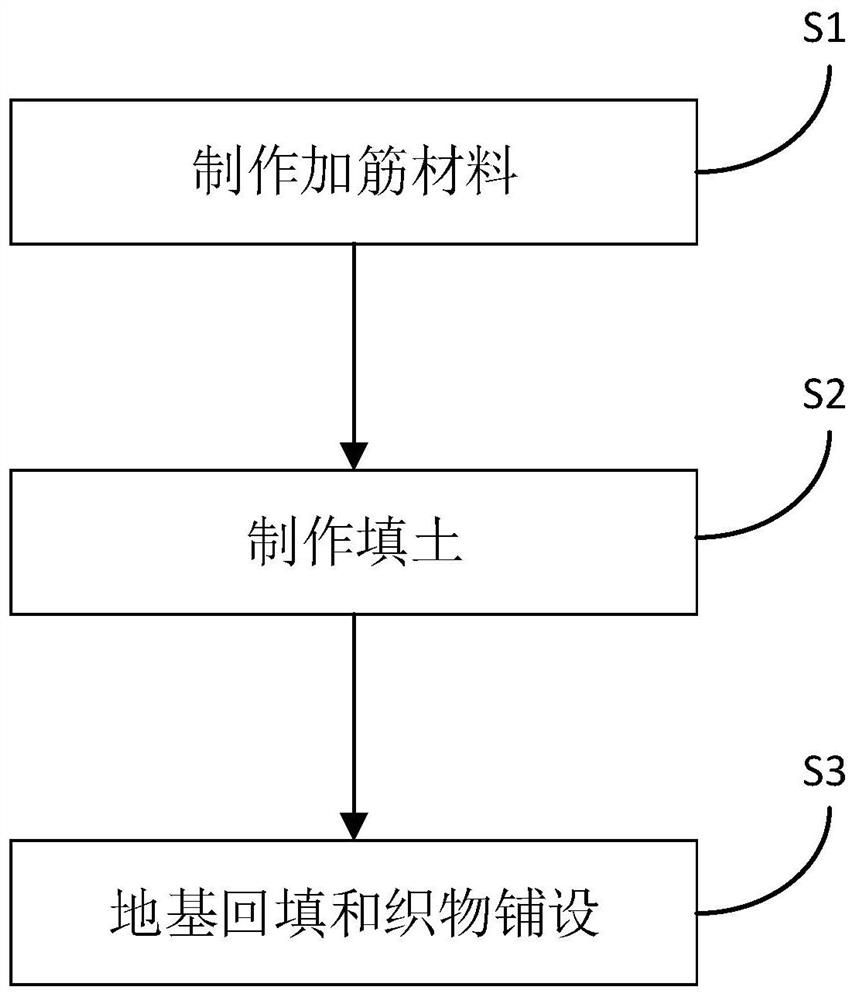

Coconut fiber and coconut geotextile composite reinforced expansive soil roadbed and construction method thereof

PendingCN114753201AStrong toughnessHigh strengthPaving reinforcementsOpen work fabricsSoil scienceRoad surface

The invention discloses a coconut fiber and coconut geotextile composite reinforced expansive soil roadbed and a construction method thereof. The coconut fiber and coconut geotextile composite reinforced expansive soil roadbed comprises a foundation layer, a roadbed layer laid on the top surface of the foundation layer and a pavement layer laid on the top surface of the roadbed layer, wherein the roadbed layer comprises a roadbed base body and a plurality of reinforced structure layers; the roadbed base body is formed by mixing and compacting coconut shell fibers and expansive soil, and the reinforced structure layer is mainly composed of coconut shell geotechnical cloth. The expansive soil roadbed mainly solves the problems of poor permeability, water swelling, water loss shrinkage, multiple cracks, humidification and the like of a current expansive soil roadbed, the coconut shell fibers and the coconut shell geotextile are used, the coconut shell fibers and the coconut shell geotextile serve as rib materials, the strength of a soil body is greatly improved, the coconut shell geotextile and the coconut shell fibers are environment-friendly materials, and therefore the expansive soil roadbed is environmentally friendly. And the method plays an important role in protecting the environment and saving resources.

Owner:HUBEI UNIV OF TECH

Erosion and sediment control above grate based inlet filter system including high traffic embodiments

ActiveUS11098472B2Fatty/oily/floating substances removal devicesSewerage structuresReticulated foamFilter system

An above grate based inlet filter system for erosion and sediment control comprises a filter mat configured to extend beyond the perimeter of the grate and a securing mechanism, such as magnets, configured to securing the filter mat around the perimeter of the grate. The system may include a filter berm secured in vicinity to the mat, and a rectangular array of magnets coupling the filter mat to the grate. The natural fiber filter mat may effectively be formed of vertically aligned coir fibers or alternatively of reticulated foam. Multiple side edges of the mat are undulating having a pattern of repeating recesses. The mat includes a plurality of high flow holes extending into the mat and which are closed at a bottom surface thereof. The mat includes at least one removable dewatering plug configured to allow for selective mat bypass.

Owner:MKB CO LLC

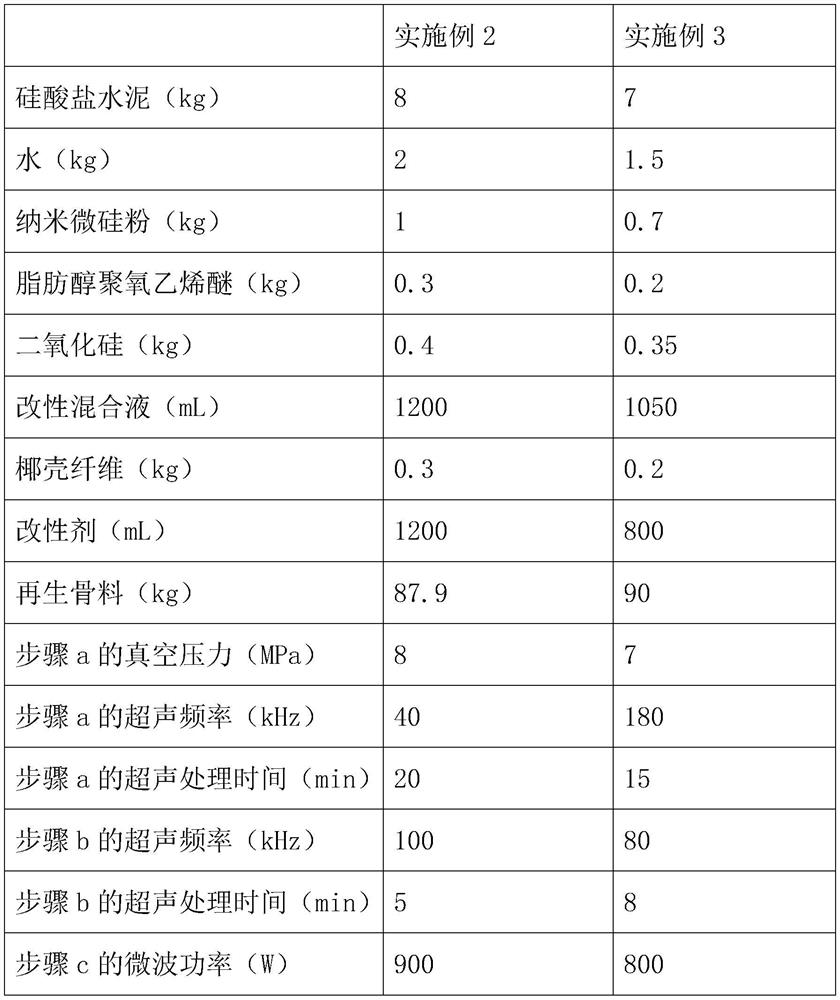

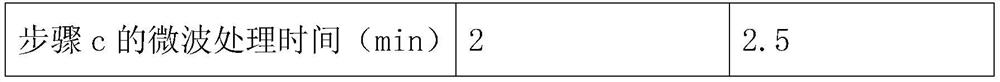

Environment-friendly regenerated brick and preparation process thereof

InactiveCN114149222AIncrease profitReduce manufacturing costSolid waste managementPolymer scienceBrick

