Environment-friendly regenerated brick and preparation process thereof

A recycled brick, environmentally friendly technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of irreparable, impact on the strength of recycled bricks, etc., to improve utilization rate, high density, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

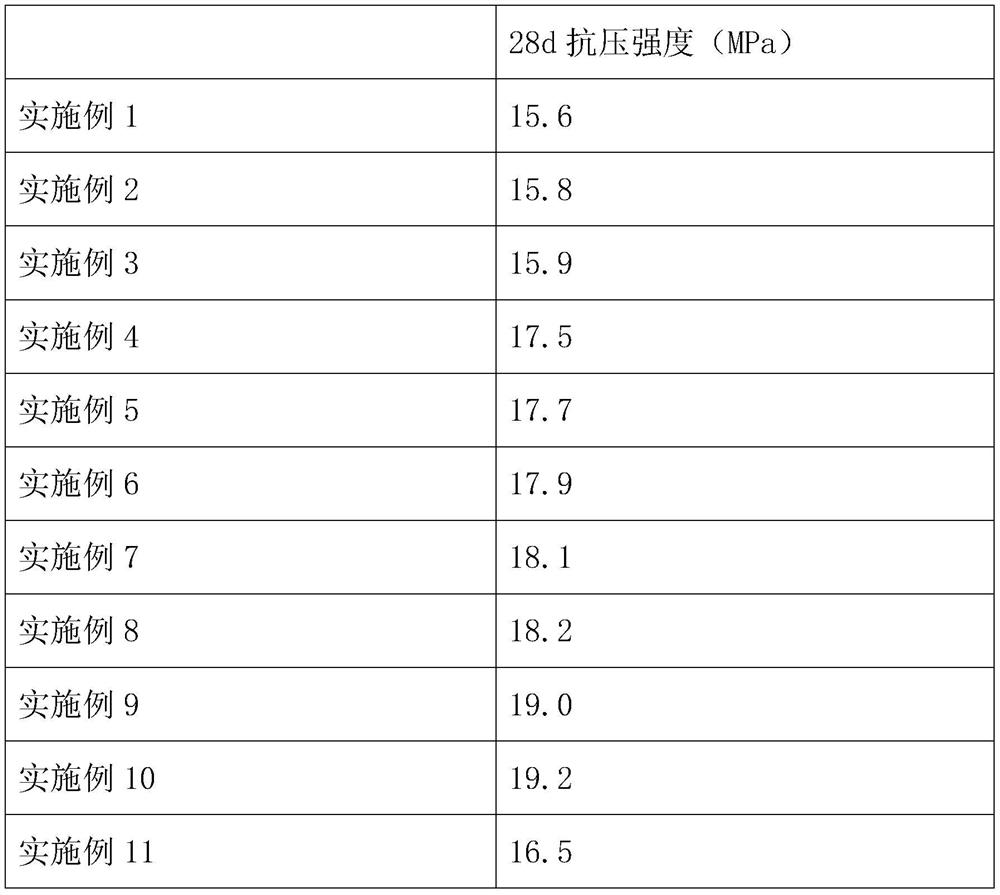

Examples

Embodiment 1

[0047] This embodiment discloses a method for preparing environmentally friendly regenerated bricks, including the following steps:

[0048] Step a, crush the construction waste, and use a screen to screen out crushed stones with a particle size of 16-20mm, crushed stones with a particle size of 1-5mm and stone powder with a particle size of 0.1-0.5mm, and take crushed stones with a particle size of 16-20mm 60kg of stone, 20kg of crushed stone with a particle size of 1-5mm and 20kg of stone powder with a particle size of 0.1-0.5mm are mixed evenly to form recycled aggregate and set aside.

[0049] Add 6kg of Portland cement, 1kg of water, 0.5kg of nano-silica fume, and 0.1kg of fatty alcohol polyoxyethylene ether into the concrete mixer in sequence, stir at a speed of 50r / min, and mix evenly to obtain a prefabricated mixture.

