Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Suitable for extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

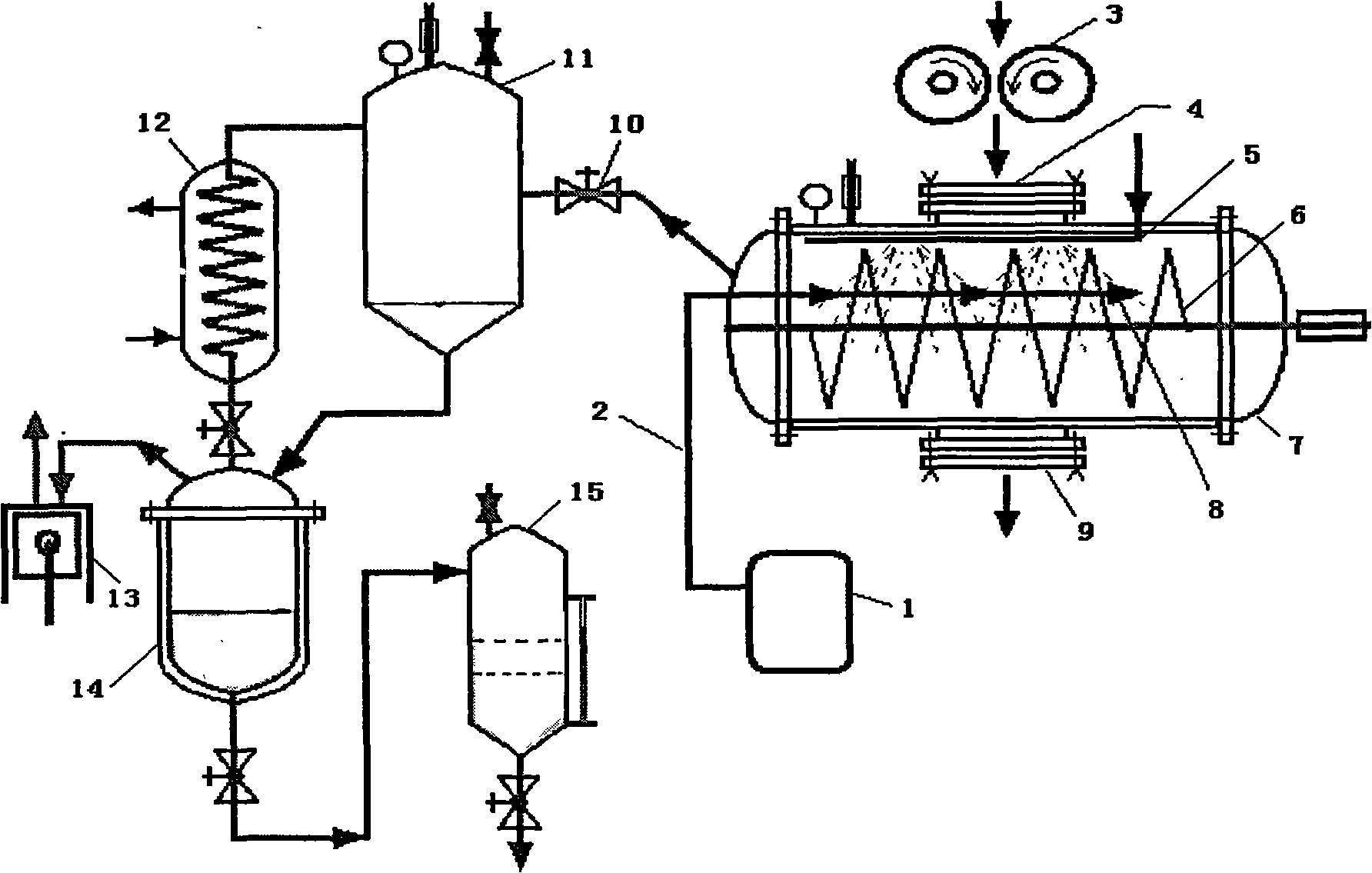

Method for preparing fresh aromatic essential oil

InactiveCN101358158ARapid pressure reductionReduce resistanceEssential-oils/perfumesAdditive ingredientMoisture

The present invention relates to a method which utilizes fresh aromatic plants as materials and combines the microwave heating technology with the vacuum technology to prepare essential oil. The method includes the following steps: the tissue structure of aromatic plant material is broken by cutting and grinding; after microwave irradiation is utilized to heat the aromatic plant material to a certain temperature, pressure is rapidly reduced to intensely gasify the moisture in the material so that the histiocytes, oil vacuoles and gland cells of the aromatic plants are broken; an aromatic substance is released from the cells and quickly volatilize; and the effect of the intense gasification and spreading of the moisture in the fresh material can effectively promote and intensify the volatilization of the aromatic ingredient, so that the abstraction of the essential aromatic plant oil can be fulfilled in a short time. The processing temperature in the process of the abstraction of the essential plant oil is low, the oxidation of sensitive ingredients can be avoided, the stability of the ingredients of the essential aromatic plant oil can be kept to the max, the time of abstraction is short, the efficiency is high, energy can be saved, and industrialized production can be conveniently realized.

Owner:SHIHEZI UNIVERSITY

Method for extracting rice bran protein by complex enzyme

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

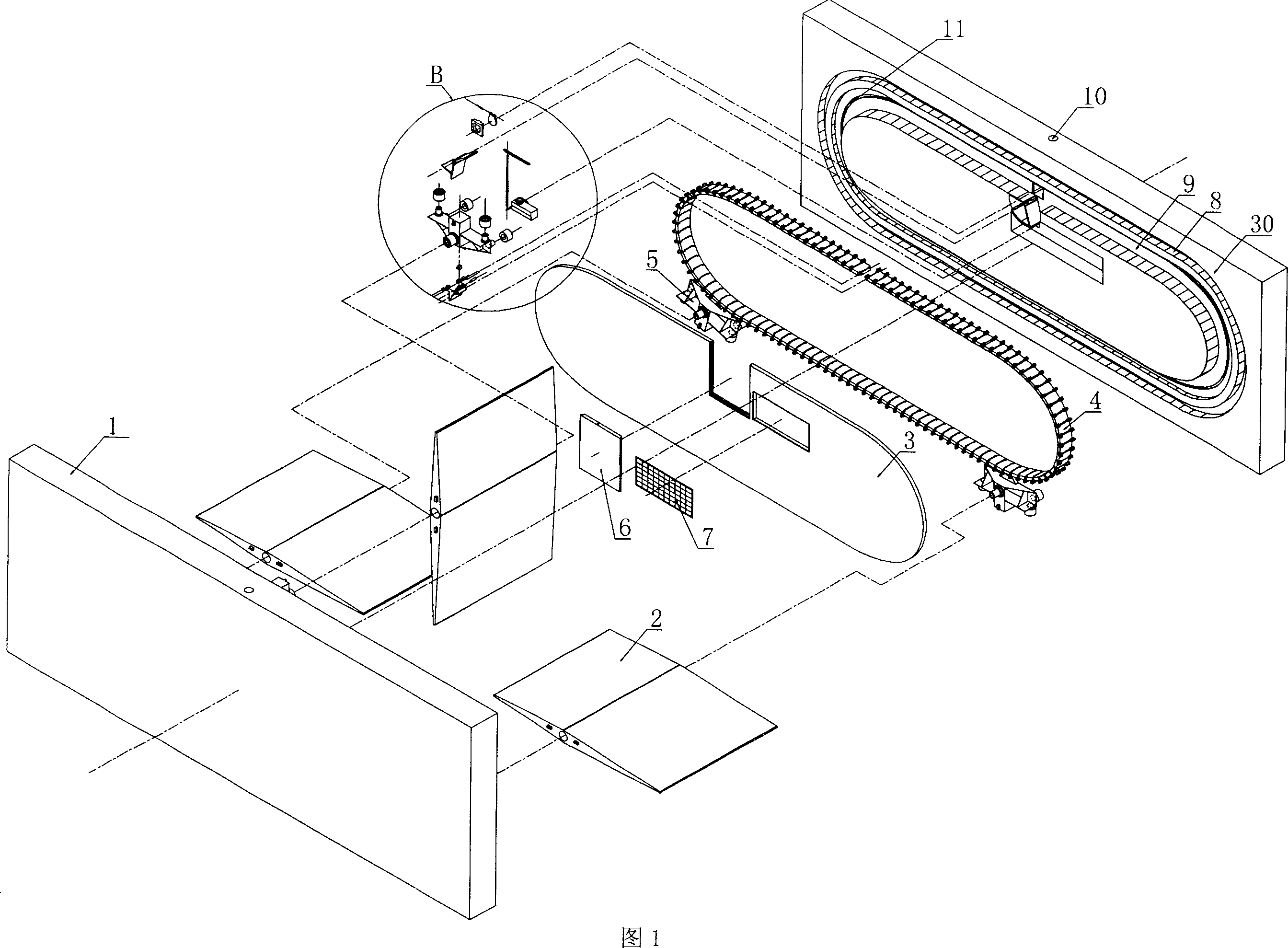

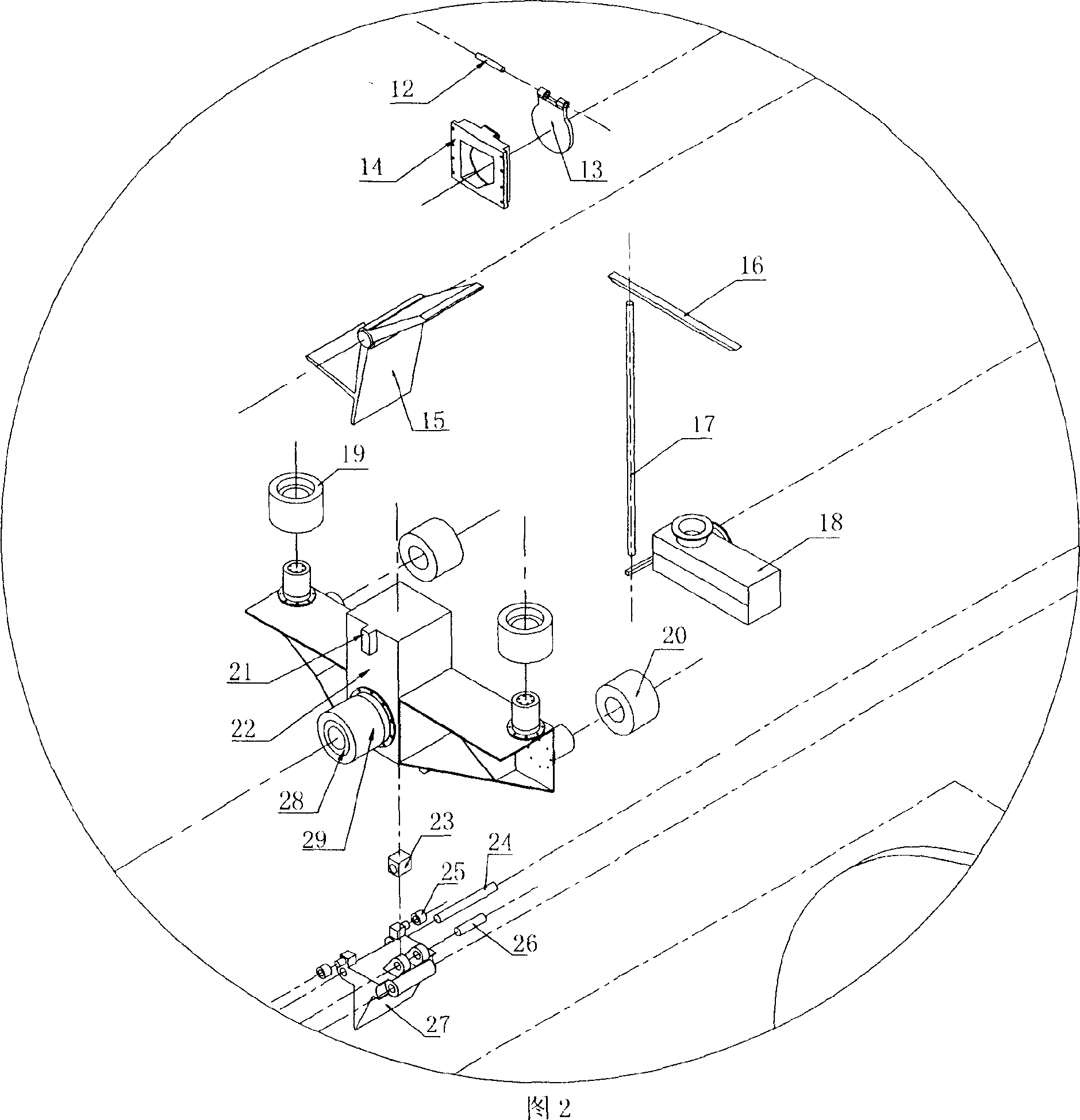

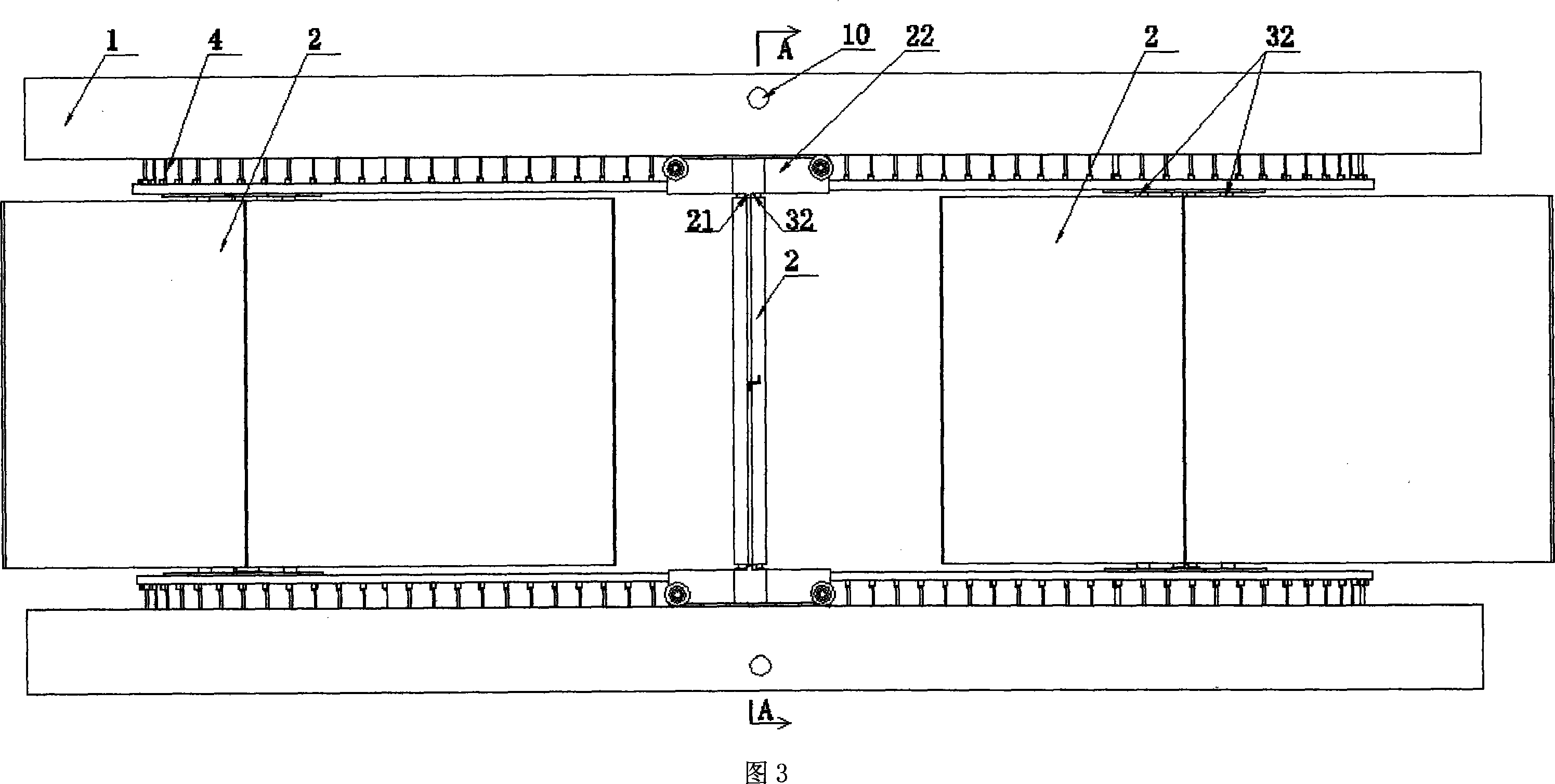

Rotating blade vehicle type fluid machine

InactiveCN101100974AWide range of wind speedImprove efficiencyOscillating piston pumpsWind motor combinationsEngineeringElectric generator

This invention is rotating blade car type fluid power generator. The chain connects to three groups of rotating blade cars. Rotating blades are evenly distributed on circulate track. Two straight tracks and two half circular arc tracks are connected to form circulating track. Under the effect of fluid, rotating blade of rotating blade car is vertical to fluid flowing direction at the straight segment of track. Thus, fluid active force is strong. At another straight segment, under the effect of fluid, rotating blade of rotating blade car is parallel to fluid flowing direction. Thus, fluid active force is little. The three groups of rotating blade cars and rotating blades undertake circulating operation along track. The chain transfers power to power generator through driving train. The flow power driving train, which is applied underground, is composed of chain pump, pipe, accumulator and water turbine. It makes power generator can be assembled on water surface. The resistance type wind power machine is driven by chain.