The invention relates to the field of regenerated bricks, and particularly discloses an environment-friendly regenerated brick and a preparation method thereof. The preparation method of the environment-friendly recycled brick comprises the following steps: step a, mixing Portland cement, water, nano silica fume and fatty alcohol-polyoxyethylene ether to form a prefabricated mixture, then infiltrating the prefabricated mixture into gaps of recycled aggregate, and mixing the prefabricated mixture with the filled recycled aggregate to obtain a mixture; step b, performing modification operation on silicon dioxide to obtain modified silicon dioxide; c, performing modification operation on the coconut shell fibers to obtain modified coconut shell fibers; step d, mixing the mixed material, the modified silicon dioxide and the modified coconut fiber, and standing, curing and forming to obtain the environment-friendly regenerated brick. The preparation method disclosed by the invention has the advantages that the environment-friendly recycled brick can completely utilize the recycled aggregate to replace natural aggregate, resources are saved, and the production cost is reduced.

Owner:深圳市坤鹏环保建筑废料处理有限公司

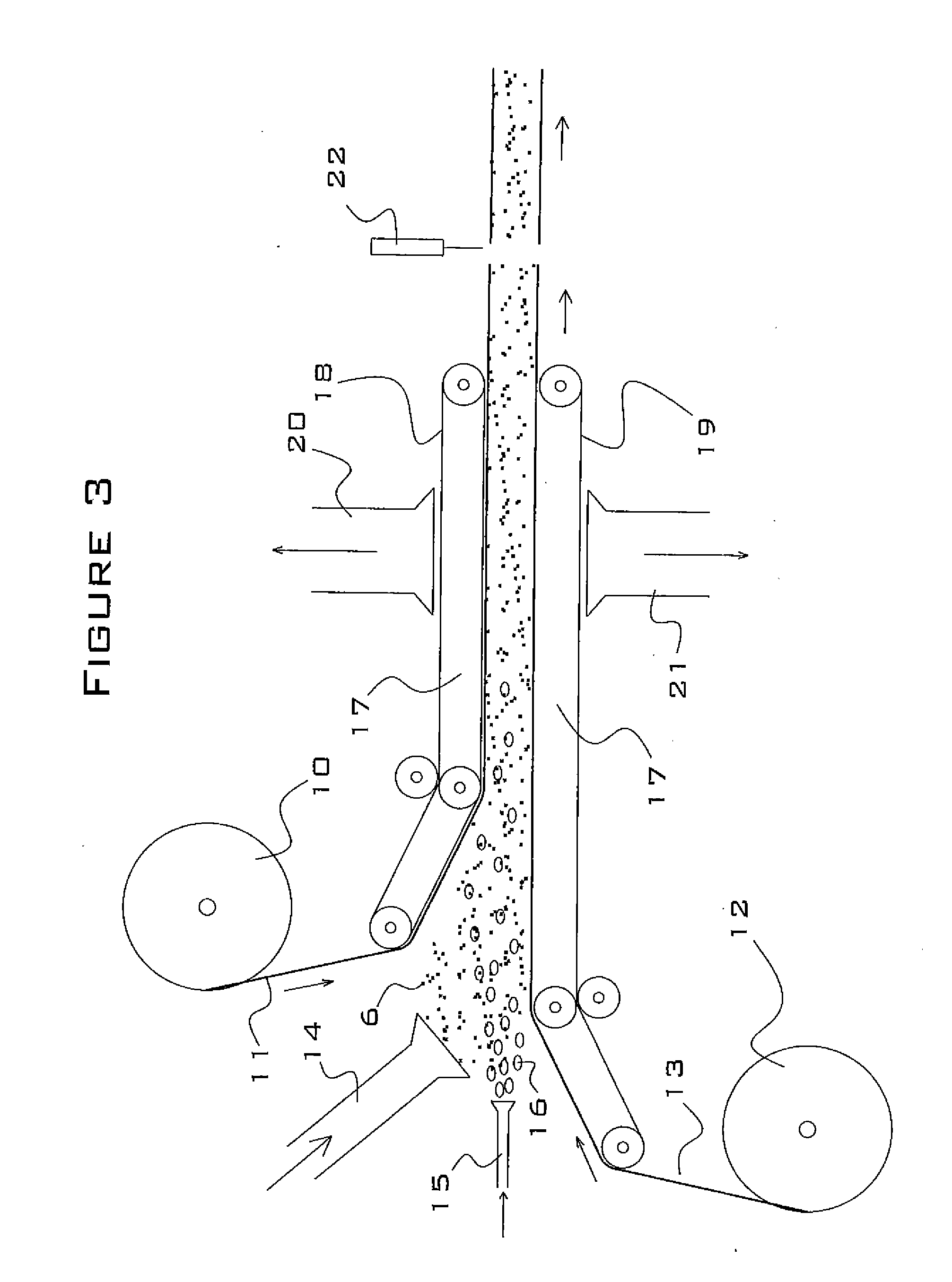

