Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "2-Ethylanthraquinone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

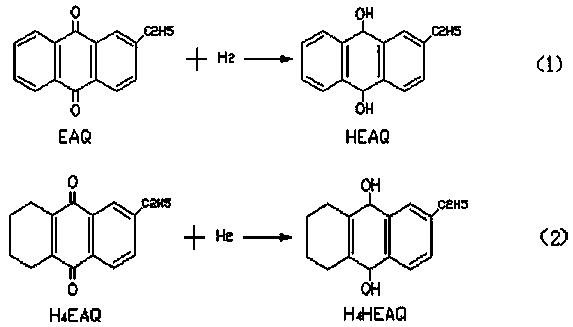

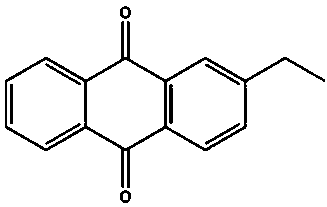

2-Ethylanthraquinone is an organic compound that is a derivative of anthraquinone. This pale yellow solid is used in the industrial production of hydrogen peroxide (H₂O₂).

Technology for preparing 2-ethylanthraquinone

InactiveCN107746372AReduce the difficulty of productionLow costMolecular sieve catalystQuinone preparation by oxidationMolecular sieveAnthracene

The invention discloses a technology for preparing 2-ethylanthraquinone from anthracene and ethylene. The technology comprises the following steps: alkylating anthracene and ethylene by using a transition metal oxide supported MWW type molecular sieve catalyst to prepare 2-ethylanthracence; and oxidizing the 2-ethylanthracence by using a molybdena supported Y type molecular sieve catalyst to prepare the 2-ethylanthraquinone. The technology has the advantages of facilitation of the proceeding of the reactions, low cost and high yield.

Owner:QINZHOU UNIV

Hydrogen peroxide working solution and its application in preparation of hydrogen peroxide

ActiveCN103588177AReduce solubilityImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOrganic solventPhosphate

The invention belongs to the technical field of hydrogen peroxide, and especially relates to a hydrogen peroxide working solution and its application in the preparation of hydrogen peroxide. The hydrogen peroxide working solution comprises 2-ethylanthraquinone having a mass concentration of 120-200g / L and an organic solvent, and the organic solvent comprises, by volume, 70-80% of a C9-C10 aromatic hydrocarbon, 14-20% of trioctyl phosphate, 4-10% of 2-methylcyclohexyl acetate and 0.4-0.9% of tertiary amine When the hydrogen peroxide working solution is used in the preparation of hydrogen peroxide, the hydrogen peroxide working solution can greatly improve the hydrogenation efficiency and the oxidation efficiency of 2-ethylanthraquinone, and has the advantages of low production cost, no peculiar smell and product yield improvement.

Owner:WEIFANG MENJIE CHEM

Method for catalytically preparing 2-ethyl anthraquinone by alkali desilicicated modified Hbeta molecular sieve

ActiveCN103833534AEasy to separateEasy to operateMolecular sieve catalystsOrganic compound preparationBenzoic acidMolecular sieve

The invention discloses a method for catalytically preparing 2-ethyl anthraquinone by an alkali desilicicated modified Hbeta molecular sieve, and relates to a method for preparing 2-ethyl anthraquinone by dehydration of 2-(4'-ethyl benzoyl) benzoic acid. The method provided by the invention aims to solve the technical problem that by adopting a concentrated sulfuric acid catalyst to industrially produce 2-ethyl anthraquinone in the prior art, a lot of acid wastewater is generated and the equipment is greatly corroded. The method comprises the following steps: I, preparing an alkali desilicicated modified Hbeta molecular sieve catalyst; and II, reacting to prepare 2-ethyl anthraquinone. The catalyst Hbeta molecular sieve used in the method is environment-friendly solid acid, the acidity and mesoporous dimension of which can be conveniently adjusted by changing conditions of alkali treatment. The process for preparing 2-ethyl anthraquinone belongs to a heterogeneous catalytic process which is simple to operate, and the catalyst after reaction can be conveniently separated, so that the alkali desilicicated modified Hbeta molecular sieve catalyst is high in activity, recyclable and free from any wastewater, so that the method is an environment-friendly method for preparing 2-ethyl anthraquinone.