Owner:陈崟

Method for preparing molybdenum nickel alloy by directly reducing and smelting molybdenum nickel ore

The invention relates to a method for preparing molybdenum nickel alloy by directly reducing and smelting molybdenum nickel ore. The method comprises the following steps: grinding the molybdenum nickel ore into molybdenum nickel ore powder with the average particle size of less than or equal to 0.18 mm; adding a slag forming agent and a reducing agent with the average particle size of less than or equal to 0.18 mm into the molybdenum nickel ore powder to obtain furnace charge; mixing the furnace charge uniformly and pelletizing to obtain pellet; heating the pellet to 1,600 to 1,800 DEG C; smelting; and collecting liquid alloy, slag, smoke dust and furnace gas respectively, wherein the liquid alloy is crude molybdenum nickel alloy; the direct yield of the molybdenum and the nickel is 96 percent and 94 percent respectively; the molybdenum content of the smoke dust is less than 0.2 percent and the nickel content of the smoke dust is less than 0.2 percent; and the SO2 concentration of thefurnace gas is less than or equal to 400 mg / m<3>. The process method is simple and reasonable, and convenient to operate; the molybdenum nickel ore is not subjected to oxidizing roasting de-sulfuration; and the crude molybdenum nickel alloy is prepared by directly reducing and smelting the molybdenum nickel ore and by using the carbon of the molybdenum nickel ore as a reducing agent, so that indirect smelting is changed into direct smelting. The prepared molybdenum nickel alloy is low in sulfur content and phosphorus content, environment friendly and low in production cost; and the method is suitable for extraction of the molybdenum nickel ore.

Owner:CENT SOUTH UNIV +2

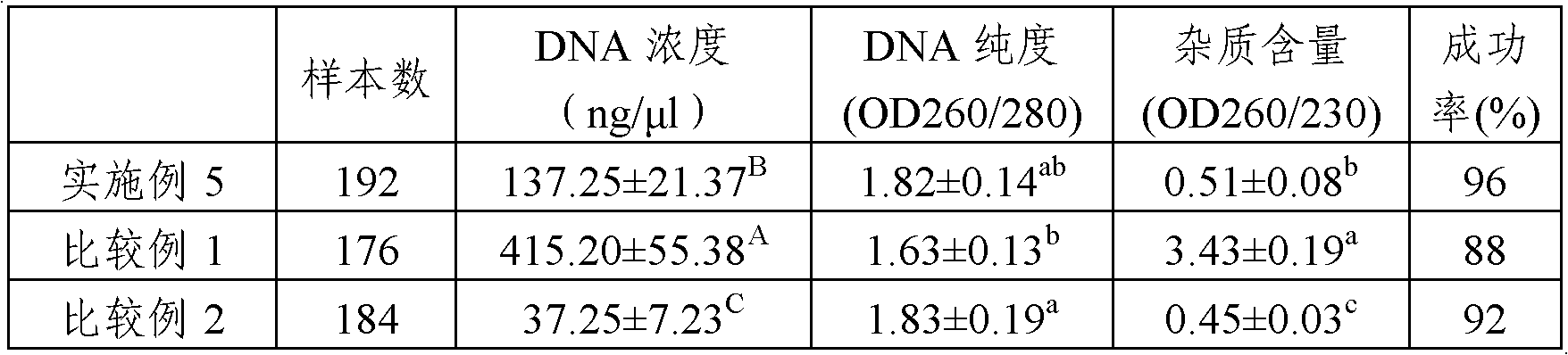

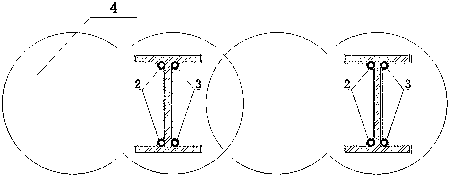

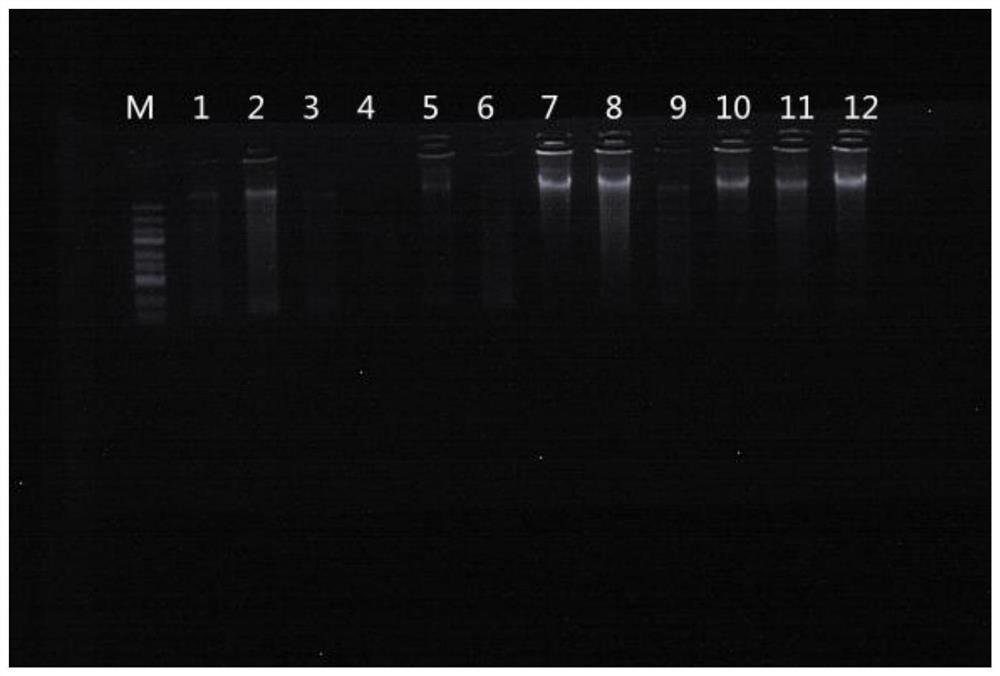

Cell lysis solution for extracting animal DNA, kit and method

The invention provides cell lysis solution for extracting animal DNA, a kit containing the lysis solution and a method for extracting animal DNA by using the kit. The cell lysis solution provided by the invention comprises Tris-base at a concentration of 20 to 30g / L, ethylene diamine tetraacetic acid (EDTA) at a concentration of 0.5 to 1.0g / L, sodium dodecyl sulfonate (SDS) at a concentration of 20 to 30g / L, NaCl at a concentration of 5 to 10g / L, urea at a concentration of 100 to 150g / L and the balance of sterile water, and the pH value of the cell lysis solution is regulated by NaOH to 8.0 to 9.0. When the animal DNA extraction kit provided by the invention is used, the extraction time is reduced by at least half hour compared with that in the prior art, the use of chloroform with strong toxic odor is avoided, the damage to the health of operators in an operation process is relieved, and the extracted DNA is high in yield and purity. The method provided by the invention is quick, simple, convenient, efficient and very repeatable. In the invention, the result is very stable, the success rate is high, extraction cost is reduced and large-scale extraction of DNA is easy.

Owner:SICHUAN AGRI UNIV

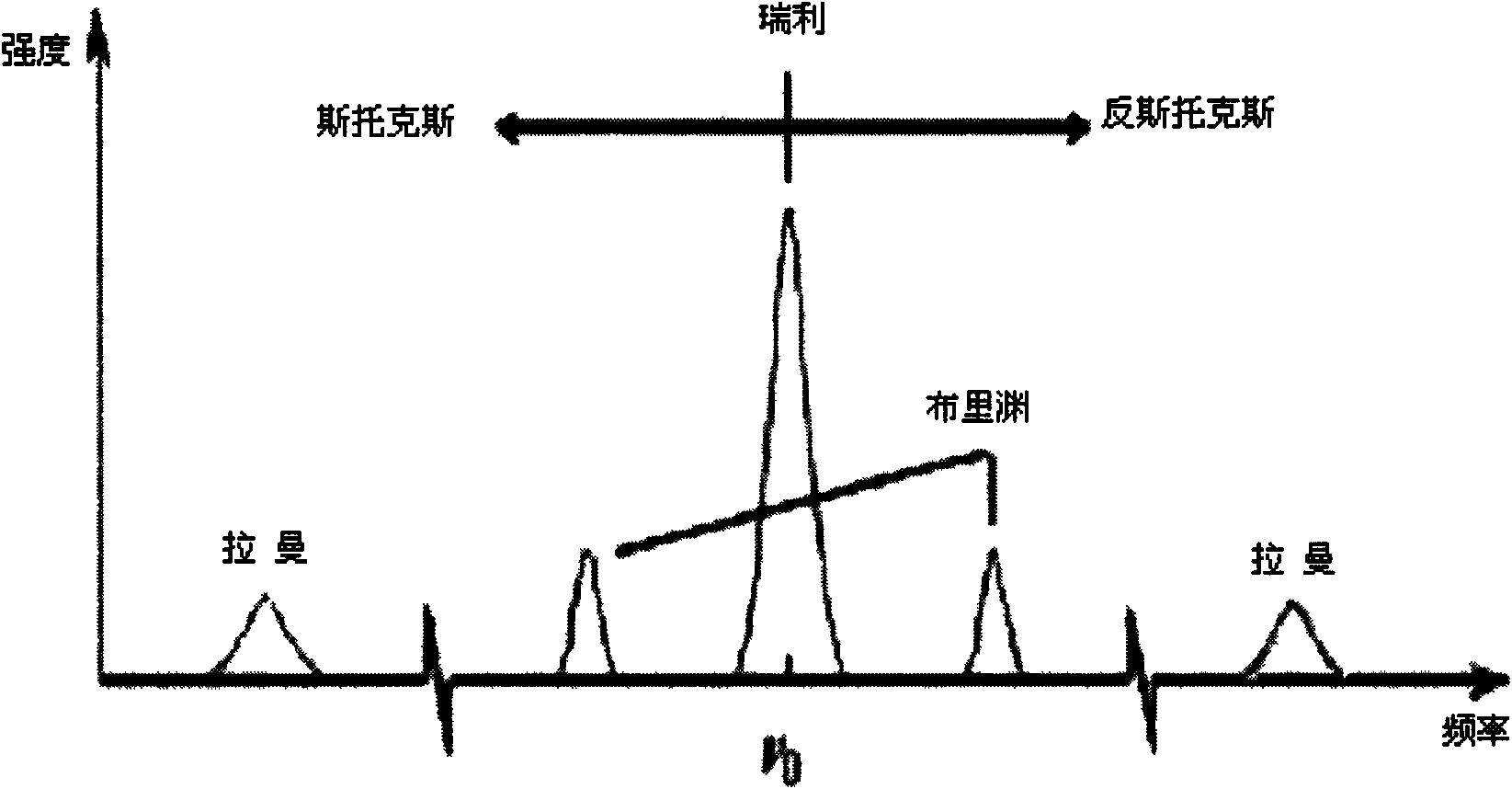

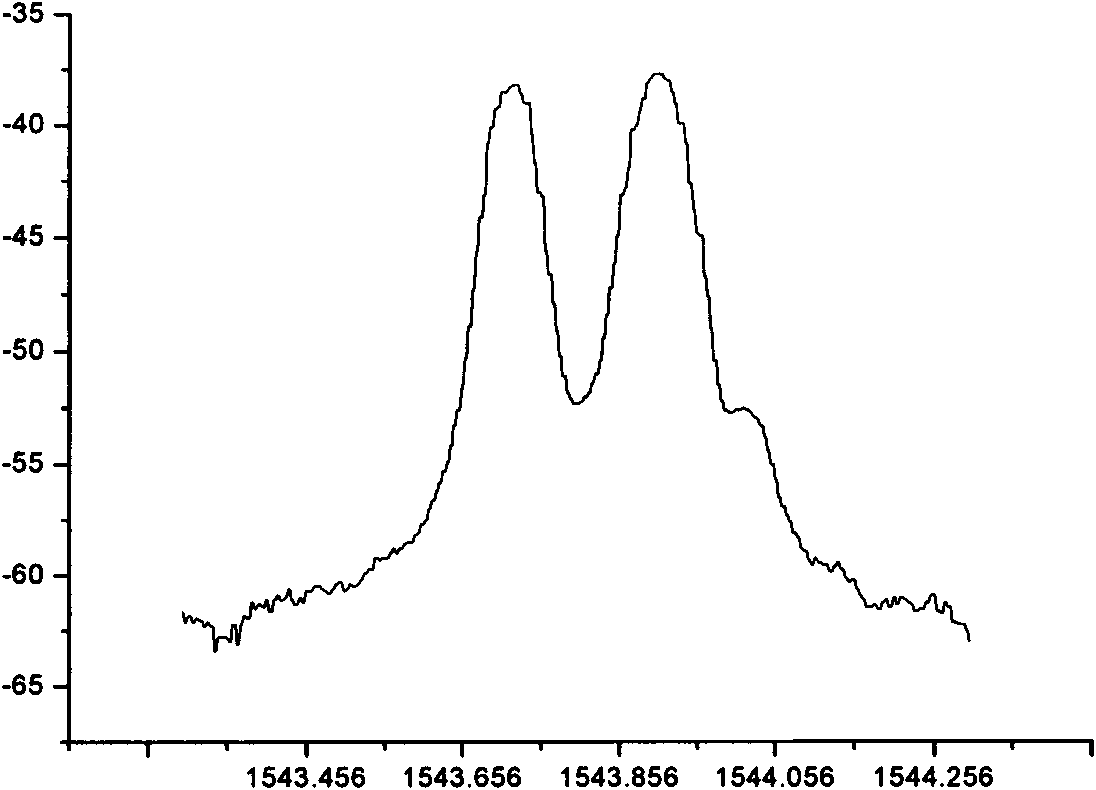

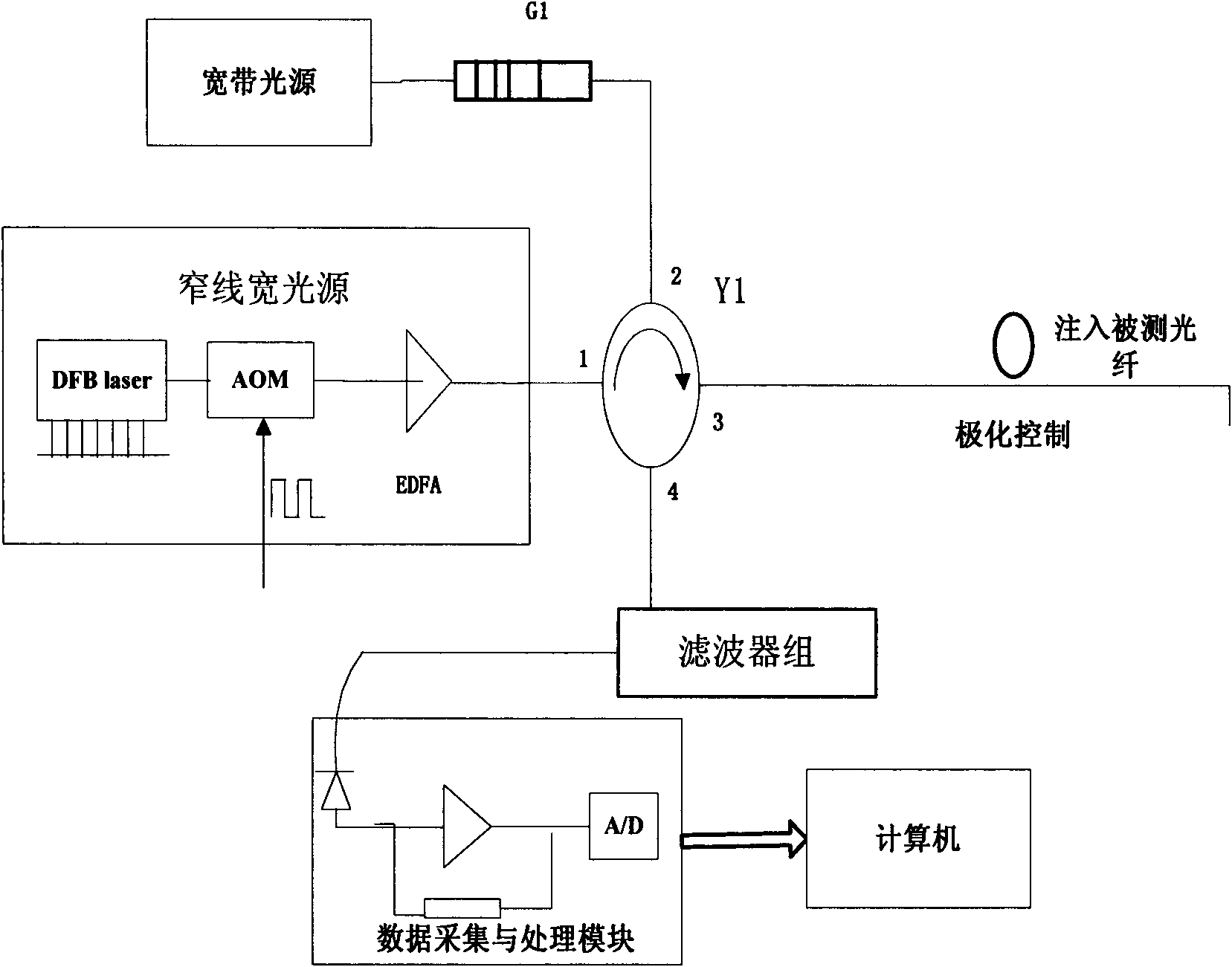

Method for measuring spontaneous Brillouin scattering based on super structured fiber grating filter