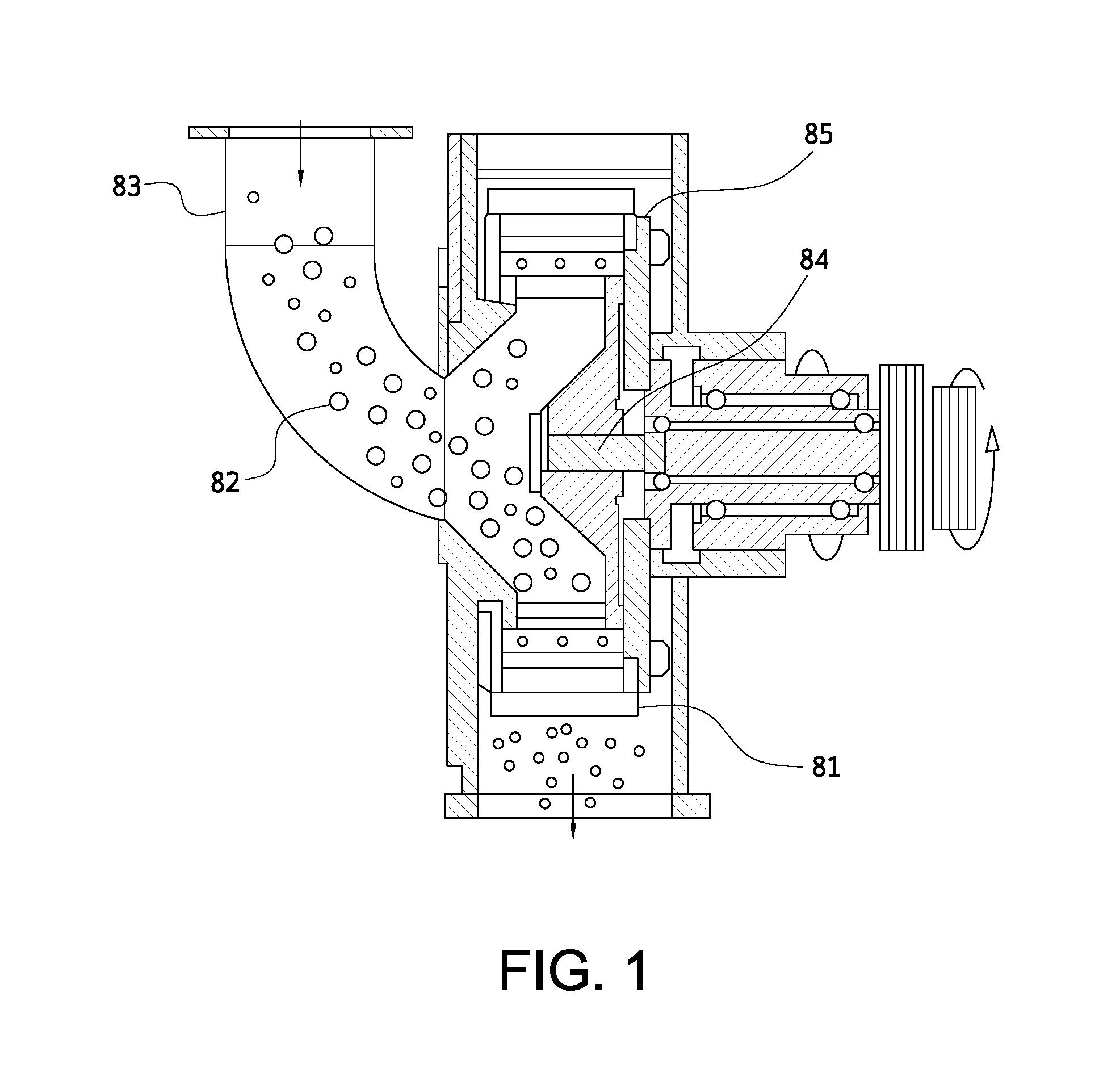

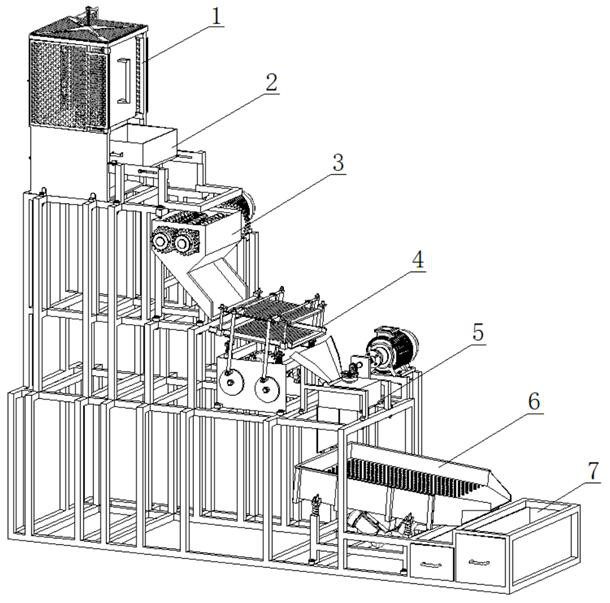

Apparatus For Processing Oilseed Flax Fiber For Use In Biocomposite Materials

ActiveUS20180000307A1Retention strengthGood conditionFibre cleaning/opening by air draught arrangementsCarpet cleanersPolymer scienceFlax fiber

A method and system for the production of fibers for use in biocomposites is provided that includes the ability to use both retted and unretted straw, that keeps the molecular structure of the fibers intact by subjecting the fibers to minimal stress, that maximizes the fiber's aspect ratio, that maximizes the strength of the fibers, and that minimizes time and energy inputs, along with maintaining the fibers in good condition for bonding to the polymer(s) used with the fibers to form the biocomposite material. This consequently increases the functionality of the biocomposites produced (i.e. reinforcement, sound absorption, light weight, heat capacity, etc.), increasing their marketability. Additionally, as the disclosed method does not damage the fibers, oilseed flax straw, as well as all types of fibrous materials (i.e. fiber flax, banana, jute, industrial hemp, sisal, coir) etc., can be processed in bio composite materials.

