Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Caesium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caesium hydroxide or cesium hydroxide (CsOH) is a chemical compound consisting of caesium ions and hydroxide ions. It is a strong base (pKb=-1.76), much like the other alkali metal hydroxides such as sodium hydroxide and potassium hydroxide. In fact, caesium hydroxide is corrosive enough to corrode through glass quickly.

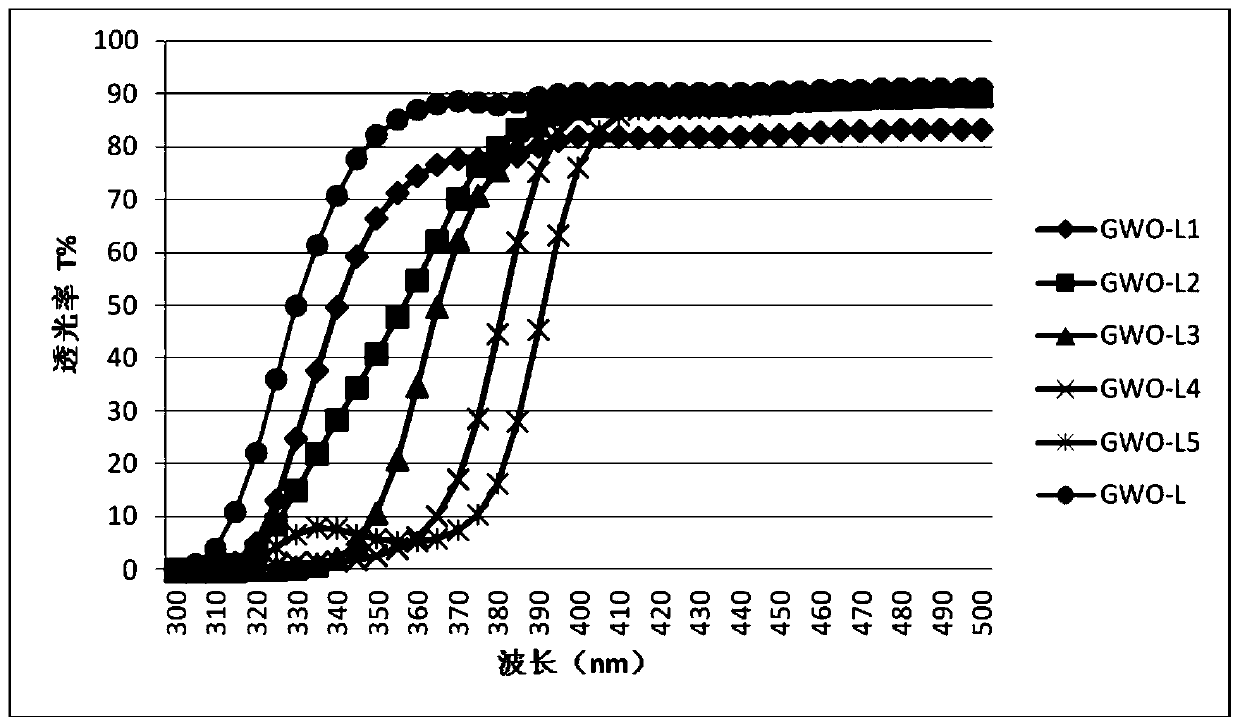

Preparation methods for cesium tungsten bronze modified powder and slurry thereof

ActiveCN107513293ASolve the problem of UV discoloration resistanceIncrease productivityNon-macromolecular adhesive additivesFilm/foil adhesivesDecompositionSlurry

The invention provides preparation methods for a cesium tungsten bronze modified powder and slurry thereof, wherein the preparation methods of the cesium tungsten bronze modified powder include the steps that a cesium hydroxide and nano tungsten oxide solid solution is subjected to decomposition reduction by ammonia water under catalytic action of nano nickel oxide, and a cesium tungsten bronze powder is obtained; and in addition, the obtained cesium tungsten bronze powder has the powder surface modified by a coupling agent and infrared and ultraviolet absorbers to obtain a cesium tungsten bronze modified powder, the modified powder is dispersed in a PVB special-effect plasticizer 3G8 dispersant by a sand mill, and furthermore, the cesium tungsten bronze modified powder slurry is obtained.

Owner:广州市黑本新材料科技有限公司

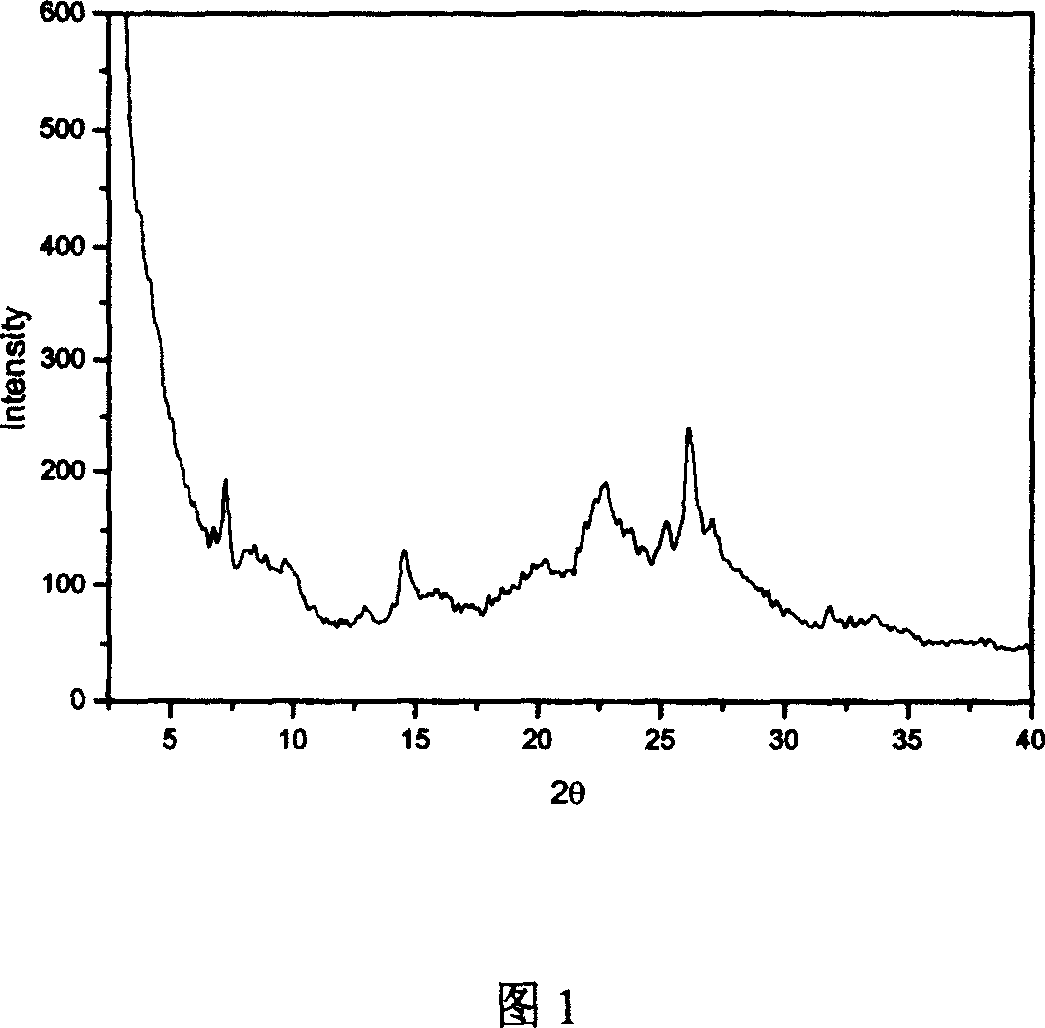

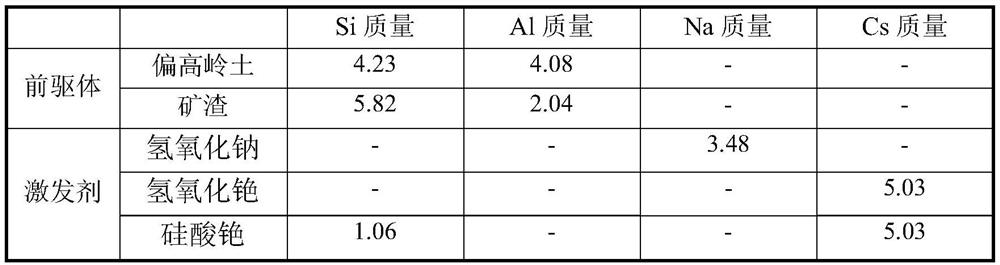

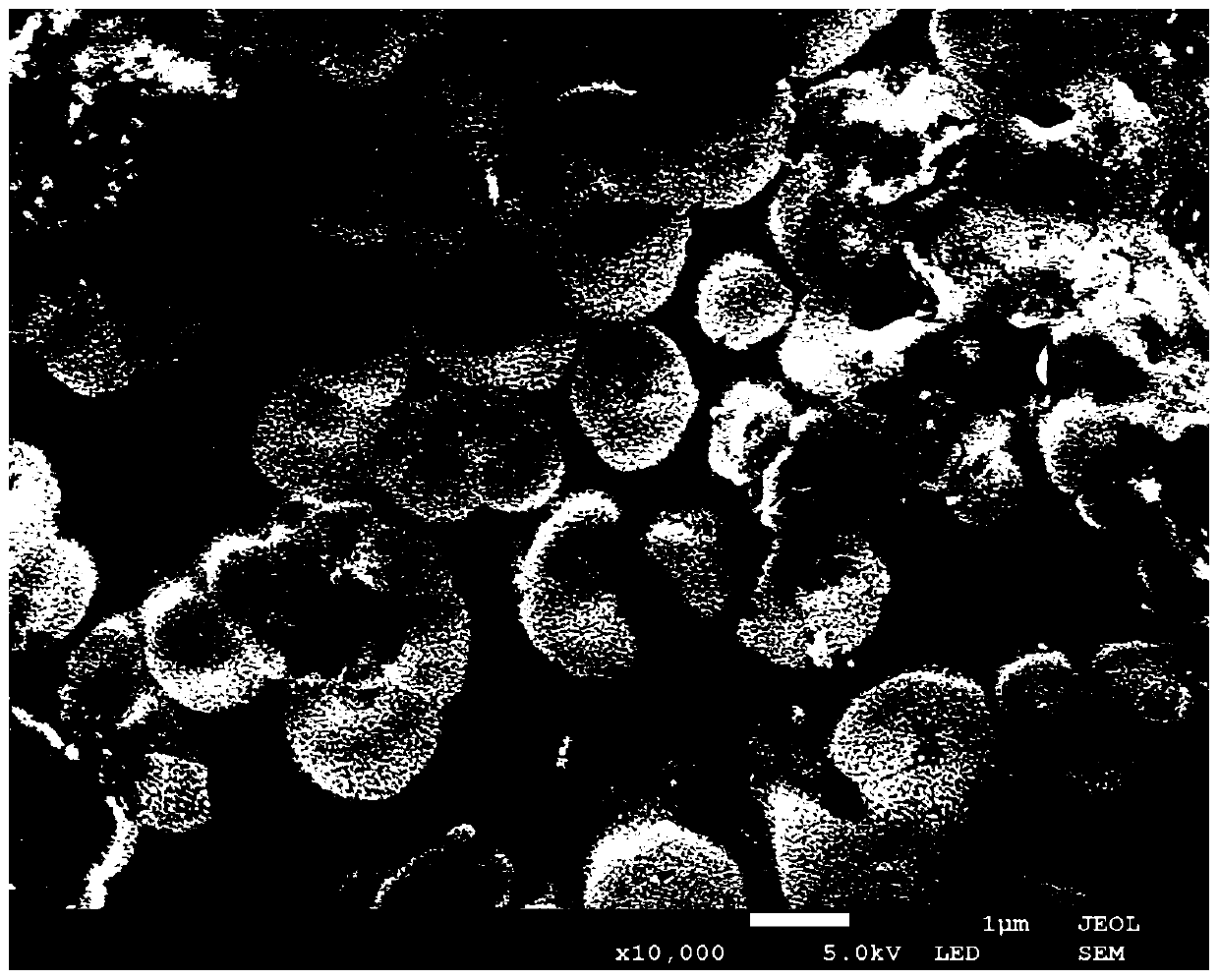

Method for synthesizing pollucite by means of aluminosilicate polymer

The invention provides a method for synthesizing pollucite by means of an aluminosilicate polymer.The method comprises the steps that cesium hydroxide and sodium hydroxide are dissolved in silica sol with the mass concentration of 25%-45%, mechanical stirring is conducted, and a mixed alkali-activated solution of cesium silicate and sodium silicate is obtained; kaolin is put into an alumina crucible, the alumina crucible containing kaolin is put into a muffle furnace, the temperature is set to range from 500 DEG C to 900 DEG C, the heat preservation time ranges from 1.5 h to 2.5 h, and metakaolin powder is obtained; the mixed alkali-activated solution is put into an ice-water bath with the temperature ranging from 0 DEG C to 5 DEG C, the metakaolin powder is added, ultrasound treatment and mechanical stirring are conducted for 25 min-45 min, an aluminosilicate polymer slurry is obtained, deionized water is added to adjust the viscosity of the slurry to be 150 mPa.s-500 mPa.s when the shearing speed is 60 S<-1>-80 S<-1>, and the aluminosilicate polymer slurry is obtained; the obtained aluminosilicate polymer slurry is poured into a mold and cured for 3 h-24 h in a drying oven with the temperature ranging from 40 DEG C to 80 DEG C, and then pollucite is obtained.

