Treatment method of landfill leachate

A landfill leachate and treatment method technology, which is applied in the field of sewage treatment, can solve the problems of large dosage of Fenton's reagent, difficult-to-handle concentrated solution, and high equipment operating costs, and achieve direct emission standards, simple process technology, and saving chemicals cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The present invention is not limited by the following examples, and specific embodiments can be determined according to the content of the present invention and actual conditions.

[0027] The original landfill leachate is injected into the regulating tank with an effective volume of 2250 cubic meters, and the hydraulic retention time is 2.25 days. An underwater agitator is installed in the adjustment tank to prevent sedimentation.

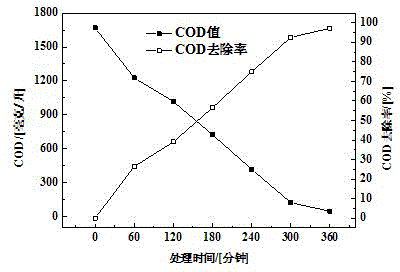

[0028]Use the submersible pump to lift the wastewater in the regulating tank to the distribution well of the anaerobic tank. The influent COD value is 10,000-20,000 mg / L, and anaerobic microorganisms are used to degrade organic matter in landfill leachate. The anaerobic pool is divided into 2 grids, the net size of each grid is 10.3m x 2.4m, the effective water depth is 3.5m, and the hydraulic retention ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com