Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Co immobilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

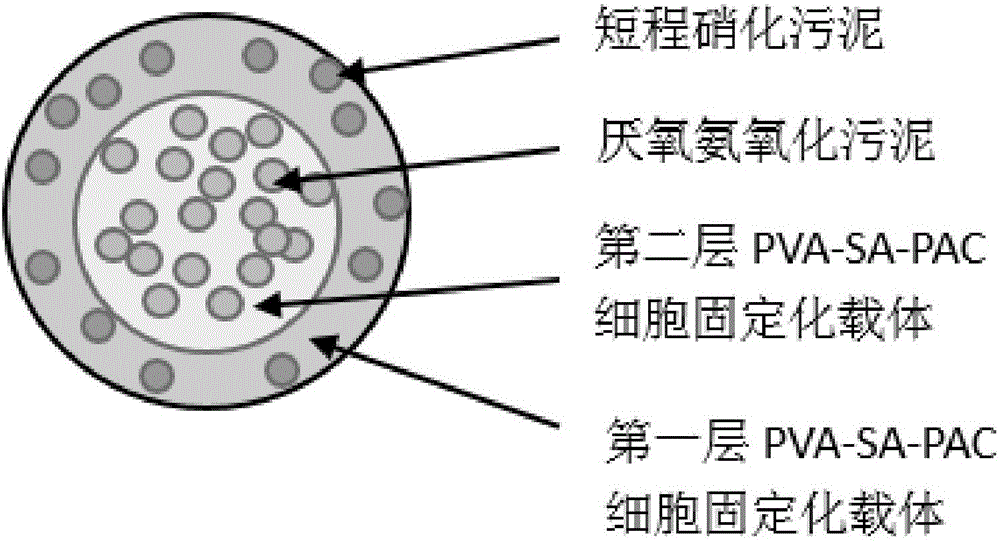

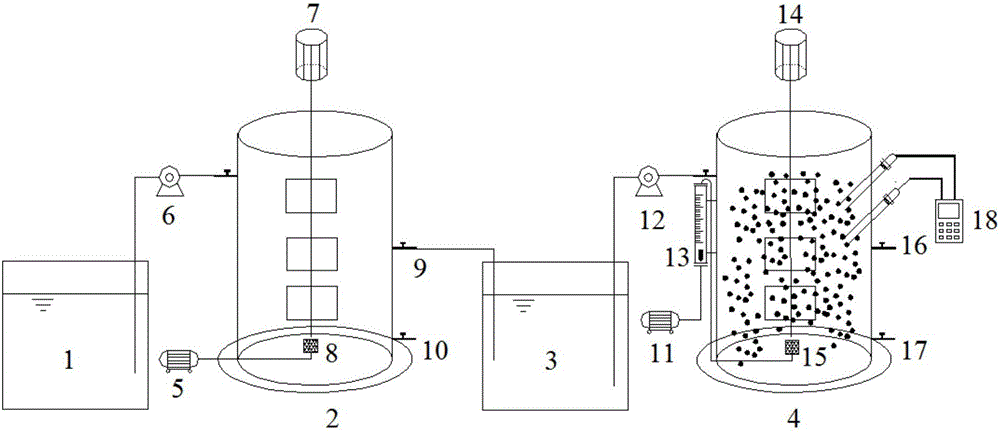

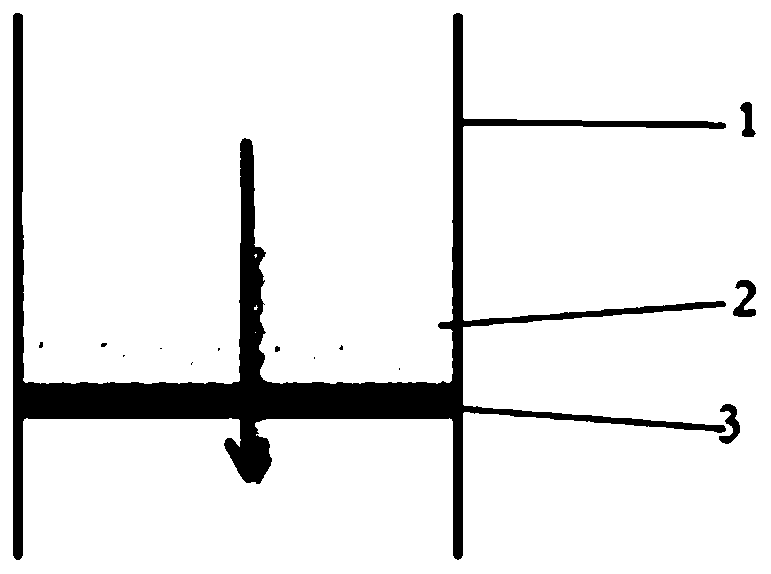

Method for co-immobilizing anaerobic ammoxidation bacteria-short-cut nitrobacteria and application thereof

InactiveCN105861479AAchieve coordinated operationStable enrichmentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentPolyvinyl alcoholSludge

A method for co-immobilizing anammox bacteria-short-range nitrifying bacteria and its application belong to the technical field of sewage treatment, using polyvinyl alcohol, sodium alginate and activated carbon as embedding agents to anaerobic ammonium oxidizing bacteria and short-range nitrifying bacteria Layered embedding and fixation, firstly mix equal volumes of anammox sludge and embedding agent uniformly, get anaerobic ammonium oxidation gel pellets after fixation, and then put them into the mixed solution of short-range nitrifying bacteria and embedding agent In the process, anammox-short-range nitrifying bacteria gel pellets were obtained after fixation, and were directly added to the autotrophic denitrification reactor after activation. The present invention uses immobilized microbial technology to co-immobilize anammox bacteria and short-range nitrification bacteria on the same carrier, and stably enrich high-activity anammox and short-range nitrification sludge, so that the biological efficacy of the two bacteria can be coordinated. , to realize the coordinated operation of short-range nitrification reaction and anammox reaction.

Owner:BEIJING UNIV OF TECH

Co-immobilization glucose oxidase/catalase microspheres and application thereof in production of gluconic acid or gluconic salt

InactiveCN102943069AFacilitates covalent attachmentExtended service lifeChemical industryOn/in organic carrierMicrosphereCatalytic oxidation

The invention discloses co-immobilization glucose oxidase / catalase microspheres and application thereof in preparation of gluconic acid (salt) for catalytic oxidation of glucose. The co-immobilization glucose oxidase / the catalase microspheres can effectively promote covalent linkage of carriers and enzyme molecules, immobilization efficiency is improved greatly, service life of immobilization glucose oxidase (GOD) / catalase (CAT) is prolonged remarkably, the co-immobilization glucose oxidase / the catalase microspheres can be used repeatedly, are low in production cost, and facilitate sustainable development. Gluconic acid (salt) prepared by the co-immobilization glucose oxidase / the catalase microspheres is high in yield, reaction condition is temperate, a device is simple and easy to obtain, and the production method is environment-friendly.

Owner:BEIJING UNIV OF CHEM TECH

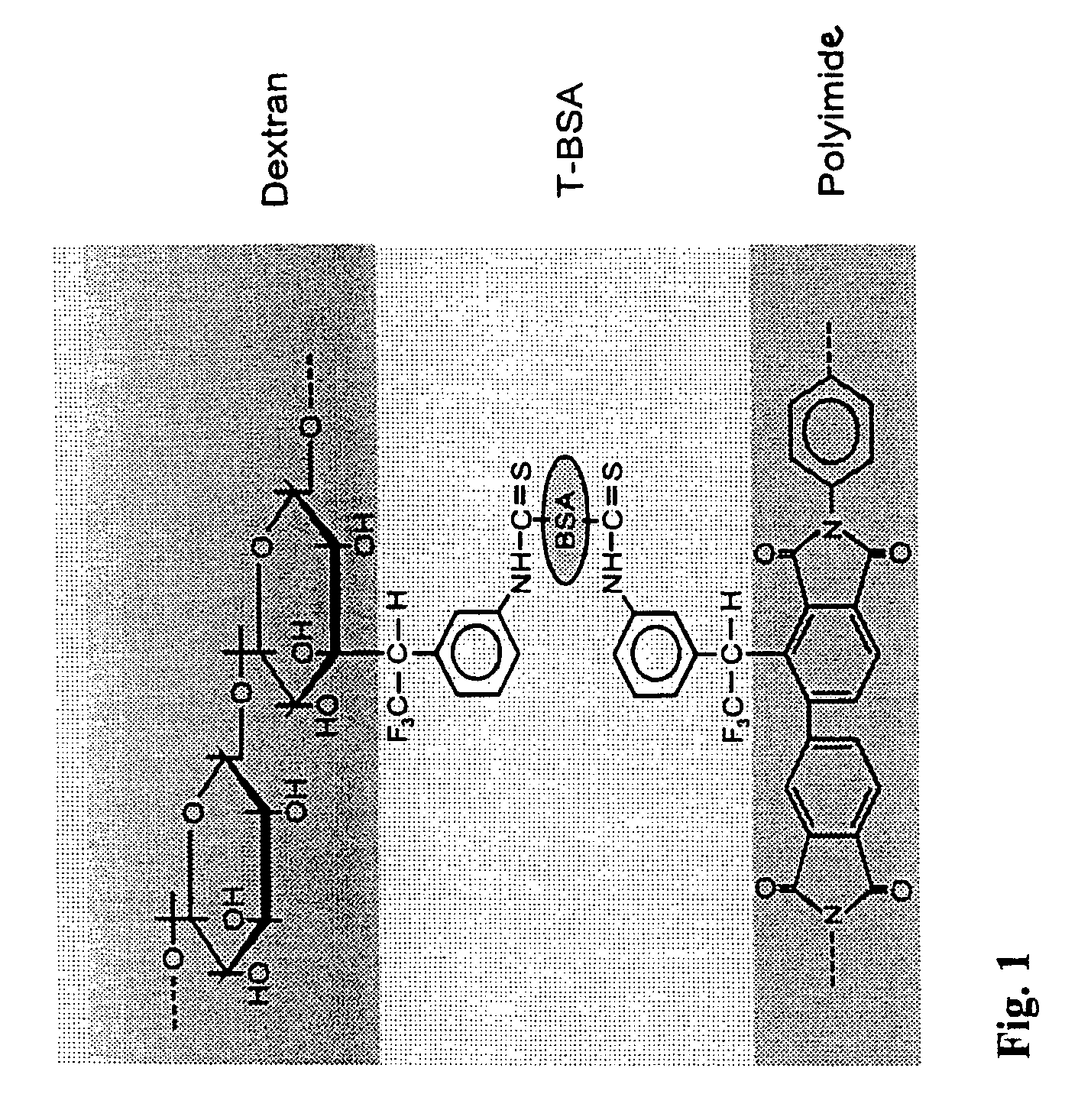

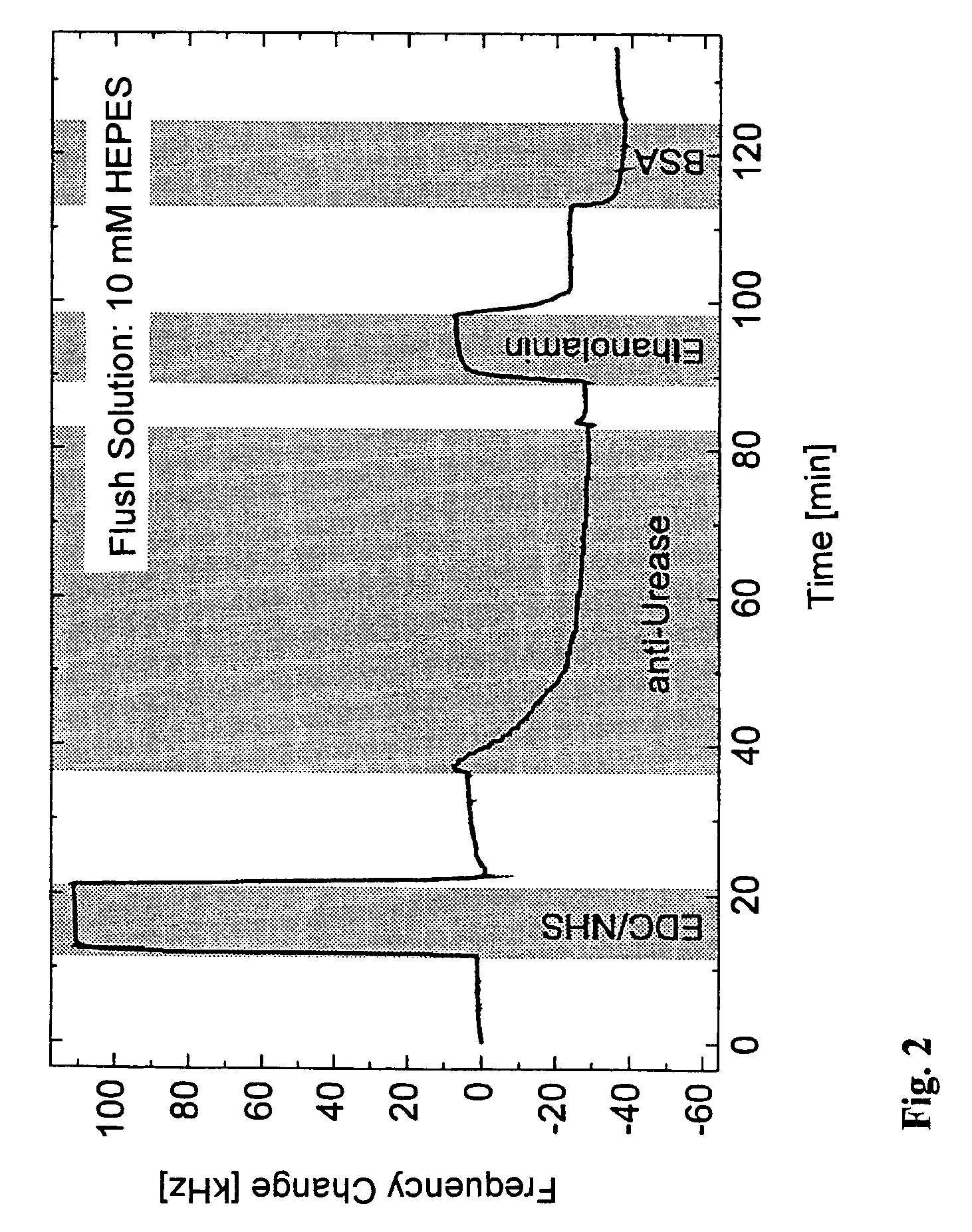

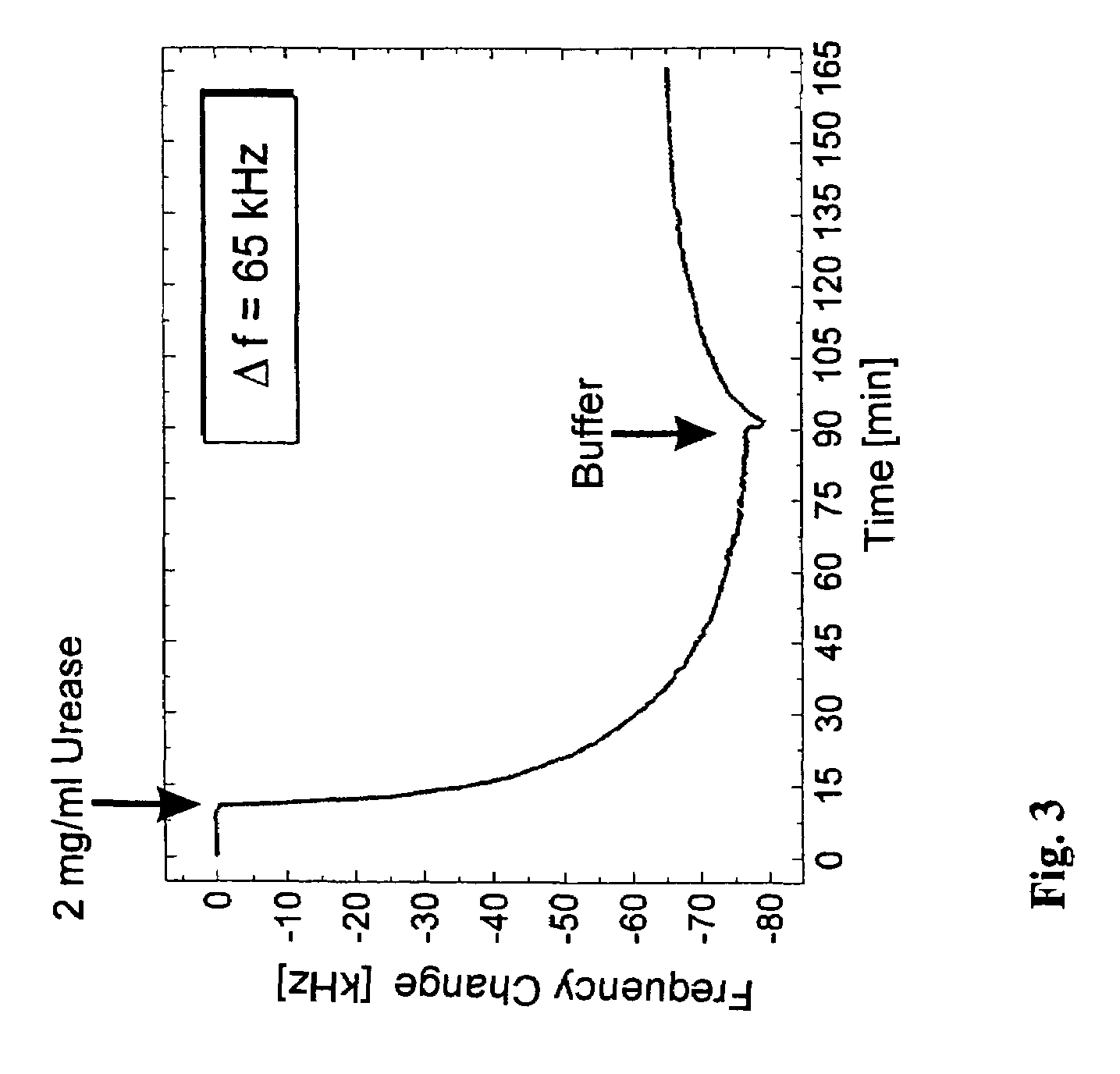

Dextran-coated surface

InactiveUS6974707B1Simple and easily reproducible methodSimple methodMicrobiological testing/measurementWeighing by absorbing componentChemistryCo immobilization