Owner:CNH IND CANADA

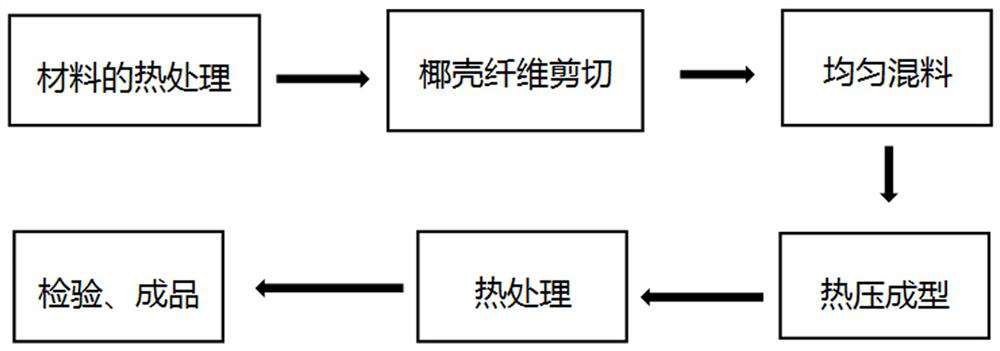

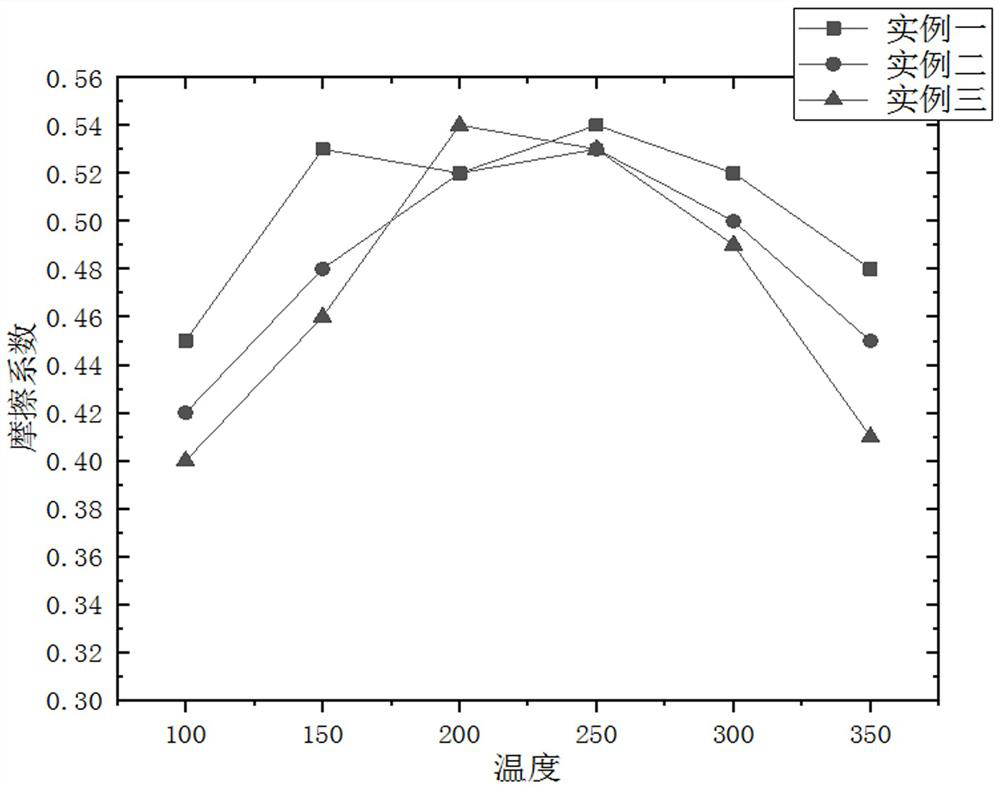

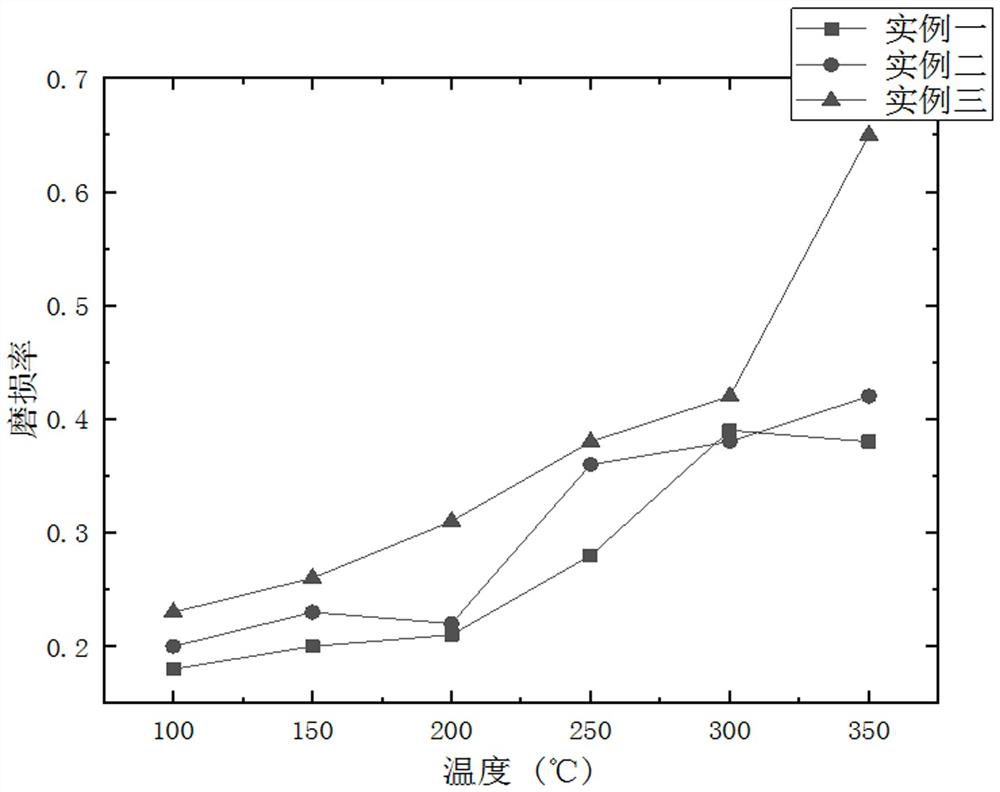

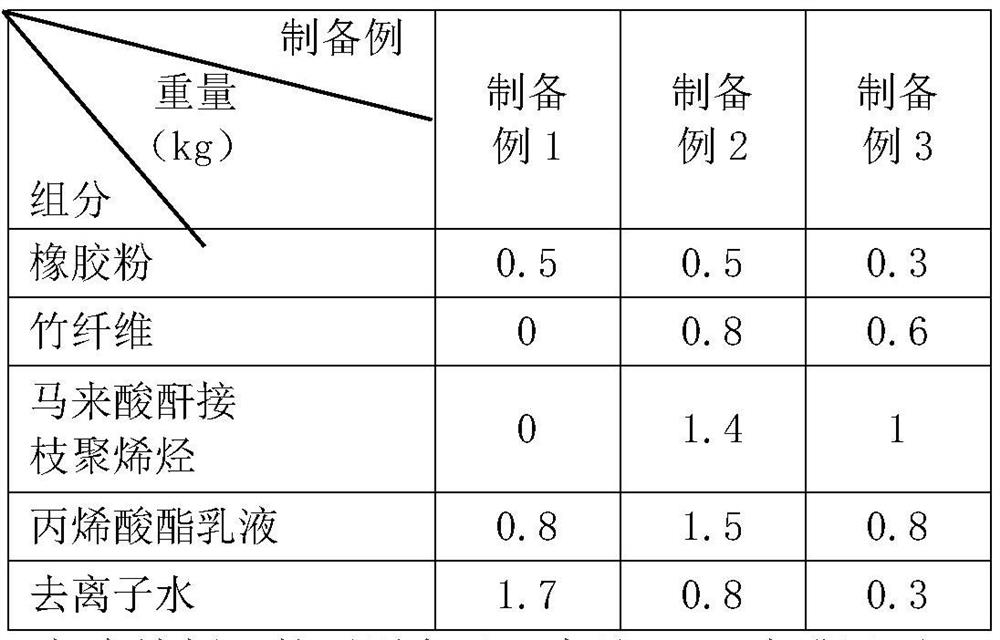

Coconut fiber brake pad and preparation method thereof

InactiveCN113294465AImprove tribological performanceLow costFriction liningActuatorsNatural fiberAluminium oxides

The invention discloses a coconut fiber brake pad and a preparation method thereof. The coconut shell fiber brake pad is prepared from the following raw materials of, by weight, 19-25 parts of resin, 5-10 parts of coconut fibers, 5-10 parts of ceramic fibers, 20-30 parts of barite, 15-20 parts of aluminum oxide, 5-15 parts of graphite, 10-15 parts of lanthanum oxide and 3-5 parts of rubber powder. The integrality of the brake pad is enhanced through the high-strength coconut fibers, the friction coefficient of the brake pad is increased, the wear rate is reduced, meanwhile the cost of the brake pad can be reduced, and by reusing the coconut fiber, the problem that the natural fiber demand of an existing brake pad is short is effectively solved, and a new way for treating the coconut fiber is also added.