[0050] Then take 92kg of the recycled aggregates prepared above and put them into a steel container, then add the prefabricated mixture into the steel ...

Embodiment 2-3

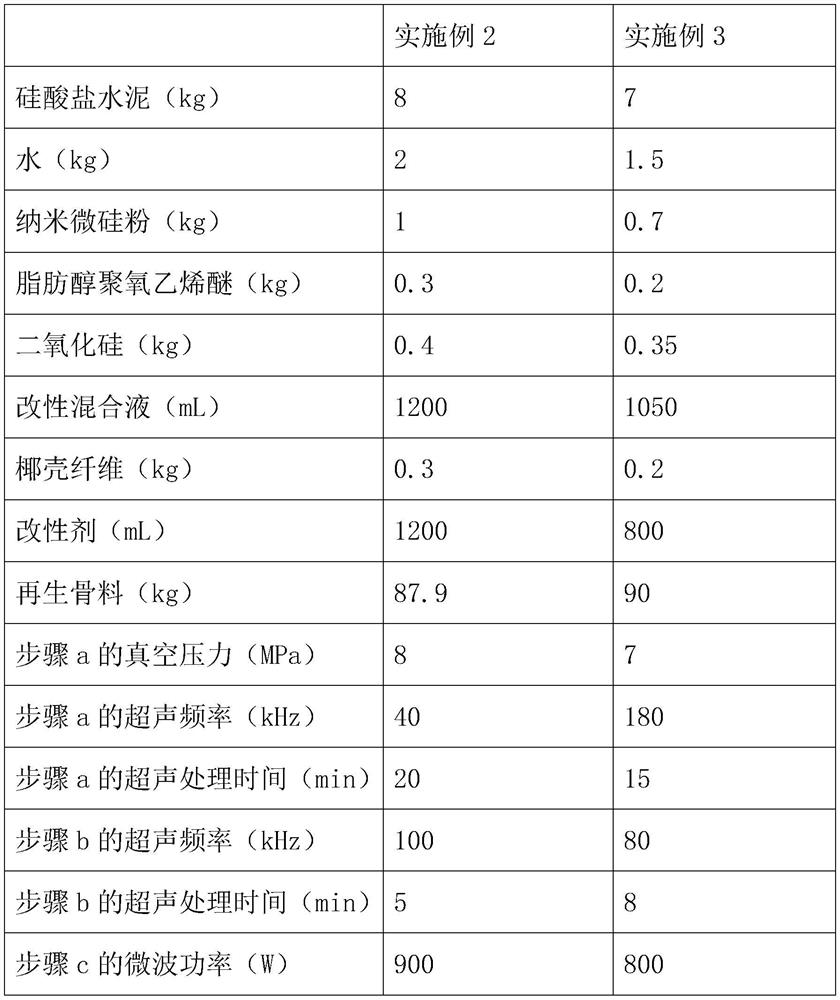

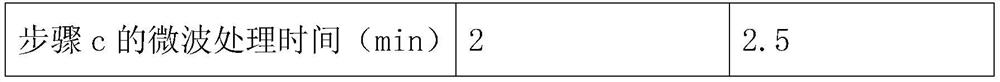

[0056] The difference from Example 1 is that the reaction conditions such as the addition amount of each component, the pressure of each step, the ultrasonic frequency, temperature and time are different, and the unit of the addition amount of each component is kg or mL. See Table 2 for details.

[0057] Among them, the modified mixed liquid is formed by uniformly mixing 800mL tetraethoxysilane, 200mL ether and 300mL ethanol; the modifier is formed by uniformly mixing 1000mL didecyldimethylammonium chloride and 400mL benzene.

[0058] Table 2

[0059]

[0060]

Embodiment 4

[0062] The difference from Example 3 is that the recycled aggregate is uniformly mixed with 60kg of gravel with a particle size of 12-15mm, 20kg of crushed stone with a particle size of 5-10mm, and 20kg of stone powder with a particle size of 0.05-0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com