In a dextran coated surface disposed on a carrier, the connections between the dextran and the carrier surface are formed by a photolinker, the dextran coating being attached to the carrier surface by co-immobilization of a mixture of dextran and the photolinker.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

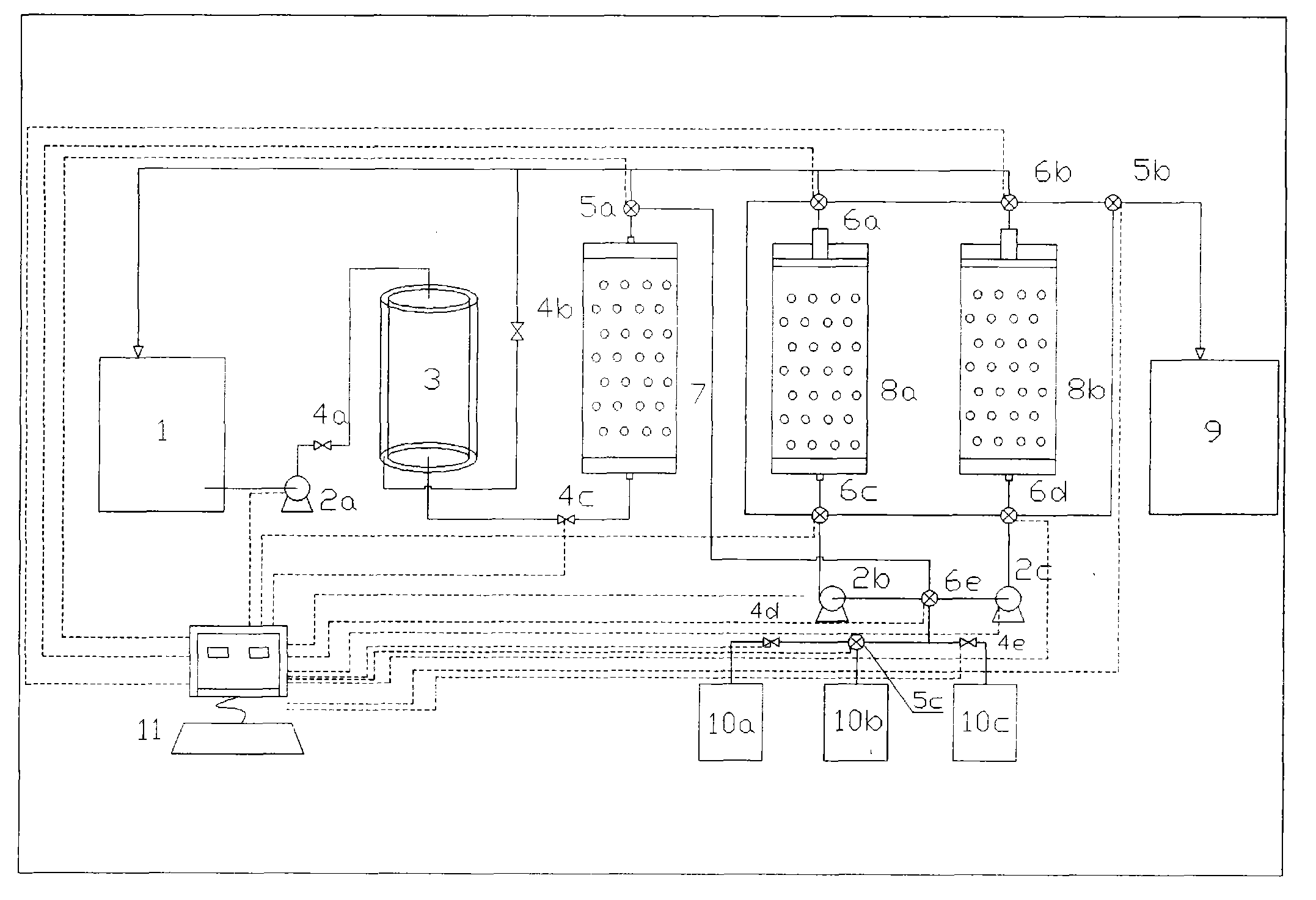

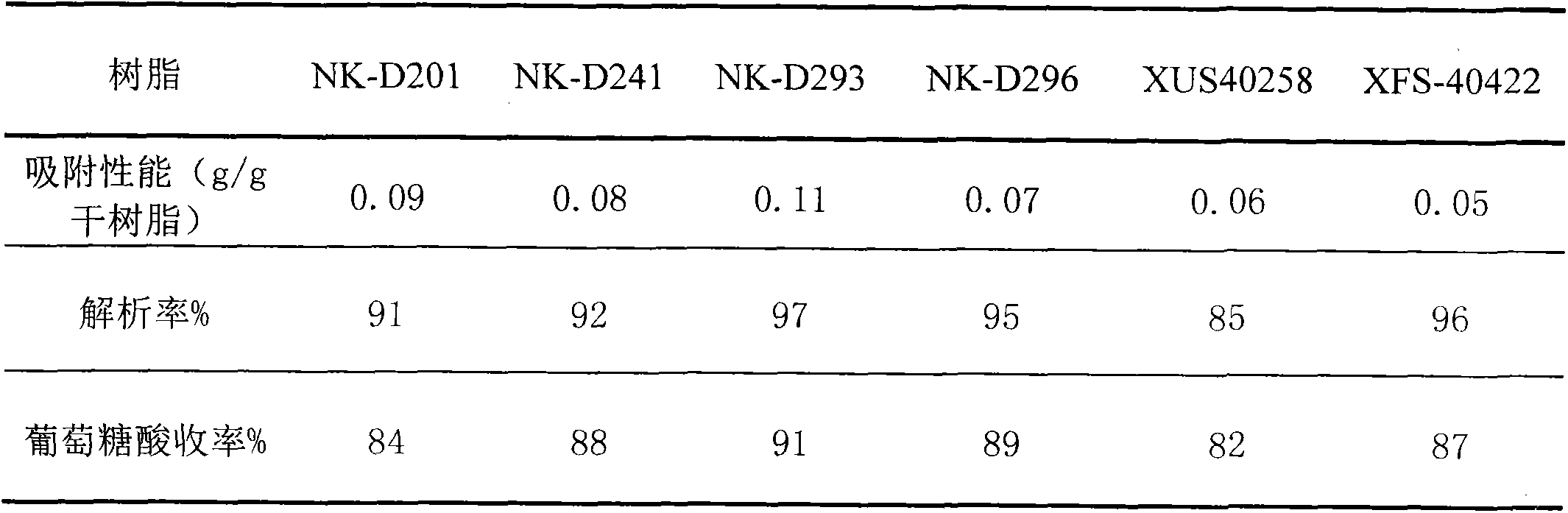

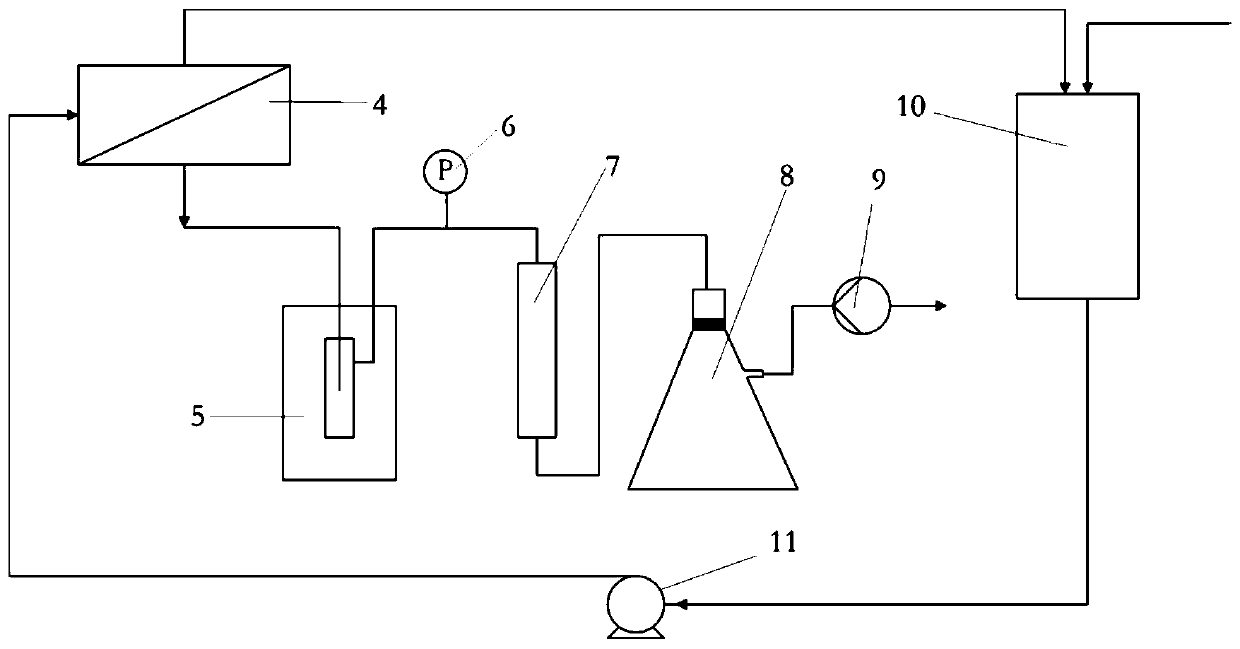

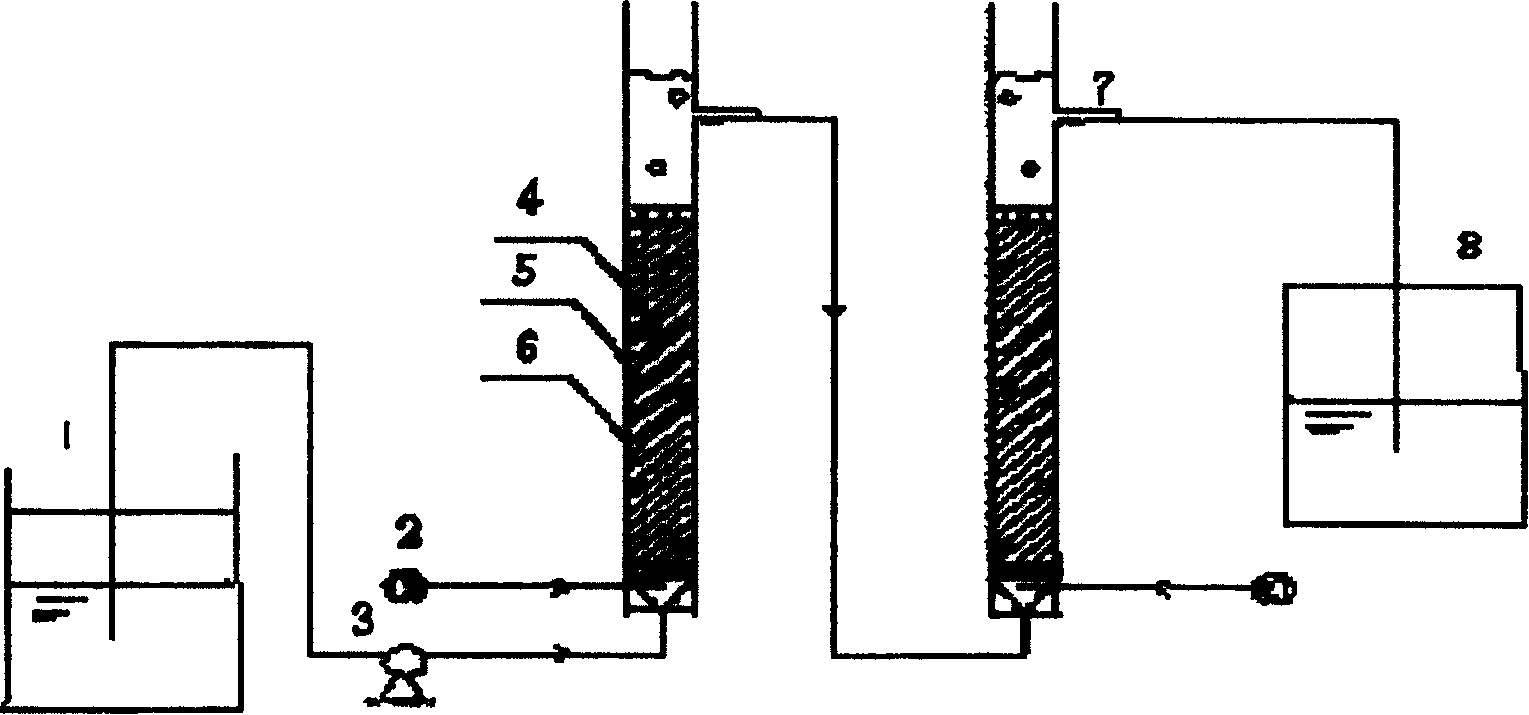

Reaction separating and coupling apparatus, and technology for preparation of gluconic acid from xylitol crystallization mother liquor

InactiveCN103409315ARealize high value utilizationHigh purityBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid storage tankGluconic acid

The invention provides a reaction separating and coupling apparatus, and a technology for preparation of gluconic acid from xylitol crystallization mother liquor. The reaction separating and coupling apparatus comprises a nanofiltration device, a co-immobilization glucose oxidase and catalase column reactor; a fixed bed chromatography column, a computer control system, a transmission pump, a raw material liquid storage tank, a product liquid storage tank, an eluate storage tank, and valves. Reaction coupling of the co-immobilization glucose oxidase and catalase column reactor and adsorption processes of the fixed bed chromatography column is realized for the first time, so that a gluconic acid solution containing a large amount of impurities is prepared from xylitol crystallization mother liquor by the immobilization enzyme column reactor, and is delivered into the fixed bed chromatography column directly, and production of high purity gluconic acid with selectivity is realized. Production efficiency of gluconic acid from xylitol crystallization mother liquor is increased; feedback inhibition is eliminated; the value of industrial waste is increased; and reaction, solid-liquid separation and purification are combined by the reaction separating and coupling apparatus, and the technology. The obtained gluconic acid is colorless crystals, yield is of 84 to 95%, and purity can reach 94 to 97%.

