Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "Three wastes are produced less" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

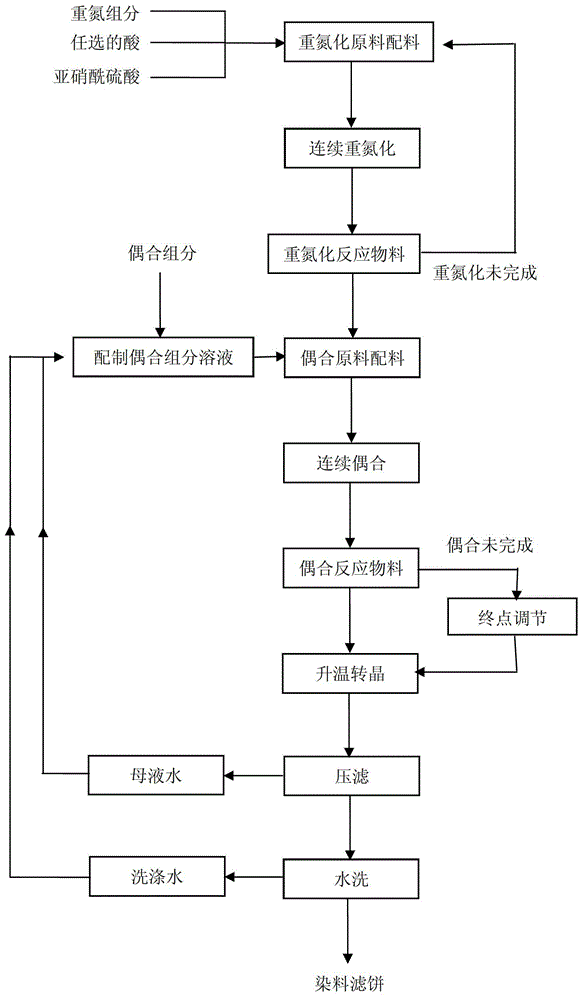

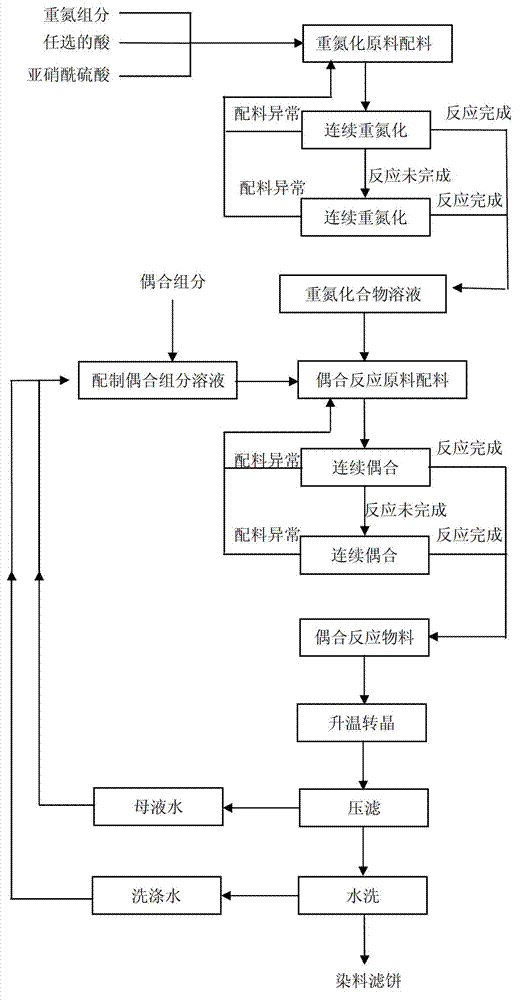

Method and device for continuously producing dyes

ActiveCN103146221ARealize automatic continuous productionThree wastes are produced lessMonoazo dyesWash waterReaction temperature

The invention discloses a method and a device for continuously producing dyes. The method comprises the following steps: adding diazotization reaction raw materials into an ingredient kettle, controlling temperature in the kettle, allowing the materials to flow in a tubular reactor through an overflow orifice, detecting the reaction state through an online detection device, continuously discharging the diazotization compound solution obtained through the reaction, continuously feeding the diazotization compound solution and a coupling component solution according to a specified ratio, allowing the materials to flow into the tubular reactor through the overflow orifice, detecting the reaction state through the online detection device, transferring the coupling reaction materials into a crystal transformation kettle, performing crystal transformation, and performing filter pressing to obtain a dye filter cake, wherein the filter cake mother solution and the wash water are circulated for preparing the coupling component solution. The reaction temperature, material flow and reaction state detection device are automatically subjected to interconnected control. According to the method, automatic and continuous dye production is realized, the production capacity, the product quality and yield are improved, the labor intensity and working conditions of workers are improved, the waste water, water gas and waste residue amounts in the dye production process are greatly reduced, and circular economy and cleaner production process are realized.

Owner:ZHEJIANG DIBANG CHEM

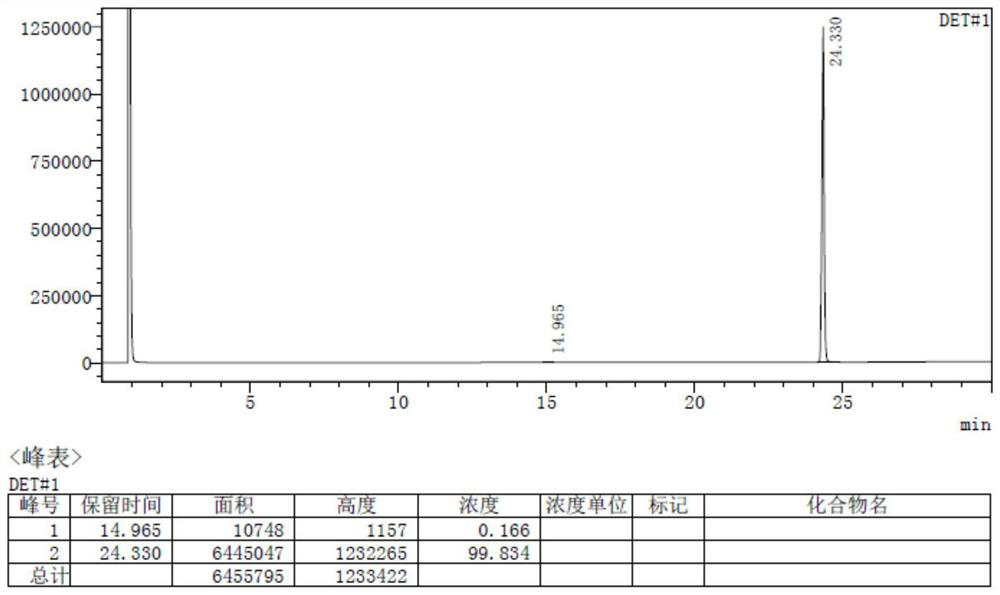

Preparation method of high purity trifluridine

InactiveCN106220699AReduce generationHigh puritySugar derivativesSugar derivatives preparationSodium methoxideTrimethylsilyl chloride

The invention provides a preparation method of high purity trifluridine. The method is as below: reacting a raw material of a compound 2 with HMDS under the action of trimethylchlorosilane to obtain a compound 3; subjecting the compound 3 and a compound 4 to condensation in the presence of a catalyst copper difluoride; conducting ethanol recrystallization to obtain a compound 5; and finally conducting deprotection on the compound 5 under the effect of sodium methylate; and recrystallizing by a mixed solvent of ethanol and acetone (1:1) to obtain the high purity object compound 1. The method has the advantages of high purity of the product, simpleness, easy purification and less industrial pollution.

Owner:HARVEST PHARMA HUNAN CO LTD

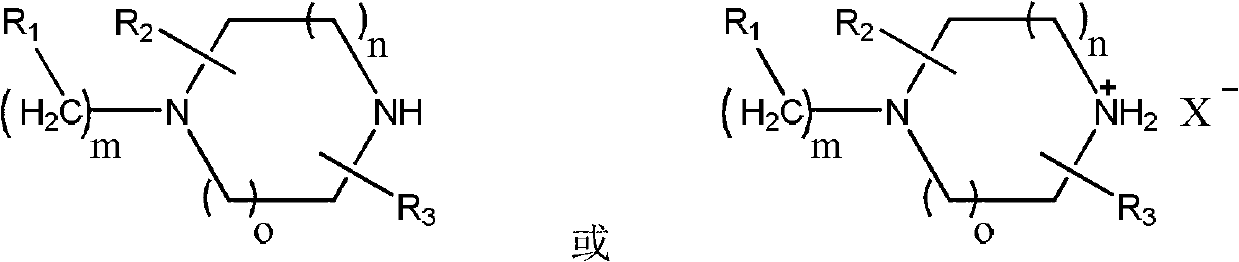

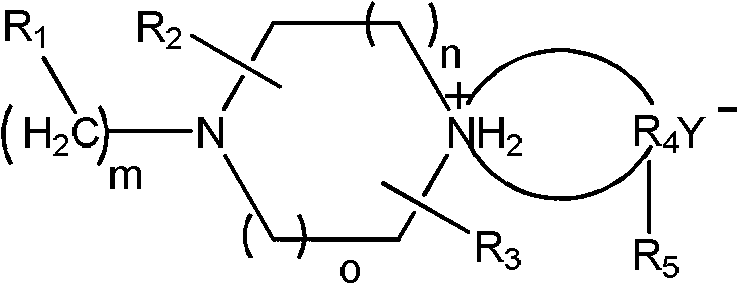

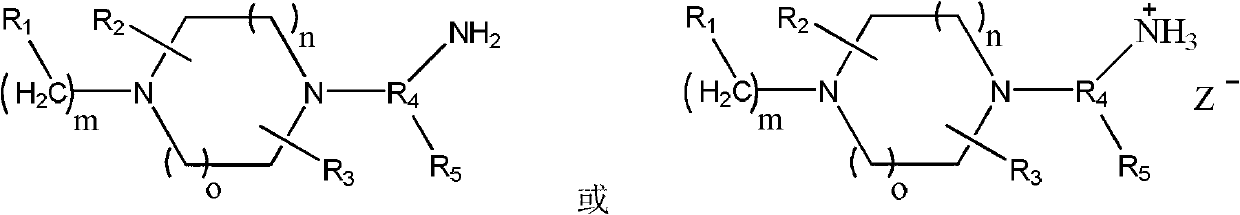

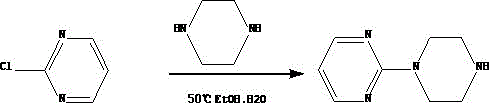

Preparation method of piperazine compound and intermediate thereof

InactiveCN102786497AEasy to separate and purifyHigh reaction yieldOrganic chemistryDiseasePiperazine

The invention discloses a preparation method of a piperazine compound and an intermediate thereof, belonging to the field of medicine synthesis. The compound and the intermediate thereof can be used for preparing medicines for treating central nervous system disease, such as analgetics, medicines for drug addiction, medicines for schizophrenia, medicines for parkinson disease, etc. The preparation method disclosed herein has the advantages of high reaction yield, short reaction time, easy obtainment and cheap raw materials, convenient product separation and purification, easy control of reaction, little generation of three wastes, low risk, etc. The piperazine compound has a wide application, thus the invention has a certain practical production meaning.

