Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Boron doped carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron Doped Carbon Nanotubes are close analogues of carbon nanotubes (MWCNTs), but composed of hexagonal B-N bonding networks.

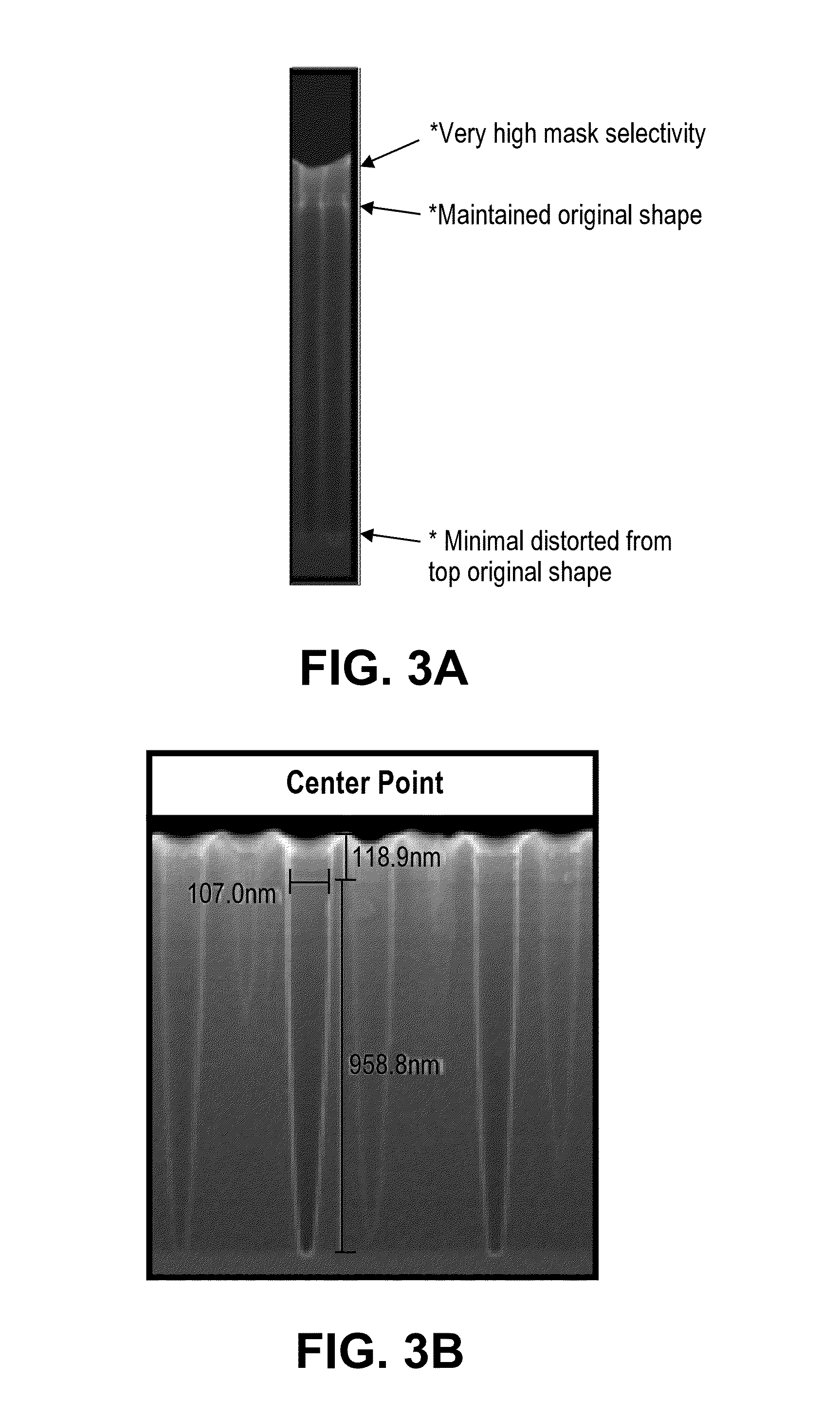

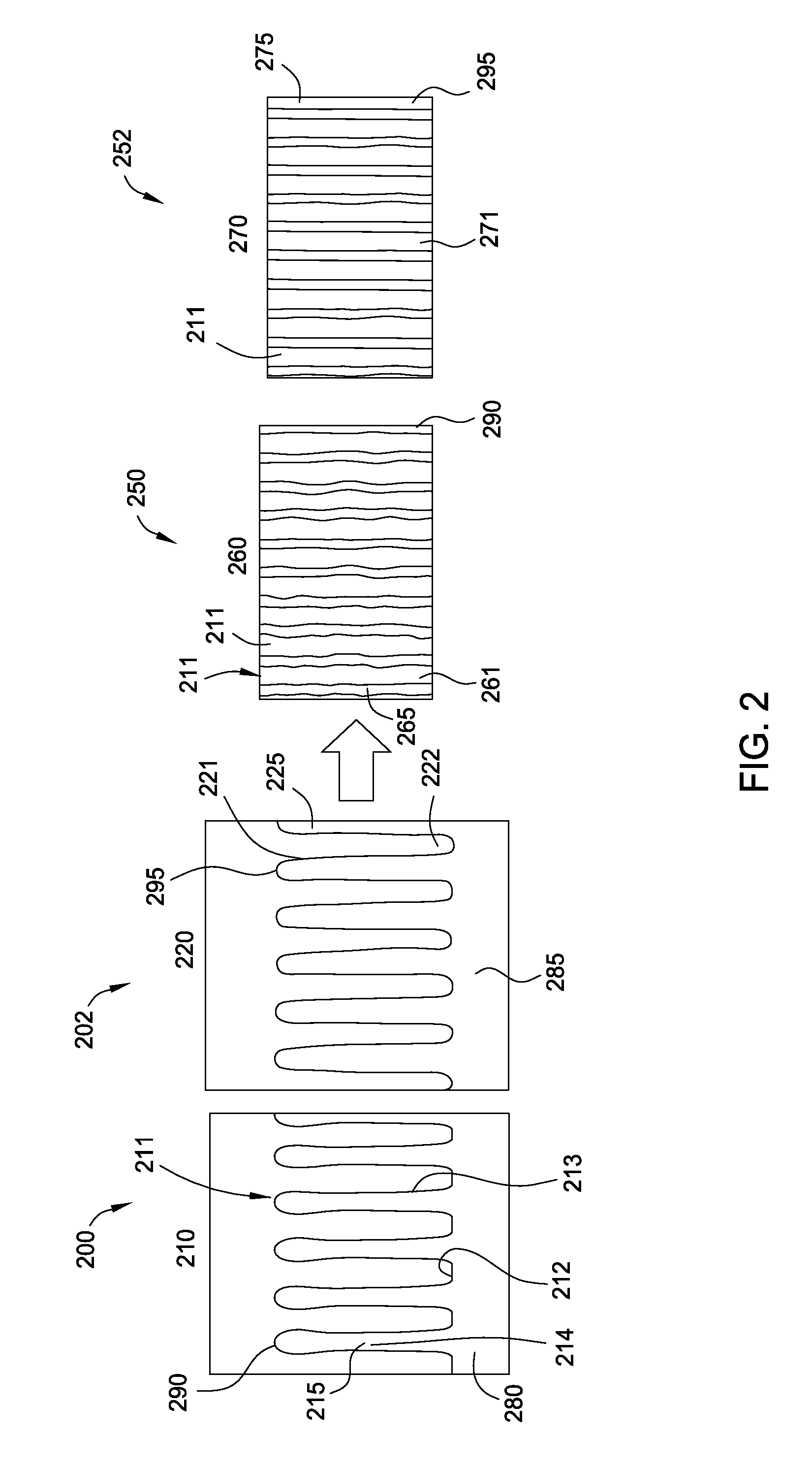

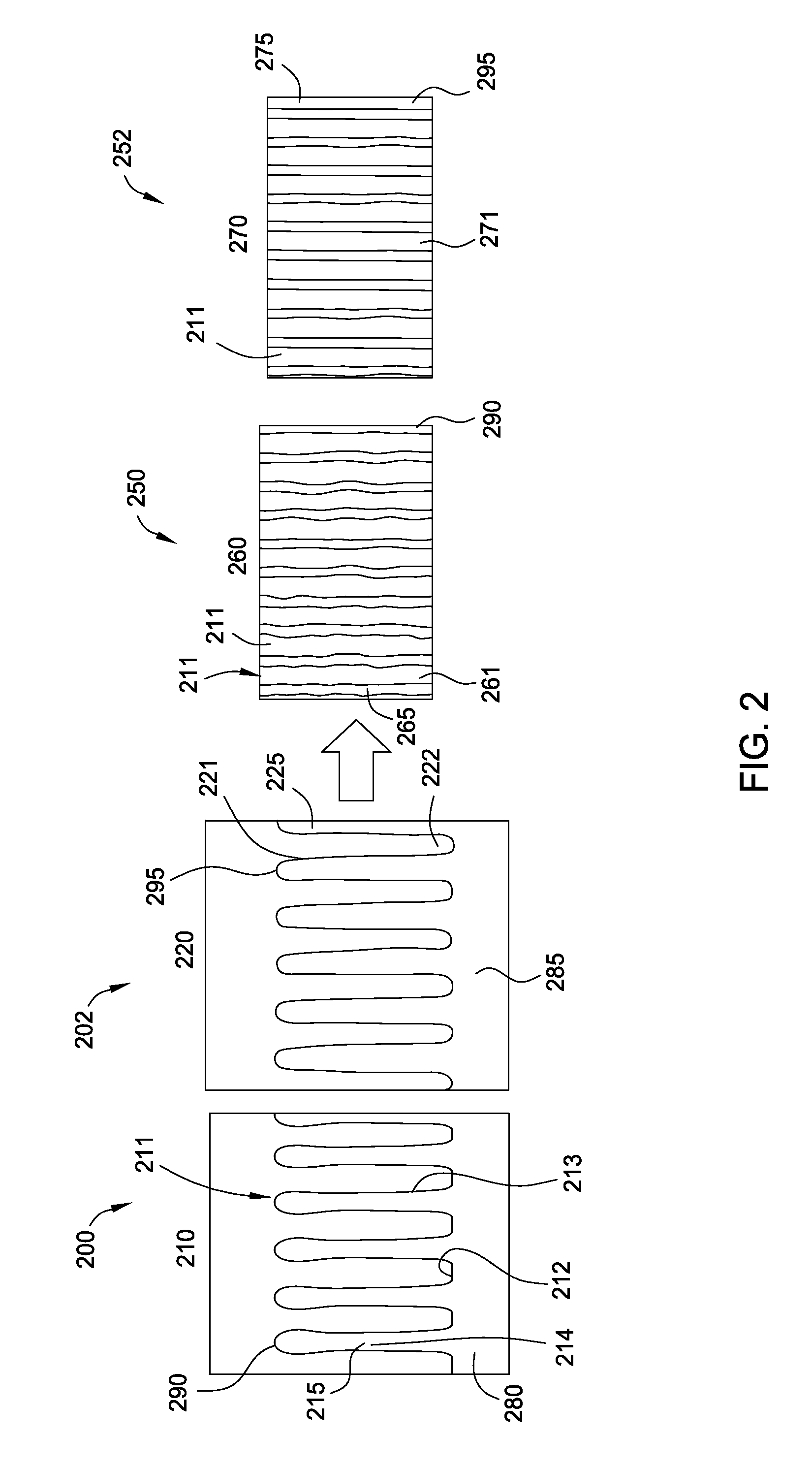

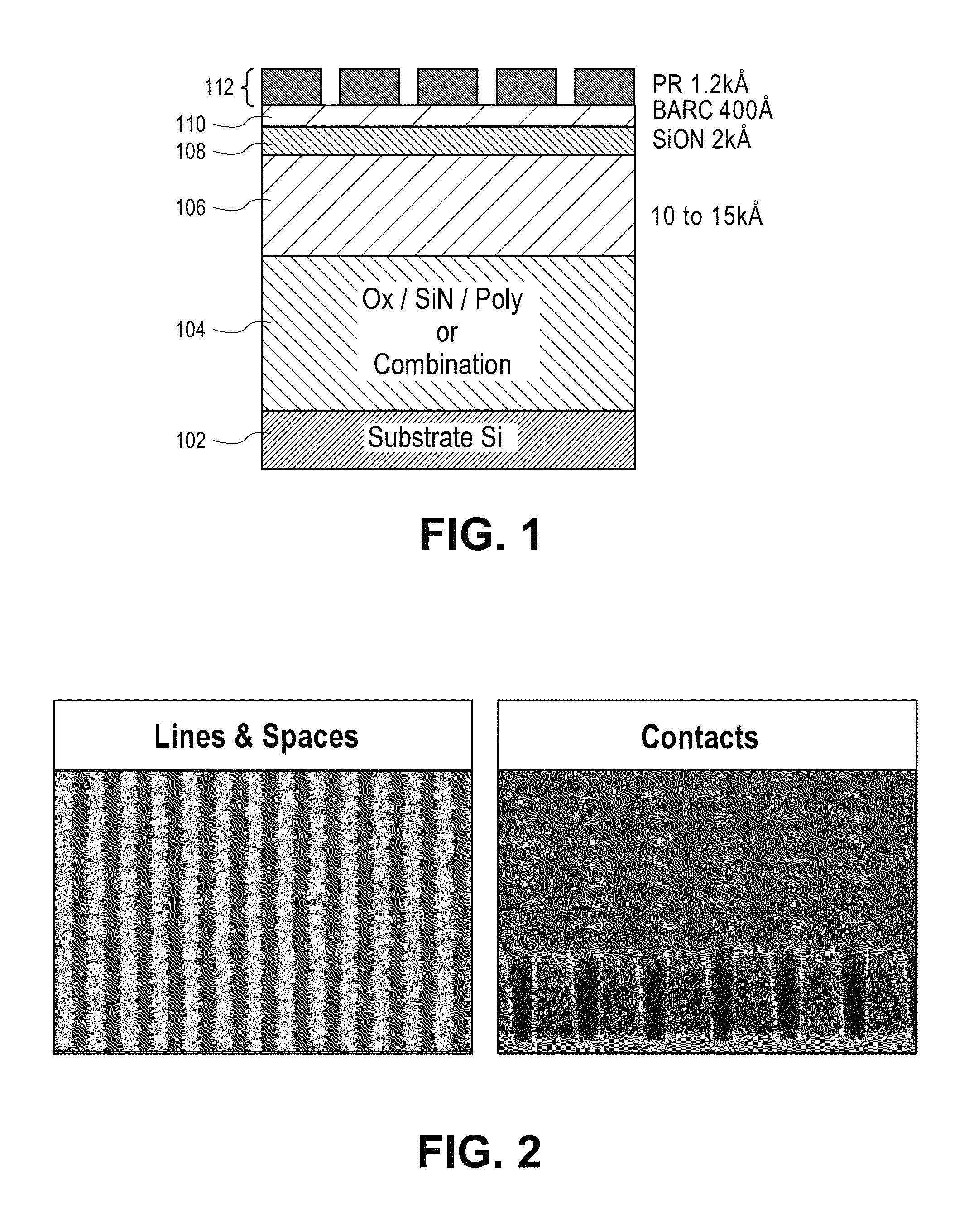

Boron-doped carbon-based hardmask etch processing

InactiveUS20140213059A1Semiconductor/solid-state device manufacturingBoron doped carbonMaterials science

Boron-doped carbon-based hardmask etch processing is described. In an example, a method of patterning a film includes etching a boron-doped amorphous carbon layer with a plasma based on a combination of CH4 / N2 / O2 and a flourine-rich source such as, but not limited to, CF4, SF6 or C2F6.

