Immobilization method for thermolysin

A technology of thermolysin and amination, which is applied in the direction of immobilization on/in the organic carrier, can solve the problems of covalent immobilization difficulties, low solubility of thermolysin, etc., to shorten the immobilization time, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of fatty acid methyl ester sulfonate solution of thermolysin

[0038] (1) Take 2 mg of thermolysin (free enzyme, purchased from Sigma-Aldrich Shanghai Branch, the same below), disperse it with 2 ml of MES-NaOH solution with pH 7.0, 0.02M, and place it at -4°C for half an hour , to obtain 1 mg / ml fatty acid methyl ester sulfonate solution of thermolysin free enzyme.

[0039] (2) Take 2mg of thermolysin, use 2ml containing 20mM ZnCl 2 pH 7.0, 0.02M MES-NaOH solution was dispersed, and placed at -4°C for half an hour to obtain a 1 mg / ml fatty acid methyl ester sulfonate solution of thermolysin free enzyme.

[0040] (3) Take 2mg thermolysin, use 2ml containing 3M NaCl, 20mM ZnCl 2 pH 7.0, 0.02M MES-NaOH solution was dispersed, and placed at -4°C for half an hour to obtain a 1 mg / ml fatty acid methyl ester sulfonate solution of thermolysin free enzyme.

Embodiment 2

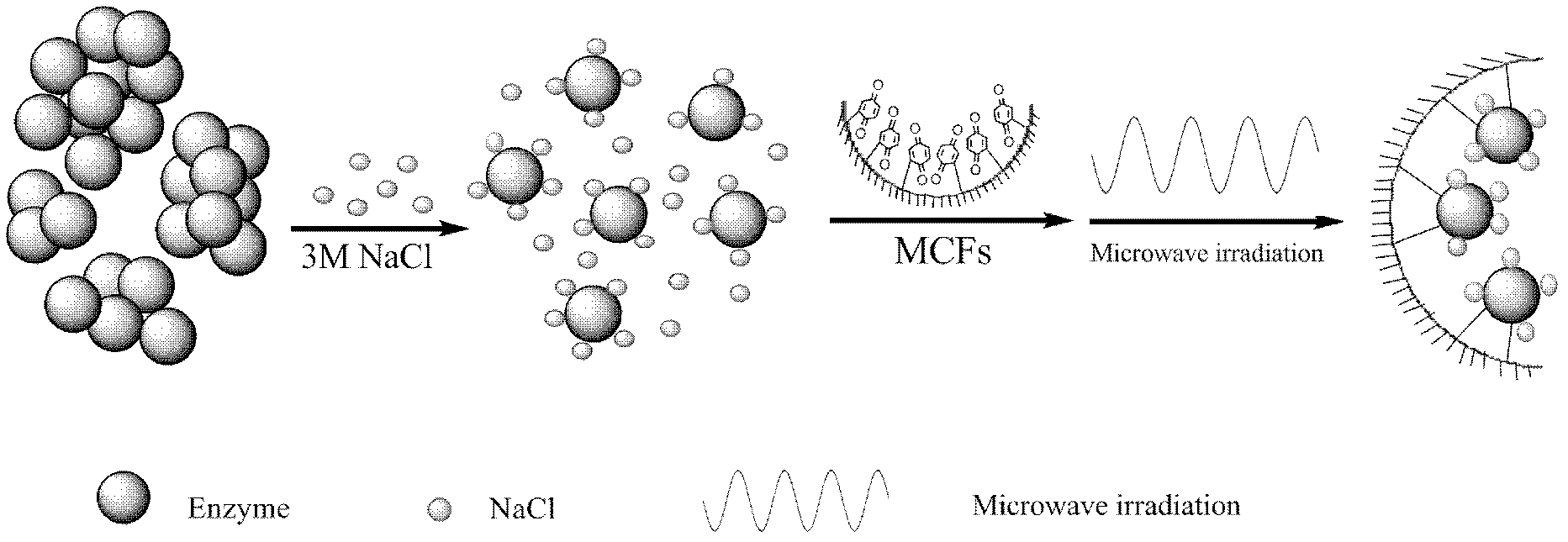

[0041] Embodiment 2: Preparation of thermolysin free enzyme into immobilized thermolysin:

[0042] A. Preparation of fatty acid methyl ester sulfonate solution of thermolysin free enzyme: take 2mg thermolysin free enzyme, use 2ml containing 3M NaCl, 20mM ZnCl 2 pH 7.0, 0.02M MES-NaOH solution was dispersed, and placed at -4°C for half an hour to obtain a 1 mg / ml fatty acid methyl ester sulfonate solution of thermolysin free enzyme.