InactiveCN101666688AHigh rejection ratioGood roll-off characteristicsForce measurement by measuring optical property variationThermometers using physical/chemical changesRayleigh scatteringLine width

The invention discloses a method for measuring spontaneous Brillouin scattering based on a super structured fiber grating filter, which inhibits coherent Rayleigh noise by the method which uses the distribution of a narrow line width to feedback a fiber optic laser and a wide band laser to obtain strength ratio of a Brillouin signal and a Rayleigh signal; the method comprises the following steps:firstly, the generated narrow line width pulsed light is fed back to a detected fiber after polarization control according to the length of the fiber; a back reflection signal enters a filter bank through a circulator port (4) and respectively regulates the adjustable super structured fiber grating filter, filters a Rayleigh signal to the largest extent, extracts a spontaneous Brillouin scatteringsignal, feeds the spontaneous Brillouin scattering signal into a highly sensitive photoelectricity conversion module and a signal processing module, and detects the intensity of the spontaneous Brillouin signal through data accumulation and wavelet-de-noising treatment; secondly, the pulsed light generated by the wide band laser passes through a rear-end module the same as in the first step to measure the Rayleigh scattering signal; and finally, the data measured at two times are processed on a computer to display the fiber temperature and stress, which solves the problem of measuring methodof the fiber spontaneous Brillouin signal.

Owner:PLA UNIV OF SCI & TECH

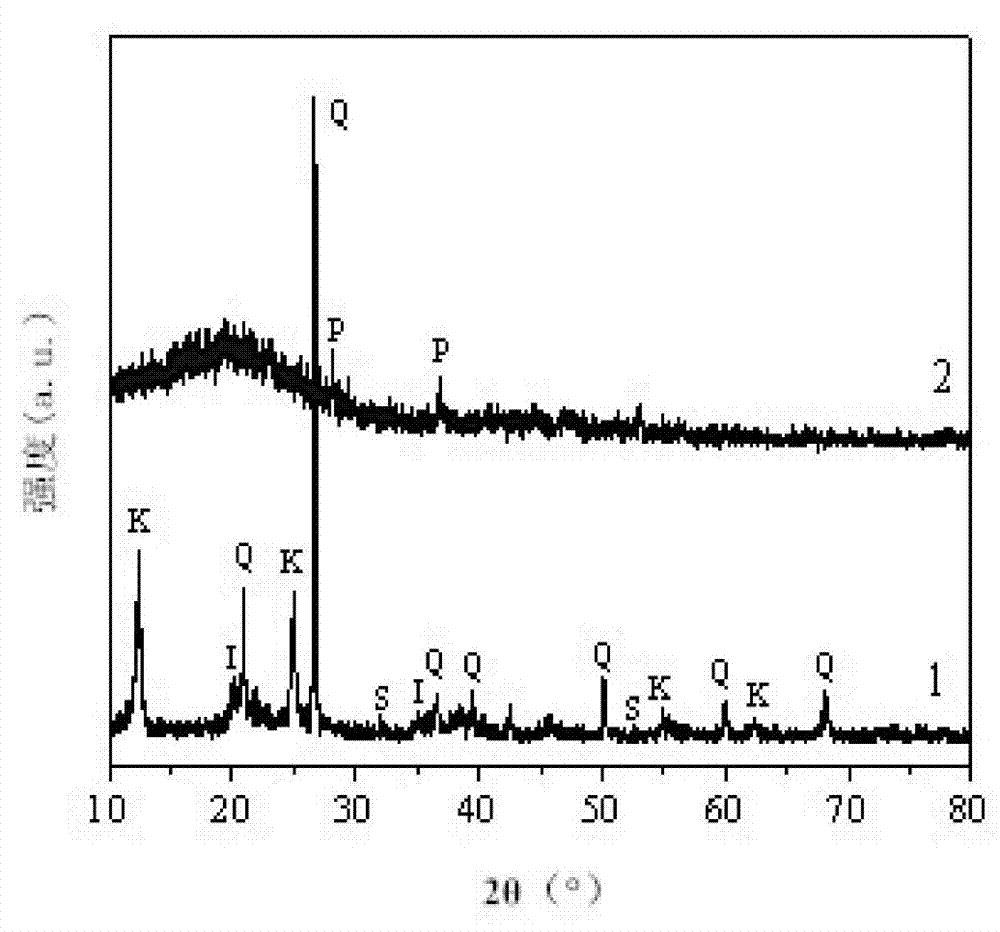

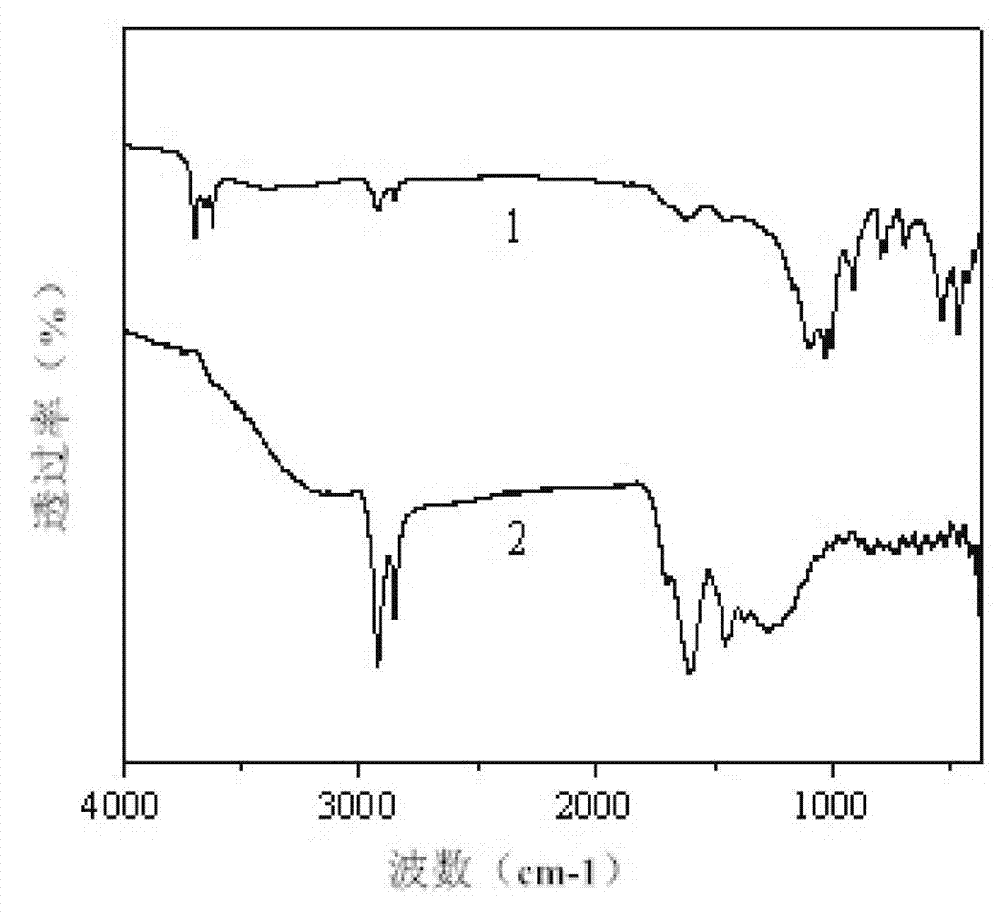

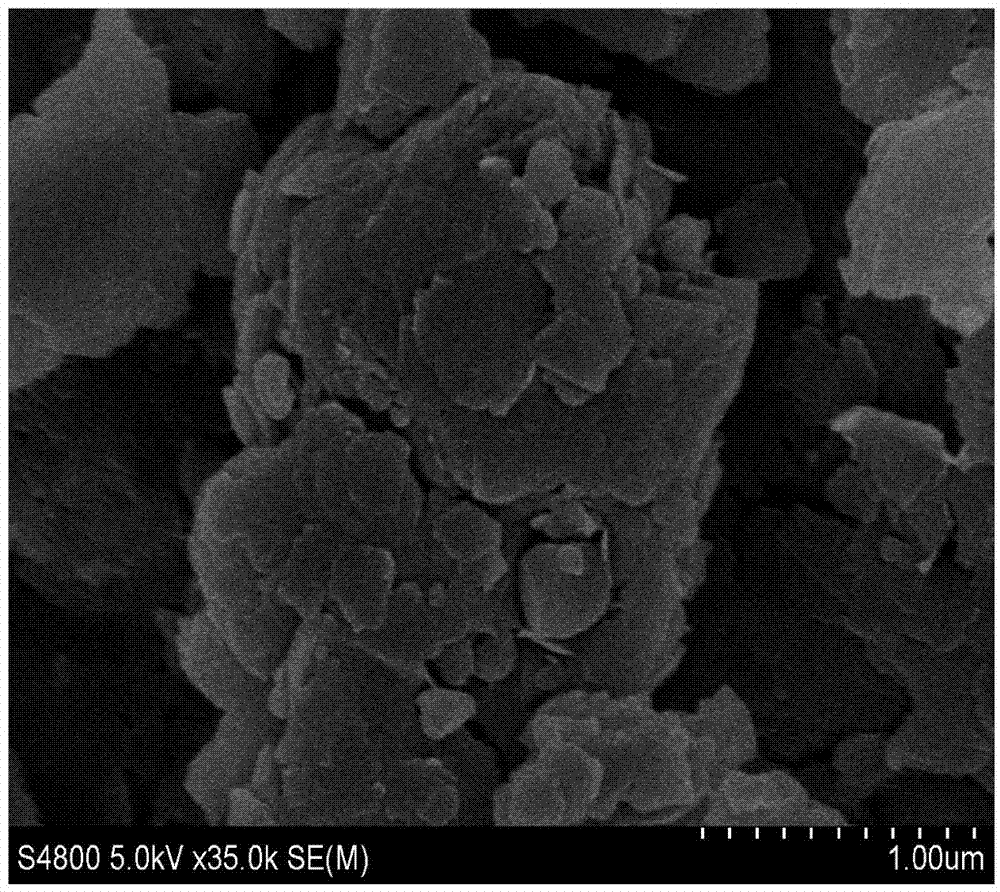

Method for extracting petrologen in oil shale

InactiveCN103666515AAchieve separationSimple processLiquid hydrocarbon mixture productionHydrofluoric acidFiltration

The invention relates to a method for extracting petrologen in an oil shale and aims to solve the problems of complicated operating process and long operating time of the conventional method. The method comprises the following steps: 1, grinding the oil shale into oil shale particles with a certain particle size; 2, weighing and adding a certain amount of the oil shale particles and a hydrofluoric acid solution into a polytetrafluoroethylene tube, oscillating the polytetrafluoroethylene tube to enable the oil shale to be in full contact with the acid, putting the polytetrafluoroethylene tube into a microwave reactor, setting the microwave power, the microwave temperature and the microwave time, and performing quality enhancement treatment on the oil shale; 3, performing suction filtration on a sample through deionized water after the reaction is finished, washing the sample to neutrality, and drying to obtain the petrologen. The method disclosed by the invention is used for extracting the petrologen in the oil shale.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Special efficient culture medium for necrotic fusobacterium and preparation method thereof

InactiveCN101519642ALow costBacteria grow vigorouslyBacteriaMicroorganism based processesLeucotoxinsCarbon source

The invention relates to a special efficient culture medium for necrotic fusobacterium and a preparation method thereof. The culture medium mainly comprises carbon source substances and nitrogen source substances. The invention is characterized in that the culture medium is prepared from 500 to 1000ml of basal culture solution 1, 40 to 50g of stomach peptone, 500 to 1000ml of basal culture solution 2, 500 to 1000ml of basal culture solution 3, 15 to 18g of Na2HPO4H.H2O, 30g of NaCl, 5 to 10g of protohemin, 0.5 to 1g of vitamin K, 2.5 to 5g of cysteine hydrochloride and 100 to 200g of glucose by regulating the pH value to 7.4-7.8. When the culture medium is used for cultivating necrotic fusobacterium, the necrotic fusobacterium grows quickly, the necrotic fusobacterium yield is large, and the cost is low. The special efficient culture medium for necrotic fusobacterium is suitable for vaccine production or extraction of leukotoxin.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

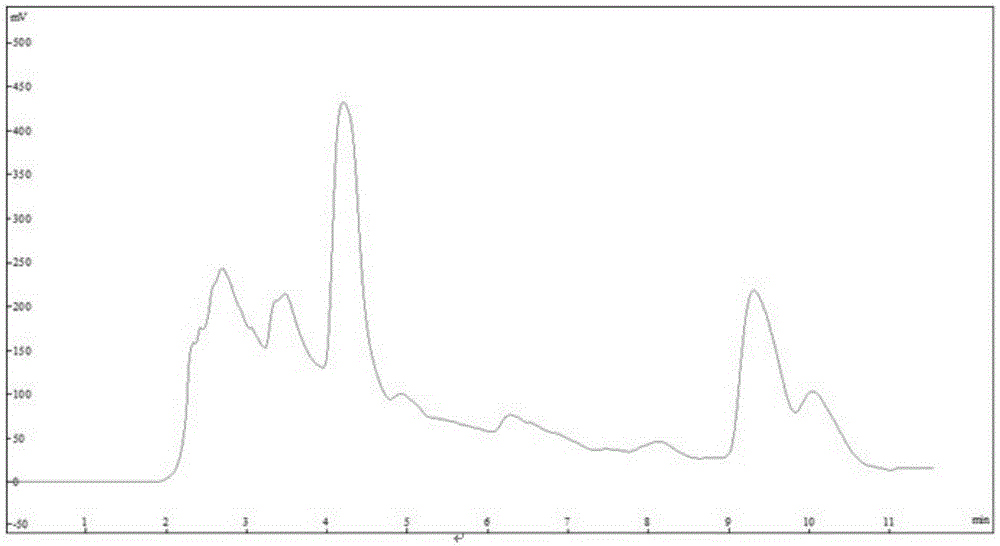

Method for simultaneously extracting three kinds of iridoid glycoside chemical reference substances from fructus ligustri lucidi

InactiveCN105330710AThe solution steps are cumbersomeAddressing Purity IssuesSugar derivativesSugar derivatives preparationChromatographic separationAlcohol

The invention discloses a method for simultaneously extracting three kinds of iridoid glycoside chemical reference substances from fructus ligustri lucidi. According to the method, extracting is performed with an ethyl alcohol aqueous solution to obtain a total fructus ligustri lucidi extract, chromatographic separation is performed with macroporous resin columns to obtain total fructus ligustri lucidi glycosides, the total fructus ligustri lucidi glycosides are purified and separated through inverse-phase efficient preparative liquid chromatography, and then the three kinds of the iridoid glycoside chemical reference substances including the specnuezhenide, the nuezhenoside G13 and the oil nuezhenoside of which the purity is larger than 98% are obtained. According to the method, the three kinds of the iridoid glycoside chemical reference substances of which the purity is up to 98% can be simultaneously obtained through simple treatment, and the problems that in the prior art, only one compound can be obtained, the steps are tedious, and the purity is low are solved.