Owner:APPLIED MATERIALS INC

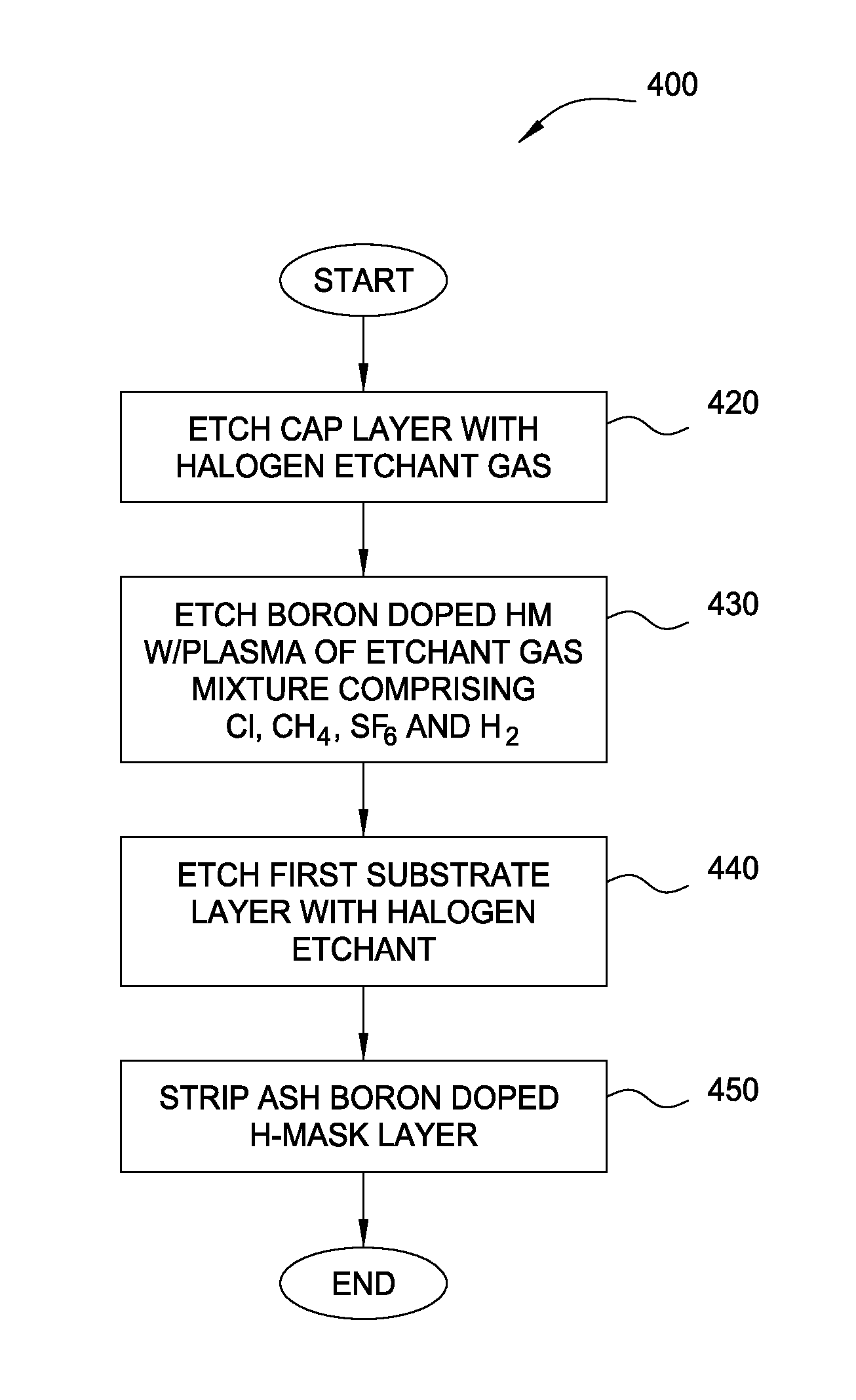

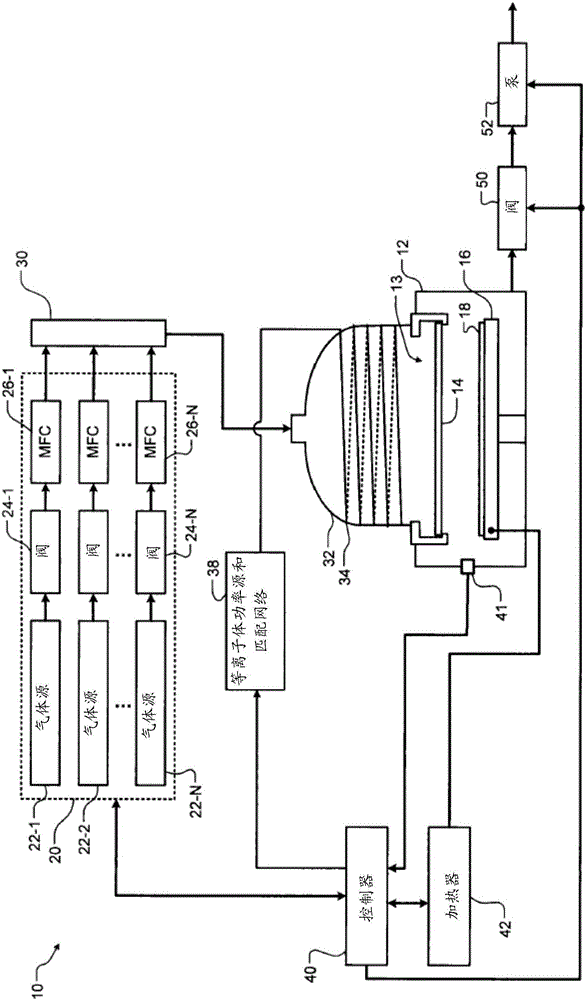

Method of etching a boron doped carbon hardmask

InactiveUS20150064914A1Electric discharge tubesSemiconductor/solid-state device manufacturingBoron doped carbonMaterials science

In one embodiment, a method is proposed for etching a boron dope hardmask layer. The method includes flowing a process gas comprising at least CH4 into a processing chamber. Forming a plasma in the process chamber from the process gas and etching the boron doped hardmask layer in the presence of the plasma. In other embodiments, the process gas utilized to etch the boron doped hardmask layer includes CH4, Cl2, SF6 and O2.

Owner:APPLIED MATERIALS INC

Method for preparing boron-doped porous carbon spheres

InactiveCN107346821ALow costSimple continuous production processSecondary cellsNegative electrodesPorous carbonBoron doped carbon

The invention relates to a method for preparing boron-doped porous carbon spheres. The method comprises the following steps: 1) dissolving a saccharide carbon source and boric acid in water, and carrying out mixing and stirring by a certain ratio, so as to obtain a transparent solution; 2) adding a silicon-based pore former so as to form a boron-doped porous carbon sphere precursor solution; 3) subjecting the obtained precursor solution to a (aerosol assisted) spray drying process, so as to obtain solid-state boron-doped carbon sphere precursor particles; 4) subjecting the obtained solid particles to pyrolysis in an inert atmosphere, so as to obtain a mixture, of which a pore template SiO2 is embedded in boron-doped carbon spheres; 5) removing the silicon-based pore former from the mixture, and carrying out drying, thereby obtaining the boron-doped porous carbon spheres. According to the method, the problems of the existing boron-doped carbon material technologies that the raw material cost is high, the preparation process is miscellaneous, the boron doped amount is low, and large-scale industrial production is difficult are solved, and an alternate material, which is superior to commercial graphite, of negative poles of lithium-ion batteries is provided.

Owner:卢云峰

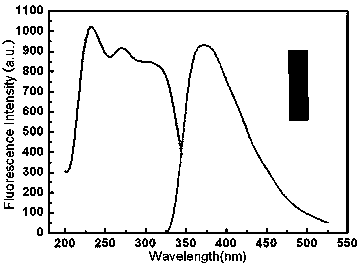

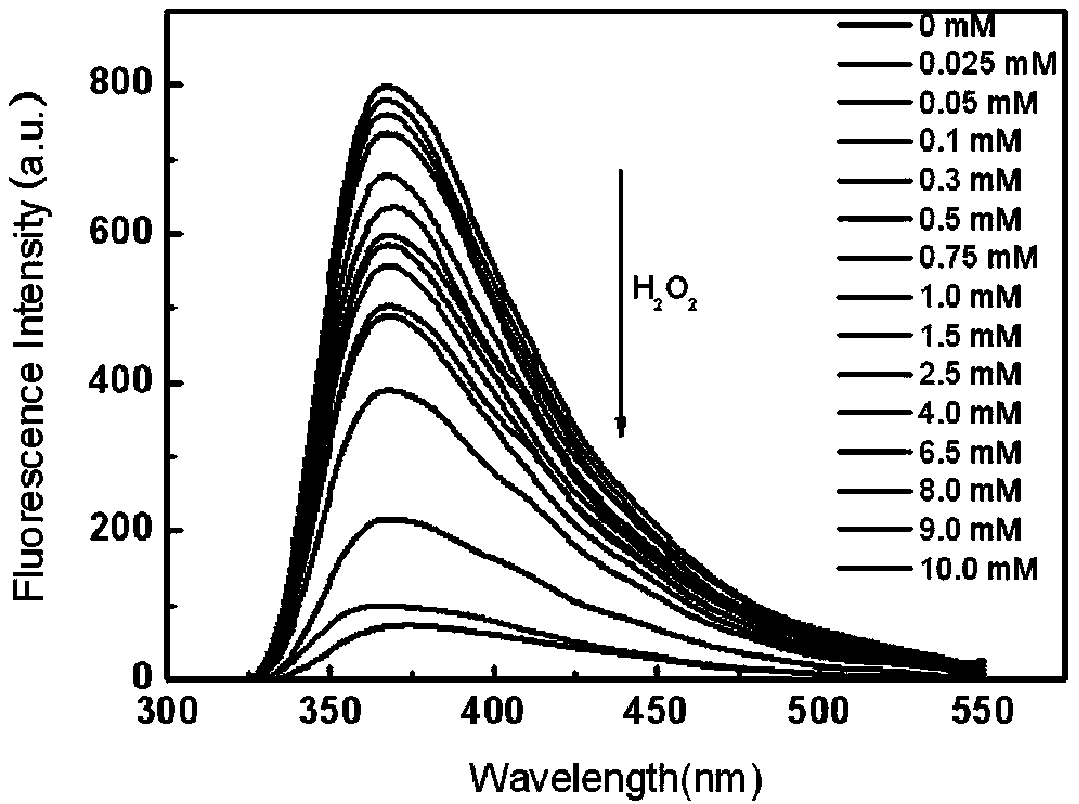

Method for preparing boron-doped carbon quantum dots by one-step solvothermal method and application of boron-doped carbon quantum dots

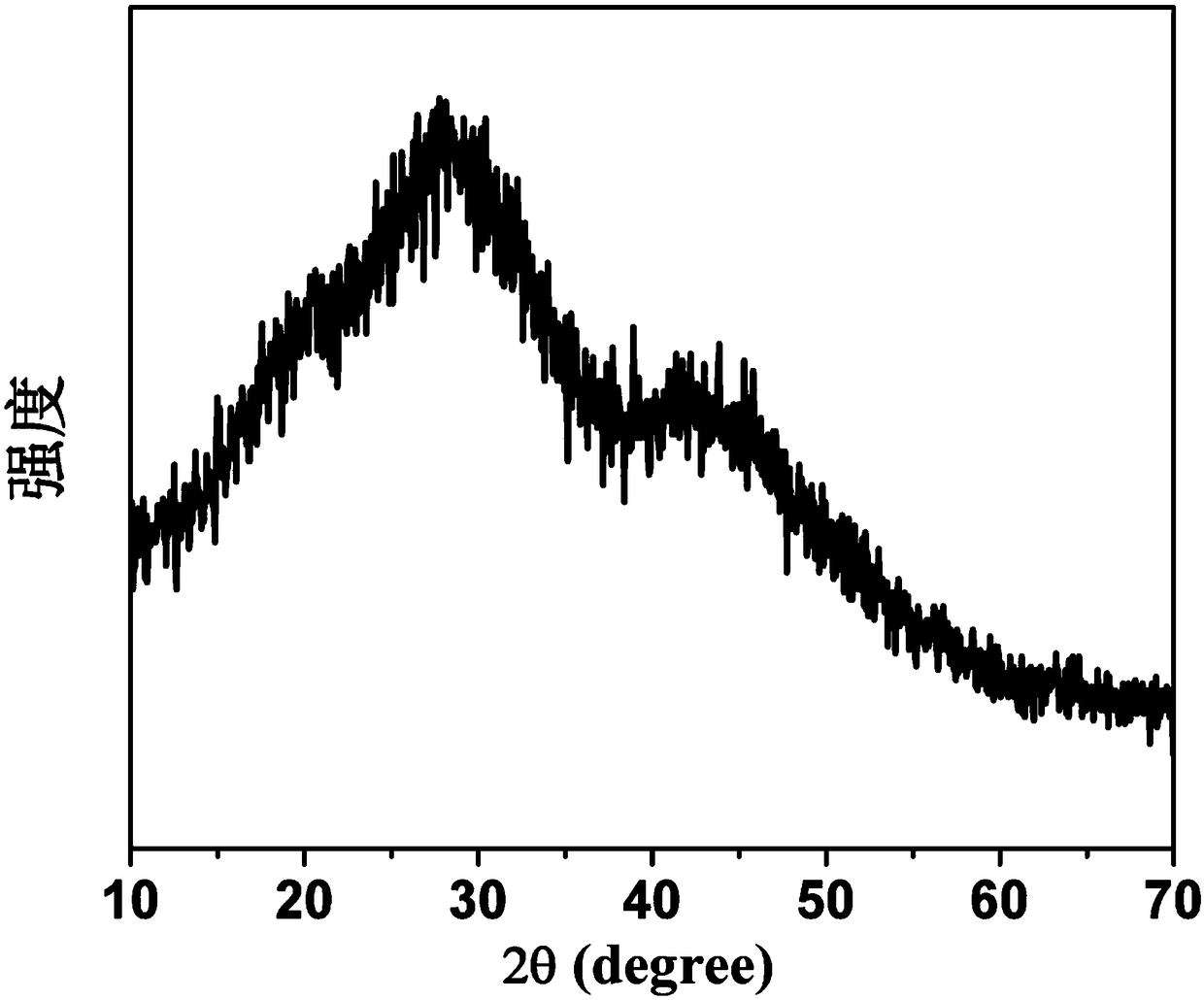

InactiveCN103881708AHigh fluorescence quantum yieldLow toxicityFluorescence/phosphorescenceLuminescent compositionsEvaporationBoron doped carbon

The invention relates to the field of carbon quantum dot preparation and in particular relates to a method for preparing boron-doped carbon quantum dots by a one-step solvothermal method and an application of the boron-doped carbon quantum dots. The preparation method comprises the steps of putting hydroquinone into a stainless steel high pressure reactor with a polytetrafluoroethylene lining, adding acetone according to the proportion of hydroquinone to acetone being 1.0g:5mL, and then dropping boron tribromide into the reactor slowly; putting the sealed reactor into an air dry oven, heating the reactor at 150-220 DEG C for 1-5 hours, and then cooling the reactor to the room temperature; concentrating and evaporating the mixed liquid in the reactor to dryness by using the mode of rotary evaporation, thus obtaining the boron-doped carbon quantum dots. The boron-doped carbon quantum dots prepared by the method can be used for detecting the contents of hydrogen peroxide and glucose.