Owner:HARBIN INST OF TECH

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

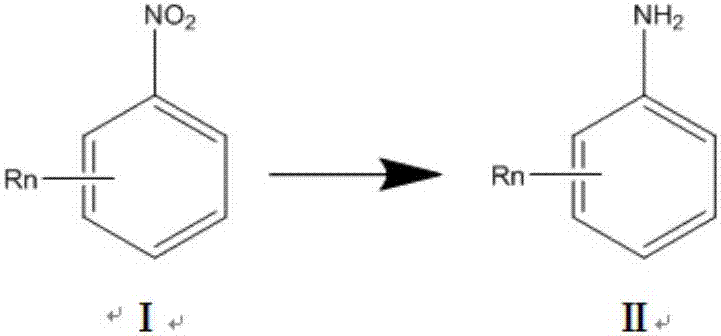

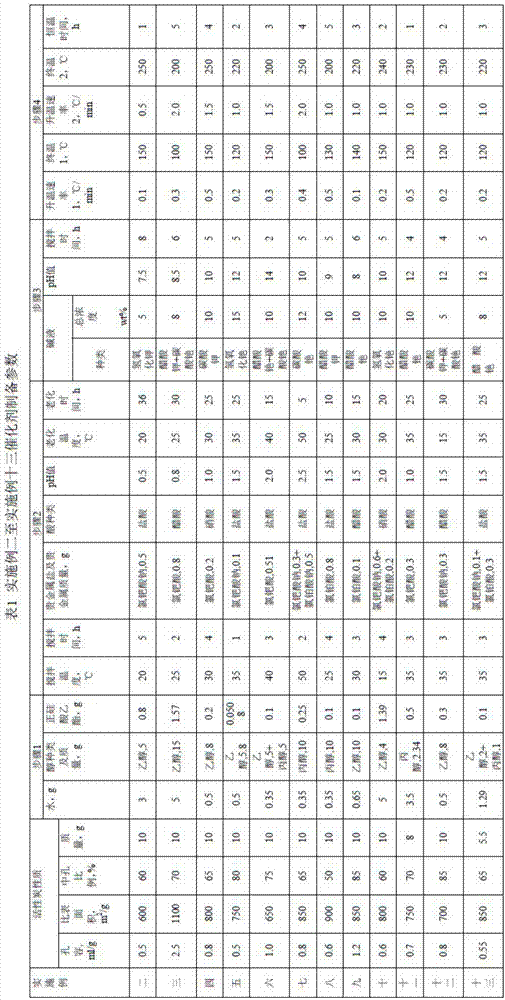

Supported noble-metal hydrogenation catalyst, and preparation method and application of catalyst

ActiveCN107469813AFast filteringImprove stabilityOrganic compound preparationCatalyst activation/preparationActivated carbonAlcohol

The invention discloses a supported noble-metal hydrogenation catalyst, and a preparation method and an application of the catalyst. The catalyst is prepared according to the following steps: (1) preparing a mixed solution consisting of water, an alcohol and tetraethyl orthosilicate; (2) pouring activated carbon into the mixed solution obtained in the step (1) and performing stirring, then adding a soluble noble metal salt, regulating the pH value of the slurry to a range of 0.5-2.5, and performing stirring aging to obtain a reaction slurry; (3) adding a base liquor into the reaction slurry to regulate the pH value to a range of 7.5-14, wherein the basic substance in the base liquor is one or a combination of more selected from a group consisting of potassium hydroxide, cesium hydroxide, potassium acetate, cesium acetate, potassium carbonate and cesium carbonate, continuing to perform stir, and finally performing filtering and washing to obtain a catalyst precursor; and (4) performing reduction on the catalyst precursor to obtain the supported noble-metal hydrogenation catalyst. The invention provides an application of the catalyst in catalyzing hydrogenation synthesis of amino phenyl ether compounds which are represented as a formula II by using compounds which are represented as a formula II, the conversion rate reaches 100%, the selectivity can reach 99.5% or more, and the catalyst can be used for 50 times or more.

Owner:ZHEJIANG UNIV OF TECH

Catalyst for producing methacrylic acid and preparation method thereof

InactiveUS7825061B2Organic compound preparationHeterogenous catalyst chemical elementsGas phaseActive component

The object of the present invention is to provide a catalyst for producing methacrylic acid in high yield and highly selectively by subjecting methacrolein, isobutylaldehyde or isobutyric acid to gas phase catalytic oxidation, and the preparation method thereof. The catalyst contains Mo, V, P, Cu, Cs and NH4 as the essential, active components, and the feature is to use for preparing the catalyst a cesium weak acid salt or cesium hydroxide as the Cs raw material and ammonium acetate as the NH4 raw material. A coated catalyst of the present invention is obtainable by supporting the active component on an inert carrier of alumina or the like.

Owner:NIPPON KAYAKU CO LTD

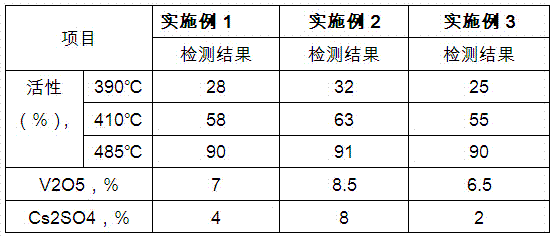

Catalyst containing caesium and vanadium and preparation method thereof

InactiveCN105435772AExtended service lifeQuality improvementSulfur compoundsMetal/metal-oxides/metal-hydroxide catalystsSulfite saltPotassium hydroxide

The invention discloses a catalyst containing caesium and vanadium and a preparation method thereof. With the total mass of the catalyst components as 100% parts, the content of vanadium pentoxide is 5-10%, the content of cesium oxide is 2-14%, the content of potassium oxide is 6-14%, the content of sodium oxide is 1-9%, and the balance is diatomaceous earth. A raw material of the cesium oxide is salt or alkali containing the cesium, such as cesium sulfate (Cs2SO4), cesium carbonate (Cs2CO3) or cesium hydroxide (CsOH). A raw material of the potassium oxide is salt or alkali containing potassium like potassium sulfate, potassium sulfite or potassium hydroxide. A raw material of the sodium oxide is salt or alkali containing sodium like sodium sulfate, sodium sulfite or sodium hydroxide. The catalyst is stable in performance, low in operating temperature, wide in areas, slow in heat fading and high in catalytic efficiency.

Owner:贵州威顿催化技术有限公司

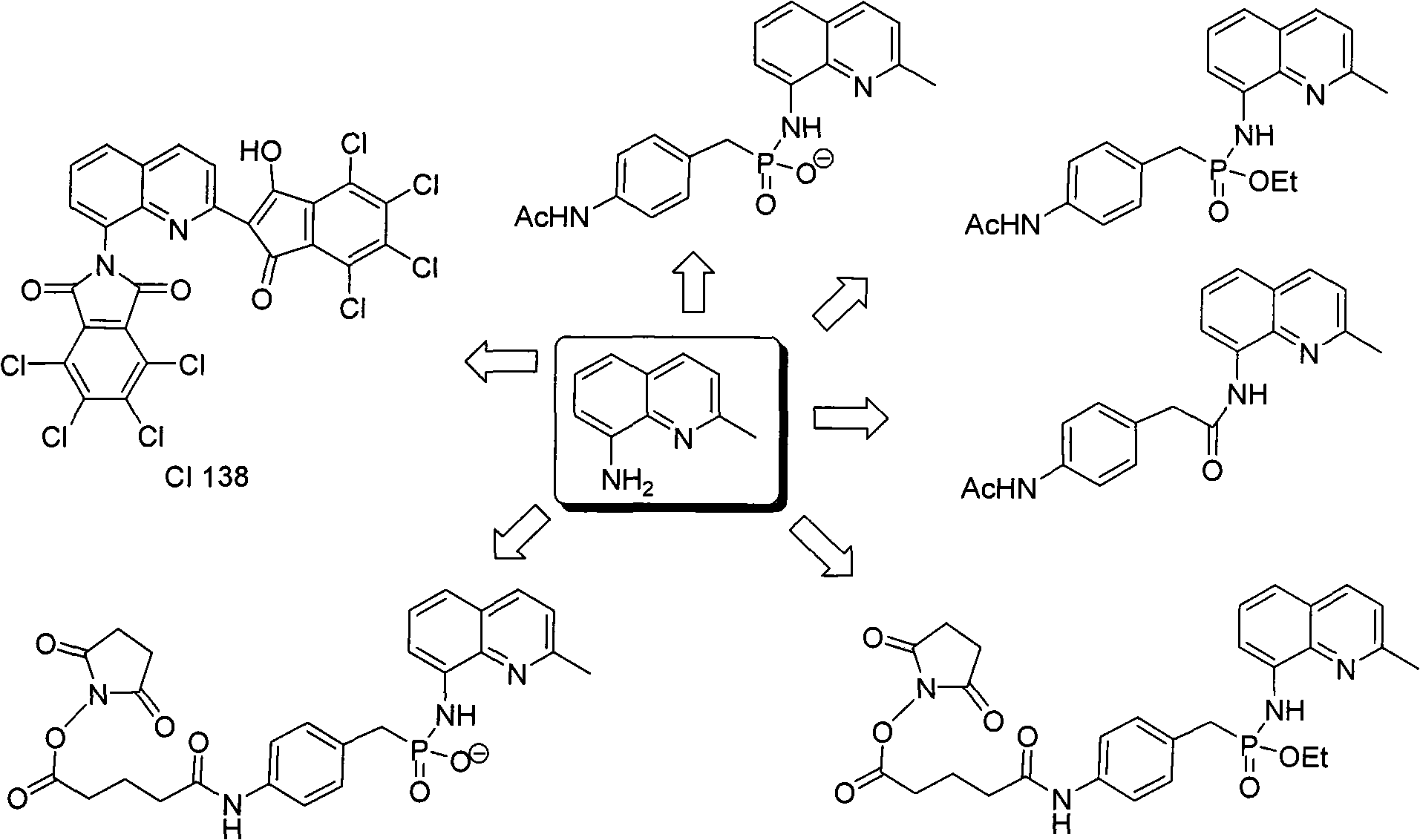

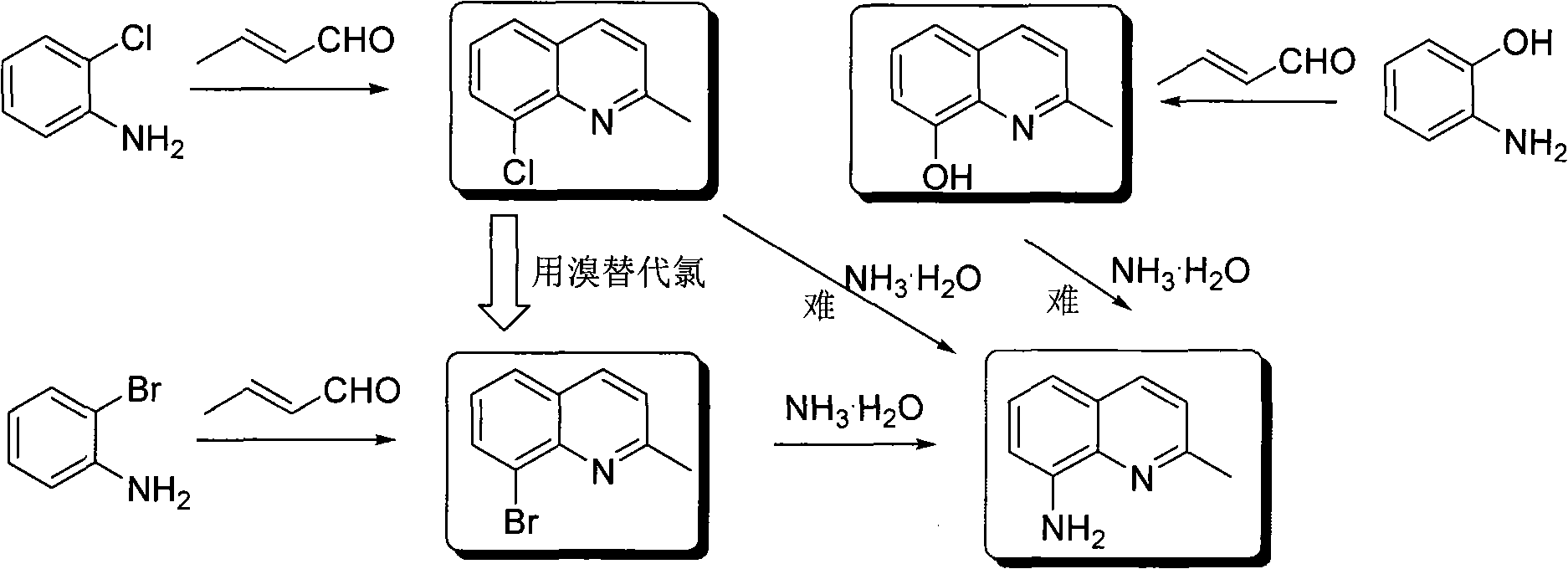

Preparation method of 2-methyl-8-aminoquinoline

InactiveCN101602723AIncrease the activity of the substitution reactionImprove responseOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChlorobenzeneCrotonaldehyde

The invention discloses a preparation method of 2-methyl-8-aminoquinoline. The preparation method of 2-methyl-8-aminoquinoline comprises the step of ammoniating 2-methyl-8-bromoquinoline in a solvent at 60-120 DEG C under the action of catalyst and strong alkali to obtain the 2-methyl-8-aminoquinoline, wherein the catalyst is one or more selected out of copper acetylacetonate, iron acetylacetonate, cobalt acetylacetonate and zinc acetylacetonate, the solvent used is one or more selected out of dimethylsulfoxide, N, N-dimethylformamide, acetylacetone, tetrahydrofuran and N-methylpyrrolidone, and the strong alkali is one or more selected out of caesium carbonate, caesium hydroxide, potassium carbonate and potassium hydroxide. The preparation method of the intermediate 2-methyl-8-bromoquinoline comprises the step of performing a cyclization reaction on o-bromoaniline and crotonic aldehyde in a solvent in the presence of oxidant and mollient, so as to obtain the 2-methyl-8-bromoquinoline, wherein the oxidant is selected out of one or more of nitrobenzene, 2-nitrobromobenzene, ammonium ceric nitrate, vanadic acid and iron oxide, the mollient is selected out of one or more of glacial acetic acid, hydrochloric acid, ferrous sulfate and boric acid, and the solvent is selected out of one or more of hydrochloric acid, sulfuric acid and chlorobenzene.

