A kind of preparation method of antibacterial anti-mite fabric

A fabric and slurry technology, applied in the field of preparation of antibacterial and anti-mite fabrics, can solve the problems of short effective time of antibacterial and anti-mite fabrics, poor strength of antibacterial and anti-mite fabrics, etc., and achieve the effects of improving effective time, good toughness and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] like Figure 1 to Figure 3 Shown, the preparation method of a kind of antibacterial anti-mite fabric of the present invention, the method comprises the following steps:

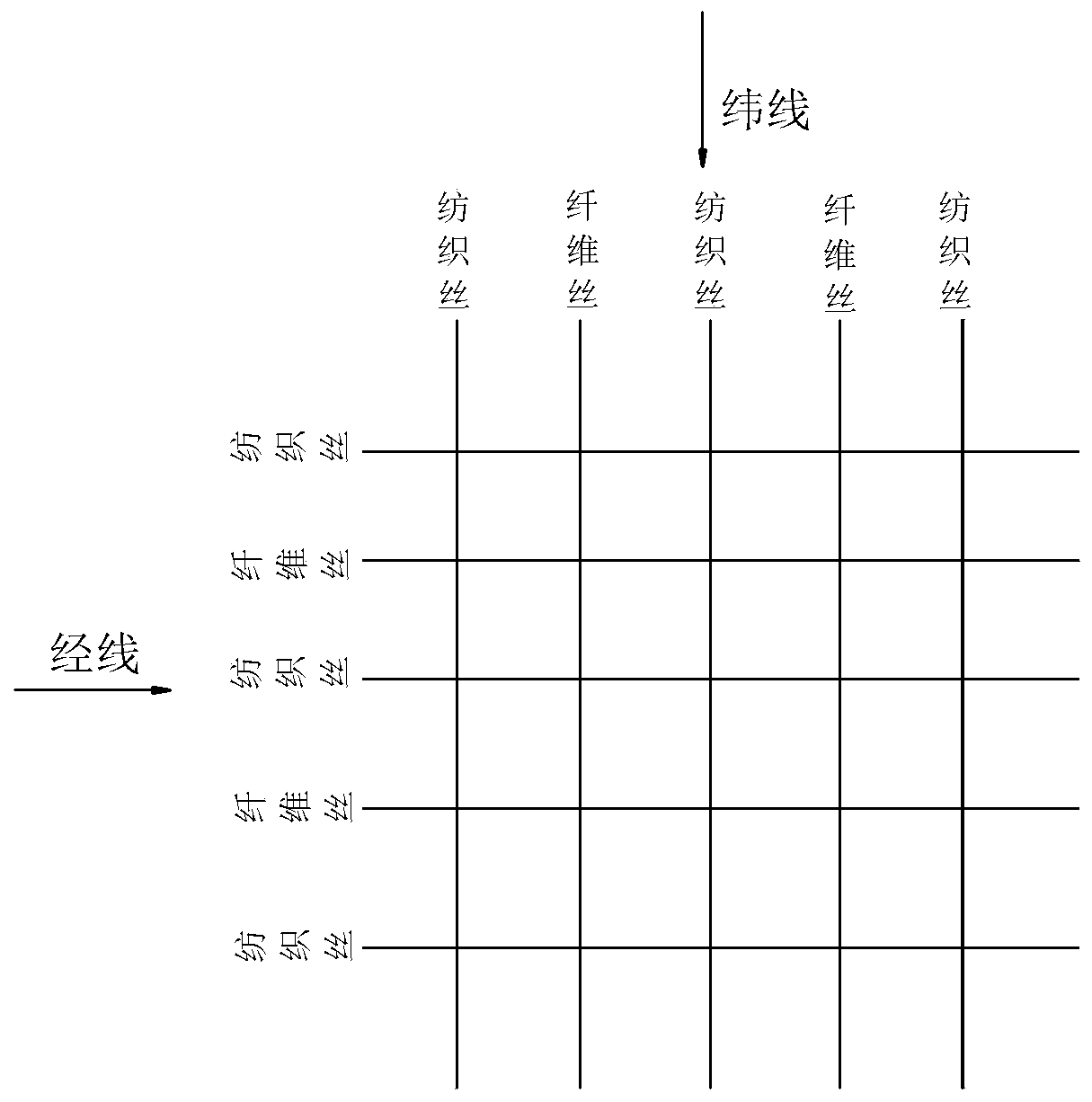

[0029] S1: Mix wormwood fiber, mint fiber, coconut shell fiber, sisal fiber, bamboo fiber and rosemary fiber through a sundries-removing mixer to make fiber strips;