Owner:CHANGZHOU UNIV

Synthetic method of 2-cyanogroup-4-nitro-6-bromaniline diazosalt

ActiveCN101671272AReduce production processThree wastes are produced lessCarboxylic acid nitrile preparationOrganic compound preparationBromineChemistry

The invention relates to a synthetic method of 2-cyanogroup-4-nitro-6-bromaniline diazosalt, solving the technical problems of simple technique and operation, low requirement for production field andequipment, and low energy consumption and low 'three wastes'. The invention comprises the following steps: using o-cyanogroup paranitroaniline as a raw material, pulping in the sulphuric acid at the mass percent of 10% to 98%, adding brominated compound and oxidant for bromination, and directly diazotizing the mixture with the diazotized agent after bromination to obtain the product, wherein the molar ratio of o-cyano paranitroaniline sulphuric acid, brominated compound, oxidant and diazotized agent is 1:3.0 to 20.0:0.5 to 1.5:0.4 to 1.5:1.0 to 2.0.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

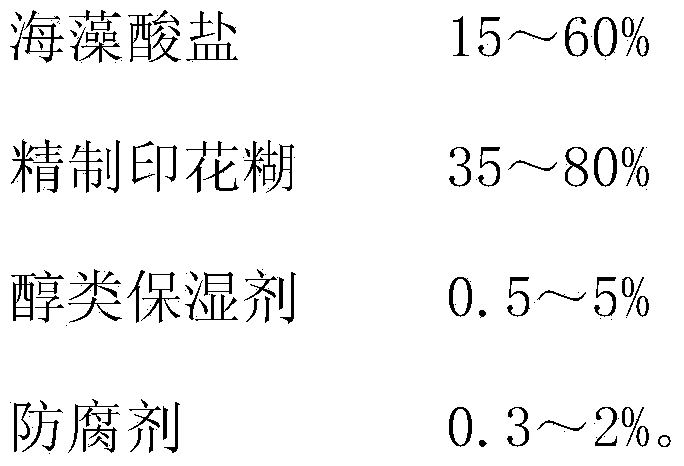

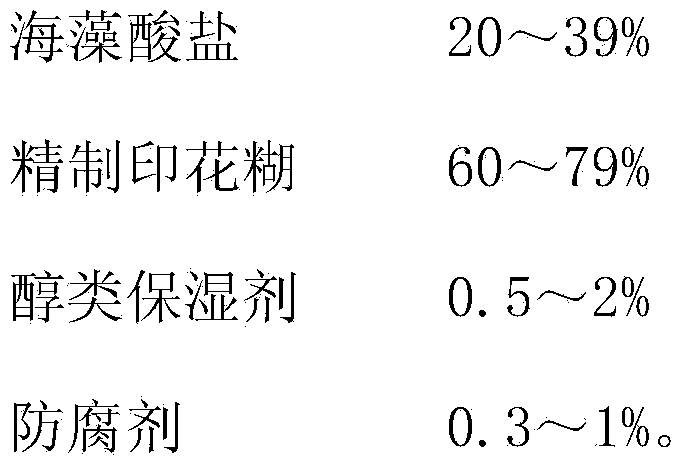

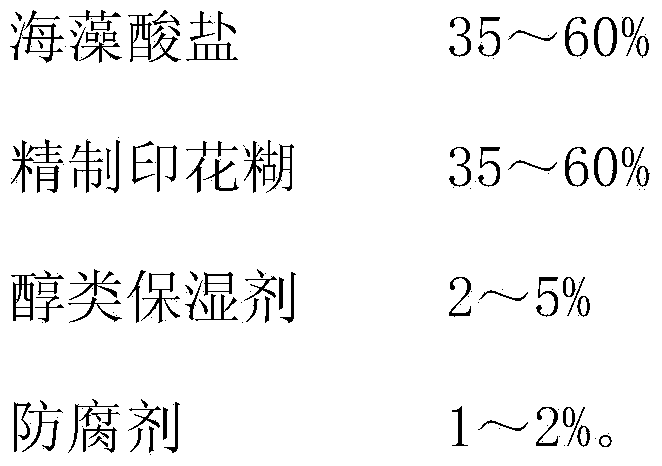

Reactive printing paste and production method thereof

The invention relates to the technical field of production methods and particularly relates to reactive printing paste and a production method thereof. The reactive printing paste comprises the following raw materials in percentage by mass: 15-60% of alginate, 35-80% of refined printing paste, 0.5-5% of an alcohol wetting agent and 0.3-2% of a preservative. According to the reactive printing paste, the raw material is less in consumption and low in cost, and the reactive printing paste is resistant to electrolyte and biodegradation, capable of increasing the color yield by 30% and greatly reducing the dye used later, beneficial to the reduction of three wastes and low in production and use costs. The preparation method of the reactive printing paste provided by the invention is simple in process, convenient to operate and beneficial to the scaled production.

Owner:DONGGUAN MILLSING CHEM SCI & TECH CO LTD

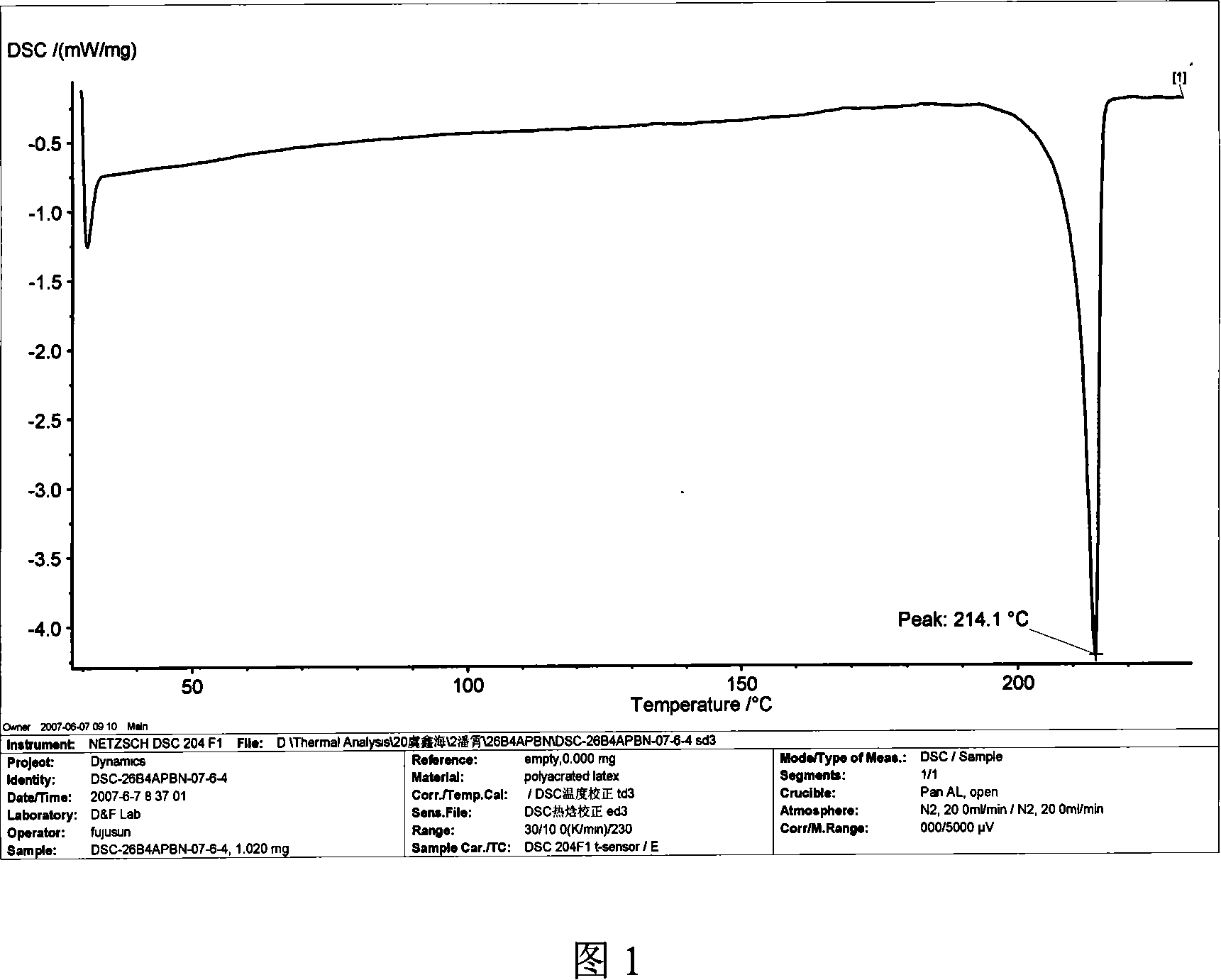

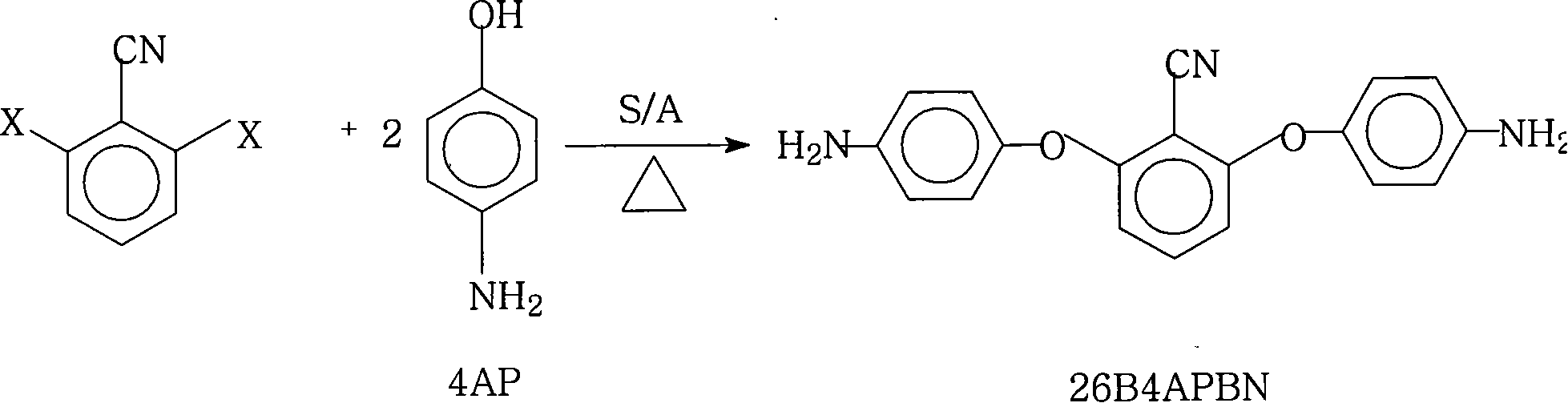

Method for preparing 2,6-di(4-amino-benzene oxygen) cyanobenzene

InactiveCN101117324ASimple manufacturing methodImprove working environmentCarboxylic acid nitrile preparationOrganic compound preparationBenzeneHalogen

