Preparation method and application of coconut shell charcoal/three-dimensional graphene composite material

A technology of composite materials and graphene, which is applied in the field of composite materials and can solve problems such as easy cracking of three-dimensional graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

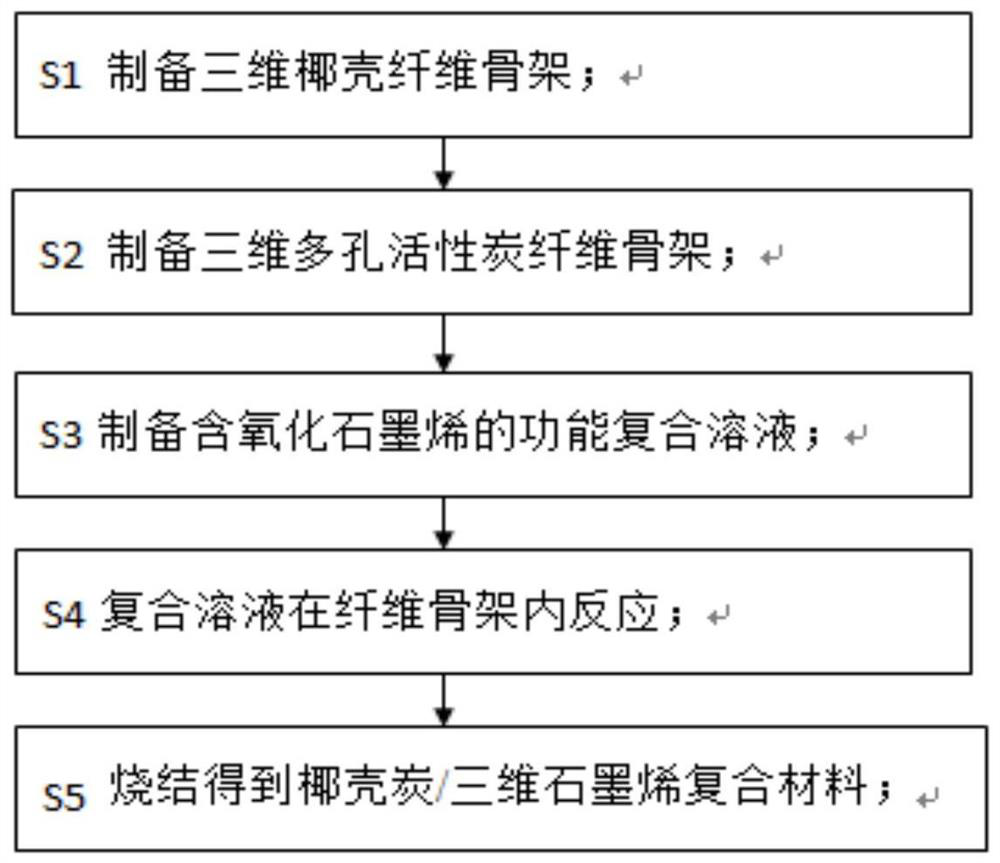

Method used

Image

Examples

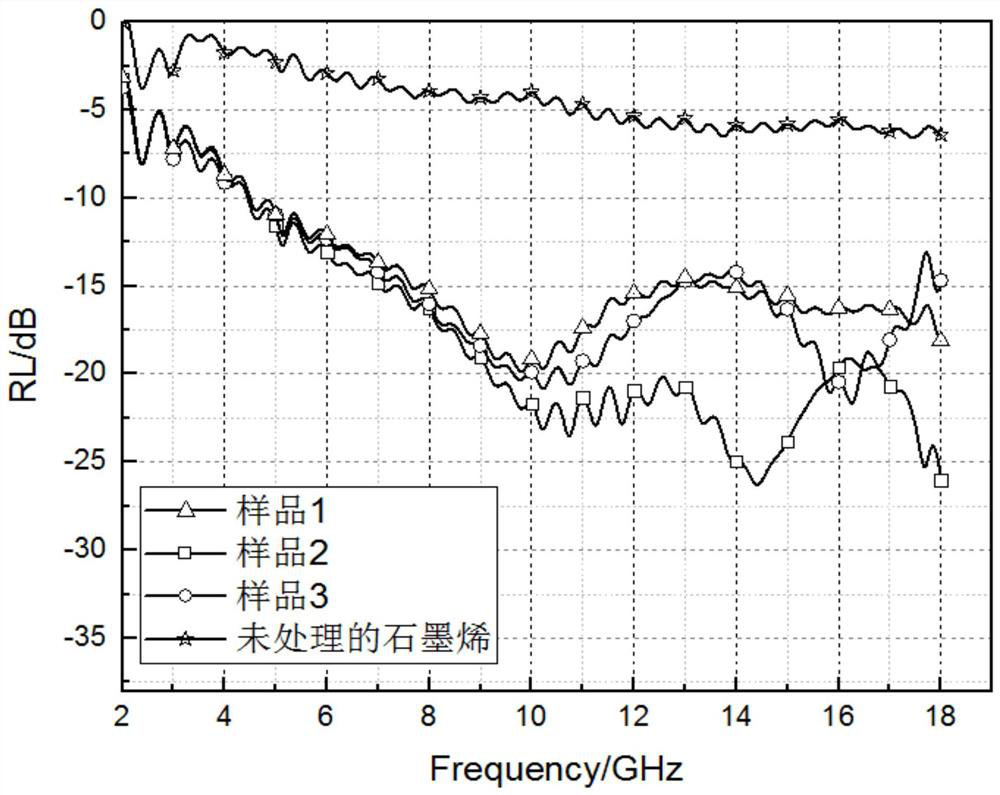

Embodiment 1

[0026] S1 flattens the coconut shell in advance, washes and dries it and soaks it in sodium hydroxide solution for 24 hours. The molar concentration of the sodium hydroxide solution is 0.02mol / L to obtain a three-dimensional coconut shell fiber skeleton structure; Carbonization under an inert atmosphere, the carbonized three-dimensional coconut shell fiber skeleton is intruded into sodium hydroxide, the molar concentration of sodium hydroxide is 10mol / L, and under high pressure, the strong alkali solution is fully pressed into the coconut shell fiber skeleton for expansion. Pore and activation treatment to obtain a three-dimensional porous activated carbon fiber skeleton, the pore diameter of the obtained three-dimensional porous activated carbon fiber skeleton is 50um. S3 adopts Humers method to prepare graphene oxide dispersion liquid, the concentration of gained graphene oxide is 1mg / ml, the D50 of graphene oxide in described graphene oxide solution90%, toward oxidation T...

Embodiment 2

[0029]S1 flatten the coconut shell in advance, wash and dry it, soak it in phosphoric acid solution for 48 hours, the molar concentration of phosphoric acid solution is 10mol / L, and obtain the three-dimensional coconut shell fiber skeleton structure; S2 carbonize the three-dimensional coconut