2-ethylanthraquinone/activated carbon-expanded graphite composite electrode, and preparation method and application thereof

An ethyl anthraquinone and expanded graphite technology, applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of poor oxygen reduction cathode conductivity and low degradation efficiency of organic pollutants, etc. Good catalytic effect, reduced energy consumption and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the present embodiment 2-ethylanthraquinone / activated carbon-expanded graphite composite electrode is made up of activated carbon modified by 2-ethylanthraquinone, expanded graphite, polytetrafluoroethylene and stainless steel mesh; the 2- The mass ratio of ethylanthraquinone modified activated carbon to expanded graphite is (2-8):1; the mass ratio of expanded graphite to polytetrafluoroethylene is 1:(6-18).

[0019] The 2-ethylanthraquinone / activated carbon-expanded graphite composite electrode described in this embodiment is used as a cathode in practical application, and the size of the stainless steel mesh is determined according to actual needs, and is the same size as the matched anode.

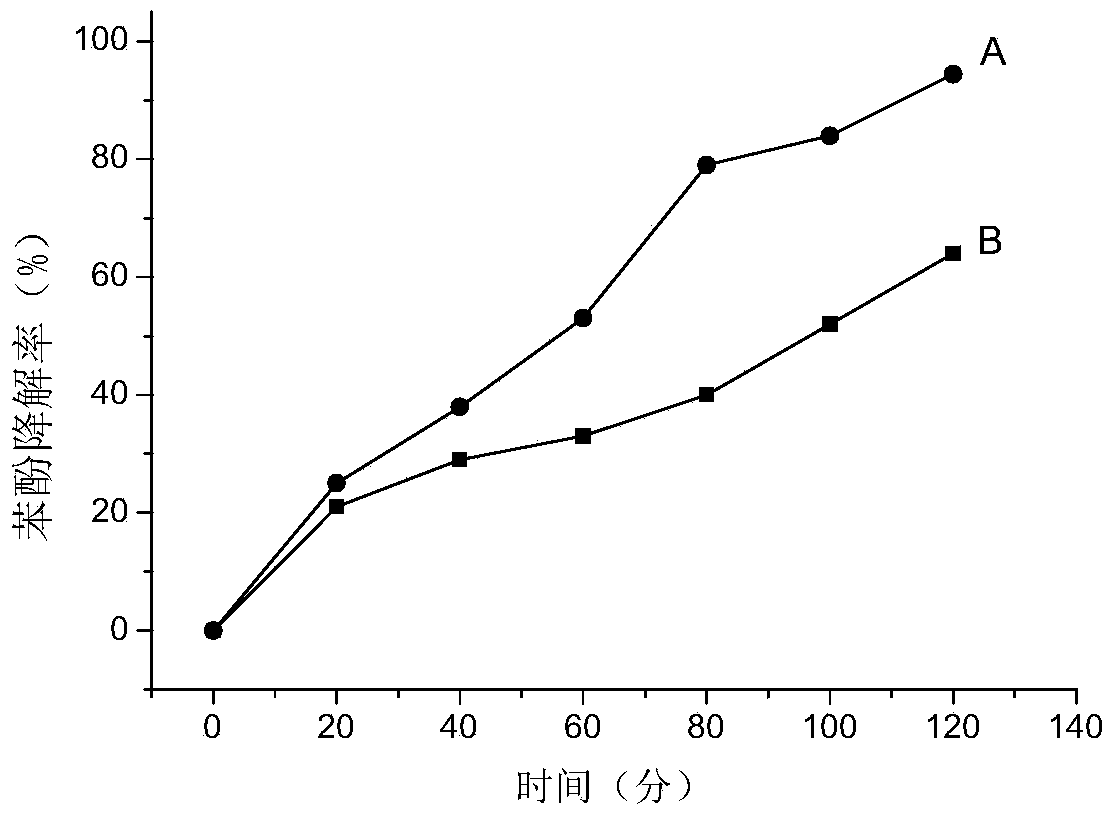

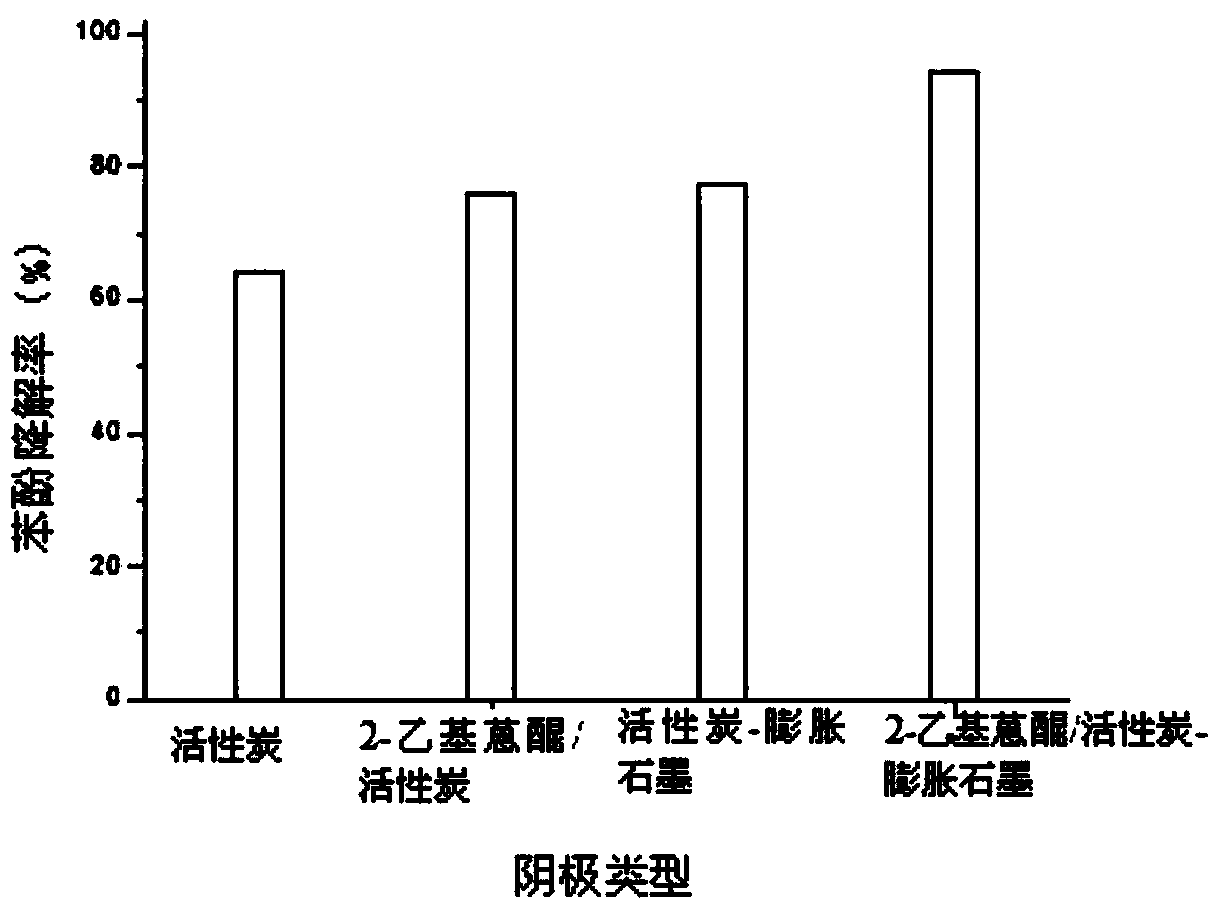

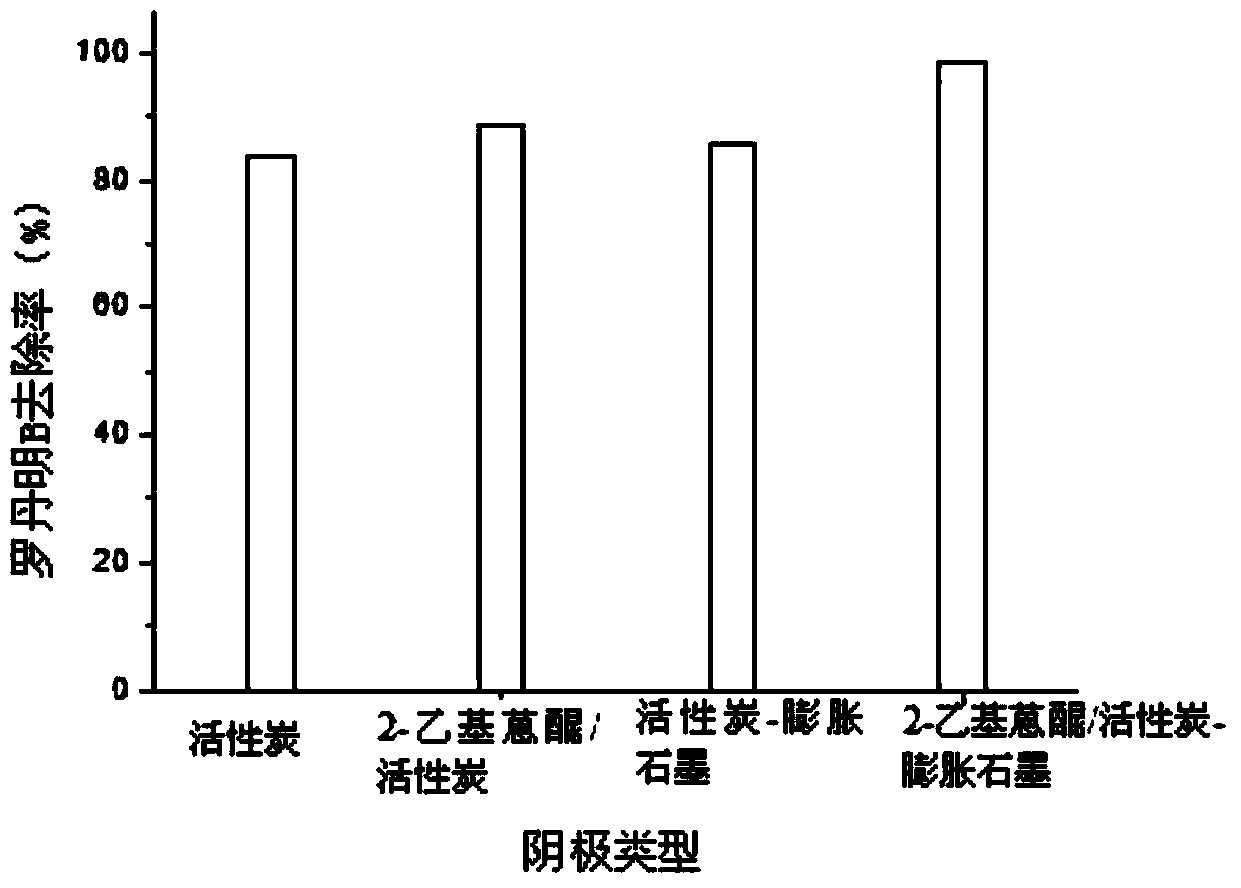

[0020] In this embodiment, 2-ethylanthraquinone and expanded graphite are used to modify the activated carbon electrode. In the non-diaphragm system, when the mass ratio of 2-ethylanthraquinone / activated carbon to expanded graphite is 3:1, the electrode ha...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the described expanded graphite is prepared according to the following steps: first mix 50 mesh-80 mesh natural flake graphite and potassium permanganate evenly, and then The mixture of natural flake graphite and potassium permanganate is added to perchloric acid under constant temperature water bath and stirring conditions of 30°C to 40°C, and reacted for 30min to 50min under constant temperature water bath conditions of 30°C to 40°C, wherein the The mass ratio of natural flake graphite and potassium permanganate is 2:(0.5~1.5), and the mass ratio of described potassium permanganate and perchloric acid is 1:(7~9); after the reaction is completed, the solid reaction obtained The product is soaked in distilled water and washed until the pH value of the filtrate is neutral to obtain the washed expandable graphite, and then dried at 80°C to 100°C for 12 hours to obtain the dried ...

specific Embodiment approach 3

[0023]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the activated carbon modified by 2-ethylanthraquinone is prepared according to the following steps: the activated carbon needs to be filtered through a 300-mesh sieve, and the retained sieve , get the sieved activated carbon, take the sieved activated carbon and soak it in the 2-ethylanthraquinone ethanol saturated solution for 8h~16h, get the activated carbon loaded with 2-ethylanthraquinone, and then wash it with absolute ethanol for 2~3 and then washed with distilled water for 3 to 5 times, after suction filtration, moved to a watch glass, put into an oven, and dried at a temperature of 80°C to 120°C for 2h to 3h to obtain 2-ethylanthraquinone modified Active carbon; the volume ratio of the mass of the sieved activated carbon to the saturated ethanol solution of 2-ethylanthraquinone is 1g: (50-150) mL. Others are the same as in the first or second embodiment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com