The invention relates to a preparation process for 2, 6-bis(4-diaminophenoxy) benzonitrile. The invention comprises the following procedures: the p-aminophenol with mole ratios of 1.0:0.1 to 2.5 and the halogen agent are made a refluence reaction for 0.5 to 5 hours in organic solvent system under inertia atmosphere, and 2, 6-dihalogenated benzonitrile is added to react together for 3 to 12 hours at 170 to 200 DEG C, then the mixing solution are filtered and cleaned as well as dried in vacuum to obtain the brown 2, 6-bis(4-diaminophenoxy) benzonitrile solid product. The preparation process of the invention has simple process, low cost, environment-friendly feature, less energy consumption work hours, high yields and purity, and is suitable for industrialized production.

Owner:DONGHUA UNIV

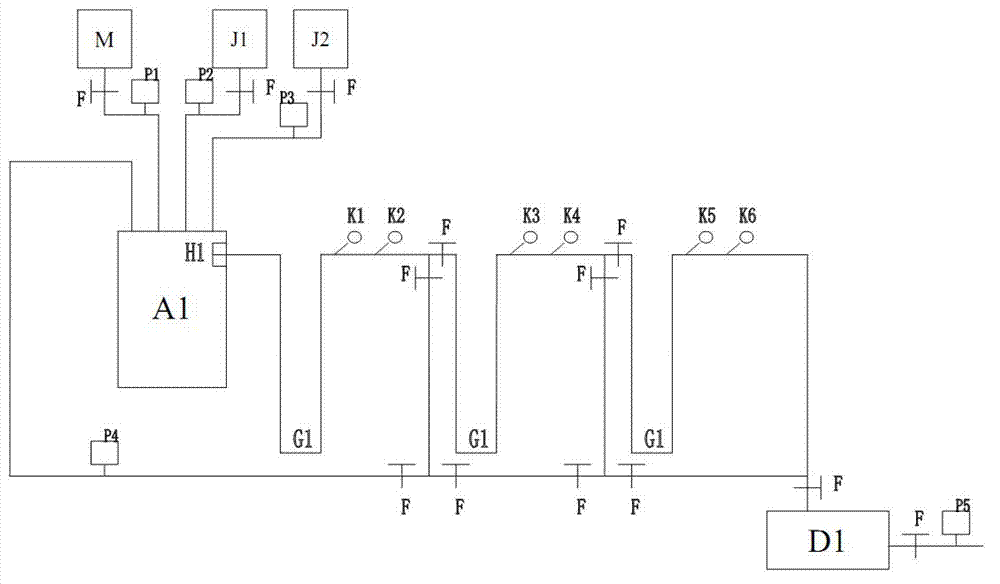

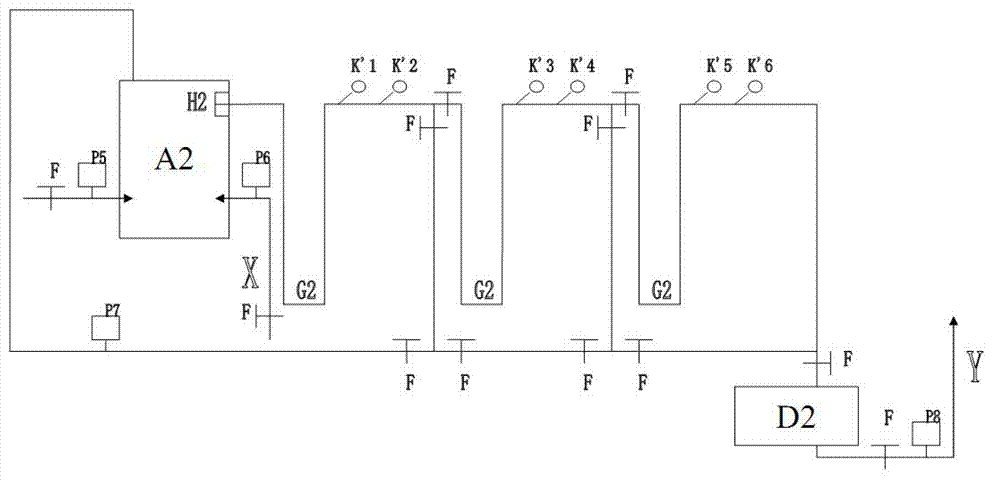

Method and device for automatic-control continuous production of dye

ActiveCN103160145ARealize low pollution and low consumptionAchieve economyMonoazo dyesAutomatic controlProcess engineering

The invention discloses a method and a device for automatic-control continuous production of dye. The method comprises that raw materials are metered, are continuously fed into a tubular reactor and undergo a reaction and the products are discharged continuously. The device is characterized in that a reactor is provided with multiple reaction state detection devices; through multipoint automatic control, the reaction liquid obtained by the reaction is timely transferred to a next process; and abnormal materials in blending are timely pumped back to a blending kettle and then are re-blended. The method and the device realize accurate and automatic-control continuous production of dye, guarantee stable product quality, shorten production time, improve production efficiency, reduce a production cost, reduce three wastes, realize pollution and energy consumption reduction, and realize recycling economy and clean production.

Owner:ZHEJIANG DIBANG CHEM

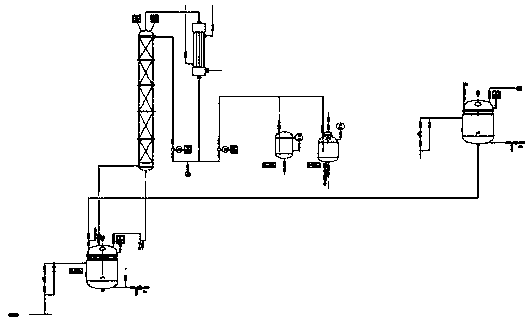

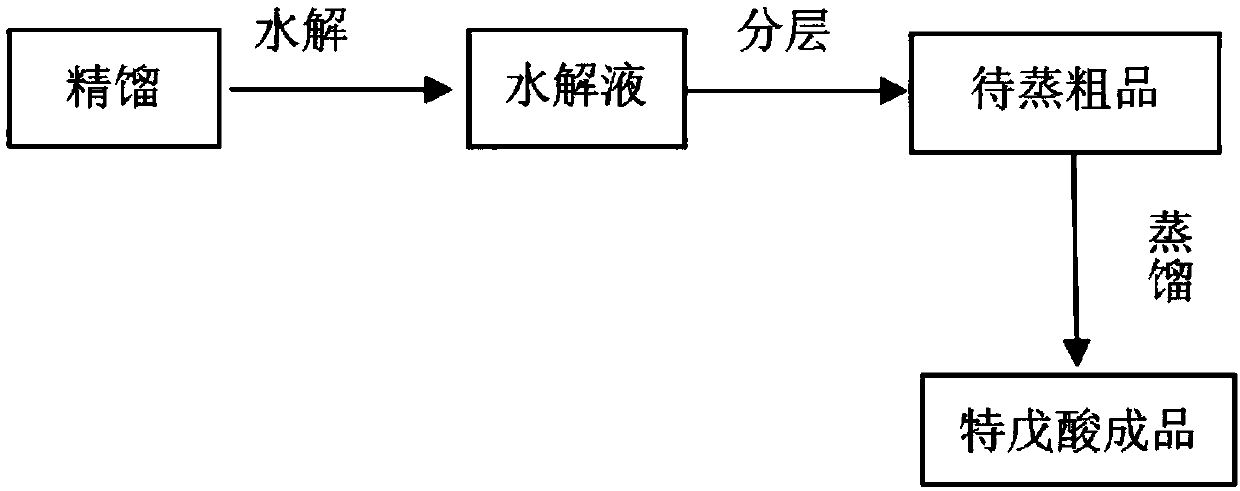

Method for recycling trimethylacetic acid from pivaloyl chloride rectification raffinate

PendingCN107721841AIncrease profitReduce pressure on environmental protectionPreparation from carboxylic acid halidePreparation from carboxylic acid anhydridesPhosphorous acidRaffinate

The invention provides a method for recycling trimethylacetic acid from pivaloyl chloride rectification raffinate. According to the technical scheme, the method has the experiment ideas that components and contents of pivaloyl chloride rectification raffinate are analyzed firstly on the basis of experiment means, on the basis, procedures such as hydrolysis, layering and rectification are confirmedaccording to chemical properties of pivaloyl chloride and trimethylacetic anhydride, and trimethylacetic acid is recycled. Specifically, the method comprises the following steps: firstly, adding a certain amount of pivaloyl chloride rectification raffinate, controlling specific temperature and pressure, adding a proper amount of water for hydrolysis reactions for multiple times to sequentially convert pivaloyl chloride and trimethylacetic anhydride into trimethylacetic acid, leaving to stand to layer water-containing phosphorous acid and a crude trimethylacetic acid product, feeding back thecrude trimethylacetic acid product to a trimethylacetic acid rectification procedure, and performing decoloring refining. By adopting the method provided by the invention, more than 90% of the pivaloyl chloride rectification raffinate can be converted into trimethylacetic acid, so that the utilization rates of raw materials are increased, the wastes are reduced, the environment protection burden of companies is alleviated, and meanwhile the production cost of products is effectively reduced.