Owner:ZHEJIANG NORMAL UNIVERSITY

Catalyst carrier, supported catalyst and preparation method and application thereof

ActiveCN110302769AWide variety of sourcesReduce manufacturing costOrganic compound preparationCatalyst activation/preparationBoron doped carbonInteraction forces

The invention relates to a catalyst carrier, a supported catalyst and a preparation method and application thereof and mainly solves the problem that metal nanoparticles are prone to gathering, growing and shedding in the process of multiphase catalytic reaction due to weak interaction force between a carbon material and loaded metal nanoparticles. A boron doped carbon material is obtained by adopting biomass sugar and a born-containing compound as precursors and performing high-temperature calcining, so that the above problem is well solved. The doped carbon material highly interacts with themetal nanoparticles; when the doped carbon material serving as a carrier loads the metal nanoparticles, the metal nanoparticles can be dispersed uniformly, gathering and shedding of the metal nanoparticles in the process of catalytic reaction are effectively contained, and activity and stability of the catalyst are improved remarkably. The doped carbon material is extensive in raw material source, low in cost, easy to obtain, simple in preparation process and good in application prospect and is an ideal metal nanoparticle carrier material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of boron-doping carbon nitride as well as product and application thereof

ActiveCN109569691AEvenly dopedImprove photocatalytic performanceWater/sewage treatment by irradiationWater treatment compoundsChemical reactionBoron doped carbon

The invention relates to a preparation method of boron-doping carbon nitride as well as a product and application thereof. By virtue of a hydrothermal reaction way of melamine and boric acid, on one hand, boron atoms have chemical reaction with melamine, so that the boron and carbon-nitrogen elements are mixed in an atomic level; on the other hand, the hydrothermal reaction is performed for the melamine in an acid environment, so that a supermolecule-like structure is formed, and the separation of a carbon nitride lamina structure in the subsequent roasting process can be facilitated; and a precursor synthesized in the reaction is roasted to prepare boron-doped carbon nitride which is uniform in doping and has a thinner lamina structure. The boron-doping carbon nitride prepared by adoptingthe preparation method of the invention is uniform in element doping, thinner in lamina, better in optical catalysis, simple in preparation operation, low in difficulty and suitable for enlarged production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

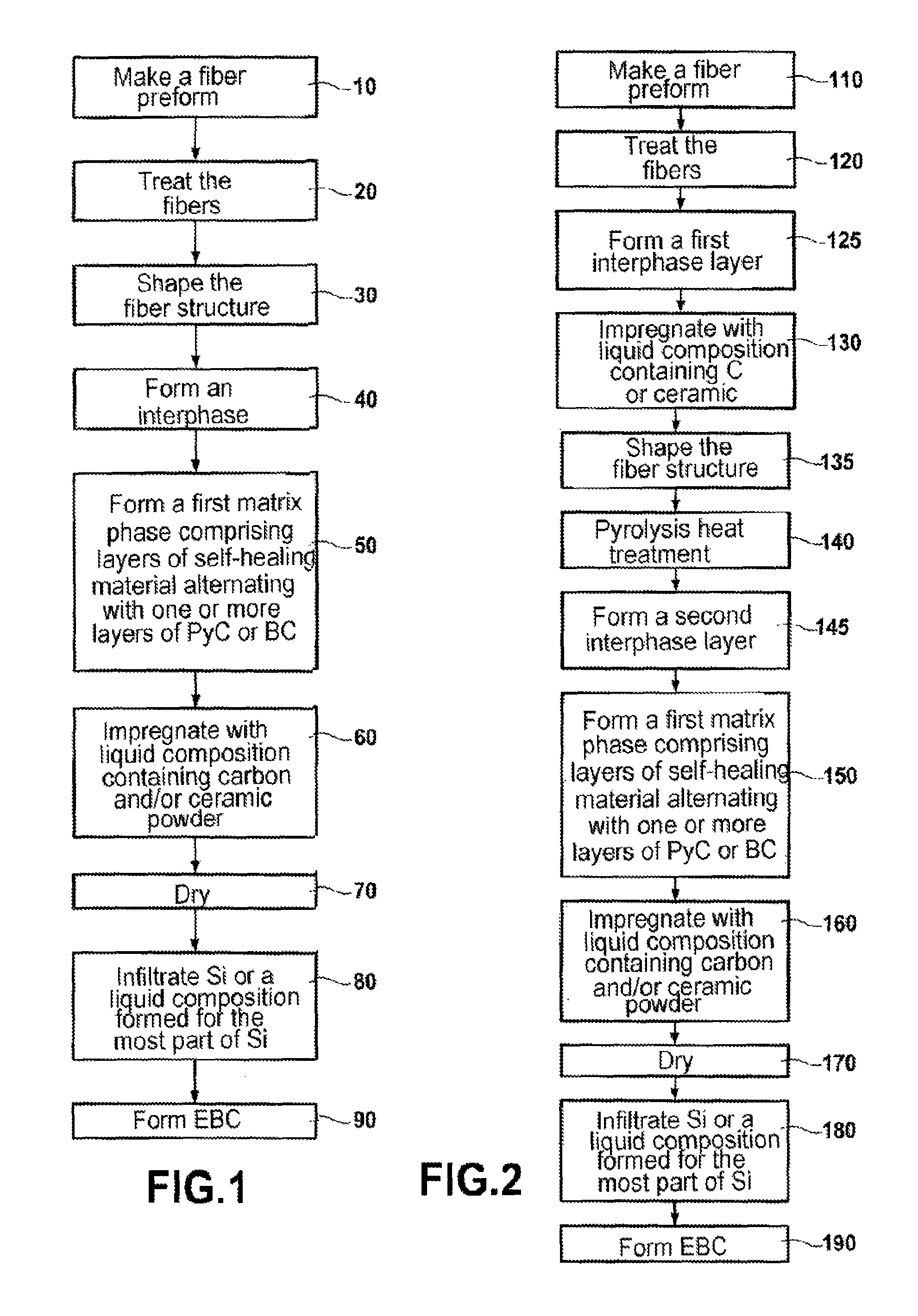

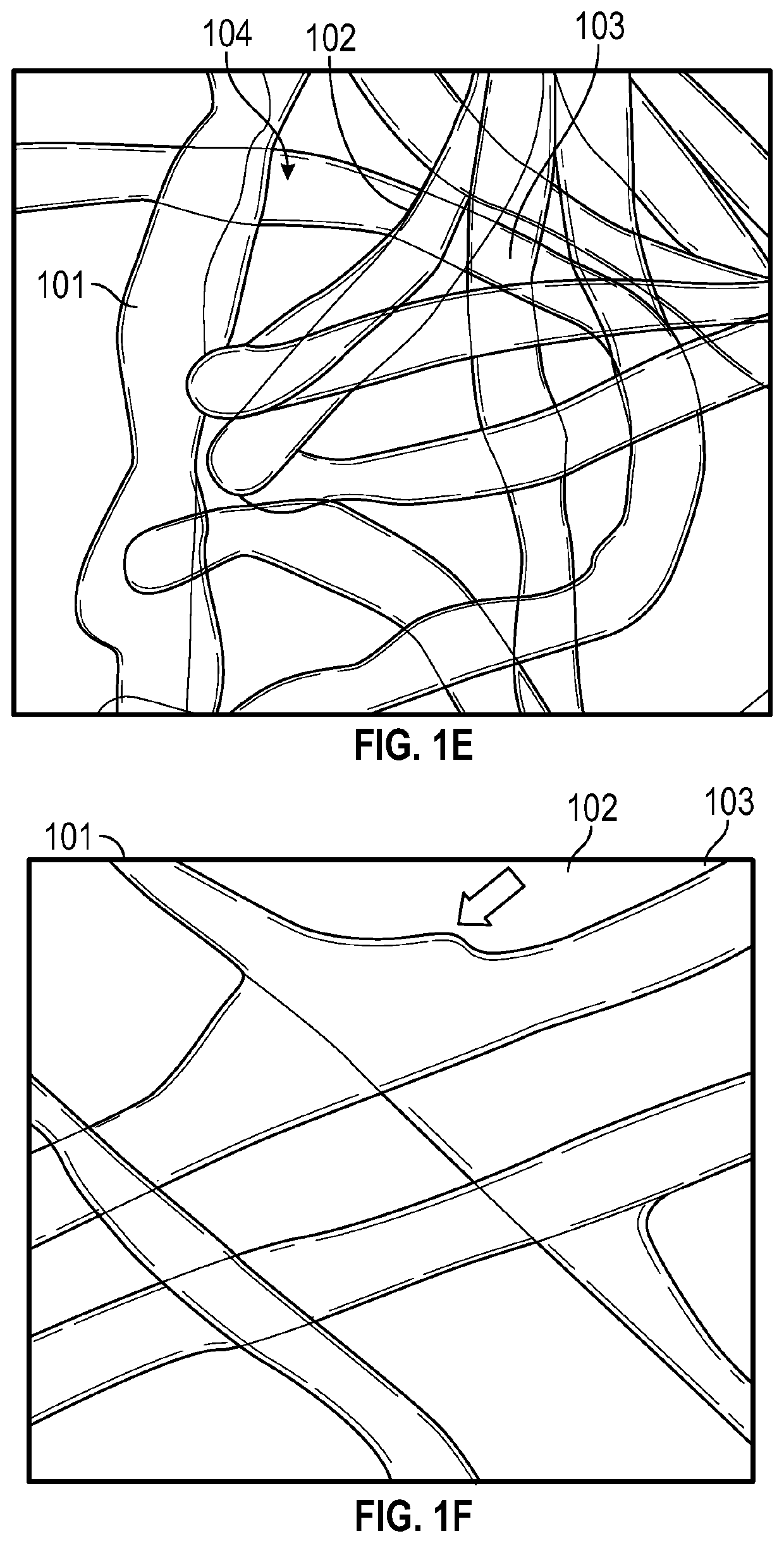

Method of fabricating a part out of cmc material

ActiveUS20150008613A1Increase deflectionPreventing and slowing down breakage of fiberCeramic shaping apparatusMachines/enginesFiberRestorative material

Fabricating a composite material part comprises the steps of making a consolidated fiber preform, the fibers of the preform being carbon or ceramic fibers that are coated in an interphase formed by at least one layer of pyrolytic carbon (PyC) or of boron-doped carbon (BC). Obtaining a partially densified consolidated fiber preform, where partial densification comprises forming a first matrix phase on the interphase, the first matrix phase comprising a plurality of layers of self-healing material alternating with one or more layers of PyC or of BC. Continuing densification by dispersing carbon and / or ceramic powder within the partially densified consolidated preform and by infiltrating molten silicon or a liquid composition formed for the most part of silicon.

Owner:SAFRAN CERAMICS SA

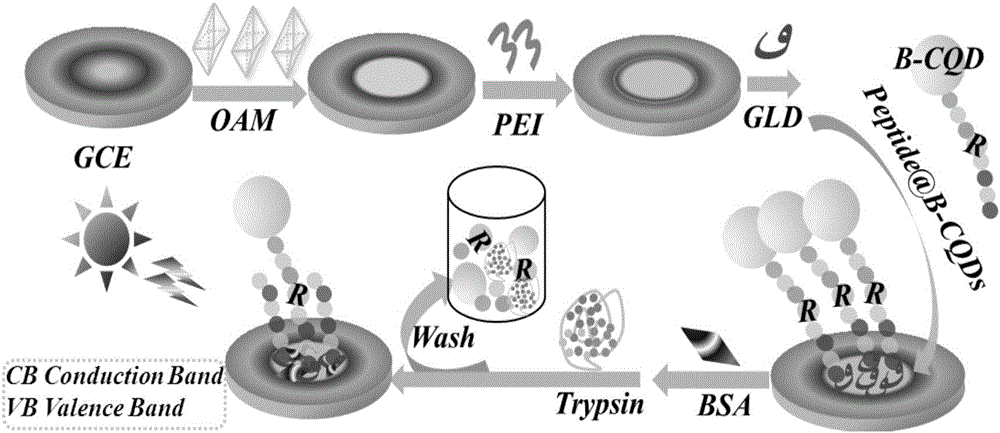

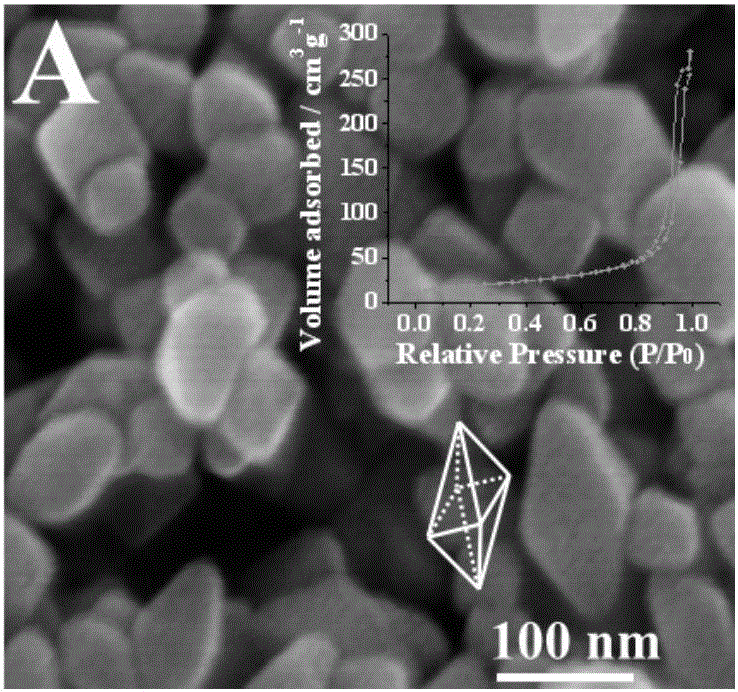

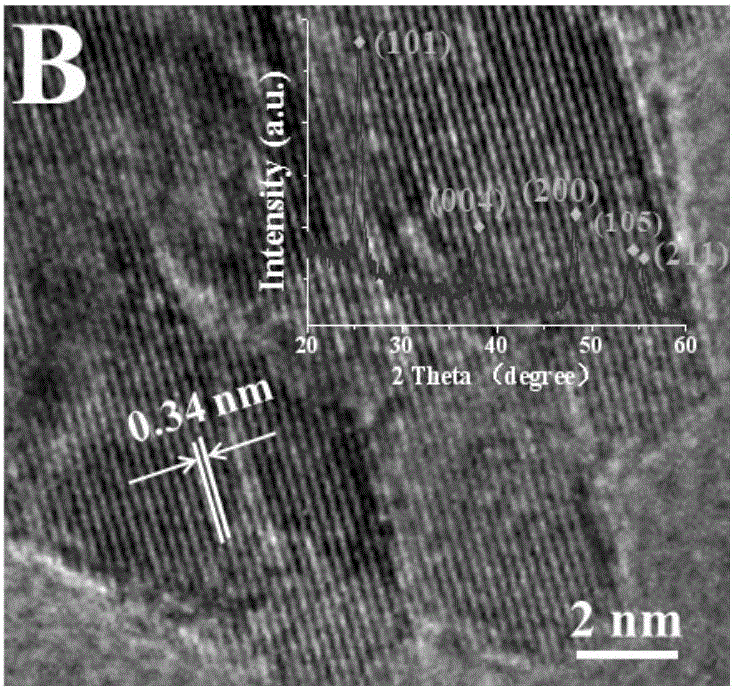

TiO2 mesoscopic crystal based trypsin photoelectrochemical detection method

InactiveCN106290528AHigh porosityFast transmissionMaterial electrochemical variablesBoron doped carbonPhotocurrent