Owner:FUZHOU UNIV

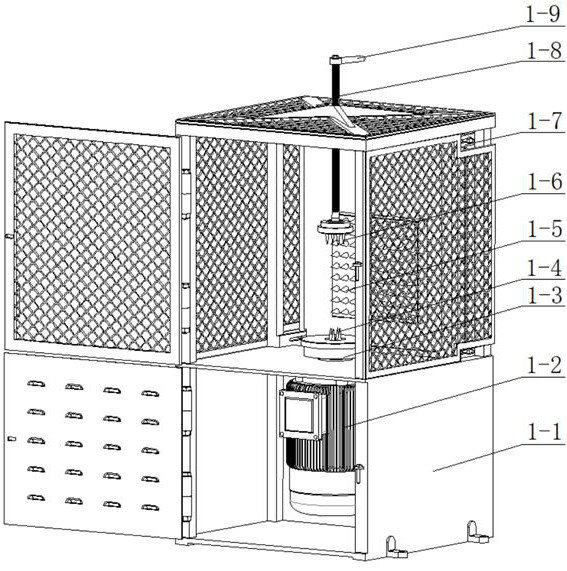

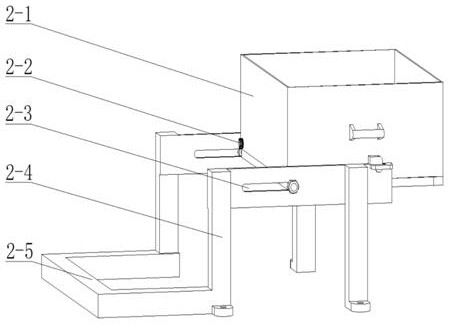

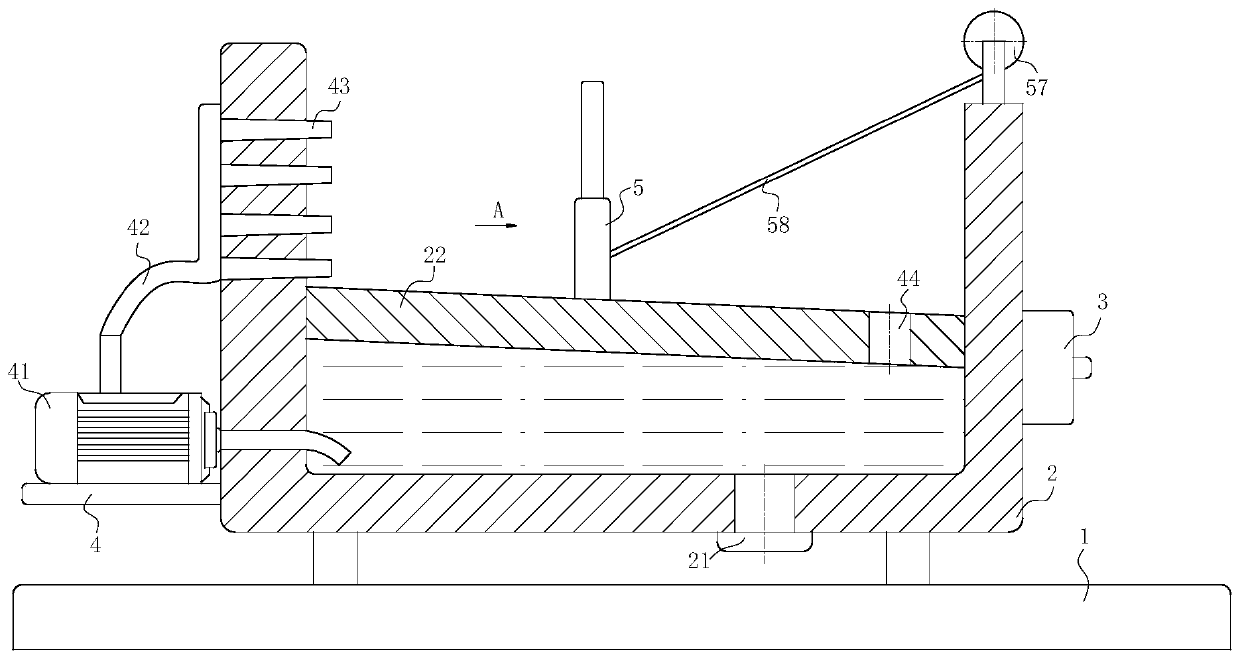

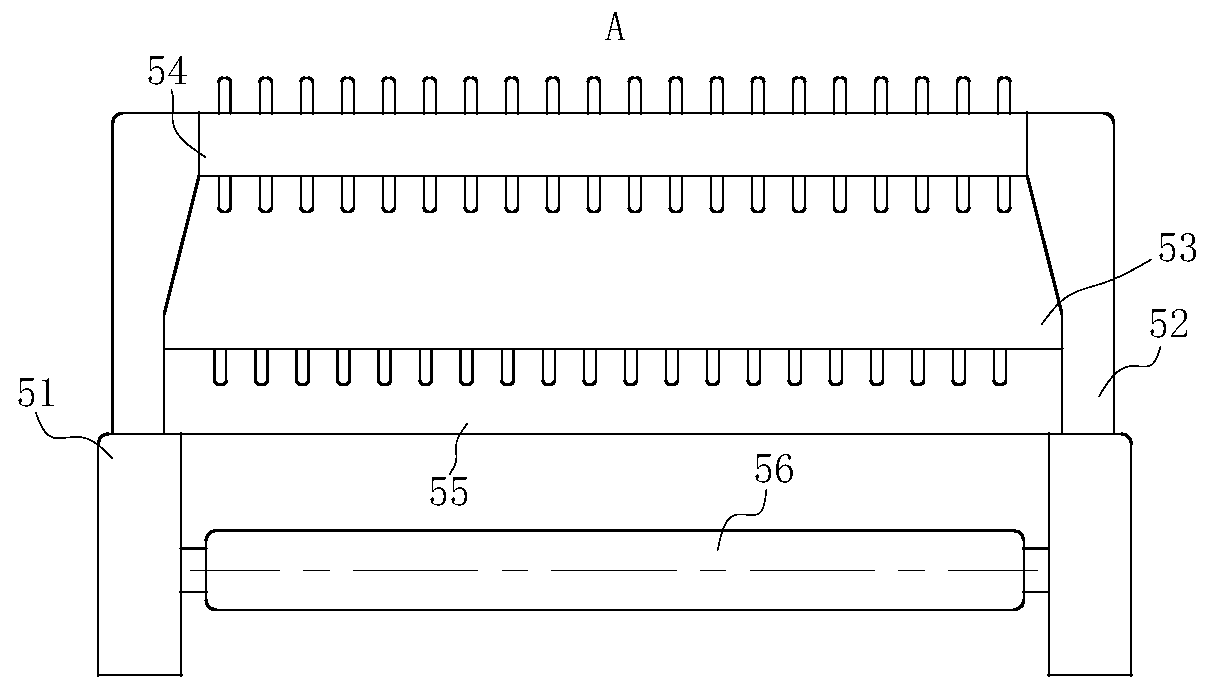

Mechanical coconut fiber extraction method and device

ActiveCN112921411AImplement extractionReduce workloadVegetable fibres from other vegetable matterEngineeringProcess engineering

The invention relates to a mechanical coconut fiber extraction method and device. The device is composed of a preliminary extraction mechanism, a soaking mechanism, a coconut shell smashing mechanism, a mechanical loosening mechanism, a drying mechanism, an impurity removing and screening mechanism and a collecting mechanism. Mature coconuts are placed in the preliminary extraction mechanism, and preliminary extraction of coconut fibers is completed by fixing, clamping and cutting the mature coconuts. Then the coconut fibers enter the soaking mechanism, after soaking is completed, large coconut shells are smashed, the coconut fibers are mechanically loosened through the mechanical loosening mechanism, and the coconut fibers are dried under the action of the drying mechanism. Finally, the coconut fibers and impurities are screened through the impurity removing and screening mechanism, and the coconut fibers and the impurities are subpackaged in a coconut fiber collecting box and an impurity collecting box, so that the whole process of coconut fiber extraction is completed. The mechanical coconut fiber extraction method and device provided by the invention are suitable for extraction of the coconut fibers of the mature coconuts, and manual operation is replaced, so that the workload is reduced, and the working efficiency is improved.

Owner:HAINAN UNIVERSITY

Pesticide bottle and preparation method thereof

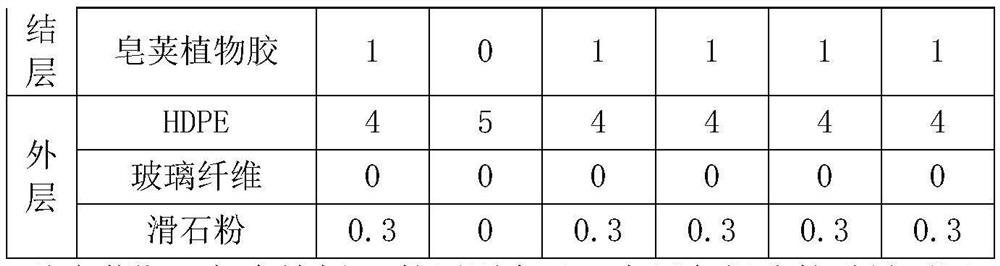

ActiveCN112876762AImprove toughnessHigh strengthSynthetic resin layered productsStarch adhesivesBlow moldingWollastonite

The invention relates to the technical field of pesticide packaging, and particularly discloses a pesticide bottle and a preparation method thereof. The pesticide bottle comprises, by weight, an inner layer, a first bonding layer, a middle layer, a second bonding layer and an outer layer from inside to outside; the inner layer comprises the following raw materials by weight: 20-25 parts of HDPE, 3-5 parts of PE, 2-3 parts of a reinforcing agent, 3-5 parts of an anti-cracking agent, 0.5-1 part of wollastonite, 0.1-0.2 part of a dispersing agent, 1-2 parts of calcium carbonate and 0.3-0.5 part of a titanate coupling agent; the reinforcing agent is prepared from titanium dioxide, alginate fiber and coconut fiber; the preparation method comprises the following steps of: respectively mixing the raw materials of the inner layer, the raw materials of the middle layer, the raw materials of the first bonding layer, the raw materials of the second bonding layer and the raw materials of the outer layer, and uniformly mixing the materials to obtain an inner layer material, a middle layer material, a first bonding layer material, a second bonding layer material and an outer layer material; subjecting the raw materials of all the layers to melt extrusion and then conducting blow molding, cooling shaping and external renovation to obtain the pesticide bottle. The pesticide bottle has the advantage of being high in strength.