Owner:宜兴利荣达科技有限公司

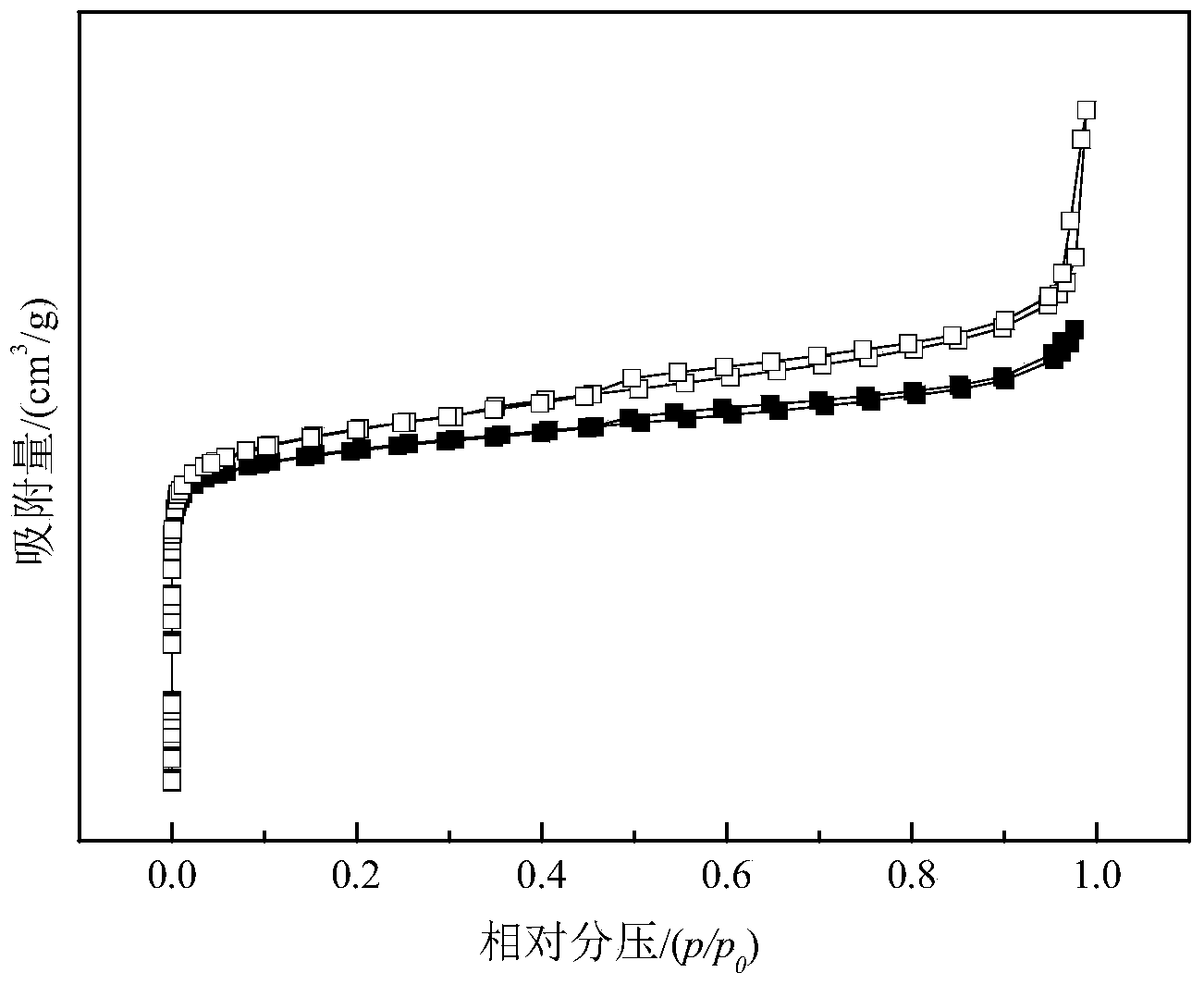

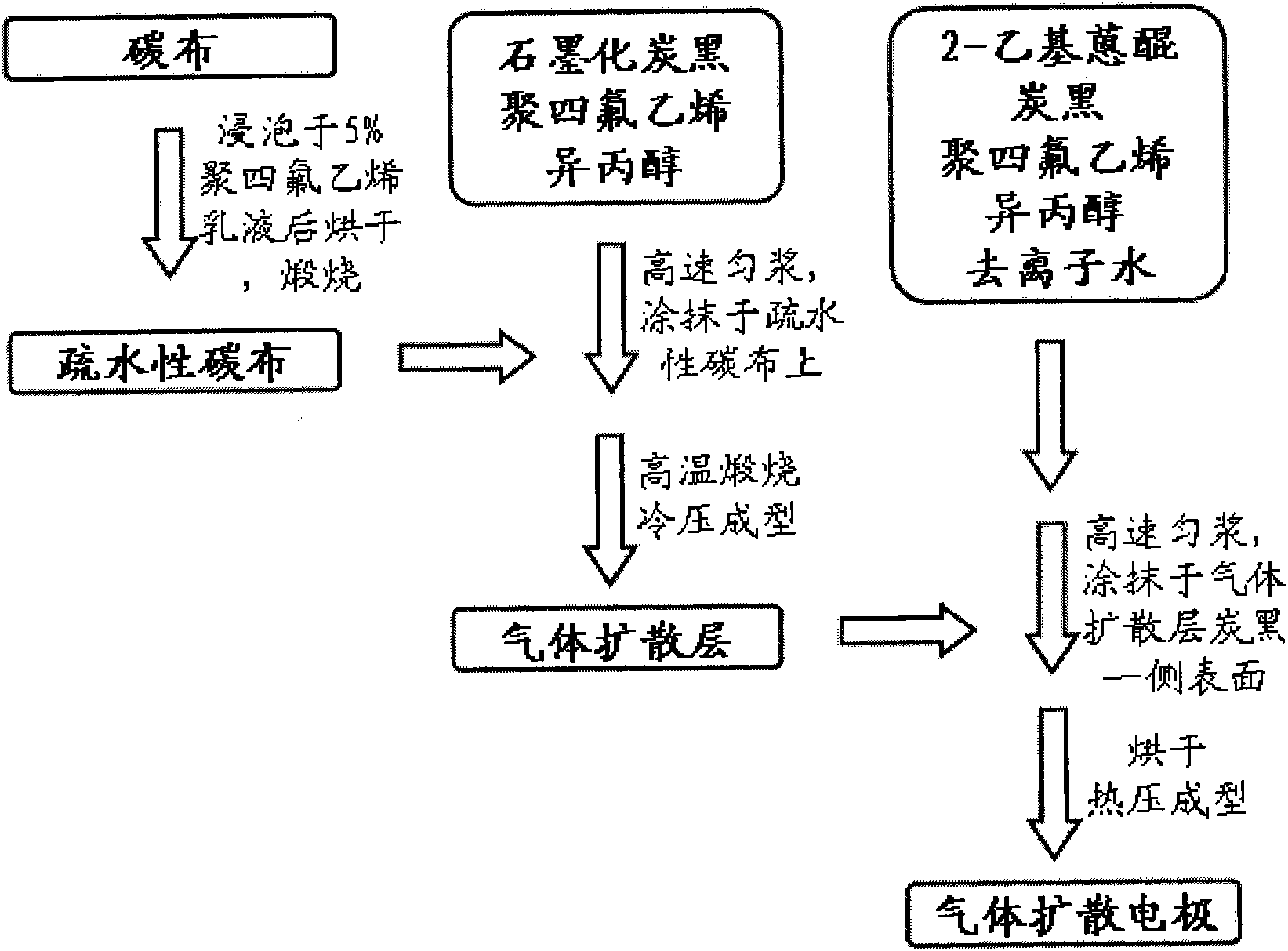

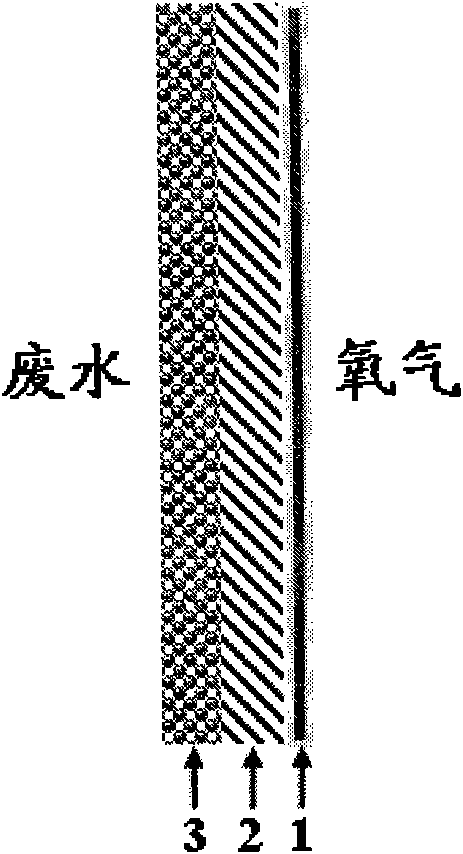

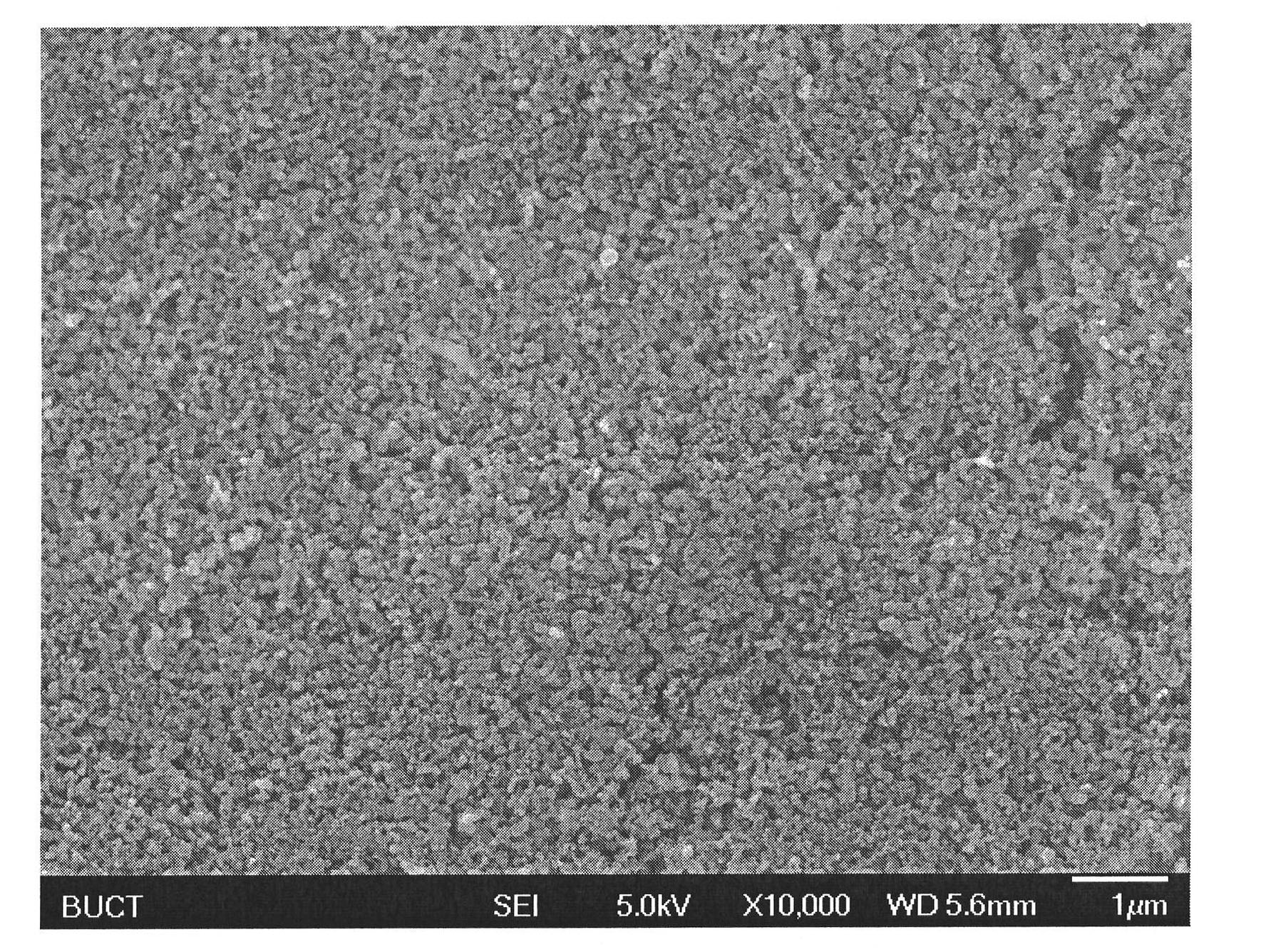

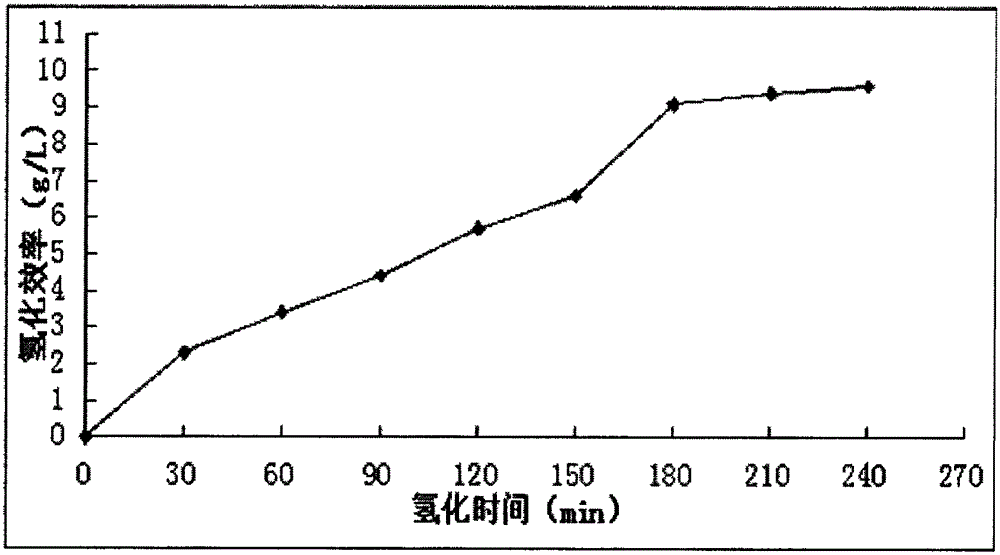

2-ethyl-anthraquinone modified gas diffusion electrode and preparation method thereof

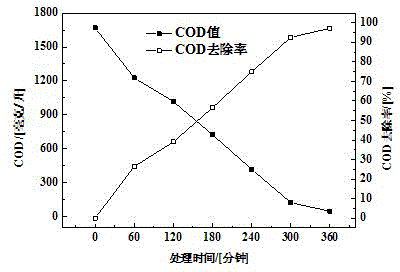

ActiveCN101774666AIncrease spawn rateIncrease productionWater/sewage treatment2-EthylanthraquinoneWastewater

The invention discloses a 2-ethyl-anthraquinone modified gas diffusion electrode which is composed of a gas diffusion layer and a catalyst layer, the gas diffusion layer is a mixture (2) of hydrophobic carbon cloth (1), graphitized Vulcan 72 carbon black and polytetrafluoroethylene coated on the hydrophobic carbon cloth, the catalyst layer (3) is a mixture of 2-ethyl-anthraquinone, Vulcan 72 carbon black and polytetrafluoroethylene coated on the diffusion layer mixture (2); the invention also discloses a preparation method of the above gas diffusion electrode, which is implemented by preparing hydrophobic carbon cloth, coating the mixture of graphitized Vulcan 72 carbon black and polytetrafluoroethylene on the hydrophobic carbon cloth, coating the mixture of 2-ethyl-anthraquinone, Vulcan 72 carbon black and polytetrafluoroethylene on the diffusion layer mixture (2), and heating. The invention can not cause secondary pollution to the environment, can is applicable to electrolyzation in organic waste water degradation industry.

Owner:BEIJING UNIV OF CHEM TECH

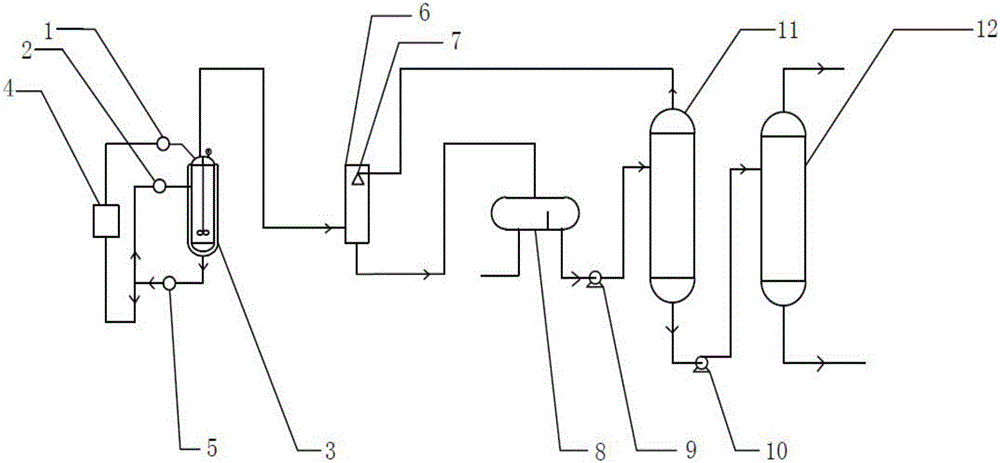

Production method of hydrogen peroxide

InactiveCN103588176ALow investment costImprove hydrogenation efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationPhosphate

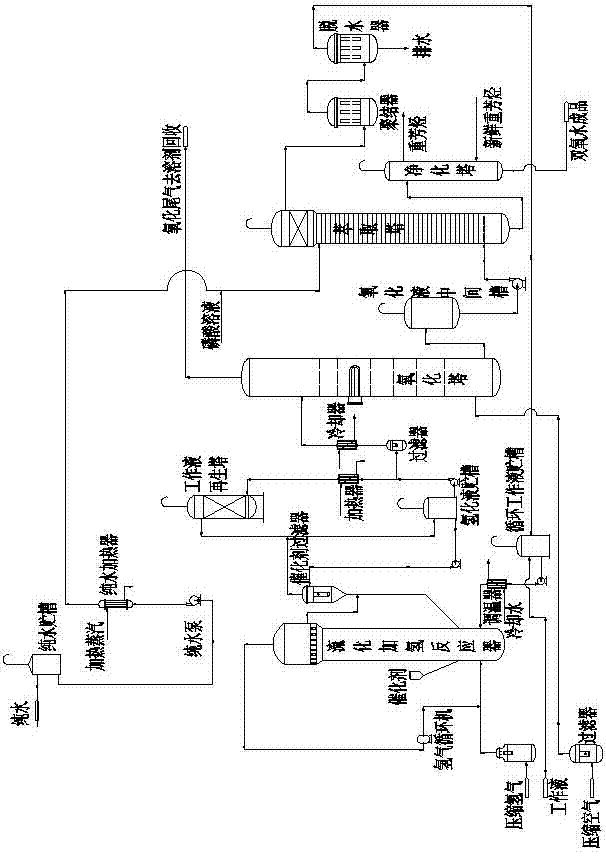

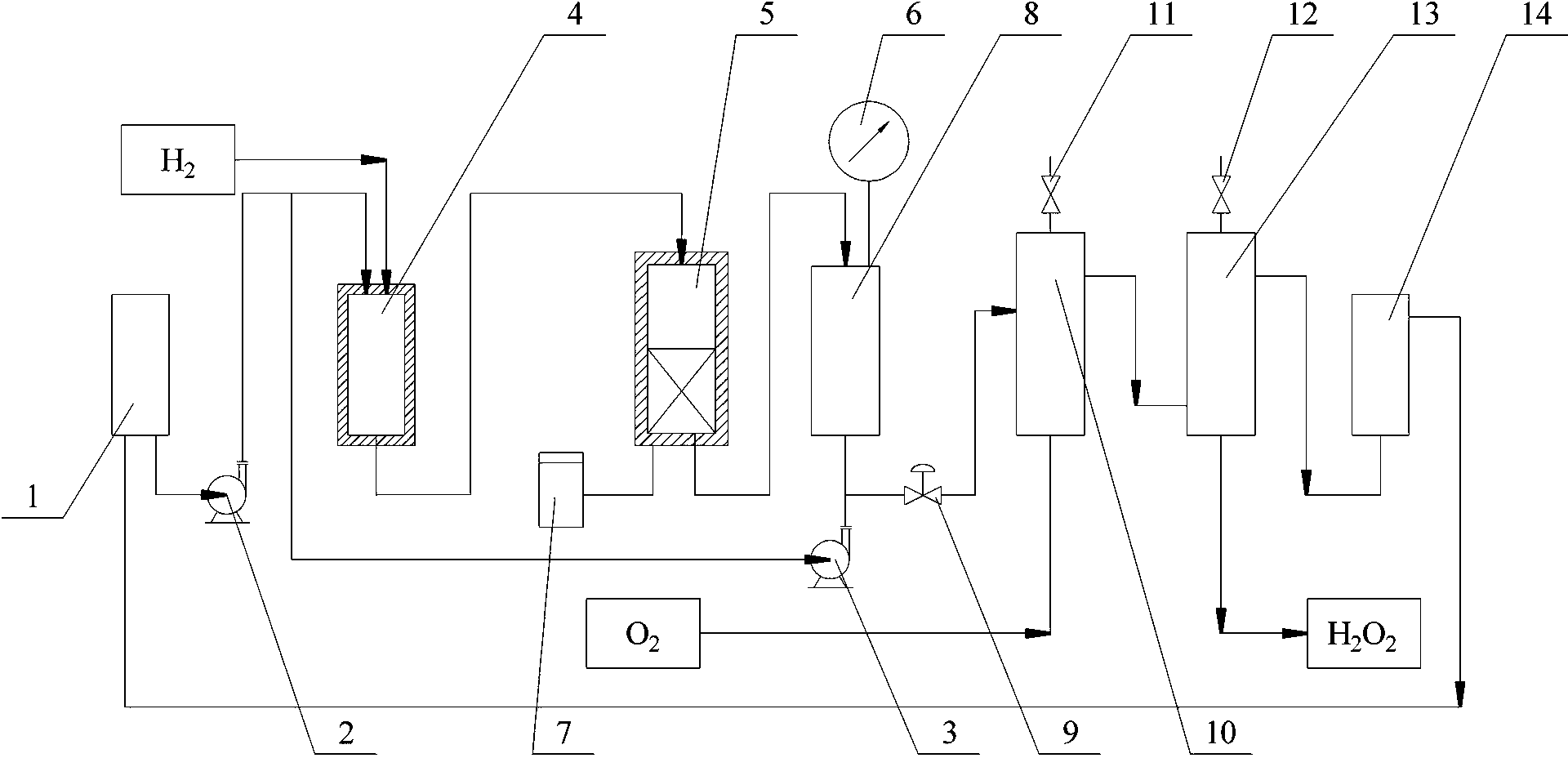

Relating to the technical field of large-scale high concentration hydrogen peroxide production technologies, particularly to hydrogen peroxide production technologies by an anthraquinone process, the invention provides a production method of hydrogen peroxide. The method includes: taking heavy aromatics, tetrabutylurea and trioctyl phosphate as solvents, adopting 2-ethylanthraquinone as a reaction material, adding a well prepared working solution into a circulating working solution storage tank, making use of a circulating working solution pump to send the working solution into a working solution thermoregulator, using circulating cooling water to lower the temperature of the working solution to about 35DEG C, then bringing the working solution to the bottom of a fluidization hydrogenation reactor, adding a hydrogenation catalyst into the fluidization hydrogenation reactor in advance through a catalyst adding groove, at the same time, passing compressed hydrogen through a hydrogen buffer filter to filter out impurities, then letting the compressed hydrogen enter the bottom of the fluidization hydrogenation reactor, using the compressed hydrogen to blow and stir the catalyst and the working solution so as to undergo hydrogenation reaction at a temperature of about 50DEG C, under a pressure of about 0.26mPa, and at hydrogenation efficiency of about 13g / L.

Owner:YANGZHOU RONGXIANG CHEM TECH DEV DESIGN

Working solution for producing hydrogen peroxide through stationary bed palladium catalyst process, and preparation method of working solution

InactiveCN103303871AImprove hydrogen efficiencyLess side effectsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonides2-EthylanthraquinoneHydrogenation reaction

The invention relates to a working solution for producing hydrogen peroxide through a stationary bed palladium catalyst process, and a preparation method of the working solution. The preparation method is characterized by comprising the steps of: with a mixture of amylanthraquinon and 2-ethylanthraquinone, or amylanthraquinon as a hydrogenated carrier, and a mixture of a C9-C10 benzene organic compound and one or more of esters, tetrabutyl urea TBU or diisobutylmethanol DIBC as a solvent, carrying out interaction on the hydrogenated carrier and the solvent to obtain a working solution system, mixing the working solution system with H2 to flow into a stationary bed reactor filled with a catalyst, carrying out a hydrogenation reaction under the conditions of temperature of 40-80 DEG C and pressure of 0.2-0.5atm to generate hydrogenated anthraquinone, then feeding the oxanthranol into an oxidation reactor for oxygen oxidization to obtain hydrogen peroxide, and oxidizing hydrogenated anthraquinone. The capability of producing the H2O2 through the unit working solution can be improved to 13-18g / l from 7-11g / l.

Owner:傅骐

Treatment method of landfill leachate

InactiveCN104891733ALow costImprove production efficiencyMultistage water/sewage treatmentSeparation technologyOxygen

The invention relates to a treatment method of landfill leachate. Pretreatment is performed through anaerobic treatment, aerobic treatment and a membrane bioreactor, and organic pollution ingredients which are easy to biodegrade are sufficiently degraded at a lower cost; deep degradation treatment is performed through a photoelectric Fenton reaction, and pollution ingredients which are difficult to biodegrade are sufficiently and quickly degraded; hydrogen peroxide is continuously produced through a gas diffusion electrode so as to maintain the Fenton reaction; the production efficiency of the hydrogen peroxide is improved by using 2-ethyl-anthraquinone as a catalyst; the regeneration of ferrous ions is ensured by using ultraviolet rays for illumination, and the Fenton reaction is circularly performed. The medicament cost is reduced, sludge containing iron is hardly produced, a membrane separation technology is not used in a final treatment link, organic waste is efficiently degraded and discharged, a concentrated solution cannot be produced, and the cost is far lower than that by using a membrane separation technology.

Owner:BEIJING UNIV OF CHEM TECH

Supported palladium catalyst for producing hydrogen peroxide by anthraquinone process and preparing method thereof

InactiveCN1175931CImprove catalytic performanceImprove overall lifespanPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsPhosphateActive component

A carried Pd-alumina catalyst for preparing hydrogen peroxide by anthraquinone method is prepared from Pd as main active component and Al2O3 as carrier through impregnation. Said Al2O3 has been coated by RE oxide and calcined at 900-1000 deg.C. It has high hydrogenating efficiency of 8-9 gH2O2 / L for 2-ethyl anthraquinone / heavy arene plus trioctyl phosphate or 10-13 gH2O2 / L for (2-tert-butyl anthraquinone plus 2-ethyl anthraquinone) / (heavy arene plus tetrabutyl urea).

Owner:FUZHOU UNIV

Method for separating and purifying 2-ethyl anthraquinone from sulphuric acid

ActiveCN102050716AReduce lossReduce labor intensityQuinone separation/purification2-EthylanthraquinoneDistillation

The invention discloses a method for separating and purifying 2-ethyl anthraquinone from sulphuric acid. The method comprises the following steps of: slowly adding a 2-ethyl anthraquinone concentrated sulphuric acid solution obtained by a closed-loop reaction to well-measured water to carry out acid separation; carrying out countercurrent extraction to the feed liquid subjected to acid separationand an extraction solvent at a temperature of 75-80 DEG C, separating a small amount of dilute sulphuric acid contained in the extract liquor from the 2-ethyl anthraquinone obtained through extraction; then, respectively carrying out caustic washing and rinsing to separate a small amount of water contained in the feed liquid; and finally, respectively carrying out room-pressure distillation and reduced-pressure distillation in a distillation kettle to obtain product of 2-ethyl anthraquinone. The invention utilizes an extraction principle and a reduced-pressure distillation principle for the post-treatment of the 2-ethyl anthraquinone concentrated sulphuric acid solution so as to lighten the labor intensity, improve the operating environment, enhance the operation safety, decrease the production cost and shorten the production flow of the post-treatment, and the product obtained through separation has high purity and stable quality.

Owner:山东门捷新材料股份有限公司

Method for preparing hydrogen peroxide through anthraquinone technology

InactiveCN105819402AImprove solubilityIncrease the conversion rate of hydrogenation reactionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityPhosphate

The invention discloses a method for preparing hydrogen peroxide through an anthraquinone technology. The method comprises the steps of a palladium catalyst fixed bed hydrogenation reaction, an air bubbling oxidation reaction, extraction and purification; the solvent of a working liquid comprises, by volume, 60-80% of trimethylbenzene, 0.5-25% of trioctyl phosphate, 0.5-25% of tetrabutyl urea, and 0.5-25% of 2-methylcyclohexyl acetate; and the reaction carrier in the working liquid is a 2-ethylanthraquinone and tetrahydro-2-ethylanthraquinone mixture, and the total content is 140-200g / L. The solubility of the reaction carrier in the solvent is large, and the concentration can reach 140-200g / L, so the conversion rate of the hydrogenation reaction is improved, and the hydrogen efficiency can reach 12-15g / L, thereby the productivity is improved; the density of the working liquid is lower than that of present working liquid systems, a difference between the density of the working liquid and the density of water is large, and the distribution coefficient of hydrogen peroxide in the extraction process is large, so extraction is facilitated, the concentration of hydrogen peroxide in a product is improved, and hydrogen peroxide with the content of 35-45% (wt) can be directly obtained through extraction; and the energy consumption and the material consumption of a device are reduced.

Owner:WUHAN YOULIKE NEW MATERIAL TECH

Technology for producing hydrogen peroxide by anthraquinone process

PendingCN110436418AReduce productionReduce lossesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhosphate2-Ethylanthraquinone

The invention relates to a technology for producing hydrogen peroxide by an anthraquinone process, and relates to the technical field of industrial production of hydrogen peroxide by the anthraquinoneprocess. The technology comprises a hydrogenation reaction, an oxidation reaction, extraction, a purification process and a regeneration process; in the hydrogenation reaction, a mixed solution formed by mixing a heavy aromatic hydrocarbon, trioctyl phosphate, 2-ethylanthraquinone, tetrabutyl urea and 2-ethyltetrahydroanthracene reacts with hydrogen under the action of a palladium catalyst to obtain a hydrogenated solution; and in the oxidation reaction, the hydrogenated solution containing phosphoric acid is oxidized by oxygen in air to obtain an oxidized solution. The technology can reducethe consumption of total anthraquinone, can increase the oxidation yield of the oxidation process by using the working fluid system, and makes the amount of the generated residual liquid small.

Owner:江苏中煦科技有限公司

Method of producing hydrogen peroxide and reaction promoters therefor

InactiveUS6355815B1Good hydrogenationLess problem-proneHydrogen peroxideBiocideHydrogen2-Ethylanthraquinone

A cyclic anthraquinone process for producing hydrogen peroxide using at least two differently substituted 2-alkylanthraquinones and / or their tetrahydro derivatives. The working solution to be used contains (i) at least one reaction carrier from the series 2-(4-methyl-3-pentenyl) anthraquinone (IHEAQ), 2-(4-methylpentyl) anthraquinone (IHAQ) and their di- and tetrahydro derivatives such as, in particular 2-(4-methylpentyl)-beta-tetrahydroanthraquinone (THIHAQ), and (ii) at least one reaction carrier from the series of the 2-(C1- to C5)-alkylanthraquinones, especially 2-ethylanthraquinone (EAQ), and their tetrahydro derivatives. The reaction carriers according to (i) make up 5 to 95 molar %, especially 20 to 50 molar % of all reaction carrier. The method is distinguished by greater H2O2 capacity, improved hydrogenation kinetics and lesser susceptibility to disturbances. A method for making THIHAQ is also disclosed.

