Co-immobilization glucose oxidase/catalase microspheres and application thereof in production of gluconic acid or gluconic salt

A technology of glucose oxidase and catalase, which is applied in the fields of immobilization on/in organic carriers, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of high immobilization cost, low recovery rate of enzyme activity, process Complicated problems, to achieve the effect of improving immobilization efficiency, high yield, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

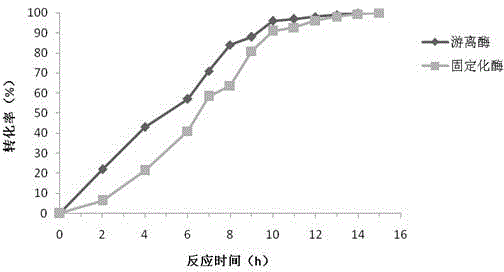

Image

Examples

Embodiment 1

[0026] A method for preparing co-immobilized glucose oxidase / catalase microspheres, the specific method steps are as follows:

[0027] Use 2% (v / v) bovine serum albumin solution as the amination reagent, the average pore size of the carrier is 100-200nm, according to the mass of the carrier: the volume of the amination reagent is 1:40, and the carrier is dispersed in the 2% (v / v) amination reagent , at pH 8.0, 200 rpm shaking reaction at 60° C. for 2 h, and the aminated carrier was collected. GOD and CAT were dissolved in 0.5 mol / l phosphate buffer at pH 6 according to the ratio of GOD:CAT activity ratio of 1:2. Disperse the aminated carrier in the enzyme solution, react at 30°C for 2 hours at a stirring speed of 200 rpm, add 2 times the volume of the reaction solution of acetone and 0.5% (v / v) glutaraldehyde to the reaction solution, and continue the reaction for 1 hour. The above reaction solution was filtered, the filtrate was discarded, and the solid matter was collected....

Embodiment 2

[0029] Use 2% (v / v) ethylenediamine solution as the amination reagent, the average pore size of the carrier is 100-200nm, according to the mass of the carrier: the volume of the amination reagent is 1:40, and the carrier is dispersed in the 2% (v / v) amination reagent , at pH 8.0, 200 rpm shaking reaction at 60° C. for 2 h, and the aminated carrier was collected. GOD and CAT were dissolved in 0.1 mol / l phosphate buffer at pH 6 according to the ratio of GOD:CAT activity ratio of 1:2. Disperse the aminated carrier in the enzyme solution, react at 30°C for 2 hours at a stirring speed of 200 rpm, add 2 times the volume of the reaction solution of acetone and 0.5% (v / v) glutaraldehyde to the reaction solution, and continue the reaction for 1 hour. The above reaction solution was filtered, the filtrate was discarded, and the solid matter was collected. For the collected solid matter, it was washed 3 times with 0.01 mol / l phosphate buffer solution of pH 7.0, and dried at 4°C to prepar...

Embodiment 3

[0031] Use 2% (v / v) ethylenediamine solution as the amination reagent, the average pore size of the carrier is 400-500nm, according to the mass of the carrier: the volume of the amination reagent is 1:40, and the carrier is dispersed in the 2% (v / v) amination reagent , at pH 8.0, 200 rpm shaking reaction at 60° C. for 2 h, and the aminated carrier was collected. GOD and CAT were dissolved in 0.1 mol / l phosphate buffer at pH 6 according to the ratio of GOD:CAT activity ratio of 1:2. Disperse the aminated carrier in the enzyme solution, react at 30°C for 2 hours at a stirring speed of 200 rpm, add 2 times the volume of the reaction solution of acetone and 0.5% (v / v) glutaraldehyde to the reaction solution, and continue the reaction for 1 hour. The above reaction solution was filtered, the filtrate was discarded, and the solid matter was collected. For the collected solid matter, it was washed 3 times with 0.01 mol / l phosphate buffer solution of pH 7.0, and dried at 4°C to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com