Aluminum melting insulating connecting furnace

A technology of aluminum melting and conjoined furnaces, which is applied in the direction of furnaces, crucible furnaces, furnace components, etc., can solve problems that cannot meet the production needs of enterprises, single-function refractory brick holding furnaces, and production cost processing, so as to reduce energy consumption and reduce Effects of air pollution and energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

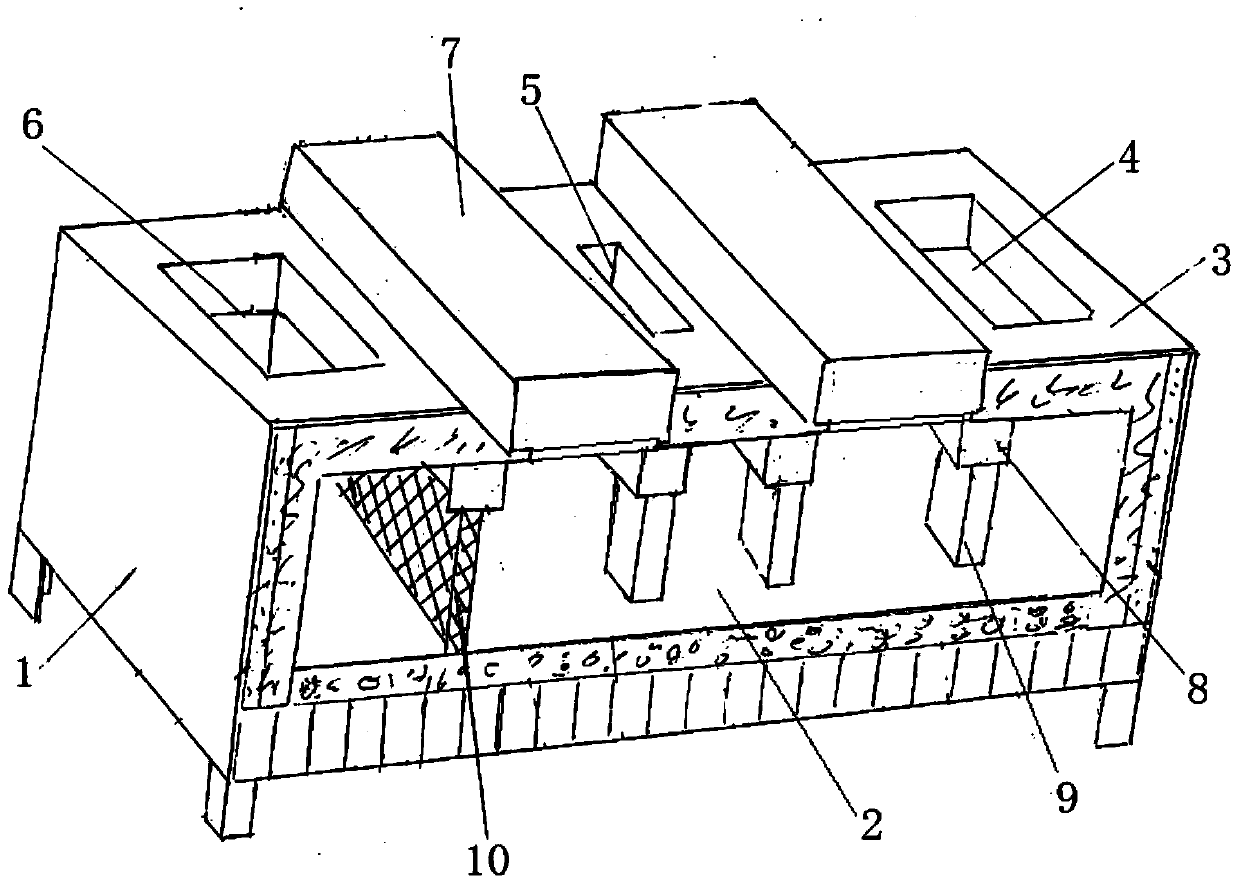

[0011] see figure 1 As shown, the figure shows the structure of an aluminum melting and heat preservation conjoined furnace provided by an embodiment of the present invention. For ease of description, only parts related to the embodiments of the present invention are shown.

[0012] see figure 1 , an aluminum melting and heat preservation one-piece furnace, comprising a box body 1, a rectangular aluminum melting and heat preservation pool 2 is arranged inside the box body 1, and a plurality of aluminum liquid partition blocks are arranged at intervals on the upper end of the aluminum melting and heat preservation pool 2 8; The upper end of the box body 1 is provided with an integrated upper cover 3, and the upper cover 3 is provided with a feeding port 4, an air release port 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com