Owner:杭州普信塑料包装有限公司

A kind of preparation method of composite plant fiber biodegradable material

The invention relates to a preparation method of a composite plant fiber biodegradable material, which comprises the following steps: (1) carrying out cellulase and pectinase enzymolysis and alkali treatment on coconut shell fibers to obtain pretreated coconut shell fibers; (2) Ramie fiber is carried out low-temperature plasma treatment, then carries out alkali treatment, obtains pretreatment ramie fiber; (3) by weight, get pretreatment coir fiber 10-15 parts, pretreatment ramie fiber 5-10 parts, polylactic acid 50-15 parts 60 parts, 5-8 parts of starch, 3-5 parts of glycerin, 5-8 parts of rubber, for subsequent use; (4) then melt and blend the above-mentioned weighed raw materials on an open mill; The melted blend is kept under pressure, the molding temperature is , and finally it is formed into a plate after being water-cooled, and the composite plant fiber biodegradable material is obtained. The composite plant fiber biodegradable material of the present invention has good comprehensive properties, compared with the composite plant fiber biodegradable material which is treated with alkali alone.

Owner:北京荣宝森瑞塑业有限公司

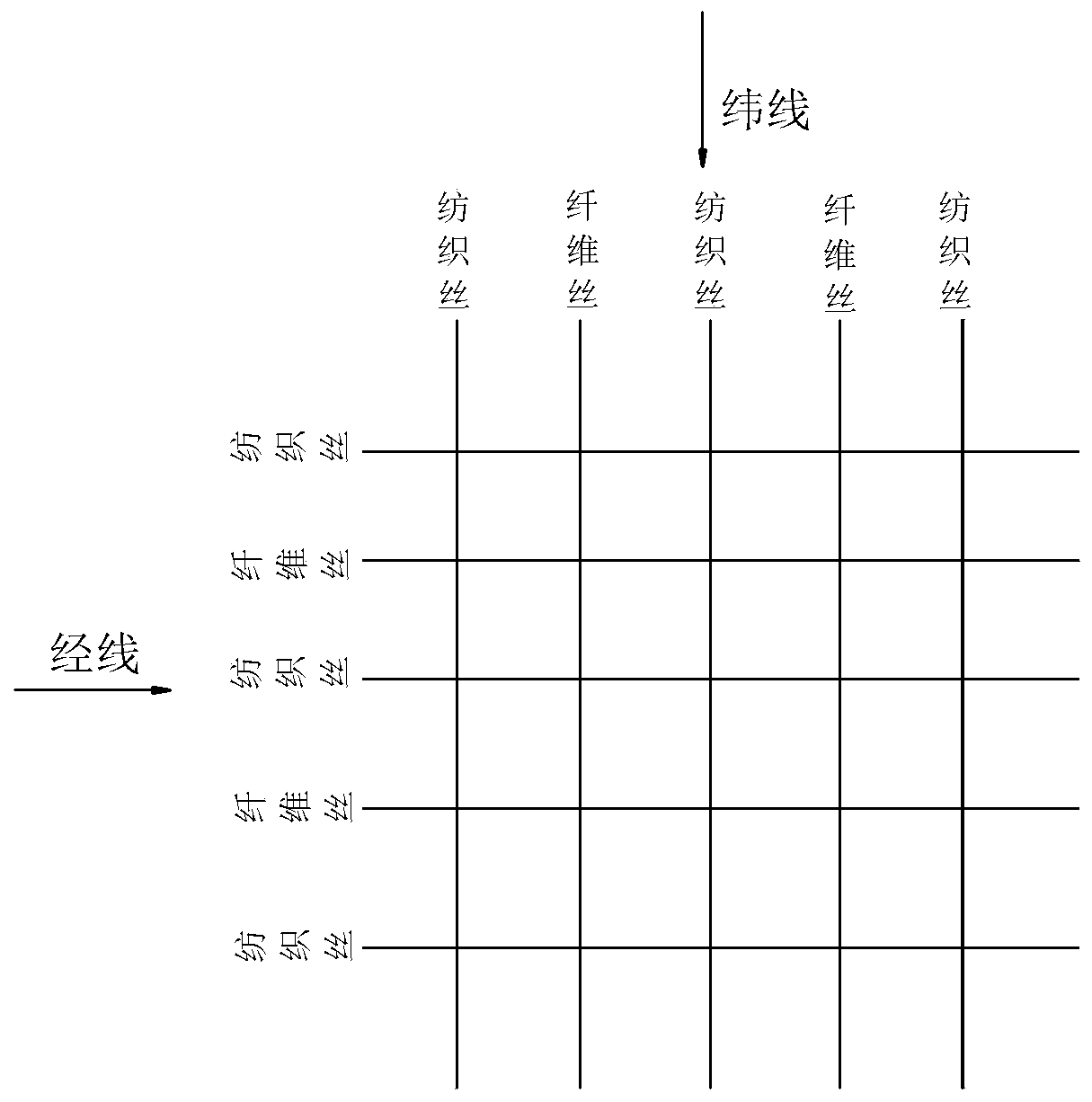

A kind of preparation method of antibacterial anti-mite fabric

ActiveCN110205815BHigh strengthImprove antioxidant capacityBiochemical treatment with enzymes/microorganismsAuxillary apparatusAntioxidant capacitySisal fiber

The invention belongs to the technical field of textiles, and particularly relates to a preparation method of antibacterial anti-mite fabric. The preparation method includes: mixing wormwood fiber, mint fiber, coconut shell fiber, sisal fiber, bamboo fiber and rosemary fiber together by an impurity-removing mixer to make a fiber strip; subjecting the fiber strip to a series of treatment steps to make cellosilk, and making the cellosilk and spun silk into the fabric. The wormwood fiber, the mint fiber, the coconut shell fiber, the sisal fiber, the bamboo fiber and the rosemary fiber are utilized to make the fiber strip by mixing through the impurity-removing mixer, and the fiber strip can serve as a raw material for preparing the antibacterial anti-mite fabric; the fiber strip contains thewormwood fiber, the mint fiber, the bamboo fiber and the rosemary fiber, thereby having good antibacterial and anti-mite performance; due to the coconut shell fiber and the sisal fiber, the fiber strip has the antibacterial and anti-mite performance and also has high toughness, strength and antioxidation ability, and strength of the antibacterial anti-mite fabric is improved.

Owner:SHENZHEN ELLASSAY FASHION CO LTD

Manufacturing and processing technology for electric stay insulator

ActiveCN113979733AAlleviate volume changesUniform and stable tissueCeramicsBoron nitrideFumed silica

The invention discloses a manufacturing and processing technology for an electric stay insulator, and relates to the technical field of insulators. The technology comprises the following steps: weighing raw materials: Zuoyun soil, a bauxite / modified fumed silica composite material, granite powder, nano boron nitride, a mica powder coated modified nano calcium carbonate composite material, lamellar mica, a potassium titanate whisker coated lignin fiber and coconut fiber composite material, modified bentonite, a zinc oxide / silicone rubber composite material and a sintering aid. The process comprises: premixing the materials except a sintering aid to obtain a premix, putting the premix into a ball mill, and adding water for ball milling to obtain a mixture; sieving, removing iron, squeezing mud, aging, pugging in vacuum, forming, fettling and drying; pre-sintering; crushing the pre-sintered material; and pressing the crushed material and a sintering aid, and sintering a pressed part. The process has the beneficial effects that a prepared insulator has the advantages of high mechanical property, high strength and the like.