Owner:EVONIK OPERATIONS GMBH

Method for preparing 2-ethyl anthraquinone through one-step reaction of ethylbenzene and phthalic anhydride under catalysis of alkali desilication modified Hbeta molecular sieve

ActiveCN104803837AImprove conversion rateHigh yieldOrganic compound preparationQuinone preparationReaction temperatureTwo step

The invention relates to a method for preparing 2-ethyl anthraquinone with a one-step method, in particular to a method for preparing the 2-ethyl anthraquinone through a one-step reaction of ethylbenzene and phthalic anhydride under catalysis of an alkali desilication modified Hbeta molecular sieve, and aims to solve technical problems that the production technology is complex, a large amount of acid wastewater is produced, equipment is corroded severely, catalysts cannot be recycled and continuity of the production process cannot be realized due to the fact that two homogeneous catalysts, namely, anhydrous aluminum trichloride and concentrated sulfuric acid, are used respectively when the 2-ethyl anthraquinone is prepared through a two-step reaction of the ethylbenzene and the phthalic anhydride at present. The method comprises steps as follows: the phthalic anhydride and the ethylbenzene are evenly mixed, then the catalyst, namely, the alkali desilication modified Hbeta molecular sieve, is added, the mixture reacts at the reaction temperature of 170-230 DEG C for 1.2-5 h, a solid-liquid mixture is obtained, the solid catalyst, namely, the alkali desilication modified Hbeta molecular sieve, is separated after cooling, and the 2-ethyl anthraquinone is obtained. The method is mild in reaction condition, high in product yield and high in phthalic anhydride conversion rate.

Owner:宜兴利荣达科技有限公司

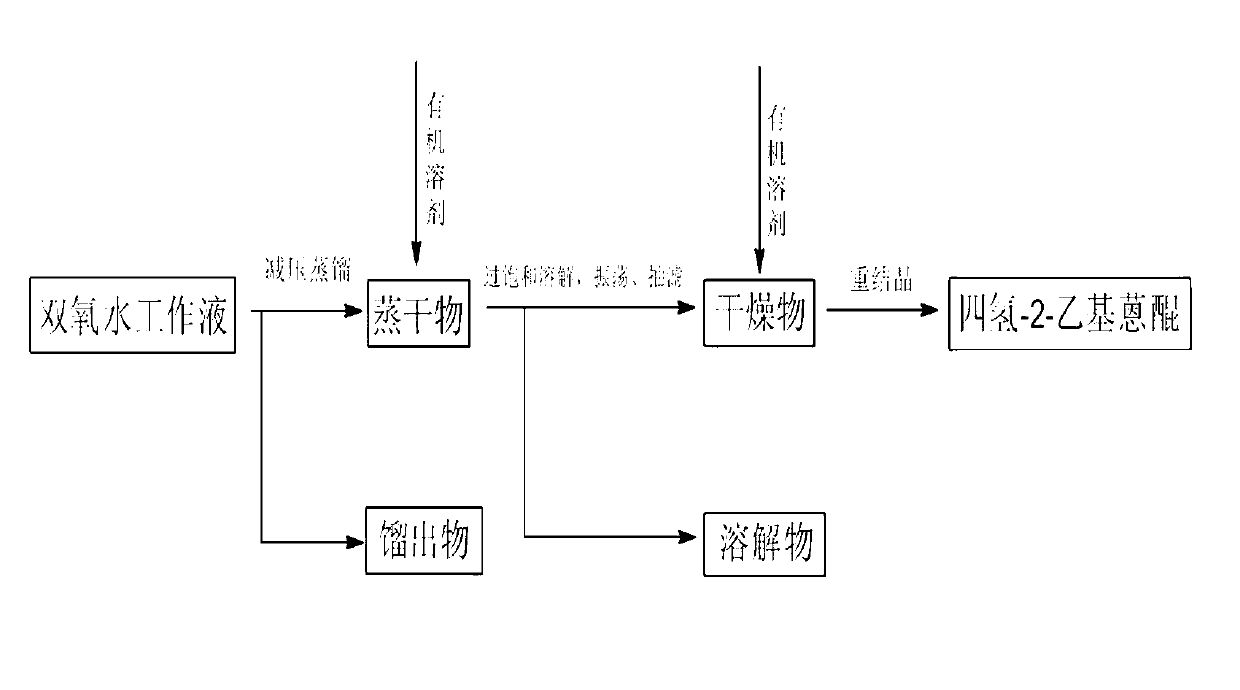

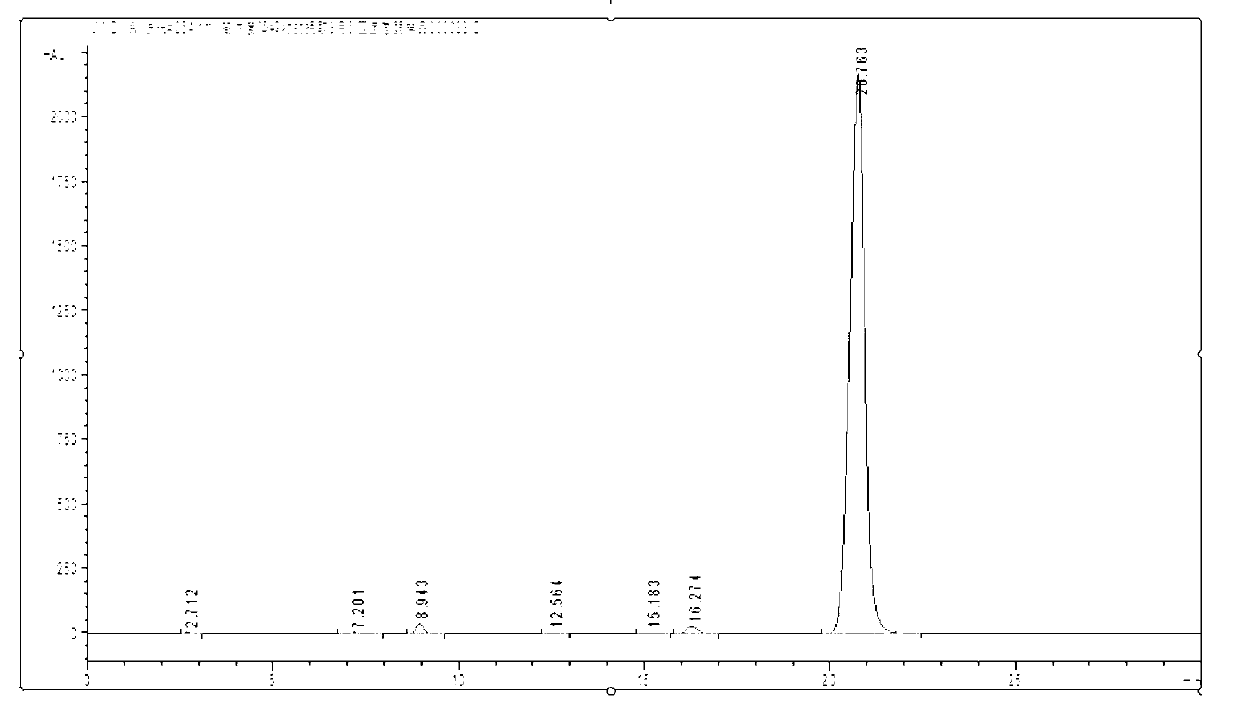

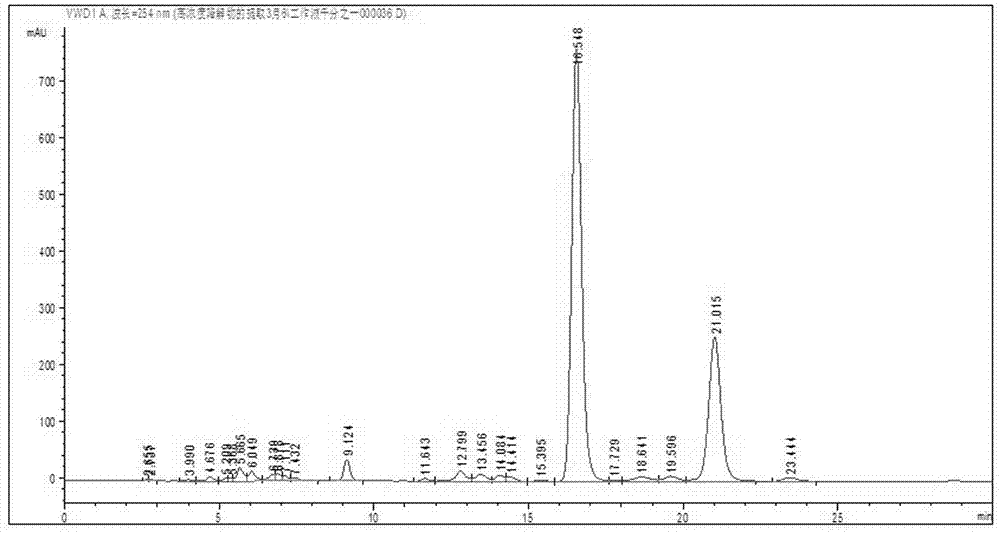

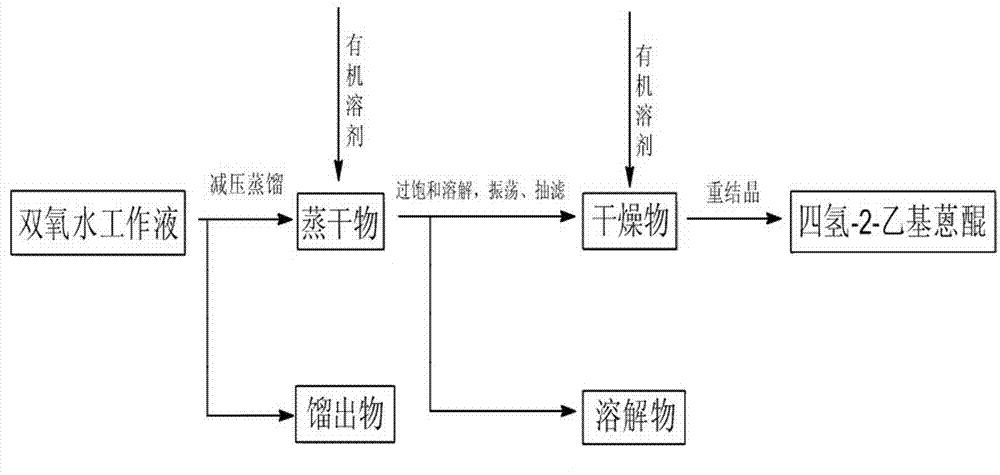

Method for preparing tetrahydro-2-ethyl anthraquinone from working solution for production of hydrogen peroxide by anthraquinone process

InactiveCN102731284ARaw materials are easy to getSimple and fast operationQuinone separation/purificationPhosphateFiltration

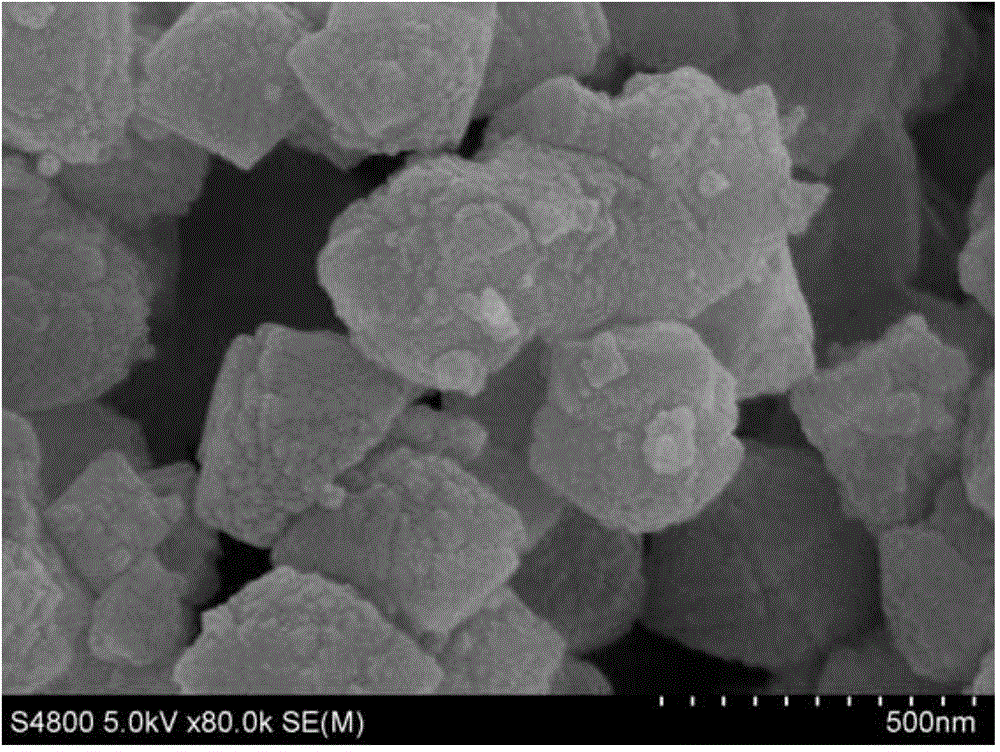

The invention relates to a method for preparing tetrahydro-2-ethyl anthraquinone from a working solution for the production of hydrogen peroxide by anthraquinone process, comprising the following steps: taking a certain amount of the working solution for the production of hydrogen peroxide by anthraquinone process to conduct vacuum distillation, removing heavy aromatics and other substances of low boiling point to obtain a dried substances; carrying out oversaturated dissolving on the obtained dried substances with organic solvents, stirring, oscillating, conducting suction filtration, letting trioctyl phosphate and 2-ethyl anthraquinone, etc. in the solvent, drying insoluble substances to obtain dried substances; dissolving the dried substances with organic solvents, and conducting recrystallization to obtain high-purity tetrahydro-2-ethyl anthraquinone. The method of the invention not only solves the problems of time consuming and labor consuming property and low conversion rate when synthesizing tetrahydro-2-ethyl anthraquinone by autoclave reaction, but also reduces the cost, shortens the operation time. Tetrahydro-2-ethyl anthraquinone prepared by the method of the invention has a purity of more than 99.5%, and can be used as a tetrahydro-2-ethyl anthraquinone standard sample for analyzing the working solution for hydrogen peroxide.