Owner:CHONGQING UNIV

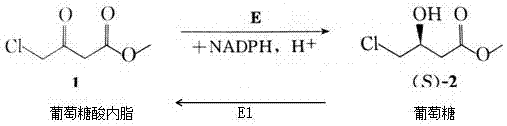

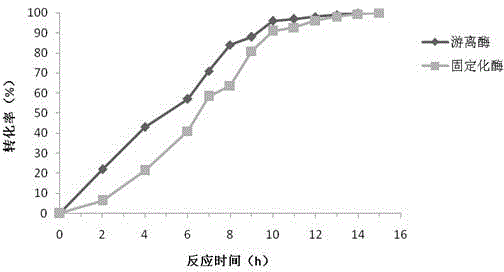

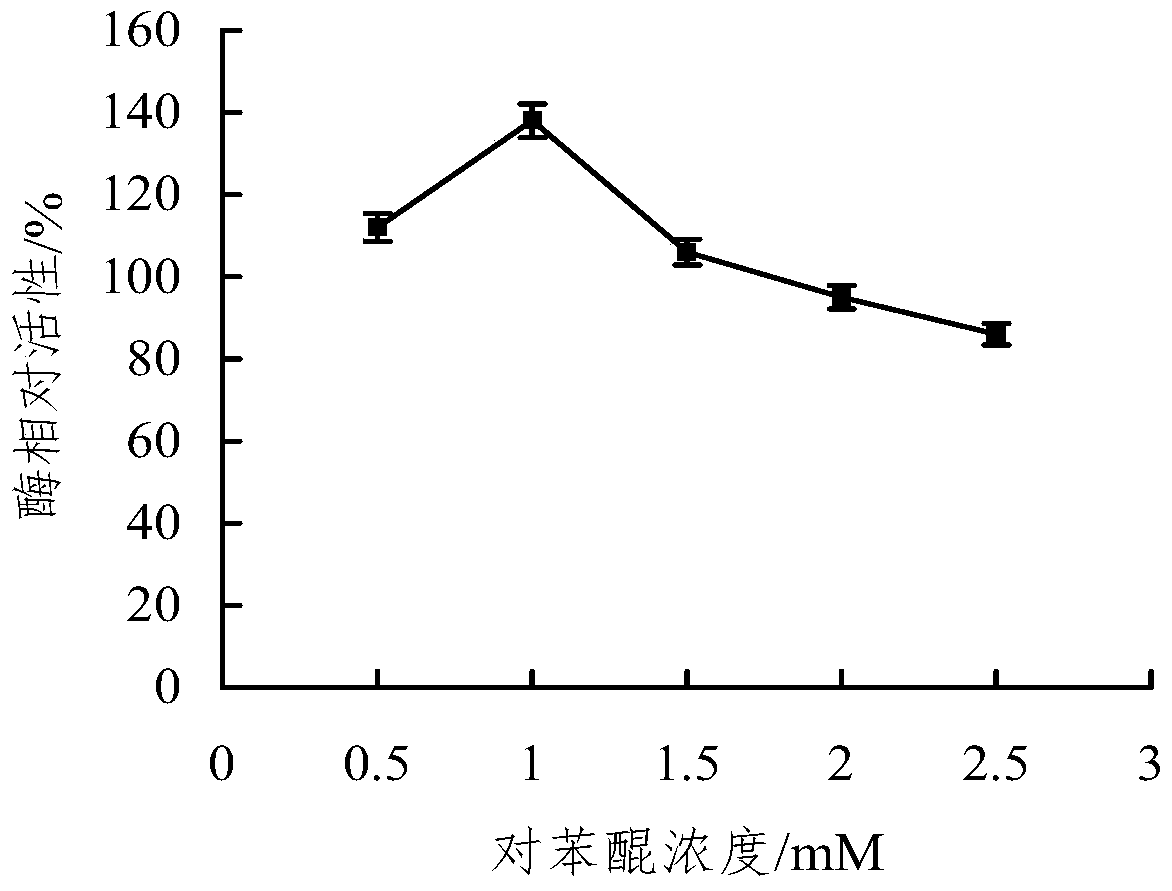

Microwave-assisted co-immobilization method of aldehyde ketone reductase and glucose dehydrogenase

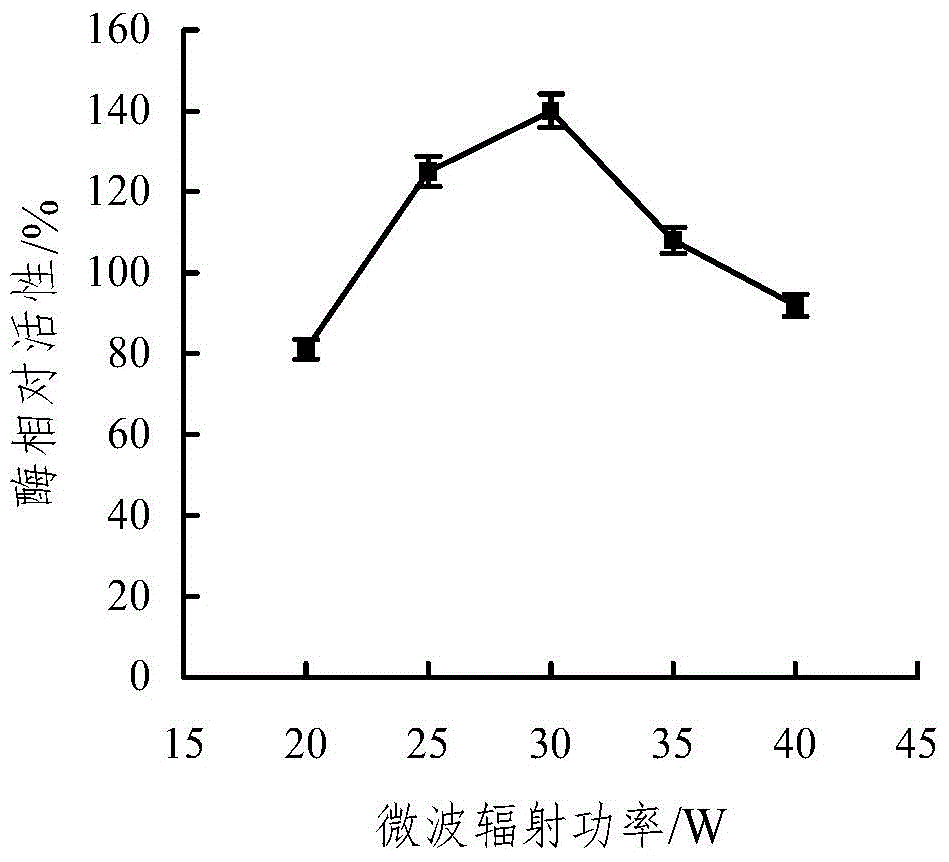

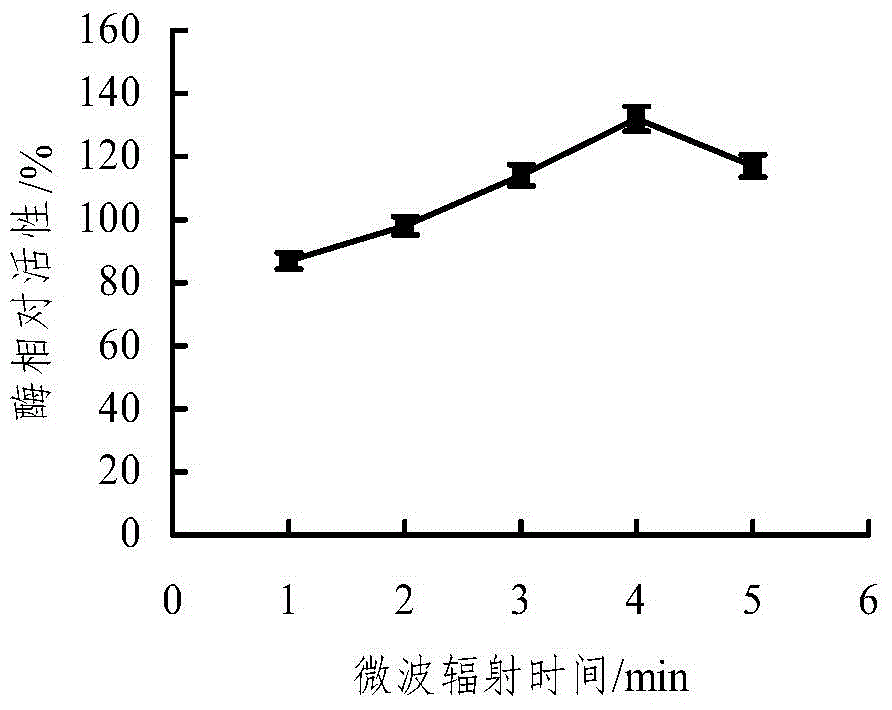

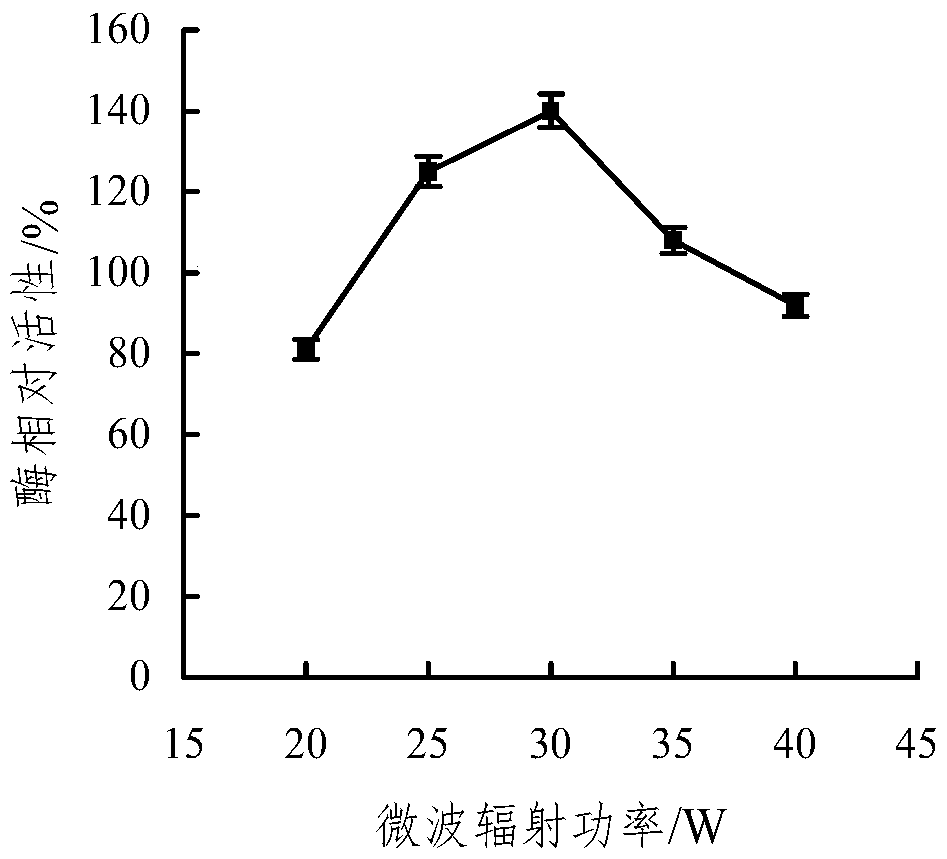

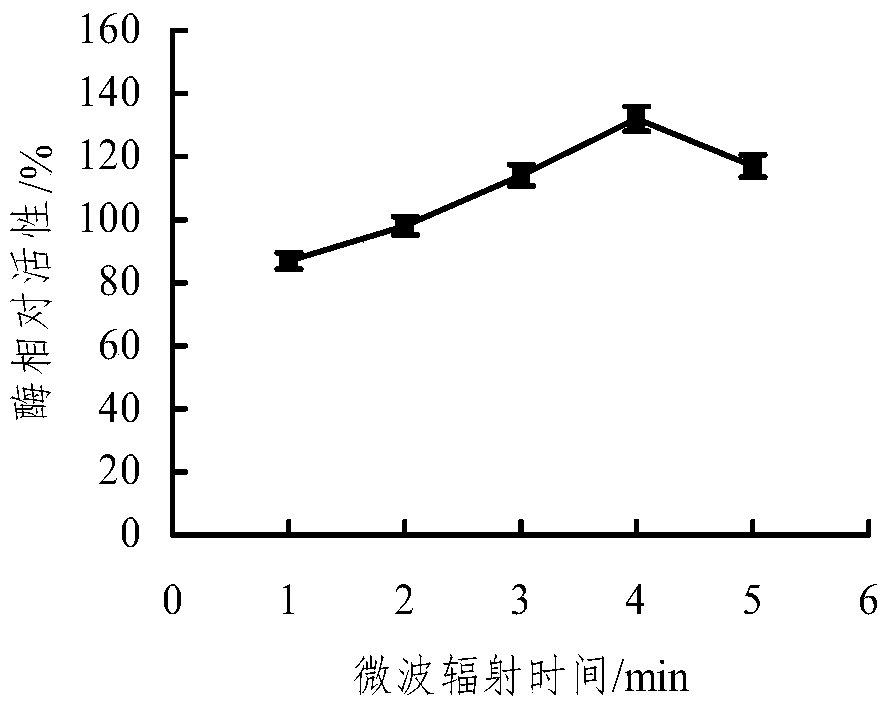

ActiveCN104988132AIncrease forceReduce manufacturing costOn/in inorganic carrierMulti-enzyme systemsThermal stabilityGlucose dehydrogenase

The invention discloses a microwave-assisted co-immobilization method of aldehyde ketone reductase and glucose dehydrogenase. The method includes the steps that a carrier and a crosslinking agent are mixed and activated, centrifuging is conduced, sediments are taken and washed through a PBS solution, centrifuging is conducted, and the sediments are re-dispersed in the PBS solution; the aldehyde ketone reductase and the glucose dehydrogenase are added to a dispersed solution, the mixed liquid is irradiated at the temperature of 0 DEG C to 10 DEG C under the 20-45 W microwave condition for 1 min to 5 min, centrifuging is conducted, sediments are taken and washed through the PBS solution, and co-immobilized enzyme is obtained; compared with free enzyme, the catalytic activity, heat stability and PH stability of the co-immobilized enzyme prepared through the method are improved; the glucose dehydrogenase serves as a coenzyme regeneration system of the glucose dehydrogenase to provide NAD(P)H required by a reaction, the cost is lowered, and industrial production is facilitated.

Owner:HANGZHOU NORMAL UNIVERSITY

Embedding and co-immobilization method of aldehyde ketone reductase and glucose dehydrogenase

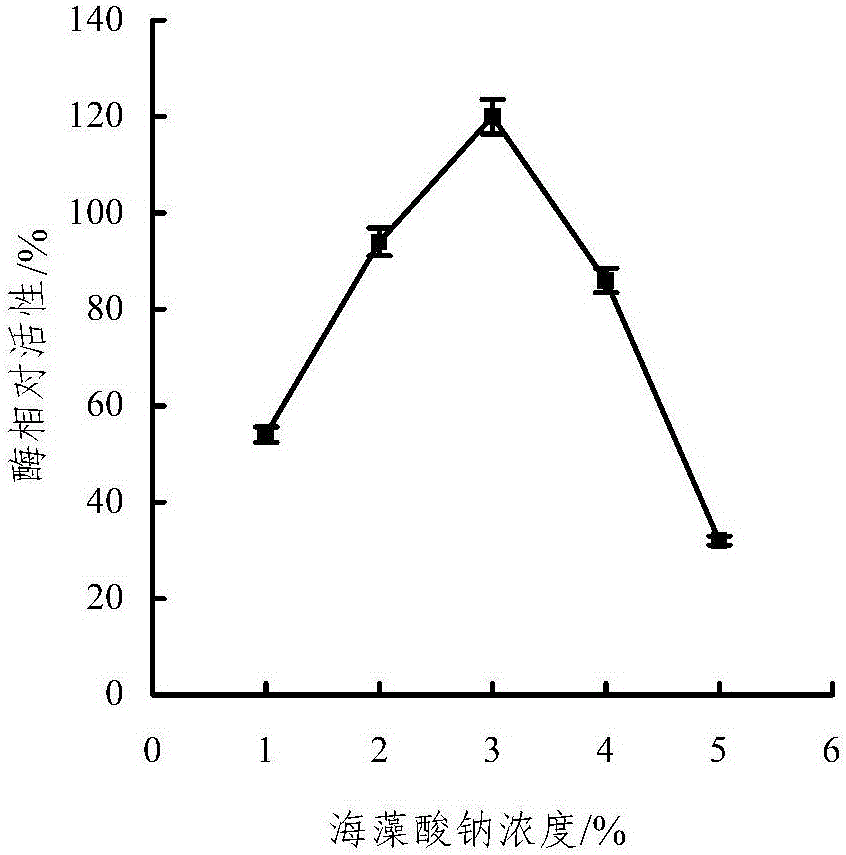

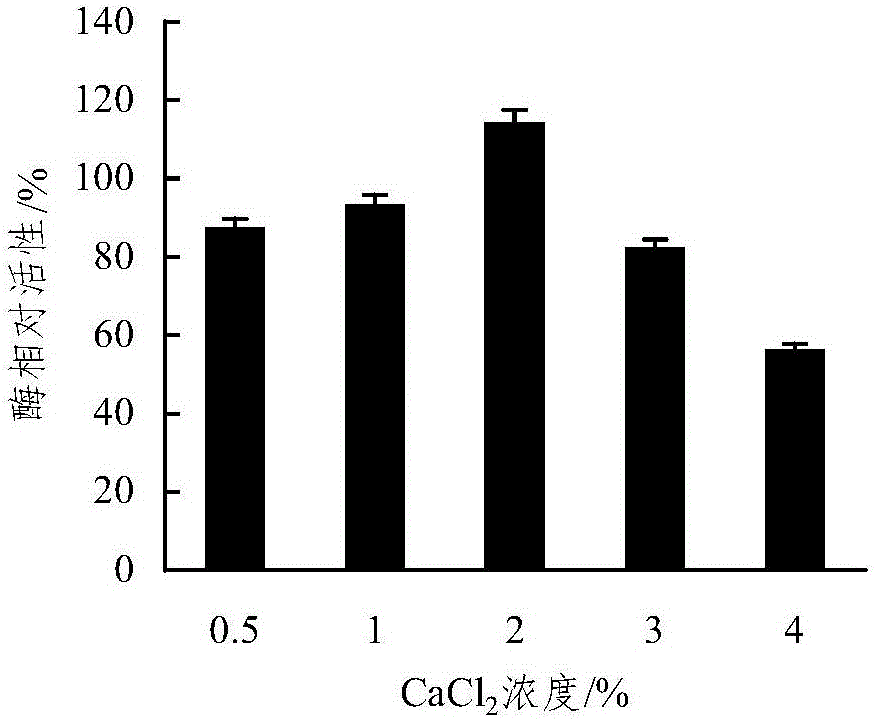

ActiveCN104988133AHigh catalytic activityImprove thermal stabilityOn/in organic carrierMulti-enzyme systemsFiltrationRefrigerated temperature