Owner:HUNAN UNIV

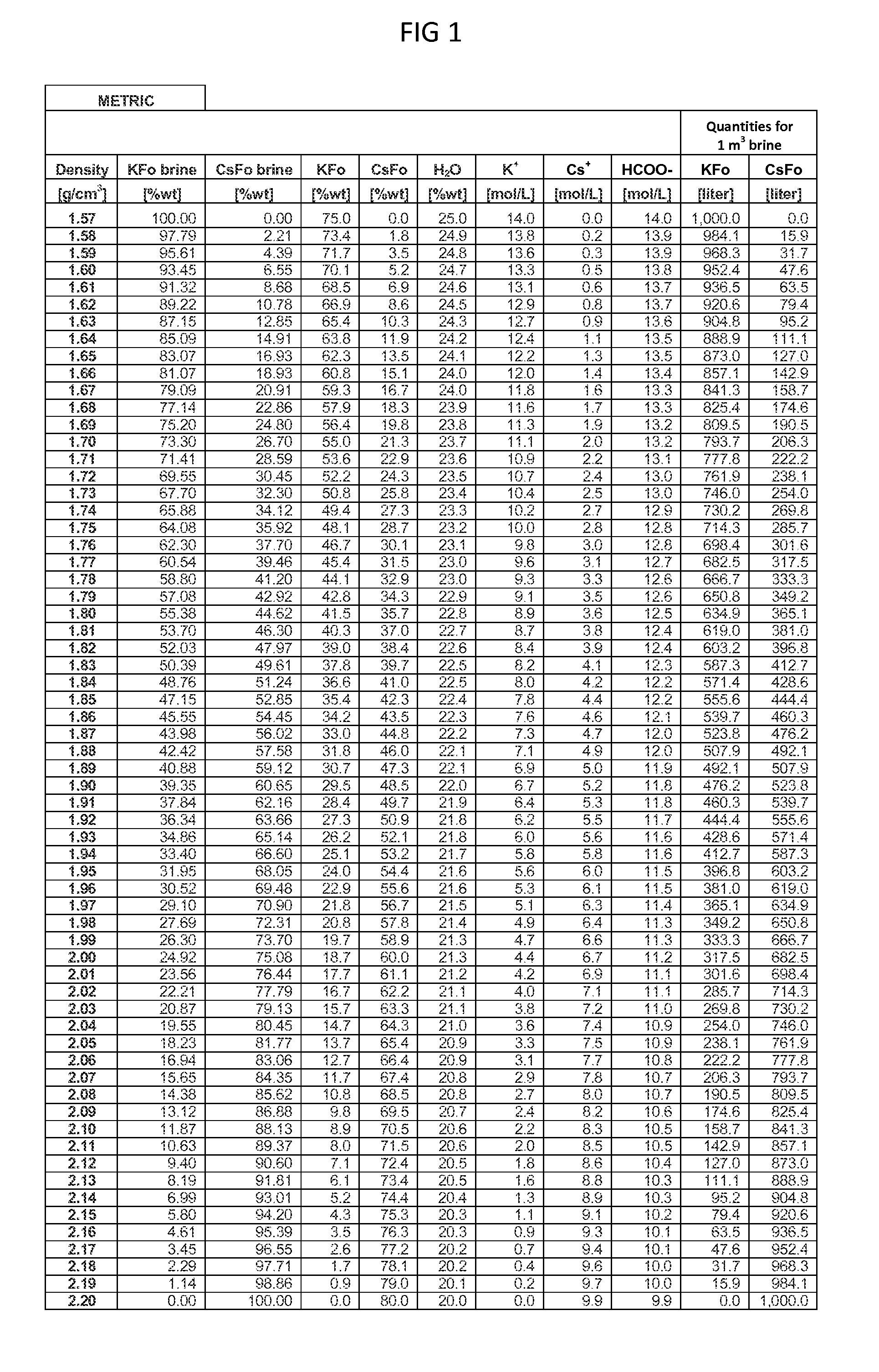

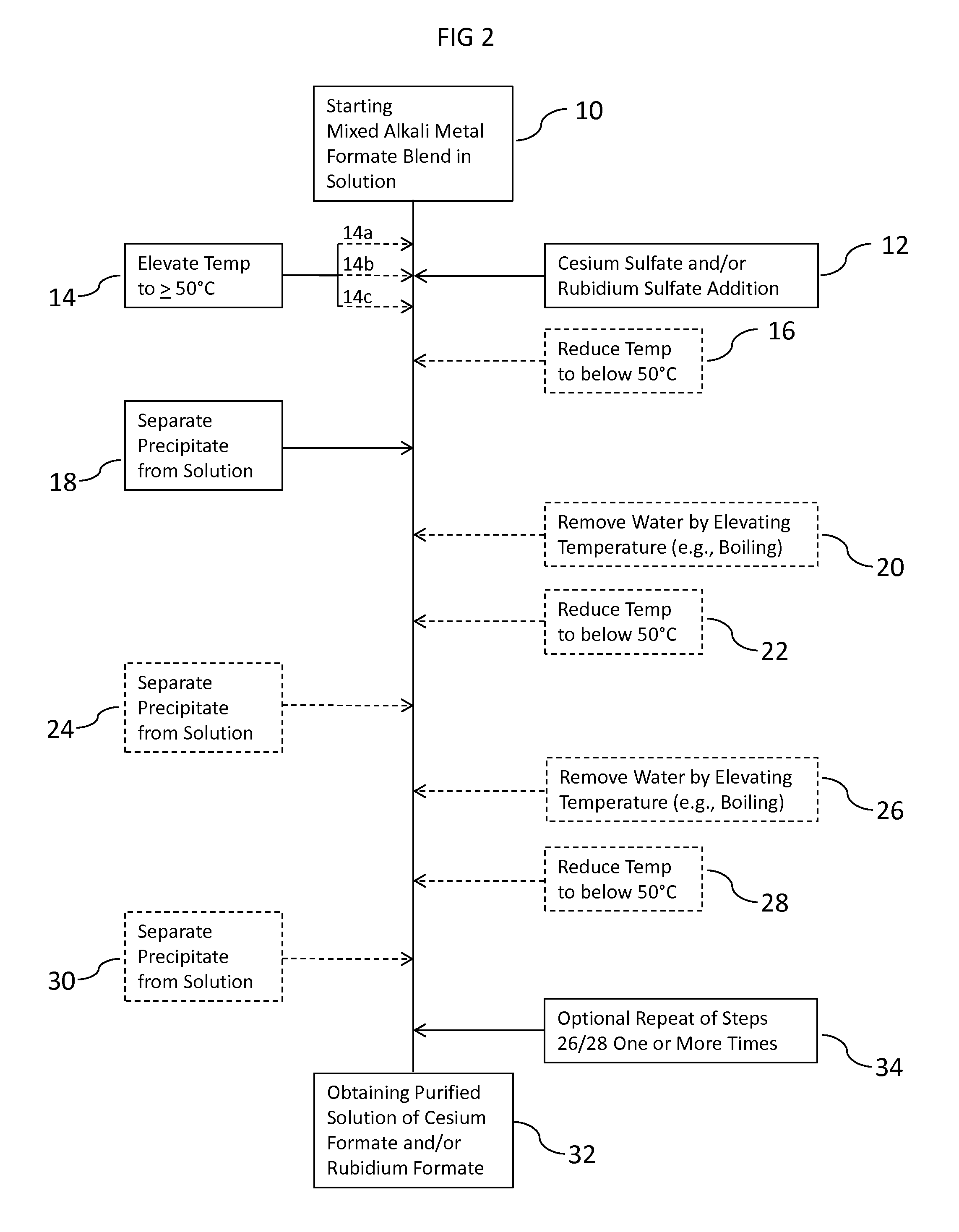

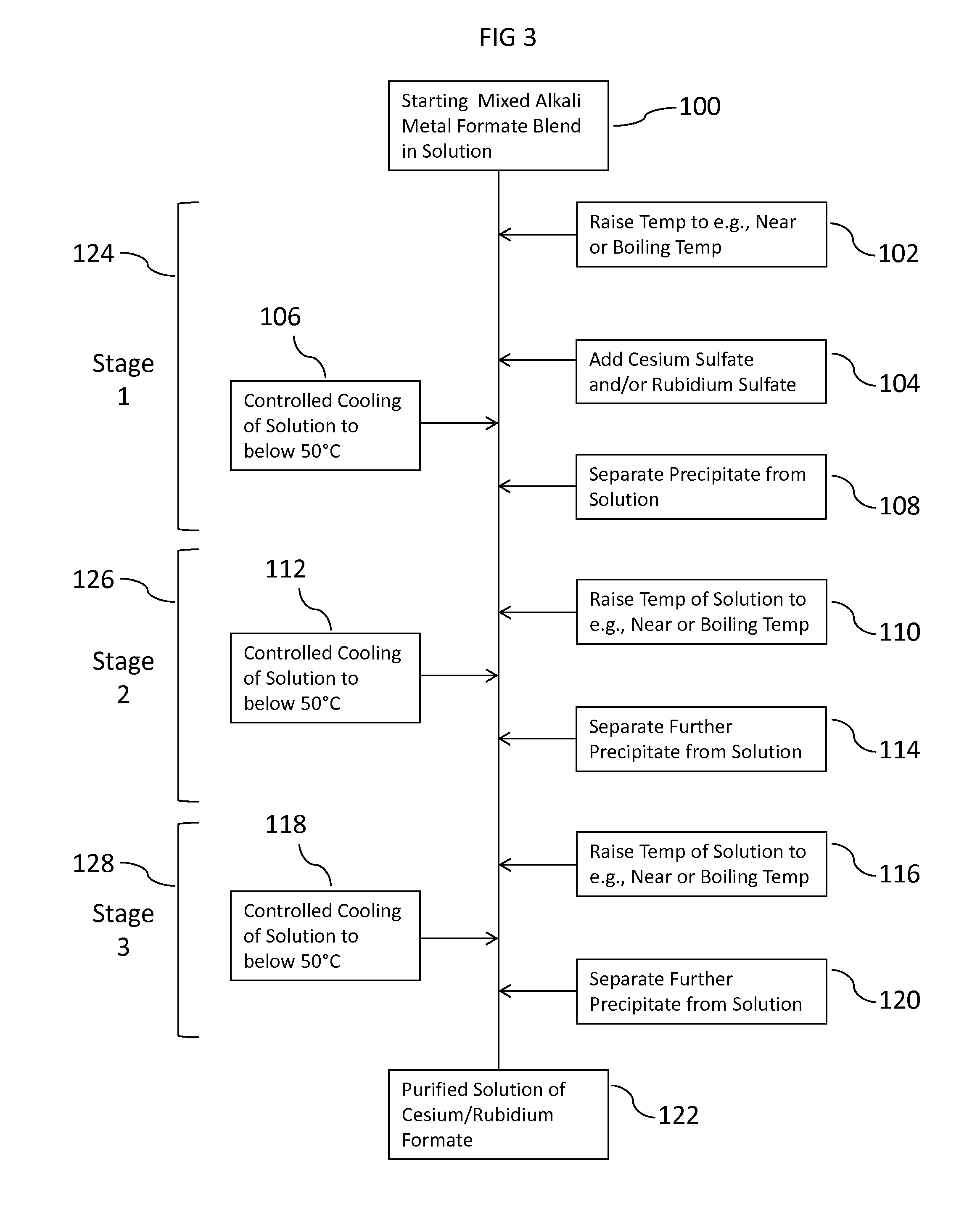

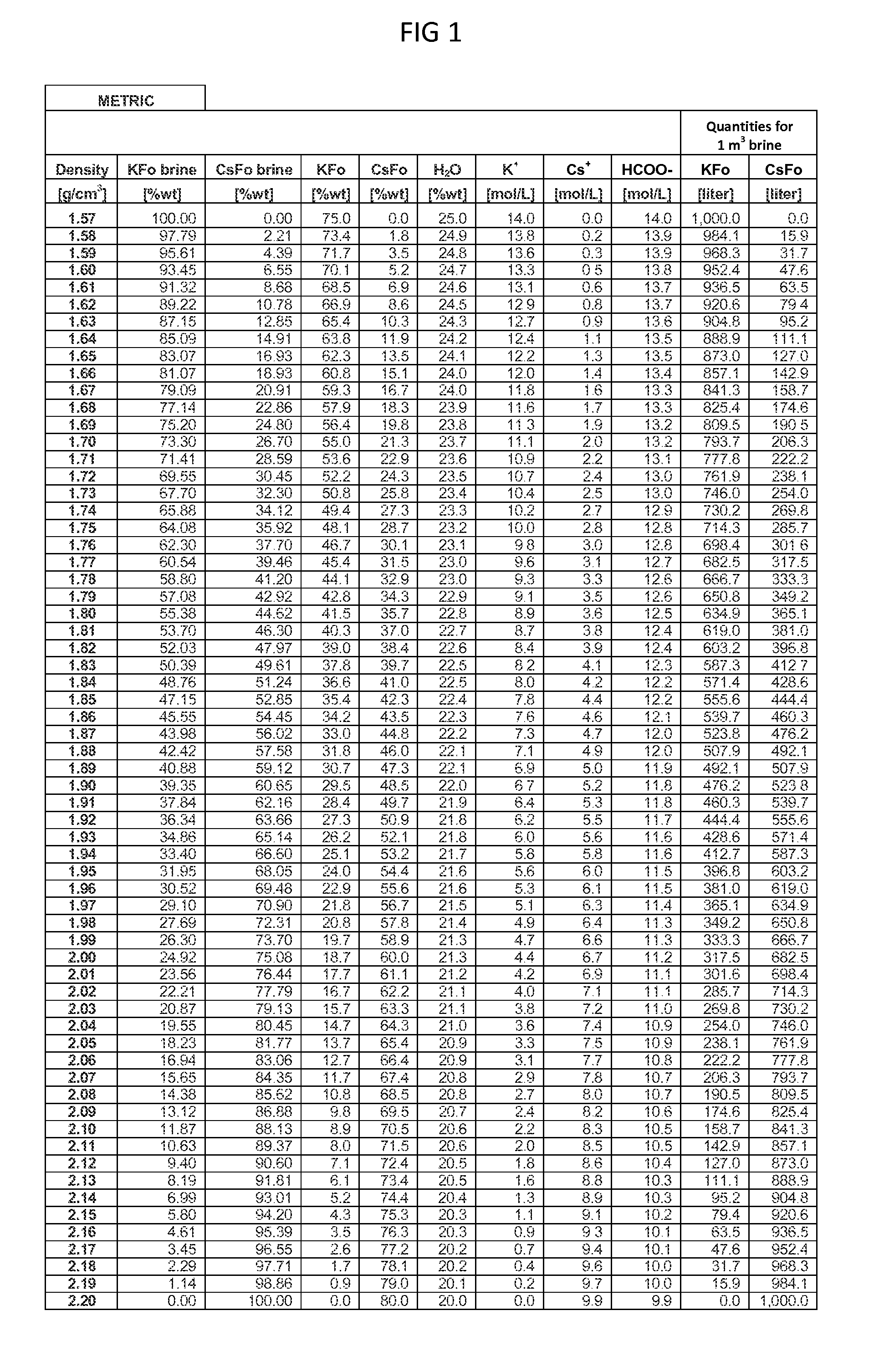

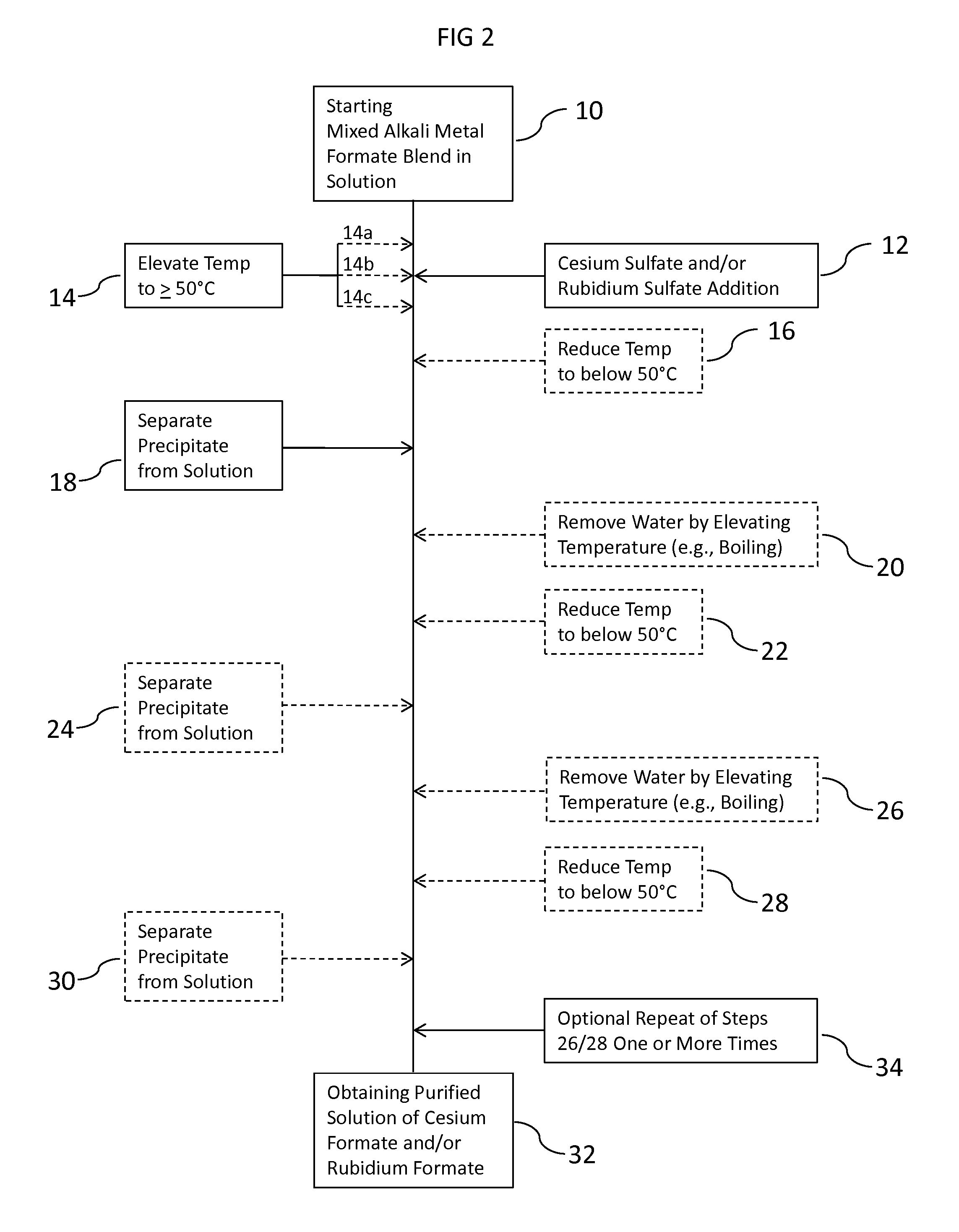

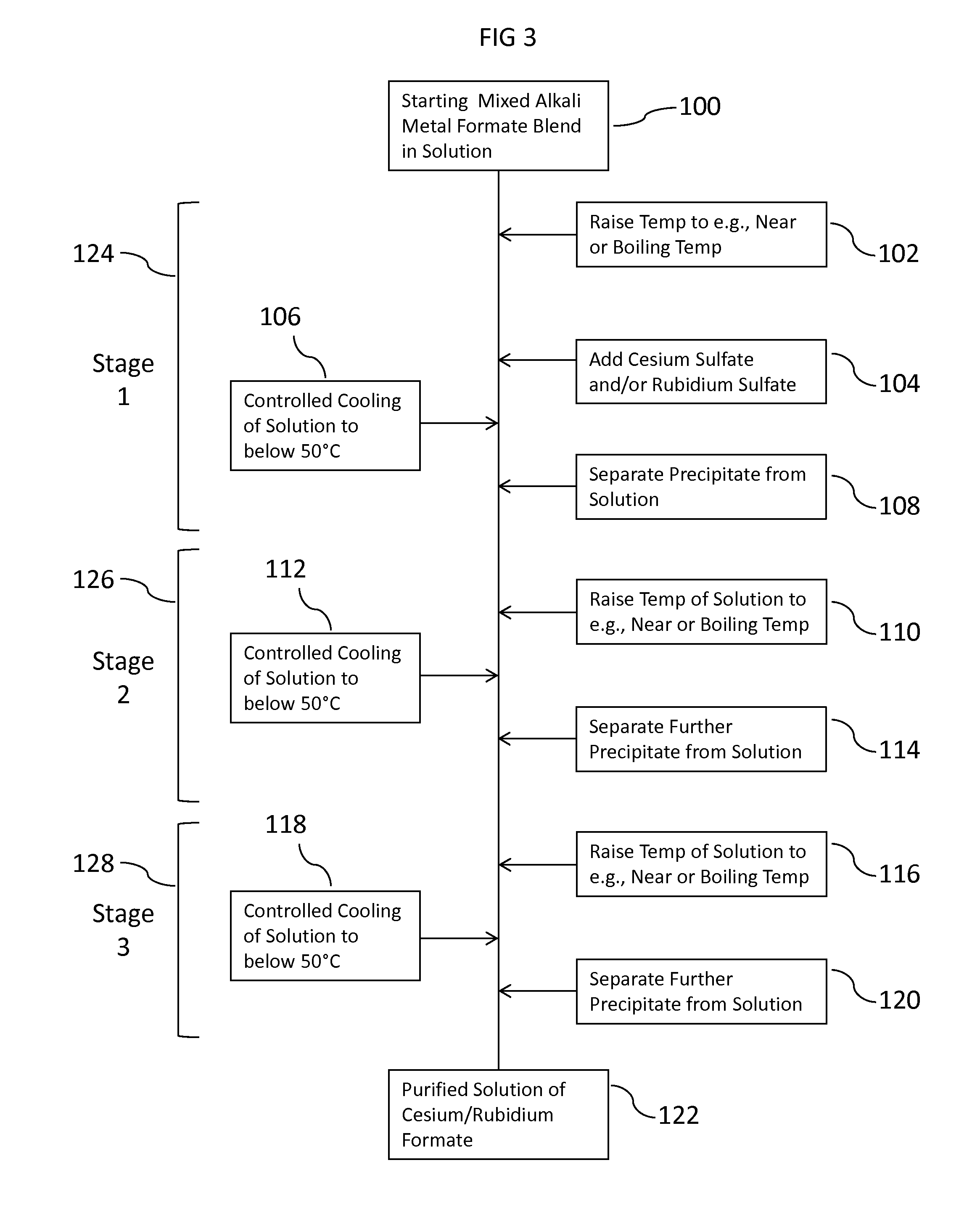

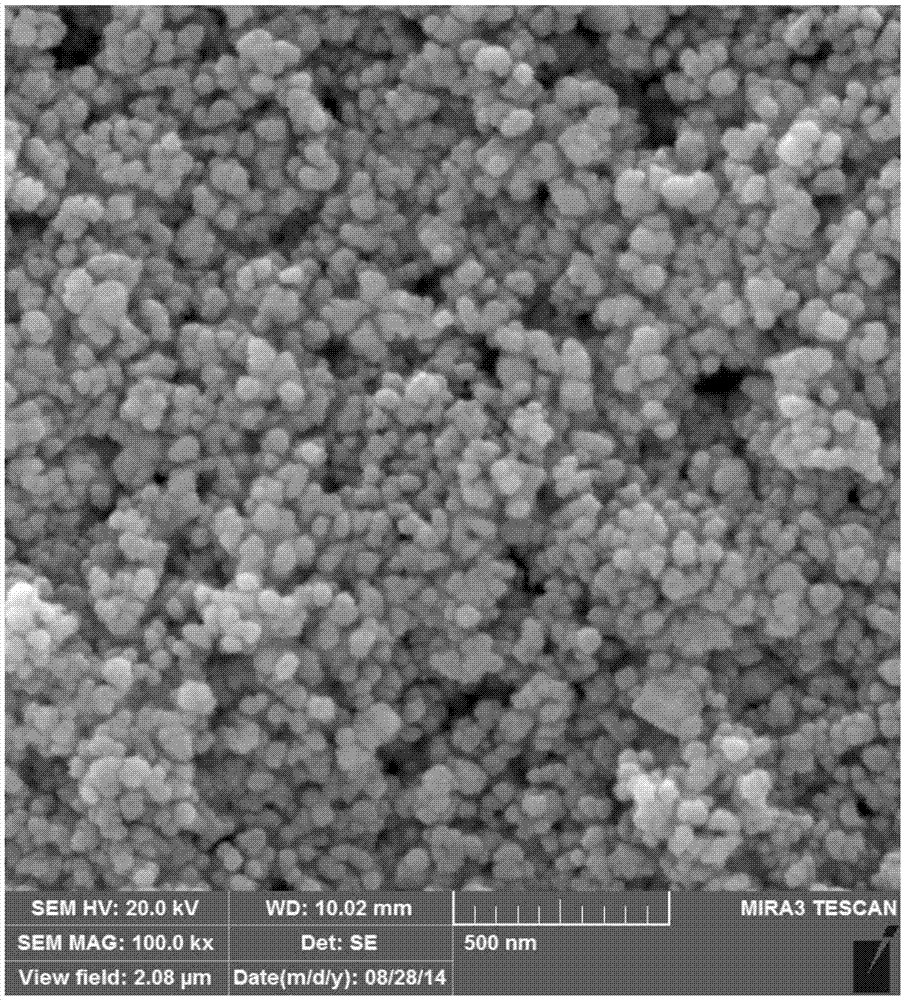

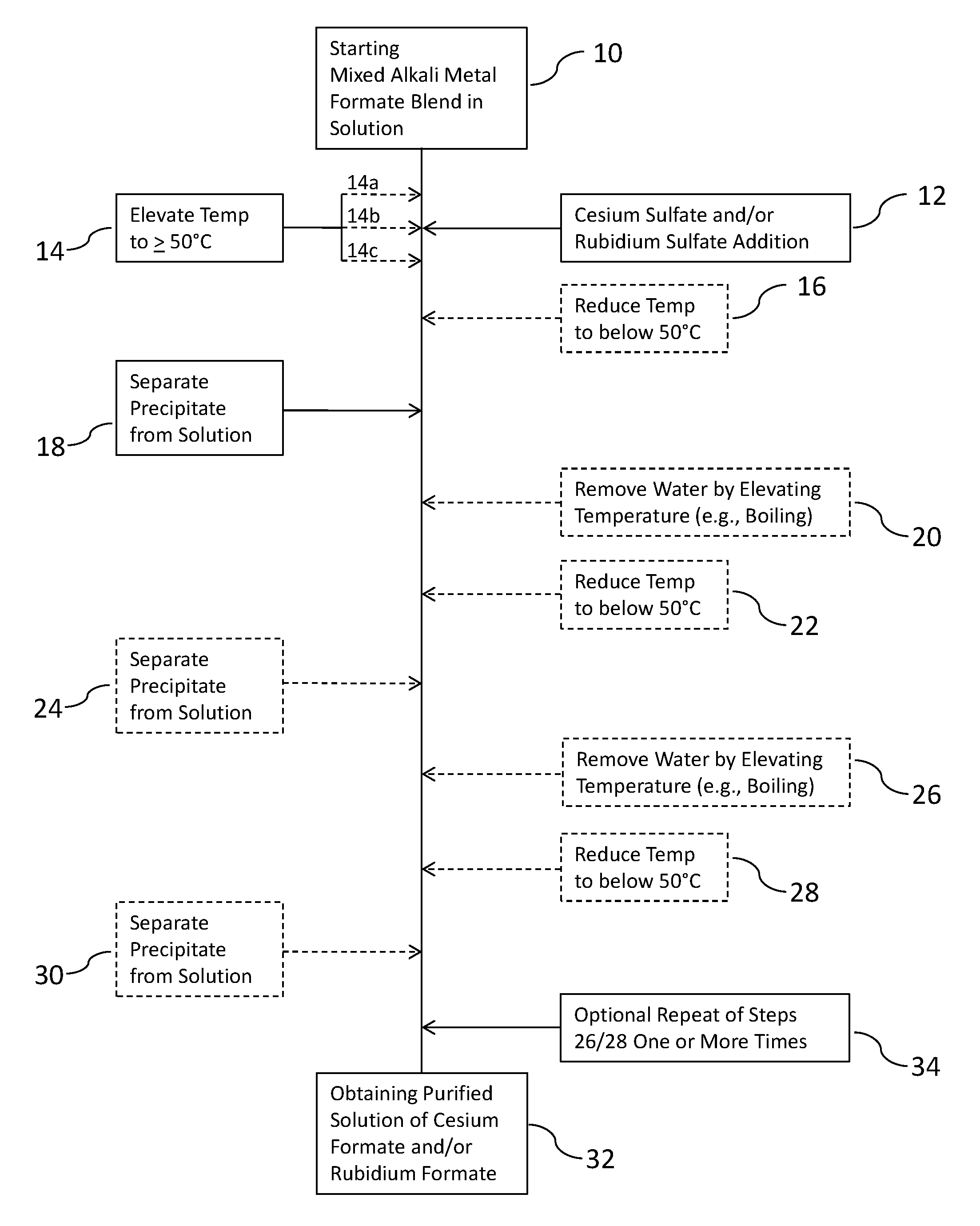

Methods To Recover Cesium Formate From A Mixed Alkali Metal Formate Blend

ActiveUS20150152033A1Efficient and inexpensivePreparation from carboxylic acid saltsOrganic compound preparationSodium bicarbonateFormate

Methods to recover or separate cesium formate or rubidium formate or both from a mixed alkali metal formate blend are described. One method involves adding cesium sulfate or rubidium sulfate to the mixed alkali metal formate blend in order to preferentially precipitate potassium sulfate from the mixed alkali metal formate blend. Another method involves adding cesium carbonate or cesium bicarbonate or both to preferentially precipitate potassium carbonate / bicarbonate and / or other non-cesium or non-rubidium metals from the mixed alkali metal blend. Further optional steps are also described. Still one other method involves converting cesium sulfate to cesium hydroxide.

Owner:CABOT SPECIALTY FLUIDS

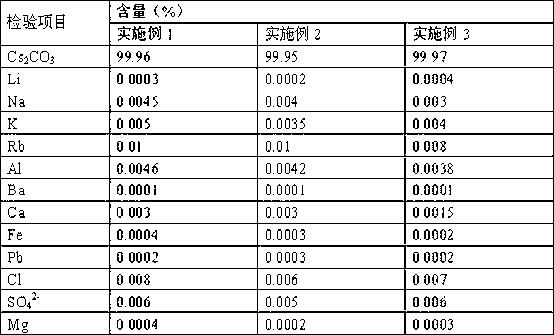

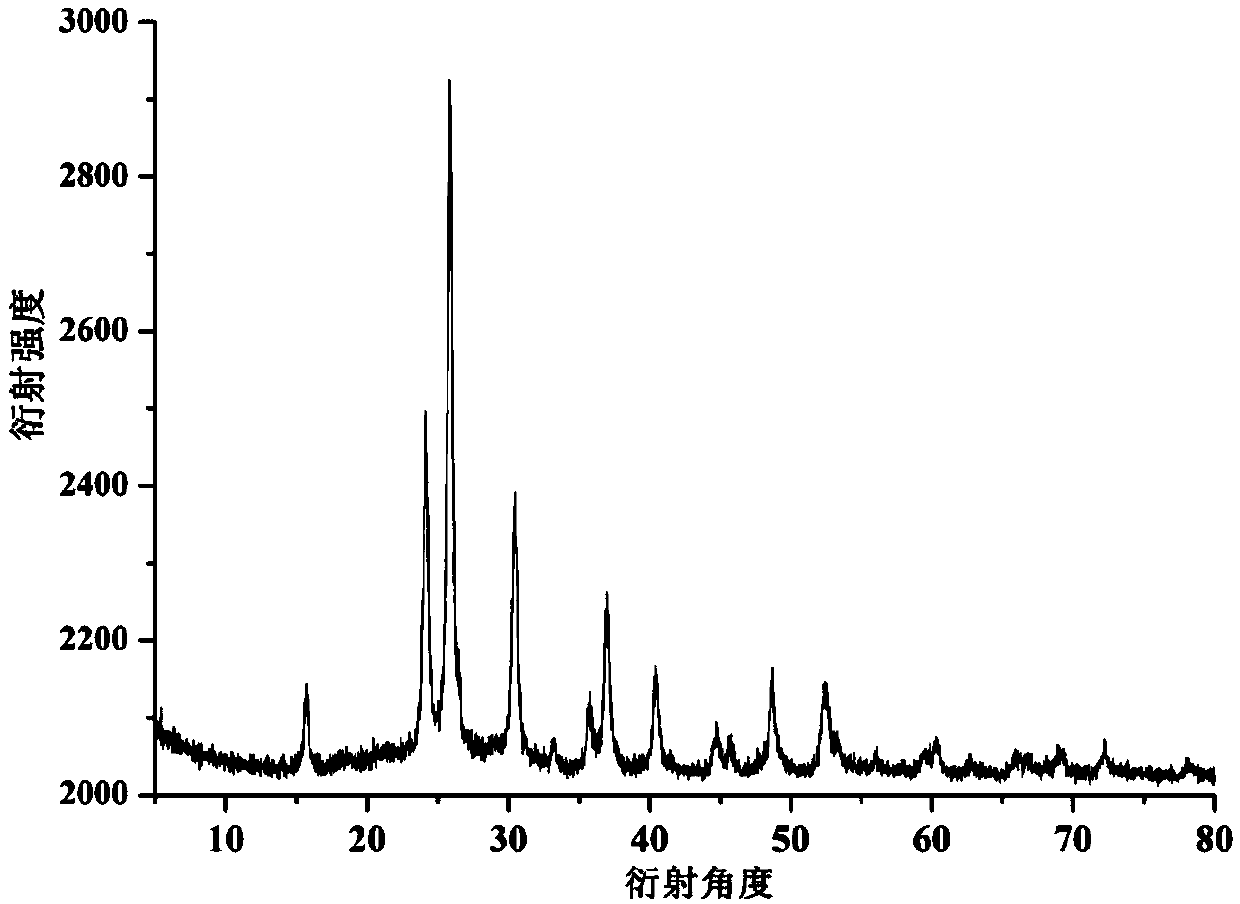

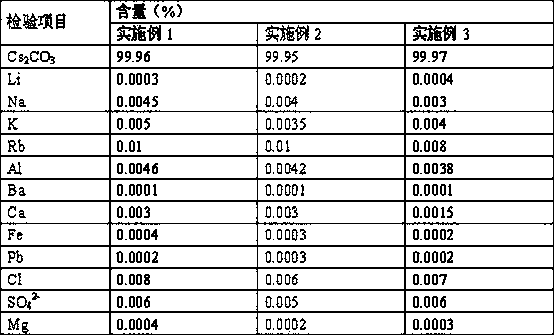

Method for preparing cesium carbonate by ion exchange method

ActiveCN103241750AWide range of market sourcesRaw materials are easy to getRubidium/caesium/francium compoundsCesium sulfateIon exchange

The invention relates to the technical field of a preparation method of cesium carbonate and in particular relates to a method for preparing cesium carbonate by an ion exchange method. The method is applicable to preparation of high-purity pollution-free cesium carbonate. The method comprises the following steps of: performing acid leaching, jarosite precipitation, recrystallization and conversion on pollucite to obtain a conversion solution of cesium sulfate; exchanging by using 201*7 strongly alkaline styrene anion exchange resin to obtain a cesium hydroxide solution; and introducing carbon dioxide into the cesium hydroxide solution and neutralizing to prepare a caesium bicarbonate solution; and concentrating, crystallizing, separating and drying to obtain the cesium carbonate finished product. The obtained product is high in purity, simple in process flow, economic and environment-friendly, and suitable for industrialized production; and the process adopting the anion exchange resin is simpler than the process adopting cation exchange resin and elution is avoided, so cesium loss in an eluting process is avoided, the system yield is increased, and the system yield after a mother liquid participates in circulation can reach 92 to 95 percent.

