Reactive printing paste and production method thereof

A reactive printing and printing paste technology, applied in dyeing, textile and papermaking, etc., can solve the problems of high cost, high pollution of imported thickeners, low color yield, etc. The effect of planned production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

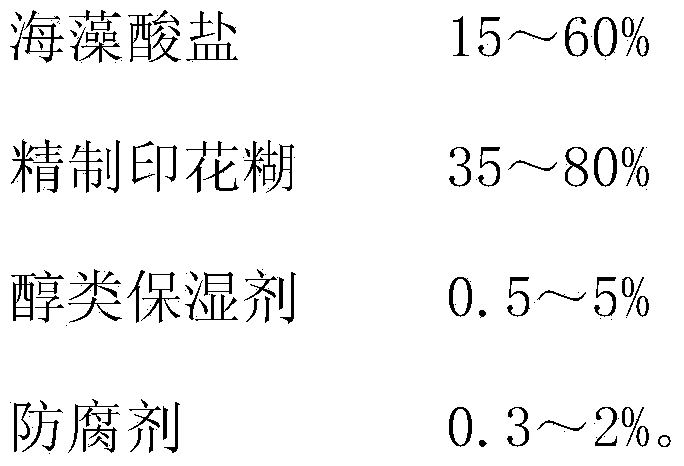

[0048] A kind of active printing paste, comprises the raw material of following mass percentage:

[0049]

[0050] Wherein, the alginate is formed by mixing sodium alginate and potassium alginate at a mass ratio of 2:1. On the one hand, the amount of sodium alginate is reduced, and the raw material cost of sodium alginate salts is reduced. The alginate compounded in a specific ratio has better thickening effect, resistance to biodegradation, electrolyte resistance, and no pollution. The refined printing paste is a compound of inorganic salt extracted from natural clay and carboxymethyl cellulose. The inorganic salt is magnesium aluminum silicate. The alcohol humectant is glycerin. The preservative is benzoate.

[0051] A method for developing active printing paste, comprising the following processing steps:

[0052] Step A1, preparing refined printing paste;

[0053] Step B1, preparing alginate tide products;

[0054] Step C1, put the printing paste prepared in step A...

Embodiment 2

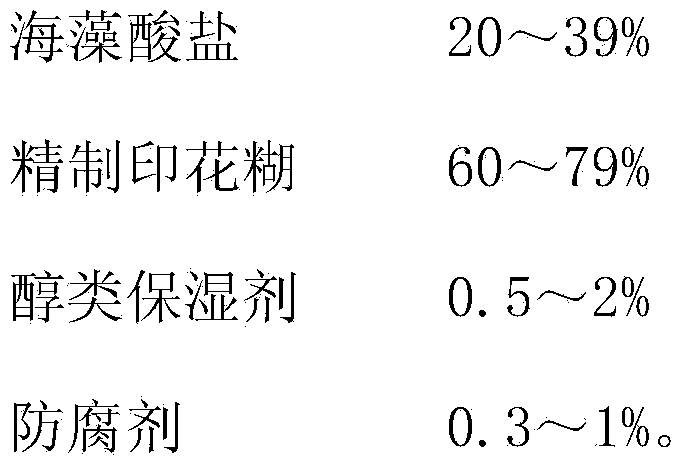

[0058] A kind of active printing paste, comprises the raw material of following mass percentage:

[0059]

[0060] Wherein, the alginate is formed by mixing sodium alginate and potassium alginate at a mass ratio of 3:2. On the one hand, the amount of sodium alginate is reduced, and the raw material cost of sodium alginate salts is reduced. The alginate compounded in a specific ratio has better thickening effect, resistance to biodegradation, electrolyte resistance, and no pollution. The refined printing paste is a compound of inorganic salt extracted from natural clay and carboxymethyl cellulose. The inorganic salt is magnesium aluminum silicate. The alcohol humectant is propylene glycol. The preservative is dibromocyanoacetamide.

[0061] A method for developing active printing paste, comprising the following processing steps:

[0062] Step A1, preparing refined printing paste;

[0063] Step B1, preparing alginate tide products;

[0064] Step C1, put the printing pas...

Embodiment 3

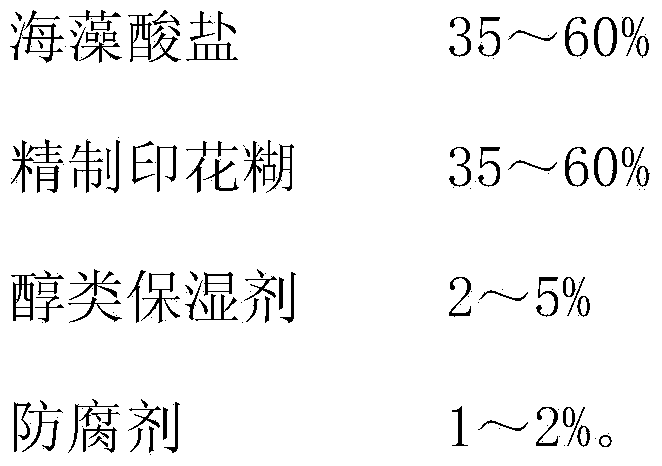

[0068] A kind of active printing paste, comprises the raw material of following mass percentage:

[0069]

[0070] Wherein, the alginate is sodium alginate. The refined printing paste is a compound of inorganic salt extracted from natural clay and carboxymethyl cellulose. The inorganic salt is magnesium aluminum silicate. The alcohol humectant is 1,3-butanediol. The preservative is Kathon.

[0071] A method for developing active printing paste, comprising the following processing steps:

[0072] Step A1, preparing refined printing paste;

[0073] Step B1, preparing alginate tide products;

[0074] Step C1, put the printing paste prepared in step A1 into the alginate wet product in step B1 and stir evenly, add preservatives and alcohol moisturizers, and continue stirring;

[0075] Step D1, pressing the material in step C1 into granules and drying;

[0076] Step E1, crushing the granules in step D1 and packing them into bags to obtain a finished reactive printing paste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com