Owner:山东民基新材料科技有限公司

Method for preparing 4-methyl nitrobenzene-2-sulfonic acid self-polycondensation dye liquid color paste

InactiveCN101805527ANarrowing the degree of polymerization distributionImprove stabilityAzo dyesTetramethylammonium hydroxideHigh concentration

The invention discloses a method for preparing 4-methyl nitrobenzene-2-sulfonic acid self-polycondensation dye liquid color paste, comprising the following steps of: dissolving 4-methyl nitrobenzene-2-sulfonic acid group methylbenzene into mixed solution of triethanolamine and diethylene glycol monomethylet, dropwise adding sodium hydroxide water solution into the mixed solution with high concentration to react and obtain an alkali coarse toning phase polycondensation reaction liquid; dropwise adding sodium hydroxide water solution into the mixed solution with low concentration to the alkali crude toning phase polycondensation reaction liquid to obtain an alkali fine toning phase polycondensation reaction liquid; adding water into the alkali fine toning phase polycondensation reaction liquid to react and obtain an alkalinity-reducing polycondensation reaction liquid; and adding ethylene glycol methyl ether into the alkalinity-reducing polycondensation reaction liquid for diluting, regulating pH by using NaHSO4 and regulating pH by using tetramethylammonium hydroxide water solution, recycling ethylene glycol methyl ether through condensing a filtering liquid after filtering to obtain the 4-methyl nitrobenzene-2-sulfonic acid self-polycondensation dye liquid color paste. The invention has the advantages of less three-waste generation, low production cost, simple process and easy control.

Owner:TIANJIN UNIV

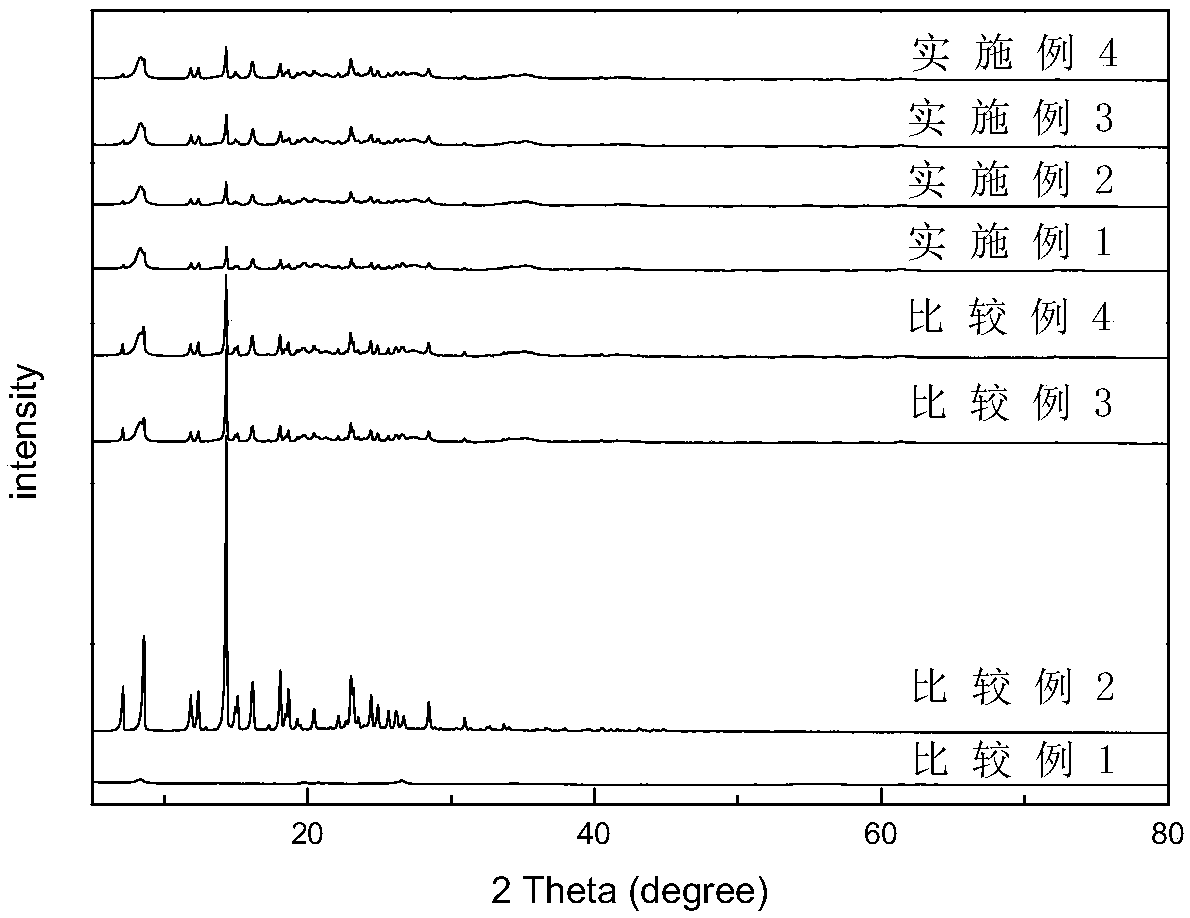

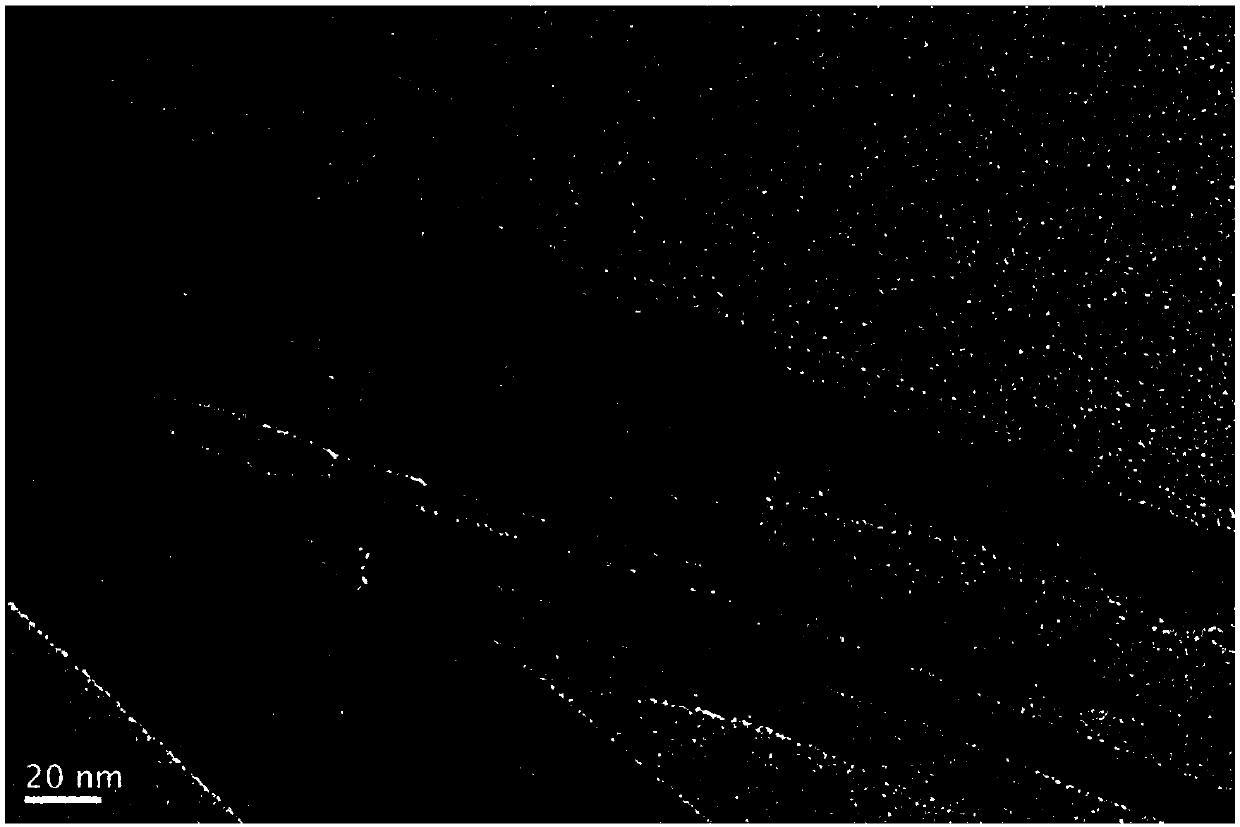

Preparation technology of ultrafine copper powder

The invention provides a preparation technology of ultrafine copper powder. The preparation technology comprises the steps of mixing copper salt and ethylene glycol, and adding alkaline liquid to prepare a mixed solution with the copper concentration being 10-100g / L; heating the mixed solution to 150-250 DEG C, performing condensing backflow on volatilized ethylene glycol steam at the temperature of 100-150 DEG C, performing condensing recycling on residual ethylene glycol steam at the temperature of 20-30 DEG C for reaction for 1-10 hours; and performing solid-liquid separation and washing on reactants, and performing vacuum drying at the temperature of 50-100 DEG C to prepare the ultrafine copper powder. The technology is low in cost and simple in flow; the obtained ultrafine copper powder is small in particle size, the particle size is 0.3-1.5 microns, and the particle size distribution is narrow.

Owner:夏正付

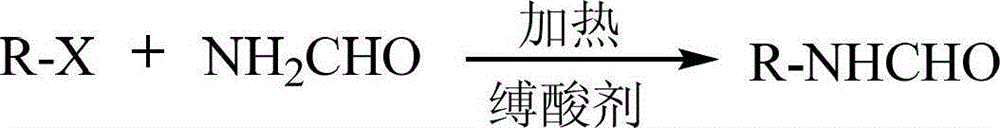

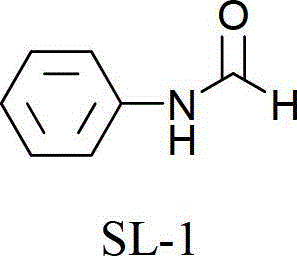

Preparation method of N-formamide compound

InactiveCN102942500ALow priceEasy to operateOrganic compound preparationCarboxylic acid amides preparationFormamideSubstance amount

The invention relates to a preparation method of N-formamide compounds, which comprises the following steps of: using halides and formamide as raw materials, reacting under the heating backflow for 3-10 hours under the conditions of solvent or no solvent, acid-binding agent and catalyst or no catalyst, and after reaction, conducting post-treatment such as extraction to reaction liquid to obtain the N-formamide compounds, wherein the ratio of amount of substance of the halides to amount of substance of the formamide is 1: (1-100) and the reaction is preferably conducted under the condition of no solvent. The preparation method provided by the invention has the advantages of high yield, convenience in post-treatment, low catalyst cost, simpleness in operation, moderate condition, easiness in reaction control, smaller quantity of three kinds of produced wastes (waste gas, waste water and waste residue), small risk and the like, and is suitable for industrial production.

