Method for co-immobilizing anaerobic ammoxidation bacteria-short-cut nitrobacteria and application thereof

An anammox bacteria, anammox technology, applied in chemical instruments and methods, immobilized on or in inorganic carriers, immobilized on/in organic carriers, etc., can solve the problem of high Anammox cell density, The accumulation rate of nitrous is difficult to maintain stable and cannot be maintained, so as to achieve the effect of weakening the sludge loss rate, high mechanical strength and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

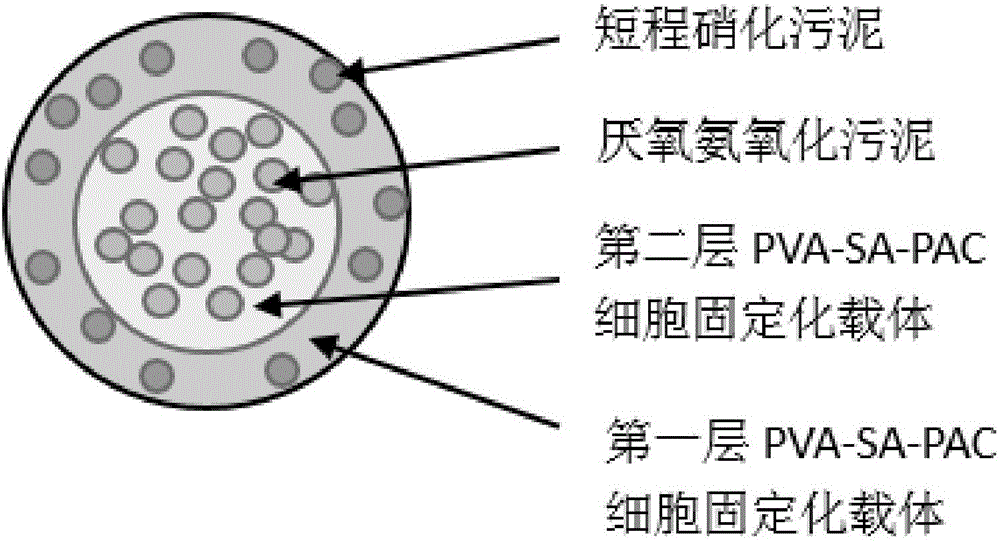

[0028] Example 1: Preparation of Anammox Bacteria-Short-range Nitrifying Bacteria Gel Beads

[0029]The anammox sludge with a sludge concentration of 8000mg / L was washed 3 times with a phosphate buffer solution with a pH of 7-7.5 and then used for later use. The short-course nitrification sludge with a nitrite accumulation rate > 90% was washed with deionized water for 3 times. Standby after repeated times; choose wooden powdery activated carbon, first wash to remove impurities and dust, and then soak for 24 hours with 10% hydrochloric acid, 2% sodium hydroxide, and normal saline with a concentration of 10% by mass. According to the concentration of 15g / L, 2g / L, 2g / L, prepare 500ml polyvinyl alcohol (PVA)-sodium alginate (SA)-activated carbon mixed solution ①, heat at 120°C for 20min to accelerate the dissolution; according to 50g / L and 2g / L mass-volume percent concentration preparation 1000ml sodium nitrate (NaNO 3 ) and calcium chloride (CaCl 2 ) mixed fixative ②. Embeddi...

Embodiment 2

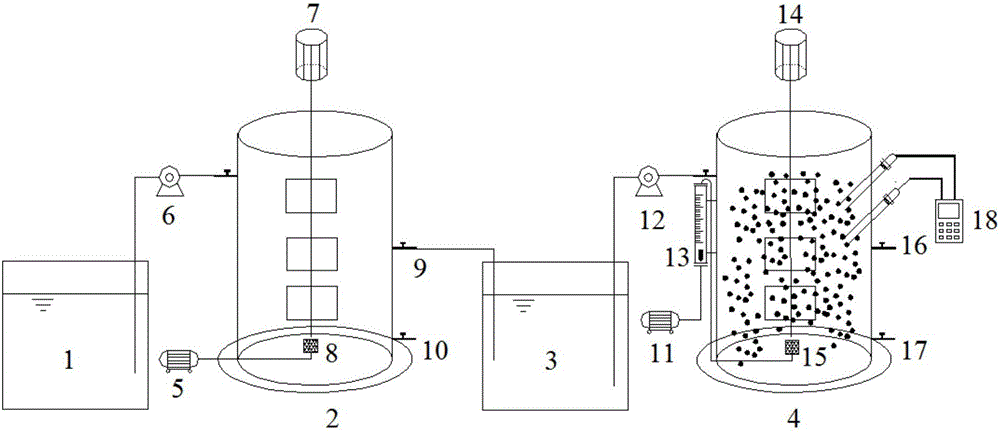

[0030] Example 2: Co-immobilization process

[0031] The system is composed of urban sewage raw water tanks, biological carbon removal reactors, intermediate water tanks and full autotrophic denitrification reactors in series; urban sewage raw water tanks are connected to the inlet pipes of biological carbon removal reactors through the first water inlet pump; biological carbon removal The reactor is equipped with a first air compressor, a first aeration head, a first agitator, a first vent valve and an outlet valve; the outlet valve of the biological carbon removal reactor is connected to the intermediate water tank through the outlet pipe; the intermediate water tank is connected through the second inlet The water pump is connected to the water inlet valve of the fully autotrophic denitrification reactor; the fully autotrophic denitrification reactor is equipped with a second air compressor, a second aeration head, a second vent valve, a second outlet valve, a second agitator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com