Owner:江西凯佳电瓷电器有限公司

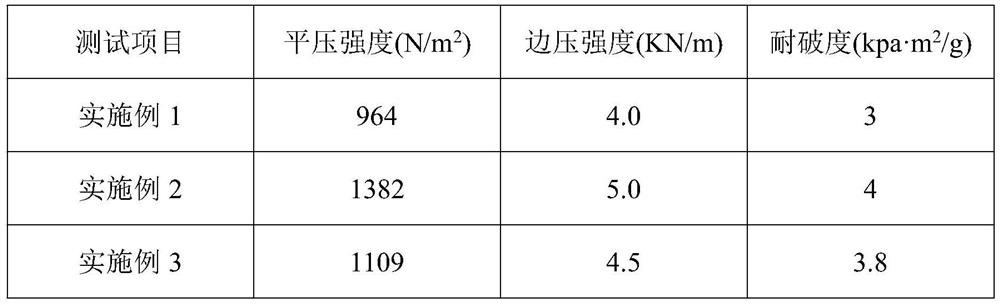

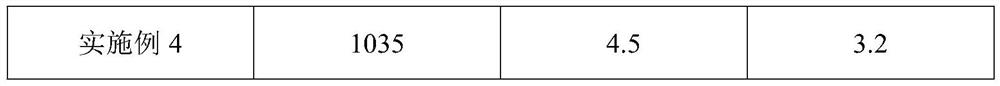

Coconut fiber epoxy resin composite fabric reinforced foundation manufacturing method and foundation

InactiveCN112267451ASolve the durability problemHigh tensile strengthGeotextilesSoil preservationEpoxyEpoxy resin composite

The invention relates to a coconut fiber epoxy resin composite fabric reinforced foundation manufacturing method and a foundation. The coconut fiber epoxy resin composite fabric reinforced foundationmanufacturing method includes the steps that coconut fibers are screened, coconut fiber segments are mixed with epoxy resin, and a composite resin melt is formed after the coconut fiber segments and the epoxy resin are evenly stirred; the composite resin melt is injected into a fabric mold for curing molding; a molded object in the mold is demolded and trimmed to form a composite fabric; the composite fabric is horizontally laid at the bottom of a foundation construction area; soil is backfilled on a first composite fabric layer in a layered mode, and then the composite fabric is horizontallylaid on the multiple layers of backfilled soil; the soil is filled above a second composite fabric layer; and the steps of filling the composite fabric and filling the soil are repeated until designedelevation is reached. The coconut fiber epoxy resin composite fabric reinforced foundation manufacturing method has the advantage that the bearing capacity of the foundation is improved.

Owner:HAINAN UNIVERSITY

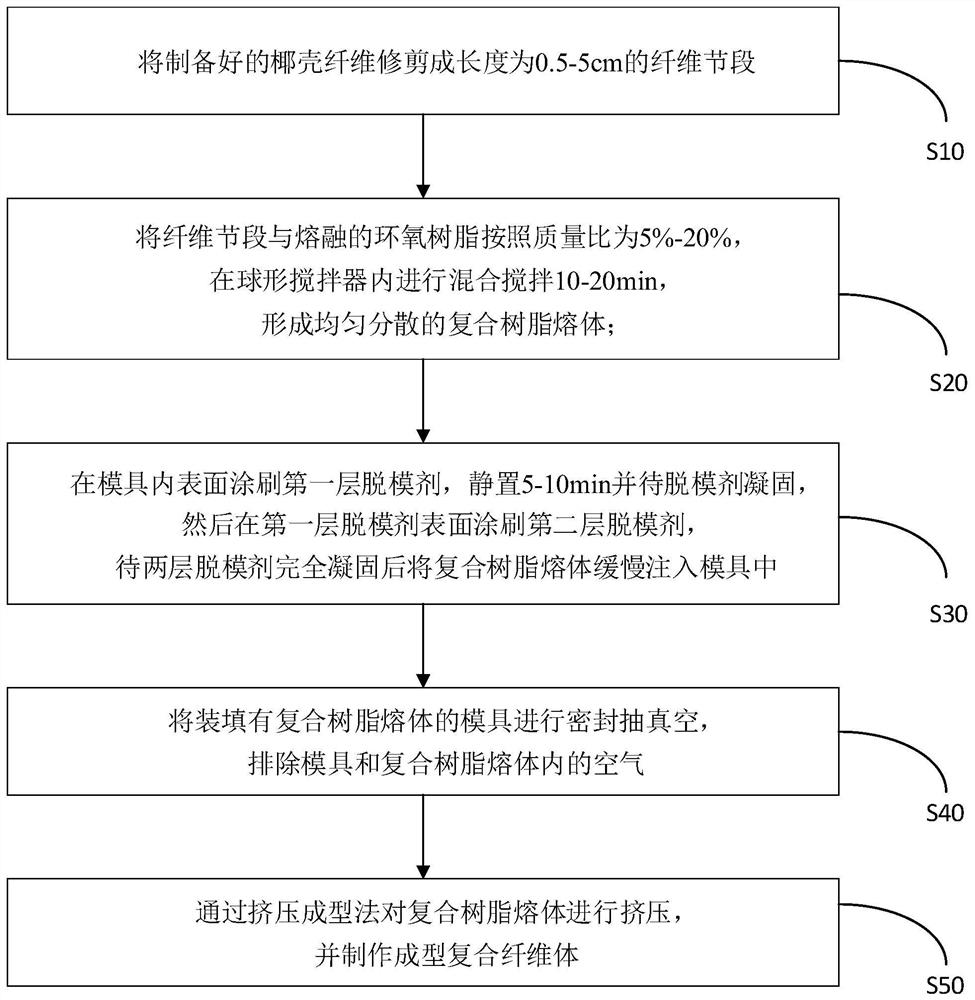

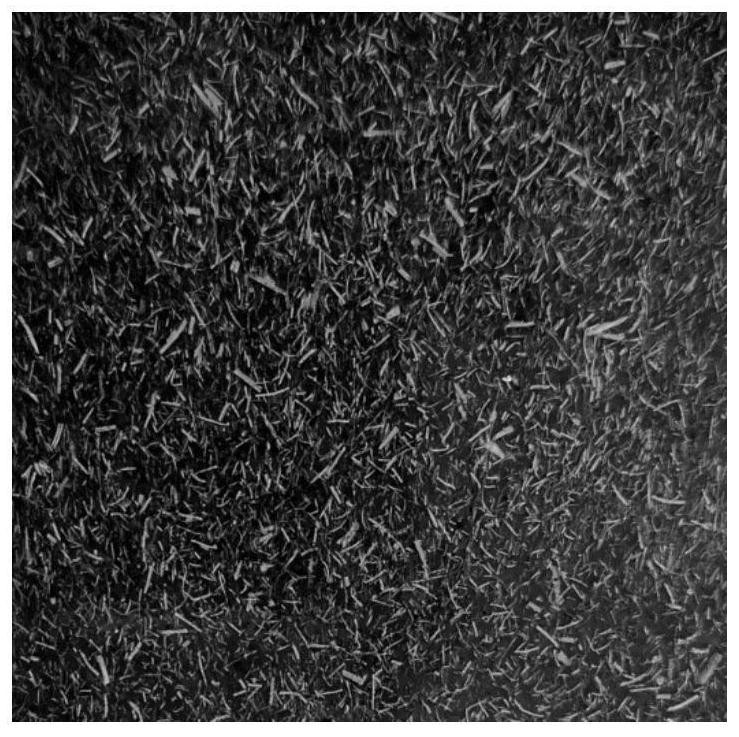

Preparation method of natural coconut fiber reinforced epoxy resin composite fiber

PendingCN112062984AStrong structural stabilityIncreased durabilityVegetable materialEpoxyPolymer science

The invention relates to a preparation method of a natural coconut fiber reinforced epoxy resin composite fiber. The preparation method of the natural coconut shell fiber reinforced epoxy resin composite fiber comprises the steps of trimming the prepared coconut shell fiber into fiber segments with the length of 0.5-5 cm; mixing and stirring the fiber segments and molten epoxy resin for 10-20 minin a spherical stirrer according to the mass ratio of 5%-20%; coating a first layer of release agent on the inner surface of a mold, standing for 5-10min and waiting for solidification of the releaseagent, then coating a second layer of release agent on the surface of the first layer of release agent, and slowly injecting the composite resin melt into the mold after the two layers of release agents are completely solidified; sealing and vacuumizing the mold filled with the composite resin melt; and extruding the composite resin melt through an extrusion molding method, and manufacturing a molded composite fiber body. The preparation method of the natural coconut fiber reinforced epoxy resin composite fiber has the advantage of high durability.