The invention discloses an embedding and co-immobilization method of aldehyde ketone reductase and glucose dehydrogenase. The method includes the steps that the aldehyde ketone reductase and the glucose dehydrogenase are mixed and then added to a sodium alginate aqueous solution to be stirred and mixed evenly, then the mixture is dropwise added to a Cacl2 aqueous solution, the mixture is made to stand in a refrigerator at the temperature of 4 DEG C, washing is conducted through distilled water, vacuum filtration is conducted, and immobilized particles are obtained. Compared with free aldehyde ketone reductase, the catalytic activity of the co-immobilized enzyme prepared through the method is increased by 1.32 times, the heat stability, the PH stability and other performance of the co-immobilized enzyme prepared through the method are improved as well, and meanwhile, the cost is lowered due to reuse of the co-immobilized enzyme.

Owner:HANGZHOU NORMAL UNIVERSITY

Method for co-immobilization of nitrite bacteria-denitrifying bacteria

InactiveCN103805591AImprove nitrogen removal efficiencyRealize short-cut nitrification-denitrificationOn/in organic carrierNitrifying bacteriaCulture mediums

The invention discloses a method for co-immobilization of nitrite bacteria-denitrifying bacteria, belonging to a method for co-immobilization of cells. The method comprises the following steps: (1) embedding the denitrifying bacteria by use of sodium alginate and calcium chloride first; (2) mixing immobilized globules prepared in step (1) with the nitrite bacteria and sodium alginate, and dripping into calcium chloride for second embedding; (3) inoculating the co-immobilized nitrite bacteria-denitrifying bacteria prepared in step (2) in a culture medium containing ammonia nitrogen for culturing, wherein the co-immobilized nitrite bacteria-denitrifying bacteria can be used for degradation of the ammonia nitrogen. The method has the advantages that 1, co-immobilization culture of the nitrite bacteria and the denitrifying bacteria in the same carrier is realized for the first time; 2, the method for preparing the co-immobilized globules is simple and convenient, the operation procedures are easy to control, and the prepared co-immobilized globules are easy to store and reuse; 3, due to the co-immobilization culture of the nitrite bacteria and the denitrifying bacteria, the co-immobilized nitrite bacteria-denitrifying bacteria have higher denitrification efficiency than the traditional strain which is not immobilized or immobilized simplex strain, and is easy to be separated from the water body and recyclable.

Owner:XUZHOU UNIV OF TECH

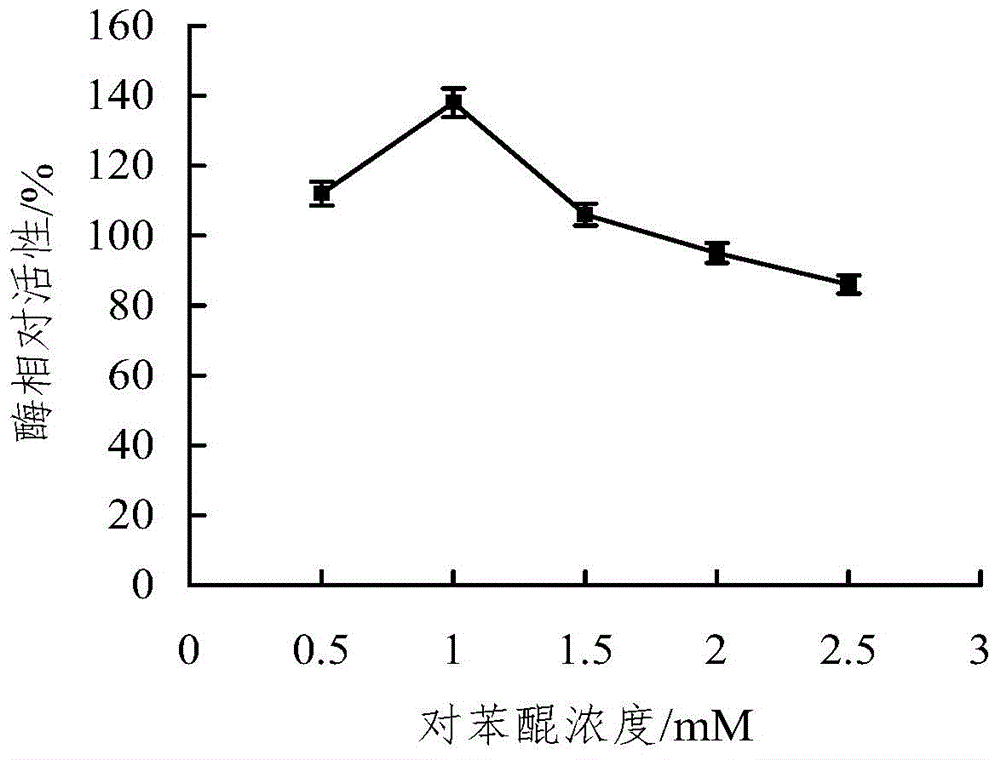

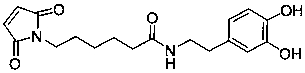

System for co-immobilizing laccase and mediator on amino silanized magnetic oxidized graphene nano particles and preparation method thereof

InactiveCN106636056AIncrease profitSimple preparation processWater treatment compoundsWater contaminantsSilanizationElectron transfer

The invention discloses a system for co-immobilizing laccase and a mediator on amino silanized magnetic oxidized graphene nano particles and a preparation method thereof. The system is obtained by co-immobilizing the laccase and the mediator on the amino silanized magnetic oxidized graphene nano particles, 0.3-0.6 mmol of mediator is fixed in every 1 g of laccase and mediator co-immobilizing system, and the laccase activity after co-immobilization is 120-300 U / g. The laccase and the mediator are co-immobilized on the magnetic oxidized graphene carrier for the first time and can be recovered and recycled through an external magnetic field, the electron transfer efficiency between the laccase and a substrate is improved through graphite oxide, accordingly the laccase utilization rate is improved, and the cost is reduced.

Owner:NANJING UNIV OF TECH

Double-strain co-immobilization fermented mulberry wine and preparation method thereof

InactiveCN106085713AImprove blood supplyRelieves symptoms of fatigue and drynessMicroorganism based processesAlcoholic beverage preparationFruit wineAlcohol

The invention discloses a double-strain co-immobilization fermented mulberry wine and a preparation method thereof. The preparation method comprises the following steps: selecting mulberries, cleaning, juicing, carrying out enzymolysis, filtering and centrifugating, regulating the components, pasteurizing, cooling, carrying out primary fermentation on immobilized Saccharomyces cerevisiae and Zygosaccharomyces cidri, clarifying, filtering, carrying out secondary fermentation, aging, filtering, purifying through an ultrafiltration membrane, and filling to obtain the finished product. The method can effectively solve problem of low storability of massive mulberries in the ripening season, and the problems of complex operation, high inactivation tendency of the strains and the like in the traditional fermented fruit wine. The method can perform mass continuous production on the mulberries, shorten the production cycle, enhance the productivity, recycle the strains and lower the production cost. The mulberry wine is clear and transparent, has the stable purple color, has the particular subtle fragrance of the mulberries, and is soft and thick in mouthfeel. Compared with the mulberry wine fermented by the traditional process, the odorous constituents are obviously enhanced. The mulberry wine has the health-care effects of tonifying the blood, nourishing yin, moisturizing the intestines, postponing aging, blackening the hair, improving the eyesight, improving the skin blood supply and the like.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

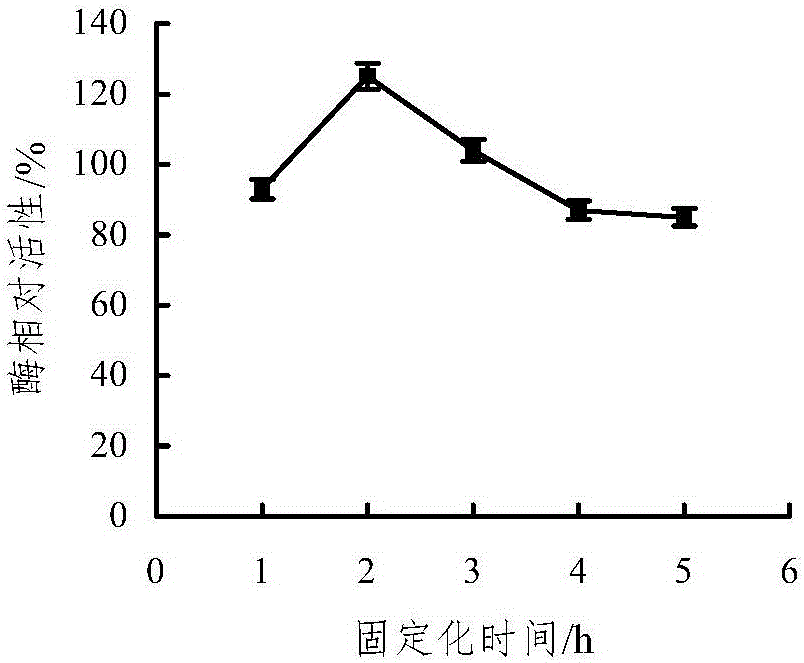

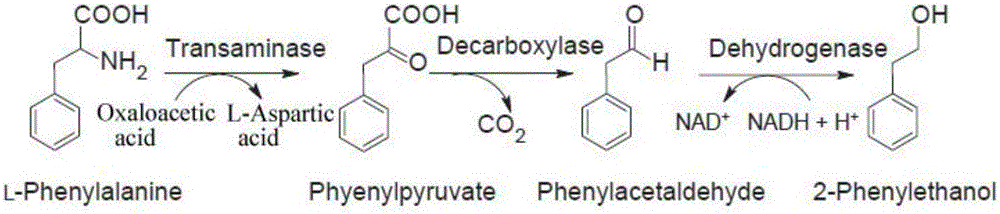

Noncellular synthetic biology based preparation method of 2-phenylethanol and application

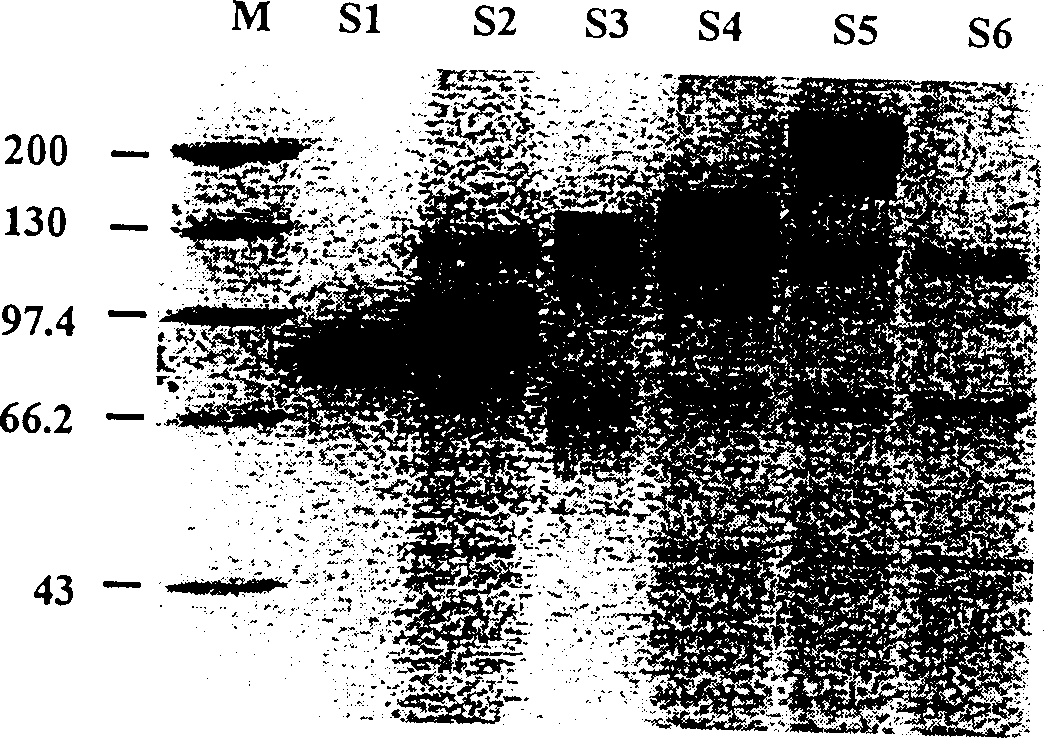

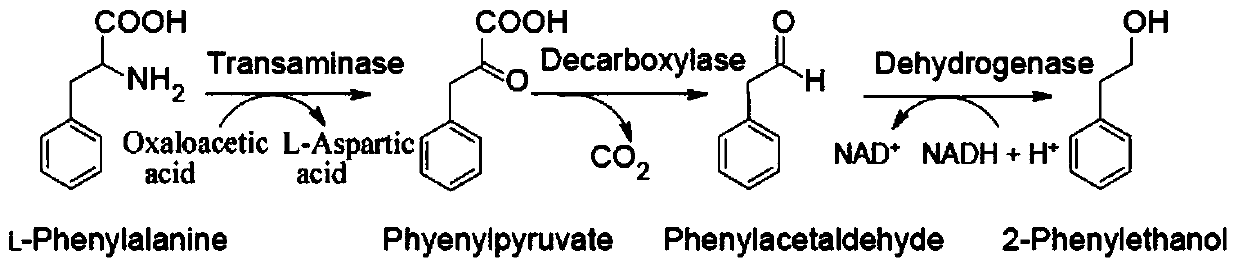

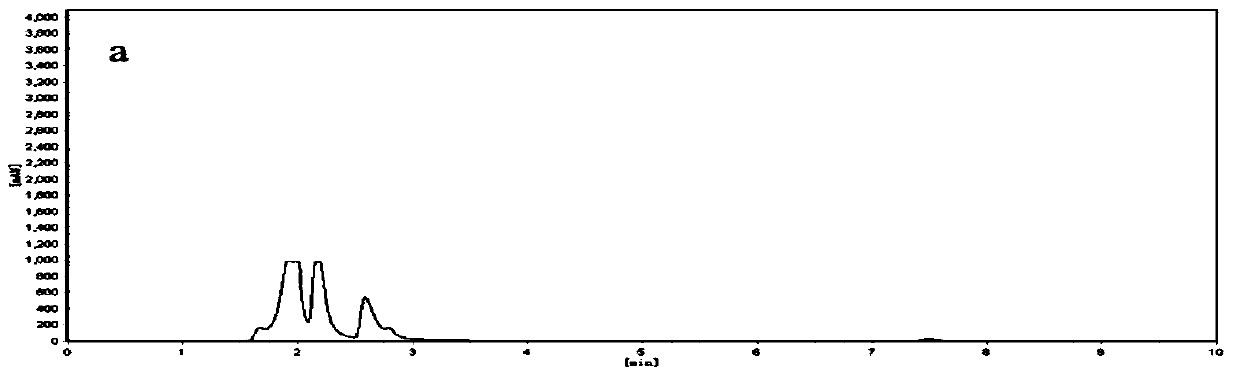

ActiveCN106011184ANo purification requiredHigh catalytic efficiencyFermentationMulti-enzyme systemsCross-linkCross-linked enzyme aggregate

The invention discloses a noncellular synthetic biology based preparation method of 2-phenylethanol and an application. According to the preparation method and the application, three recombinases including ARO8, ARO10 and ADH1 are utilized to constitute a co-reaction system, and a complicated metabolic process of an Ehrlich pathway requiring multi-step continuous reaction and multi-enzyme participation for synthesis of 2-phenylethanol in microorganisms is simplified to be performed in the same reaction system in vitro, so that the environmental pollution is reduced and the reaction process is shortened. Furthermore, the three recombinases are subjected to carrier-free co-immobilization with glutaraldehyde serving as a cross-linking agent, Combi-CLEAs (Combi-Cross-linked Enzyme Aggregates) are prepared, a target product is synthesized in vitro, accordingly, the enzymes are further recycled on the basis of the beneficial effects, and the production cost is reduced; the preparation method fills up the technical blank of multi-enzyme preparation of 2-phenylethanol in vitro, and important reference is provided for biological preparation of 2-phenylethanol.