Owner:DALIAN MEDICAL UNIVERSITY

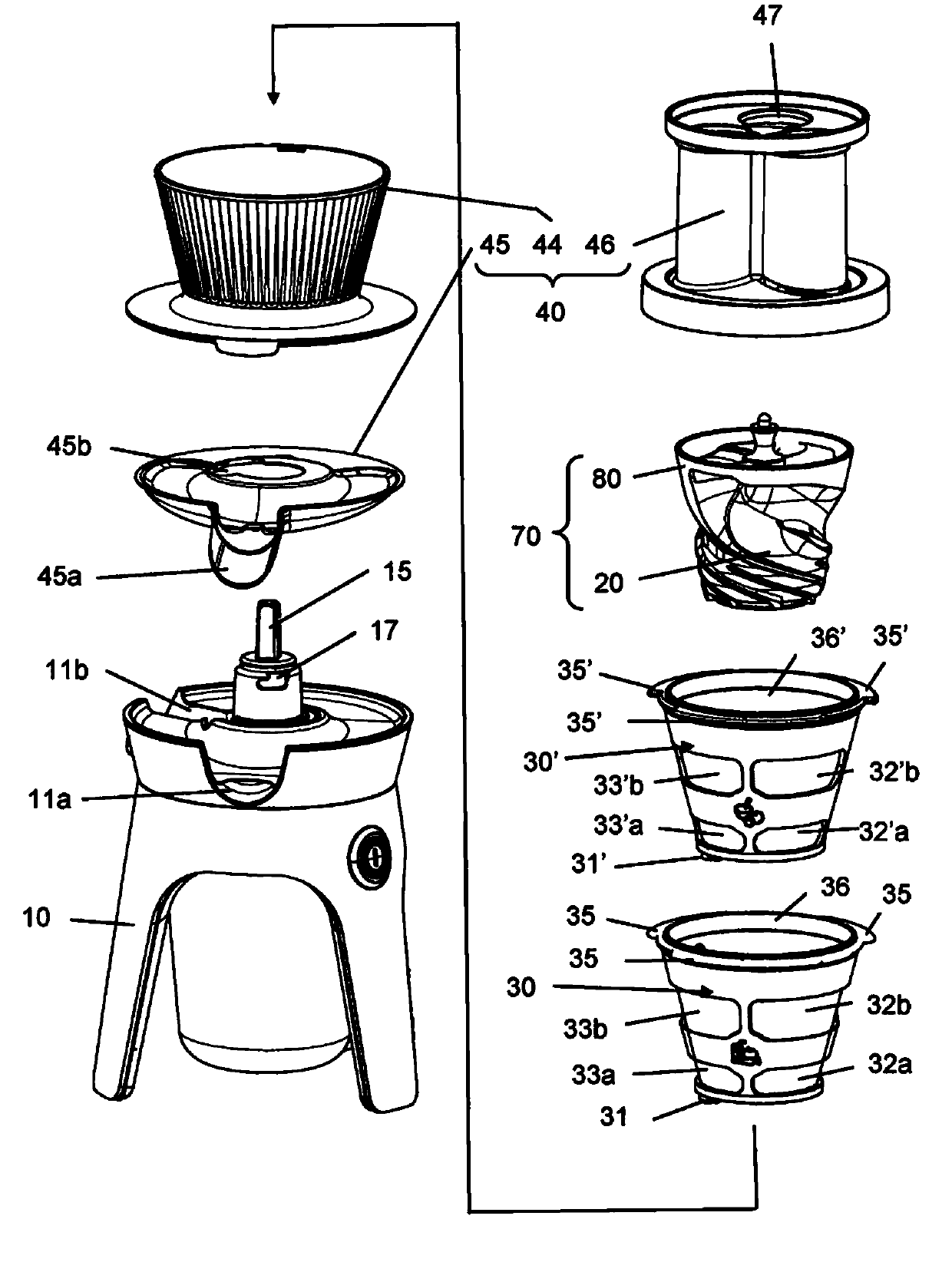

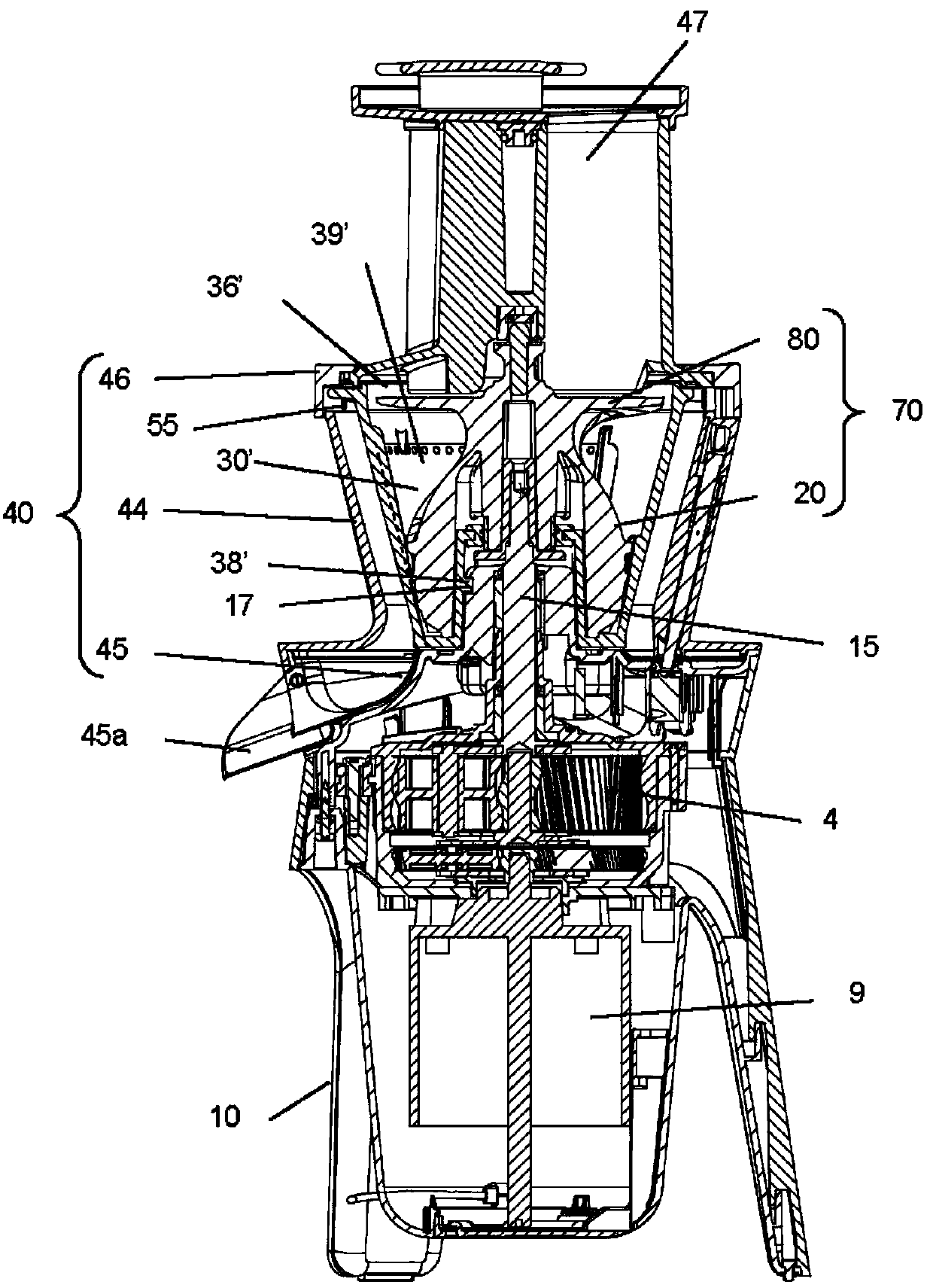

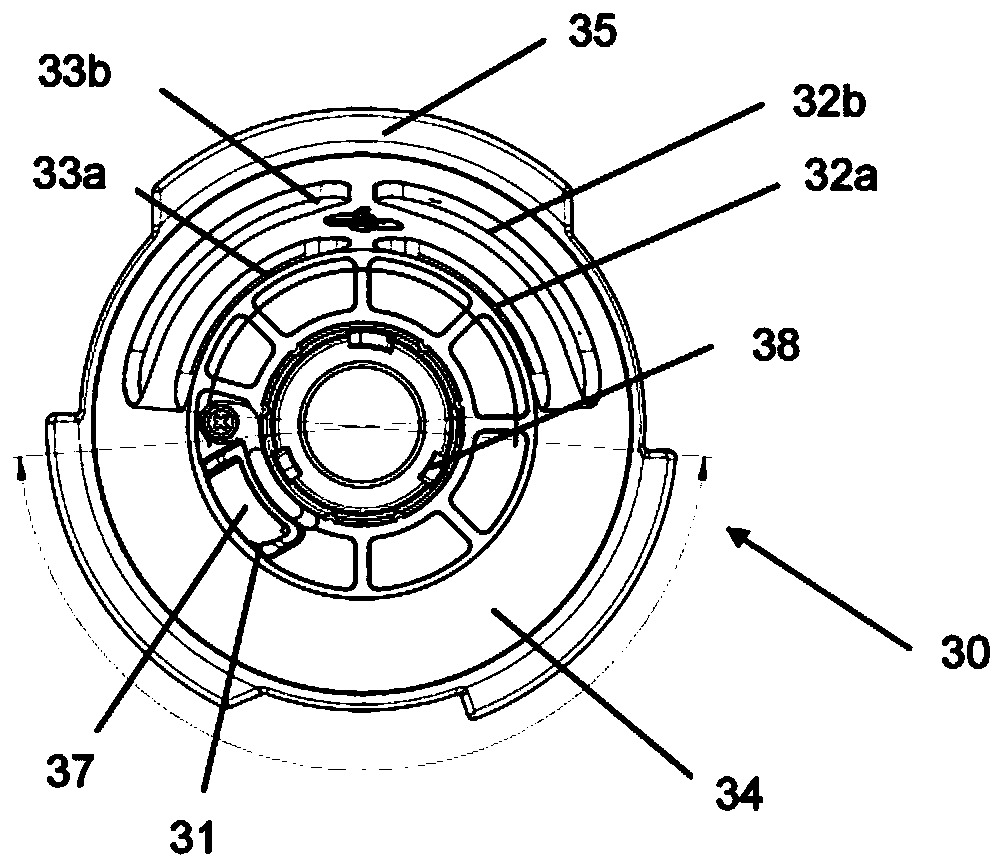

Electric household appliance for culinary preparation, comprising a pressing screw and at least one filter

