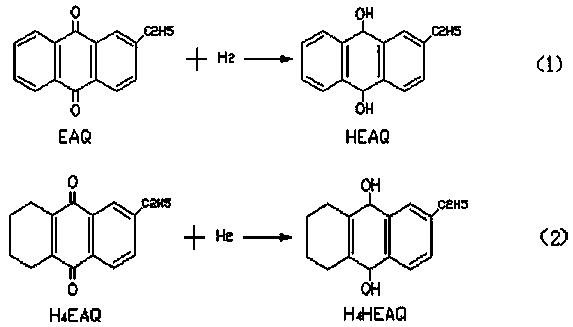

Technology for producing hydrogen peroxide by anthraquinone process

A hydrogen peroxide, anthraquinone method technology, applied in the direction of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of hydrogenation liquid gas-liquid separator The outlet pipeline and the hydrogenation liquid filter are blocked, the production cannot be carried out smoothly, and the hydrogen efficiency is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] One, main equipment of the present invention:

[0063] Hydrogenation tower, oxidation tower, extraction tower, purification tower, flash tank, clay bed, hydrogenated clay bed, hydrogen buffer filter, air filter, hydrogenation liquid filter, security filter, primary filter, secondary filter , working fluid thermostat, working fluid heater (hydrogenation), working fluid heat exchanger (hydrogenation), hydrogenated fluid cooler, pure water heater, extract cooler, primary flash cooler, secondary flash Cooler, hydrogenated liquid storage tank, oxidizing liquid high level tank, regeneration liquid storage tank, pure water storage tank, primary flash tank, secondary flash tank, 1# tail gas condensate receiving tank, 2# tail gas condensate receiving tank, hydrogenation Liquid pumps, oxidation liquid pumps, hydrogenation liquid circulation pumps, regeneration liquid pumps, pure water pumps, phosphoric acid pumps, phosphoric acid metering pumps, aromatic hydrocarbon pumps.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com