shell fiber skeleton under an inert atmosphere, Invade the carbonized three-dimensional coconut shell fiber skeleton into hydrochloric acid, the molar concentration of hydrochloric acid is 1mol / L, under the action of high pressure, fully press the hydrochloric acid solution into the coconut shell fiber skeleton, and carry out hole expansion and activation treatment under the action of high pressure steam A three-dimensional porous activated carbon fiber skeleton is obtained, and the pore diameter of the obtained three-dimensional porous activated carbon fiber skeleton is 100 um. S3 adopts humers method to prepare graphene oxide dispersion liquid, the concentration of gained graphene oxide ...

Embodiment 3

[0031] S1 flatten the coconut shell in advance, wash and dry it, soak it in ammonia solution for 48 hours, the molar concentration of ammonia solution is 10mol / L, and obtain the three-dimensional coconut shell fiber skeleton structure; S2 carbonize the three-dimensional coconut shell fiber skeleton under an inert atmosphere, Invade the carbonized three-dimensional coconut shell fiber skeleton into the sodium hydroxide solution, the molar concentration of sodium hydroxide is 5mol / L, under the action of high pressure, fully press the hydrochloric acid solution into the coconut shell fiber skeleton, and carry out the process under the action of high pressure steam The three-dimensional porous activated carbon fiber skeleton is obtained through hole expansion and activation treatment, and the pore diameter of the obtained three-dimensional porous activated carbon fiber skeleton is 10 μm. S3 adopts Humers method to prepare graphene oxide dispersion liquid, the concentration of gaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com