The invention discloses a TiO2 mesoscopic crystal based trypsin photoelectrochemical detection method. According to the method, a polyethylenimine(PEI)-sensitized TiO2 octahedral anatase mesoscopic crystal is utilized as a photoactive substrate material, and a signal amplification function on the substrate material by boron-doped carbon quantum dot labeling peptide (B-CODs@petide) is utilized to prepare a photoelectrochemical sensor to be applied to trypsin detection. Based on the stability and excellent conductivity of PEI, PEI and OAM can be compounded to accelerate the transfer rate of photo-generated electrons and improve photocurrent signals; through the introductions of B-CODs with the competitive light capturing ability and space hampered peptide chains, the photocurrent signals can be significantly reduced; when a modified electrode is incubated in a trypsin solution, trypsin can conduct catalytic hydrolysis on peptide bonds, and B-CODs@petide can be released from the surface of the electrode, so as to improve the photocurrent signals; the photocurrent signals and the trypsin concentration are linear in the range of 1*10<-7> to 1.0 mg / mL. The method can be used for monitoring screening of various proteases and inhibitors in early diagnoses of different diseases.

Owner:FUJIAN NORMAL UNIV

Preparation method of solid carbon dot fluorescent powder with high quantum yield and application of solid carbon dot fluorescent powder in LED (Light Emitting Diode) lamp bead

InactiveCN108795423ALow costFast preparationNanoopticsLuminescent compositionsQuantum yieldSolid carbon

Owner:JILIN UNIV

A boron-doped composite for lithium-sulfur battery, a process for preparing said composite, an electrode material and a lithium-sulfur battery comprising said composite

InactiveCN106463703AImprove conductivityImprove cycle stabilityElectrode thermal treatmentLi-accumulatorsLithium–sulfur batterySulfur

Owner:ROBERT BOSCH GMBH +1

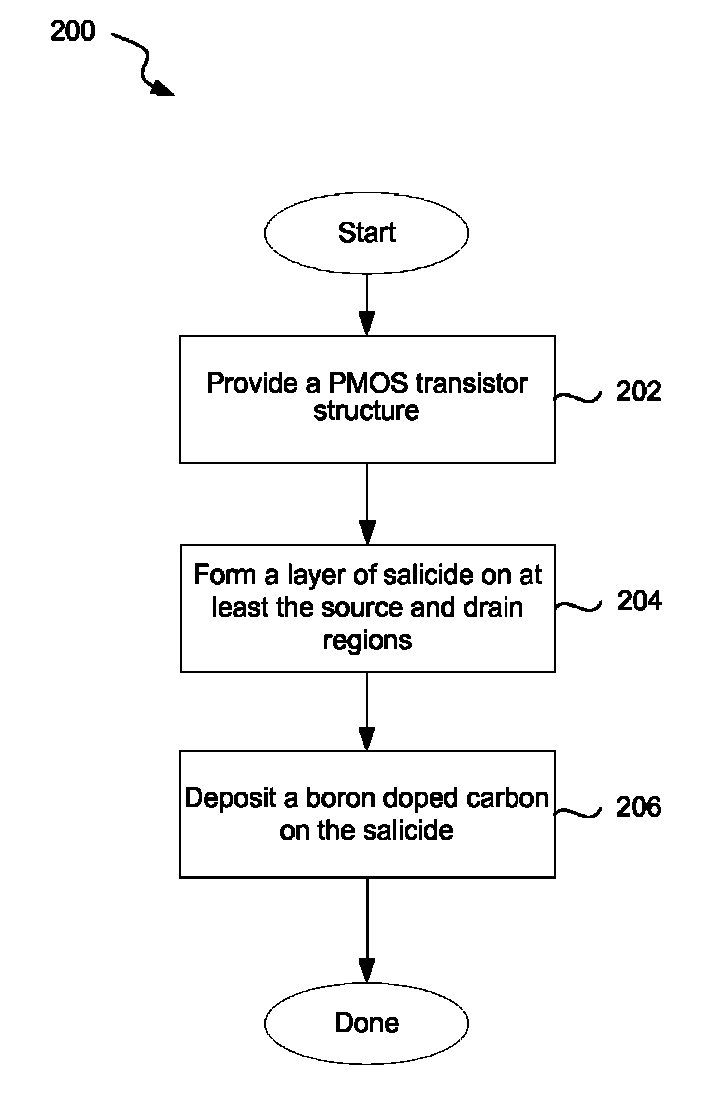

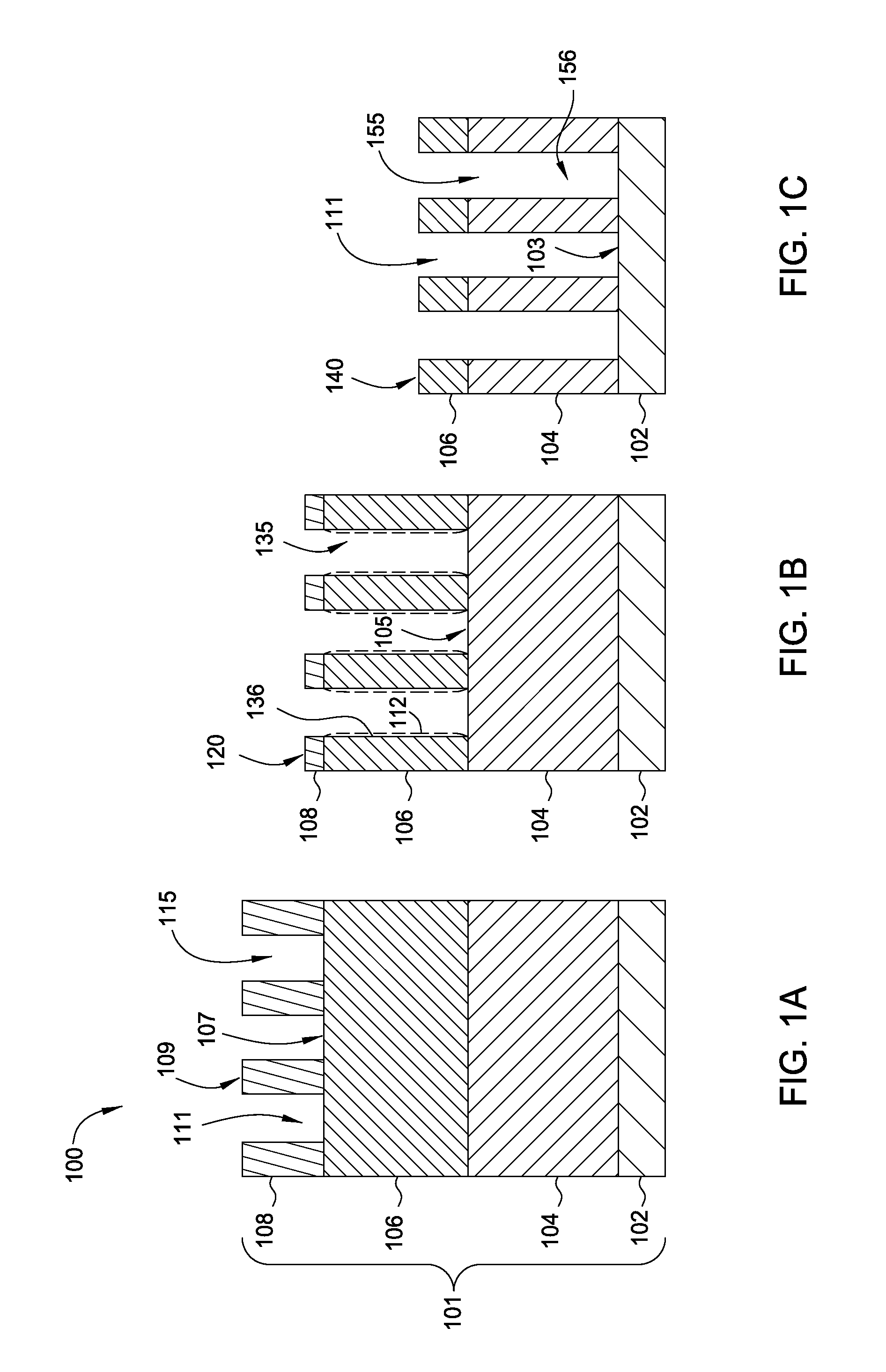

Method for making high stress boron-doped carbon films

ActiveUS7998881B1Preserving material qualityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesCarbon filmSalicide

Transistor architectures and fabrication processes generate channel strain without adversely impacting the efficiency of the transistor fabrication process while preserving the material quality and enhancing the performance of the resulting transistor. Transistor strain is generated is PMOS devices using a highly compressive post-salicide boron doped carbon capping layer applied as a blanket over on at least the source and drain regions. The stress from this capping layer is uniaxially transferred to the PMOS channel through the source-drain regions to create compressive strain in PMOS channel.

Owner:NOVELLUS SYSTEMS

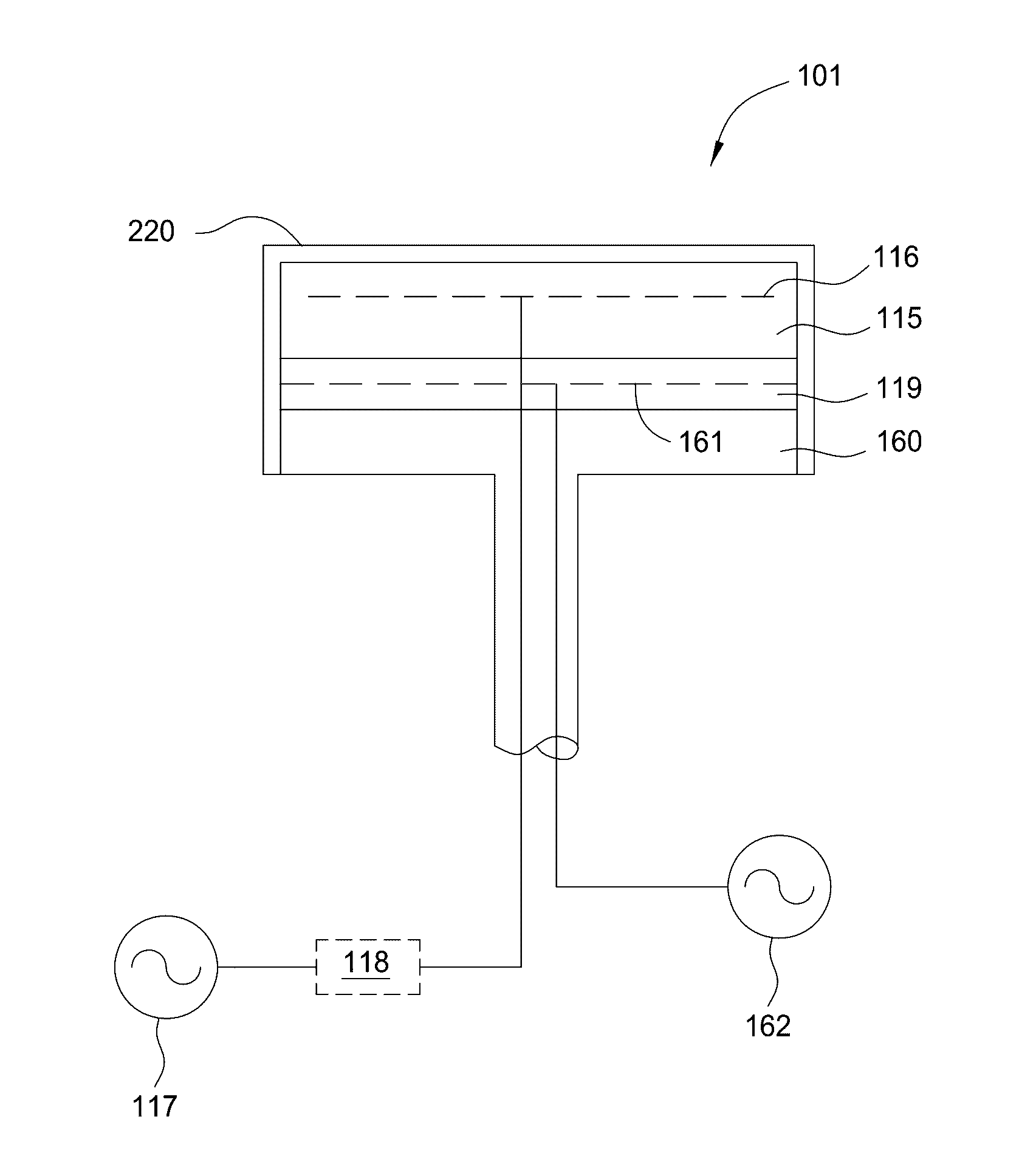

Graded in-situ charge trapping layers to enable electrostatic chucking and excellent particle performance for boron-doped carbon films

ActiveUS20160358804A1Reduce flow rateElectric discharge tubesSemiconductor/solid-state device manufacturingTrappingCarbon nitride

The present disclosure generally relates to processing chamber seasoning layers having a graded composition. In one example, the seasoning layer is a boron-carbon-nitride (BCN) film. The BCN film may have a greater composition of boron at the base of the film. As the BCN film is deposited, the boron concentration may approach zero, while the relative carbon and nitrogen concentration increases. The BCN film may be deposited by initially co-flowing a boron precursor, a carbon precursor, and a nitrogen precursor. After a first period of time, the flow rate of the boron precursor may be reduced. As the flow rate of boron precursor is reduced, RF power may be applied to generate a plasma during deposition of the seasoning layer.