Owner:CHINA PETROLEUM & CHEM CORP

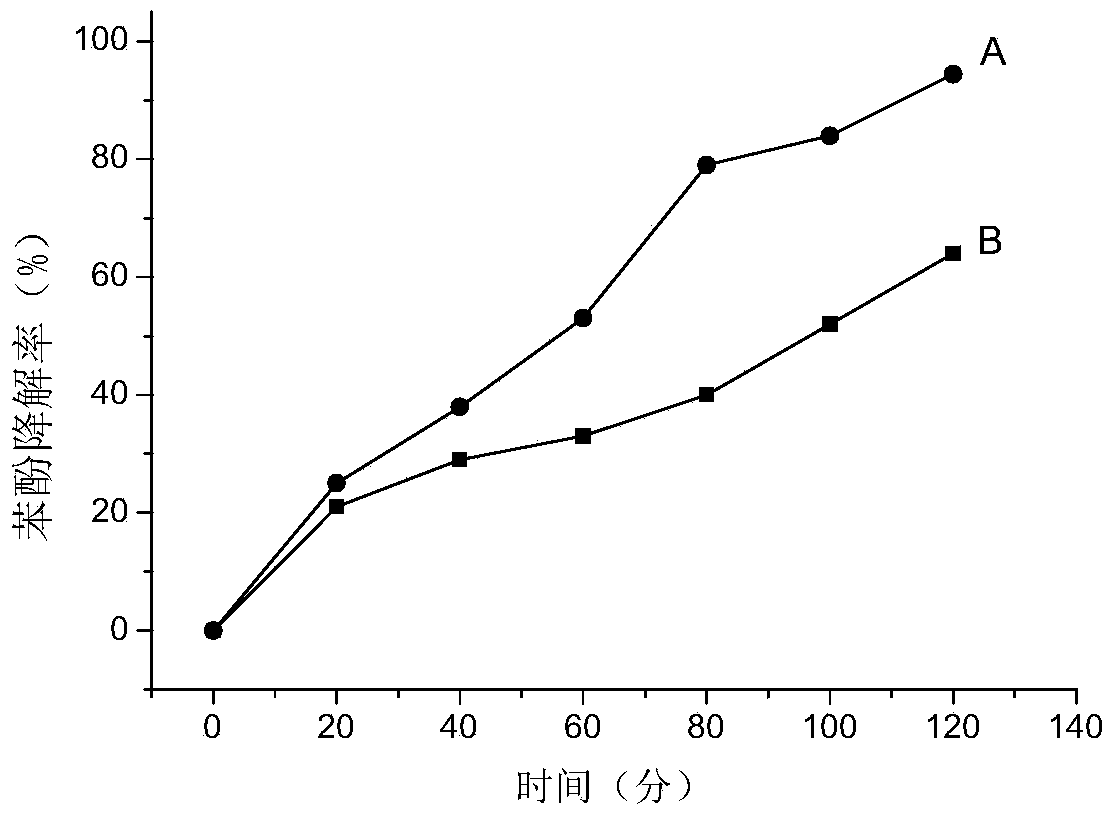

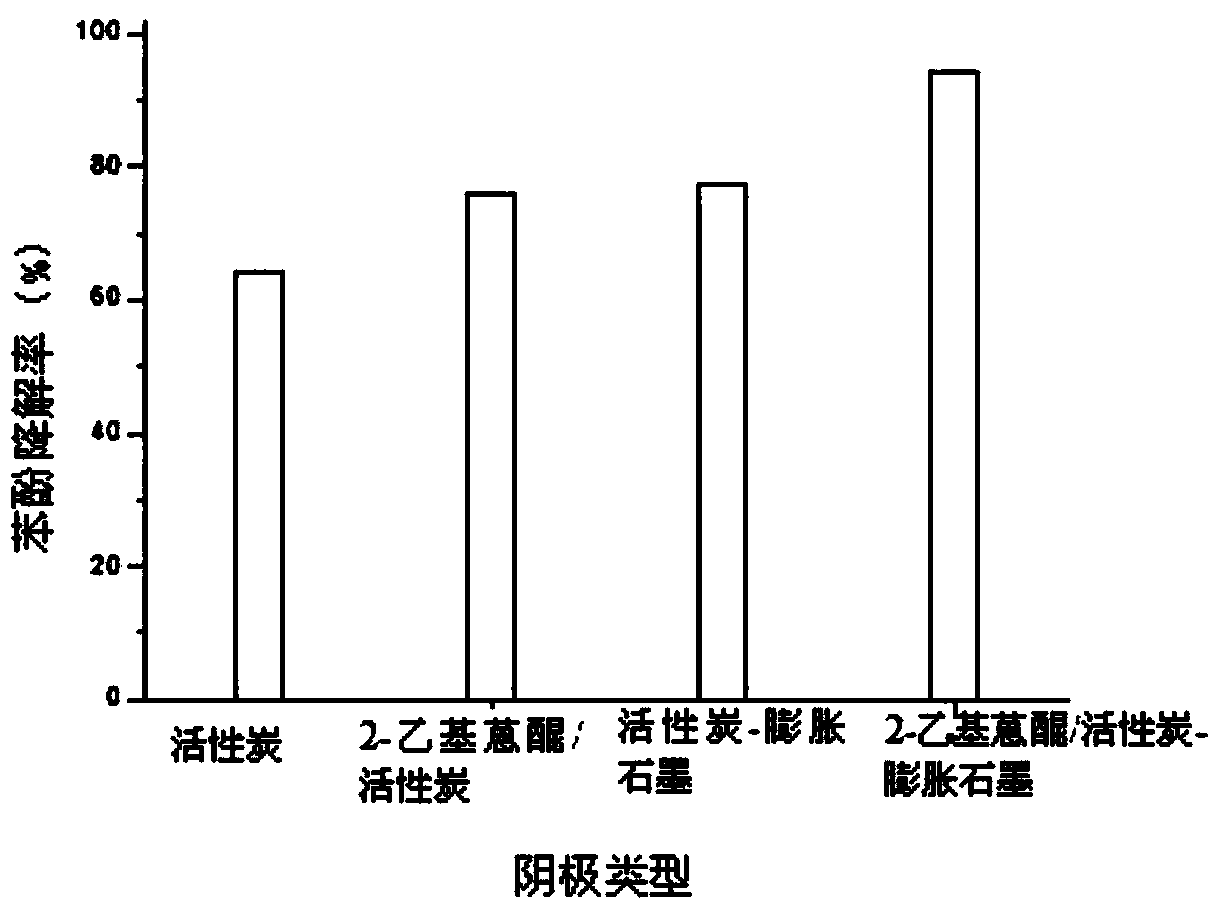

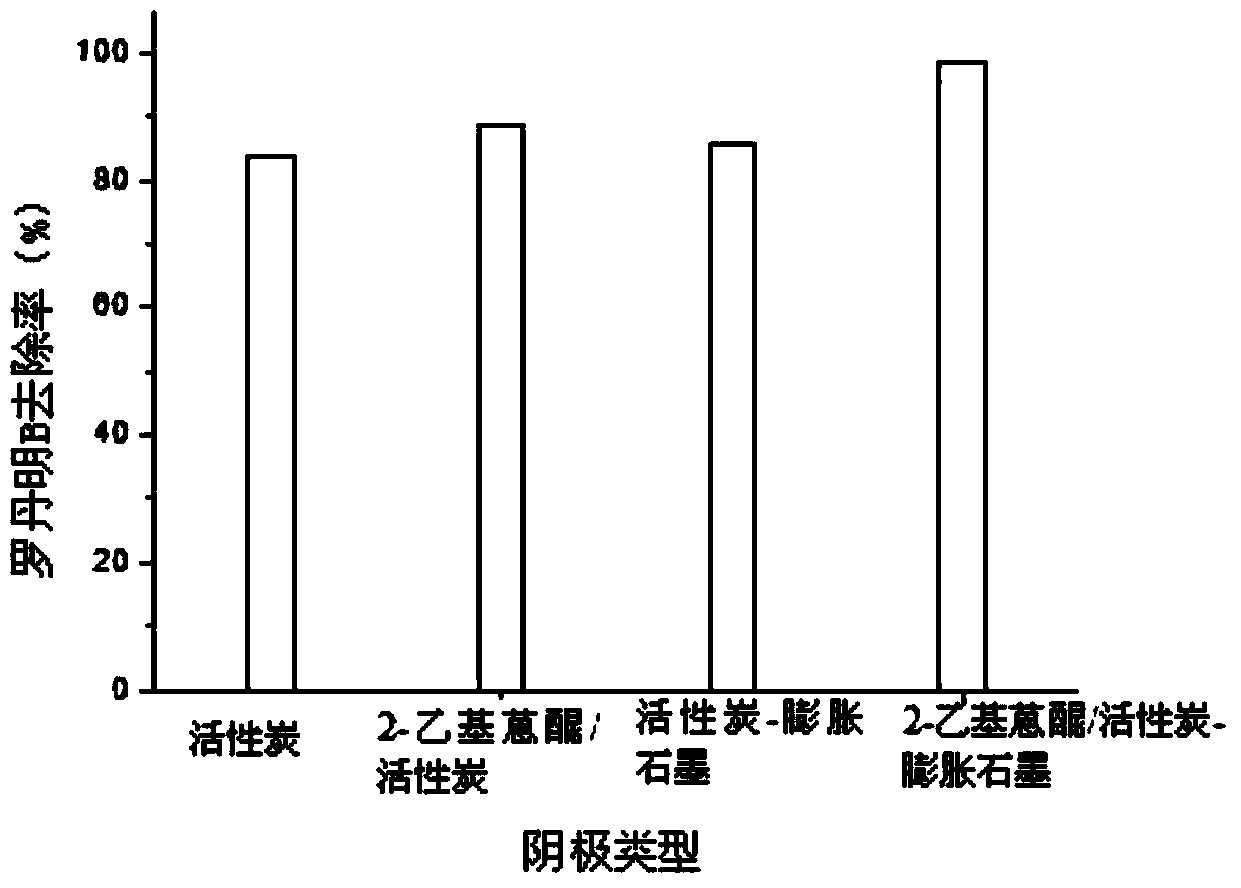

2-ethylanthraquinone/activated carbon-expanded graphite composite electrode, and preparation method and application thereof

InactiveCN103936107AImprove conductivityHigh activityWater contaminantsWater/sewage treatment by oxidationElectrolysisOxygen

The invention discloses a 2-ethylanthraquinone / activated carbon-expanded graphite composite electrode, and a preparation method and an application thereof and relates to the composite electrode, and the preparation method and the application thereof. The invention aims at solving the problems that the electric conductivity of an oxygen reduction cathode for degrading wastewater containing organic pollutants is poor and the degradation efficiency of the organic pollutants is not high. The 2-ethylanthraquinone / activated carbon-expanded graphite composite electrode disclosed by the invention comprises activated carbon modified by 2-ethylanthraquinone, expanded graphite, polytetrafluoroethylene and a stainless steel wire mesh. The preparation method comprises the following steps: 1) pretreatment of the stainless steel wire mesh; 2) paste mixing; 3) roller pressing; 4) pretreatment of the electrode; and 5) pre-electrolysis of the electrode. The application of the 2-ethylanthraquinone / activated carbon-expanded graphite composite electrode is that the 2-ethylanthraquinone / activated carbon-expanded graphite composite electrode is used for degrading phenol and decoloring rhodamine B. Due to good electric conductivity of the expanded graphite mixed in the composite electrode, the electric conductivity of the electrode is improved, and the degradation efficiency against the pollutants is simultaneously high.

