Pesticide bottle and preparation method thereof

A pesticide bottle and outer layer technology, applied in chemical instruments and methods, epoxy glue, adhesives, etc., can solve problems such as strength to be improved, glass bottles with heavy tare, and increased transportation costs, so as to enhance toughness and protect the environment , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

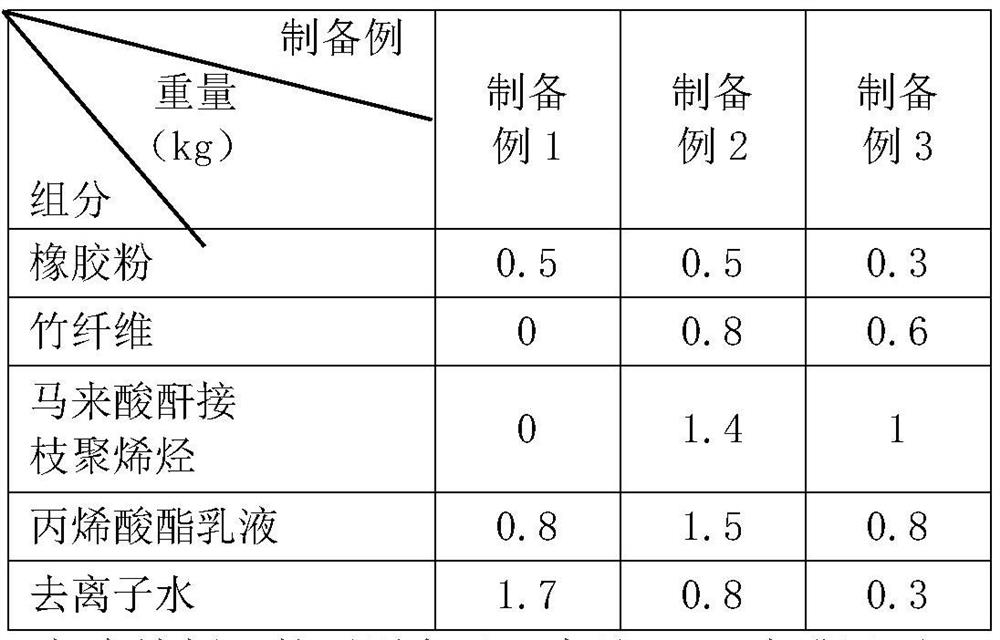

[0064] Preparation example 1: a kind of anti-cracking agent, included concrete component and weight are as shown in table 2, are made by following steps:

[0065] (1) Add deionized water and rubber powder into the stirring tank and stir at a stirring speed of 800r / min; obtain the first mixture after stirring evenly;

[0066] (2) Mix the first mixture with the acrylic emulsion, control the temperature to 55° C., and stir at a stirring speed of 1000 r / min, and obtain an anti-cracking agent after stirring evenly.

preparation example 2

[0067] Preparation example 2: a kind of anti-cracking agent, included concrete component and weight are as shown in table 2, are made by following steps:

[0068] (1) adding deionized water, bamboo fiber, and rubber powder into the mixing tank and stirring, the stirring speed is 900r / min, and the first mixture is obtained after stirring;

[0069] (2) Mixing and stirring the acrylate emulsion and the maleic anhydride grafted polyolefin in another stirring tank, the stirring speed is 900r / min, and the second mixture is obtained after being uniformly stirred;

[0070] (3) Mix and stir the first mixture and the second mixture, raise the temperature to 55° C., control the stirring speed to 1200 r / min, and obtain the anti-cracking agent after stirring evenly.

preparation example 3

[0071] Preparation example 3: a kind of anti-cracking agent, and the difference of preparation example 2 is that the weight of each component is different, and the concrete component that comprises and weight are as shown in table 2.

[0072] Concrete components and weight of table 2 preparation example 1-3

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com