Owner:CHANGZHOU UNIV

The preparation method of two [propyltriethoxysilane] disulfide

ActiveCN103772427BWide variety of sourcesLarge industrial production operation safetyGroup 4/14 element organic compoundsPtru catalystOrganic solvent

The object of the present invention is to provide a kind of method that does not contain buffering agent and synthesizes two [propyltriethoxysilane] disulfides under aqueous phase conditions, comprising the following steps: A, making sodium polysulfide aqueous solution, chloropropane Base triethoxysilane reacts under the aqueous phase condition of phase-transfer catalyst and water-insoluble organic solvent, produces reaction mixture; B, separates two [propyl triethoxysilane] disulfides from above-mentioned reaction mixture . The method for separating the product bis[propyltriethoxysilane] disulfide from the reaction mixture in the step B comprises the following steps: a, organic phase separation: the upper layer of the reaction mixture obtained in step A is an organic phase, and the lower layer is water phase, separate the organic phase; b, purify the organic phase: distill and purify the above organic phase to obtain the product bis[propyltriethoxysilane] disulfide. Using the method of the invention improves the yield, reduces the generation of three wastes, and eases the pressure on environmental protection.

Owner:南京曙光新材料有限公司

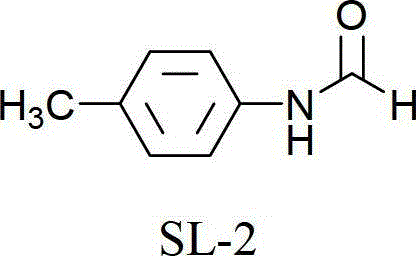

Synthesis process of hexamethylenediamine piperidine

InactiveCN111825602AReduce generationImprove responseOrganic chemistryChemical recyclingPtru catalystHexamethylenediamine

The invention relates to a synthesis process of hexamethylenediamine piperidine. The process comprises the steps of: carrying out heating dehydration reaction on 2, 2, 6, 6-tetramethyl-4-piperidone and 1, 6-hexamethylenediamine in a negative pressure environment until no water is removed from the system, and adding a water removing agent to separate the residual water from the liquid system so asto obtain an intermediate Schiff base; introducing hydrogen into the obtained Schiff base in the presence of a catalyst for hydrogenation reaction to obtain hydrogenation liquid; and filtering out thecatalyst from the hydrogenation liquid, rectifying the filtrate, and carrying out crystallization-desolvation to obtain the hexamethylenediamine piperidine finished product. According to the method,a small amount of residual water is removed by using the water removal agent, so that the Schiff base is prevented from being decomposed in the presence of trace water, the purity of the Schiff base is improved, the yield of hexamethylenediamine piperidine is increased, and few solid wastes are generated; according to the method, negative pressure reaction and crystallization treatment are innovatively adopted, so that the quality of hexamethylenediamine piperidine is high, the solvent can be continuously recycled and reused, and no organic waste liquid is generated.

Owner:江苏富比亚化学品有限公司

Method for preparing 4-trifluoromethylphenyl piperazine

InactiveCN102060712AHigh reaction yieldIncrease contentOrganic compound preparationAmino compound preparationTrifluoromethylphenylpiperazineN-Butyl Alcohol

The invention relates to a method for preparing 4-trifluoromethylphenyl piperazine, which comprises the following steps of: firstly, reacting diethanol amine with thionyl chloride to obtain bis(2-chloroethyl)amine, reacting 4-trifluoromethylaniline with bis(2-chloroethyl)amine in normal butanol or diethylene glycol monomethyl ether under the heating condition to obtain 4-trifluoromethylphenyl piperazine hydrochloride, and neutralizing with an alkaline to obtain the 4-trifluoromethylphenyl piperazine. The method for preparing the 4-trifluoromethylphenyl piperazine has the advantages of high reaction yield, less production of three wastes, easy reaction control, small production danger, simple product purification, high content and the like.

Owner:天津均凯农业科技有限公司

Preparation method of attapulgite-based full-wave-band ultraviolet shielding material

ActiveCN107722362AAvoid reunionLow priceCosmetic preparationsToilet preparationsAcetic acidFull wave

The invention belongs to the technical field of preparation of materials with protection functions, and particularly relates to a preparation method of an attapulgite-based full-wave-band ultravioletshielding material. The preparation method comprises the steps that a cation surfactant solution is added into attapulgite slurry, then a coupling agent solution is added, full mixing and heat-preservation curing are conducted, and organic surface-modified attapulgite is prepared; obtained attapulgite is dispersed in ethyl acetate, MBBT is added, full mixing and heating are conducted to remove ethyl acetate, and the ATPatMBBT composite material, namely the attapulgite-based full-wave-band ultraviolet shielding material, is obtained.

Owner:常州大学盱眙凹土研发中心

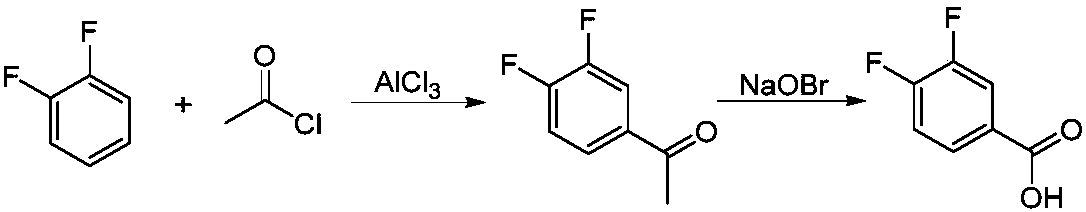

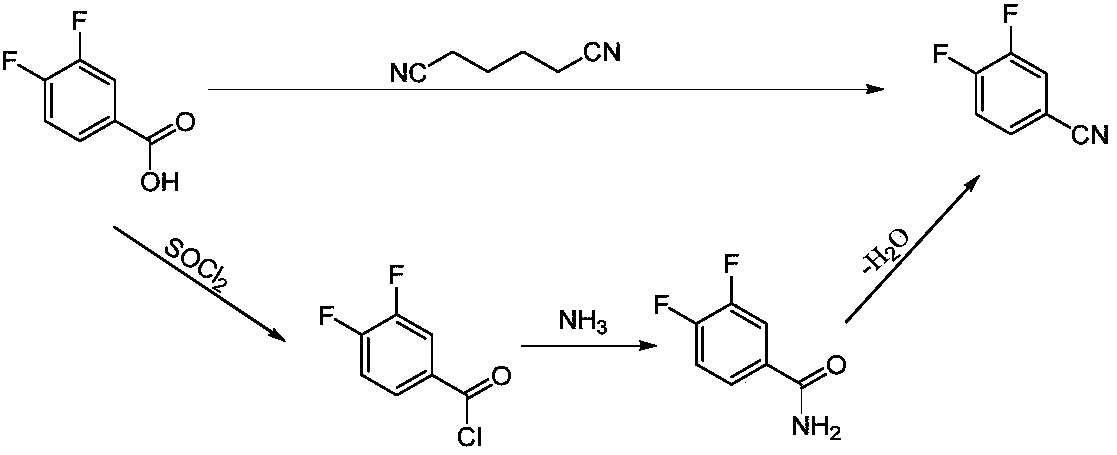

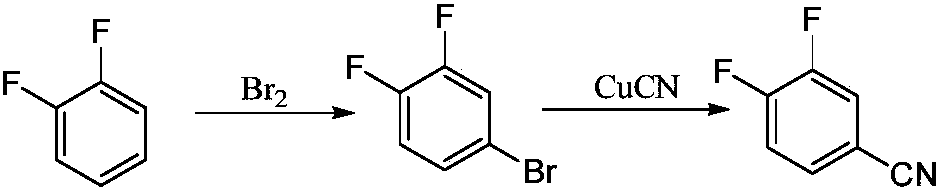

3,4-difluorobenzonitrile preparation method

ActiveCN108409605AHigh activityLow reaction temperatureCarboxylic acid nitrile preparationOrganic compound preparationPotassium fluoridePotassium

The invention discloses a 3,4-difluorobenzonitrile preparation method. The 3,4-difluorobenzonitrile preparation method comprises the following steps of taking 3,4-difluorobenzonitrile as a raw material, potassium fluoride as a fluorinated reagent and bis-(N,N'-1,3-dimethyl-2-imidazolinyl)-chloride ammonium salt as a phase transfer catalyst, then adding a reducing agent and a dispersant, and performing reaction to prepare the 3,4-difluorobenzonitrile. In the method, the temperature of fluorination reaction is relatively low, the reaction time is short, the total molar yield can reach about 90 percent, and the solvents and the catalyst can be recycled; produced potassium chloride in reaction becomes a pure product with the purity being 99 percent or above after recrystallization, and the pure product can be directly sold, so that the production cost is reduced; in addition, the technology is safe and environmentally friendly, is small in quantities of three wastes (waste water, waste solid and waste gas) and is suitable for industrial production.