Owner:SOUTH CHINA AGRI UNIV

Keto group reduction catalytic system construction and cyclic operation method

InactiveCN108004276ASolve technical bottlenecksSimple and effective means of recyclingFermentationGluconic acidImpurity

The invention discloses a keto group reduction catalytic system construction and cyclic operation method. The method comprises the following technical implementation steps that a carrier is used for conducting co-immobilization treatment on reductase for catalyzing a keto group reaction and glucose dehydrogenase for catalyzing regeneration of coenzyme to prepare immobilized multi-enzyme; a keto group reduction cyclic catalysis system composed of an immobilized multienzyme reactor, a product extraction device and a 300-600Da nanofiltration device is adopted; in the immobilized multienzyme reactor, coenzyme is free in a reaction solution and cooperates with the immobilized multi-enzyme, and the keto group reduction reaction and the cyclic regeneration of the coenzyme are completed. After thereaction is completed, the immobilized enzyme is filtered and recycled, and a product is extracted from filtrate; mother liquor is extracted, calcium chloride is added to remove gluconic acid, then inorganic salt is removed by the 300-600Da nanofiltration device, and meanwhile the coenzyme is recycled, so the cyclic operation of the keto group reduction catalysis system is achieved. The method has the advantages that the cost is low, the efficiency is high, the operation is simple, the product quality is high, and few impurities are generated.

Owner:SHANDONG RUIYING PIONEER PHARMA

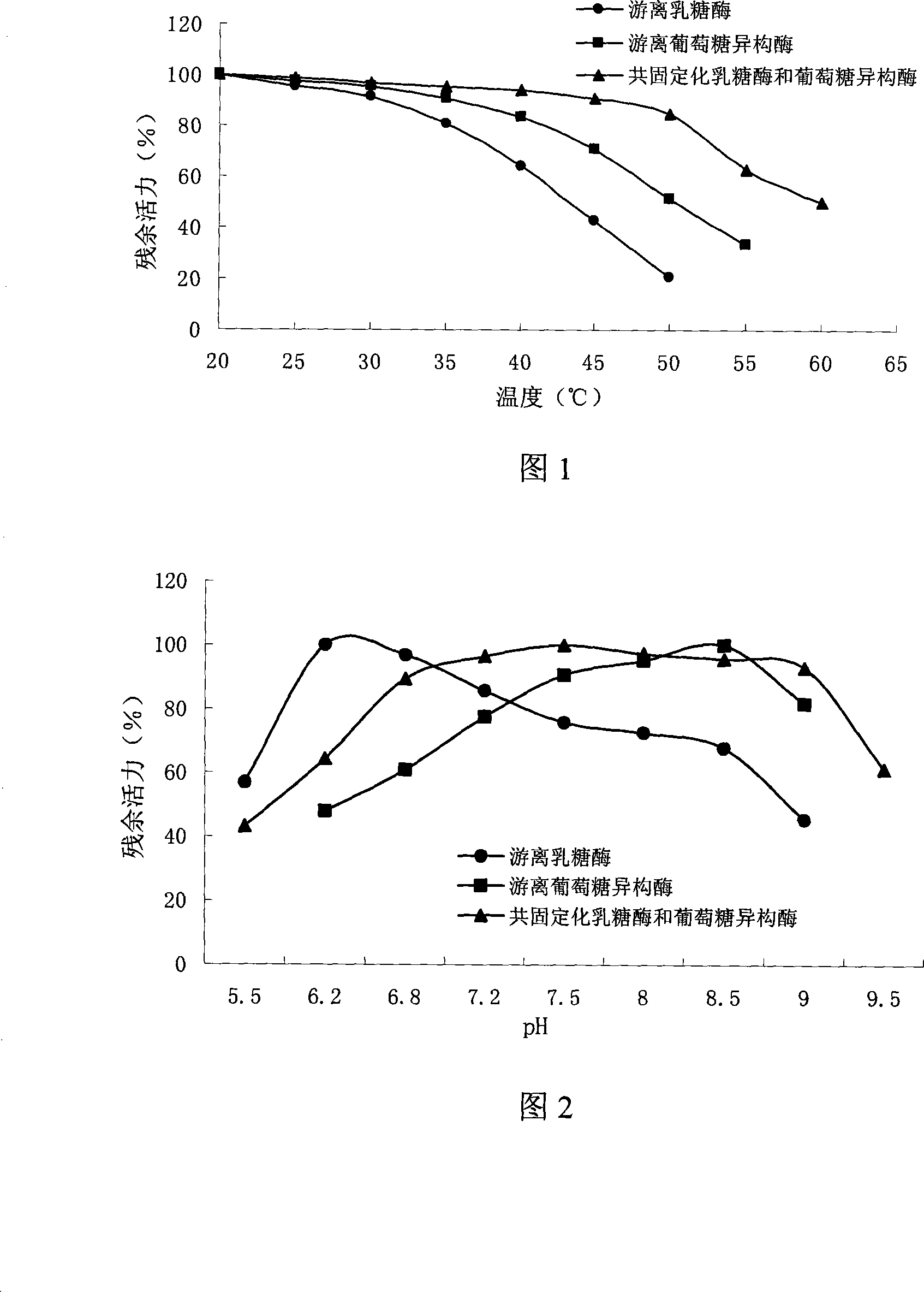

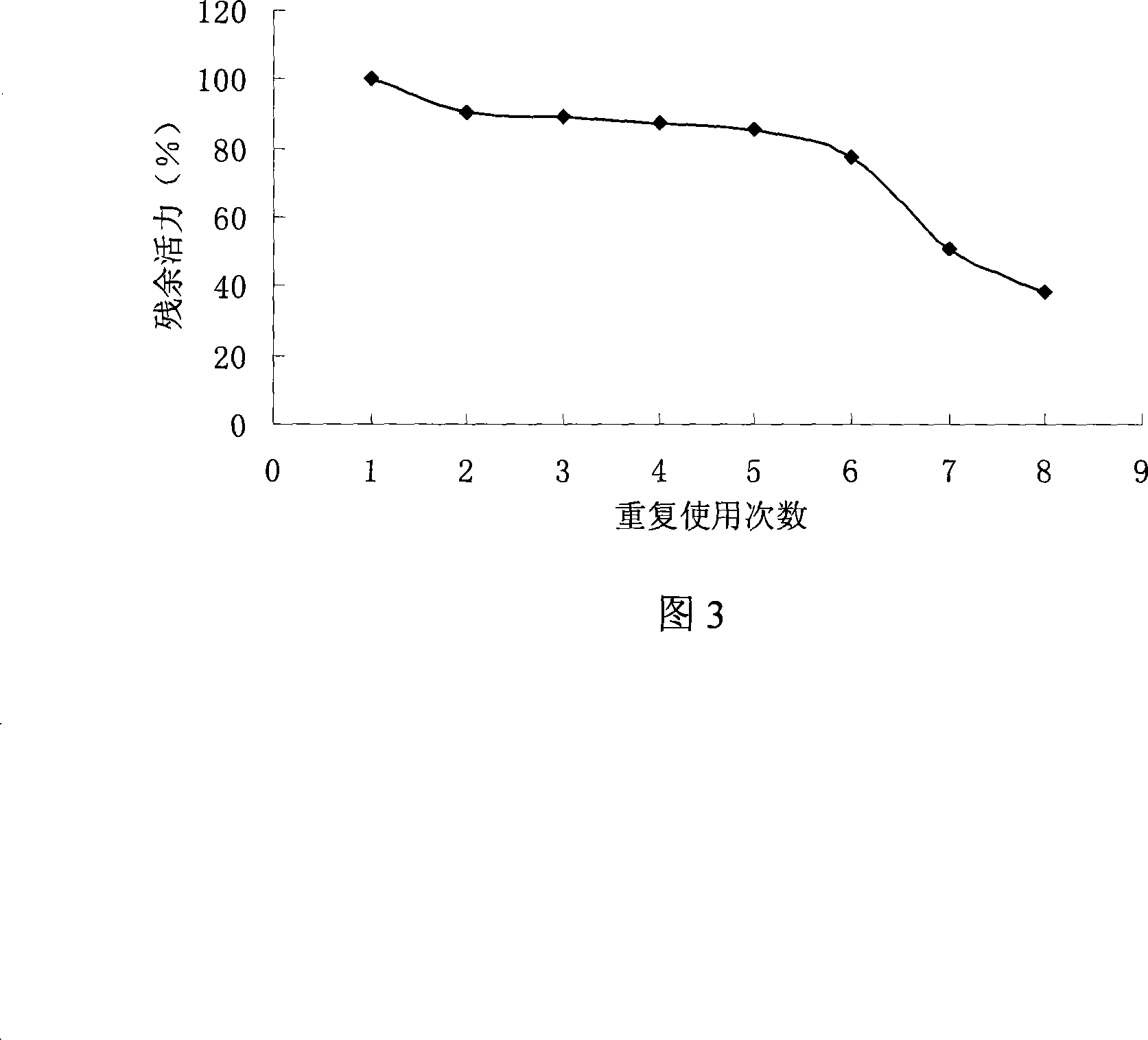

Lactose enzyme and common immobilization method of glucose isomerase

InactiveCN101182508ASimplify downstream separation stepsReduce economic costsOn/in organic carrierLactaseCarrageenan

A co-immobilization method for lactase and glucose isomerase belongs to the food biology technology area. The invention uses gelatine, sodium polymannuronate and / or carrageenan as the carrier; the first embedding and after cross linking process is applied; or the nylon net is used as the carrier; the first cross linking and after covalent combination method is used for the co-immobilization of lactase and glucose isomerase. The distinct characteristics of the invention are that the co-immobilization of lactase and glucose isomerase can not only realize recycle utilization of the enzyme which saves the economic cost and simplifies the downstream separation steps, but also exert the cooperation function between two enzymes which improves the reaction efficiency. The invention has a novel idea, a simple process and a strong practicality. The obtained lactase and glucose isomerase can be used for the transformation of lactose for the preparation of lactulose. The invention has good application prospect.

Owner:JIANGNAN UNIV

Method for preparing calcium gluconate through co-immobilization of glucose oxidase and catalase

InactiveCN106591275AHigh purityHeavy metal content was not detectedChemical industryOxidoreductasesCatalytic oxidationCalcium alginate

The invention discloses a method for preparing calcium gluconate through co-immobilization of glucose oxidase and catalase. With glucose as a substrate, a technology adopting glucolactone, chitosan and calcium alginate for co-immobilization of glucose oxidase and catalase for catalytic oxidation of glucose is used for preparing calcium gluconate; the technology can significantly improve the enzyme activity and reduce conversion steps, the sugar conversion rate is greatly increased, energy consumption is saved, and the production cost is reduced.

