Preparation method of moisture-proof light-cured molded coal

A light-curing and moisture-resistant technology, applied in the direction of solid fuel, petroleum industry, fuel, etc., can solve the problems of easy pollution of the environment, low cold strength, high preparation cost, etc., and achieve high economic value, convenient operation, and short preparation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Implement a kind of preparation method of moisture-resistant light-cured briquette, and this method is carried out according to the following steps:

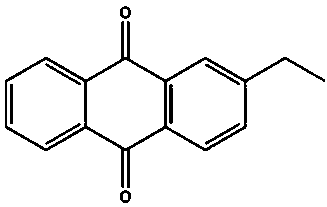

[0031] In the first step, the photoinitiator 2-ethylanthraquinone and the solid sulfur-fixing agent calcium hydroxide were weighed respectively, and the mixture was fully stirred until uniformly mixed to obtain a mixture A;

[0032] The second step is to weigh raw coal, crush and sieve to obtain coal powder;

[0033] In the third step, the mixture A obtained in the first step and the pulverized coal obtained in the second step are fully stirred and mixed to obtain a mixture B;

[0034] In the fourth step, polyacrylate and solvent water are respectively added to the mixture B obtained in the third step, and the mixture is mixed quickly to obtain a mixture C;

[0035] In the fifth step, the mixture C obtained in the fourth step is pressed and molded by a pressure molding machine. After the compression molding, it is irradi...

Embodiment 1

[0040] Implementation of a method for preparing moisture-resistant light-cured briquettes

[0041] In the first step, 100 g of photoinitiator 2-ethylanthraquinone and 10 g of sulfur-fixing agent calcium hydroxide solid were weighed respectively, and were fully stirred until uniformly mixed to obtain mixture A;

[0042] In the second step, 1000 g of raw coal is weighed, crushed and sieved to obtain coal powder with a particle size range of 0.1-0.5 mm;

[0043] In the third step, the mixture A obtained in the first step and the pulverized coal obtained in the second step are fully stirred and mixed to obtain a mixture B;

[0044] In the fourth step, add 10 g of polyacrylate and 50 g of water to the mixture B obtained in the third step, stir and mix quickly until uniform, and obtain mixture C;

[0045] In the fifth step, the mixture C obtained in the fourth step is pressed and formed by a pressure forming machine, and after the compression is formed, it is irradiated with 250-42...

Embodiment 2

[0048] Implementation of a method for preparing moisture-resistant light-cured briquettes

[0049] In the first step, 50 g of photoinitiator 2-ethylanthraquinone and 50 g of sulfur-fixing agent calcium hydroxide solid were weighed respectively, and fully stirred until uniformly mixed to obtain mixture A;

[0050] In the second step, 1000 g of raw coal is weighed, crushed and sieved to obtain coal powder with a particle size range of 0-1.0 mm;

[0051] In the third step, the mixture A obtained in the first step and the pulverized coal obtained in the second step are fully stirred and mixed to obtain a mixture B;

[0052] In the fourth step, add 200 g of polyacrylate and 100 g of water to the mixture B obtained in the third step, stir and mix quickly until uniform, and obtain mixture C;

[0053] In the fifth step, the mixture C obtained in the fourth step is pressed and formed by a pressure molding machine, and after the compression is formed, it is irradiated with 250-420nm ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com