Owner:APPLIED MATERIALS INC

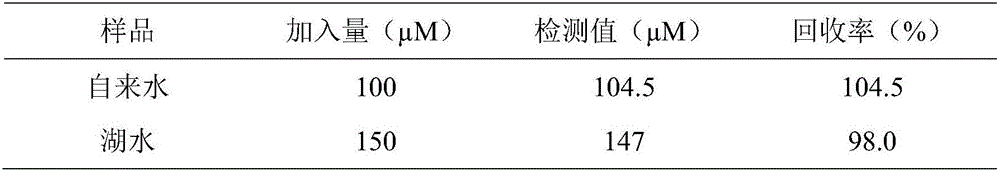

Boron-doped carbon-base fluorescent nano material, and preparation method and application thereof

InactiveCN106675555AHigh sensitivityHigh selectivityFluorescence/phosphorescenceLuminescent compositionsDevice materialBoron doped carbon

The invention discloses a boron-doped carbon-base fluorescent nano material, and a preparation method and application thereof. The surface B atom content of the nano material is 11.61%; and a hydrothermal process is utilized to prepare the boron-doped carbon-base (B-Cdots) fluorescent nano material which is used for detecting lead ions and copper ions. The simple hydrothermal synthesis process is adopted to synthesize the high-B-content B-Cdots fluorescent nano material, thereby effectively enhancing the B atom doping content, being beneficial to widening the application range of the carbon-base fluorescent material in environmental detection, solving the technical problem of demands for harsh experimental conditions by the synthesis of the B-doped nano material, and implementing the high-selectivity detection on heavy metal ions. The fluorescent experiment test indicates that the B-Cdots fluorescent nano material has favorable specific effects on Pb<2+> and Cu<2+>, and can implement high-sensitivity detection on the Pb<2+> and Cu<2+>. The product not only can be used for detecting heavy metal ions, but also can be used as a fluorescent probe for other fluorescent sensors and in the fields of pollutant treatment, preparation of fluorescent device materials and composite nano materials, and the like.

Owner:YANCHENG INST OF TECH

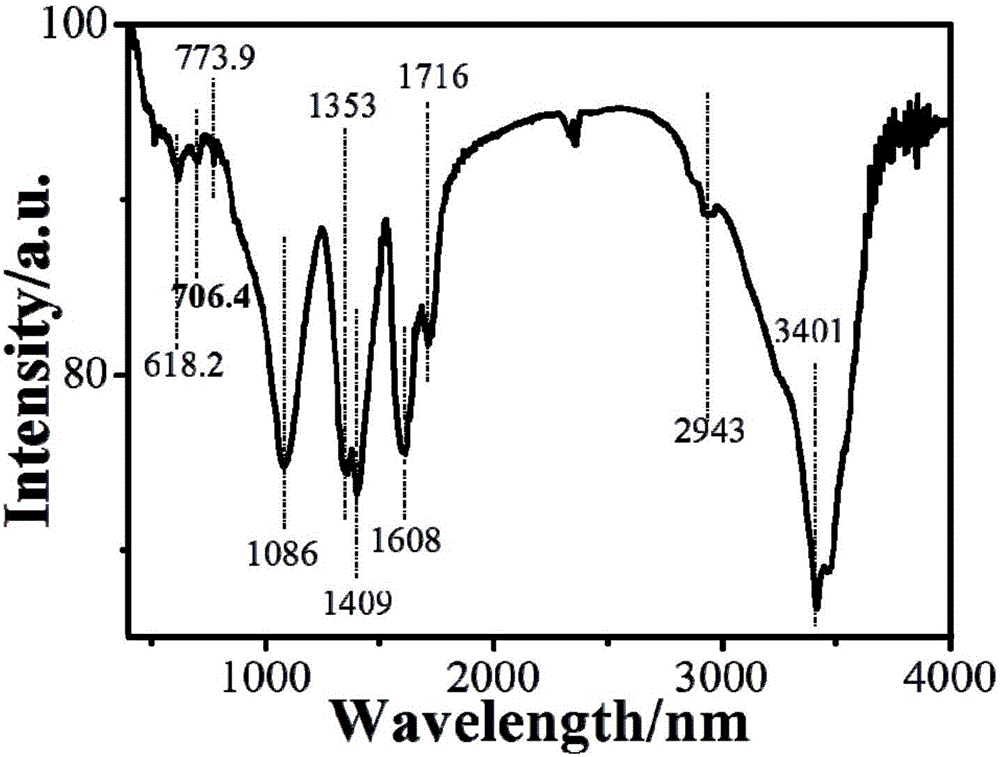

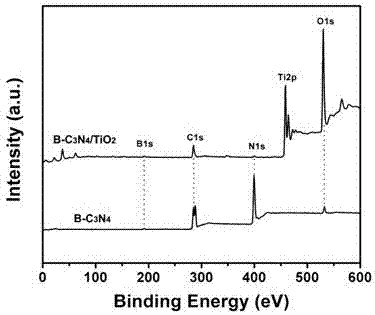

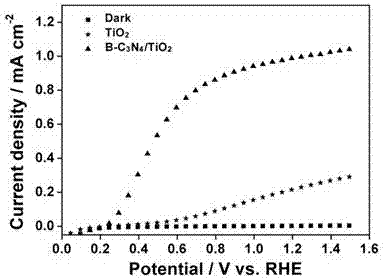

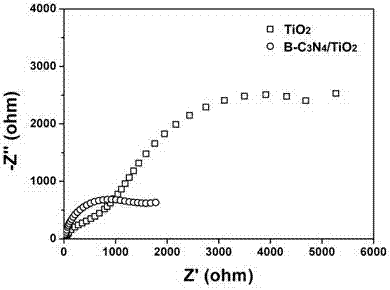

Boron-doped carbon nitride modified titanium dioxide composite photoelectrode and preparing method and application of boron doping carbon nitride modified titanium dioxide composite photoelectrode

InactiveCN107130256AExpand the scope of absorptionInhibitory complexLiquid/solution decomposition chemical coatingElectrodesSemiconductor materialsDecomposition

The invention discloses a preparing method of a boron-doped carbon nitride modified titanium dioxide composite photoelectrode. The preparing method includes the following steps that a titanium source compound is added into hydrochloric acid dropwise, then conducting glass is inserted into a mixture for a hydrothermal reaction, then the conducting glass is taken out to be washed, dried, calcined and cooled to room temperature, and a TiO2 photo-anode is obtained; urea and boric acid are dissolved into deionized water to form modification liquid, the TiO2 photo-anode is steeped into the modification liquid to be died, calcined and cooled to room temperature, and the boron doping carbon nitride modified titanium dioxide composite photoelectrode is obtained. According to the preparing method, TiO2 grows to the surface of an FTO conducting glass material, then the surface of a semiconductor material is modified with boron-doped g-C3N4, an even modification layer is formed, the spectral absorption scope can be enlarged, the light capture rate is increased, photogenerated charge separation can be effectively promoted, and finally the photoelectrocatalysis water decomposition efficiency of the composite electrode is finally improved.

