Preparation method of 2, 2, 6, 6-tetramethyl-4-aminopiperidine

A technology of tetramethylpiperidone and aminopiperidine is applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. Adverse effects and high production costs, achieving the effect of more application times, low price and less usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 329g mass concentration is 30% ammonia water, 3g supported nickel catalyst is added in the hydrogenation tank;

[0057] Add 200g of 2,2,6,6-tetramethylpiperidone into the hydrogenation kettle, and heat up after nitrogen replacement. When the temperature of the hydrogenation kettle rises to 120°C, the hydrogen gas will start the reaction, and the pressure in the hydrogenation kettle will be maintained at 2.0Mpa, the temperature is 120°C until the end of the reaction;

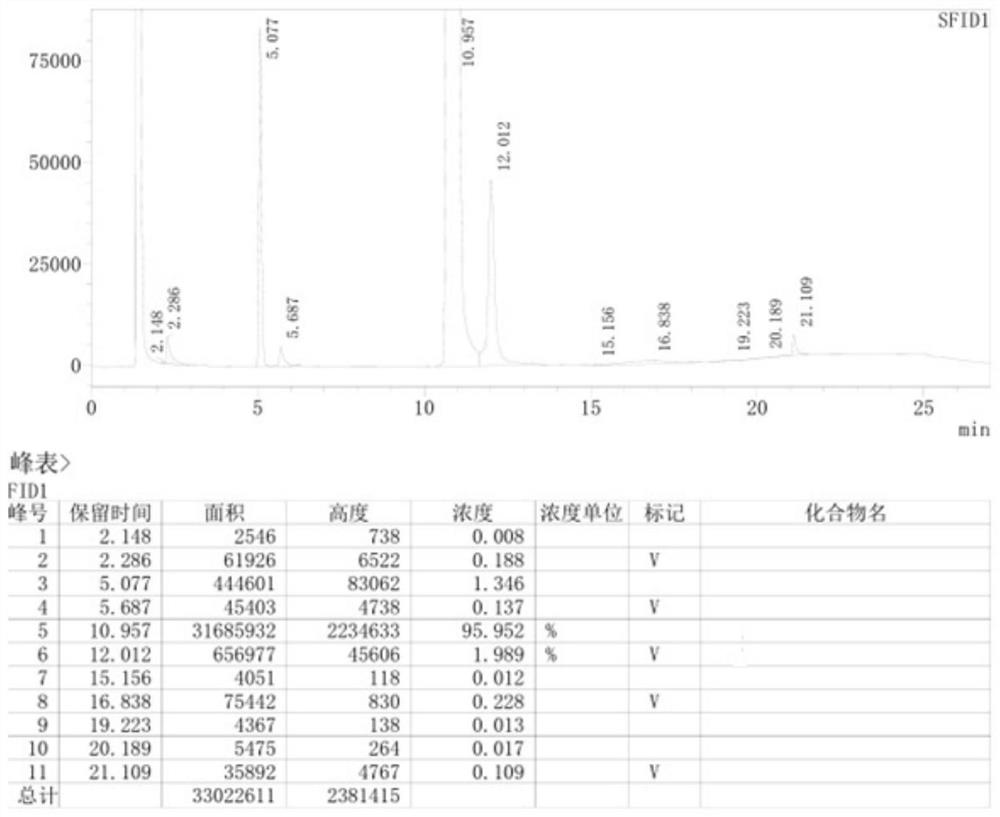

[0058] The GC content of the target product 2,2,6,6-tetramethyl-4-aminopiperidine is 96.54%, and the by-product piperidinol content is 2.06% (see attached figure 1 ).

[0059] Lower the temperature until it falls below 90°C, preferably below 80°C;

[0060] After settling, the reaction system is divided into upper and lower layers, and the catalyst is recovered from the lower layer for mechanical application;

[0061] Filter the supernatant liquid, then rectify, deammoniaize at normal pressure first, rec...

Embodiment 2

[0064] Add 329g30% ammonia water and 2.5g loaded nickel catalyst into the hydrogenation tank

[0065] Add 200g of 2,2,6,6-tetramethylpiperidone into the hydrogenation kettle, heat up after replacement, and when the temperature of the hydrogenation kettle rises to 120°C, the hydrogen gas will start to react, and the pressure in the hydrogenation kettle will be maintained at 2.5 Mpa, temperature is 120 ℃, until reaction finishes;

[0066] The GC content of the target product 2,2,6,6-tetramethyl-4-aminopiperidine is 95.95%, and the by-product piperidinol content is 1.99% ((as attached image 3 shown).

[0067] Lower the temperature until it falls below 90°C, preferably below 80°C;

[0068] After settling, the reaction system is divided into upper and lower layers, and the catalyst is recovered from the lower layer for mechanical application;

[0069] Filter the supernatant liquid, then rectify, deammoniaize at normal pressure first, rectify water at normal pressure, and recove...

Embodiment 3

[0072] It is basically the same as Example 1, except that the temperature in the reaction is 130° C. After the reaction, the GC content of the target product 2,2,6,6-tetramethyl-4-aminopiperidine is 92.39%, while The content of by-product piperidinol is 6.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com