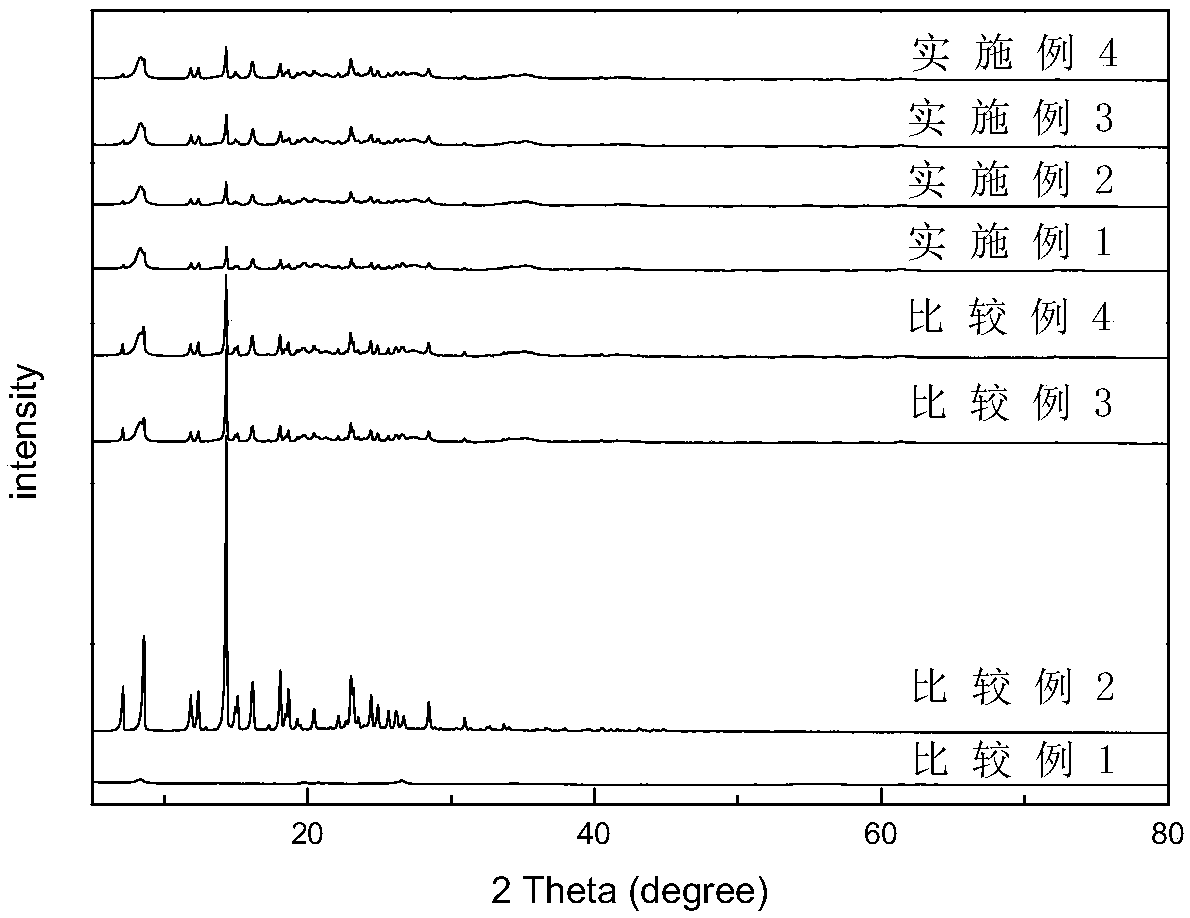

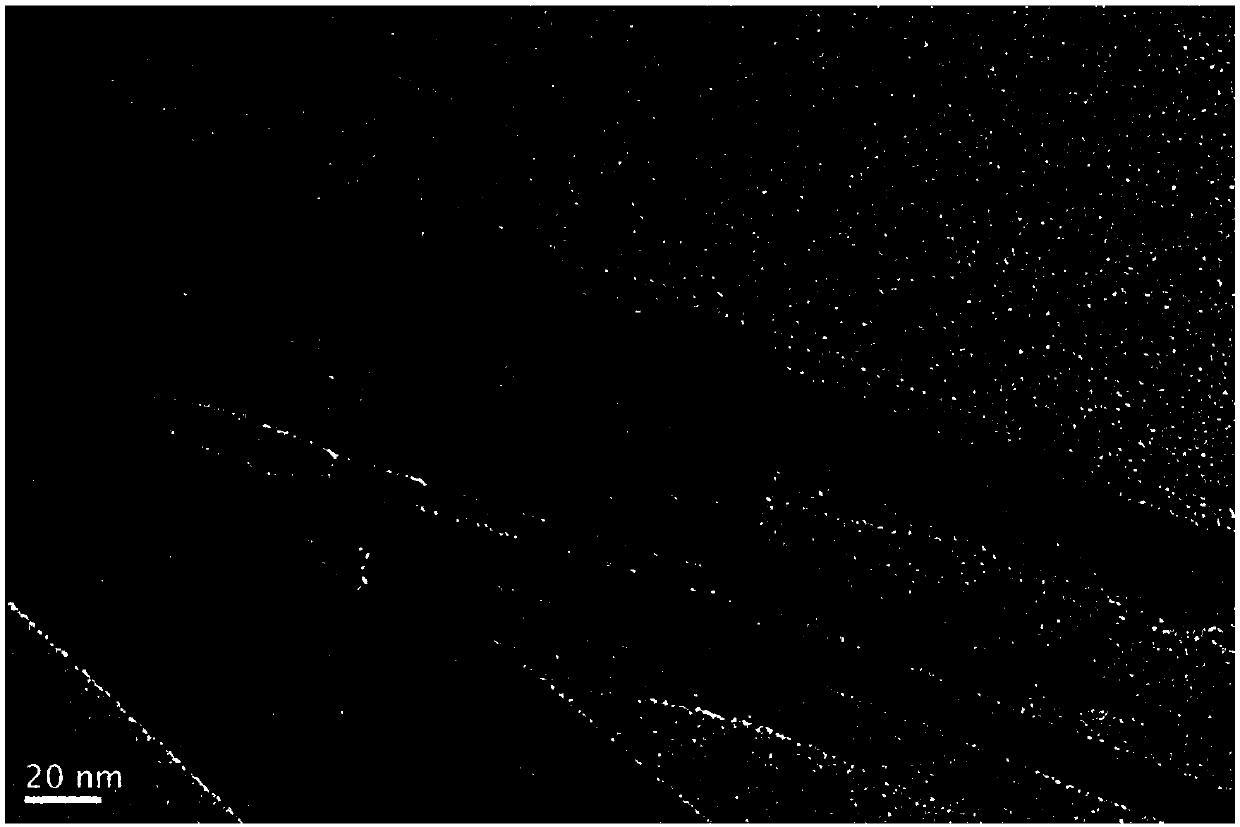

Preparation method of attapulgite-based full-wave-band ultraviolet shielding material

An attapulgite, full-band technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of reducing the crystallinity of MBBT, poor UV shielding performance, etc., to improve the degree of dispersion, cost control, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) At a temperature of 70°C, while stirring, add 1.0 liter of dodecyldimethylbenzyl ammonium chloride aqueous solution with a molar concentration of 1.0 mol / liter to 15 liters of attapulgite with a content of 50 grams / liter. 1 liter of slurry, after heat preservation and aging for 1 hour, add 0.7 liter of ethanol solution of KH540 with a molar concentration of 0.5 mol / liter while stirring, and after heat preservation and aging for 1 hour, suction filter, wash the filter cake and dry it at 80° Dry and pulverize to obtain organic surface modified attapulgite;

[0022] (2) Disperse the attapulgite with organic surface modification obtained in step (1) into 4.5 liters of ethyl acetate, and at a temperature of 60°C, add 500 liters of 1 gram / liter of ethyl acetate while stirring. After adding the ethyl acetate solution of MBBT, increase the temperature by 80°C until all the ethyl acetate is evaporated (the evaporated ethyl acetate is condensed and recovered), and the ATP@MBB...

Embodiment 2

[0024] (1) At a temperature of 80°C, while stirring, add 0.5 liter of cetyltrimethylammonium chloride aqueous solution with a molar concentration of 3.0 mol / liter to 13 liters of attapulgite content of 60 g / liter In the slurry, after heat preservation and aging for 1.5 hours, add 1.0 liter of ethanol solution of KH550 with a molar concentration of 0.7 mol / liter while stirring, and after heat preservation and aging for 1.5 hours, suction filter, wash the filter cake and dry it at 100°C. Pulverizing, that is, attapulgite with organic surface modification;

