Method for catalytically preparing 2-ethyl anthraquinone by alkali desilicicated modified Hbeta molecular sieve

A technology of alkali desiliconization modification and β molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the preparation of organic compounds. Achieve the effect of convenient separation, high activity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

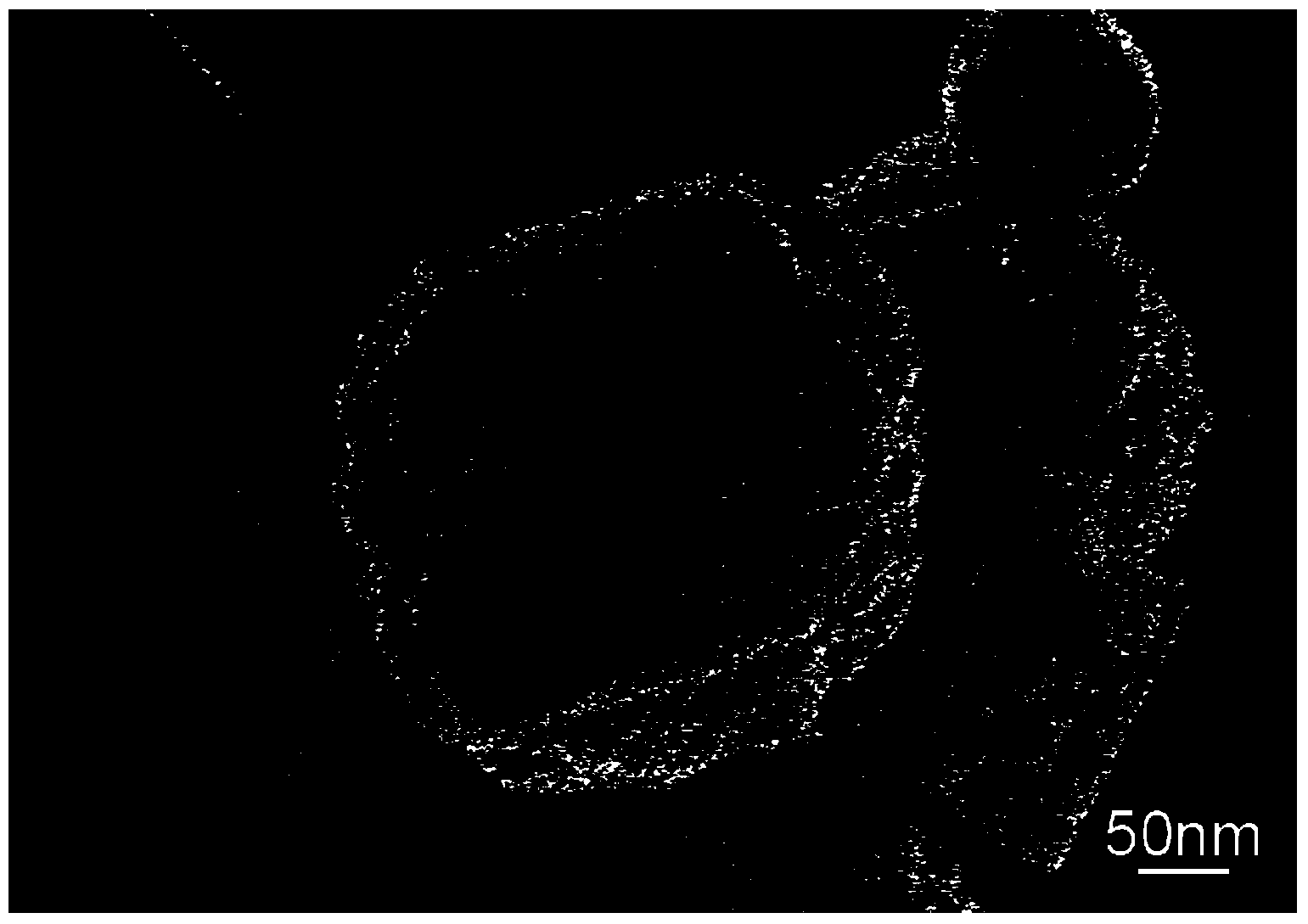

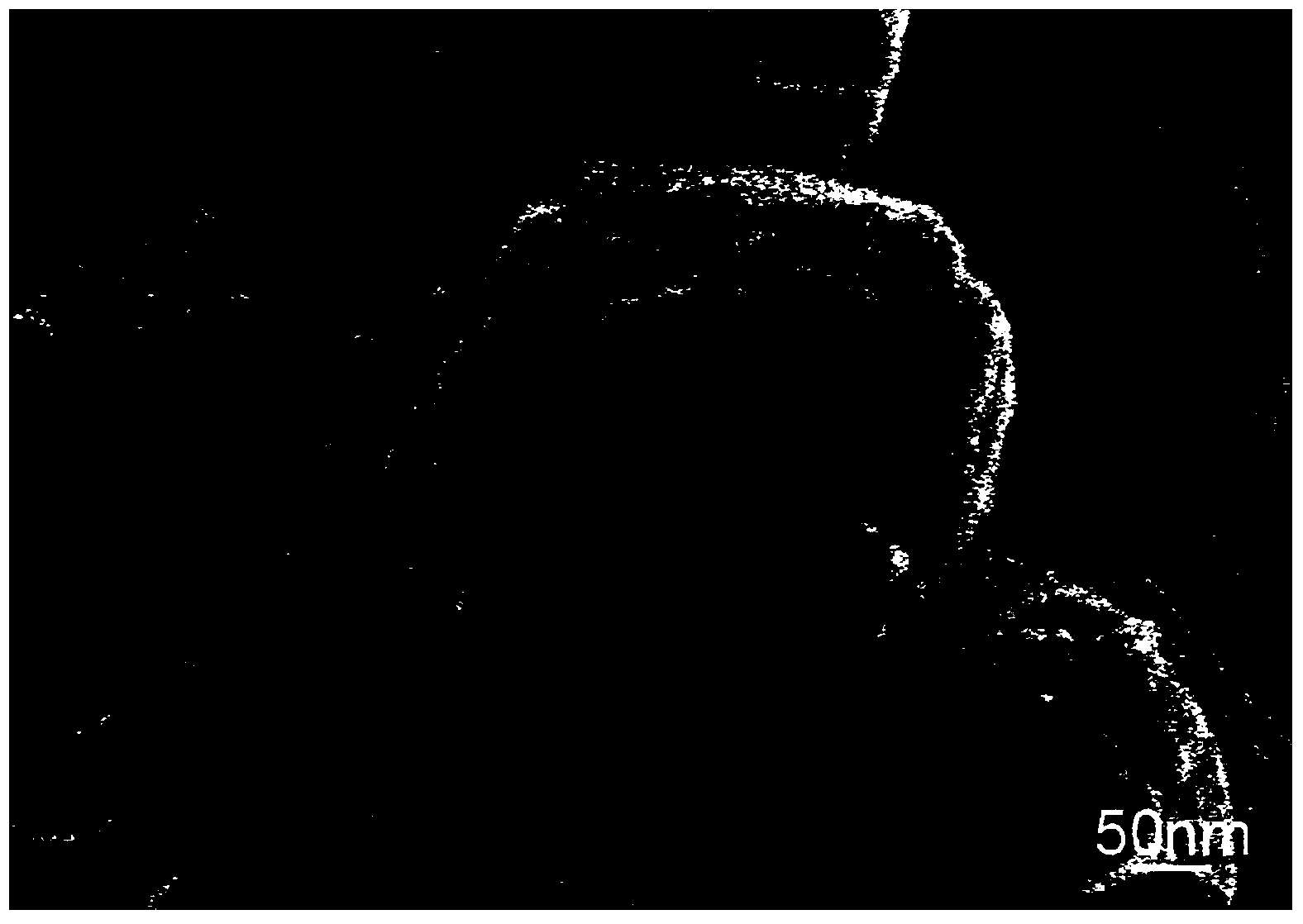

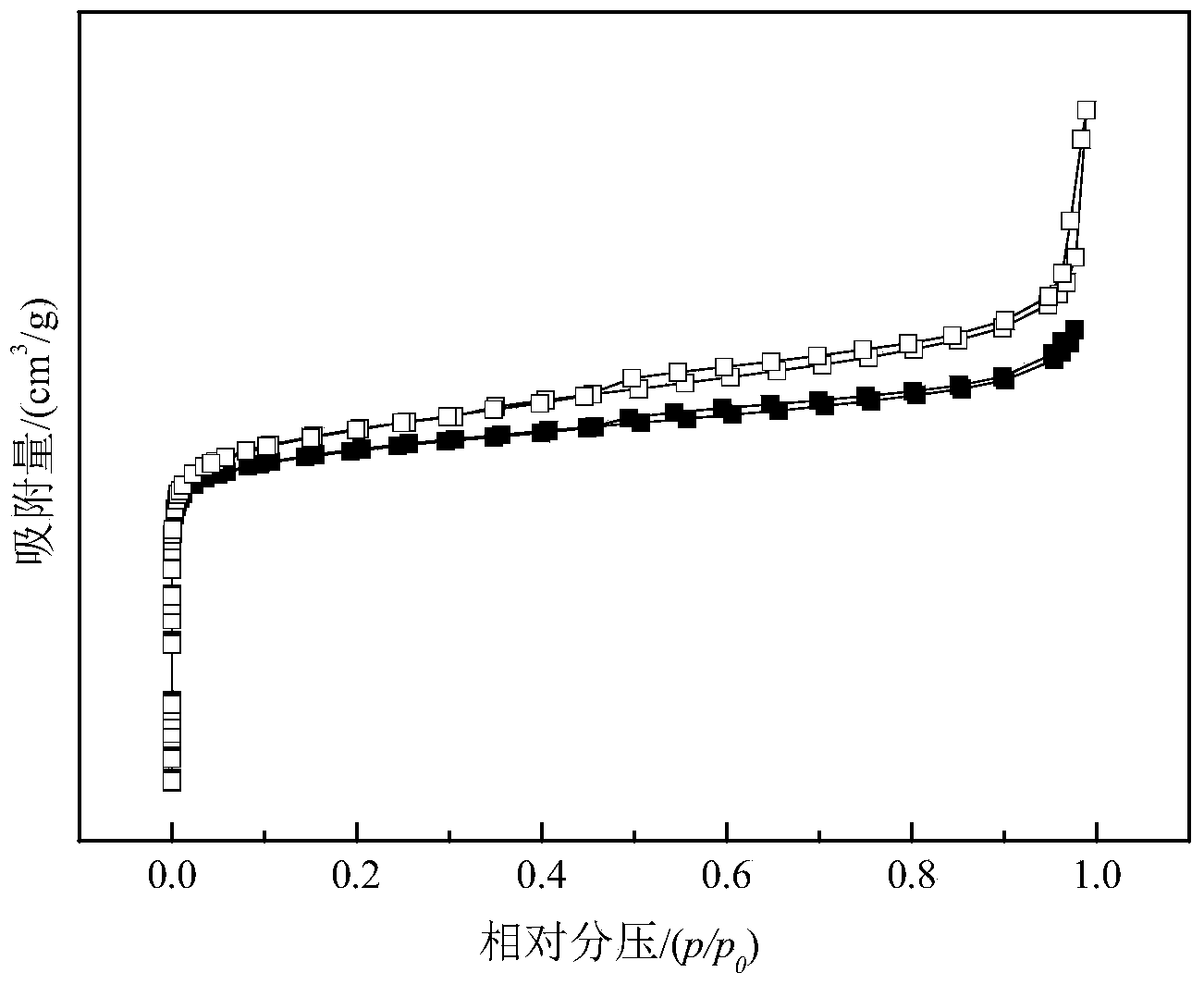

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: In this embodiment, a method for catalytically preparing 2-ethylanthraquinone by modifying Hβ molecular sieve by alkali desiliconization is completed according to the following steps:

[0019] 1. Mix the original powder of zeolite beta molecular sieve and alkali solution evenly, and then treat it at a temperature of 30°C to 90°C for 0.5h to 6h, then filter, wash, then dry, and then roast to obtain the zeolite molecular sieve without the template agent, Then according to the solid-to-liquid mass ratio of zeolite molecular sieve removing template agent and ammonium nitrate aqueous solution is 1: (20-50), mix zeolite molecular sieve removing template agent and ammonium nitrate aqueous solution, and then under the condition of temperature 60℃~90℃ Stirring for 2h to 10h, and then roasting to obtain the alkali desiliconization modified Hβ zeolite molecular sieve catalyst;

[0020] 2. Mix 2-(4′-ethylbenzoyl)benzoic acid with the alkali desiliconization...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the ratio of silicon to aluminum in the raw powder of zeolite beta molecular sieve described in step 1 is 25-65. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 in that: in step 1, the alkali solution is sodium hydroxide solution with a concentration of 0.1 mol / L-2 mol / L. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com