Owner:温县兴发生物科技有限公司

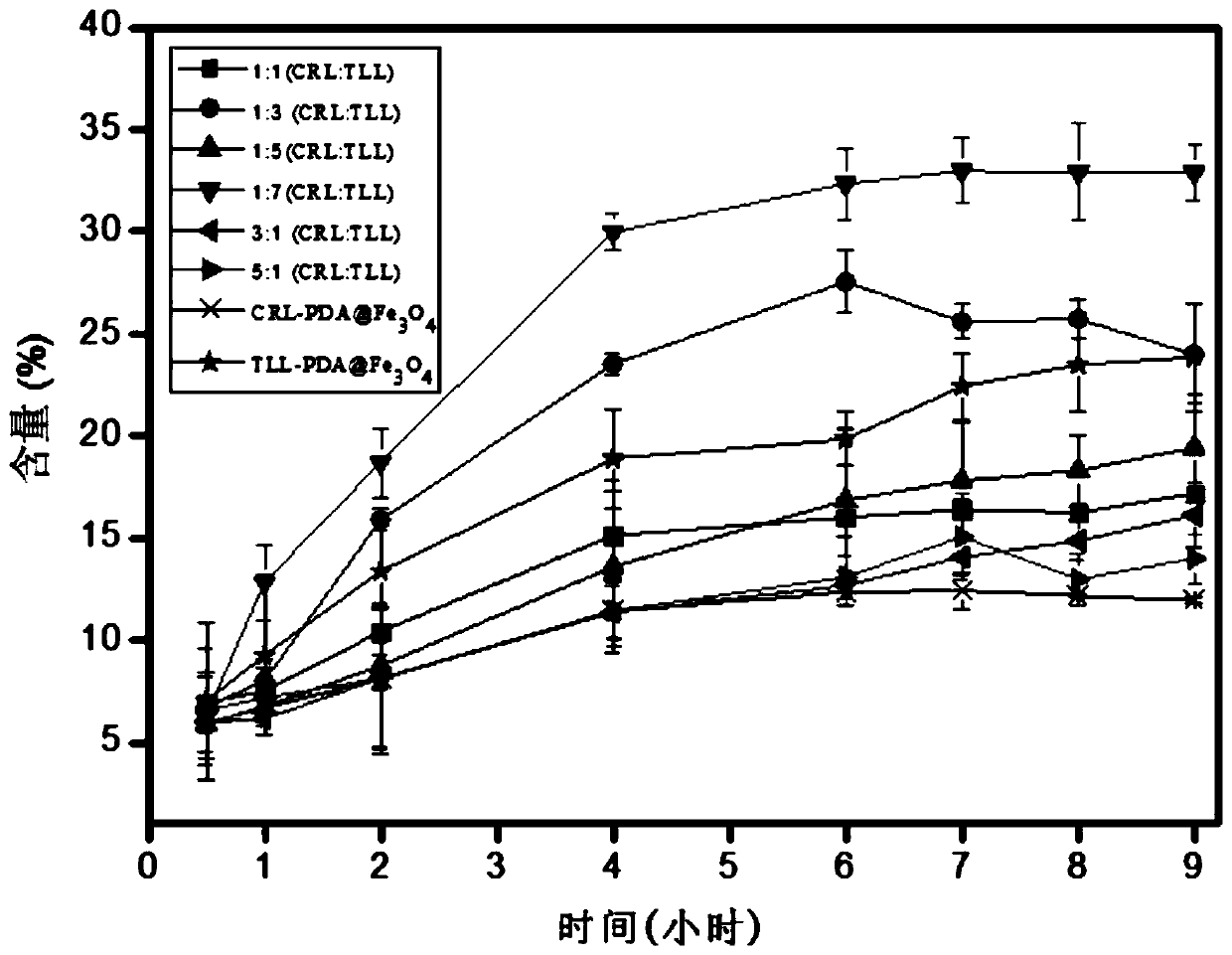

Immobilized enzyme and preparation method thereof

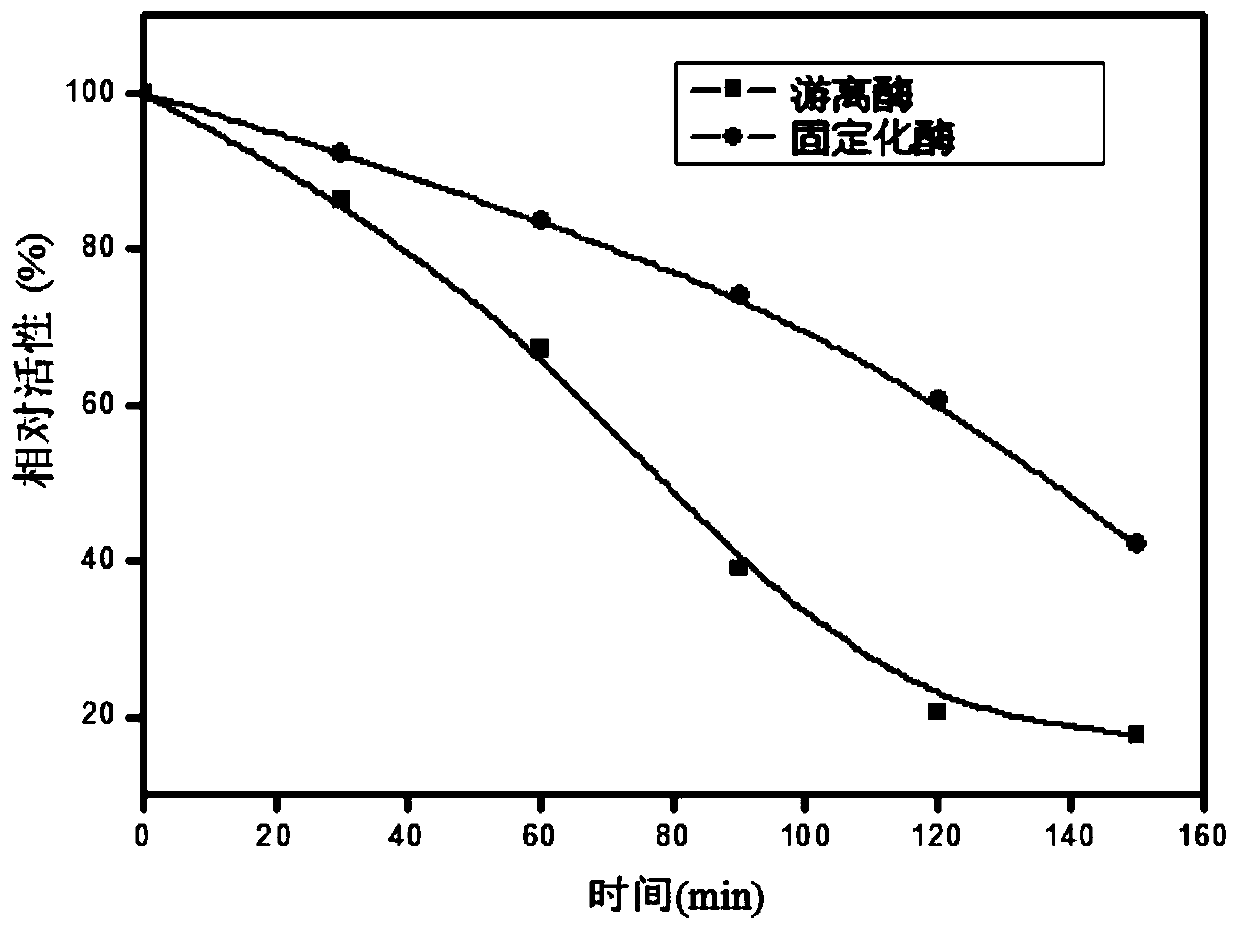

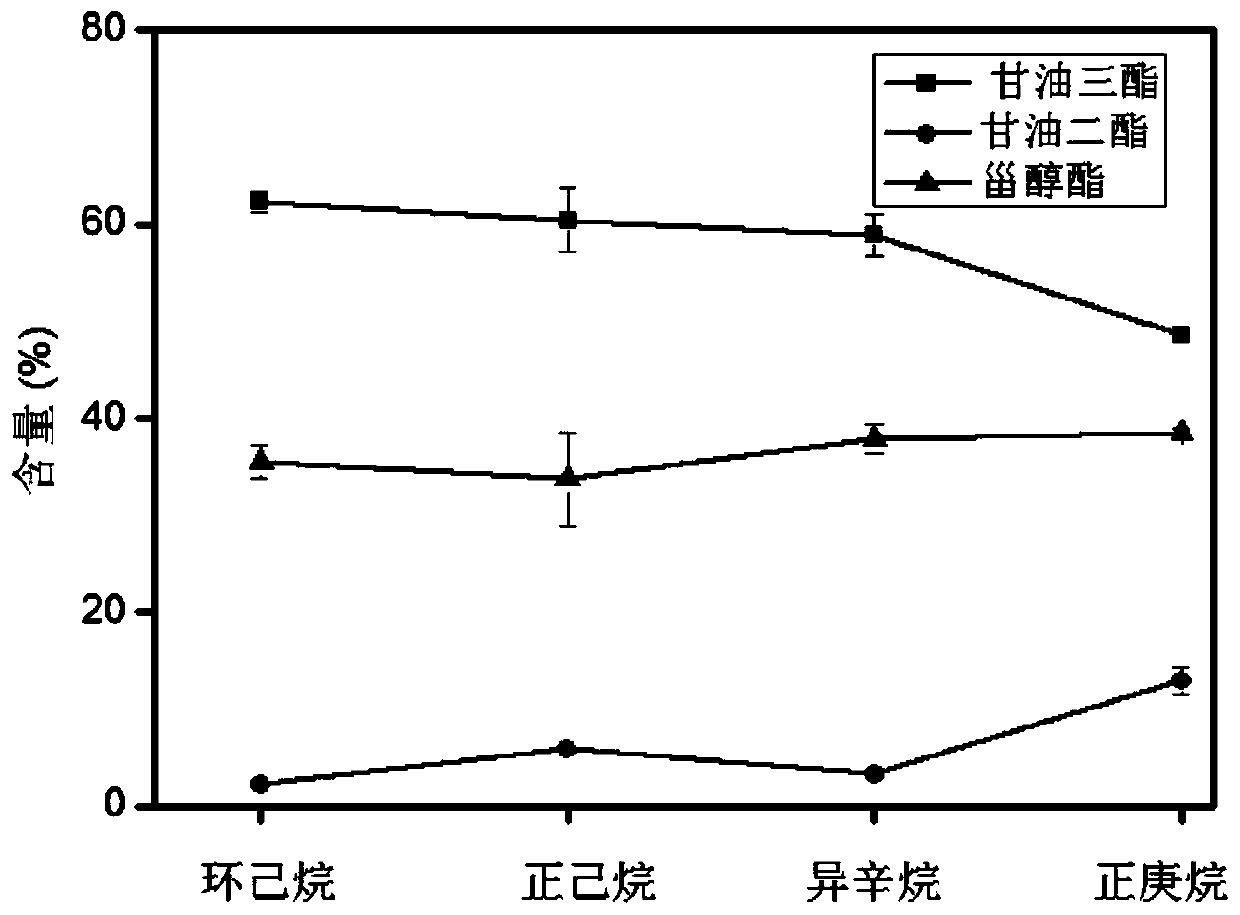

The invention discloses an immobilized enzyme and a preparation method thereof. The preparation method of the immobilized enzyme comprises the following steps: dissolving ferroferric oxide in a firstbuffer solution to obtain a base material solution, and adding a dopamine salt for coating treatment so as to obtain a polydopamine coated ferroferric oxide nanocomposite; dissolving nonspecific lipase and sn-1,3 specific lipase in a second buffer solution so as to obtain an enzyme buffer solution; enabling the polydopamine coated ferroferric oxide nanocomplex to be in contact with the enzyme buffer solution, and obtaining the immobilized double enzyme through covalent fixation. According to the method, the ferroferric oxide nanocomposite is used as a fixed carrier, and the sn-1,3 specific lipase and the nonspecific lipase are subjected to co-immobilization treatment to obtain the immobilized double enzyme. The preparation process is simple, the conditions are mild, meanwhile the stabilityof the prepared immobilized double enzyme is good, the catalytic effect is high, the separation and recovery are easy, the repeated use effect is good, and the enzyme is convenient for industrial production.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

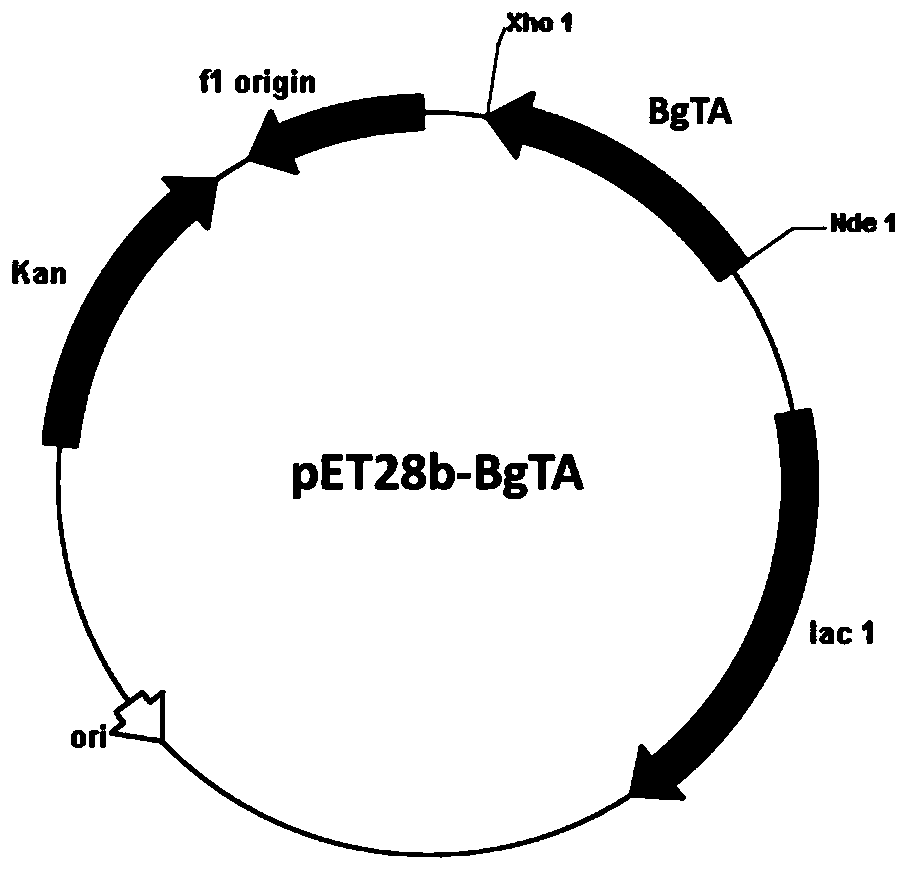

Transaminase-coenzyme co-immobilization engineering bacteria and application

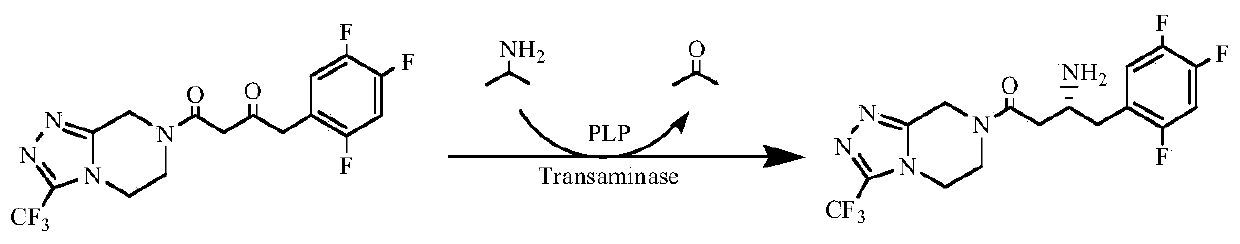

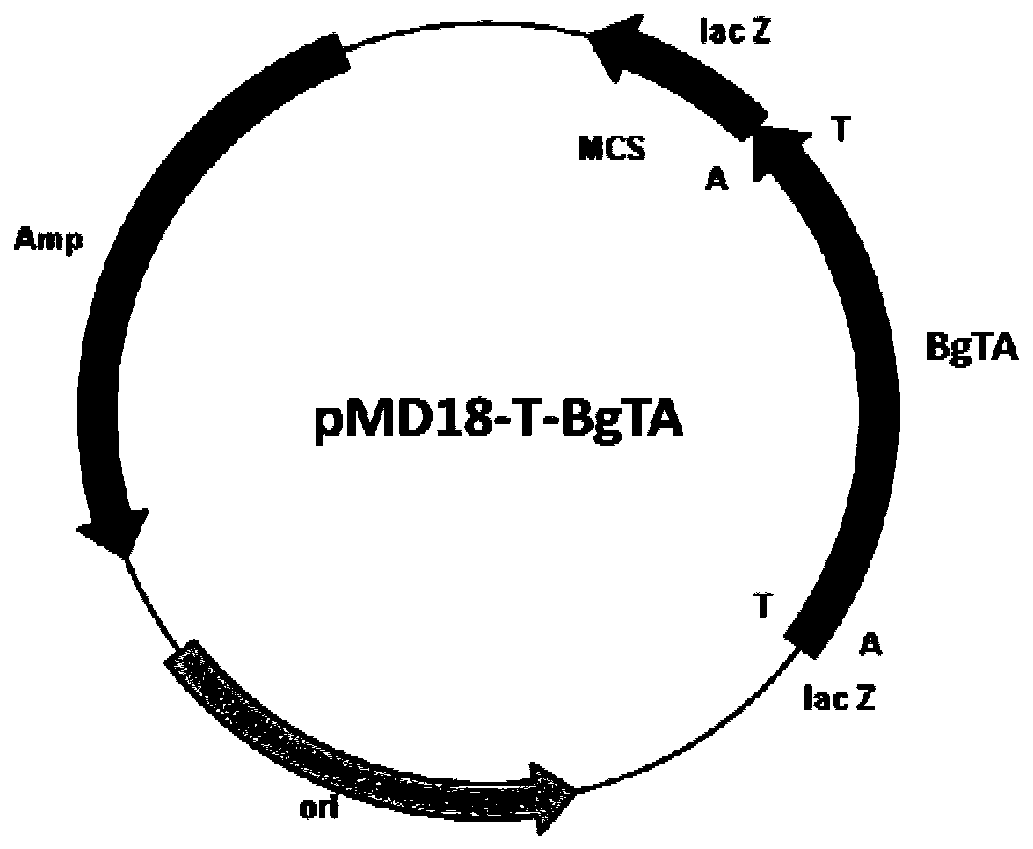

ActiveCN110106130AEmission reductionHigh yieldBacteriaMicroorganism based processesEscherichia coliSitagliptin

The invention provides a method for catalytic synthesis of a sitagliptin chiral intermediate (3R)-3-amino-1-[3-(trifluoromethyl)-5,6,7,8-teralin-1,2,4-triazol[4,3-a]pyrazine-1-yl]-4-(2,4,5-trifluoro-phenyl)buta-1-one by means of engineering bacterium cells containing transaminase-coenzyme pyridoxal phosphate co-immobilization Escherichia coli, E.coli). The method comprises the steps of culturing engineering bacteria containing transaminase Escherichia coli, preparing co-immobilization cells, and synthesizing the immobilization cell asymmetric catalysis itagliptin chiral intermediate. The transaminase-PLP co-immobilization cells are adopted as a catalyst, the stability is good, the service life is long, the organic solvent is good in tolerance, repeated usage can be performed, no expensiveexogenous coenzyme needs to be added in the reaction process, and the production cost is greatly lowered. The method is simple in technology, low in cost and high in product yield and purity, and hasthe quite high application value in the industrial production of the sitagliptin chiral intermediate.

Owner:ZHEJIANG UNIV OF TECH

Reversible double enzyme co-immobilization method capable of regulating and controlling enzyme ratio

ActiveCN107760666AMild reaction conditions for immobilizationKeep activeOxidoreductasesOn/in inorganic carrierMagnetite NanoparticlesA-DNA

The invention relates to a reversible double enzyme co-immobilization method capable of regulating and controlling enzyme ratio. By the method, various kinds of enzyme are fixed on the surfaces of multifunctional magnetic nanoparticles modified by dopamine and derivative thereof through a DNA mediated immobilization technology, the method is mild in synthesis condition, and the immobilization quantity of different enzyme in a multi-enzyme reaction system can be controlled by adjusting the number of the functional groups on the surfaces of the magnetic nanoparticles. The immobilized multi-enzyme system established by the method has the advantages of high activity, high stability and the like.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting collagen peptide from grass carp scales

InactiveCN107522781AImprove physicsImprove adsorption capacityConnective tissue peptidesPeptide preparation methodsDPPHUltrafiltration

The invention discloses a method for extracting a collagen peptide from grass carp scales. The method comprises steps as follows: fish scale pretreatment, protease co-immobilization, enzymolysis, ultrafiltration and freeze drying. 1-ethyl-3-(3-methylamino)propyl carbodiimide is used for activating chitosan, chitosan is coupled with glutaraldehyde to form a lipase immobilized carrier, and the hydrolysis degree, the enzymatic hydrolysis speed and the end group changing type of protein of the grass carp scales are improved through coordinated coordinated enzymatic hydrolysis of soybean protease and bromelain. The method has the benefits as follows: the obtained collagen peptide has small molecular weight and high purity and can directly reach the corium layer of skin to make skin tight, fine and smooth. The collagen peptide has a better antioxidant function, has a high scavenging rate for free radicals including DPPH., super O2<-> and .OH and has a remarkable anti-aging effect. The collagen peptide has an unexpected anti-tumor effect and has an anti-tumor specific T lymphocyte immune response while enhancing the non-specific immunity in a body.