Owner:HUANGHE S & T COLLEGE

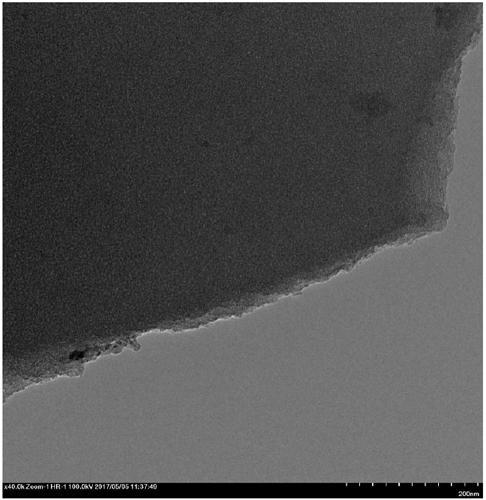

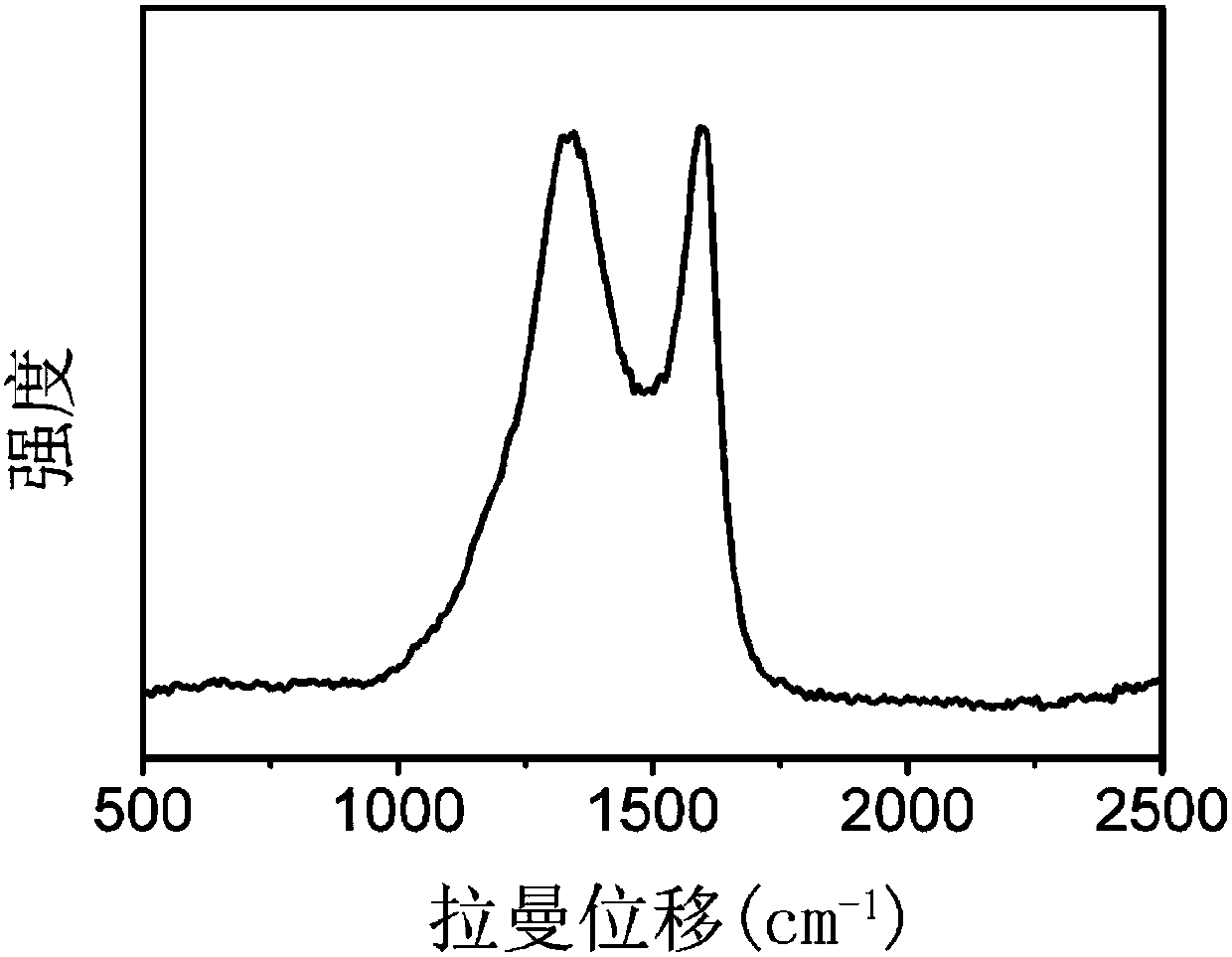

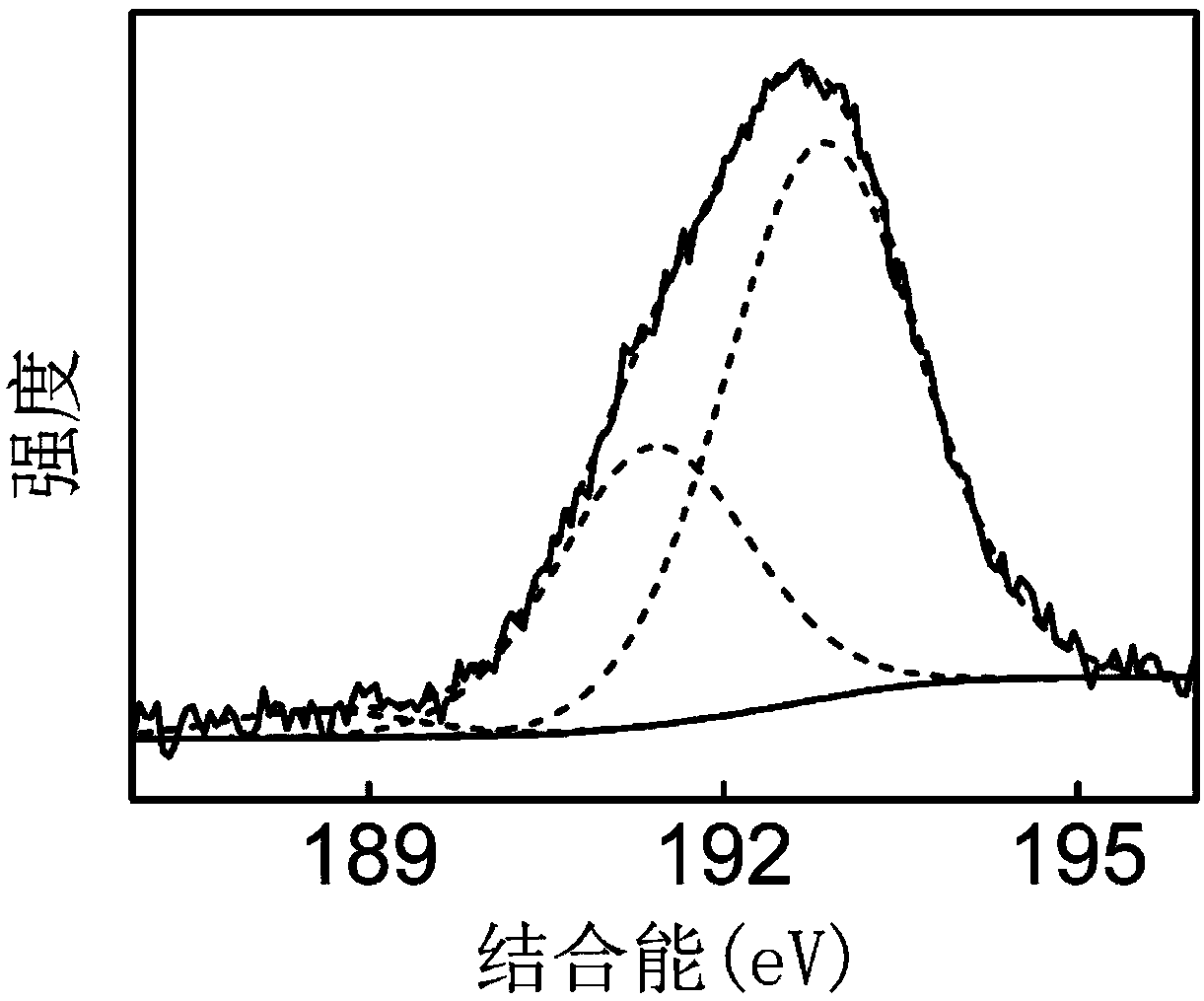

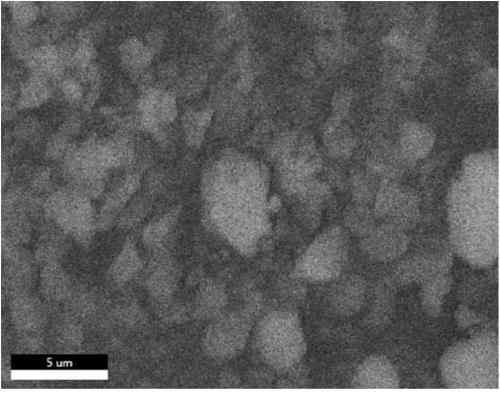

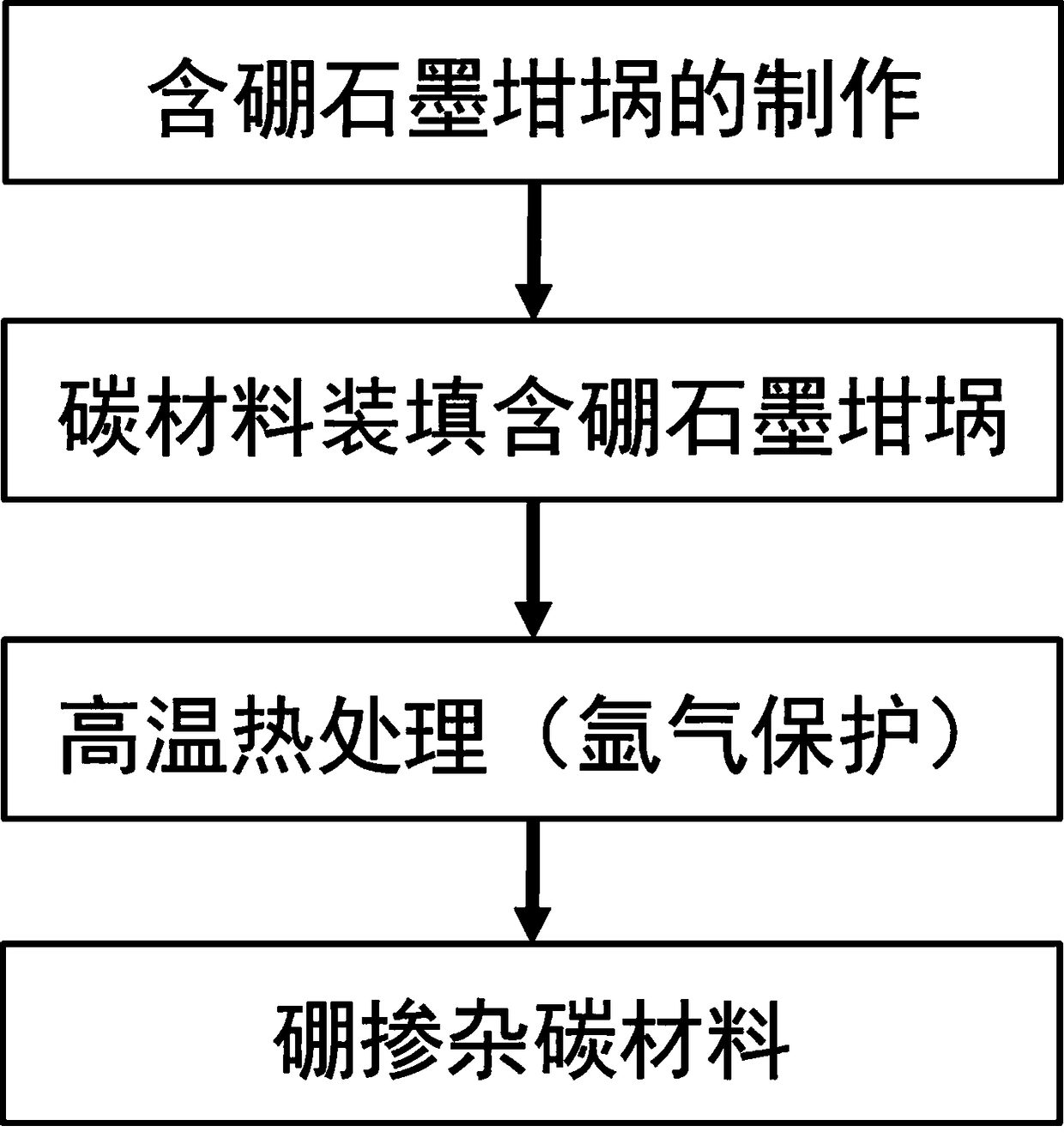

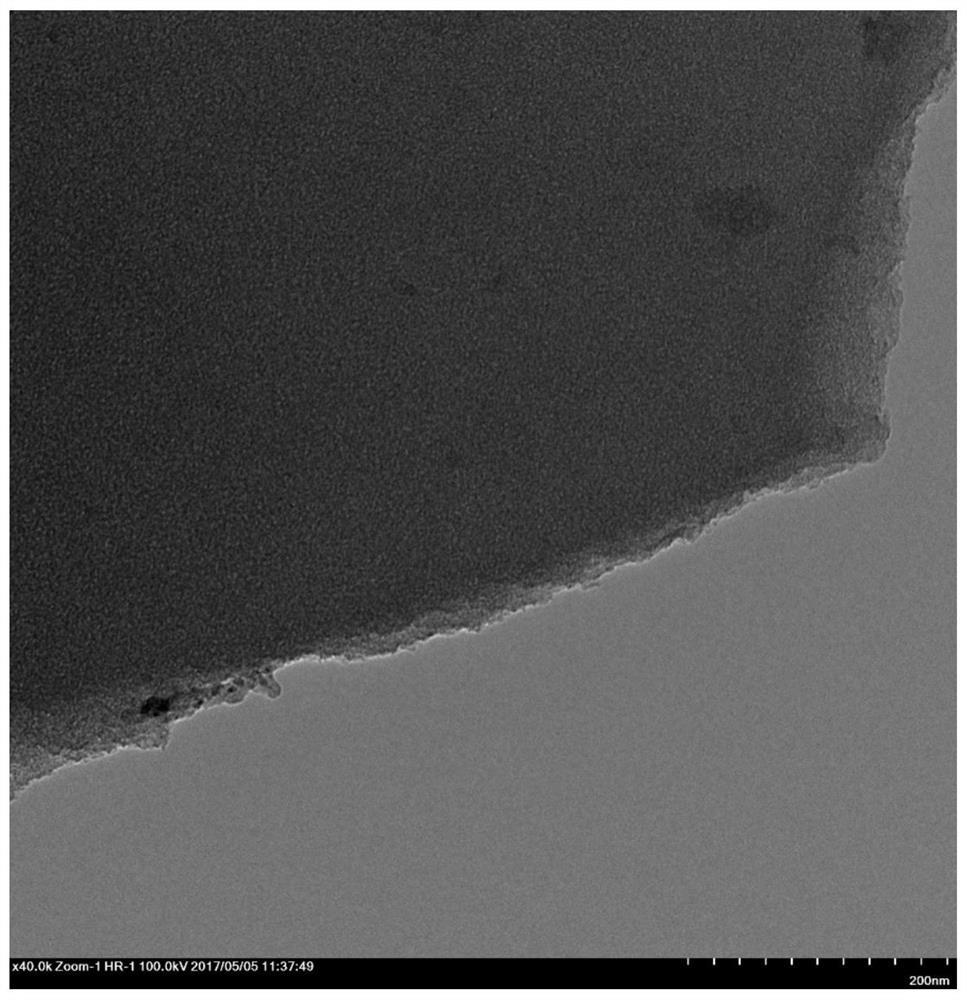

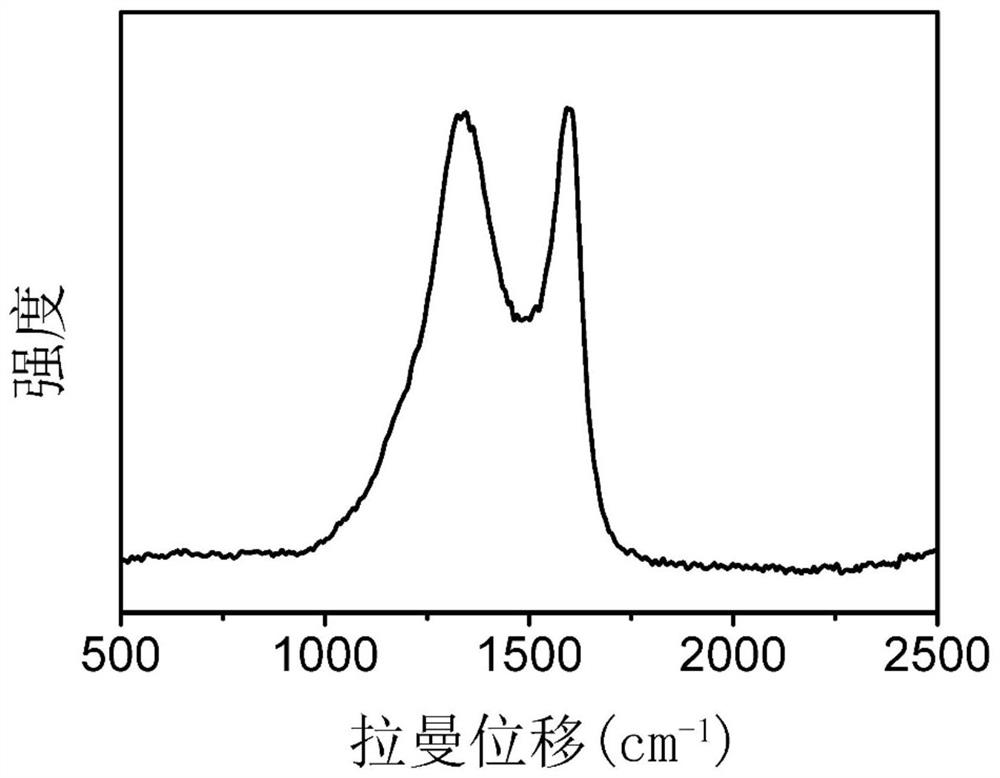

Preparation method of atomic crystal boron-doped carbon material

The invention discloses a preparation method of an atomic crystal boron-doped carbon material. The preparation method comprises the following steps: firstly filling a boron-containing graphite crucible with a carbon material, sealing with threads, then putting the boron-containing graphite crucible in a constant-temperature zone of a graphitization furnace, increasing the temperature to 2000-3000DEG C, then maintaining the constant temperature for 0.5-3 hours and reducing to a room temperature to prepare the boron-doped carbon material. According to the invention, a gas phase boron doping method is utilized, and the boron-doped carbon material is prepared by gas-solid reaction. The boron-doped carbon material prepared by the preparation method disclosed by the invention has the characteristics of being uniform in boron distribution, adjustable in boron content, high in surface activity, few in defect, high in electrical conductivity and the like and has potential applications in the fields of electrode material conductive agents, active substances and other batteries.

Owner:北京墨烯科技有限公司

Method of fabricating a part out of CMC material

ActiveUS9440888B2Increase deflectionPreventing and slowing down breakage of fiberCeramic shaping apparatusMachines/enginesFiberBoron doped carbon

Fabricating a composite material part comprises the steps of making a consolidated fiber preform, the fibers of the preform being carbon or ceramic fibers that are coated in an interphase formed by at least one layer of pyrolytic carbon (PyC) or of boron-doped carbon (BC). Obtaining a partially densified consolidated fiber preform, where partial densification comprises forming a first matrix phase on the interphase, the first matrix phase comprising a plurality of layers of self-healing material alternating with one or more layers of PyC or of BC. Continuing densification by dispersing carbon and / or ceramic powder within the partially densified consolidated preform and by infiltrating molten silicon or a liquid composition formed for the most part of silicon.

Owner:SAFRAN CERAMICS SA

Method of etching a boron doped carbon hardmask

InactiveUS9287124B2Electric discharge tubesSemiconductor/solid-state device manufacturingBoron doped carbonMaterials science

In one embodiment, a method is proposed for etching a boron dope hardmask layer. The method includes flowing a process gas comprising at least CH4 into a processing chamber. Forming a plasma in the process chamber from the process gas and etching the boron doped hardmask layer in the presence of the plasma. In other embodiments, the process gas utilized to etch the boron doped hardmask layer includes CH4, Cl2, SF6 and O2.

Owner:APPLIED MATERIALS INC

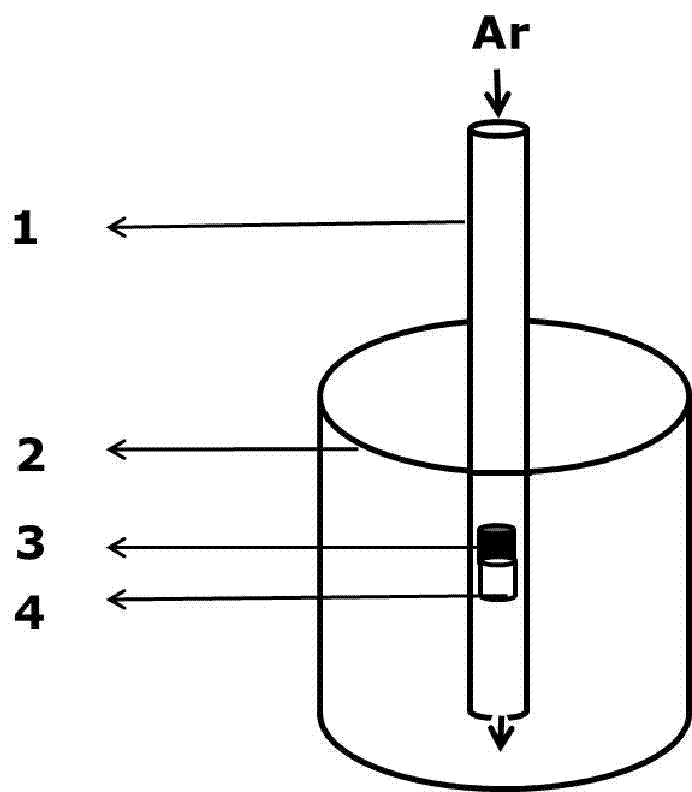

Preparation method of boron-doped p type carbon nanotube with high seebeck coefficient

InactiveCN103496689AEasy to acidifyImprove acidificationCarbon compoundsBoron doped carbonTemperature difference

The invention relates to a preparation method of a boron-doped p type carbon nanotube with a high seebeck coefficient. The preparation method comprises the following steps: carrying out boron doping onto the carbon nanotube under a high temperature by using B2O3 as a boron source, wherein atoms B in B2O3 and atoms C in the carbon nanotube generate the following replacement reaction: XB2O3<+>(2+3x) C (nanotubes) to 2BxC (nanotubes)+3xCO; and then, washing, filtering and drying to obtain the boron-doped carbon nanotube (BxC). Percentage of atoms B in the boron-doped carbon nanotube (BxC) can be remarkably increased by increasing a ratio of a reactant B2O3 to the carbon nanotube, and maximum value of x can reach 0.1. According to the preparation method disclosed by the invention, reaction steps are simple and controllable, thermo-electric effect of the boron-doped carbon nanotube is remarkably strengthened and seebeck coefficient is greatly increased; moreover, the greater the x value is, the more obvious the improved seebeck coefficient is. Internal current carriers of the prepared boron-doped carbon nanotube focus on p type current carriers, so that the seebeck coefficient can reach up to 24.05 mu V / K which is increased by about 35% in comparison with that of the original carbon nanotube. The boron-doped carbon nanotube prepared by the method disclosed by the invention can be widely applied to a novel thermoelectric energy material based on temperature difference power generation.