Owner:HAINAN UNIVERSITY

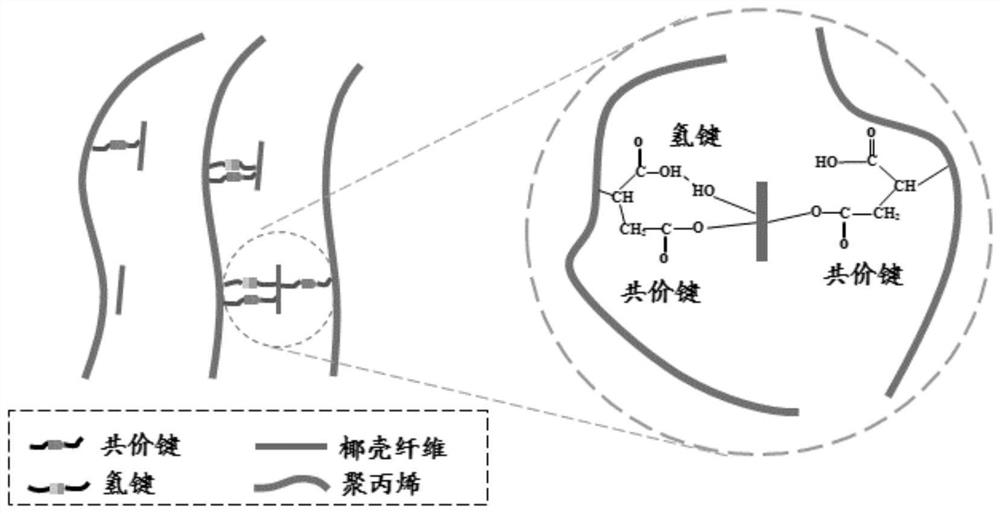

Filamentous-appearance high-performance flame-retardant coconut fiber modified polypropylene composite material as well as preparation method and application thereof

The invention provides a filamentous-appearance high-performance flame-retardant coconut fiber modified polypropylene composite material as well as a preparation method and an application thereof. Themodified polypropylene composite material is prepared from the following components in percentage by mass: 50-74.6% of polypropylene, 20-40% of flame-retardant coconut fiber, 3-7% of talcum powder, 2-4% of a compatilizer, 0.2-0.5% of an antioxidant and 0.2-0.4% of a lubricant; and the material is prepared by adopting melt blending and molding processing methods. According to the preparation method, the flame-retardant coconut fibers are obtained by utilizing NaOH and AlCl3 solution treatment, and a NaOH solution treatment of the coconut fibers and compatibilization of the compatilizer are combined, so that the modified polypropylene composite material has excellent flame-retardant property and mechanical property through cooperation, and the problem that the fiber filler modified polypropylene composite material is easy to warp is solved, and the product has a special filamentous appearance and can be widely applied to the fields of home furnishing, decoration and the like.

Owner:WANHUA CHEM (SICHUAN) CO LTD +2

High-strength environment-friendly carton and preparation method thereof

The invention discloses a high-strength environment-friendly carton and a preparation method thereof. The high-strength environment-friendly carton is finally obtained through pulping, papermaking and hot press molding. The paper base is reinforced through the synergistic effect of the two kinds of environment-friendly fibers, the mechanical strength of the carton is enhanced, the adopted polylactic acid / polycaprolactone composite fibers have biodegradability, polylactic acid and polycaprolactone are mixed, so that the brittleness of polylactic acid is reduced, the toughness is enhanced; and the coconut shell fibers modified through magnesium oxide act together, therefore, the high-strength environment-friendly carton has excellent mechanical strength.

Owner:张功定

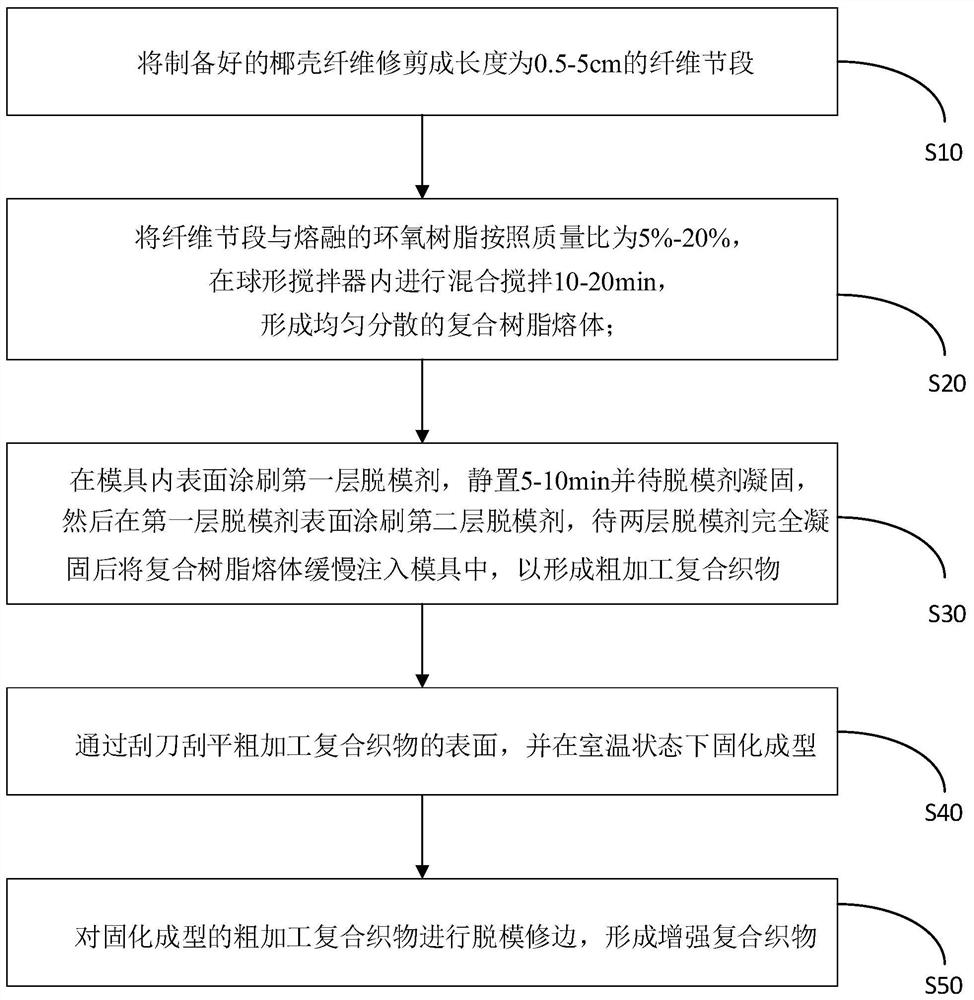

Preparation method of natural coconut fiber reinforced epoxy resin composite fabric

The invention relates to a preparation method of a natural coconut fiber reinforced epoxy resin composite fabric. The preparation method of the natural coconut shell fiber reinforced epoxy resin composite fabric comprises the steps of trimming prepared coconut shell fibers into fiber segments with the length of 0.5-5 cm; mixing and stirring the fiber segments and molten epoxy resin for 10-20 min in a spherical stirrer according to the mass ratio of 5%-20% to form uniformly-dispersed composite resin melt; coating a first layer of release agent on the inner surface of the mold, standing, coatinga second layer of release agent after the release agent is solidified, and slowly injecting the composite resin melt into the mold after the two layers of release agents are completely solidified; scraping and roughly machining the surface of the composite fabric through a scraper, and conducting curing forming in the room temperature state; and demolding and trimming the cured rough machining composite fabric to form the reinforced composite fabric. The preparation method of the natural coconut fiber reinforced epoxy resin composite fabric has the advantage of high durability.

Owner:HAINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com