Refining method of high-purity propofol

A refining method and technology of propofol, applied in the field of medicine and chemical industry, can solve problems such as low yield and slow crystallization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

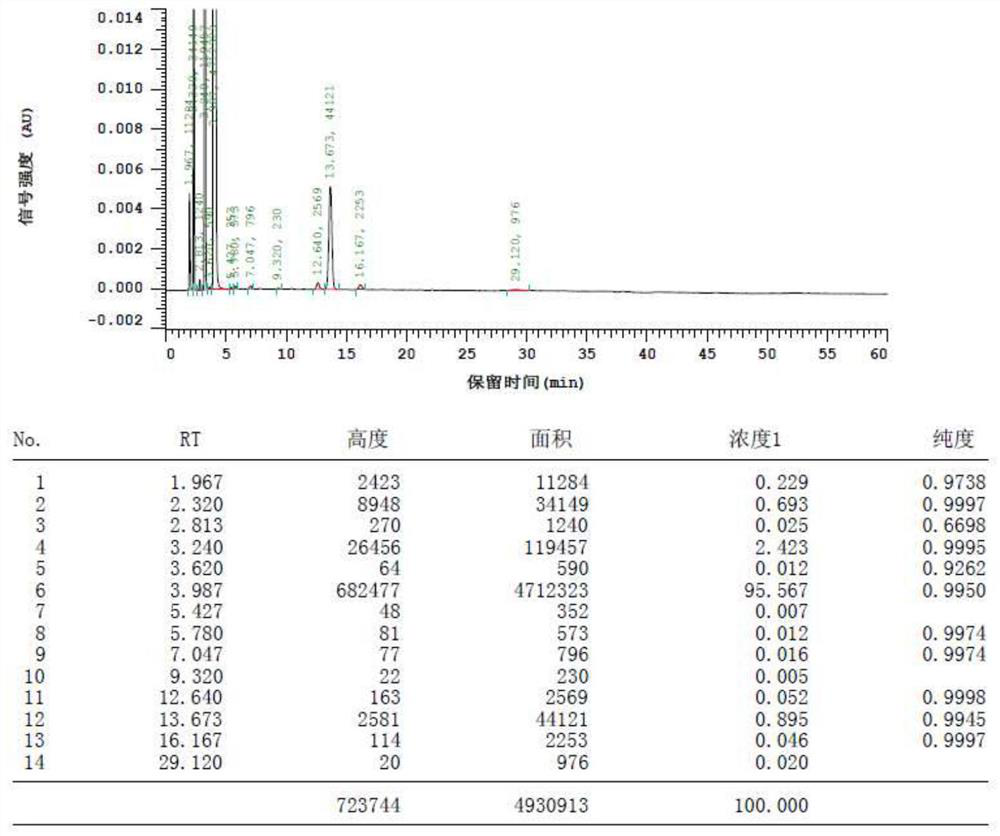

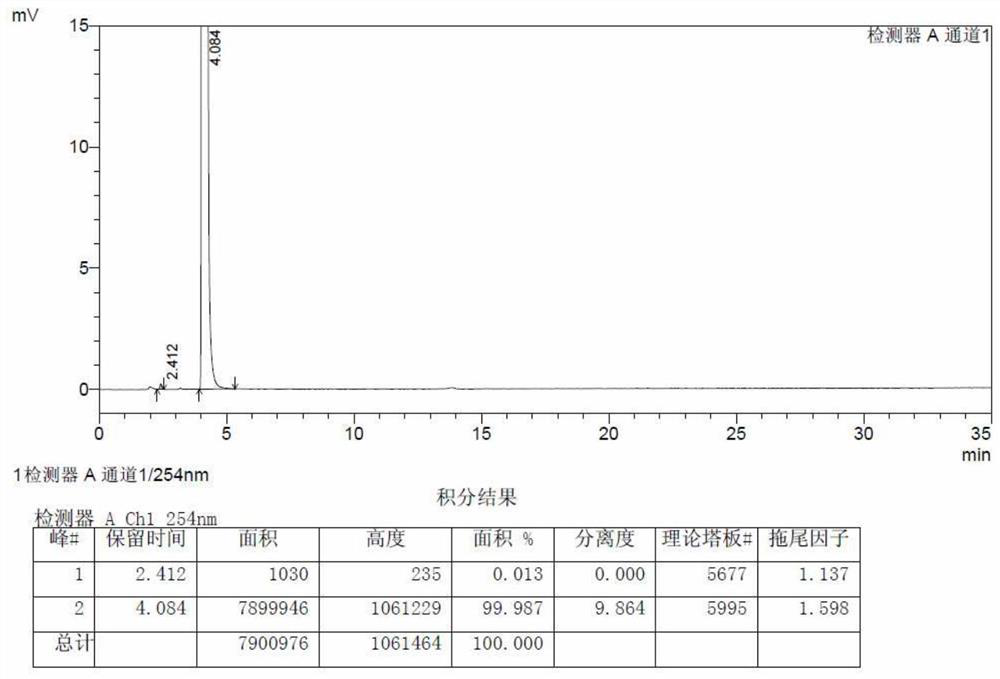

[0041] Take 198.2g of propofol crude product, the liquid phase purity is 95.567%, add 60.8g of n-hexane, add 3.1g of water, seal it, shake it evenly, put it into the freezer at -25~-20℃ for 24 hours, take it out, pour it out Or filter the uncrystallized yellow mother liquor, and the remaining ice-like solid melts in a water bath. Add n-hexane and water at the same ratio each time, and then repeat this operation 3 times, then dry the refined product of propofol, distill under reduced pressure at 800pa vacuum, collect fractions at 55-75°C to obtain 129.2g of propofol, The liquid phase purity is 99.987%, and the yield is 65.2%.

[0042] Liquid phase conditions: Porous silica gel packing column (Ptomosil Silica, 5μm, 4.6×200mm); column temperature 25°C; detection wavelength 275nm; n-hexane-acetonitrile-ethanol (990:7.5:1) The flow rate is 1.5ml / min, the same below.

Embodiment 2

[0044] Take 202.5g of propofol crude product, the liquid phase purity is 95.567%. After adding 61.2g of n-hexane, add 3.2g of acetic acid, seal and shake evenly, put it in a freezer at -25~-20℃ for 24 hours, take it out, The yellow mother liquor was decanted and the remaining icy solid was melted in a water bath. Then repeat this operation 3 times, add n-hexane and acetic acid in the same proportion each time, then wash and dry the refined propofol product, distill under reduced pressure at 800pa vacuum, collect fractions at 55-75°C to obtain 139.3g of propofol , liquid phase purity 99.997%, yield 68.8%.

Embodiment 3

[0046] Take 185.6g of propofol crude product, the liquid phase purity is 95.567%. After adding 59.3g of n-hexane, add 2.9g of formic acid, seal it, shake it evenly, put it into the freezer at -25~-20℃ for 24 hours, take it out, The yellow mother liquor was decanted and the remaining icy solid was melted in a water bath. Add n-hexane and formic acid in the same ratio each time, repeat this operation 3 times, then wash and dry the refined propofol product, distill under reduced pressure at 800pa vacuum, collect fractions at 55-75°C to obtain 123.4g of propofol, The liquid phase purity is 99.951%, and the yield is 66.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com