Owner:百杰瑞(荆门)新材料有限公司

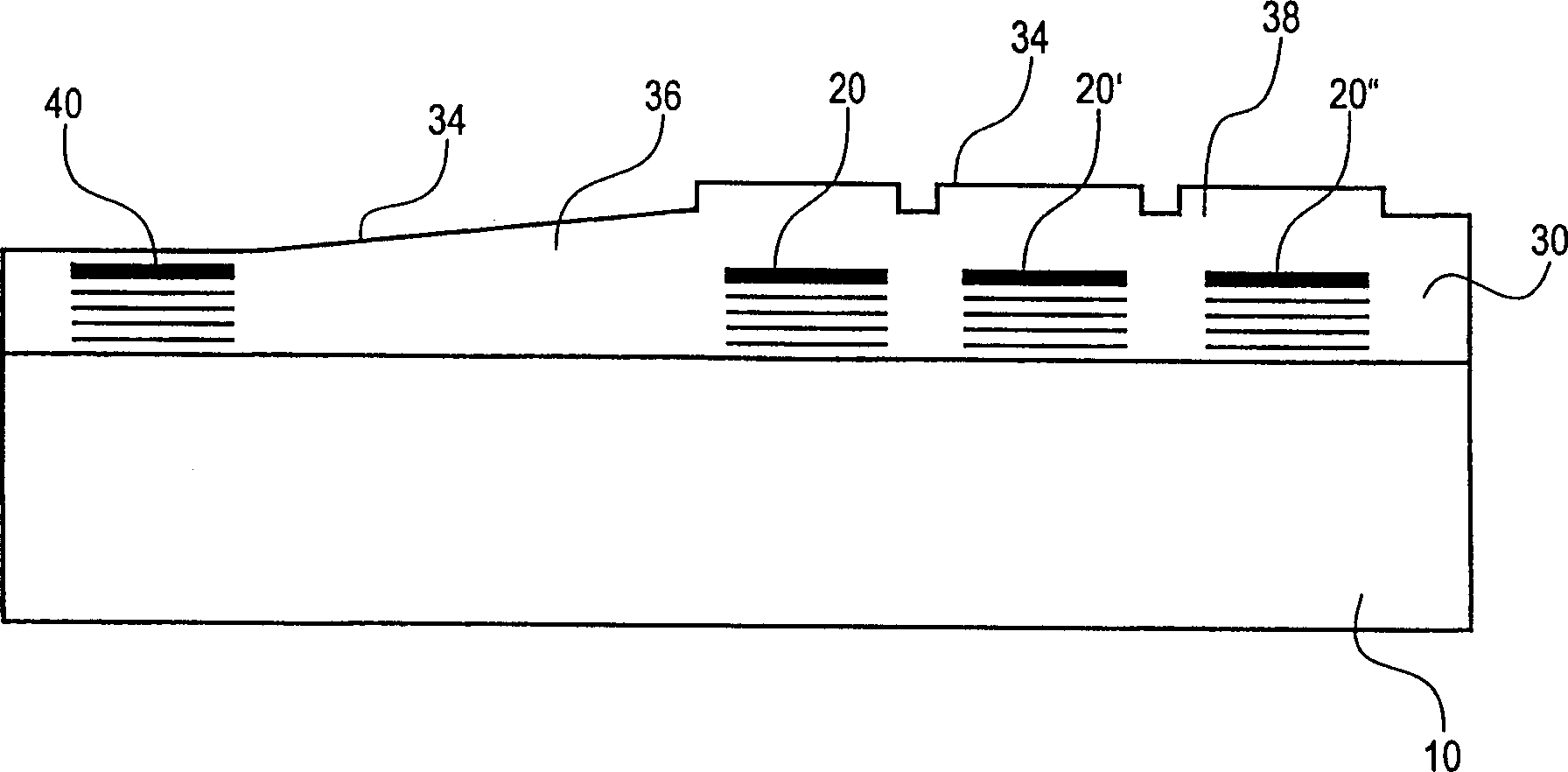

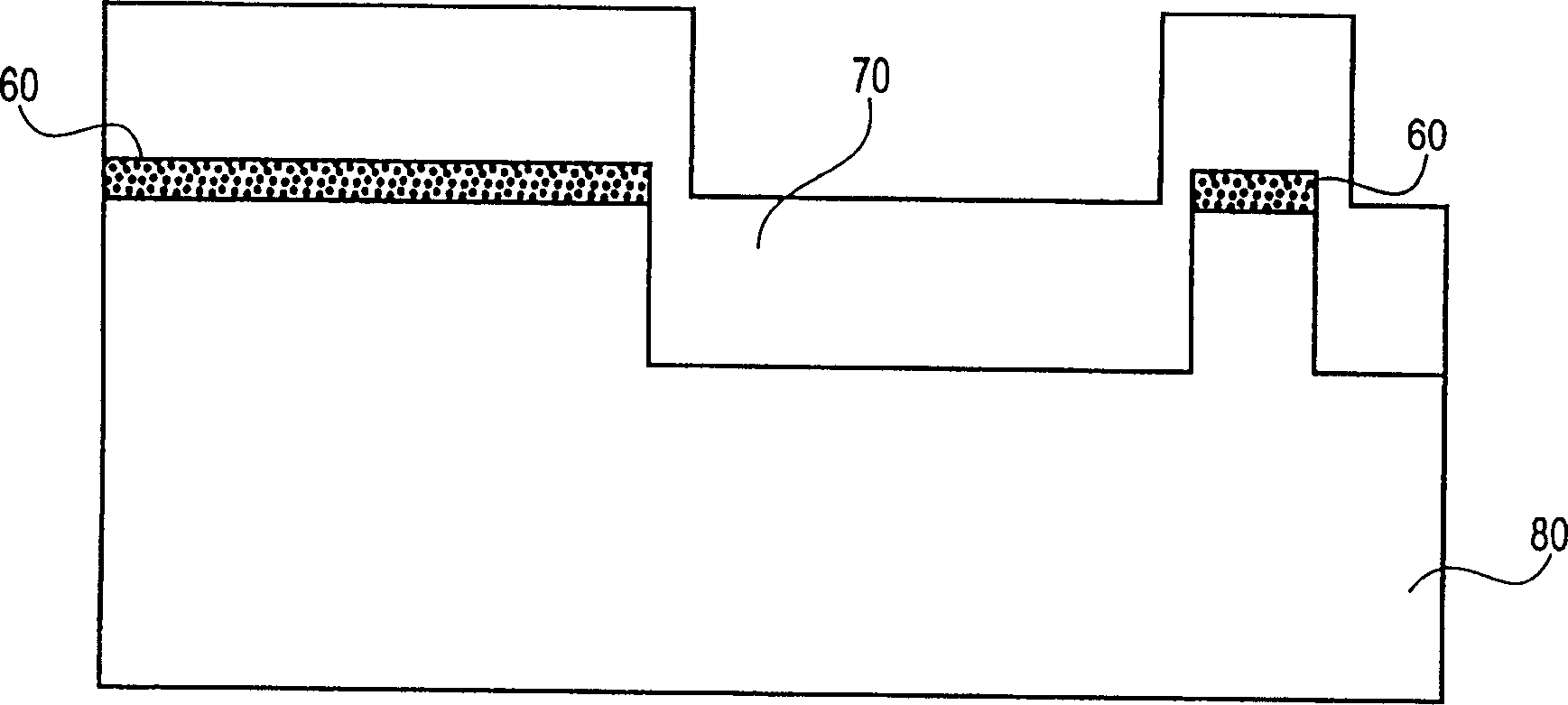

Use of CsOH in dielectric CMP slurry

InactiveCN1387556AOther chemical processesSemiconductor/solid-state device manufacturingPhysical chemistrySlurry

Owner:CABOT MICROELECTRONICS CORP

Preparation method of microcrystalline glass for treating radioactive cesium contaminated soil

InactiveCN110981205ASimple processLower melting temperatureContaminated soil reclamationContaminated soilsCaesium hydroxide

The invention relates to a preparation method of microcrystalline glass for treating radioactive cesium contaminated soil, which is characterized by comprising the following steps: (1) dissolving cesium hydroxide monohydrate in 20-40% silica sol according to the molar ratio of cesium metal ions to silicon atoms of 1: 2, and stirring for 12-24 hours to obtain a cesium silicate solution; (2) addingmetakaolin powder, controlling the molar ratio of silicon ions to aluminum ions to be 2: 1, stirring for 60-90min, pouring an obtained mixture into a mold, standing at 60-90 DEG C for 5-7 days to obtain a blocky solid, and grinding to obtain cesium-containing precursor powder; (3) mixing the following raw materials in percentage by weight: 50-65% of SiO2, 4-8% of Al2O3, 15-20% of B2O3, 15-25% of Na2CO3 and 8-10% of CaCO3, melting, forming, cooling to prepare glass, and grinding into glass powder; and (4) mixing the cesium-containing precursor powder and glass powder according to a mass ratio of 1: (4-5), melting at 1000-1200 DEG C for 2-5 hours, molding, and cooling. The preparation method has the beneficial effects of simple process, low melting temperature and easiness in process control; the chemical stability is good, the curing effect is obvious, and the leaching resistance rate is high.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

A kind of cesium tungsten bronze modified powder and preparation method thereof

ActiveCN107513293BSolve the problem of UV discoloration resistanceIncrease productivityNon-macromolecular adhesive additivesFilm/foil adhesivesDecompositionSlurry

The invention provides preparation methods for a cesium tungsten bronze modified powder and slurry thereof, wherein the preparation methods of the cesium tungsten bronze modified powder include the steps that a cesium hydroxide and nano tungsten oxide solid solution is subjected to decomposition reduction by ammonia water under catalytic action of nano nickel oxide, and a cesium tungsten bronze powder is obtained; and in addition, the obtained cesium tungsten bronze powder has the powder surface modified by a coupling agent and infrared and ultraviolet absorbers to obtain a cesium tungsten bronze modified powder, the modified powder is dispersed in a PVB special-effect plasticizer 3G8 dispersant by a sand mill, and furthermore, the cesium tungsten bronze modified powder slurry is obtained.

Owner:广州市黑本新材料科技有限公司

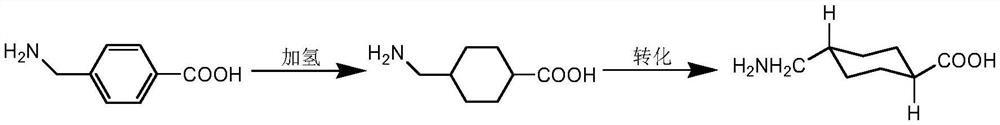

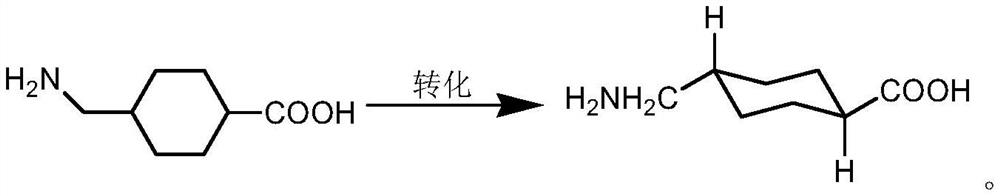

Catalyst, application and preparation method of trans-tranexamic acid

ActiveCN114225929ASimplify the refining process stepsIncrease productivityOrganic compound preparationOrganic chemistry methodsPtru catalystPhysical chemistry

The invention discloses a catalyst, application and a preparation method of trans-tranexamic acid. The catalyst is cesium hydroxide or cesium oxide. The cesium hydroxide or cesium oxide is used for catalyzing the conversion of cis-tranexamic acid to trans-tranexamic acid, so that the conversion rate of cis-tranexamic acid to trans-tranexamic acid is increased, the refining difficulty of tranexamic acid is reduced, the product yield is increased, and the production cost is reduced.

Owner:JIANGSU TIANHE PHARMA CO LTD

Method for preparing C.I. pigment red 179

The invention relates to a method for preparing N,N'-dimethyl-3,4,9,10-perylenetetracarboxylic diimide (C.I. pigment red 179). A reaction is conducted on N-methyl-1,8-naphthalimide in a system composed of a mixed base composed of caesium hydroxide or hydrate thereof and DBU and polar aryl halide at 140 DEG C-190 DEG C, and N,N'-dimethyl-3,4,9,10-perylenetetracarboxylic diimide can be obtained. After pigment-based processing is conducted on N,N'-dimethyl-3,4,9,10-perylenetetracarboxylic diimide, the crystal form of N,N'-dimethyl-3,4,9,10-perylenetetracarboxylic diimide is the same as that of a C.I. pigment red 179 product.