Owner:HEILONGJIANG UNIV

Preparation process of high-purity hydrogen peroxide

InactiveCN104401944AHigh activityEasy to recyclePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingRetention time2-Ethylanthraquinone

The invention discloses a preparation process of high-purity hydrogen peroxide. The process comprises the steps of weakly acidic anthraquinone working solution preparation, nano-palladium catalyst preparation, catalytic hydrogenation, oxidation, extraction, post-treatment, and the like. According to the invention, the carbon-nanotube-loaded nano-palladium catalyst is used for catalysing normal-pressure hydrogenation of 2-ethylanthraquinone. The catalyst has high activity, and is easy to recycle. The catalyst can be repeatedly used, and has a good stability, such that catalyst dose can be greatly reduced. Ananthrahydroquinone microchannel reactor oxidation technology is adopted, and working solution retention time can be reduced to within 1min. The ananthrahydroquinone conversion rate reaches 95%, and the oxidation reactor volume is greatly reduced, such that the production efficiency and the working solution utilization rate are improved.

Owner:GUANGXI TIANDONG DASHENG CHEM TECH

Method for synthesizing 2-carboxyl anthraquinone by using dichromic acid to oxidize 2-ethyl anthraquinone

ActiveCN101823957AEasy to operateLow costCarboxylic preparation by oxidationAnthranil2-Ethylanthraquinone

The invention discloses a method for synthesizing 2-carboxyl anthraquinone by using dichromic acid to oxidize 2-ethyl anthraquinone, comprising the steps of: leading the 2-ethyl anthraquinone and potassium dichromate to have reaction under the condition of existence of sulphuric acid, and preparing the 2-carboxyl anthraquinone. The method has convenient operation, low cost and little pollution, and can be taken as new material to be applied in the industries such as pigment, spinning, electronics, paper making and the like on a large scale.

Owner:柏盛新材料(甘肃)有限公司

High performance supported Pd catalyst for 2-ethyl anthraquinone hydrogenation and preparation method thereof

InactiveCN106000417APeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalysts2-EthylanthraquinoneHigh activity

The invention relates to a high performance supported Pd catalyst for 2-ethyl anthraquinone hydrogenation and a preparation method thereof. The method includes: adopting cheap and easily available sodium metaaluminate as a precursor salt for preparation of a catalyst carrier, taking a Pluronic triblock copolymer P123 as the template agent, preparing a hydroxide precipitate by sol-gel method under an alkaline condition, then carrying out separation, vacuum drying, equivolumetric co-impregnation of Ba- and Fe- precursor salts, vacuum drying and roasting in order, thus obtaining Ba-Fe / gamma-Al2O3; further conducting equivolumetric co-impregnation of a Pd- precursor salt, ordinary drying and roasting, thus obtaining a Pd-Ba-Fe / gamma-Al2O3 catalyst. The prepared catalyst has high activity, high selectivity and high stability, and the hydrogenation efficiency is up to 9-10g H2O2 / L working fluid.

Owner:WUHAN UNIV OF TECH

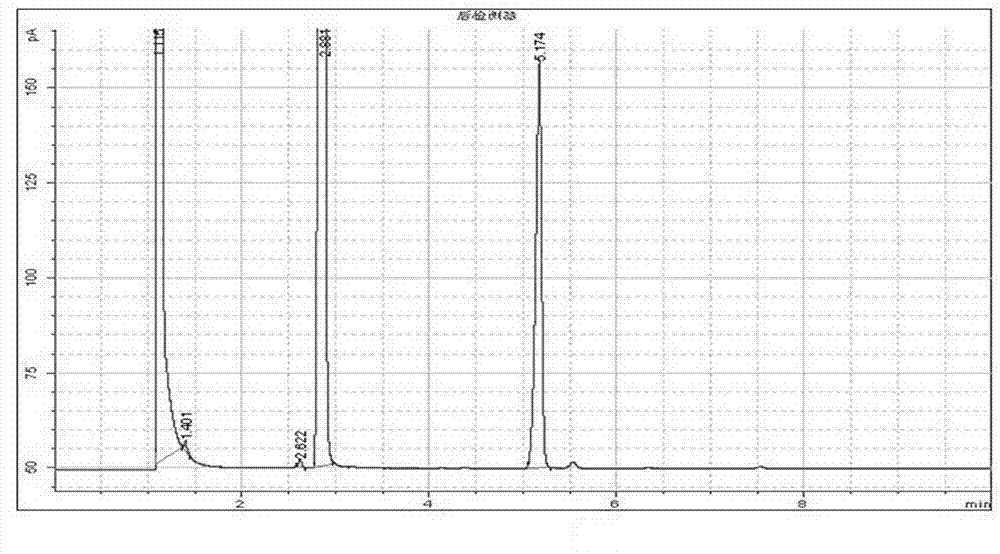

Detection method of chlorine content in 2-ethylanthraquinone

InactiveCN108982750AImprove weighing accuracyDetection speedChemical analysis using titrationWorkstationData stability

The invention discloses a detection method of the chlorine content in 2-ethylanthraquinone. The detection method comprises the following steps of 1) preparing an organic chlorine standard solution; 2)preparing a sample, and weighing about 4 micrograms of sample in a sample weighing cup with an analysis scale; 3) putting the sample on a micro-coulometry sulfur-chlorine determinator for detection,wherein integration resistance of a data workstation of the micro-coulometry sulfur-chlorine determinator is equal to 1 K, and the amplification factor is equal to 2000; 4) calculating an average conversion rate; and 5) sending the sample into the micro-coulometry titrator for determination by using a solid sample feeding boat. In the detection method, as the feeding quantity required for detection is small and is less than 4 micrograms, the detection cost can be reduced, and the detection speed is increased. The practical application discovers that the detection method is short in detection time, good in data stability and simpler in operation compared with the prior art and can lower the labor intensity of detecting personnel.

Owner:HUZHOU JICHANG CHEM

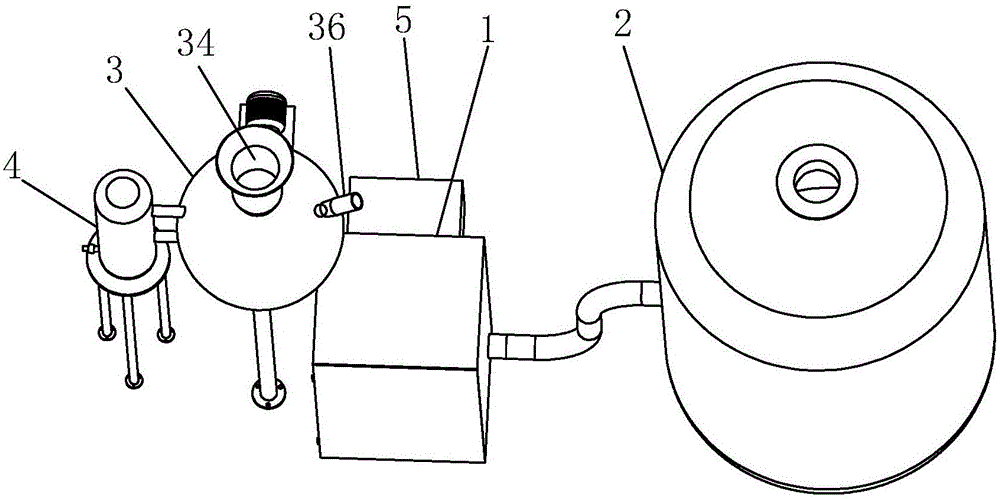

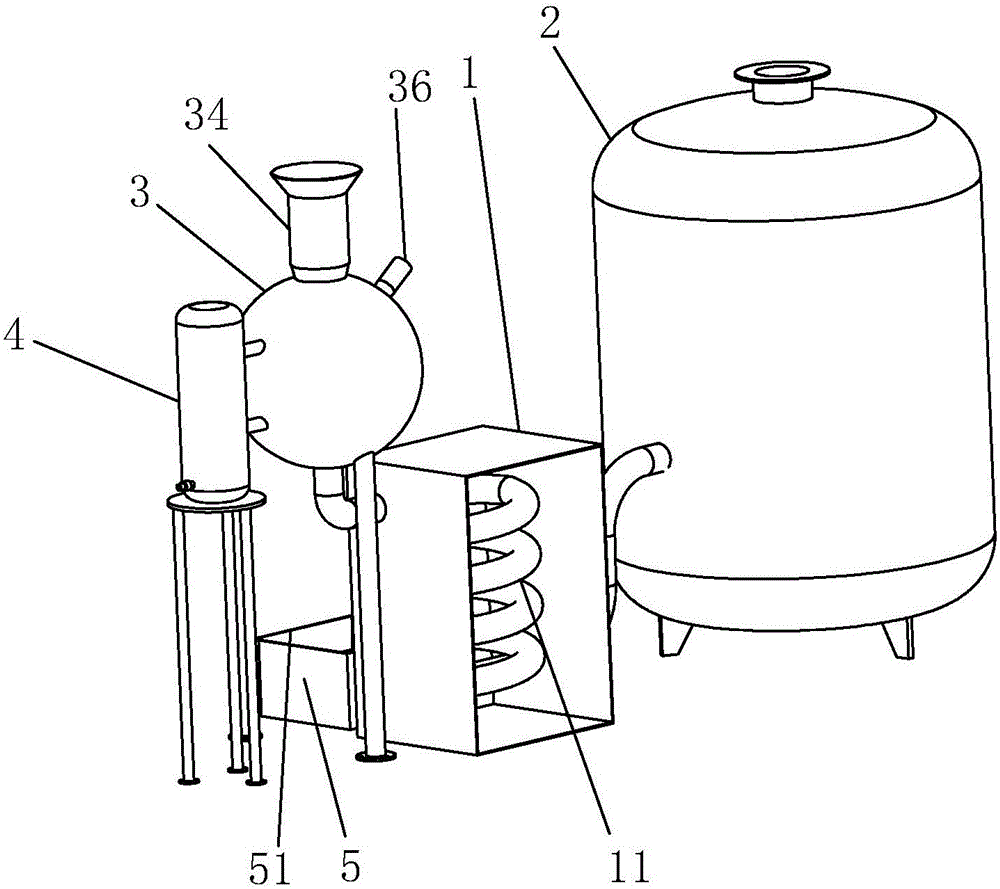

2-EAQ (2-ethylanthraquinone) synthesis device and technology

ActiveCN106045838AJoin slowlyMaintain physical and chemical propertiesOrganic compound preparationQuinone preparation2-EthylanthraquinoneProcess engineering

The invention discloses a 2-EAQ (2-ethylanthraquinone) synthesis device and technology. The technical scheme is characterized in that the 2-EAQ synthesis device comprises a tubular reactor, a hydrolysis kettle and a sphere mixer, wherein a feed chute allowing a solid material to be fed is formed in the sphere mixer; a sprinkling nozzle for jetting a fluid material is arranged in the sphere mixer; a feed tube communicated with the sprinkling nozzle is further arranged on the sphere mixer; the sphere mixer is communicated with one end of the tubular reactor, and the other end of the tubular reactor is communicated with the hydrolysis kettle; with the adoption of the sprinkling mode of the sprinkling nozzle, fuming sulphuric acid is added more slowly, so that the temperature in the sphere mixer is prevented from being increased to be too high due to too high mixing speed of the materials during mixing of the materials, the temperature in a mixing process is controlled to be in a safe mixing temperature range of the two materials, and the mixing process is safer and more stable.

