Method for recycling trimethylacetic acid from pivaloyl chloride rectification raffinate

A technology of pivaloyl chloride and pivalic acid, which is applied in the field of chemical technology, can solve the problems that pivalic acid components cannot be effectively recovered, and the environmental pollution of waste liquid is discharged, so as to reduce the pressure on environmental protection, reduce the generation of three wastes, and improve the utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

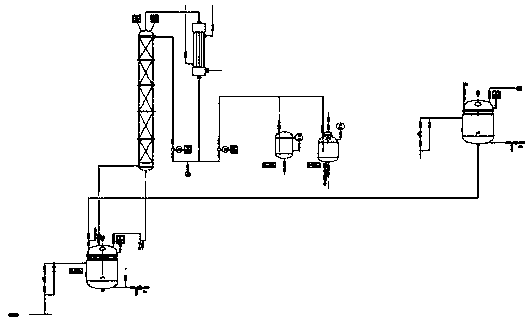

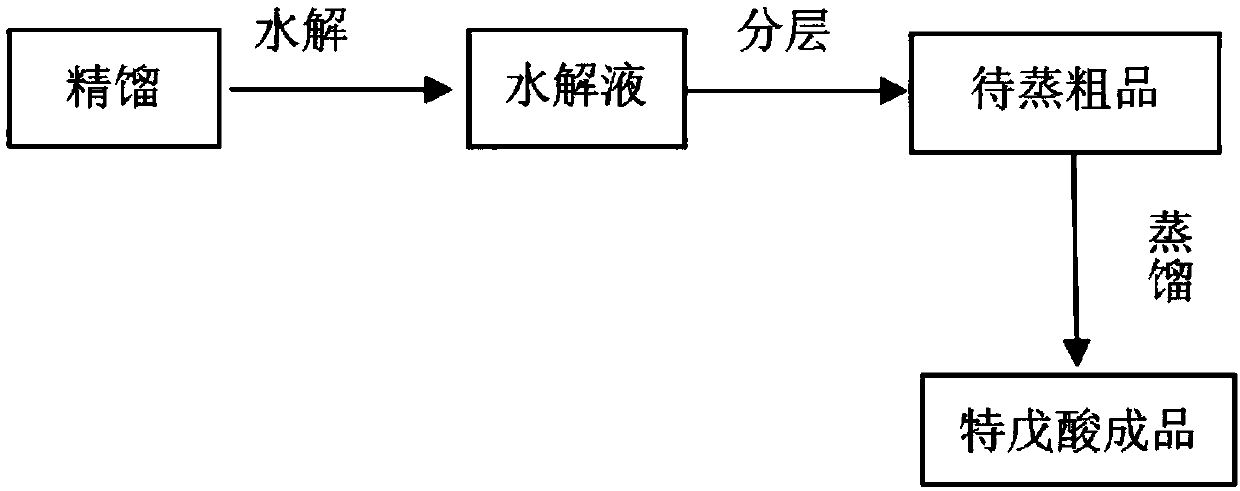

Image

Examples

Embodiment 1

[0018] Add 2500kg of residual liquid into the hydrolysis tank, turn on mechanical stirring, heat to 39~41℃ under 10kpa gauge pressure, add 175kg of water to the reactor at a rate of 100L / h, control the temperature of the hydrolysis tank at 60~61℃; adjust to 50L / h 200kg of water was added at the speed of h, and the vacuum degree was controlled to -10kpa during the period. After the water was added, the temperature was kept for 1 hour, and then it was allowed to stand for 0.5 hours. The lower layer first separates black water-containing phosphorous acid, and then red and yellow pivalic acid, which is sent to the distillation section of the pivalic acid production workshop for decolorization and refining.

Embodiment 2

[0020] Add 2300kg of residual liquid into the hydrolysis tank, turn on mechanical stirring, heat to 38~42℃ under vacuum degree of -8kpa, add 184kg of water to the reactor at a rate of 100L / h, control the temperature of the hydrolysis tank at 59~62℃; adjust to Add 207kg of water at a rate of 50L / h, during which the vacuum degree is controlled to -10kpa, after the addition of water, the temperature is kept for 1h, and the layer is left to stand for 0.5h. The lower layer first separates black water-containing phosphorous acid, and then red and yellow pivalic acid, which is sent to the distillation section of the pivalic acid production workshop for decolorization and refining.

Embodiment 3

[0022] Add 2500kg of residual liquid into the hydrolysis tank, turn on mechanical stirring, heat to 37~43℃ under 6kpa gauge pressure, add 175kg of water to the reactor at a rate of 100L / h, control the temperature of the hydrolysis tank at 58~63℃; adjust to 50L / h Add 175kg of water at the speed of h, and control the vacuum degree to -9kpa during the period. After the addition of water, the temperature is kept and reacted for 1 hour, and then it is allowed to stand for 0.5h. The lower layer first separates black water-containing phosphorous acid, and then red and yellow pivalic acid, which is sent to the distillation section of the pivalic acid production workshop for decolorization and refining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com