Owner:LIAONING LIANGANG PIGMENT & DYESTUFF CHEM +2

Catalyst for hydrogen fuel cell and preparation method thereof

InactiveCN107946602ALow costImprove catalytic performanceCell electrodesAlkaneHexamethylenetetramine

The invention discloses a catalyst for a hydrogen fuel cell. The catalyst is prepared from the following raw materials in parts by weight: 16-20 parts of iron oxide, 2-5 parts of caesium hydroxide, 135-140 parts of carbon black, 8-12 parts of chitosan oligosaccharide, 1-2 parts of ferric citrate, 0.4-0.8 part of trimethylol propane, 0.2-0.5 part of hexamethylenetetramine, 0.04-0.07 part of seconary alkane sulphonate sodium and 4-5 parts of urea. The invention also discloses a method for preparing a high-performance catalyst for the hydrogen fuel cell. The catalyst for the hydrogen fuel cell prepared by the scheme of the invention has better catalytic performance for the oxidation of hydrogen, since no precious metal platinum is used, the cost of the catalyst for the hydrogen fuel cell canbe reduced, and thus the cost of the hydrogen fuel cell can be reduced, and an important market value can be achieved.

Owner:中能国盛动力电池技术(北京)有限公司

Porous material and its synthesis method

ActiveCN1314589CHas a compound pore structureMolecular sieve catalystsCrystalline aluminosilicate zeolitesRubidium oxideAluminium chloride

A process material with compound artery is prepared from the Si source chosen from amorphous SiO2, si sol, silicon oxide solid, silicon gel, diatomite and water glass, the Al source chosen from sodium aluminate, sodium metaaluminate, aluminium sulfate, aluminium nitrate, etc, at least one of lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide and cesium hydroxide, and template agent through proportional mixing, reaction, ageing and crystallizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature-resistant ceramizable cement-based material and preparation method thereof

ActiveCN111825412AImprove thermal shock resistanceSynergistic mechanical propertiesCement productionSilicic acidKaolin clay

The invention provides a high-temperature-resistant ceramizable cement-based material and a preparation method thereof. The cement-based material comprises the following components in percentage by weight: 60-75% of a precursor and an excitant, 10-20% of a reinforcing phase and 15-20% of an anti-shrinking agent, wherein the sum of the components is 100%. The high-temperature-resistant ceramizablecement-based material further comprises a water reducing agent accounting for 0.5-2% of the total mass of the precursor, the reinforcing phase, the excitant and the anti-shrinking agent, wherein the precursor is selected from a combination of two or more of metakaolin, slag or fly ash, and the excitant is selected from a combination of two or more of cesium hydroxide, cesium silicate and sodium hydroxide. The high-temperature-resistant ceramizable cement-based material has excellent workability after being mixed with water; the cement concrete has better mechanical properties and durability than common cement concrete after being hardened at normal temperature, can resist the high temperature of 1800 DEG C in case of fire or other high-temperature environments, and has the advantages of improved mechanical properties, hardness and thermal shock resistance, stable volume and no cracks or shrinkage.

Owner:WUHAN UNIV OF TECH

Recovery process of rhodium-containing waste catalyst solution

InactiveCN102910720AEfficient and fast recycling methodRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsChemical recyclingChemical industryPtru catalyst

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for synthesizing caesium doped sodium tantalum oxide

The invention aims at providing a method for preparing caesium doped sodium tantalum oxide. The method is characterized by comprising the following steps: adding sodium hydroxide, caesium hydroxide and tantalum pentoxide powder into deionized water; uniformly stirring the tantalum pentoxide powder, transferring the mixed solution into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, screwing and sealing the reaction kettle, and standing in a constant-temperature oven at 180-220 DEG C to react for 6-12 hours; and washing and drying to obtain a final product caesium doped sodium tantalum oxide. The method is simple in process flow, low in synthesizing temperature and uniform in product size, has excellent photocatalytic performance, can be applied to the fields of photoelectric devices, fuel batteries and the like besides the field of catalysis.

Owner:合肥萃励新材料科技有限公司

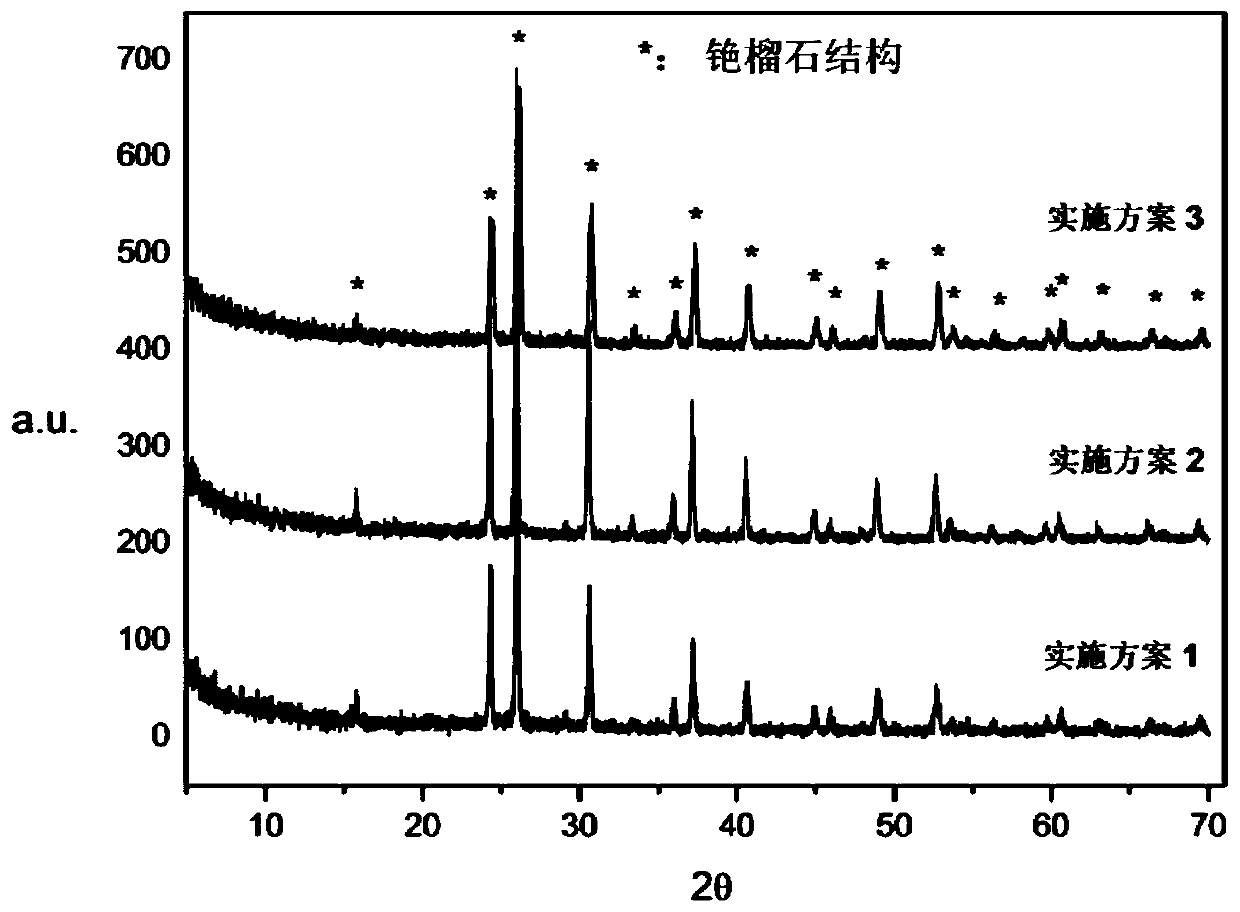

Method for preparing pollucite glass ceramic by low-temperature liquid phase sintering

InactiveCN110028248AReduce leaching concentrationLow leaching fractionGlass shaping apparatusPolluciteKaolin clay

The invention discloses a method for preparing pollucite glass ceramic by low-temperature liquid phase sintering. Activated kaolin, boric acid, barium hydroxide monohydrate and sodium hydroxide are used as raw materials, then properly proportioned and weighed, and then pulverized by an aqueous solution solid phase ball grinding process, and are subjected to forming and normal-pressure sintering. By adoption of a low-temperature liquid phase sintering mode, the pollucite glass ceramic can be prepared at a relatively low sintering temperature, and caesium can be effectively solidified.

Owner:SOUTHWEST JIAOTONG UNIV

Novel method for preparing allene by cesium hydroxide catalysis

InactiveCN104973999AWide variety of sourcesHigh selectivityOrganic compound preparationOrganic isomerisationEnzyme inhibitionCytotoxicity

A compound containing an allene group is an important component in organic chemistry research and some compounds containing allene groups are important component units of drugs. Functionalized allene has wide antibacterial properties, cytotoxicity and enzyme inhibition activity. The method utilizes cesium hydroxide as a catalyst, utilizes an oxygen-containing nitrogenous terminal alkyne compound as a reaction raw material, is free of a nitrogen atmosphere and can realize high-yield reaction of a series of allene compounds in the presence of a polar solvent. The method has the advantages of low cost, simple processes and no pollution and has a certain feasibility in industrial production. The method provides a cheap and green approach for allene preparation.

Owner:HUNAN UNIV

Composition, preparation method and application of catalyst for preparing isobutanol from synthesis gas

ActiveCN112206788APhysical/chemical process catalystsOrganic compound preparationIsobutanolPtru catalyst

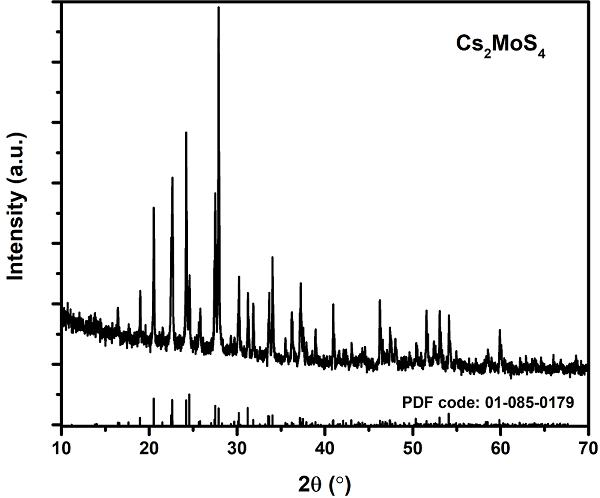

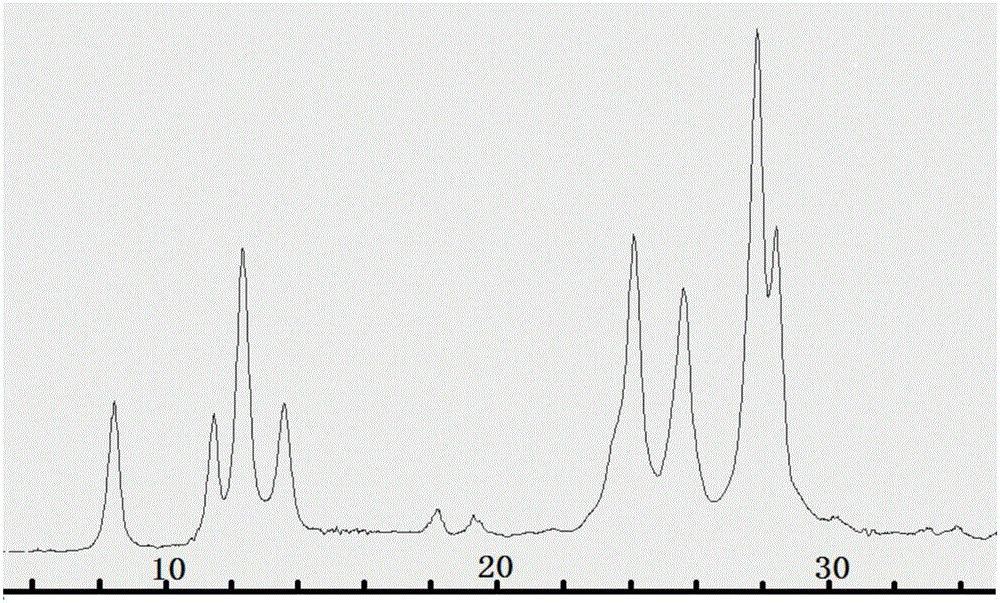

The invention discloses a catalyst for directly preparing isobutanol from synthesis gas. The composition of the catalyst is cesium tetrathiomolybdate. The preparation method of cesium tetrathiomolybdate comprises the following steps: respectively dissolving ammonium tetrathiomolybdate and cesium hydroxide in water, dropwisely adding an ammonium tetrathiomolybdate solution into the cesium hydroxidesolution, carrying out suction filtration on the obtained precipitate, and carrying out vacuum drying to obtain cesium tetrathiomolybdate. The obtained cesium tetrathiomolybdate can be used for preparing isobutanol from synthesis gas after being granulated. The catalyst provided by the invention has the advantages of simple preparation method, high total alcohol selectivity and high isobutanol content in total alcohol, is suitable for synthesis gas with a low H2 / CO ratio, and has a good application prospect.