Owner:SEB SA

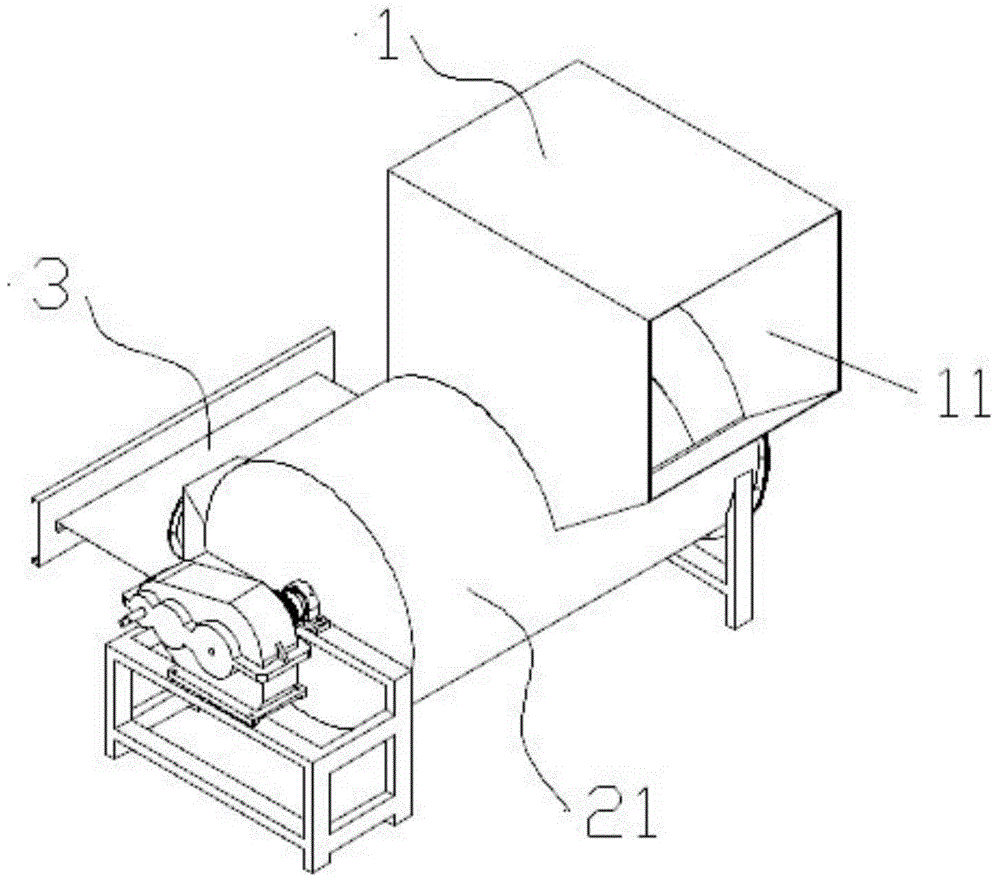

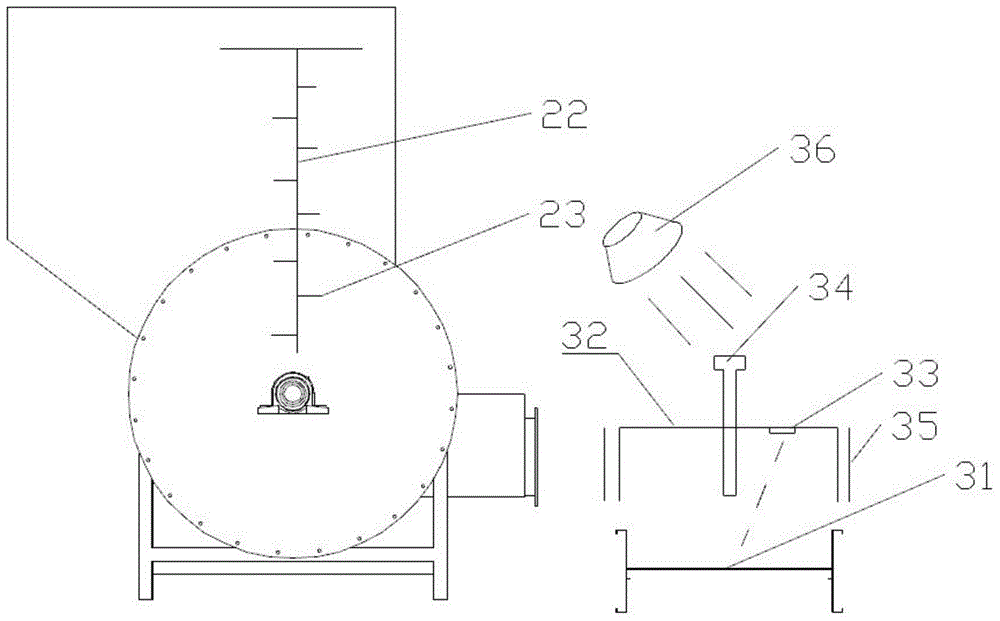

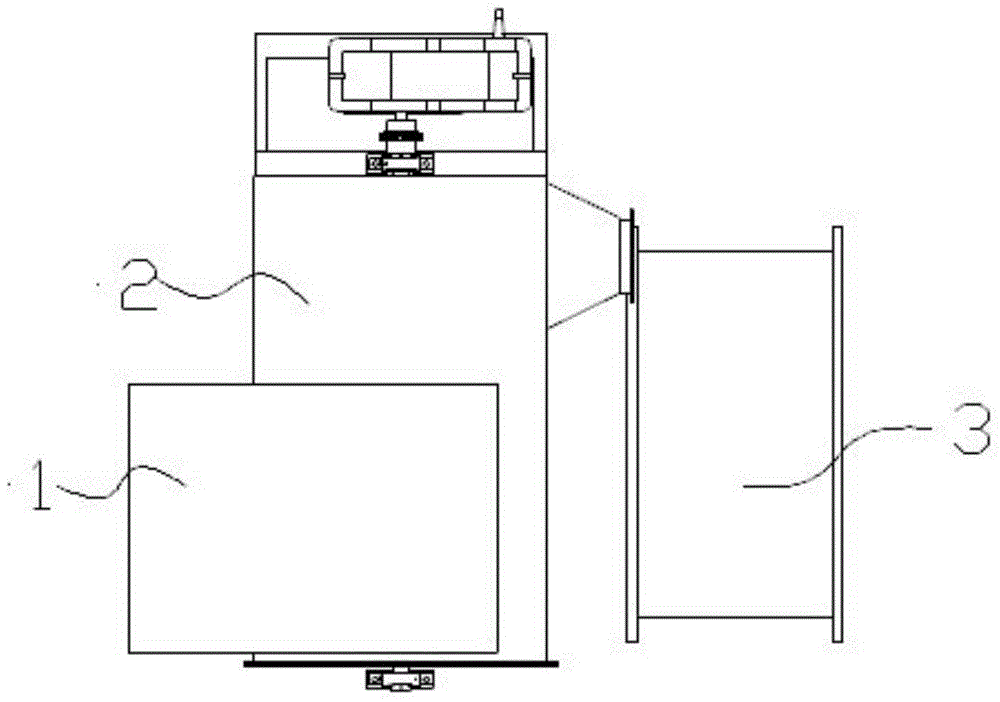

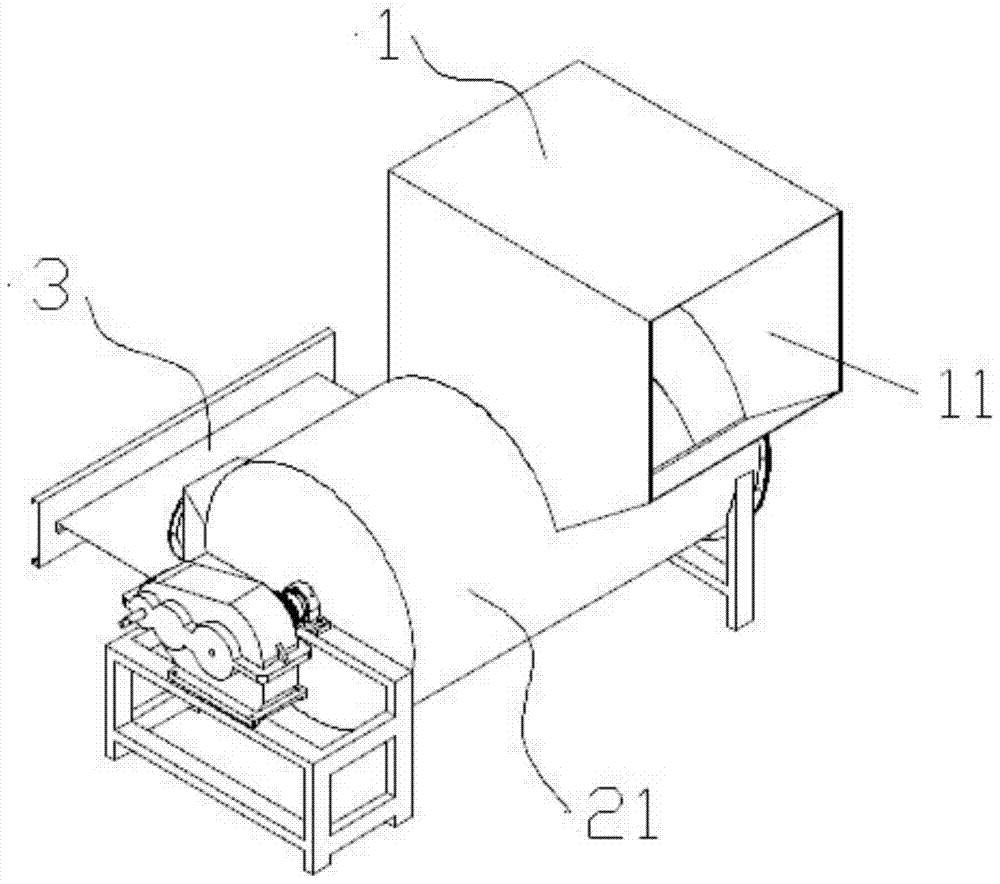

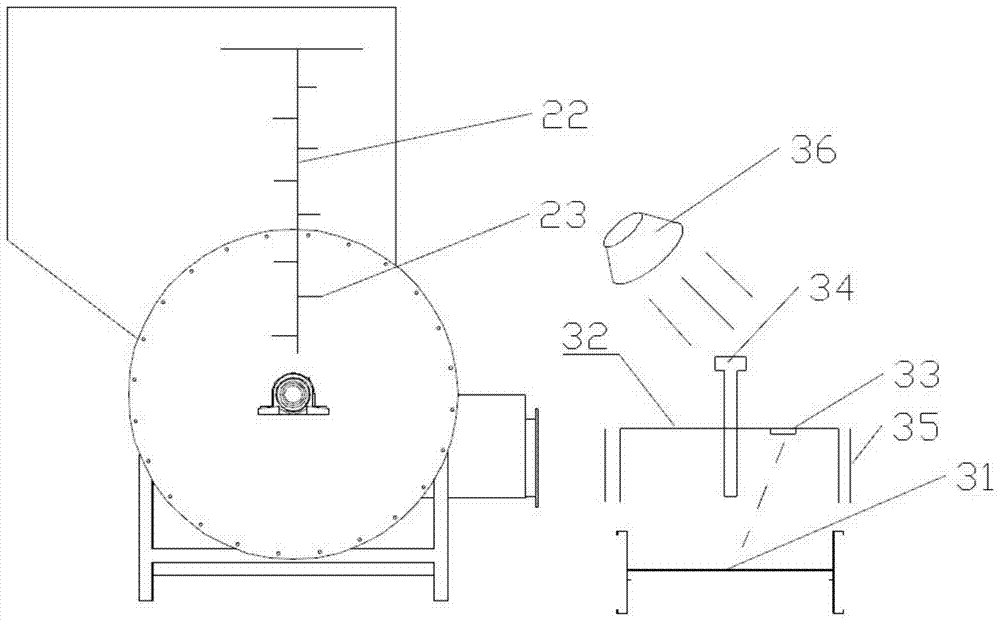

Intelligent crushing and sorting machine

InactiveCN104669465ASuitable for extractionHigh degree of intelligencePlastic recyclingSortingOptical pickupOptical property

The invention provides an intelligent crushing and sorting machine, which comprises a crushing device, a primary sorting device and an intelligent sorting device. The intelligent sorting device is added and comprises a conveyer belt which is connected with the primary sorting device; sealing devices are arranged on two sides of the conveyer belt and above the conveyer belt; and an optical pickup recognition device is arranged above the conveyer belt, so that impurities in foam fragments show different optical characteristics to be recognized under ray illumination. The optical pickup recognition device is electrically connected with an intelligent pickup manipulator for picking up impurities in the foam fragments. The intelligent crushing and sorting machine is high in intelligent degree, high in efficiency, high in accuracy and suitable for extraction of impurities in foam recovery.

Owner:高伟

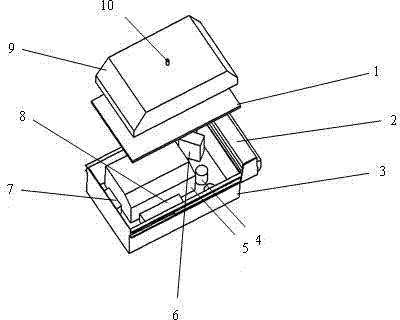

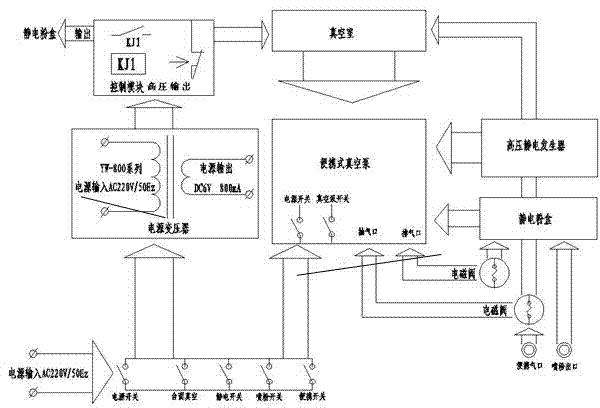

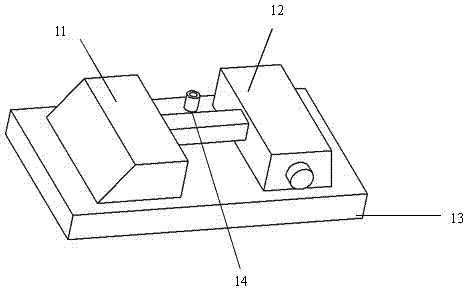

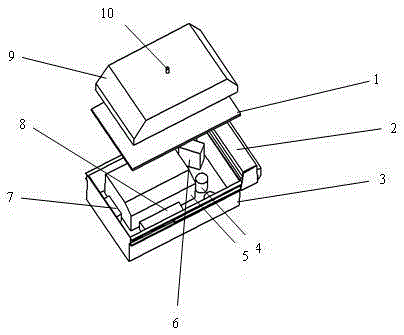

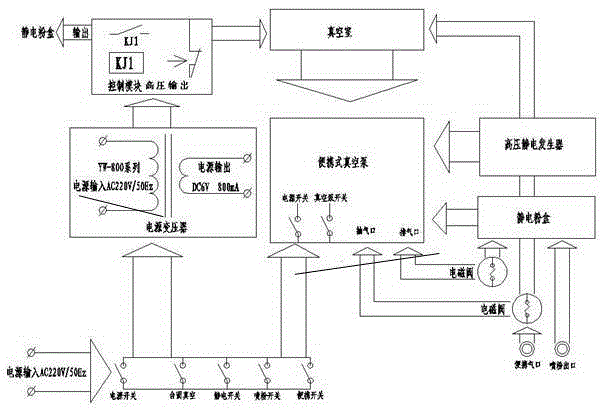

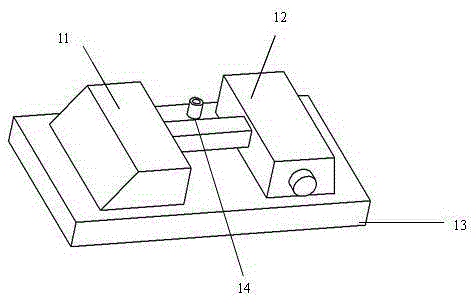

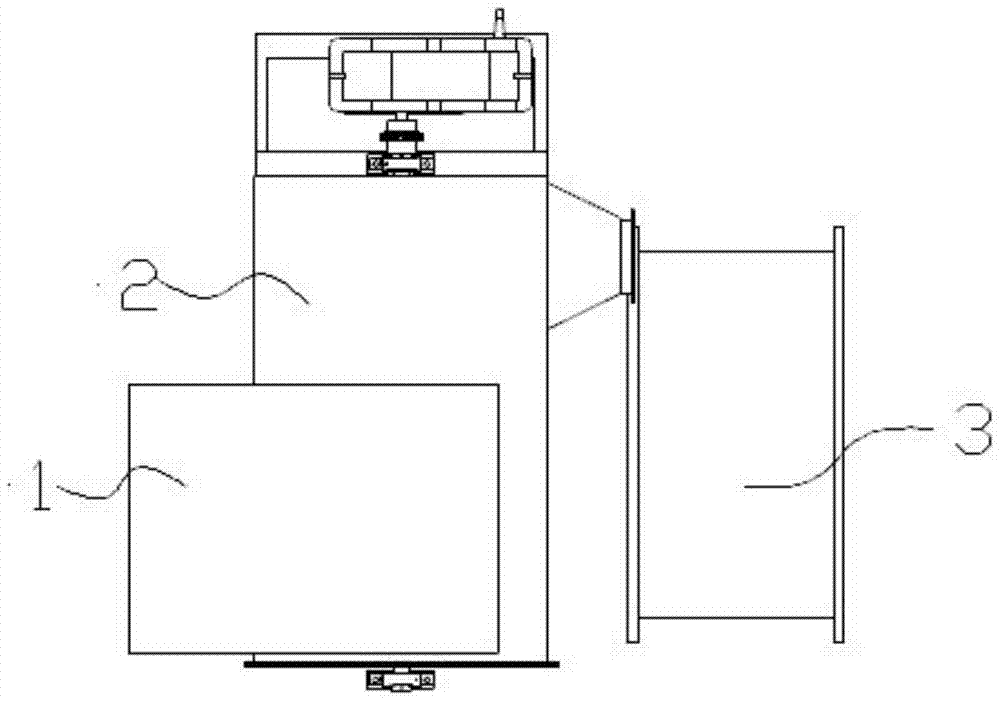

Split type vacuum electrostatic imprint extraction device and application method thereof

InactiveCN102846322AApplicable to a wide range of objectsGood practicalityPerson identificationSensorsHigh frequencyVacuum pump

The invention relates to a split type vacuum electrostatic imprint extraction device and an application method thereof. The extraction device comprises a power supply module, a high voltage electrostatic generation module and a vacuumizing structure. The power supply module is electrically connected with the high voltage electrostatic generation module and the vacuumizing structure. The high voltage electrostatic generation module is used for converting low voltage direct current power into high voltage direct current power for output via high frequency oscillation, so as to generate continuous direct current high voltage static electricity. The vacuumizing structure includes a vacuum chamber and a vacuum pump connected with the vacuum chamber, and the vacuum pump is connected with a control module. The inventive split type vacuum electrostatic imprint extraction device has diversified functions, and is portable, wide in application range, practical and high in performance-to-price ratio.

Owner:CHINA CRIMINAL POLICE UNIV

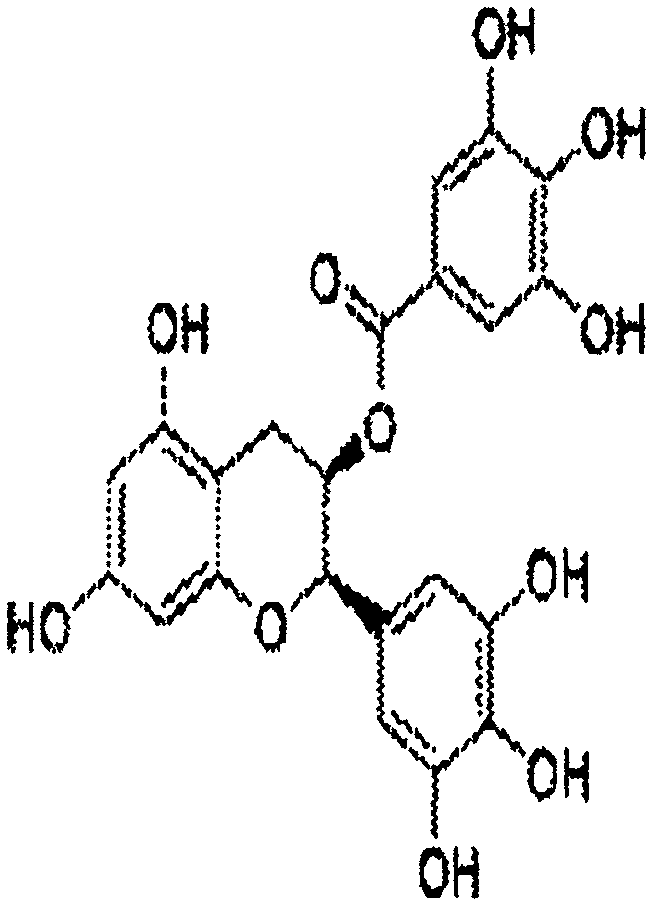

Separation and purification of gallic acid from suaeda salsa by SF-SMB

InactiveCN107903171AEasy solvent recoveryReduce energy consumptionBulk chemical productionCarboxylic compound separation/purificationSolventSimulated moving bed

The invention discloses separation and purification of gallic acid from suaeda salsa by SF-SMB, and relates to a method for separating and purifying the gallic acid from the suaeda salsa. In the wholeprocesses of extracting, separating and purifying the gallic acid from the suaeda salsa, water or ethanol which is environmentally-friendly to equipment and environments is taken as a solvent, and the solvent is conveniently recovered and the energy consumption is low; flavonoids constituents are not stable and easily oxidized, especially more susceptibly oxidized in high temperature environments, the separation and purification of the gallic acid from the suaeda salsa can be completed at room temperature by using an extraction method, the highest extraction temperature is controlled to be not higher than 70 DEG C, and conditions are relatively mild, thereby not affecting the extraction effect of flavonoids constituents, and further being beneficial to the stable existence of the flavonoids constituents; and by adopting the method of the invention, the continuity is enhanced, the purity of the gallic acid is high, the production cycle is shortened, and the cost is low.

