Preparation method of solid carbon dot fluorescent powder with high quantum yield and application of solid carbon dot fluorescent powder in LED (Light Emitting Diode) lamp bead

A high-quantum, fluorescent powder technology, applied in the field of nanomaterials, can solve problems such as complex purification processes, and achieve the effects of simple operation, fast preparation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

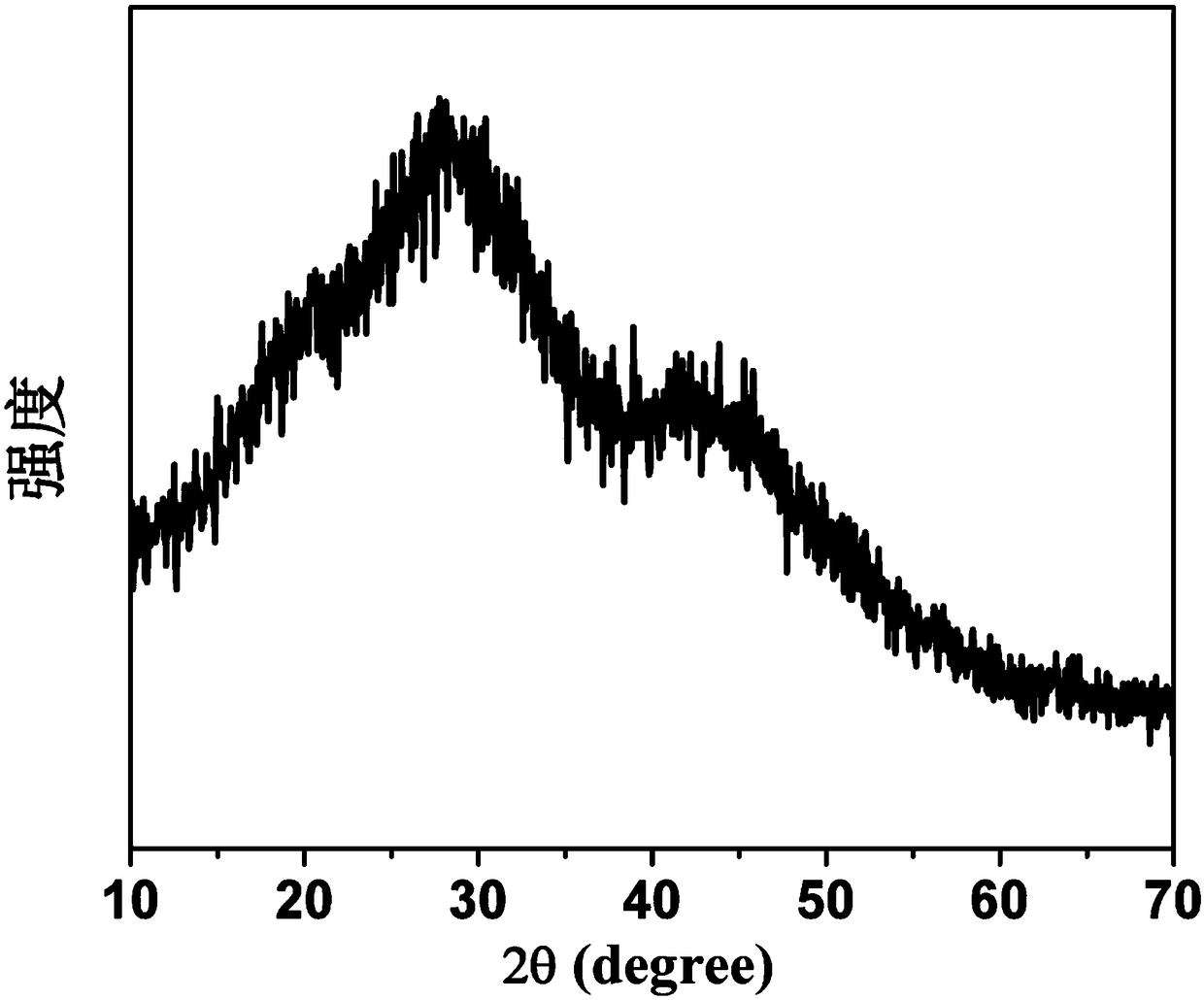

Image

Examples

Embodiment 1

[0047] Weigh 1.0g of potassium hydrogen phthalate, 0.5g of sodium azide, and 1.0g of boric acid, put them in a 250mL beaker, dissolve them in 20mL of formaldehyde solution, ultrasonicate for 5min to dissolve, put the mixed solution in a household microwave oven and heat it with a power of 225W 10min. After the reaction, the liquid was completely evaporated to obtain a white powder with an absolute quantum yield of 5.4%.

Embodiment 2

[0049] Weigh 0.5g of potassium hydrogen phthalate, 0.5g of sodium azide, and 0.75g of boric acid, put them in a 250mL beaker, dissolve them in 20mL of formaldehyde solution, ultrasonicate for 5min to dissolve, put the mixed solution in a household microwave oven and heat it with a power of 375W 4min. After the reaction, the liquid evaporated completely to obtain a white powder with an absolute quantum yield of 7.2%.

Embodiment 3

[0051] Weigh 0.25g of potassium hydrogen phthalate, 0.5g of sodium azide, and 1.0g of boric acid, put them in a 250mL beaker, dissolve them in 15mL of formaldehyde solution, ultrasonicate for 5min to dissolve, put the mixed solution in a household microwave oven and heat it with a power of 375W 6min. After the reaction, the liquid evaporated completely to obtain a white powder with an absolute quantum yield of 11.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com