Owner:INNER MONGOLIA UNIVERSITY

Process for preparing c.i. Pigment Red 179

The invention relates to a method for preparing N,N'-dimethyl-3,4,9,10-perylenetetracarboxylic diimide (C.I. pigment red 179). A reaction is conducted on N-methyl-1,8-naphthalimide in a system composed of a mixed base composed of caesium hydroxide or hydrate thereof and DBU and polar aryl halide at 140 DEG C-190 DEG C, and N,N'-dimethyl-3,4,9,10-perylenetetracarboxylic diimide can be obtained. After pigment-based processing is conducted on N,N'-dimethyl-3,4,9,10-perylenetetracarboxylic diimide, the crystal form of N,N'-dimethyl-3,4,9,10-perylenetetracarboxylic diimide is the same as that of a C.I. pigment red 179 product.

Owner:LIAONING LIANGANG PIGMENT & DYESTUFF CHEM +2

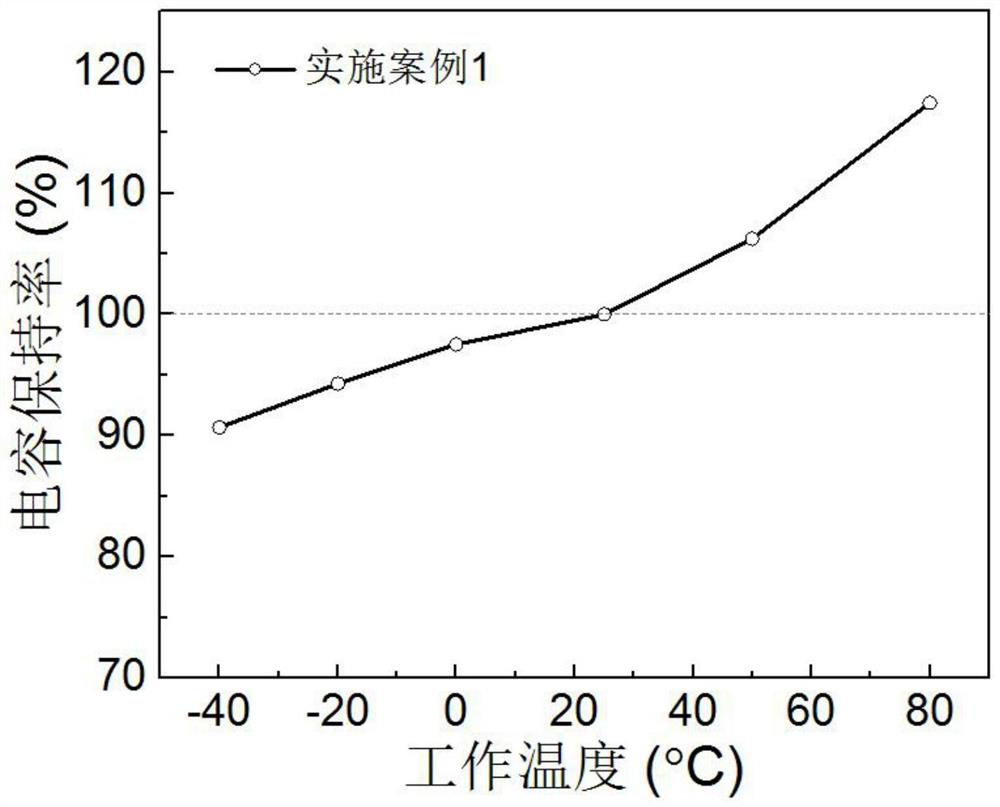

Supermolecule-based aqueous alkaline electrolyte with ultra-wide working temperature range and application thereof

ActiveCN113421777AStable energy storage performanceWide operating temperature rangeHybrid capacitor electrolytesElectrolytic agentRubidium oxide

The invention discloses a supermolecule-based aqueous alkaline electrolyte with an ultra-wide working temperature range and an application thereof. The aqueous alkaline electrolyte is a solution formed by mixing a solute and a solvent, the solute is one or more than two of alkali metal hydroxides, and the alkali metal hydroxides are lithium hydroxide, sodium hydroxide, potassium hydroxide, rubidium hydroxide or cesium hydroxide; and the solvent is a supramolecular solvent composed of water and dimethyl sulfoxide. The supermolecule-based aqueous alkaline electrolyte with the ultra-wide working temperature range has an extremely wide working temperature range of-70 DEG C to 100 DEG C, is relatively stable in performance, and can greatly improve the applicability of electrochemical energy storage devices such as supercapacitors and batteries based on the aqueous alkaline electrolyte in the all-day, all-season and extreme temperature fields.

Owner:KUNMING UNIV OF SCI & TECH

Methods to recover cesium formate from a mixed alkali metal formate blend

ActiveUS9452966B2Efficient and inexpensivePreparation from carboxylic acid saltsOrganic compound preparationSodium bicarbonateFormate

Methods to recover or separate cesium formate or rubidium formate or both from a mixed alkali metal formate blend are described. One method involves adding cesium sulfate or rubidium sulfate to the mixed alkali metal formate blend in order to preferentially precipitate potassium sulfate from the mixed alkali metal formate blend. Another method involves adding cesium carbonate or cesium bicarbonate or both to preferentially precipitate potassium carbonate / bicarbonate and / or other non-cesium or non-rubidium metals from the mixed alkali metal blend. Further optional steps are also described. Still one other method involves converting cesium sulfate to cesium hydroxide.

Owner:CABOT SPECIALTY FLUIDS

A kind of production method of nano cesium tungstate powder

ActiveCN106587157BGood dispersionIncrease productivityMaterial nanotechnologyTungsten compoundsTungstateAmmonium paratungstate

The invention relates to a method for producing nano cesium tungstate powder and provides a preparation method of nano cesium tungstate powder which is free of washing, high in production efficiency and low in cost. According to the method, ammonium tungstate, ammonium paratungstate and ammonium metatungstate serve as tungsten sources, cesium hydroxide, cesium carbonate, cesium oxalate and cesium citrate serve as cesium sources, urea, PVP, PVA, oxalic acid and ammonium oxalate serve as dispersing agents, the materials are dissolved in water respectively and sequentially and evenly mixed with at least two of organic solvents containing alcohol, ether and ester functional groups, concentration and drying are conducted to obtain a powder substance, the powder substance is calcined to obtain blue powder, the blue powder is stirred in a high-pressure kettle under the hydrothermal condition at 120-250 DEG C, and then the blue powder is filtered, dried and smashed to obtain the blue nano cesium tungstate powder. The nano cesium tungstate powder produced through the method does not need to be washed, is hardly agglomerated and is easily dispersed into nano particles, production efficiency is high, the process is relatively safe and environmentally friendly, cost is low, and industrial production is convenient.

Owner:GANZHOU RUIDE CHEM

Preparation method of porous pollucite profile

The invention discloses a preparation method of a porous pollucite profile. The preparation method is characterized by comprising the following steps: taking and mixing 100 weight parts of metakaolin,75-210 weight parts of an amorphous form spherical silicon dioxide ultrafine powder, 145 weight parts of cesium hydroxide monohydrate at the weight ratio; taking and adding water of which the weightis 20% of the total weight of the metakaolin, the amorphous form spherical silicon dioxide ultrafine powder and the cesium hydroxide monohydrate, and stirring evenly to obtain a slurry; injecting theslurry into a steel mold, sealing, processing in an air dry oven of 50-100 DEG C for 24 hours, then demolding to obtain a solid profile; putting the solid profile in an autoclaving reaction kettle, hydrothermally reacting in a water vapor environment of 160-220 DEG C for 12-24 hours, taking out the solid profile and drying to obtain the porous pollucite profile. By adopting the preparation method,the porous pollucite profile having the advantages of excellent mechanical property and high porosity is directly obtained, and the porous pollucite profile can be used as a catalytic reactor, a high-temperature resistant catalyst carrier and a high-temperature resistant thermal insulating layer in the fields like chemical engineering and environments.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing cesium carbonate by ion exchange method

ActiveCN103241750BHigh puritySimple processRubidium/caesium/francium compoundsCesium sulfateIon exchange

The invention relates to the technical field of a preparation method of cesium carbonate and in particular relates to a method for preparing cesium carbonate by an ion exchange method. The method is applicable to preparation of high-purity pollution-free cesium carbonate. The method comprises the following steps of: performing acid leaching, jarosite precipitation, recrystallization and conversion on pollucite to obtain a conversion solution of cesium sulfate; exchanging by using 201*7 strongly alkaline styrene anion exchange resin to obtain a cesium hydroxide solution; and introducing carbon dioxide into the cesium hydroxide solution and neutralizing to prepare a caesium bicarbonate solution; and concentrating, crystallizing, separating and drying to obtain the cesium carbonate finished product. The obtained product is high in purity, simple in process flow, economic and environment-friendly, and suitable for industrialized production; and the process adopting the anion exchange resin is simpler than the process adopting cation exchange resin and elution is avoided, so cesium loss in an eluting process is avoided, the system yield is increased, and the system yield after a mother liquid participates in circulation can reach 92 to 95 percent.

Owner:百杰瑞(荆门)新材料有限公司

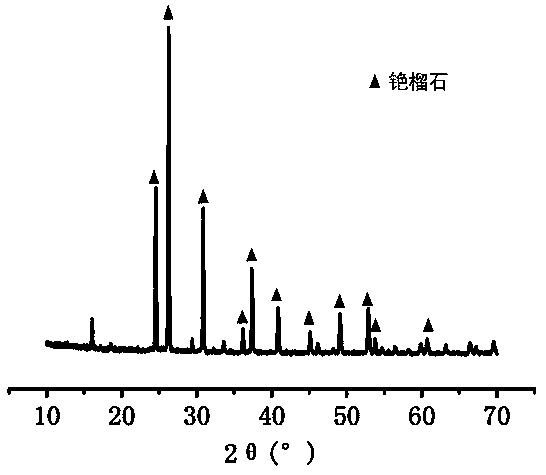

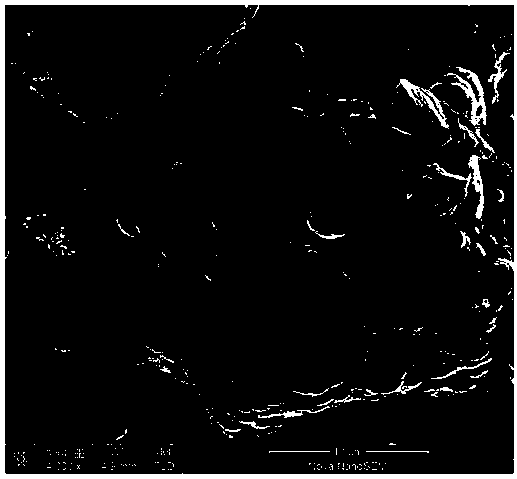

A method for preparing cesium garnet glass-ceramics by low-temperature liquid-phase sintering

InactiveCN110028248BReduce leaching concentrationLow leaching fractionGlass shaping apparatusPhysical chemistryKaolin clay

The invention discloses a method for preparing cesium garnet glass-ceramics by low-temperature liquid-phase sintering. Activated kaolin, boric acid, cesium hydroxide monohydrate and sodium hydroxide are used as raw materials. The powder is made by ball milling process, and then it is shaped and sintered under normal pressure. The invention adopts a low-temperature liquid-phase sintering method, can prepare cesium garnet glass ceramics at a relatively low sintering temperature, and can effectively solidify cesium.

Owner:SOUTHWEST JIAOTONG UNIV

Methods To Recover Cesium Formate From A Mixed Alkali Metal Formate Blend

ActiveUS20160355406A1Efficient and inexpensivePreparation from carboxylic acid saltsOrganic compound preparationFormatePrecipitated sulphur

Methods to recover or separate cesium formate or rubidium formate or both from a mixed alkali metal formate blend are described. One method involves adding cesium sulfate or rubidium sulfate to the mixed alkali metal formate blend in order to preferentially precipitate potassium sulfate from the mixed alkali metal formate blend. Another method involves adding cesium carbonate or cesium bicarbonate or both to preferentially precipitate potassium carbonate / bicarbonate and / or other non-cesium or non-rubidium metals from the mixed alkali metal blend. Further optional steps are also described. Still one other method involves converting cesium sulfate to cesium hydroxide.

Owner:CABOT SPECIALTY FLUIDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com