Composition, preparation method and application of catalyst for preparing isobutanol from synthesis gas

A catalyst and synthesis gas technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of high content, harsh reaction conditions of the catalyst system, and low content of isobutanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

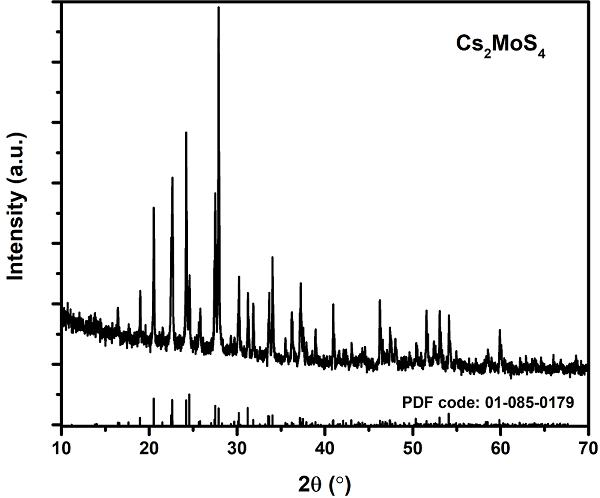

[0012] Dissolve 1.68 g of cesium hydroxide in 25 mL of deionized water to prepare a cesium hydroxide solution. After dissolving 2.60 g of ammonium tetrathiomolybdate in 50 mL of deionized water, it was added dropwise into the cesium hydroxide solution under mechanical stirring, and an orange precipitate was formed immediately. Stirring was continued for 4 hours to fully react the starting material. The obtained orange precipitate was suction-filtered, washed with ethanol three times, and vacuum-dried overnight at 60 degrees Celsius to obtain cesium tetrathiomolybdate (Cs 2 MoS 4 ). The prepared Cs 2 MoS 4 Tablet granulation, take 40-60 mesh granules for later use.

[0013] The Cs prepared by the above steps 2 MoS 4 Catalysts were evaluated for catalytic performance in a stainless steel fixed-bed reactor. Before the reaction starts, the catalyst is heated in the reactor with hydrogen at 310 o C for 2 hours. Reaction conditions: temperature 350°C-390°C, pressure 10 MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com