Owner:BOHAI UNIV

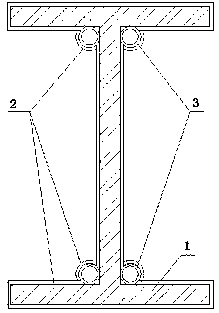

Sectional steel pulling-out method for SMW construction method pile

InactiveCN110629757AAvoid breakingDoes not affect strengthBulkheads/pilesArchitectural engineeringBuilding construction

The invention discloses a sectional steel pulling-out method for a SMW construction method pile. The method comprises the following steps: wrapping a layer of PVC sleeve pipe with a shape which is thesame as the shape of the outer surface of I-shaped sectional steel for stirring construction in the length direction of the outer surface of the I-shaped sectional steel; after the stirring construction is concluded, locating a crane in place, then connecting a hook crane with a hoisting hole of the I-shaped sectional steel and pulling out the I-shaped sectional steel, starting to grout through reserved grouting pipes, and realizing the synchronization of the pulling-out for the I-shaped sectional steel and the grouting. According to the method, the PVC sleeve with the shape which is the sameas the shape of the I-shaped sectional steel is adopted for wrapping the I-shaped sectional steel and inserted into a stirring pile with the I-shaped sectional steel, so that the instability of pulling resistance for the I-shaped sectional steel is avoided; with the adoption of the synchronization of the pulling-out for the I-shaped sectional steel and the grouting, a pressure on the bottom surface of the PVC sleeve, of the grouting and an upward pulling force on the I-shaped sectional steel, of the crane, friction resistance between the PVC sleeve and the I-shaped sectional steel is overcome, and the I-shaped sectional steel can be smoothly pulled out; and moreover, due to the existence of the PVC sleeve, the section of a space after the sectional steel is pulled out can be stabilized. The method is applicable to other sectional steel of the SMW construction method pile.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Cell lysis buffer, kit and method for yeast genome extraction

PendingCN113265397AShorten the lysis timeGood effectDNA preparationGuanidine isothiocyanateThiocyanic acid

The invention relates to the technical field of DNA extraction, and provides a cell lysis buffer, a kit and a method for yeast genome extraction. The cell lysis buffer for extracting the yeast genome is prepared from the following components: 50 to 60 g / L of guanidine isothiocyanate, 1 to 10 g / L of Tris-base, 8 to 15 g / L of EDTA.2Na and 1 to 10 percent of Tween-20. Compared with the prior art, the yeast genome extraction kit provided by the invention is time-saving, labor-saving and thorough in cell lysis, chloroform is not used in the experiment process, the harm to experiment operators is reduced, and the extracted genome is high in yield and can be directly used for subsequent experiments, and does not need to be purified.

Owner:JIERUI BIOENG SHANGHAI

Method for extracting rice bran protein by complex enzyme

InactiveCN101012471BSuitable for extractionOptimizing the Compounding RatioFermentationProtein solutionPhytase

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

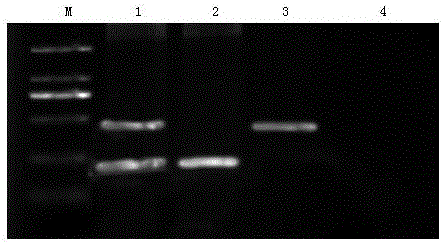

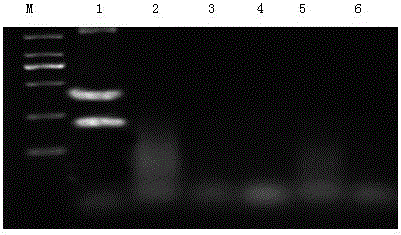

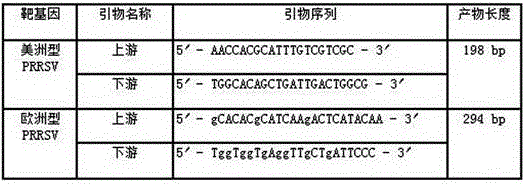

Multiple RT-PCR detection kit for American type porcine reproductive and respiratory syndrome virus and porcine parvovirus

InactiveCN105861754ARapid responseTimely extinguish or interrupt transmissionMicrobiological testing/measurementMicroorganism based processesSmall sampleTyping

The invention provides a multiple RT-PCR detection kit for American type porcine reproductive and respiratory syndrome virus and porcine parvovirus, comprising a primer pair 1 for amplifying a target gene of American type porcine reproductive and respiratory syndrome virus and a primer pair 2 for amplifying a target gene of porcine parvovirus. The invention also provides a use method of the detection kit. The detection kit provided by the invention is quick as compared with the classical method of virus isolation, single RT-PCR and serotype typing, and can conveniently identify and distinguish any one of the American type porcine reproductive and respiratory syndrome virus and porcine parvovirus once, so that timely and quick response can be made to epidemic disease conditions, regions and environments, and a correct method of disposition can be decided in the shortest time, which has a positive meaning for stopping or blocking infectious disease transmission; and simultaneously the detection kit is especially suitable for extraction of small samples and has broad market application prospects.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

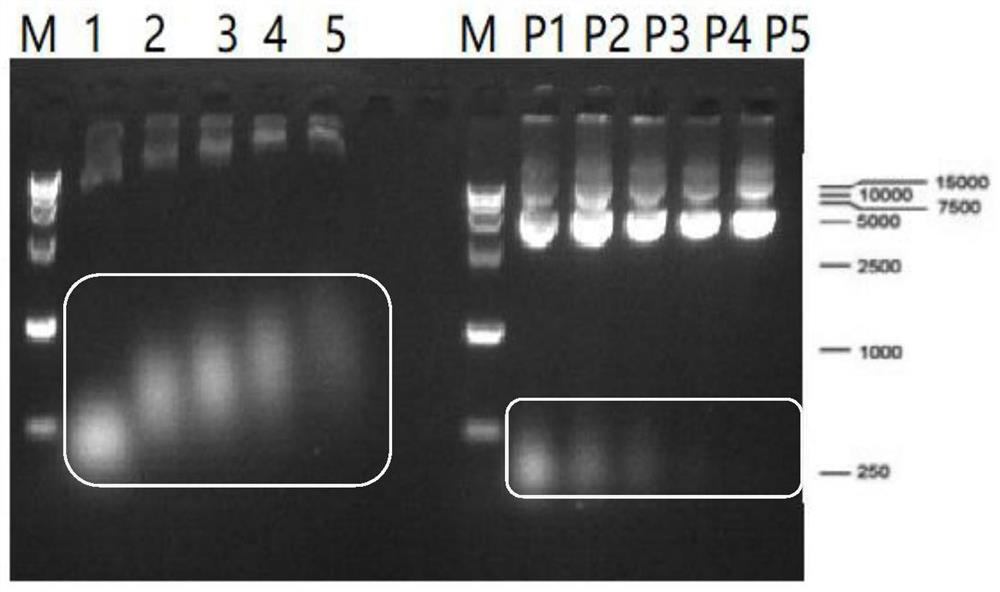

Method for extracting plasmids with endotoxin removed on large scale

ActiveCN107502606AImprove pollutionEliminate pollutionMicrobiological testing/measurementDNA preparationEndotoxin removalDigestion

The invention relates to a method for extracting plasmids with endotoxin removed on a large scale. The method comprises the steps of acquiring roughly-separated plasmid DNA by virtue of a classical alkaline lysis method, sequentially adding isopropanol, an NH4Ac solution, RNase A and NaCl, adding a mixed solution of PEG6000 and NaCl, dissolving and precipitating by virtue of a TE solution, repeatedly precipitating by virtue of absolute ethyl alcohol, washing and precipitating by virtue of 70% alcohol, simultaneously coordinating with centrifugation, drying, and finally dissolving and precipitating by virtue of the TE solution, so as to obtain target plasmids. According to the method, the pollution caused by endotoxin to plasmid DNA can be well removed, all reagents are standing chemical reagents in a laboratory, and the operation method is simple, easy to control and suitable for large-scale extraction of plasmids. The concentration of the plasmids can reach 5mg / mL, the endotoxin is lower than 5EU / mu g, and the plasmids can be applied to digestion, DNA sequencing, cell transfection, virus packaging and clinic animal immunization experiments.

Owner:上海埃秀马生物科技有限公司

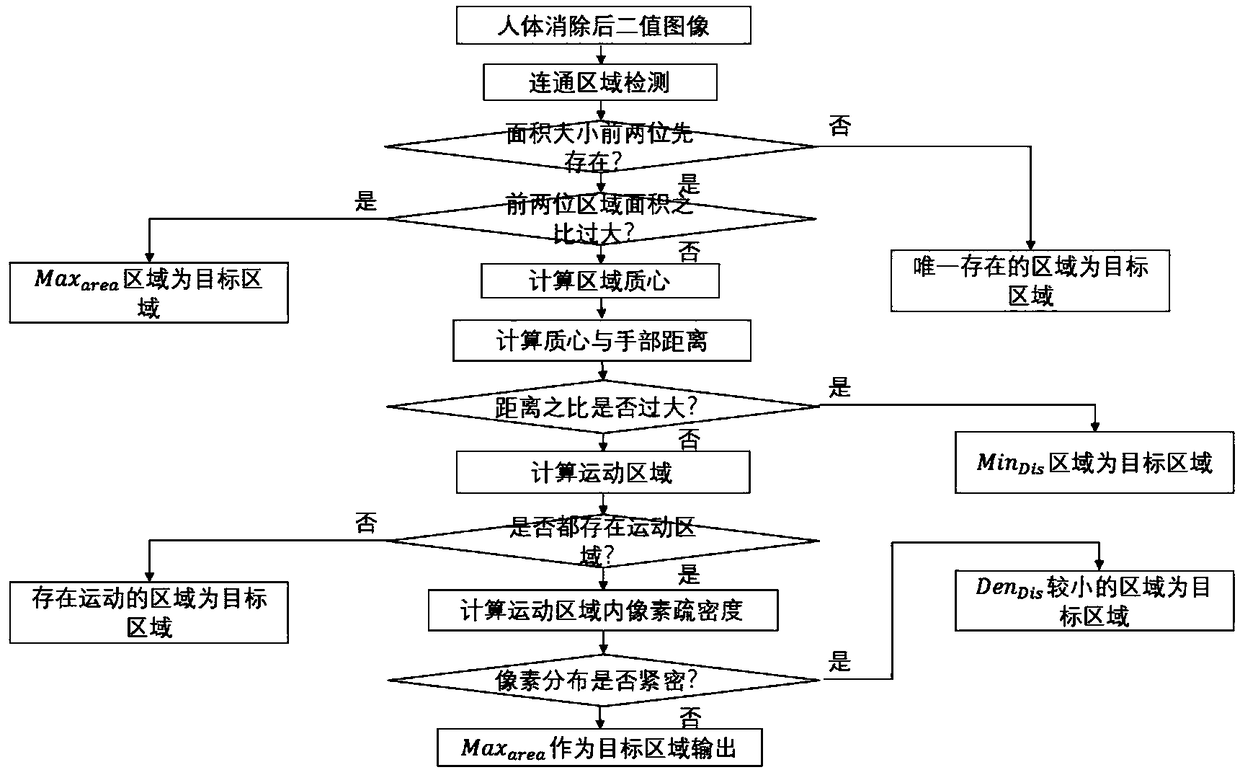

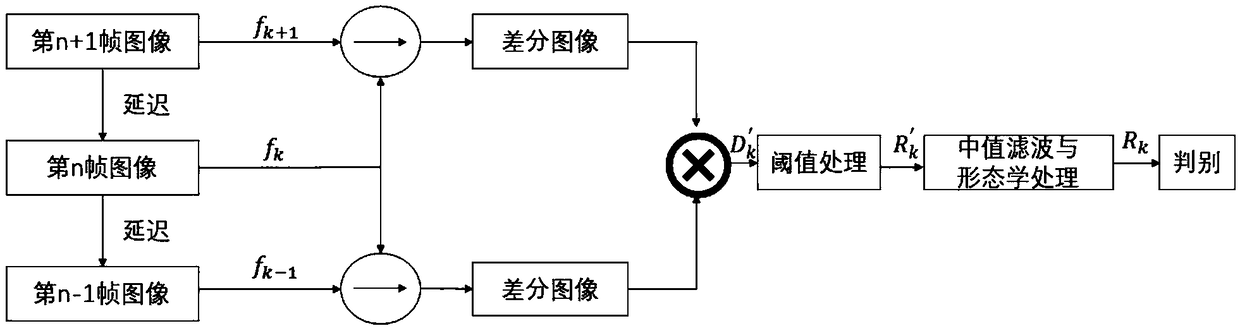

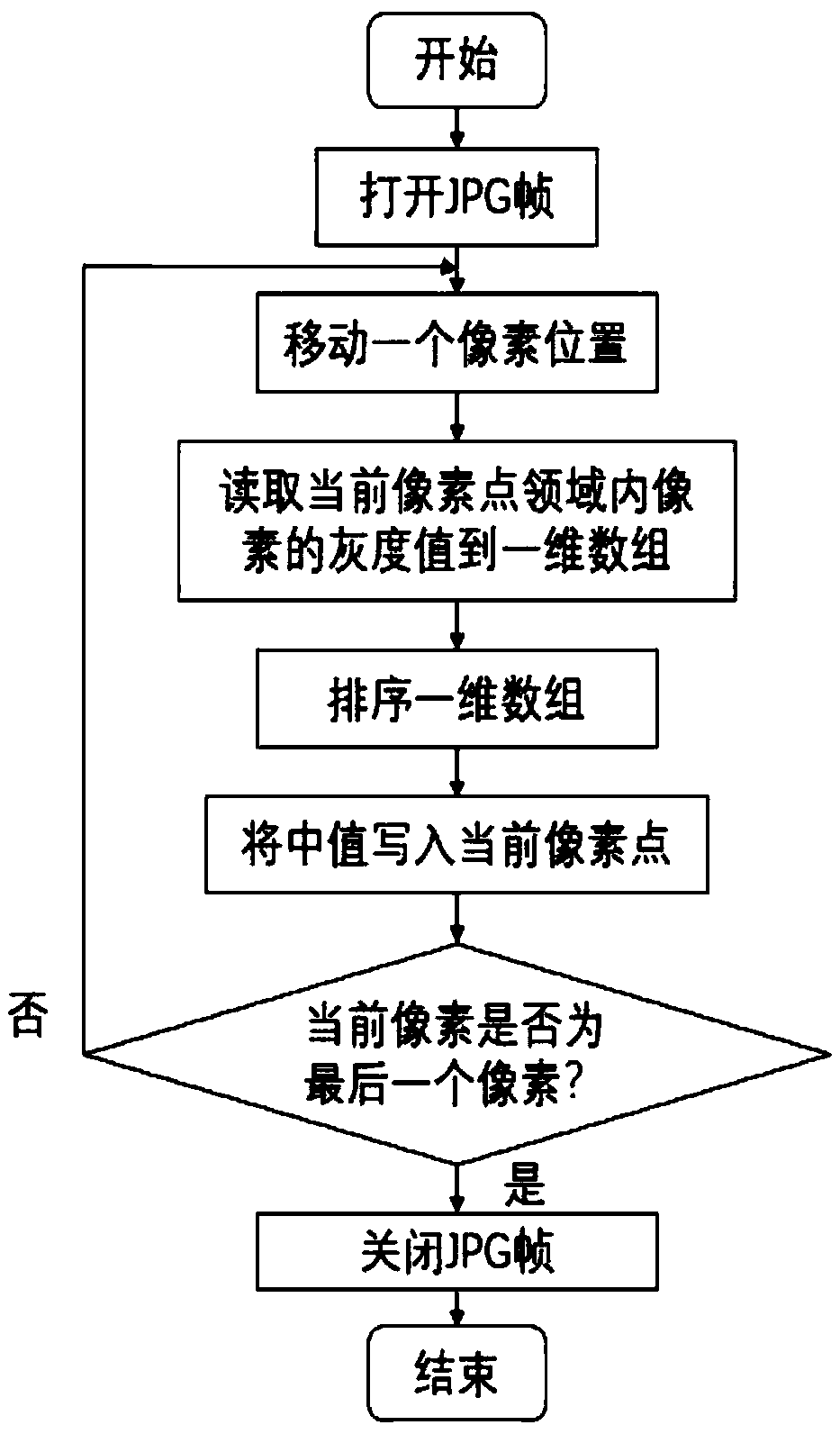

A new method of target tracking and location based on pixel features

ActiveCN109300165ASuitable for extractionAdapt to the requirements of target tracking and positioning processingImage enhancementImage analysisFrame differenceHuman body

The invention discloses a novel target tracking and positioning method based on pixel characteristics, which comprises the following steps of: removing human body region: extracting foreground by three frame difference methods for RGB components of pixel points of an image, and binarizing the foreground image to obtain a binary image; detecting the key points of human body in binary image, including hand key points, eyebrow center key points and bipedal midpoint; Marking all connected regions of the binary image; Target tracking and positioning: according to the pixel distribution characteristics of the connected region, the target position and the target positioning point are determined. Motion feature correction: According to the pixel distribution characteristics in the detected connected region, the vector direction of the region is obtained by dimension reduction method and the position of the target point is corrected. The method of the invention can quickly extract motion features, and can quickly and accurately track and locate a moving target in either a simple background or a complex scene, especially when the moving time is short and the target is long and slender, the method is very practical, and has a good popularization prospect.