[0025] (2) Disperse the attapulgite with the organic surface modification obtained in step (1) into 3 liters of ethyl acetate, and at a temperature of 70°C, add 600 liters of 1.2 g / l of acetic acid while stirring. After adding the ethyl acetate solution of MBBT, increase the temperature by 75°C until all the ethyl acetate is evaporated (the evaporated ethyl acetate is condensed and recovered), and the ATP@MBBT composite mater...

Embodiment 3

[0027] (1) At a temperature of 70°C, while stirring, add 1.5 liters of octadecyl phosphate-substituted ammonium aqueous solution with a molar concentration of 1.5 mol / liter to 17.5 liters of a slurry with an attapulgite content of 100 g / liter After heat preservation and aging for 2 hours, add 1.5 liters of KH570 ethanol solution with a molar concentration of 1.0 mol / liter while stirring, and after heat preservation and aging for 0.5 hours, filter with suction, wash the filter cake and dry it at 110°C, and crush it. That is, attapulgite with organic surface modification is obtained;

[0028] (2) Disperse the attapulgite with the organic surface modification obtained in step (1) into 6 liters of ethyl acetate, and at a temperature of 65°C, add 1270 liters of 1.1 g / l of acetic acid with a mass concentration of 1.1 g / l while stirring After adding the ethyl acetate solution of MBBT, increase the temperature by 90°C until all the ethyl acetate is evaporated (the evaporated ethyl ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com