High-strength environment-friendly carton and preparation method thereof

An environmentally friendly, high-strength technology, used in packaging paper, wrapping paper, textiles and papermaking, etc., can solve problems such as environmental pollution, and achieve the effect of improving mechanical properties, good biodegradability, and enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

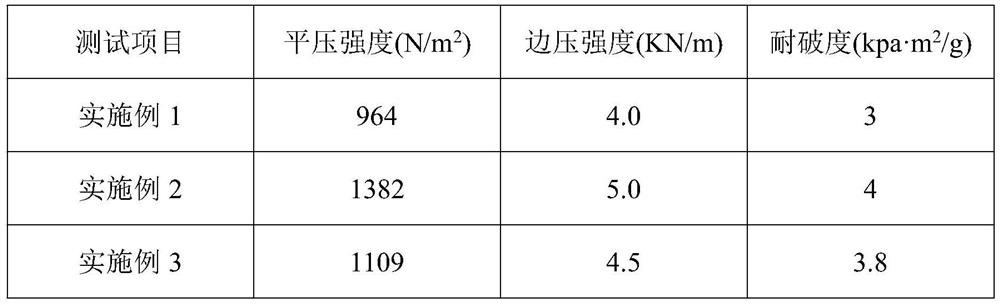

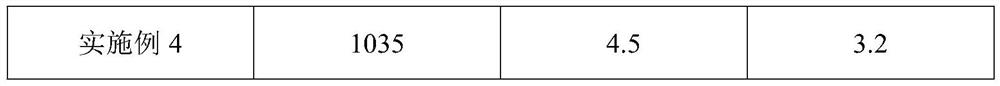

Examples

Embodiment 1

[0023] A kind of preparation method of high-strength environment-friendly type carton, concrete steps are as follows:

[0024] (1) Put corn stalks and dried rice straws into pieces and decoct them in water for 6 hours, and filter to obtain pulp;

[0025] (2) use a beater to beat the pulp, and the degree of beating is 45 ° SR;

[0026] (3) Add polylactic acid / polycaprolactone composite fiber and modified coconut fiber to pulp and continue beating for 4h; paper pulp, polylactic acid / polycaprolactone composite fiber and modified coconut fiber mass ratio are 100:18: 8.

[0027] (4) Inject the mixed pulp into the paper machine for papermaking, and dry the paper sheets obtained by papermaking. The drying temperature is 80 ° C, and the drying time is 6 hours;

[0028] (5) Heat-press the dried paper to make a high-strength environment-friendly carton.

[0029] The preparation method of polylactic acid / polycaprolactone composite fiber is as follows: after drying polylactic acid and ...

Embodiment 2

[0033] A kind of preparation method of high-strength environment-friendly type carton, concrete steps are as follows:

[0034] (1) Put corn stalks and dried rice straws into pieces and decoct them in water for 6 hours, and filter to obtain pulp;

[0035] (2) use a beater to beat the pulp, and the degree of beating is 50 ° SR;

[0036] (3) Add polylactic acid / polycaprolactone composite fiber and modified coconut fiber to pulp and continue beating for 4h; paper pulp, polylactic acid / polycaprolactone composite fiber and modified coconut fiber mass ratio are 100:20: 14.

[0037] (4) Inject the mixed pulp into the paper machine for papermaking, and dry the paper sheets obtained by papermaking. The drying temperature is 70 ° C, and the drying time is 6 hours;

[0038] (5) Heat-press the dried paper to make a high-strength environment-friendly carton.

[0039] The preparation method of polylactic acid / polycaprolactone composite fiber is as follows: after drying polylactic acid and...

Embodiment 3

[0043] A kind of preparation method of high-strength environment-friendly type carton, concrete steps are as follows:

[0044] (1) Put corn stalks and dried rice straws into pieces and decoct them in water for 6 hours, and filter to obtain pulp;

[0045] (2) use a beater to beat the pulp, and the degree of beating is 40 ° SR;

[0046] (3) Add polylactic acid / polycaprolactone composite fiber and modified coconut fiber to pulp and continue beating for 3h; paper pulp, polylactic acid / polycaprolactone composite fiber and modified coconut fiber mass ratio are 100:20: 13.

[0047] (4) Inject the mixed pulp into the paper machine for papermaking, and dry the paper sheets obtained by papermaking. The drying temperature is 80 ° C, and the drying time is 4 hours;

[0048] (5) Heat-press the dried paper to make a high-strength environment-friendly carton.

[0049] The preparation method of polylactic acid / polycaprolactone composite fiber is as follows: after drying polylactic acid and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| edge compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com