[0030]Wormwood contains volatile oil, flavonoids, semiterpene lactones, coumarin derivatives, triterpenes, etc., which have antifungal and antibacterial properties, and also have the effect of preventing mites; mint contains eight kinds of catechin naphtholic acids , has a good antibacterial effect; the cellulose content in the coconut shell fiber is high, and the hemicellulose content is very small, so the coconut shell fiber has excellent mechanical properties; sisal fiber is a hard fiber, and the fiber extracted from sisal has a texture Tough and tough, bamboo fiber has natural antibacterial, antibacterial, anti-mite, and deodorant fu...

specific Embodiment approach

[0034] As a specific embodiment of the present invention, the diameter of the wormwood fiber is controlled at 200-600 μm, the length is controlled at 12-20 cm, the diameter of the coconut shell fiber is controlled at 100-450 μm, the length is controlled at 20-35 cm, the diameter of the sisal fiber Controlled at 450-700μm, length controlled at 15-20cm, bamboo fiber diameter controlled at 600-700μm, length controlled at 20-25cm, rosemary fiber diameter controlled at 150-400μm, length controlled at 15-30cm, sweet orange blossom The fiber diameter is controlled at 600-700 μm, and the length is controlled at 20-25 cm.

[0035] As a specific embodiment of the present invention, the parts by weight of the wormwood fiber are 30-40 parts, the parts by weight of the mint fiber are 20-30 parts, and the parts by weight of the coconut shell fiber are 20-40 parts, The parts by weight of the sisal fiber are 30-40 parts, the parts by weight of the bamboo fiber are 30-40 parts, and the parts b...

Embodiment approach

[0039] As a specific embodiment of the present invention, the spun yarn is polyester yarn or cotton yarn.