Owner:江苏丰山生化科技有限公司

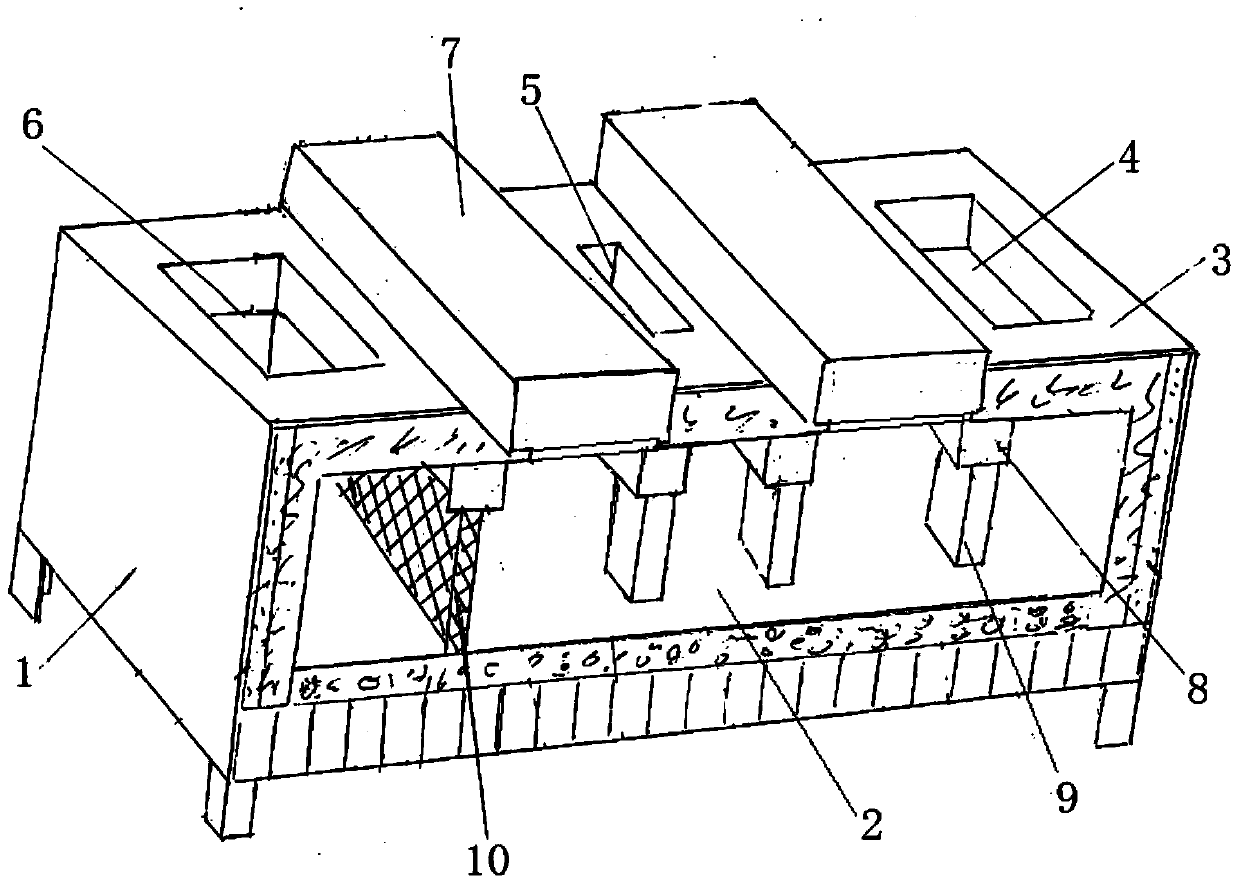

Aluminum melting insulating connecting furnace

InactiveCN103438706AReduce consumptionReduce pollutionFurnace componentsCrucible furnacesResource consumptionWastewater

The invention belongs to the technical field of aluminum melting insulating furnaces, in particular to an aluminum melting insulating connecting furnace. The aluminum melting insulating connecting furnace comprises a box body which is internally provided with a cuboid aluminum melting insulating pool. A plurality of molten aluminum partition blocks are arranged at the upper end inside the aluminum melting insulating pool at intervals, the upper end of the box body is provided with an integrated upper cover, and a charging port, a gas vent and a liquid taking port are formed in the upper cover. A ceramic filtering plate is arranged on one side inside the aluminum melting insulating pool below the liquid taking port, and a plurality of electric heating devices are arranged on the box body. According to the aluminum melting insulating connecting furnace, thermal loss can be effectively reduced, the insulating effect is improved, energy consumption is reduced, production cost is saved, industrial wastewater, waste gases and residues are reduced, and energy and resource consumption of the society is reduced, the environment is protected, and the atmosphere pollution is reduced.

Owner:TIANJIN YAXING METAL DIE CASTING

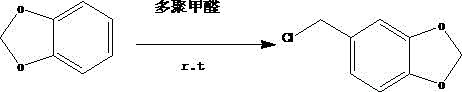

Synthetic method of piribedil

ActiveCN106432212AIncrease profitThe synthesis steps are simpleOrganic chemistryAfter treatmentParaformaldehyde

The invention relates to a synthetic method of piribedil. The synthetic method is a brand new process comprising the steps of synthesizing piperonyl piperazine in one step under the effects of pentamethyleneamine, piperazine pyrimidine and paraformaldehyde, and reacting by virtue of piperonyl piperazine and dichloropyrimidine so as to synthesize piribedil. Piperonyl piperazine has not been synthesized by virtue of the synthetic method before. Compared with a traditional synthetic method of piribedil, the synthetic method has the advantages that synthetic steps are simplified, the three wastes are reduced, the utilization ratio of pentamethyleneamine is remarkably increased, and the after-treatment is relatively environment-friendly.

Owner:SUZHOU HOMESUN PHARMA

A method of continuously preparing 3,5,5-trimethyl-3-cyclohexene-1-one

ActiveCN104761443APromote regenerationEasy to recycleOrganic compound preparationChemical industryIsomerization2 cyclohexene 1 one

The invention relates to a method of continuously preparing 3,5,5-trimethyl-3-cyclohexene-1-one (beta-isophorone) by utilization of a heterogeneous catalyst. 3,5,5-trimethyl-2-cyclohexene-1-one is adopted as a raw material, and is subjected to an isomerization reaction by adoption of a reactive distillation column under conditions of a solid alkali catalyst without adding other organic alkalis to obtain the 3,5,5-trimethyl-3-cyclohexene-1-one. The method has advantages of high conversion ratio, good selectivity, less heavy components, easy catalyst recovery, and the like and is a green synthetic process.

Owner:WANHUA CHEM GRP CO LTD

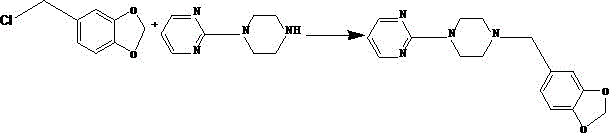

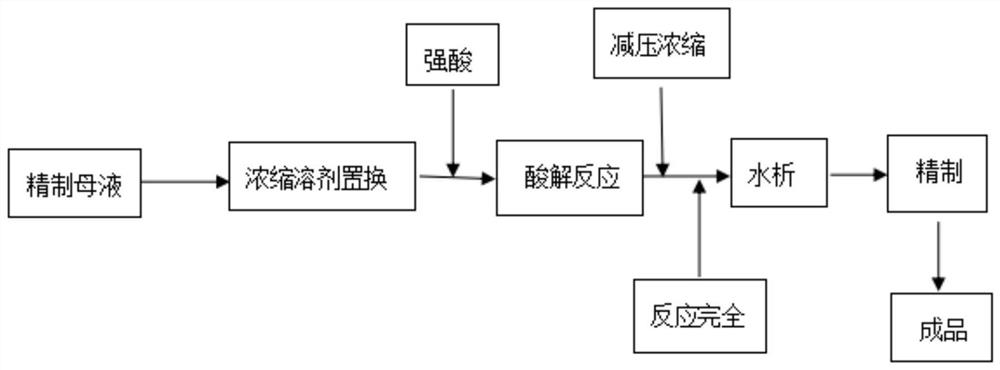

Preparation method of dienogest and method for recovering dienogest from dienogest mother liquor

The invention belongs to the technical field of steroid hormone drug preparation, and particularly relates to a preparation method of dienogest and a method for recovering the dienogest from dienogestmother liquor. The preparation method of the dienogest comprises the following steps: dissolving 17 alpha-cyanomethyl-17 beta-hydroxyl-5, 9-androstane diene-3, 17-diketone-3,3-ethyleneketal, adding fluoboric acid, carrying out acidolysis to remove protection, and after the reaction is completed, carrying out treatment to obtain the dinogestrol. The method for recovering the dienogestrol from thedienogestrol mother liquor comprises the following steps: dissolving the dienogestrol with a solvent to obtain the dienogestrol mother liquor, adding perchloric acid or concentrated hydrochloric acid,reacting for a period of time, heating to 45-55 DEG C, concentrating under reduced pressure, removing part of the solvent by concentrating until a solid is separated out, stopping concentrating, cooling, continuing the reaction, and treating to obtain the dienogestrol. The product provided by the invention has high purity and high yield.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

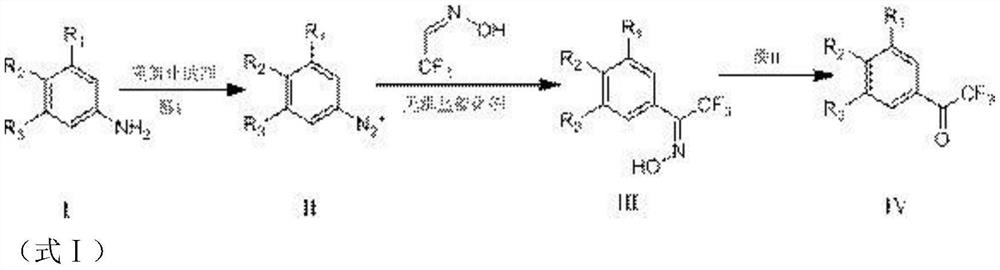

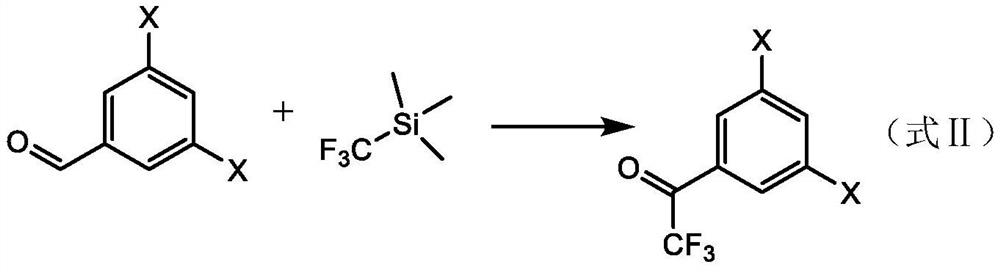

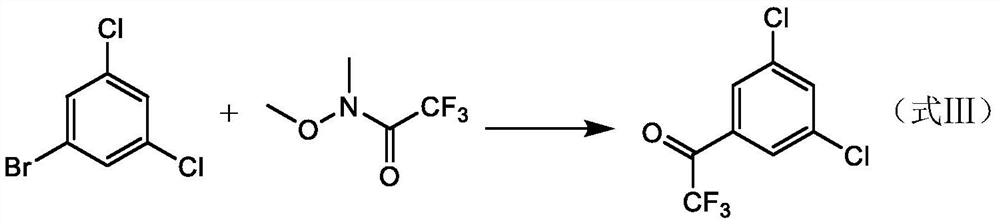

Preparation method of trifluoroacetophenone derivative

PendingCN113461503ARaw materials are easy to obtainShort reaction processOrganic compound preparationOximes preparationOrganic synthesisCombinatorial chemistry

The invention relates to the field of organic synthesis, in particular to a preparation method of a trifluoroacetophenone derivative. Substituted aniline is used as a raw material, and preparation of the trifluoroacetophenone derivative is completed through three steps including diazotization reaction, coupling reaction and hydrolysis reaction. The preparation method has the advantages of simple process, high yield and less three wastes generated by the whole reaction, and is suitable for large-scale industrial production.

Owner:TAIZHOU ABSOBIOTEC CO LTD

Method for preparing 5-acetoxyl-3-indole carboxylic acid ethyl ester

A method for preparing 5-acetoxyl-3-indole carboxylic acid ethyl ester. The invention relates to a method for preparing the 5-acetoxyl-3-indole carboxylic acid ethyl ester which is a key intermediate of a widely-used antiviral drug Arbidol Hydrochloride. The method successively comprises the following steps that, by using 3-chlorine-4-nitrophenol as raw materials, phenolic hydroxyl groups are reacted with an acetylation reagent, then products obtained are subjected to a substitution reaction with sodium salt of malonate, and at last a hydrogenated cyclization reaction is carried out under pressurized conditions to get the 5-acetoxyl-3-indole carboxylic acid ethyl ester. The method provides a novel synthesizing route, and has advantages of concise steps, simple technology and cheap and easily-available raw materials. Each reaction step is relatively conventional operations and production cost can be effectively reduced.

