Electrodes comprising three-dimensional heteroatom-doped carbon nanotube macro materials

A nanotube, three-dimensional technology, applied in the field of electrodes containing three-dimensional heteroatom-doped carbon nanotube macromaterials, can solve problems such as increasing unit production costs and being unsuitable for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0137] Coated on top of the CNT foam substrate:

[0138] Similar to conventional battery electrode coating operations, the active material can be applied to the 3D foam core using standard doctor blade coating methods. This includes all forms of conventional coating methods used in the battery industry, such as slot die, reverse roll, comma coat, and the like. Film deposition methods can also be used, including electroless and electroplating methods, and vapor deposition methods.

[0139] Depending on the composition and pore size of the CNT foam substrate, a variety of techniques can be used to coat the material inside the CNT foam substrate:

[0140] The CNT foam is pretreated with a thin layer of metallized material. This not only enhances conductivity and adhesion, but can significantly reduce the first cycle loss of the complete battery.

[0141] The electrode material is injected into the CNT foam structure matrix. This can be accomplished in a variety of ways, eit...

Embodiment 1

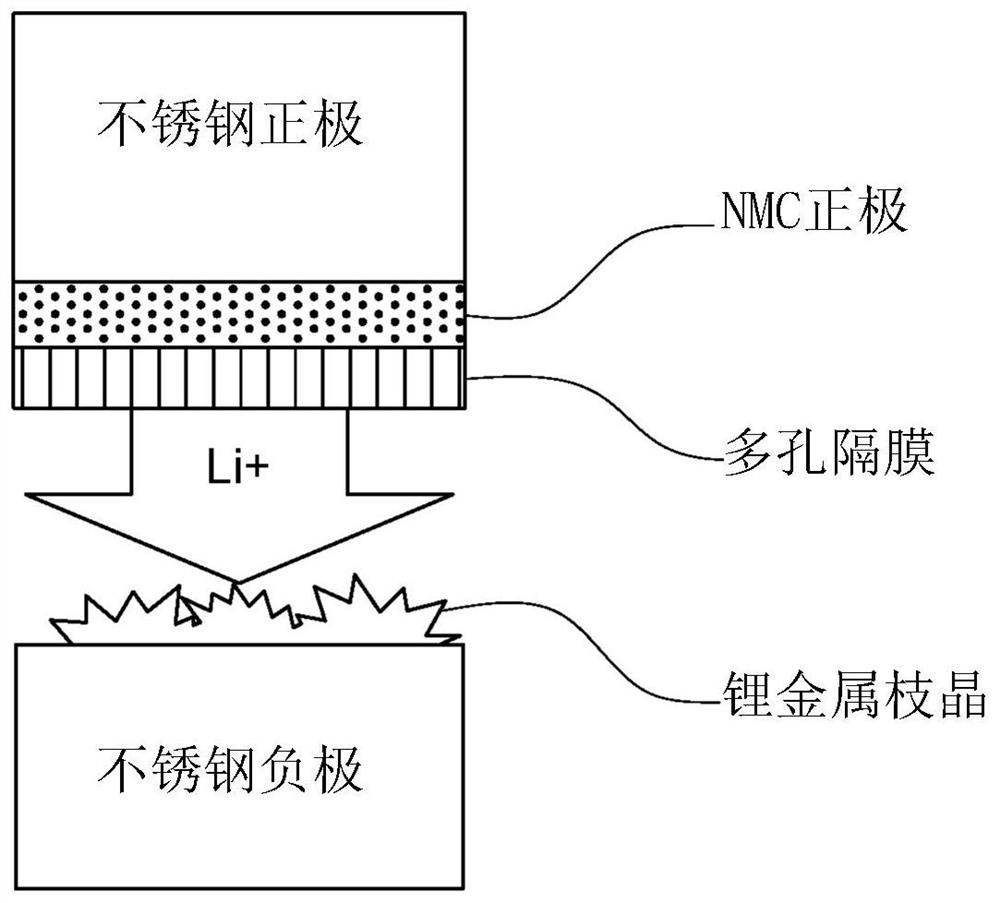

[0280] Example 1: Anode performance evaluation / comparison between stainless steel / 3D foam anodes

[0281] Development principle

[0282] The following examples were performed on three-dimensional nanotube materials prepared according to the teachings of US Patent Application No. 13 / 424,185.

[0283] The "holy grail" of the lithium battery industry is making practical lithium "metal" batteries. In terms of volumetric and gravimetric energy density, lithium metal has the highest energy density among all anodes. Graphite as a negative electrode material has an energy capacity of about 360 mAhr / g. Lithium metal has an energy density of 3860mAhr / g. This is not a 10x improvement in battery performance, but a 10x improvement in negative electrode performance. Since the negative electrode is 30-50% of the battery volume / mass, the increase in battery performance is more consistent with a 2x or 3x increase in battery performance, which represents a significant improvement in battery...

Embodiment 2

[0358] Example 2: Evaluation of 3D CNF Foam vs. Lithium Metal in Half-Cell Configuration

[0359] The purpose of this set of tests was to measure the fundamental properties of 3D CNT foams vs. lithium metal in a half-cell configuration.

[0360] Configurations tested in Swagelok cells are as follows image 3 shown. The current is controlled at a specified rate and the voltage profile of the battery is measured during this current flow. Lithium disks that provide as much Li as the counter electrode can be used. This allows the anode to reach full capacity without the need for lithium metal plating.

[0361] To be clear, Li + Intercalation of ions cannot penetrate the sidewalls of fully intact nanotubes. Similar to graphite, Li + Ions can only penetrate the edges of graphene structures, whether they are flat or cylindrical. If there is damage (branching, dislocation...) somewhere in the nanotube wall, Li + Ions may have the ability to penetrate the walls of nanotubes. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| magnetism | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com