Owner:浦江县欧立生物技术有限公司

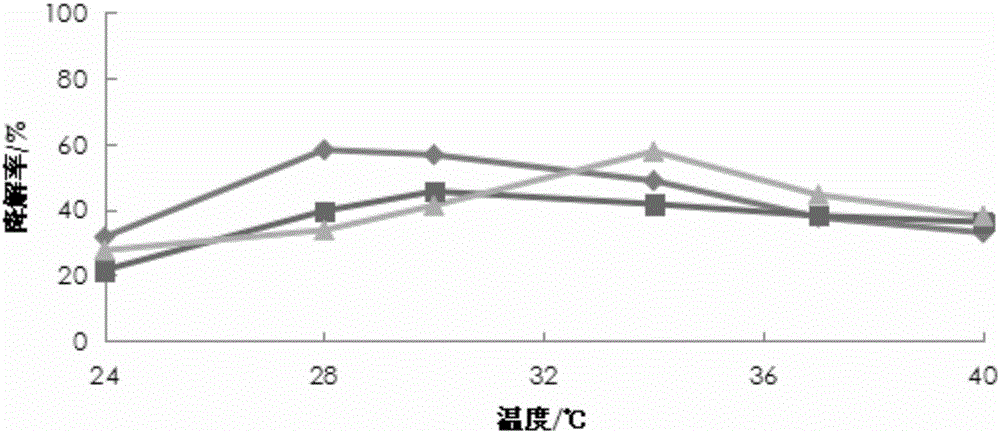

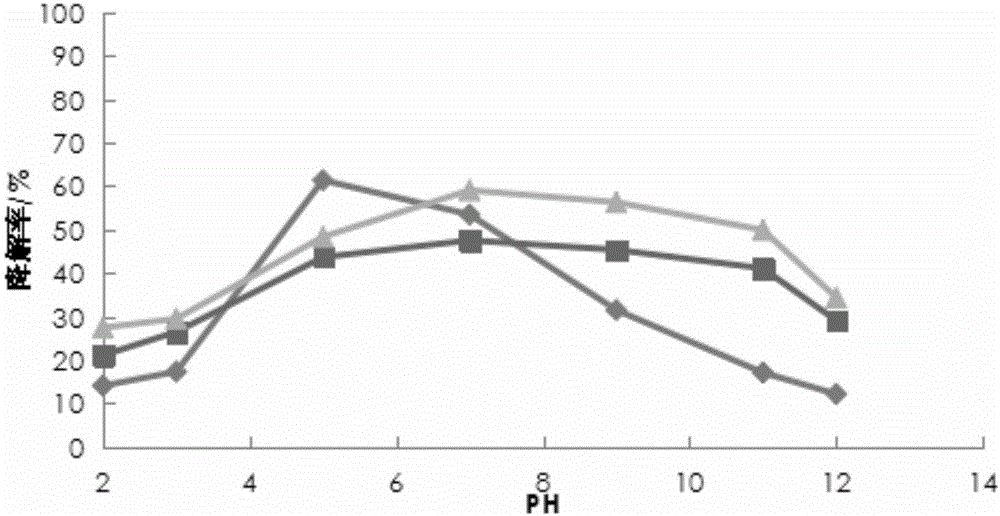

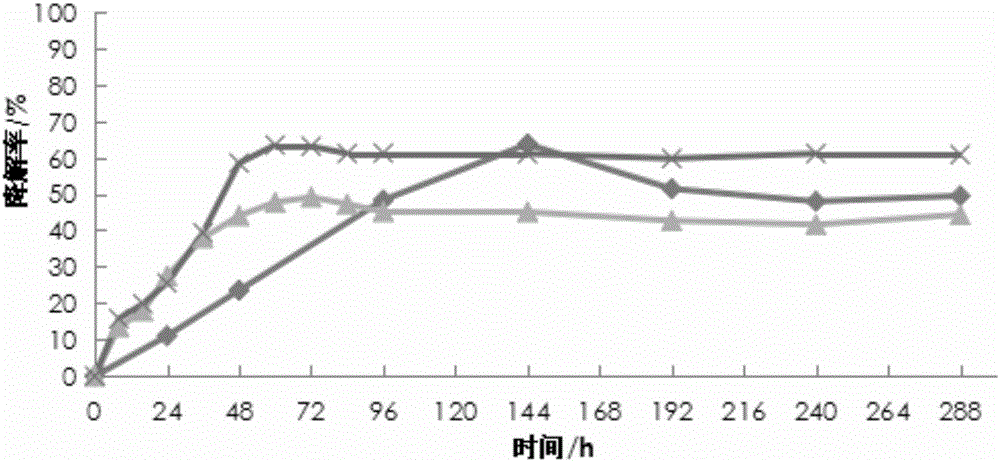

Preparation method and application of co-immobilization mycelium pellets with function of removing various pollutants

ActiveCN106282154AImprove degradation rateEasy to handleWater contaminantsMicroorganism based processesSnow moldTherapeutic effect

The invention belongs to the field of wastewater treatment, discloses a preparation method and application of co-immobilization mycelium pellets with the function of removing various pollutants, and relates to a preparation method and application of co-immobilization mycelium pellets. The problems that an existing mycelium pellet degradation function is single and the degradation effect is poor are solved. The method comprises the steps of preparing an aspergillus fumigatus spore suspension and a bacillus cereus suspension; 2, taking the aspergillus fumigatus spore suspension and the bacillus cereus suspension, inoculating the aspergillus fumigatus spore suspension and the bacillus cereus suspension into a mycelium pellet pelletizing culture medium, performing shake cultivation, and obtaining the compound mycelium pellets. The co-immobilization mycelium pellets are used for degrading lignin, cellulose, hemicellulose, dyes and heavy metal ions. The compound mycelium pellets can treat paper waste, can also be used for treating dye wastewater and heavy metal ion wastewater, and has the good treatment effect in a system with high alkaline and high temperature.

Owner:HARBIN UNIV OF SCI & TECH

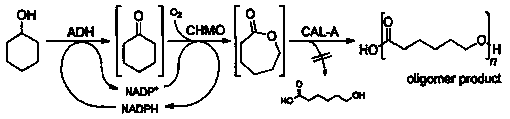

Orderly, directional and co-immobilization enzyme membrane reactor and preparation method and application thereof

PendingCN110540938AImmobilization method is simpleImprove transfer efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEthanol dehydrogenaseCyclohexanone monooxygenase

The invention discloses an orderly, directional and co-immobilization enzyme membrane reactor and a preparation method and application thereof. On the basis of a pervaporation membrane assembly, the pervaporation membrane assembly comprises a pervaporation membrane composited with a microfiltration membrane, immobilized enzymes of combination enzymes needed for a reaction are sequentially immobilized to the microfiltration membrane according to the enzyme catalysis cascade reaction sequence, the combination enzymes are any one of combination of horse radish peroxidase and glucose oxidase, combination of tyrosinase and alkaline phosphatase, combination of long-chain alcohol oxidase and omega-transaminase, and combination of ethanol dehydrogenase, cyclohexanone monooxygenase and lipase, thecatalytic reaction efficiency is advantageously improved, the immobilized enzymes are integrated on one microfiltration membrane, and the multi-step catalytic intermediate product transferring efficiency is improved; by arranging the microfiltration membrane, reacting and separating are integrated, and reaction balance advantageously moves in the favorable direction; and reaction conditions are mild, and an enzyme immobilization method is simple.

Owner:ZHEJIANG SCI-TECH UNIV

Method for extracting myricetin through microbial fermentation

ActiveCN110628840AHigh extraction rateHigh purityMicroorganism based processesFermentationSporeMicroorganism

The invention belongs to the technical field of separation of natural products, and relates to a method for extracting myricetin through microbial fermentation. The method comprises the following steps of (1) preparing co-immobilization gel beads containing aspergillus niger spore suspension and lactobacilli suspension; (2) mashing myricetin extraction raw materials, adding ethanol, performing reflow extraction for 1-5 times, combining filtrate, performing concentration, and drying filter residues; (3) adding water to a fermenter, adding the co-immobilization gel beads obtained in the step (1), an extract obtained in the step (2) and 1 / 5-4 / 5 of dried filter residues, and performing fermentation and extraction at 40-50 DEG C for 140-170h; (4) after the fermentation is completed, filtratingfermentation liquid with a screen mesh, and removing the co-immobilization gel beads; (5) performing reflow extraction on the filtered fermentation liquid with ethanol for 1-5 times, combining filtrate, and performing concentration so as to obtain precipitate; and (6) repeatedly washing the precipitate with water for 4-6 times so as to obtain finished products. Through the adoption of the extraction method, the yield and the purity of the myricetin are greatly increased, and the method is environmentally-friendly and safe.

Owner:宁波德康生物制品有限公司

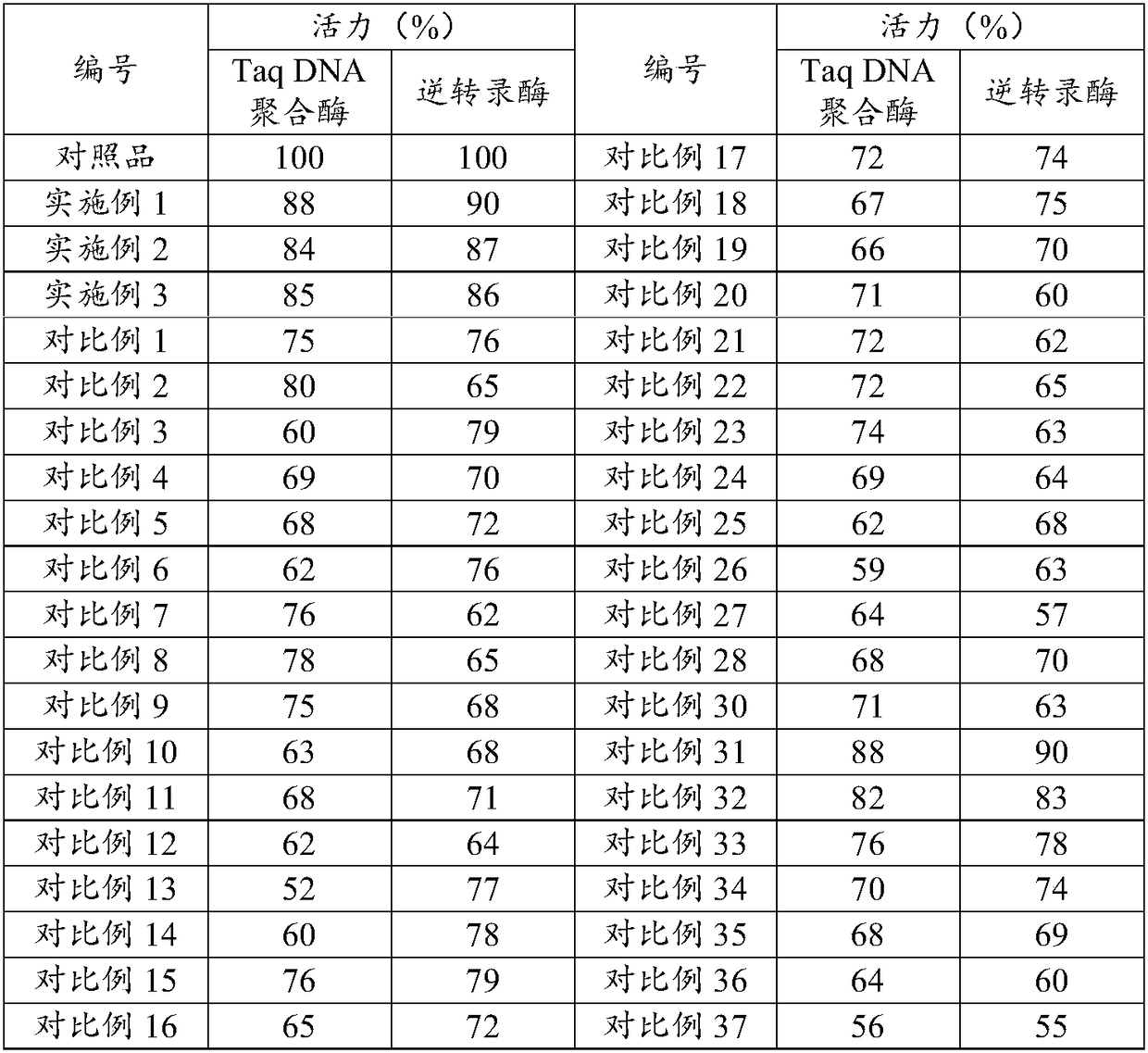

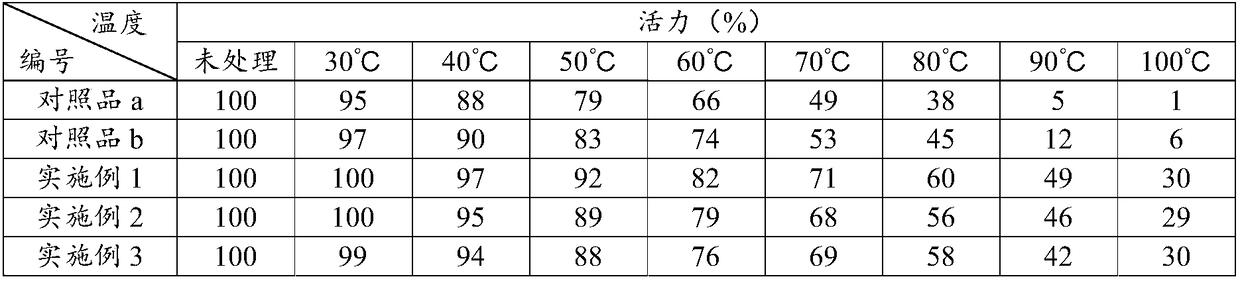

Co-immobilization method for DNA polymerase and reverse transcriptase, and application of co-immobilized DNA polymerase and reverse transcriptase

ActiveCN108342380AAchieve one-step conversionHigh catalytic efficiencyMicrobiological testing/measurementTransferasesBiotechnologyReverse transcriptase

The invention specifically relates to a co-immobilization method for DNA polymerase and reverse transcriptase, belonging to the field of enzyme engineering. The method comprises the following steps: adding sodium alginate into a first buffer, then adding DNA polymerase, carrying out mixing and immobilizing, and then carrying out vacuum drying so as to obtain immobilized DNA polymerase; adding a second buffer and reverse transcriptase into the immobilized DNA polymerase, carrying out mixing and immobilizing, then carrying out vacuum drying and then carrying out washing with the second buffer; and then carrying out lyophilization so as to obtain the co-immobilized DNA polymerase and reverse transcriptase. According to the invention, DNA polymerase and reverse transcriptase are co-immobilizedon a same carrier, so one-step conversion of a RT-PCR reaction is realized, and the catalytic properties of DNA polymerase and reverse transcriptase are integrated to eliminate certain interference factors, and thus, the overall catalytic efficiency of DNA polymerase and reverse transcriptase to RT-PCR reactions is improved.

Owner:SUZHOU BAIYUAN GENT CO LTD

Method for preparing zinc gluconate through co-immobilization of glucose oxidase and catalase

InactiveCN106754857AEnergy savingReduce manufacturing costOxidoreductasesOn/in organic carrierCatalytic oxidationGluconic acid

The invention discloses a method for preparing zinc gluconate through co-immobilization of glucose oxidase and catalase. Glucose is used as a substrate, and glucolactone, chitosan and calcium alginate are adopted for co-immobilization of glucose oxidase and catalase so as to achieve catalytic oxidation of glucose, so that zinc gluconate is prepared. By the adoption of the technique, enzyme activity is improved remarkably, the number of transformation steps is reduced, the glucose conversion rate is increased greatly, energy consumption is reduced, and production cost is reduced.