Owner:吉林紫瑞新材料有限公司

Preparation method of high-selectivity palladium catalyst

InactiveCN105536780AHigh purityLarge specific surface areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsPalladium catalystAluminium isopropoxide

The invention provides a preparation method of a high-selectivity palladium catalyst, which comprises the following steps of: (1) dissolving 2-ethyl anthraquinone in isopropanol at room temperature by sufficiently stirring, adding aluminum isopropoxide to the solution according to the mass ratio of 2-ethyl anthraquinone to aluminum isopropoxide being 1:(28.57-100), heating, sufficiently stirring for dissolving, dripping mixed liquid of acetic acid and water, and sufficiently stirring at room temperature for hydrolysis; (2) aging a hydrolysis product at 80 DEG C for 20h, separating, washing, drying and calcining to obtain gamma-Al2O3 powder; and (3) isometrically immersing the gamma-Al2O3 powder with sodium tetrachloropalladate solution, washing, drying and calcining to obtain the efficient loaded palladium catalyst. The preparation method has the advantages of novelty, simple operation, controllable specific area, pore diameter and other structure properties of the product and the like; and the prepared 2-ethyl anthraquinone regulated and controlled catalyst has good selectivity and activity on anthraquinone hydrogenation reaction.

Owner:WUHAN UNIV OF TECH

Synthesis method of 2-alkyl anthraquinone

ActiveCN1315768CSimple processEfficient processOrganic compound preparationQuinone preparationBenzoic acidSynthesis methods

A process for preparing 2-alkylanthraquinone from 2-(4'-alkylbenzoyl) benzoic acid includes such steps as mixing said raw material with solid acid catalyst and closed-loop dewatering reacting. Its advantages are high purity, high transform rate and high selectivity.

Owner:DALIAN UNIV OF TECH

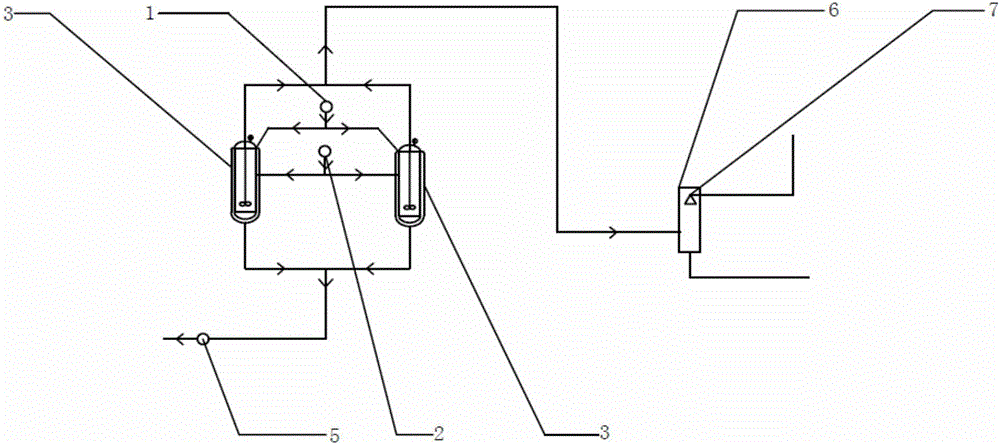

Device for industrially continuously producing 2-ethylanthraquinone

PendingCN106810434AHigh yieldControl outputOrganic compound preparationQuinone separation/purification2-EthylanthraquinonePhase splitter

The invention relates to a device for industrially continuously producing 2-ethylanthraquinone. The device comprises a reacting tank, an absorbing column, a phase splitter, a solvent tower and a rectifying column, wherein an outlet pipeline of the reaction tank is connected with an inlet of the absorbing column; the reacting tank is provided with a BE acid storing tank inlet, a solid acid catalyst storing tank inlet and a base material collecting tank outlet which are correspondingly connected with a solid acid catalyst storing tank, a BE acid storing tank and a base material collecting tank; a catalyst regenerating tank outlet is correspondingly connected with the solid acid catalyst storing tank inlet and the BE acid storing tank inlet; the outlet pipeline of the absorbing column is connected with the inlet of the phase splitter; a liquid distributor is arranged at the inner upper part of the absorbing tower; an organic phase outlet pipeline of the phase splitter is connected with a solvent column feeding port; a bottom outlet pipeline of the solvent column is connected with a rectifying column feeding port; a top outlet of the solvent column is connected with the liquid distributor in the absorbing column through a pipeline; a 2-ethylanthraquinone outlet is arranged on the top of the rectifying column. Compared with an existing industrial device, the device has the advantages that the cost can be obviously decreased, and the environmental protection is improved.

Owner:TIANJIN UNIV

Photocurable coating for ceramics

ActiveCN104178019BWidely producedPolyurea/polyurethane coatingsEpoxy resin coatingsCeramic coatingAdipic acid

A photocurable coating for ceramics, its raw materials are proportioned as follows in parts by weight: 100 parts of polyurethane acrylate; 5-15 parts of hydroquinone; 10-20 parts of titanium dioxide; 1,4-cyclohexanedione mono- 1-10 parts of 2,2-dimethyltrimethylene ketal; 80-100 parts of water; 20-30 parts of 2-ethylanthraquinone; 1-5 parts of coloring pigment; 15-25 parts of N-vinylpyrrolidone 25-35 parts of trimethylolpropane triacrylate; 30-40 parts of isophthalic acid; 35-45 parts of crosslinking agent; 5-25 parts of maleic anhydride; 10-30 parts of epoxy acrylate; 20‑40 parts of adipic acid; 15‑35 parts of diethylene glycol; product gloss 120%‑130%, hardness 8‑10H; surface dry time 15‑30s, solid dry 15‑30min, alkali resistance 1‑2d, Acid resistance 24‑36h; water resistance 3‑7d, flexibility 1mm; adhesion level 1, can be widely produced and continuously replace existing materials.

Owner:钦州市丁火陶瓷有限公司

Method for preparing tetrahydro-2-ethyl anthraquinone from working solution for production of hydrogen peroxide by anthraquinone process

InactiveCN102731284BRaw materials are easy to getSimple and fast operationQuinone separation/purificationProblem of timeFiltration

The invention relates to a method for preparing tetrahydro-2-ethyl anthraquinone from a working solution for the production of hydrogen peroxide by anthraquinone process, comprising the following steps: taking a certain amount of the working solution for the production of hydrogen peroxide by anthraquinone process to conduct vacuum distillation, removing heavy aromatics and other substances of low boiling point to obtain a dried substances; carrying out oversaturated dissolving on the obtained dried substances with organic solvents, stirring, oscillating, conducting suction filtration, letting trioctyl phosphate and 2-ethyl anthraquinone, etc. in the solvent, drying insoluble substances to obtain dried substances; dissolving the dried substances with organic solvents, and conducting recrystallization to obtain high-purity tetrahydro-2-ethyl anthraquinone. The method of the invention not only solves the problems of time consuming and labor consuming property and low conversion rate when synthesizing tetrahydro-2-ethyl anthraquinone by autoclave reaction, but also reduces the cost, shortens the operation time. Tetrahydro-2-ethyl anthraquinone prepared by the method of the invention has a purity of more than 99.5%, and can be used as a tetrahydro-2-ethyl anthraquinone standard sample for analyzing the working solution for hydrogen peroxide.

Owner:CHINA PETROLEUM & CHEM CORP

Porous membrane cathode for photoelectric-fenton processing system and its preparation process

InactiveCN104071866BHigh reduction catalytic performanceLong electrode lifeWater/sewage treatment by irradiationWater/sewage treatment by oxidationPolytetrafluoroethyleneMethanol

The invention discloses a porous membrane cathode for a photoelectric-Fenton treating system, as well as a preparation technology of the porous member cathode. The preparation technology comprises the following steps: pretreating graphite powder to obtain a substance B, and treating the substance B through a KNO3 water solution, a nonylphenol polyoxyethylene ether water solution, ethanol, tertbutyl alcohol and polytetrafluoroethylene emulsion to obtain cream A; smearing the cream A on one side of a treated nickel screen, and extruding to obtain a substance E; preparing a solution C; preparing a cream B from the substance B, a KNO3 water solution, a nonylphenol polyoxyethylene ether water solution, ethyl ether, methanol, 2-ethylanthraquinone, the solution C and the polytetrafluoroethylene emulsion; and smearing the cream B on the other side of the substance E, and extruding, forging and cooling to obtain the porous membrane cathode for the photoelectric-Fenton treating system.

Owner:BEIJING NORMAL UNIVERSITY

Preparation method of moisture-proof light-cured molded coal

The invention discloses a preparation method of moisture-proof light-cured molded coal. According to the preparation method, 2-Ethylanthraquinone, calcium hydrate, polyacrylate, and solvent water aretaken as raw materials; the raw materials are mixed with coal powder at a certain mass ratio, mechanical compacting molding is adopted, and an obtained product is subjected to ultraviolet irradiationso as to obtain light cured molded coal. The bonding index of the light cured molded coal is larger than 70, the cold strength is larger than 2MPa, the hot strength is as high as 5MPa, the thermal stability is excellent, the cold strength and the hot strength are high, and solidification is achieved quickly under ultraviolet ray.

