A production and assembly machine and method for cable hoops of electric installation accessories

A technology for assembling machinery and accessories, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low efficiency of hoop assembly, and achieve the effect of improving installation efficiency and assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

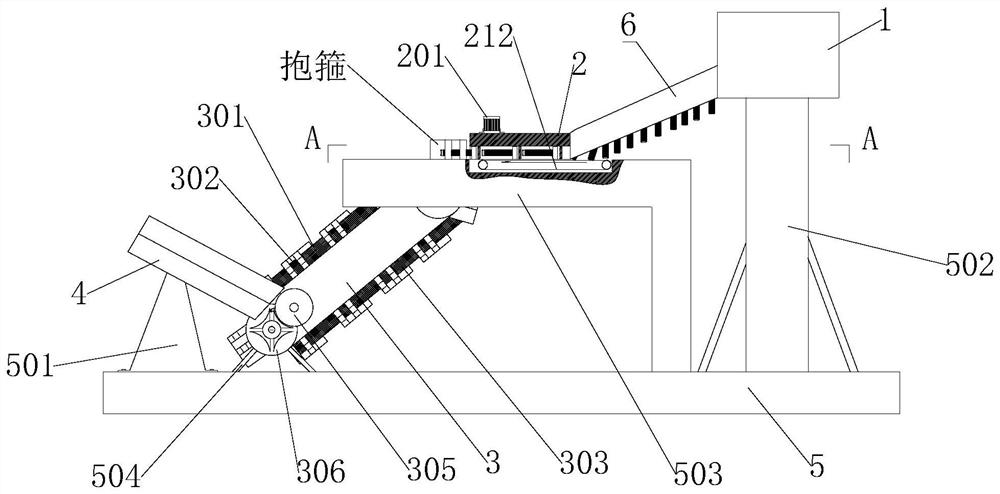

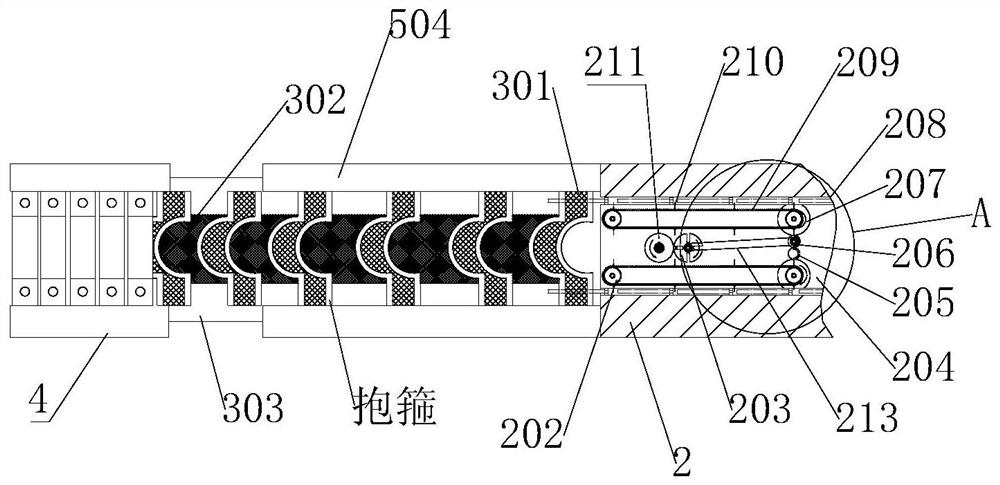

[0048] see Figure 1-8 as well as Figure 10 , is a schematic diagram of the overall structure of a cable hoop production and assembly machine for electric installation accessories, a cable hoop production and assembly machine for electric installation accessories, including a vibrating plate 1, an assembly chassis 2, an arrangement conveying component 3, and a feeding plate 4 , the base 5, the guide plate 6, and the vibrating plate 1 are set at the highest point of the cable hoop production of the power installation accessories to cooperate with the assembly machine. Image 6 Arranged in the same pattern, the bolts are slid down in an orderly manner through the guide plate 6, which is convenient for inserting the bolts into the connecting holes of the hoop. Among them, the vibrating plate 1 is a double-track screw vibrating plate sold on the market, and the double-track screw vibrates The disc 1 is connected with two inclined guide plates 6 to continuously feed the two guide...

Embodiment 2

[0064] see Figure 1-10 , is a schematic diagram of the overall structure of a production and assembly method for cable hoops of electric installation accessories. This embodiment has the same content as the above-mentioned embodiment 1, and the similarities will not be described in this embodiment. The specific differences in:

[0065] The production and coordination assembly method of the cable hoop of the electric installation accessory is completed by the production and coordination of the assembly machine of the cable hoop of the electric installation accessory in Embodiment 1, and specifically includes the following steps:

[0066] S1, preparation before assembly, pour the bolts to be assembled into the vibrating plate 1, spread the hoops to be assembled in the hoop groove 401 of the feeding plate 4;

[0067] S2. Arrange the bolts. Arrange the bolts placed in the vibrating plate 1 in step S1. Arrange the bolts through the vibrating plate 1 so that each bolt is placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com