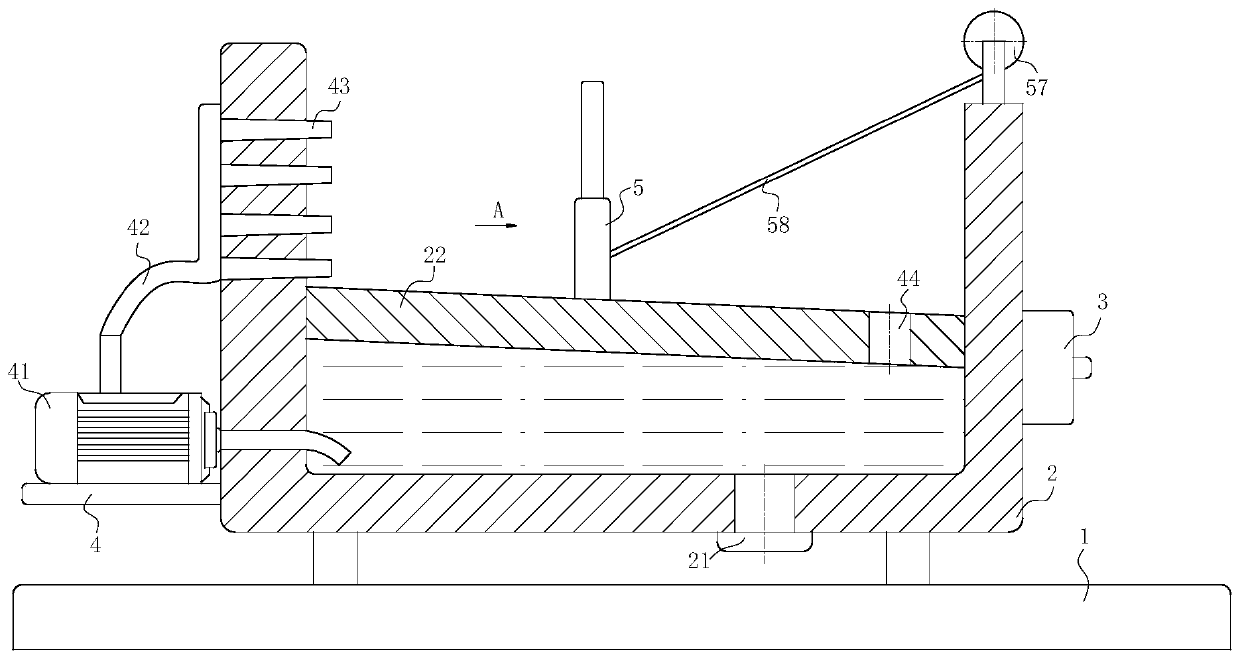

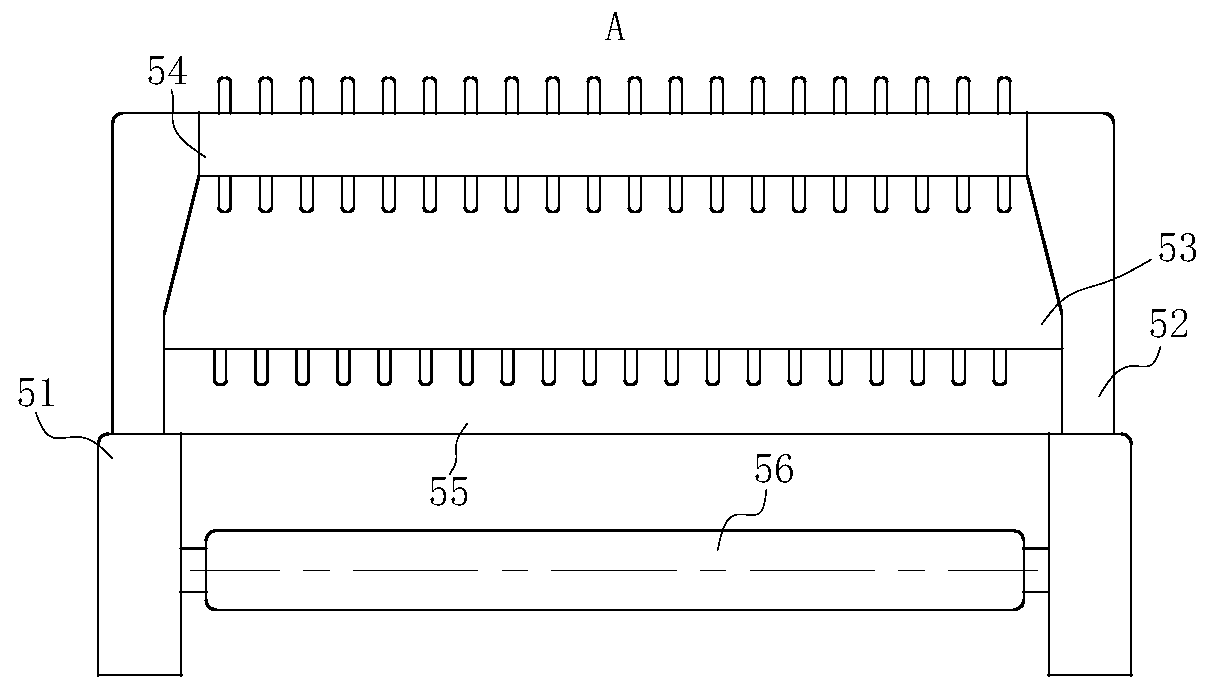

[0040] A weaving device, the weaving device is used to weave the above-mentioned textile filaments and fiber filaments with a starch layer into a fabric; the textile device includes a support base 1, a water storage tank 2 and a controller 3; the water storage tank The bottom of the water tank 2 is provided with a water exchange port 21, the water storage tank 2 is fixedly connected to the support seat 1, and the inclined plate 22 is fixedly connected in the water storage tank 2; a fixed seat 4 is fixedly connected to one side of the water storage tank 2, and the fixed seat 4 is welded There is a water pump 41; the water inlet end of the water pump 41 is located in the water storage tank 2, and the water outlet end communicates with the inclined pipe 43 placed above the water storage tank 2 through a hose 42; the side of the inclined plate 22 away from the inclined pipe 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com