Owner:TONGJI UNIV

Preparation method of silicon-boron doped carbon quantum dots

InactiveCN106318389AConvenient sourceRegular structureMaterial nanotechnologyNano-carbonWater bathsBoron doped carbon

The invention discloses a preparation method of silicon-boron doped carbon quantum dots. The preparation method includes following steps: adding hydrotalcite passing a sieve with 20-50 meshes into a trimethylsilyle sodium phenylborate solution of 0.1-1% in mass percent concentration according to a proportion that each gram of hydrotalcite corresponds to 1-1.5mmol of trimethylsilyle sodium phenylborate, stirring in constant-temperature water bath at 60-70 DEG C for 5-6h, aging for 12-24h, performing solid-liquid separation, using deionized water to wash precipitate for 2-3 times, and drying to obtain hydrotalcite modified by 4-trimethylsilyle sodium phenylborate; putting hydrotalcite in a vacuum tubular furnace, heating to 400-600 DEG C in a vacuum condition, vacuum calcining for 2-4h, and cooling to room temperature; adding powder after calcining into a hydrochloric acid solution of 20-40% in mass percent concentration according to a proportion that each gram of the powder corresponds to 10-15ml of the hydrochloric acid solution, stirring for 3-4h under protection of nitrogen, and centrifuging at a high speed after a hydrotalcite sheet layer is completely dissolved to obtain the silicon-boron doped carbon quantum dots. The preparation method is simple in material and mild in condition.

Owner:CHANGZHOU UNIV

Production method of boron doped carbon quantum dots

InactiveCN106365143AConvenient sourceRegular structureNano-carbonLuminescent compositionsWater bathsBoron doped carbon

The invention discloses a production method of boron doped carbon quantum dots. The production method sequentially comprises the following steps: adding hydrotalcite which is sieved by a 20-50 mesh sieve to a sodium tetramethylborate solution with the mass percentage concentration of 0.1-1% according to a ratio of sodium tetramethylborate to hydrotalcite of 1-1.5 mol:1 g, stirring hydrotalcite and the sodium tetramethylborate solution in 60-70 DEG C constant temperature water bath for 5-6 h, ageing the obtained solution for 12-24 h, carrying out solid-liquid separation, washing the above obtained precipitate with deionized water 2-3 times, and drying the washed precipitate to obtain sodium tetramethylborate modified hydrotalcite; putting the sodium tetramethylborate modified hydrotalcite in a vacuum tubular furnace, heating the sodium tetramethylborate modified hydrotalcite under a vacuum condition to 400-600 DEG C, carrying out vacuum calcining for 2-4 h, and cooling the obtained calcined powder to room temperature; and adding the calcined powder to a hydrochloric acid solution with the mass percentage concentration of 20-40% according to ratio of 10-15 mL:1 g, stirring the calcined powder and the hydrochloric acid solution for 3-4 h until hydrotalcite sheets are completely dissolved, and carrying out high speed centrifuge in order to obtain the boron doped carbon quantum dots. The method has the advantages of simple materials and mild conditions.

Owner:CHANGZHOU UNIV

Boron-doped carbon-based hardmask etch processing

InactiveUS9129911B2Semiconductor/solid-state device manufacturingBoron doped carbonMaterials science

Boron-doped carbon-based hardmask etch processing is described. In an example, a method of patterning a film includes etching a boron-doped amorphous carbon layer with a plasma based on a combination of CH4 / N2 / O2 and a flourine-rich source such as, but not limited to, CF4, SF6 or C2F6.

Owner:APPLIED MATERIALS INC

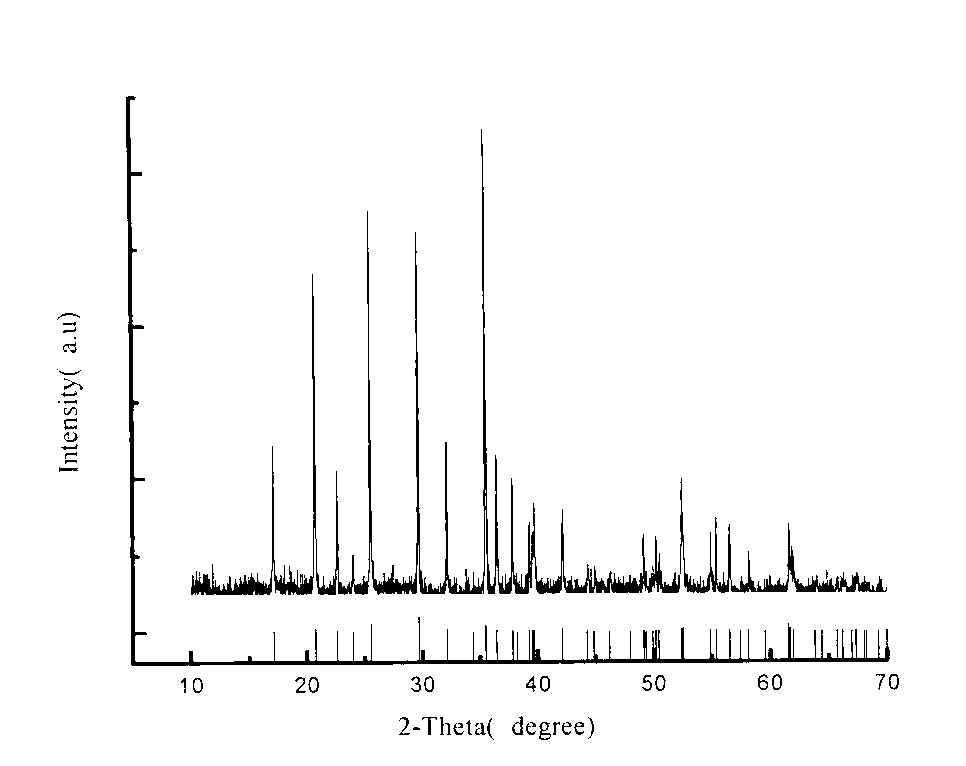

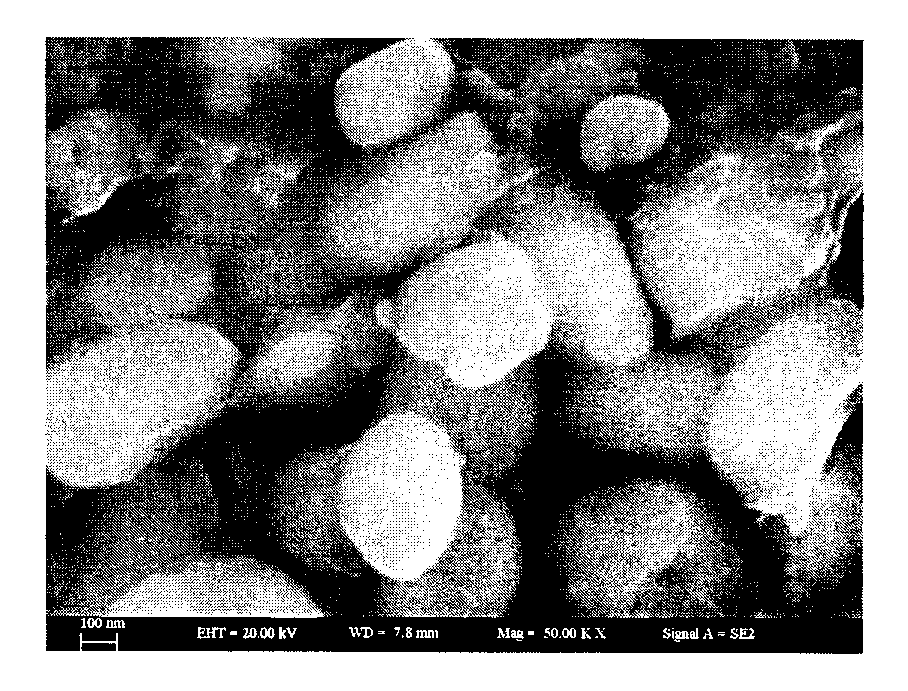

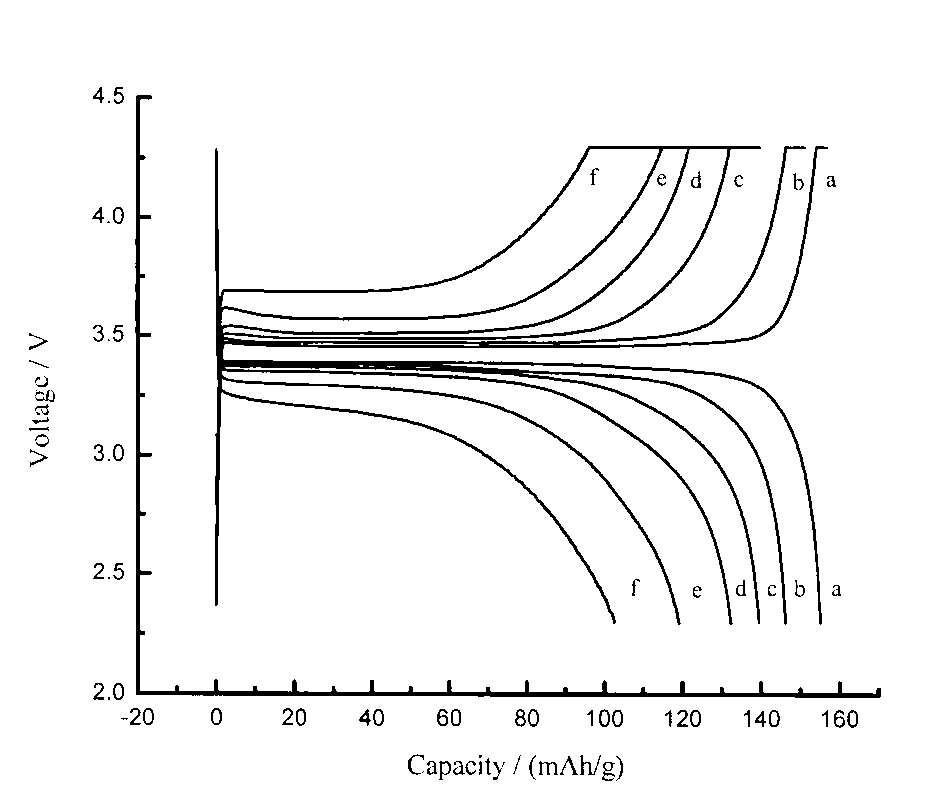

Preparation method of phosphate potential boron-doped carbon-wrapped phosphoric acid iron-lithium material

InactiveCN103219516AImprove electrochemical performanceImprove fullyCell electrodesWater bathsLithium iron phosphate

The invention relates to a preparation method of a phosphate potential boron-doped carbon-wrapped phosphoric acid iron-lithium material. According to the preparation method, phosphoric acid iron, a lithium source, boric acid, oxalic acid and a carbon source which are taken as raw materials are prepared into a carbon-wrapped mixed primary raw material in a liquid phase through water bath stirring, and the carbon-wrapped mixed primary raw material is subjected to rapid high-temperature thermal treatment to generate a carbon-wrapped boron-doped lithium iron phosphate LiFeP1-xBxO4 / C (x is greater than or equal to 0.05 and less than or equal to 0.20) anode material. The lithium iron phosphate anode material prepared by using the preparation method has the advantages that crystal grains grow sufficiently, the grain appearance is regular, and excellent electrochemical property is achieved. The preparation method provided by the invention has the advantages of simplicity and easiness in synthesis process, environmental-friendliness, easiness in in-scale production and industrialization.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Porous boron-doped carbon-loaded platinum nanoparticle catalyst based on electrostatic spinning technology, and preparation method and application thereof

InactiveCN110508311AImprove electrocatalytic activityImprove current efficiencyPhysical/chemical process catalystsFilament/thread formingAir atmosphereBoron doped carbon

The invention discloses a porous boron-doped carbon-loaded platinum nanoparticle catalyst based on an electrostatic spinning technology, and a preparation method and application thereof. The preparation method of the catalyst comprises the following steps: adding a surfactant coated with platinum nanoparticles, a boron-containing compound and a high-molecular polymer into an organic solvent, and carrying out stirring at 60-80 DEG C for 2-4 hours to form a viscous mixed solution; transferring the obtained viscous mixed solution into an injector, and carrying out spinning under the conditions that a voltage is 14-18 kV and a propelling speed is 1-2.5 mL / h to obtain a blocky spun material; and oxidizing the obtained blocky spun material in an air atmosphere at 180-250 DEG C for 1-3 hours, andcarrying out high-temperature calcination on the obtained oxidized material in a high-purity gas atmosphere at 700-1000 DEG C for 2-4 hours so as to obtain the catalyst disclosed by the invention. The catalyst provided by the invention is low in preparation cost, has relatively high electrocatalytic activity and super-strong stability when applied to preparation of ozone through electrolysis of water, and obviously improves the current efficiency of the preparation of ozone through electrolysis of water.