Owner:温县兴发生物科技有限公司

Amino-acid oxidase supported catalyst used for oxidizing amino acid to prepare ketonic acid

InactiveCN107129981ALow water solubilityImprove lipophilicityOrganic-compounds/hydrides/coordination-complexes catalystsOn/in organic carrierKetopinic acidKetonic acids

The invention discloses an amino-acid oxidase supported catalyst used for oxidizing amino acid to prepare ketonic acid and relates to the technical field of biological enzyme catalysts. A preparation method of the amino-acid oxidase supported catalyst includes the steps of firstly, preparing a co-immobilization agent; secondly, preparing a compound carrier; thirdly, preparing an activating carrier; fourthly, preparing the amino-acid oxidase supported catalyst. The prepared amino-acid oxidase supported catalyst can evidently increase the yield of the ketonic acid converted from the amino acid, the yield of an ketonic acid intermediate prepared from cephalosporin C is increased to above 95%, and the purity of the ketonic acid intermediate reaches above 99%.

Owner:MUDANJIANG MEDICAL UNIV

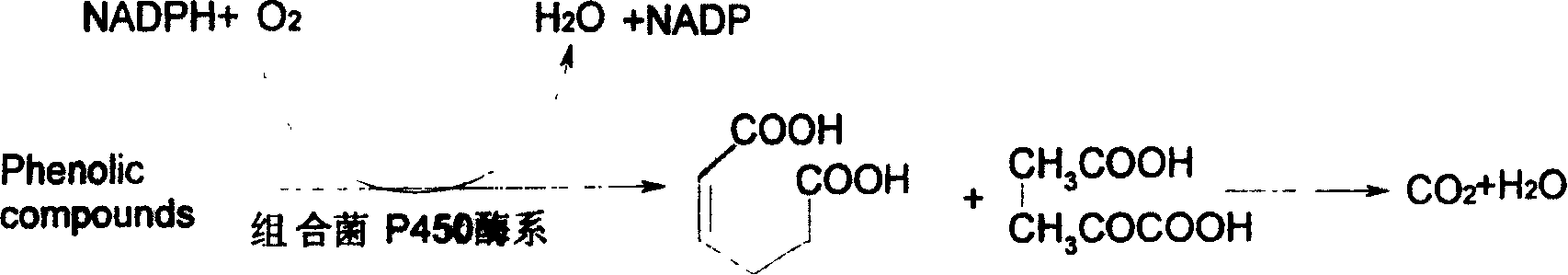

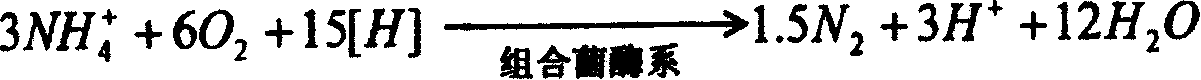

Method and apparatus for immobilizing cells to treat wastewater

InactiveCN100384761CQuality improvementHigh removal rateOn/in biological cellBiological water/sewage treatmentMyceliumEnzyme system

Owner:NANJING TECH UNIV

Co-immobilization glucose oxidase/catalase microspheres and application thereof in production of gluconic acid or gluconic salt

InactiveCN102943069BFacilitates covalent attachmentExtended service lifeChemical industryOn/in organic carrierMicrosphereCatalytic oxidation

The invention discloses co-immobilization glucose oxidase / catalase microspheres and application thereof in preparation of gluconic acid (salt) for catalytic oxidation of glucose. The co-immobilization glucose oxidase / the catalase microspheres can effectively promote covalent linkage of carriers and enzyme molecules, immobilization efficiency is improved greatly, service life of immobilization glucose oxidase (GOD) / catalase (CAT) is prolonged remarkably, the co-immobilization glucose oxidase / the catalase microspheres can be used repeatedly, are low in production cost, and facilitate sustainable development. Gluconic acid (salt) prepared by the co-immobilization glucose oxidase / the catalase microspheres is high in yield, reaction condition is temperate, a device is simple and easy to obtain, and the production method is environment-friendly.

Owner:BEIJING UNIV OF CHEM TECH

A method for co-immobilizing nitrosating bacteria-denitrifying bacteria

InactiveCN103805591BImprove nitrogen removal efficiencyRealize short-cut nitrification-denitrificationOn/in organic carrierDenitrifying bacteriaNitrifying bacteria

The invention discloses a method for co-immobilization of nitrite bacteria-denitrifying bacteria, belonging to a method for co-immobilization of cells. The method comprises the following steps: (1) embedding the denitrifying bacteria by use of sodium alginate and calcium chloride first; (2) mixing immobilized globules prepared in step (1) with the nitrite bacteria and sodium alginate, and dripping into calcium chloride for second embedding; (3) inoculating the co-immobilized nitrite bacteria-denitrifying bacteria prepared in step (2) in a culture medium containing ammonia nitrogen for culturing, wherein the co-immobilized nitrite bacteria-denitrifying bacteria can be used for degradation of the ammonia nitrogen. The method has the advantages that 1, co-immobilization culture of the nitrite bacteria and the denitrifying bacteria in the same carrier is realized for the first time; 2, the method for preparing the co-immobilized globules is simple and convenient, the operation procedures are easy to control, and the prepared co-immobilized globules are easy to store and reuse; 3, due to the co-immobilization culture of the nitrite bacteria and the denitrifying bacteria, the co-immobilized nitrite bacteria-denitrifying bacteria have higher denitrification efficiency than the traditional strain which is not immobilized or immobilized simplex strain, and is easy to be separated from the water body and recyclable.

Owner:XUZHOU UNIV OF TECH

A Microwave-Assisted Co-immobilization Method of Aldoketone Reductase and Glucose Dehydrogenase

ActiveCN104988132BIncrease forceReduce manufacturing costOn/in inorganic carrierMulti-enzyme systemsThermal stabilityGlucose dehydrogenase

The invention discloses a microwave-assisted co-immobilization method of aldehyde and ketone reductase and glucose dehydrogenase. The method comprises: mixing and activating a carrier cross-linking agent, centrifuging, washing the precipitate with PBS solution, centrifuging, and redispersing the precipitate In PBS solution; add aldehyde ketone reductase and glucose dehydrogenase to the dispersion liquid, irradiate the mixed solution at 0-10°C, 20-45W microwave conditions for 1-5min, centrifuge, take the precipitate and wash it with PBS solution to obtain a total Immobilized enzyme; compared with free enzyme, the co-immobilized enzyme prepared by the present invention has improved catalytic activity, thermal stability, and pH stability; glucose dehydrogenase as its coenzyme regeneration system can provide NAD required for the reaction (P)H reduces costs and is conducive to industrial production.

Owner:HANGZHOU NORMAL UNIVERSITY

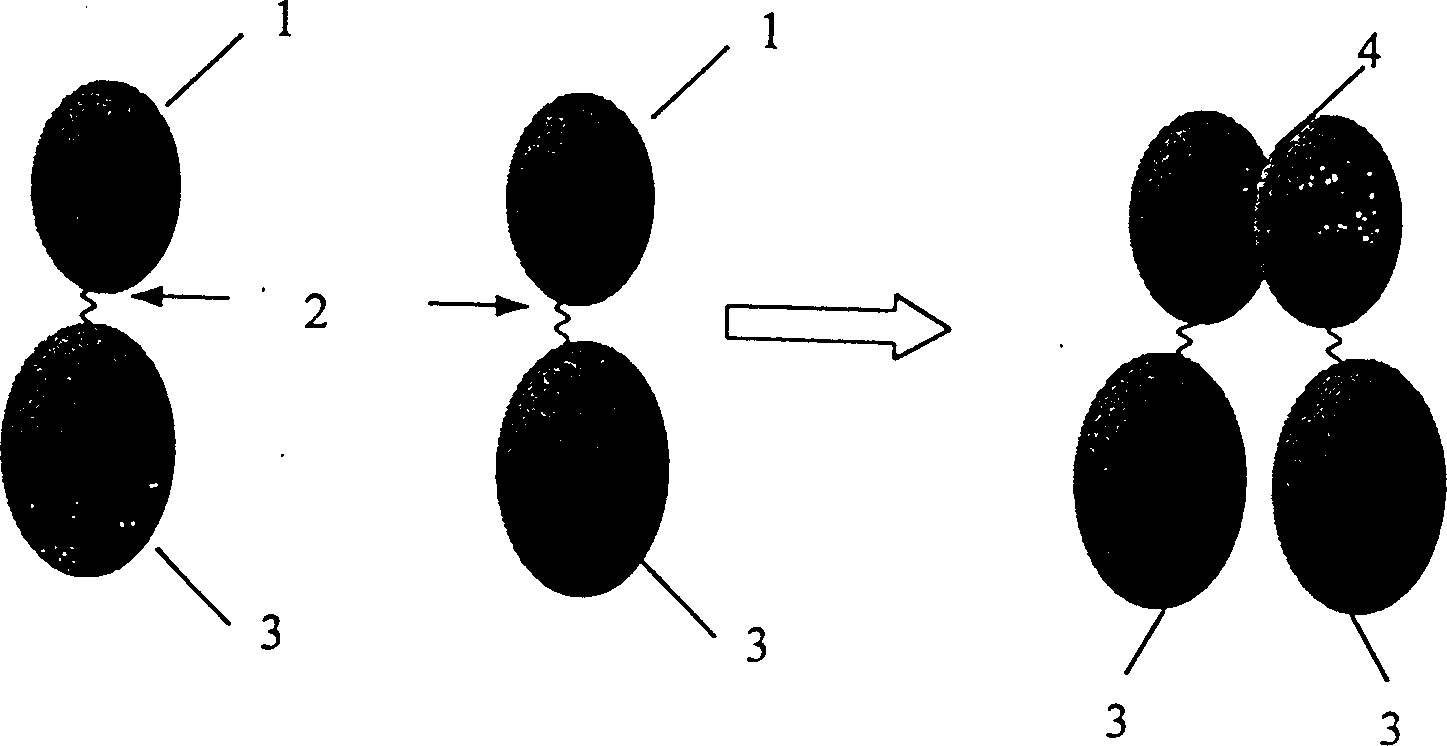

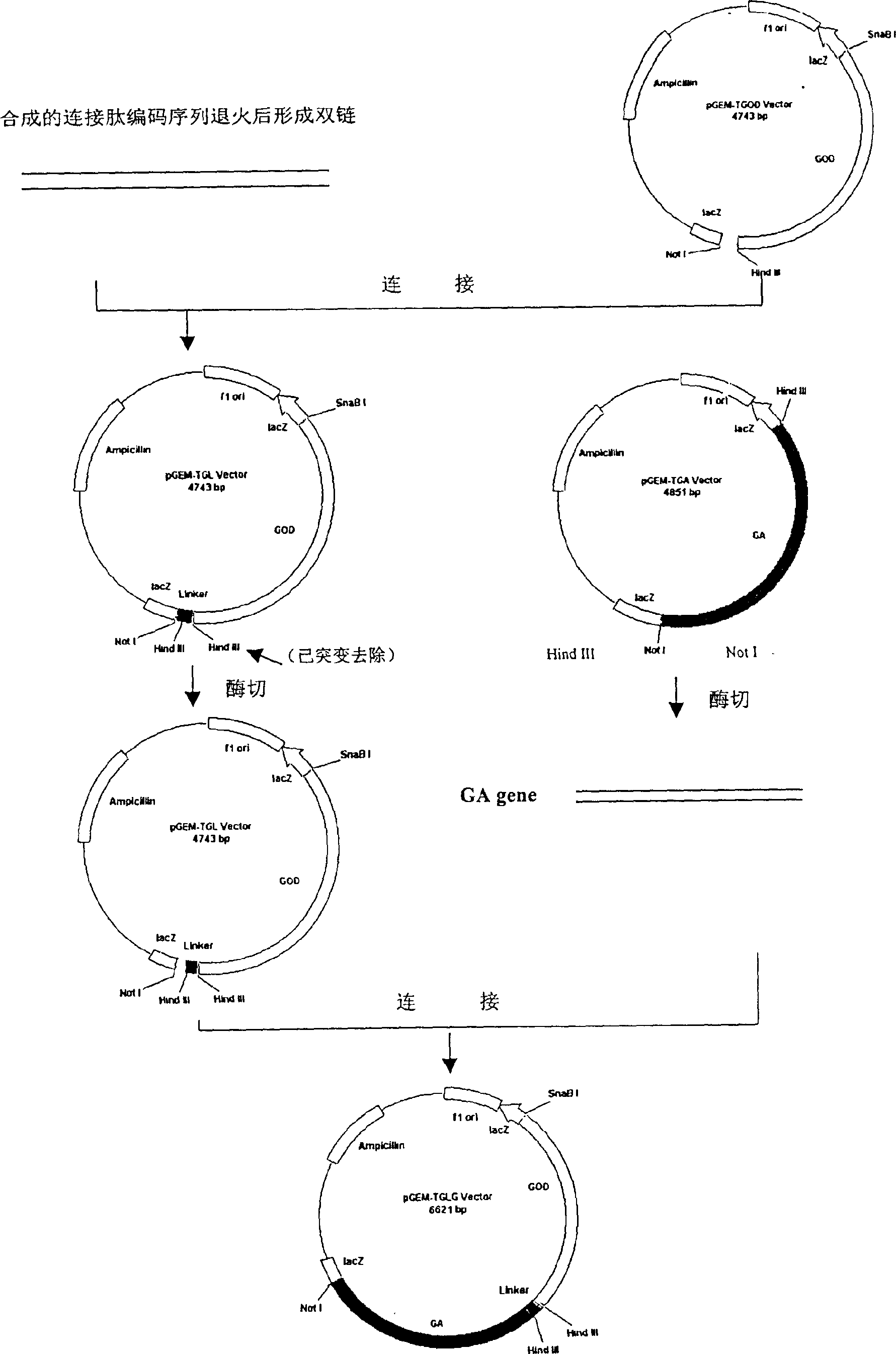

Method for catalyzing sequential enzyme reaction by using fusion protein

The present invention discloses a method for catalyzing sequential enzyme reaction (coupling reaction) by using fusion protein. Its steps are: utilizing external gene to splice, constitute and express "enzyme-connecting peptide-enzyme" double catalytic activity fusion protein to obtain pure fusion protein product, and comparing and analyzing catalytic kinetic property of fusion protein. The connecting peptide is used for increasing molecular distance between two enzymes are reducing their steric hindrance, and making the fusion protein maximally retain its original biological activity. Said fusion protein possesses catalytic activity of two enzymes simultaneously, and in the preparation of sequential enzyme sensor and enzyme reactor implements sequential active enzyme controlled co-immobilization so as to raise the reaction rate of sequential enzyme reaction. It is suitable for making high-quality sequential enzyme sensor and immobilized enzyme reactor.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

Method for preparing sodium gluconate through co-immobilization of glucose oxidase and catalase

InactiveCN106754858AEnergy savingReduce manufacturing costOxidoreductasesOn/in organic carrierCatalytic oxidationCalcium alginate

The invention discloses a method for preparing sodium gluconate through co-immobilization of glucose oxidase and catalase. Glucose is used as a substrate, and glucolactone, calcium alginate and chitosan are adopted for co-immobilization of glucose oxidase and catalase so as to achieve catalytic oxidation of glucose, so that sodium gluconate is prepared. By the adoption of the technique, enzyme activity is improved remarkably, the number of transformation steps is reduced, the glucose conversion rate is increased greatly, energy consumption is reduced, and production cost is reduced.

Owner:温县兴发生物科技有限公司

Preparation method and application of 2-phenylethanol by non-cell synthetic biology

ActiveCN106011184BAchieve recyclingReduce pollutionFermentationMulti-enzyme systemsCross-linkCross-linked enzyme aggregate

The invention discloses a noncellular synthetic biology based preparation method of 2-phenylethanol and an application. According to the preparation method and the application, three recombinases including ARO8, ARO10 and ADH1 are utilized to constitute a co-reaction system, and a complicated metabolic process of an Ehrlich pathway requiring multi-step continuous reaction and multi-enzyme participation for synthesis of 2-phenylethanol in microorganisms is simplified to be performed in the same reaction system in vitro, so that the environmental pollution is reduced and the reaction process is shortened. Furthermore, the three recombinases are subjected to carrier-free co-immobilization with glutaraldehyde serving as a cross-linking agent, Combi-CLEAs (Combi-Cross-linked Enzyme Aggregates) are prepared, a target product is synthesized in vitro, accordingly, the enzymes are further recycled on the basis of the beneficial effects, and the production cost is reduced; the preparation method fills up the technical blank of multi-enzyme preparation of 2-phenylethanol in vitro, and important reference is provided for biological preparation of 2-phenylethanol.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com