[0043] B. Preparation of Thermolysin Free Enzyme as Immobilized Thermolysin:

[0044] (1) Carrier MCFs-NH 2 Preparation of:

[0045] ① Hydrothermal process: first weigh P123 (triblock copolymer: poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol), PEO-PPO-PEO) 5.34g and batch with water Dissolve for the first time so that it can be completely transferred to the container, then add 61.34mg of ammonium fluoride and start stirring, then add 6.2ml of TMB (1.3.5-trimethylbenzene) and 27.4ml of hydrochloric acid (36.5wt%). ...

Embodiment 3

[0050] Embodiment 3: Thermolysin free enzyme is prepared into immobilized thermolysin by microwave method:

[0051] A. Preparation of fatty acid methyl ester sulfonate solution of thermolysin free enzyme: take 2mg thermolysin free enzyme, use 2ml containing 3M NaCl, 20mM ZnCl 2 PH 7.0, 0.02M MES-NaOH solution was dispersed, and placed at -4°C for half an hour to obtain a 1 mg / ml fatty acid methyl ester sulfonate solution of thermolysin free enzyme.

[0052] B. Preparation of Thermolysin Free Enzyme as Immobilized Thermolysin:

[0053] (1) Preparation of carrier:

[0054] With embodiment 2.

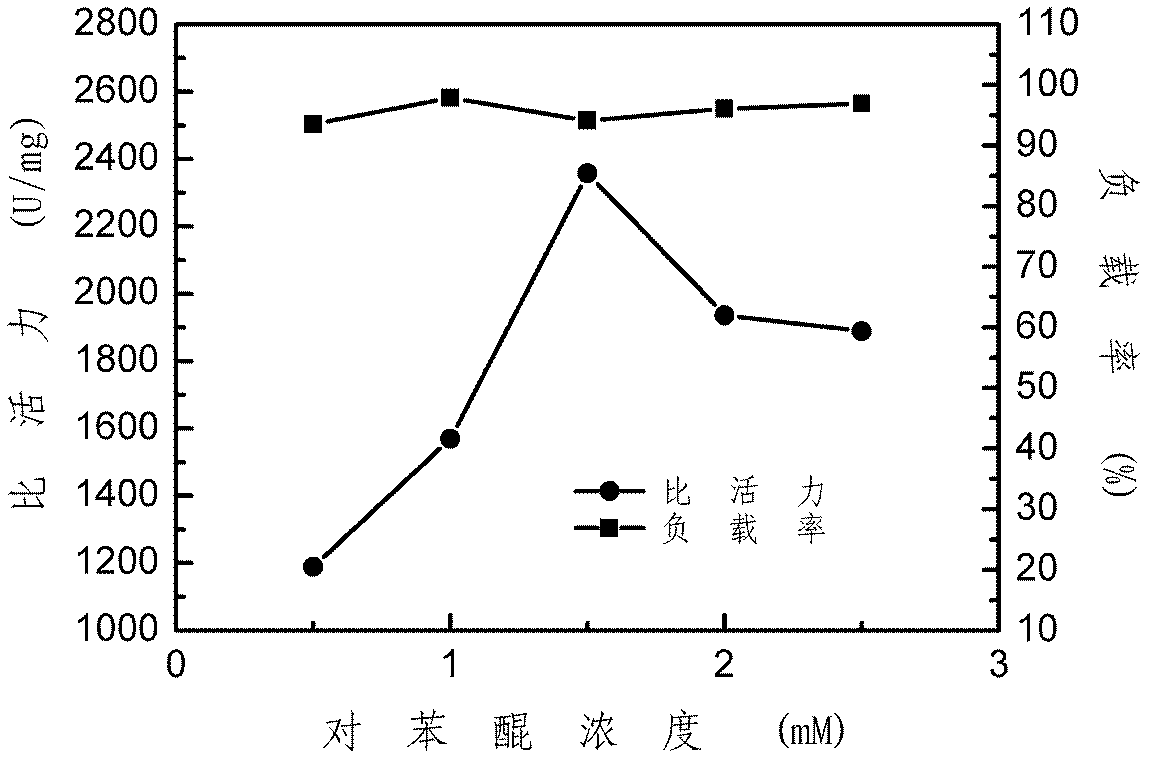

[0055] (2) Activate the carrier: select 3ml of p-benzoquinone solution so that the final concentration in the reaction solution is 1.5mM and 10mg of MCFs-NH 2 Shake in a constant temperature water bath shaker at 25°C at 160rpm for 2 hours, centrifuge, wash the precipitate with 20% ethanol and pure water, and redisperse the washed precipitate in 2.6ml containing 3M NaCl, 20mM ZnCl 2 PH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com