2-ethyl-anthraquinone modified gas diffusion electrode and preparation method thereof

An ethyl anthraquinone, diffusion electrode technology, applied in the field of 2-ethyl anthraquinone modified gas diffusion electrode and its preparation, can solve the influence of hydrogen peroxide reaction activity, transportation and storage increase cost, hydrogen peroxide reaction The problem of high activity is to avoid transportation, improve hydrophobicity, and achieve the effect of high reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

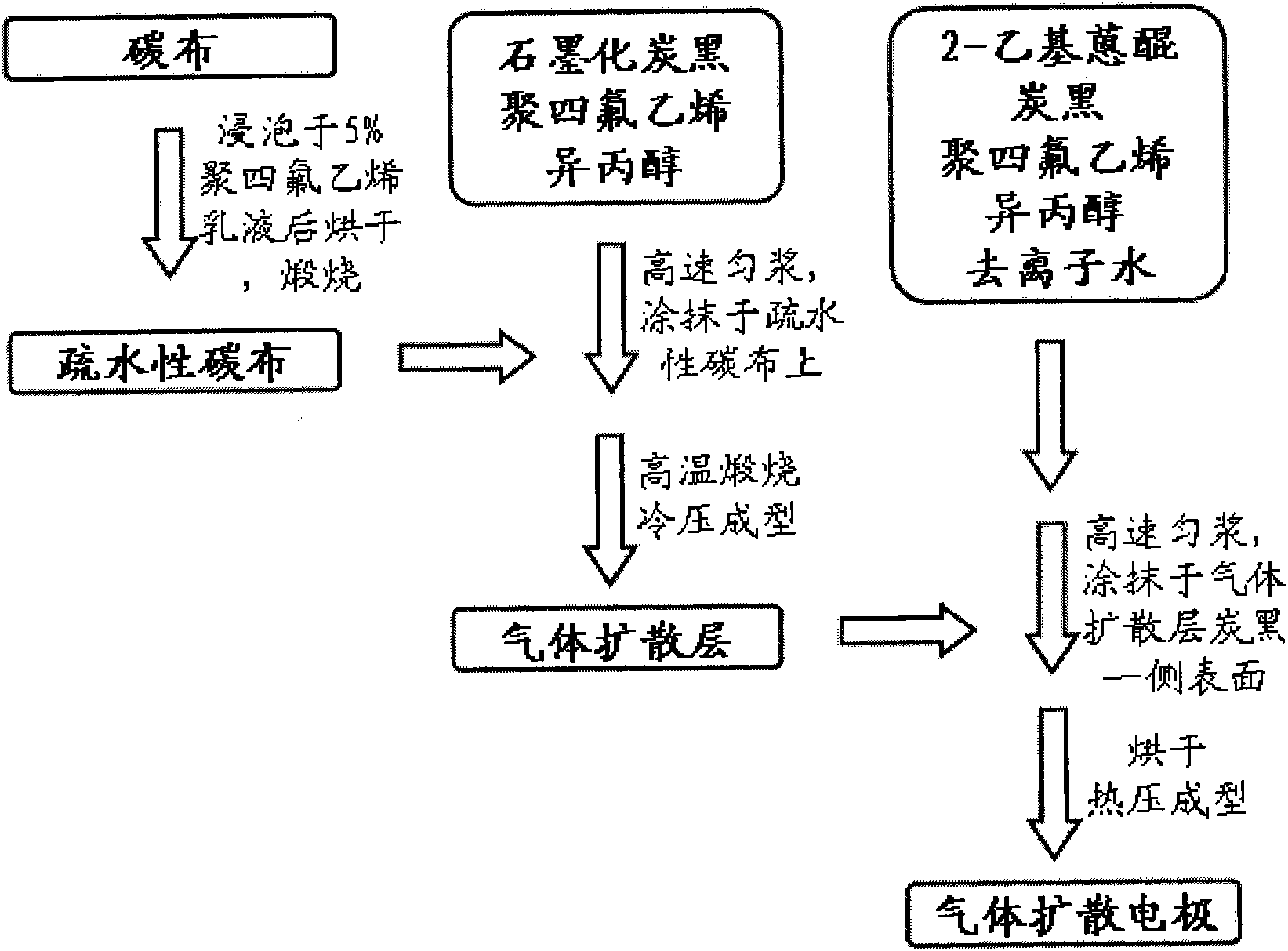

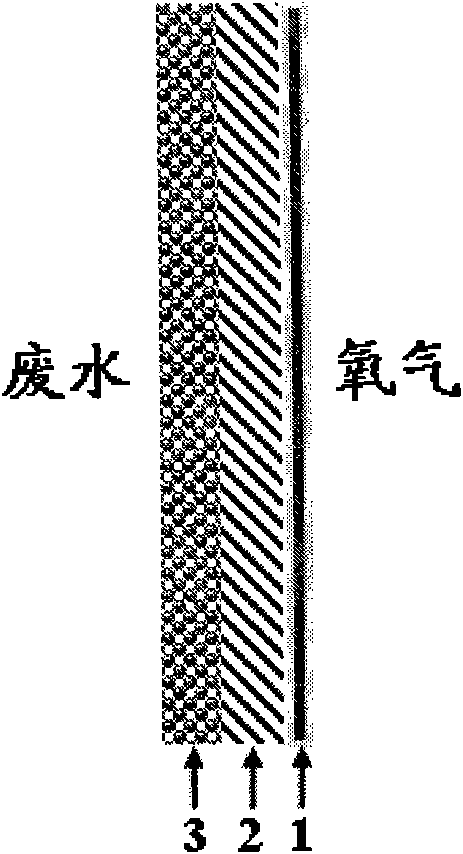

[0031] 1) Soak a 6cm*6cm carbon cloth in 5% polytetrafluoroethylene emulsion for 5 seconds, dry it at 80°C for 10 minutes and weigh it. Calcined for 3min to obtain a hydrophobic carbon cloth, and obtain a hydrophobic carbon cloth as a current collector and a support;

[0032] 2) Graphitize Vulcan 72 carbon black at 2800°C for 2 hours to obtain graphitized Vulcan 72 carbon black; weigh 0.36g of graphitized Vulcan 72 carbon black and dissolve it in 30ml of isopropanol (24g), then add 0.1ml After the polytetrafluoroethylene emulsion (0.15g) with a mass fraction of 60% is stirred evenly, it is spread on a 6cm*6cm hydrophobic carbon cloth, dried at 80°C for 1h, and calcined at 360°C for 3min in a muffle furnace , press on a hot press at 0.7MPa and room temperature for 30s to obtain a gas diffusion layer.

[0033] 3) The mixed solution of isopropanol and deionized water is used as a dispersant, the volume ratio of isopropanol to deionized water is 1:4, 0.045g 2-ethylanthraquinone a...

Embodiment 2

[0036] 1) Soak a 6cm*6cm carbon cloth in 5% polytetrafluoroethylene emulsion for 5 seconds, dry it at 80°C for 20 minutes and weigh it. Calcined for 4 minutes to obtain a hydrophobic carbon cloth as a current collector and a support.