Owner:ZHEJIANG GENEBEST PHARMA

Preparation method of 4-nitro-3-trifluoromethylaniline

InactiveCN102093229ALess impuritiesHigh reaction yieldOrganic compound preparationAmino compound preparationAnilineProtic solvent

The invention provides a preparation method of 4-nitro-3-trifluoromethylaniline. The preparation method comprises the following steps: nitrifying m-trifluoromethyl)phenyl]acetamide obtained by reacting m-(trifluoromethyl)aniline with acetylchloride in a non-protic solvent so as to obtain 4-nitro-3-trifluoromethylacetanilide; and removing acetyl protection in ethanol solution by potassium carbonate so as to obtain the 4-nitro-3-trifluoromethylaniline. The preparation method has the advantages that reaction yield is high, generated three wastes are less, reaction is easy to control, impurities in product position positional isomers are less, yield is high, rectification is simple and the like.

Owner:天津均凯农业科技有限公司

Preparation method for N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine

ActiveCN104744273AHigh yieldHigh purityOrganic compound preparationAmino-hyroxy compound preparationNitrophenolEthyl ester

The invention relates to a preparation method for N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine. The preparation method comprises the following steps: mixing 2-amino-5-nitrophenol used as a raw material with an alkali and a solvent, then adding a hydroxyethylation reagent, and reacting at certain pressure and temperature to generate 2-(3-nitro-6-aminophenoxy) ethanol; and then reacting 2-(3-nitro-6-aminophenoxy) ethanol with chloroethyl chloroformate under the action of a catalyst, and obtaining N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine through condensation and hydrolysis. The N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine disclosed by the invention has the advantages of being high in yield, high in purity, good in quality, moderate in production process, less in three-waste generation, and the like; the preparation method disclosed by the invention is economical and environmentally friendly, and suitable for industrialized production.

Owner:ZHEJIANG DINGLONG TECH

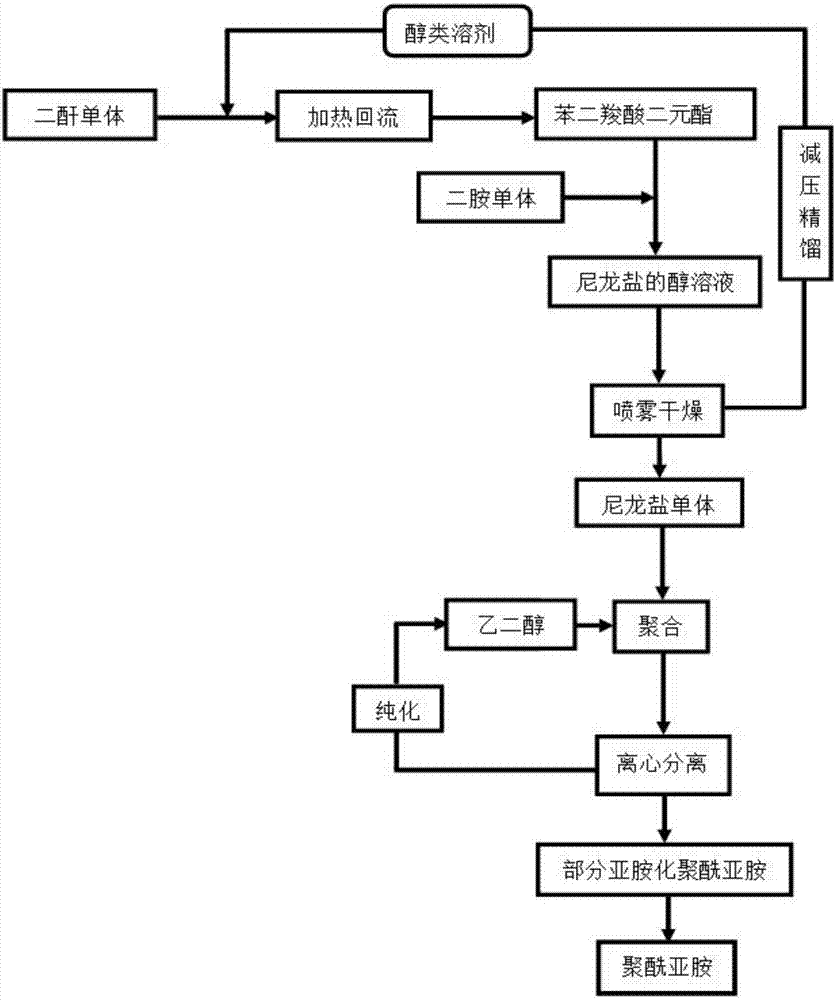

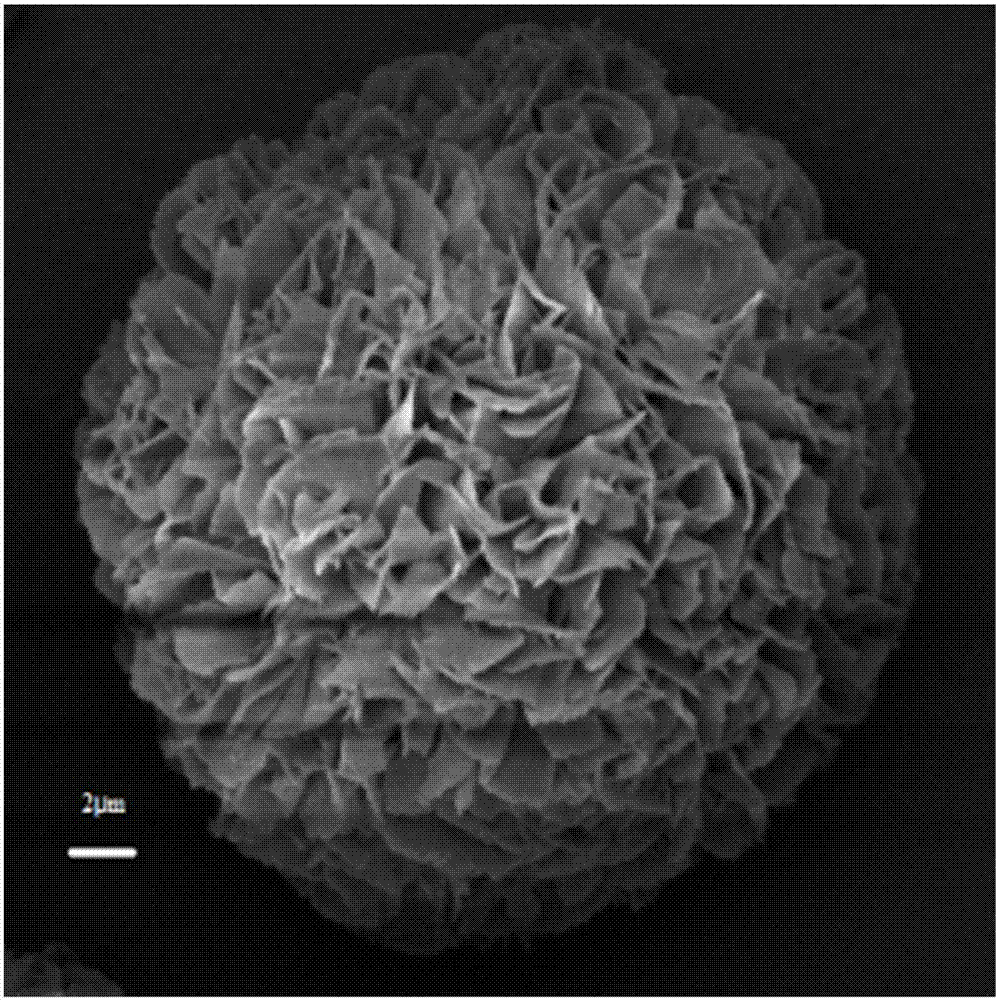

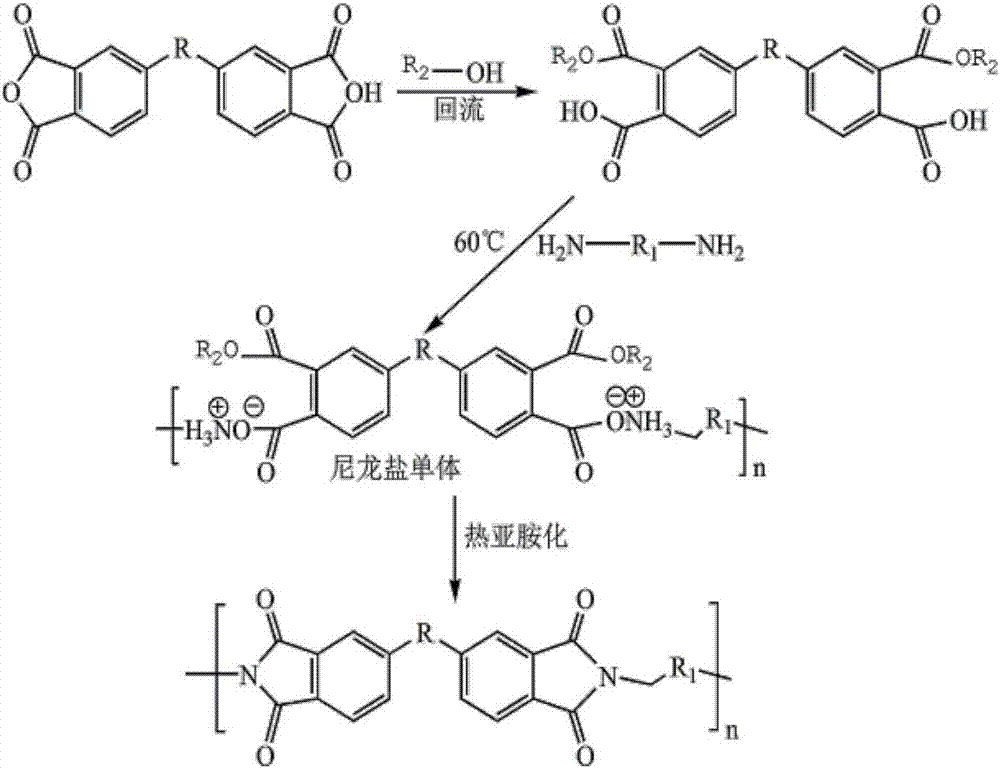

Synthesis method of flower-like structure polyimide

The invention discloses a synthesis method of flower-like structure polyimide. The method comprises the following steps of (1) carrying out esterification reaction on a dianhydride monomer and alcohol to obtain aromatic tetrabasic acid dibasic ester; (2) obtaining a pyrazinecarboxamide salt of dibasic ester from a dianhydride monomer and the aromatic tetrabasic acid dibasic ester; (3) carrying out spray drying on the pyrazinecarboxamide salt of the dibasic ester to obtain a white powder solid; (4) adding the white powder solid to dihydric alcohol, raising the temperature and carrying out heat preservation reaction in a nitrogen atmosphere to obtain a product a; (5) centrifugally separating the product a, and washing the solid product by adopting an eluent; and (6) drying the washed solid product in the nitrogen atmosphere to obtain the flower-like structure polyimide. The method is a novel method and way for simply, efficiently and quickly preparing the flower-like structure polyimide, and the method has important application value.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