Owner:NANJING UNIV OF POSTS & TELECOMM

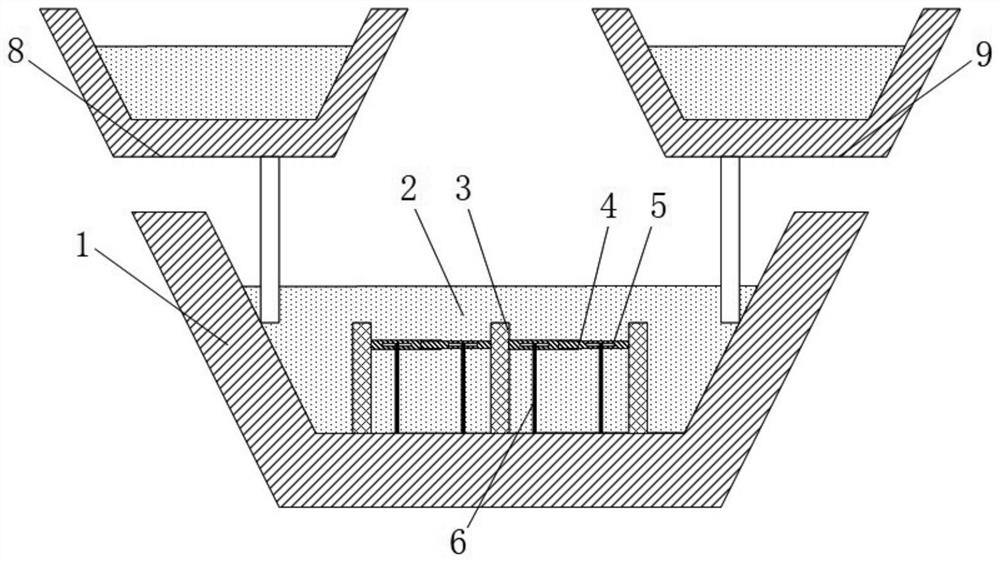

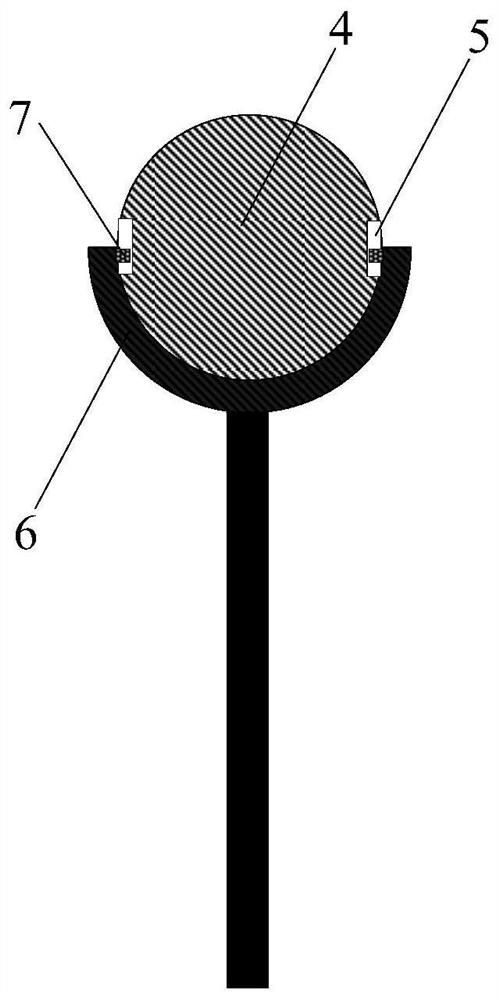

Lithium carbonate solar pond and lithium carbonate extraction method

ActiveCN113336250AEfficient recyclingHigh yieldLithium carbonates/bicarbonatesSalt lakeLithium carbonate

The invention discloses a lithium carbonate solar pond and a lithium carbonate extraction method, belongs to the technical field of lithium extraction, and solves the problems that the concentration of CO3 < 2-> in existing salt lake brine is relatively low, the lithium precipitation effect after heating is poor, and the lithium carbonate yield is relatively low due to incomplete precipitation of Li < + >. The lithium carbonate solar pond comprises a tail brine pond, a brine forming pond and a lithium separating pond, wherein brine in the lithium separating pond is mixed brine of the tail brine and the brine forming pond, the concentration of Li < + > in the tail brine in the tail brine pond is greater than the concentration of Li < + > in the brine forming pond, and the concentration of CO3 < 2-> in the tail brine in the tail brine pond is less than the concentration of CO3 < 2-> in the brine forming pond. According to the extraction method, tail brine in the tail brine pond and finished brine in the brine forming pond are mixed, the brine is poured into the lithium precipitation pond to prepare the salt gradient solar pond, and lithium carbonate is extracted when the salt gradient solar pond enters a stable temperature rise lithium precipitation stage. The lithium carbonate solar pond and the lithium carbonate extraction method can be used for extracting lithium carbonate in field salt lakes, and the yield of lithium carbonate is high.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

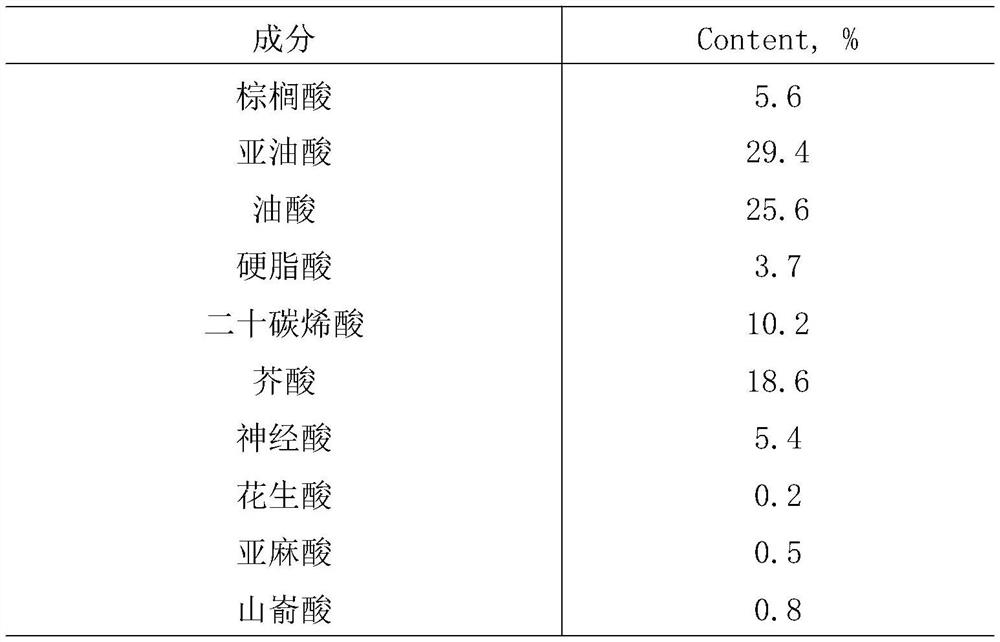

Method for extracting acer truncatum oil by combining ultrahigh pressure with subcritical extraction technology

InactiveCN112048376AReduce extraction timeReduce energy consumptionFatty-oils/fats productionOil and greasePhysical chemistry

The invention relates to the technical field of grease extraction processes, in particular to a method for extracting acer truncatum oil by combining ultrahigh pressure with a subcritical extraction technology. The method comprises the following steps: selecting raw materials; shelling: selecting acer truncatum seeds; crushing; ultrahigh-pressure treatment: performing ultrahigh-pressure treatmenton the acer truncatum seed powder under certain conditions; subcritical extraction: weighing about 100-300g of powder, putting the powder into a material bag, putting the material bag into a subcritical extraction tank, and vacuumizing the extraction tank until the vacuum degree is -0.1 Mpa; taking butane as an extracting agent, and extracting for 3-5 times under the conditions that the extractiontemperature is 20-50 DEG C, the extraction time is 30-120 minutes; and separation: after the extraction is finished, introducing the extraction liquid into a separation tank, reducing the pressure to-0.1 Mpa, and separating butane from the acer truncatum oil to obtain the acer truncatum oil. The extraction time is short; the energy consumption is low; and the oil yield is high.