Owner:ZHEJIANG UNIV OF TECH

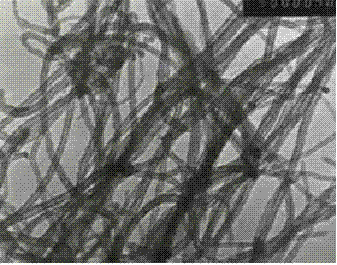

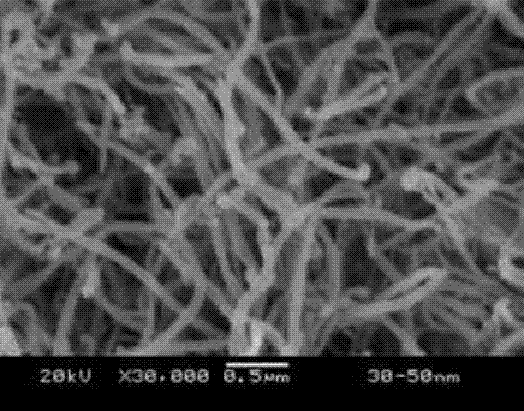

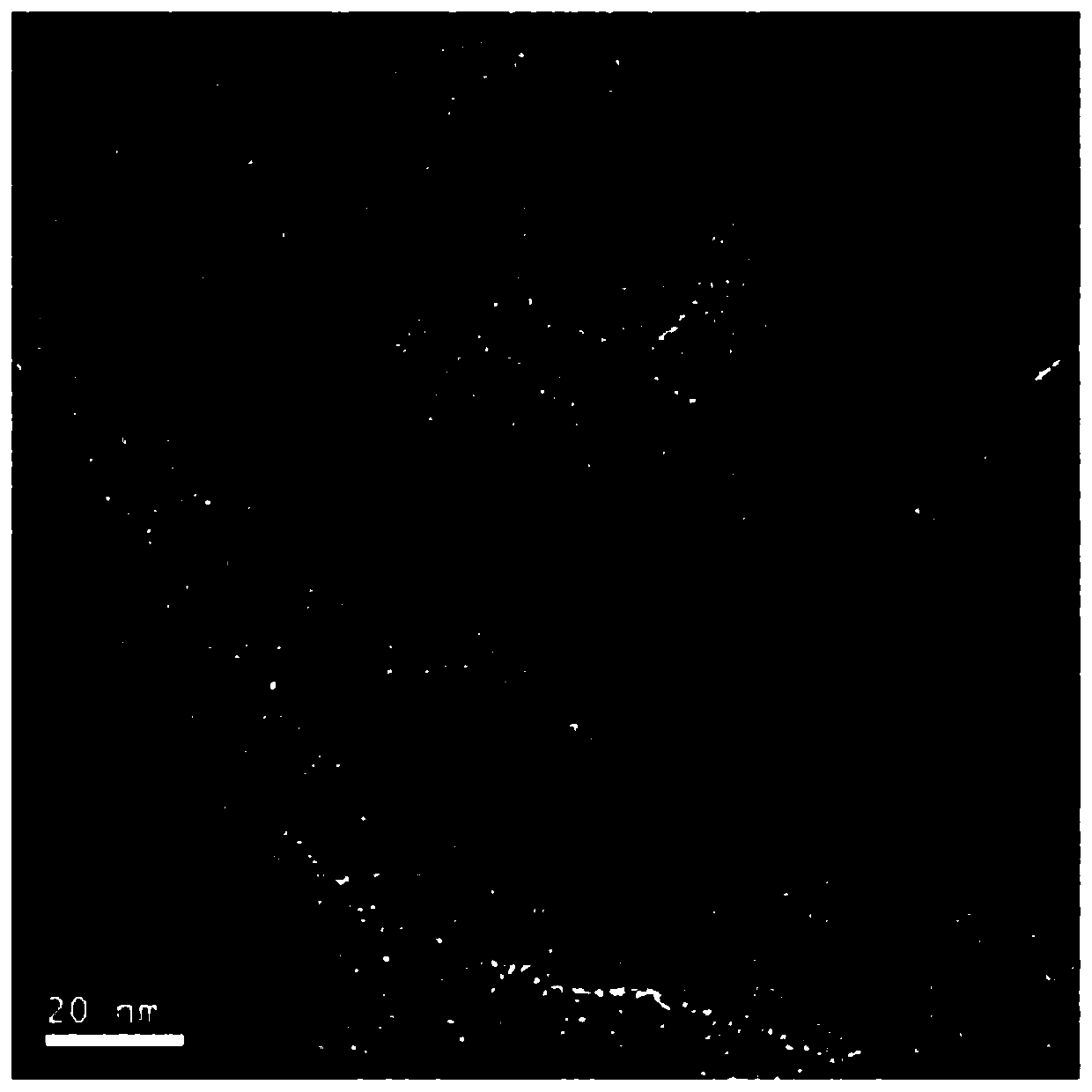

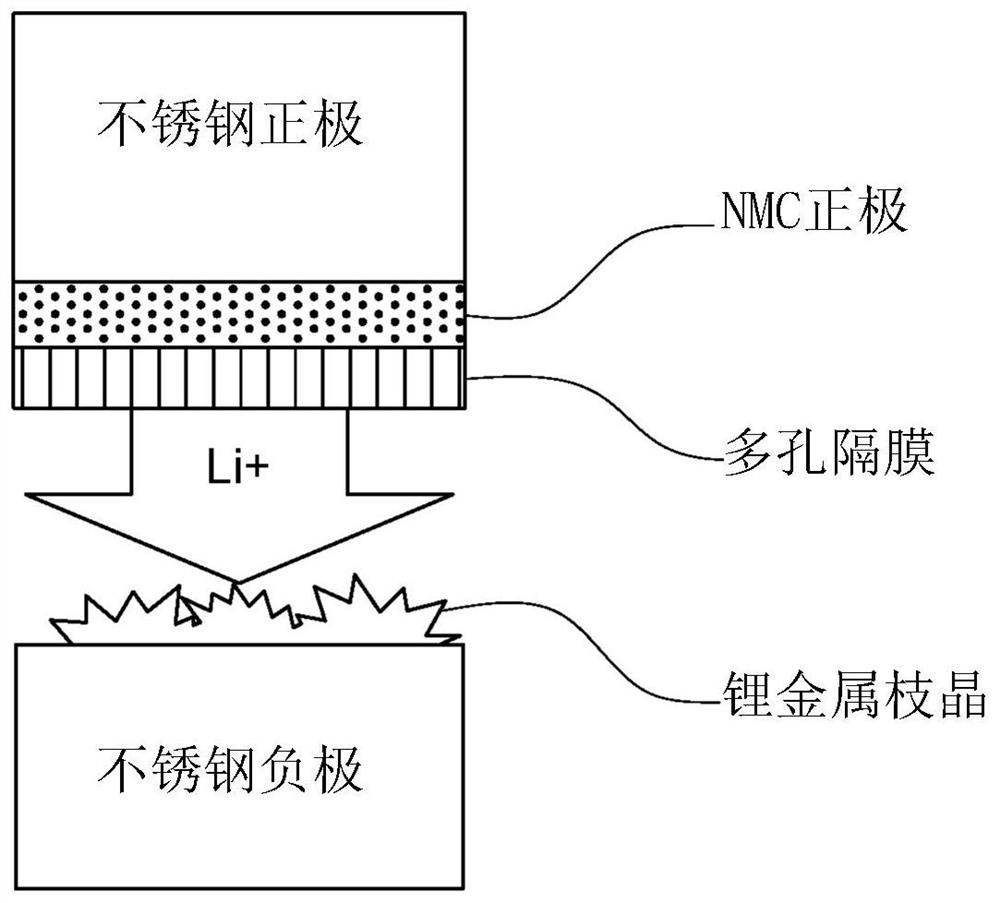

Electrodes comprising three-dimensional heteroatom-doped carbon nanotube macro materials

Electrodes, including anodes and / or cathodes, comprising a three-dimensional boron- doped carbon nanotube macromaterial are disclosed. The anode and / or cathode can be prepared using chemical vapor deposition, using a metal foil, such as a copper foil, as a substrate, and in other embodiments, or can be adhered to a metal foil following preparation. The anode and / or cathode are porous, and a portion of the pores can be filled with appropriate anode or cathode active materials. Preferred active materials for the anode comprise lithium metal or lithium-containing alloys. Preferred active materials for the cathode comprise lithium salts, such as lithium oxide or lithium sulfide, Batteries, capacitors and supercapacitors comprising these anodes and / or cathodes are also disclosed.

Owner:3D NANO BATTERIES INC

Three-dimensional carbon nanotube sponge materials as absorbers of phase change materials

PendingUS20220234895A1Improve the effect of chemical reactionsCarbon compoundsHeat-exchange elementsBoron doped carbonPhase-change material

Composite materials comprising a phase change material (PCM) and a macroscale 3D carbon nanotube material, such as a macroscale 3D heteroatom-doped carbon nanotube material, including boron doped carbon nanotube materials, and methods for using the composite materials in various applications where temperature control is critical. Heteroatom-doped carbon nanotube sponge materials are strongly oleophilic, and can soak up large quantities of organic PCMs. One representative application for the composite materials is in thermal energy storage (TES) systems for shipping and storage of pharmaceuticals, medical and life science products.

Owner:CSS NANOTECH LLC

Electrodes comprising three-dimensional heteroatom-doped carbon nanotube macro materials

PendingUS20210273228A1Extend instrument lifeMaintain good propertiesHybrid capacitor electrodesElectrolytic capacitorsLithium oxideMetal foil

Electrodes, including anodes and / or cathodes, comprising a three-dimensional boron-doped carbon nanotube macro-material are disclosed. The anode and / or cathode can be prepared using chemical vapor deposition, using a metal foil, such as a copper foil, as a substrate, and in other embodiments, or can be adhered to a metal foil following preparation. The anode and / or cathode are porous, and a portion of the pores can be filled with appropriate anode or cathode active materials. Preferred active materials for the anode comprise lithium metal or lithium-containing alloys. Preferred active materials for the cathode comprise lithium salts, such as lithium oxide or lithium sulfide, Batteries, capacitors and supercapacitors comprising these anodes and / or cathodes are also disclosed.

Owner:3D NANO BATTERIES LLC

A kind of preparation method of nitrogen-boron doped carbon-based catalyst

ActiveCN104998675BIncrease ORR activityImprove stabilityPhysical/chemical process catalystsCell electrodesFuel cellsNitrogen

The invention discloses a preparation method for a nitrogen-boron-doped carbon-based catalyst, which belongs to the technical field of catalytic materials. The method comprises the following steps: pretreating a carbon material; then mixing the pretreated carbon material with a nitrogen supplying agent, a boron supplying agent and an activator and carrying out mechanical ball milling; then subjecting a mixture obtained after ball milling to nitrogen-boron co-penetration heat treatment of the carbon material at a temperature of 500 to 1100 DEG C under the protection of inert gas for 1 to 3 h; and finally carrying out pickling so as to prepare the nitrogen-boron-doped carbon-based catalyst. The nitrogen-boron-doped carbon-based catalyst prepared by using the method can be used as a negative electrode oxygen reducing catalyst for a fuel cell; the preparation method has the advantages of low prices of raw materials, simple process, low requirements on equipment and applicability to large-scale production of the catalyst; and the catalyst shows good oxygen reduction activity and stability under both acidic and alkaline conditions.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method for carbon nanotube heterostructure

The invention relates to a preparation method for a carbon nanotube heterostructure. The method comprises the steps of: taking an Si sample as the anode and platinum as the cathode, electrolyzing the anode and cathode in an electrolyte solution formed by mixing of deionized water, ethanol absolute and hydrofluoric acid to form taper holes on the Si surface; synthesizing an Fe3O4 nanoparticle catalyst by a high temperature liquid phase technique; dissolving ferric acetylacetonate into oleic acid grease and diol, and carrying out high-temperature pyrolysis in a phenyl ether environment; dripping the prepared Fe3O4 nanoparticle solution on the porous silicon surface, and performing natural drying in the air; placing the well prepared porous silicon sample in a vacuum chamber, conducting base vacuum pumping and introducing H2, opening a microwave source to perform pretreatment, raising the temperature of the substrate to a predetermined temperature through a heating system and plasma bombardment together; after pretreatment, introducing CH4 and B2H6 gas to prepare a boron doped carbon nanotube; stopping introducing B2H6, and increasing the CH4 flow to prepare the pure carbon nanotube. The method provided by the invention is simple and is low in cost. The obtained heterostructure has stable performance, and stronger optical and electrical properties.

Owner:CHONGQING XUXING CHEM

Catalyst carrier, supported catalyst, preparation method and application thereof

ActiveCN110302769BWide variety of sourcesReduce manufacturing costOrganic compound preparationCatalyst activation/preparationPtru catalystBoron doped carbon

The invention relates to a catalyst carrier, a supported catalyst and a preparation method and use thereof. It mainly solves the problem that the interaction force between the carbon material and the supported metal nanoparticles is weak and the metal nanoparticles are easily formed during the heterogeneous catalytic reaction process. Problems with gathering, growing and falling off. The present invention uses biomass sugars and boron-containing compounds as precursors, and obtains boron-doped carbon materials through high-temperature roasting, which better solves the above problems. There is a strong interaction between the doped carbon material and metal nanoparticles. When used as a carrier to load metal nanoparticles, it can uniformly disperse the metal nanoparticles and effectively curb the aggregation and shedding of metal nanoparticles during the catalytic reaction process, which significantly Improve the activity and stability of the catalyst. The doped carbon material has a wide range of raw materials, is cheap and easy to obtain, and has a simple preparation process. As an ideal metal nanoparticle carrier material, it has good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

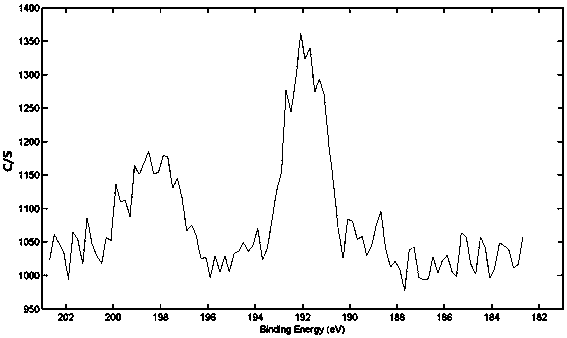

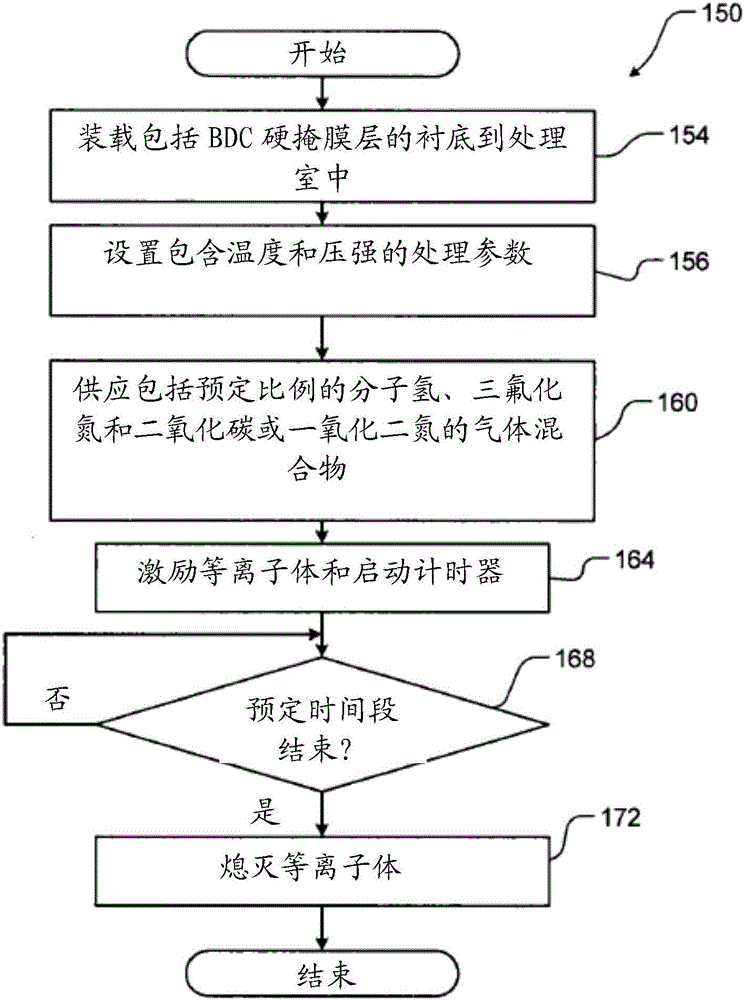

Selective removal of boron doped carbon hard mask layer

ActiveCN106298499AElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenBoron doped carbon

Systems and methods for processing a substrate include arranging a substrate including a film layer on a substrate support in a processing chamber. The film layer includes a boron doped carbon hard mask. A plasma gas mixture is supplied and includes molecular hydrogen, nitrogen trifluoride, and a gas selected from a group consisting of carbon dioxide and nitrous oxide. Plasma is struck in the processing chamber or supplied to the processing chamber for a predetermined stripping period. The plasma strips the film layer during the predetermined stripping period and the plasma is extinguished.

Owner:LAM RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com