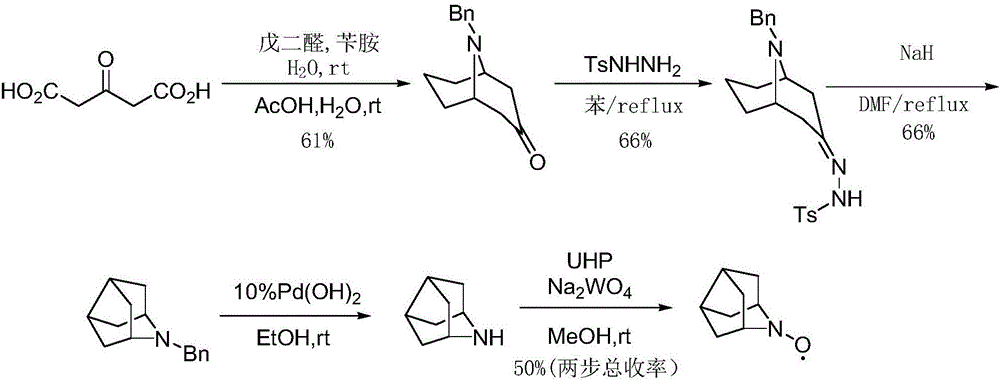

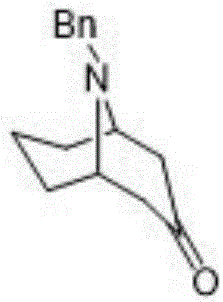

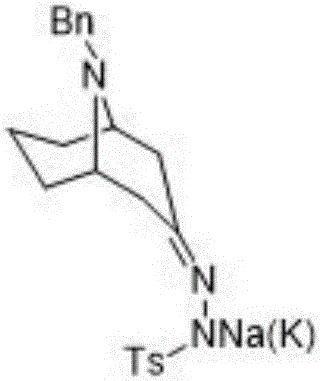

Preparation method of 2-azanoradamantane-N-Oxyl

ActiveCN106366082AReduce usageThe reaction conditions are mild and safeOrganic chemistryBenzeneSulfohydrazide

The invention discloses a preparation method of 2-azanoradamantane-N-Oxyl (Nor-AZADO). The method comprises the following steps: placing acetonedicarboxylic acid, glutaraldehyde and benzylamine in an aqueous hydrophosphate solution, and carrying out condensation and decondensation to obtain 9-benzyl-9-azabicyalo-[3,3,1]-nonyl-3-one; carrying out condensation dehydration on 9-benzyl-9-azabicyalo-[3,3,1]-nonyl-3-one and benzene or benzene ring substituted sulfohydrazide, and adding an alkali to obtain 2-(9-benzyl-9-azabicyalo-[3,3,1]-nonane-3-ylidene)-1-benzene or benzene ring substituted sulfohydrazide sodium / potassium salt; carrying out refluxing ring closing on the 2-(9-benzyl-9-azabicyalo-[3,3,1]-nonane-3-ylidene)-1-benzene or benzene ring substituted sulfohydrazide sodium / potassium salt in an organic solvent to obtain N-benzyl-2-azanoradamantane; debenzylating N-benzyl-2-azanoradamantane to obtain 2-azanoradamantane; and oxidizing 2-azanoradamantane by a peroxide oxidant to obtain the Nor-AZADO. The preparation method has the advantages of great increase of the synthesis yield, greenness and environmental protection, high efficiency, low cost, and easiness in industrial large-scale production.

Owner:深圳市宏辉浩医药科技有限公司

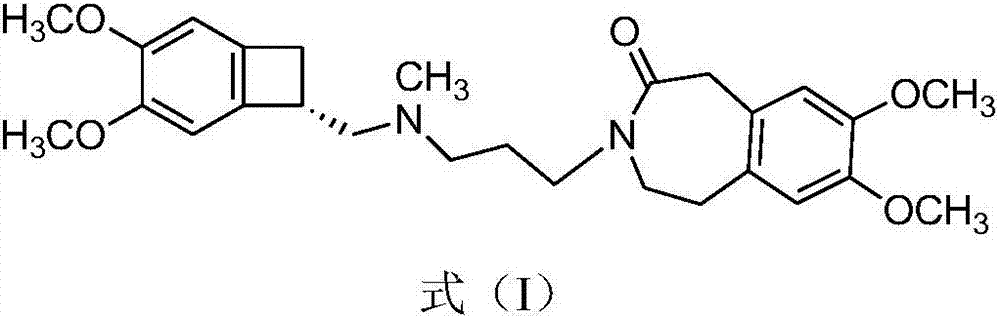

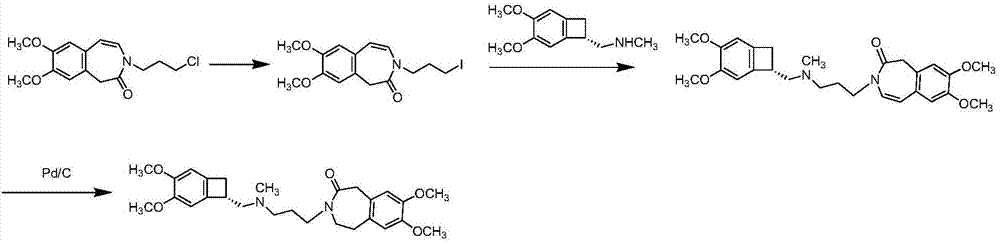

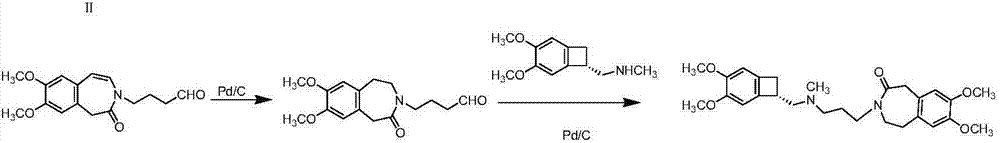

Synthetic method of ivabradine

InactiveCN108003102AEasy to operateMild reaction conditionsOrganic chemistryPalladium on carbonAlkyl transfer

The invention provides a synthetic method of ivabradine. The synthetic method of ivabradine comprises following steps: 1, a compound II and bromo chloropropane are subjected to alkylation reaction under the catalytic effect of a first alkali so as to obtain a compound III; 2, the compound III is subjected to hydrogenation reaction in a palladium on carbon and ammonium formate system so as to obtain a compound IV; 3, the compound IV and an iodination reagent are subjected to iodization reaction so as to obtain a compound V; 4, the compound V and the compound VI are subjected to condensation reaction under the catalytic effect of a second alkali so as to obtain a compound I. Operation is simple; reaction conditions are mild; the raw materials are commercially available; the synthetic methodis simple; cost is low; and the ivabradine synthesis difficulty is reduced greatly.

Owner:HARVEST PHARMA HUNAN CO LTD

Refining method of high-purity propofol

ActiveCN113372198APromote crystallizationEasy to operateOrganic chemistryOrganic compound preparationFluid phaseDistillation

The invention provides a refining method of high-purity propofol, which comprises the following steps of: adding an organic solvent into an industrial propofol crude product, then adding an inducer, freezing and crystallizing, filtering to remove impurities which are still liquid, heating and melting a filter cake, repeating the step until the requirements of related substances are met, carrying out reduced pressure distillation, and collecting stable fractions to obtain the high-purity propofol. The method is ingenious in conception, simple in process and suitable for industrial production, the single impurity of the prepared propofol is smaller than 0.05%, and the liquid phase purity can reach 99.9% or above.

Owner:SHANDONG WEIGAO PHARM CO LTD

Preparation method of 2, 2, 6, 6-tetramethyl-4-aminopiperidine

ActiveCN111689893AHigh selectivityHigh yieldOrganic chemistryCatalyst activation/preparationNickel catalystPtru catalyst

The invention relates to a preparation method of 2, 2, 6, 6-tetramethyl-4-aminopiperidine. The preparation method comprises the following steps: adding ammonia water into a hydrogenation kettle, adding a supported nickel catalyst, finally adding 2, 2, 6, 6-tetramethylpiperidone, mixing while stirring, heating the hydrogenation kettle, heating the kettle to 110-125 DEG C, introducing hydrogen, controlling the pressure to 1.5-2.5 MPa, and maintaining the hydrogenation kettle to react at a certain pressure and a certain temperature until the reaction is finished; and rectifying to obtain a finished product of 2, 2, 6, 6-tetramethyl-4-aminopiperidine. According to the method, the 2, 2, 6, 6-tetramethyl-4-aminopiperidine with the purity higher than 99% is obtained with high selectivity and highyield, and the production cost is reduced.

Owner:江苏富比亚化学品有限公司

Synthetic method of semi-aromatic polyimide and application thereof

The invention relates to a synthetic method of semi-aromatic polyimide. The synthetic method comprises the following steps: (1) performing an esterification reaction on a dianhydride monomer and alcohol to obtain aromatic quadribasic binary ester; (2) performing a reaction on a diamine monomer and the aromatic quadribasic binary ester to obtain amine carboxylate of binary ester; (3) spraying and drying the amine carboxylate of binary ester to obtain a white powdery solid; (4) adding the white powdery solid into water to fully react in a high pressure reaction kettle to prepare a product a; (5) performing centrifugal separation on the product a and then washing the solid product by an eluant; and (6) drying the washed solid product in a nitrogen atmosphere to obtain the semi-aromatic polyimide. The prepared polyimide is used for modifying a nylon material, the electric insulating performance and the bending strength of the modified nylon material can be obviously improved, and the hygroscopic property can be reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method for N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine Preparation method for N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/591107ff-edeb-4b60-a0b3-0ba9323ae6e6/DEST_PATH_IMAGE002.PNG)