Owner:岳阳振兴中顺新材料科技股份有限公司

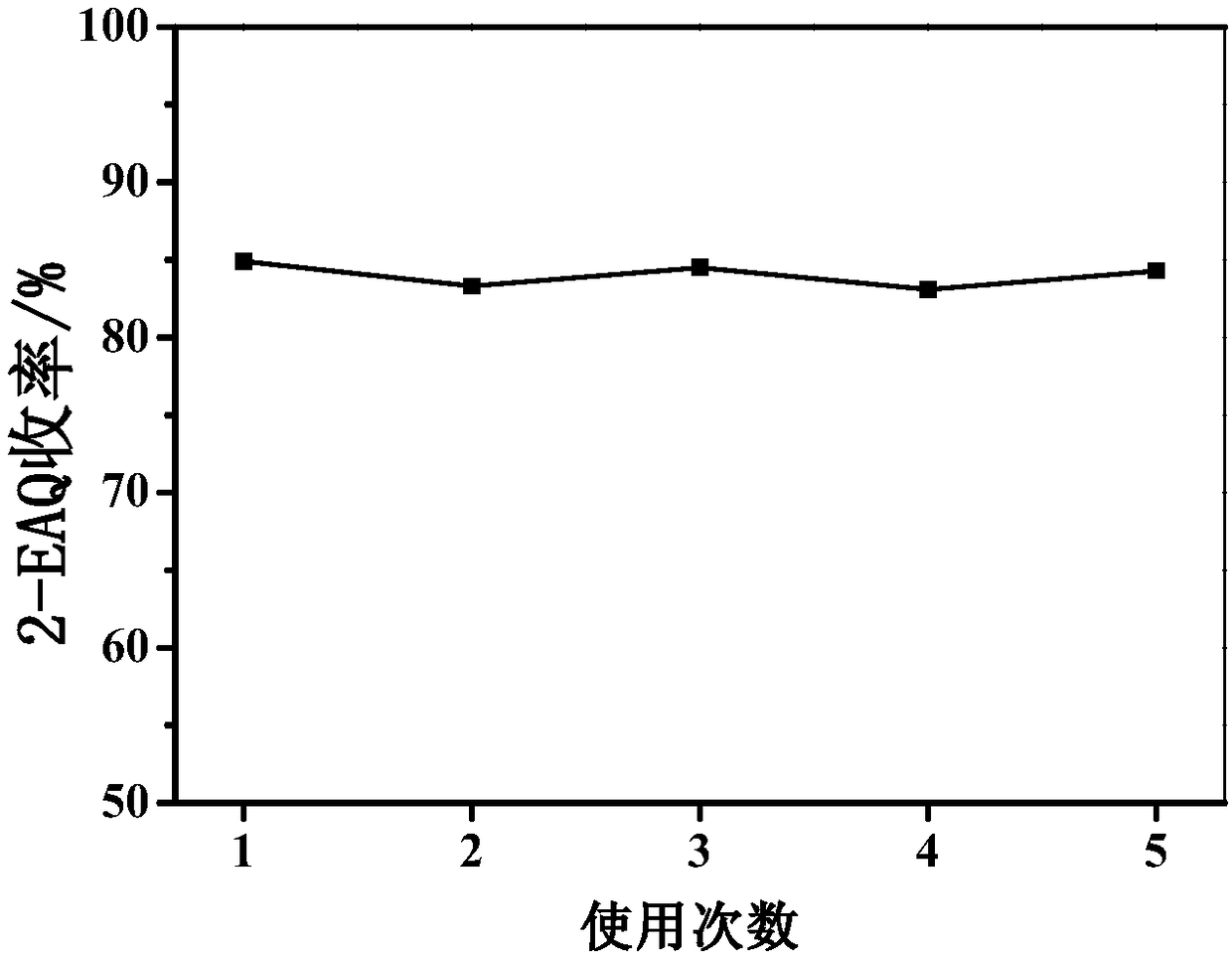

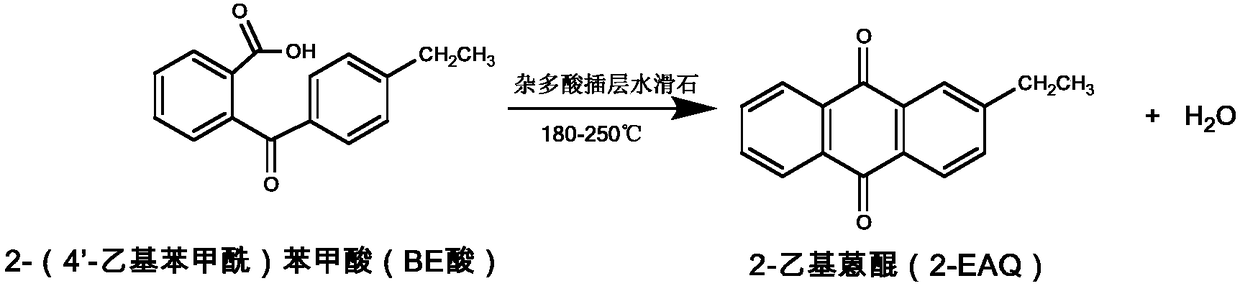

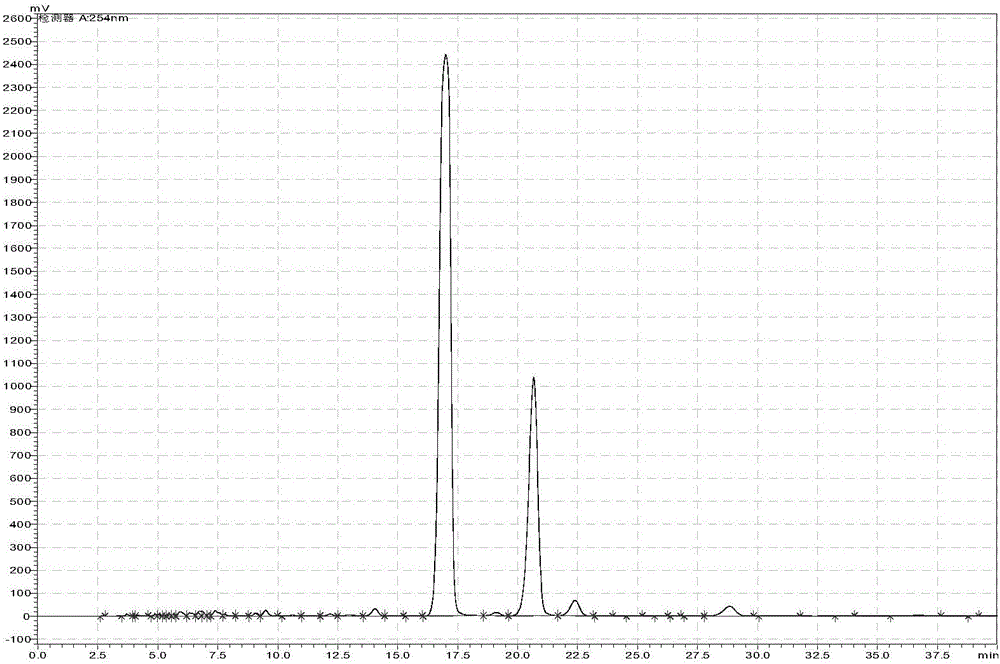

Method for synthesizing 2-ethylanthraquinone by taking heteropoly acid intercalated hydrotalcite as catalyst

InactiveCN108147957ARealize green productionAvoiding the Drawbacks of Refractory Spent AcidOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidOleum

The invention discloses a method for synthesizing 2-ethylanthraquinone by taking heteropoly acid intercalated hydrotalcite as a catalyst. According to the method, the 2-ethylanthraquinone is producedin a closed-loop manner through enabling 2-(4'-ethylbenzoyl)benzoic acid, which serves as a raw material, to react for 1.0 to 4.0 hours at the temperature of 180 DEG C to 250 DEG C in the presence ofthe heteropoly acid intercalated trihydroxymethyl hydrotalcite, which serves as the catalyst. The adopted heteropoly acid intercalated trihydroxymethyl hydrotalcite catalyst is prepared through takingtrihydroxymethyl modified magnalium hydrotalcite as a precursor and carrying out ion exchange with heteropoly acid. According to the method, the defect in the prior art that a large volume of unmanageable waste acid is generated due to fuming sulfuric acid is avoided.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting tetrahydro-2-ethylanthraquinone from working solution for producing hydrogen peroxide with anthraquinone method

ActiveCN105967993AImprove hydrogenation efficiencyReduce degradation reactionQuinone separation/purificationAnthranilHydrogen

The invention creatively provides a method for extracting tetrahydro-2-ethylanthraquinone from a working solution for producing hydrogen peroxide with an anthraquinone method. The method comprises the following steps: S1: taking a circulating working solution for producing the hydrogen peroxide with the anthraquinone method; steaming out a component at 110 DEG C to 140 DEG C; slowly cooling steamed residual liquid to be lower than 25 DEG C until crystals are formed in the steamed residual liquid; S2: filtering the cooled steamed residual liquid to obtain a filter cake; washing the filter cake with ethanol and drying to obtain a dried material; S3: washing the dried material by utilizing an organic solvent under a suction filtration condition so as to reduce or eliminate needle-shaped crystals and show or remain sheet-shaped crystals; taking filtrate and evaporating to obtain the tetrahydro-2-ethylanthraquinone. The method provided by the invention is simple to operate and relatively high in efficiency.

Owner:CHINA TIANCHEN ENG +2

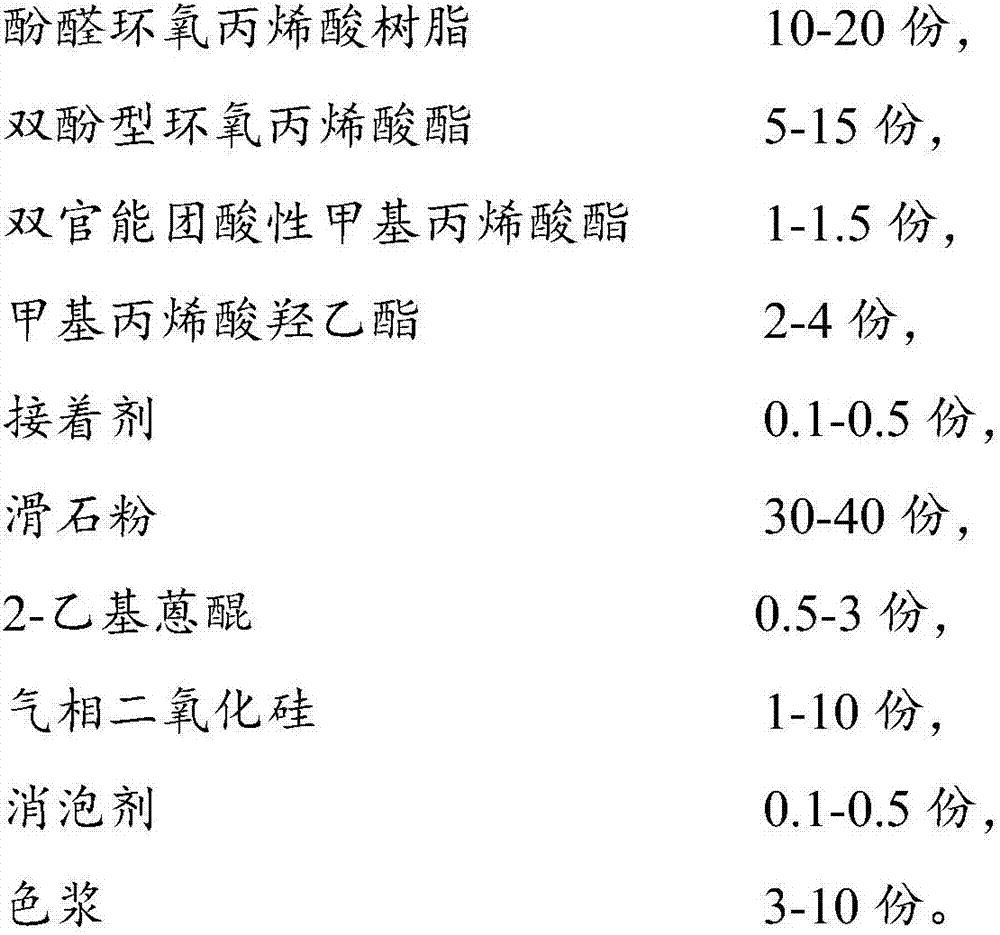

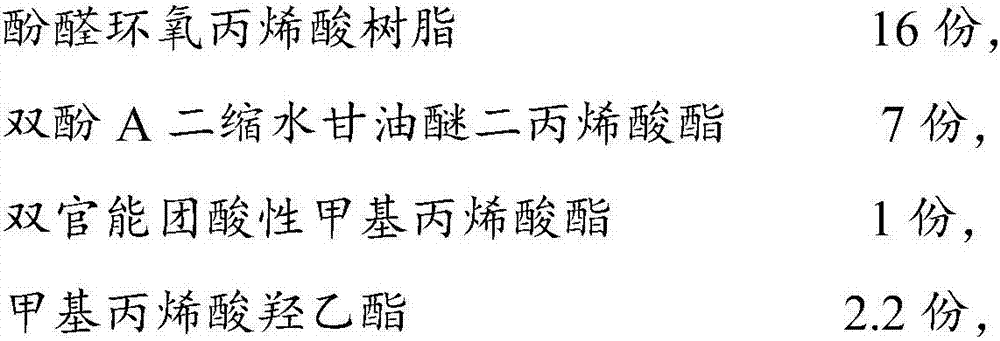

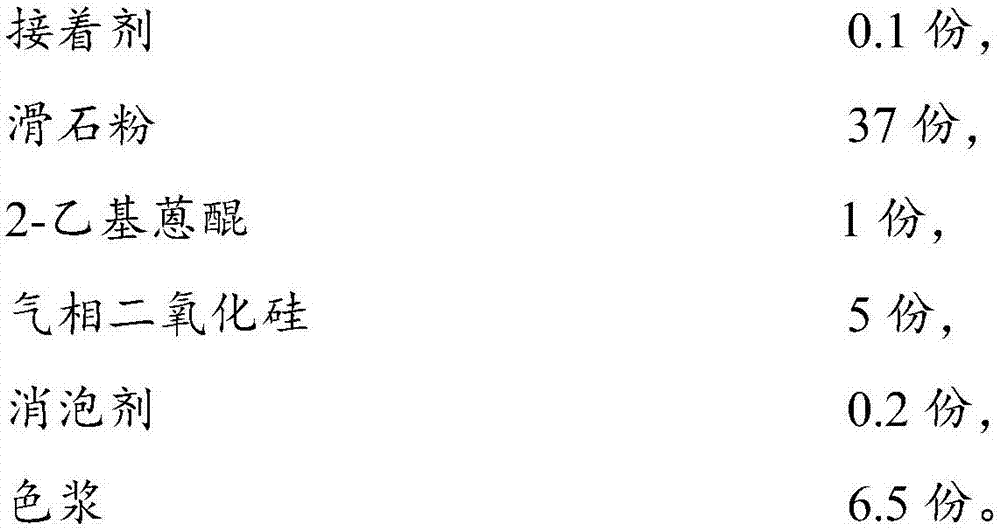

Circuit board UV ink with high temperature resistance and preparation method thereof

InactiveCN107400406AStrong adhesionImprove corrosion resistanceInks(Hydroxyethyl)methacrylateAcrylic resin

The invention provides circuit board UV ink with high temperature resistance and a preparation method thereof. The circuit board UV ink with the high temperature resistance is prepared from the following components in parts by weight: 10-20 parts of phenolic epoxy acrylic resin, 5-15 parts of bisphenol epoxy acrylate, 1-1.5 parts of bifunctional acid metacrylic acid ester, 2-4 parts of hydroxyethyl methacrylate, 0.1-0.5 part of adhesives, 30-40 parts of talcum powder, 0.5-3 parts of 2-ethylanthraquinone, 1-10 parts of fumed silica, 0.1-0.5 part of defoaming agents and 3-10 parts of color paste. The ink has high adhesion, corrosion resistance, weather resistance, high temperature resistance and good printing adaptability, is easily available in raw materials and low in cost, and is suitable for large-scale industrial production, popularization and application.

Owner:BAUHINIA VARIEGATA INK & CHEM (ZHONGSHAN) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com