High performance supported Pd catalyst for 2-ethyl anthraquinone hydrogenation and preparation method thereof

A high-performance technology of ethylanthraquinone, applied in the field of high-performance supported Pd-catalyst for hydrogenation of 2-ethylanthraquinone and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

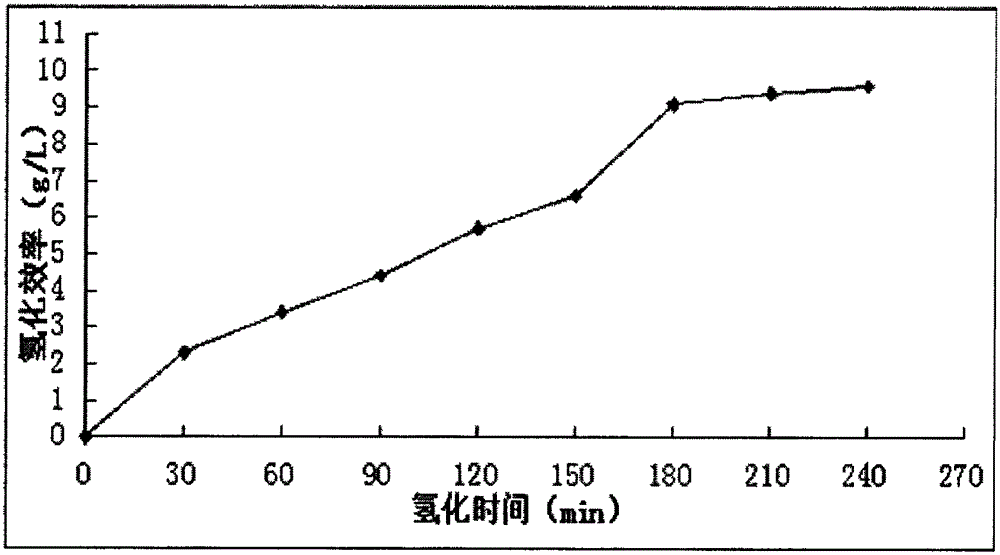

Image

Examples

Embodiment 1

[0014] 1. γ-Al 2 o 3 Preparation of vector

[0015] Weigh 5.5g of sodium metaaluminate and dissolve it in 60mL of deionized water, adjust the pH to 7 with concentrated hydrochloric acid, put it in a water bath at 80°C for 8h, wash the precipitate with deionized water until neutral, separate it and dry it in vacuum at 70°C for 8h The aluminum hydroxide precursor was obtained, and then calcined in a muffle furnace under a static air atmosphere at 650 °C for 4 hours to obtain γ-Al 2 o 3 carrier.

[0016] 2. Loading of Pd-

[0017] Take 1.0g of the γ-Al prepared above 2 o 3 carrier, with PdCl 2 The solution was impregnated in equal volume at 60°C for 2h (the loading capacity of Pd- was 0.3wt%), and then washed three times with 0.1mol / L NaOH solution (1h interval between each time), and then washed with deionized water until neutral, and then Normal drying at 120°C for 4h, and finally calcining in a muffle furnace at 550°C under a static air atmosphere for 4h to prepare cat...

Embodiment 2

[0021] 1. γ-Al 2 o 3 Preparation of vector

[0022] Weigh 1.0g of P123 and dissolve it in 60mL of deionized water. After the dissolution is complete, add 5.5g of sodium metaaluminate until it is completely dissolved, adjust its pH to 8 with concentrated hydrochloric acid, bathe in water at 80°C for 6 hours, and wash the precipitate with deionized water to Neutral, washed once with ethanol, separated and dried in vacuum at 80°C for 10h to obtain the aluminum hydroxide precursor, and then roasted in a muffle furnace for 4h under a static air atmosphere at 550°C to obtain γ-Al 2 o 3 carrier.

[0023] 2. Loading of Pd

[0024] Take 1.0g of the γ-Al prepared above 2 o 3 carrier, with PdCl 2 The solution was impregnated in equal volume at 60°C for 2h (the loading capacity of Pd- was 0.3wt%), and then washed three times with 0.1mol / L NaOH solution (1h interval between each time), and then washed with deionized water until neutral, and then Normal drying at 120°C for 4h, and f...

Embodiment 3

[0026] 1. γ-Al 2 o3 Preparation of vector

[0027] Weigh 1.0g of P123 and dissolve it in 60mL of deionized water. After the dissolution is complete, add 5.5g of sodium metaaluminate until it is completely dissolved, adjust its pH to 8 with concentrated hydrochloric acid, bathe in water at 70°C for 8 hours, and wash the precipitate with deionized water until Neutral, then washed once with ethanol, separated and dried in vacuum at 80 °C for 10 h to obtain the precursor of aluminum hydroxide, and used Fe(NO 3 ) 3 9H 2 O was co-impregnated with equal volume of the above-mentioned vacuum-dried product at 60°C for 2h (the loading of Fe- was 1wt%), and further vacuum-dried the impregnated product in a vacuum drying oven, and then in a static air atmosphere at 600°C in a muffle furnace. Under roasting for 4h, the carrier can be prepared.

[0028] 2. Loading of Pd

[0029] Take 1.0g of the γ-Al prepared above 2 o 3 carrier, with PdCl 2 The solution was impregnated in equal volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrogenation efficiency | aaaaa | aaaaa |

| Hydrogenation efficiency | aaaaa | aaaaa |

| Hydrogenation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com