[0037] 2) Vulcan 72 carbon black was graphitized at a high temperature of 2800° C. for 2 hours to obtain graphitized Vulcan 72 carbon black. Weigh 0.315g of graphitized Vulcan 72 carbon black and dissolve it in 40ml of isopropanol (32g), then add 0.18ml of 60% polytetrafluoroethylene emulsion (0.225g) by mass and stir evenly, then smear on 6cm* 6cm hydrophobic carbon cloth, dried at 80°C for 2h, calcined in a muffle furnace at 360°C for 4min, and pressed on a hot press at 1.4MPa and room temperature for 60s to obtain a gas diffusion layer.

[0038] 3) A mixed solution of isopropanol and deionized water is used as a dispersant, and the volume ratio of isopropanol to deionized water is 1:5. 0.09g 2-ethylanthraquinone and 0.315g Vulcan 72 carbon ...

Embodiment 3

[0040] 1) Soak a 6cm*6cm carbon cloth in 5% polytetrafluoroethylene emulsion for 5 seconds, dry it at 80°C for 20 minutes and weigh it. Calcined for 4 minutes to obtain a hydrophobic carbon cloth as a current collector and a support.

[0041] 2) Graphitize Vulcan 72 carbon black at 2800°C for 2 hours to obtain graphitized Vulcan 72 carbon black, weigh 0.315g of graphitized Vulcan 72 carbon black and dissolve it in 40ml of isopropanol (32g), then add 0.18ml The polytetrafluoroethylene emulsion (0.225g) with a mass fraction of 60% is stirred evenly, spread on a 6cm*6cm hydrophobic carbon cloth, dried at 80°C for 2h, and calcined at 360°C for 4min in a muffle furnace , pressed on a hot press at 1.4MPa and room temperature for 60s to obtain a gas diffusion layer.

[0042] 3) The mixed solution of isopropanol and deionized water is used as a dispersant, and the volume ratio of isopropanol to deionized water is 1:5, and 0.135g 2-ethylanthraquinone (the mass of 2-ethylanthraquinone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com