Owner:QILU UNIV OF TECH +1

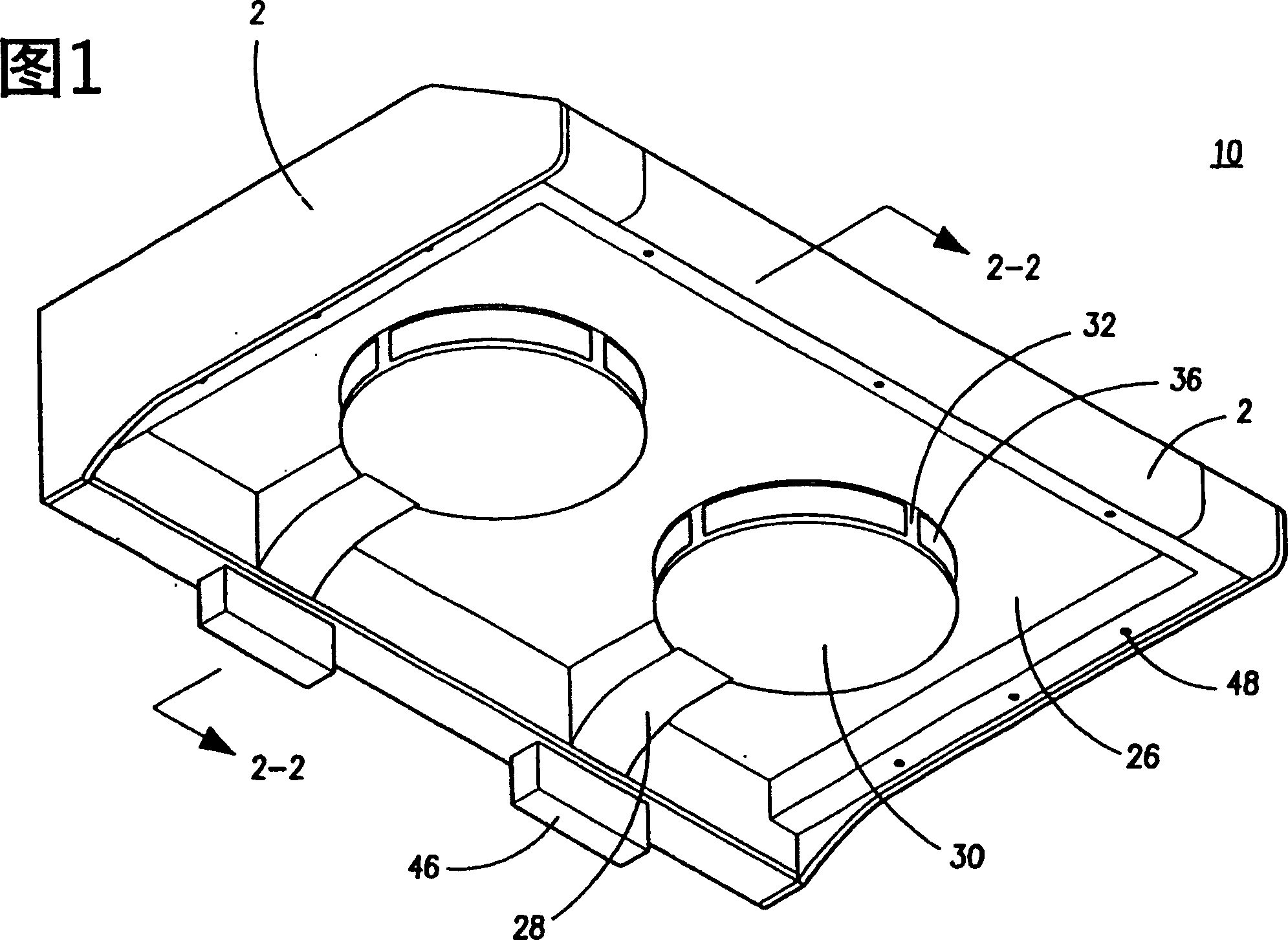

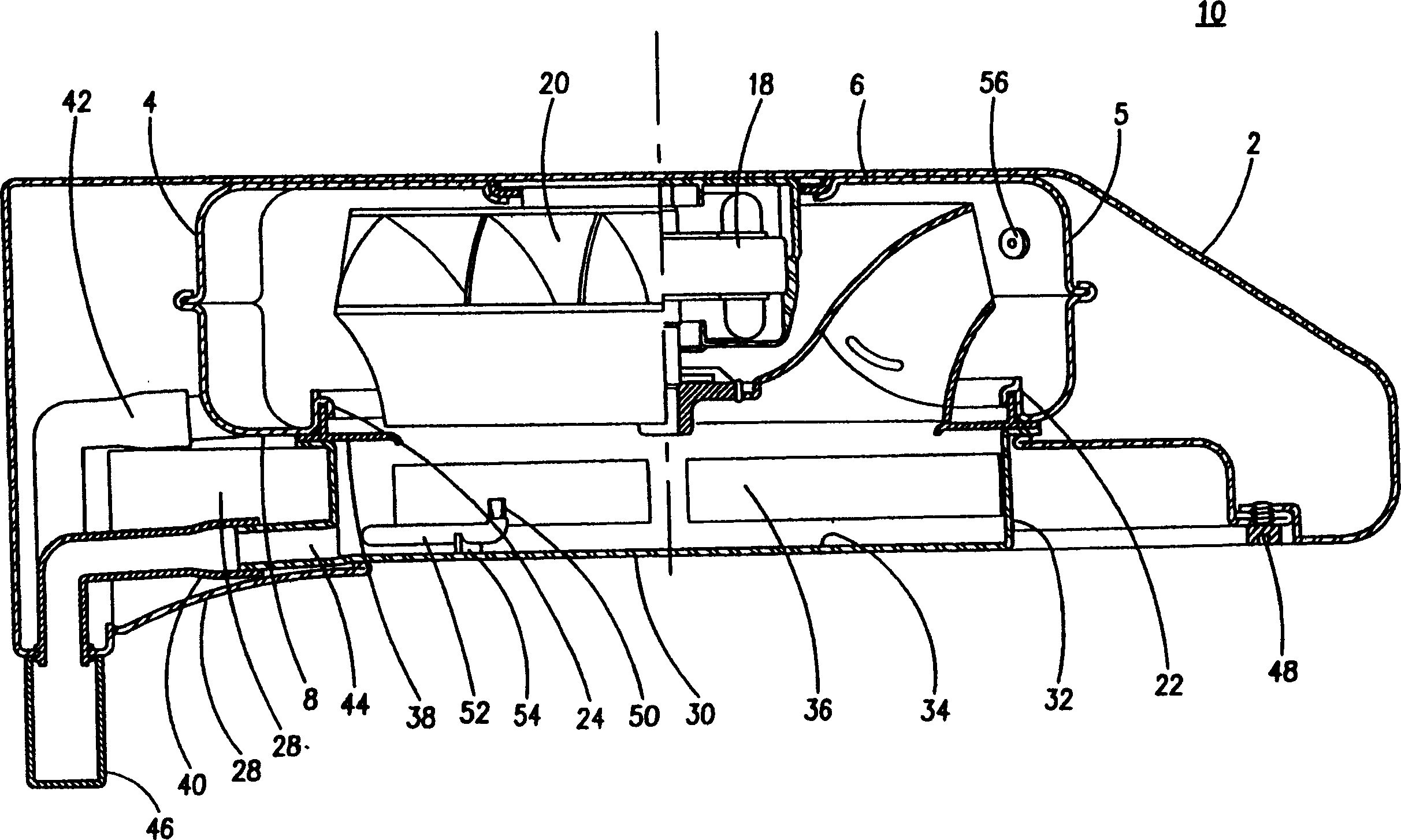

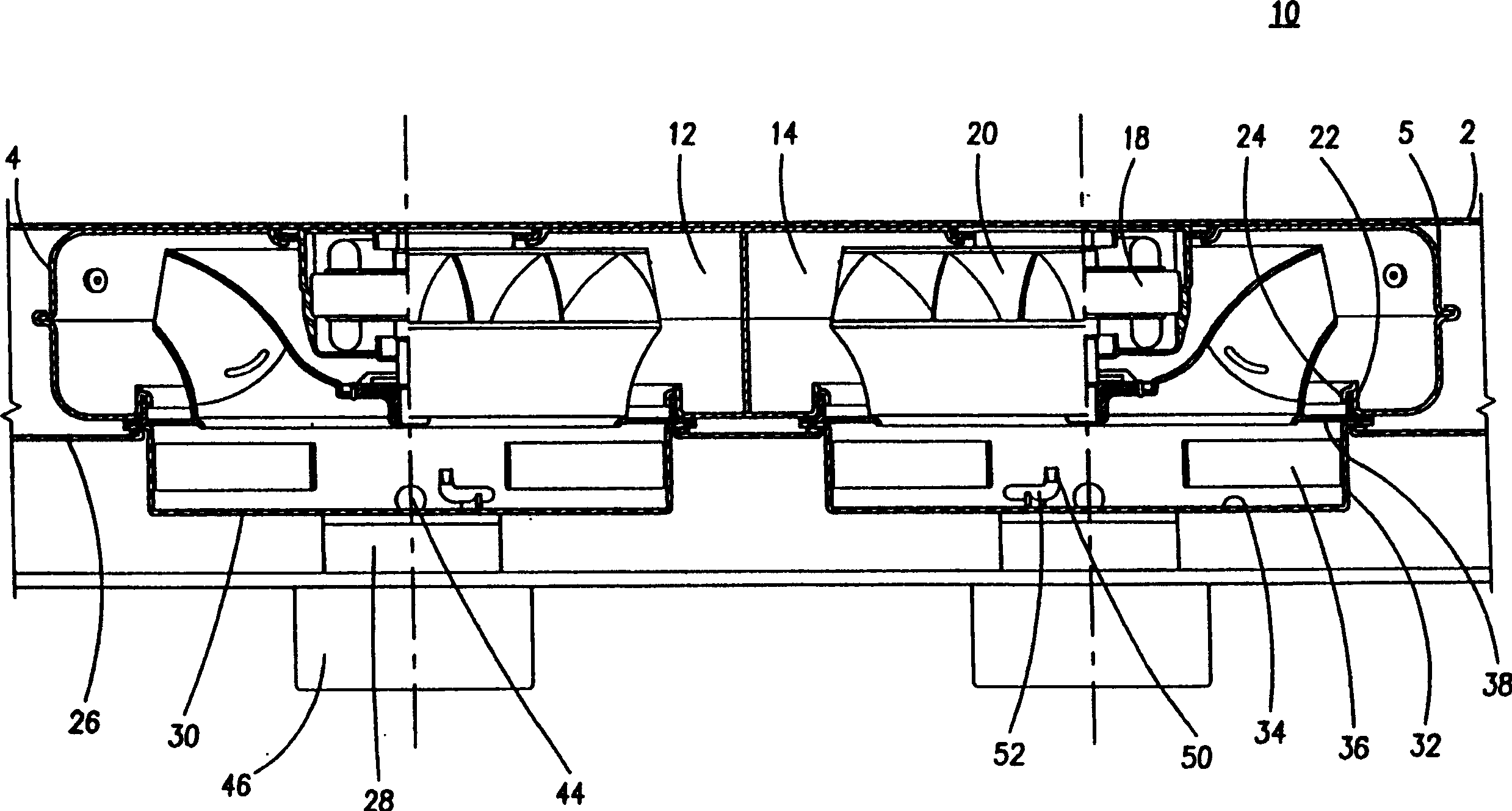

Double - motor kitchen fumes exhausting hood with peripheral air inlet

InactiveCN1291190CSuitable for extractionDomestic stoves or rangesLighting and heating apparatusSpray nozzleAbutment

A kitchen range hood for exhausting gases comprises an outer hood body within which a motor housing is mounted. The motor housing has top, bottom and perimeter side surfaces defining a pair of substantially similar air chambers, a motor and fan being housed in each chamber. An opening in the bottom surface of the housing is aligned below each of the fans. A tray is located in abutment with the housing below the opening in the bottom surface. The tray has a wall and a floor, with at least one air inlet opening in the wall. A bottom panel is connected to the bottom of the hood body about the tray. Air is drawn into the range hood through the air inlet in the tray wall. The range hood is also equipped with an automatic cleaning system, comprising a spray nozzle and hose seated above the floor of the tray.

Owner:GRANT MILLION INVESTMENTS

A kind of preparation method of Jiruge-6 flavor suppository

Owner:INNER MONGOLIA MEDICAL UNIV

A split-type vacuum electrostatic trace extractor and its application method

InactiveCN102846322BApplicable to a wide range of objectsImprove practicalityPerson identificationSensorsElectricityVacuum extractor

The invention relates to a split type vacuum electrostatic imprint extraction device and an application method thereof. The extraction device comprises a power supply module, a high voltage electrostatic generation module and a vacuumizing structure. The power supply module is electrically connected with the high voltage electrostatic generation module and the vacuumizing structure. The high voltage electrostatic generation module is used for converting low voltage direct current power into high voltage direct current power for output via high frequency oscillation, so as to generate continuous direct current high voltage static electricity. The vacuumizing structure includes a vacuum chamber and a vacuum pump connected with the vacuum chamber, and the vacuum pump is connected with a control module. The inventive split type vacuum electrostatic imprint extraction device has diversified functions, and is portable, wide in application range, practical and high in performance-to-price ratio.

Owner:CHINA CRIMINAL POLICE UNIV

Method for separating and purifying quercetin in common seepweed herb by use of supercritical simulated moving bed chromatographic system

InactiveCN107935977AEasy to recycleDoes not affect the extraction effectOrganic chemistryBulk chemical productionGallic acid esterSimulated moving bed

The invention relates to a method for separating and purifying quercetin in common seepweed herb, in particular to a method for separating and purifying quercetin in common seepweed herb by use of a supercritical simulated moving bed chromatographic system. The whole process of extracting, separating and purifying quercetin from common seepweed herb adopts water or ethyl alcohol which is friendlyto equipment and the environment as a solvent, the solvent is convenient to recover, and the energy consumption is low. As flavonoid constituents are unstable, have high probability of being oxidized,and have probability of being oxidized particularly in a high-temperature environment. The adopted extraction method can be finished at the room temperature; the extraction temperature is controllednot to exceed 70 DEG C; and the condition is mild; not only is the flavonoid constituent extraction effect not influenced, but also stable existence of the flavonoid constituents is facilitated. By adoption of the method, the continuity is enhanced, the purity of gallic acid is high, the production cycle is shortened, and the cost is low.

Owner:BOHAI UNIV

A method for large-scale extraction of endotoxin-removed plasmids

ActiveCN107502606BImprove pollutionEliminate pollutionMicrobiological testing/measurementDNA preparationEnzyme digestionEndotoxin removal

The invention relates to a large-scale method for extracting endotoxin-removed plasmids, which comprises firstly obtaining crudely separated plasmid DNA by classical alkaline lysis, and then adding isopropanol, NH 4 Ac solution, RNase A, NaCl, and then add the mixed solution of PEG6000 and NaCl, during the period, use TE solution to dissolve the precipitate, re-precipitate with absolute ethanol, wash the precipitate with 70% ethanol and cooperate with centrifugation, and finally dissolve the precipitate with TE solution after drying , to obtain the target plasmid. The invention can well remove the pollution of endotoxin to plasmid DNA. All the reagents used in the invention are chemical reagents that are always in the laboratory. The operation method is simple and easy to control, and is suitable for large-scale plasmid extraction. The concentration of the plasmid obtained by the present invention can reach 5mg / mL, and the endotoxin is lower than 5EU / μg, and the plasmid can be used for enzyme digestion, DNA sequence sequencing, cell transfection, virus packaging and clinical animal immune experiments.

Owner:上海埃秀马生物科技有限公司

Intelligent crushing and sorting machine

InactiveCN104669465BSuitable for extractionHigh degree of intelligencePlastic recyclingSortingOptical pickupElectricity

The invention provides an intelligent crushing and sorting machine, which comprises a crushing device, a primary sorting device and an intelligent sorting device. The intelligent sorting device is added and comprises a conveyer belt which is connected with the primary sorting device; sealing devices are arranged on two sides of the conveyer belt and above the conveyer belt; and an optical pickup recognition device is arranged above the conveyer belt, so that impurities in foam fragments show different optical characteristics to be recognized under ray illumination. The optical pickup recognition device is electrically connected with an intelligent pickup manipulator for picking up impurities in the foam fragments. The intelligent crushing and sorting machine is high in intelligent degree, high in efficiency, high in accuracy and suitable for extraction of impurities in foam recovery.

Owner:高伟

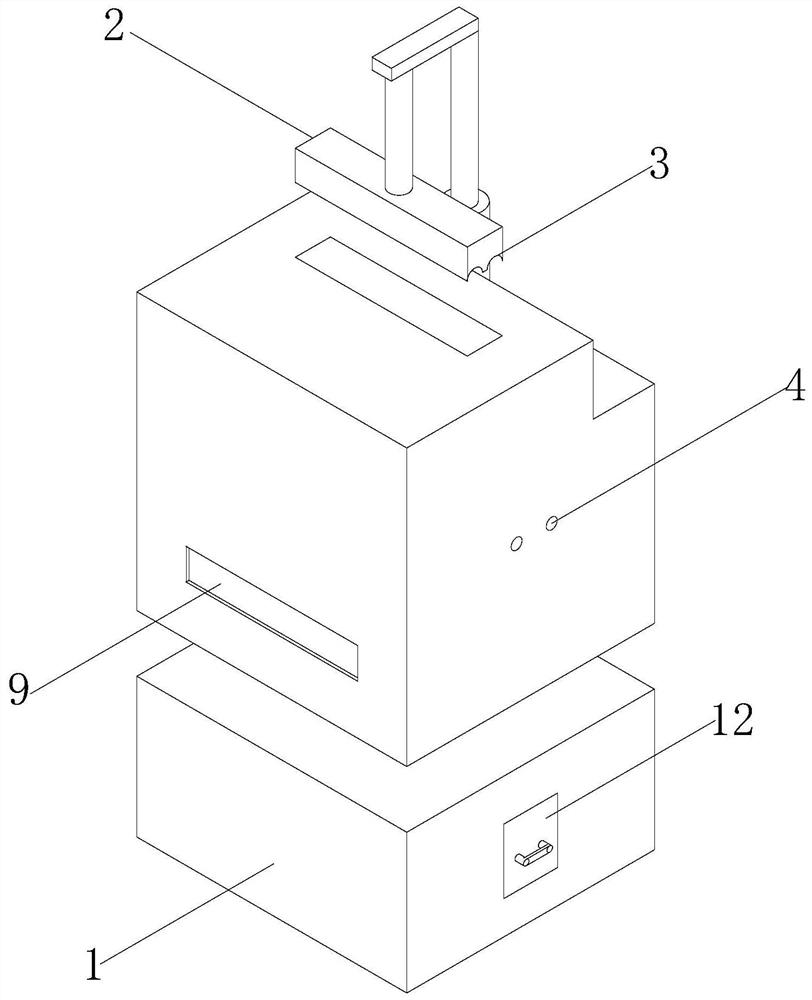

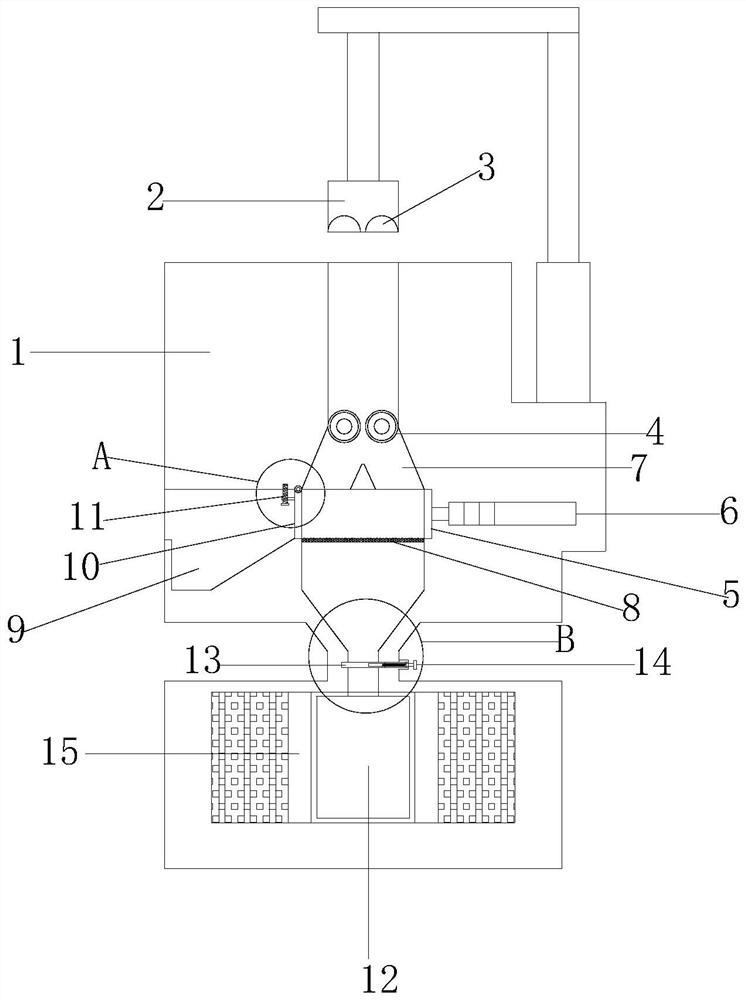

Multi-layer squeezing and extracting device for traditional Chinese medicine

InactiveCN114801285AImprove crushing efficiencyFully filteredGrain treatmentsPressesMedicinal herbsEngineering

The invention relates to the technical field of extraction devices, and discloses a traditional Chinese medicine multi-layer squeezing extraction device which comprises a mounting table, a processing cavity is formed in the mounting table, a smashing part is arranged in the processing cavity, an extrusion block is arranged above the smashing part, and a linear lifting part for driving the extrusion block to move up and down is arranged on the mounting table. According to the multi-layer squeezing and extracting device for the traditional Chinese medicine, medicinal materials can be smashed and subjected to multi-layer squeezing and extracting, meanwhile, liquid medicine and medicine residues can be separated conveniently, after the medicinal materials are extracted, the storage temperature of the liquid medicine can be adjusted at any time, the medicinal material extracting efficiency and the finished product quality are improved, and the device is suitable for popularization and application. The method is suitable for medicinal material extraction.

Owner:HEFEI CAREER TECHNICAL COLLEGE

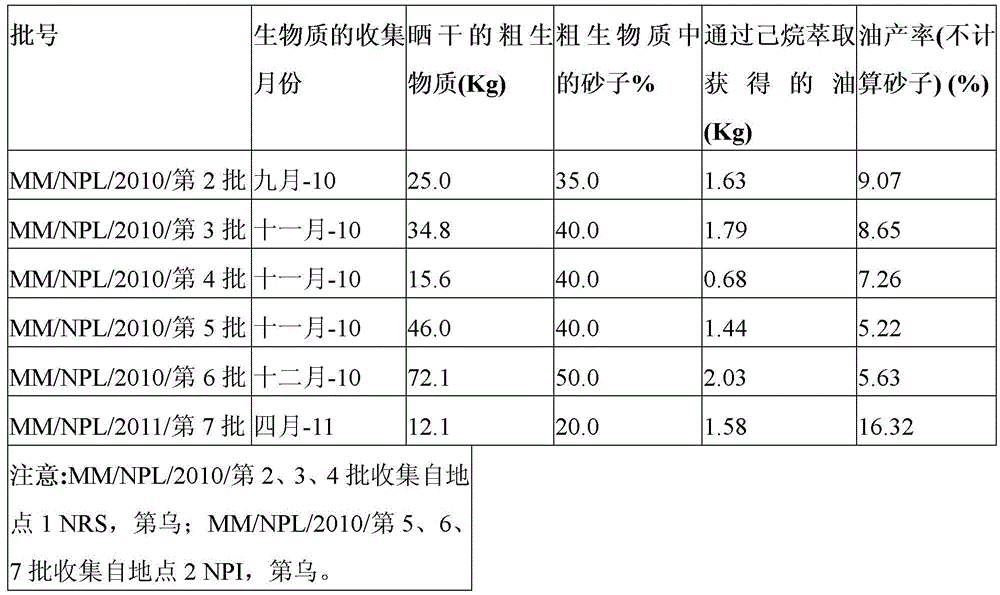

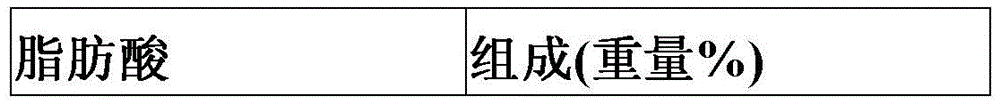

Value Addition of Engine-Usable Fatty Acid Methyl Esters (Biodiesel) and By-Products from Naturally Occurring Marine Microalgae Populations and Marine Microalgae Cultivated in Open-air Salt Pans

InactiveCN103842514BHigh biomass productivityGood lipid contentFatty acid esterificationBiofuelsBiologyFatty acid methyl ester

The present invention teaches the obtained instructions and method for producing engine-useable marine microalgal fatty acid methyl esters (biodiesel) using naturally occurring populations of marine microalgae and culturing marine microalgae in sun-dried salt pans in a cost-effective manner . The utility of by-product streams adds to the attractiveness of the present invention.

Owner:COUNCIL OF SCI & IND RES

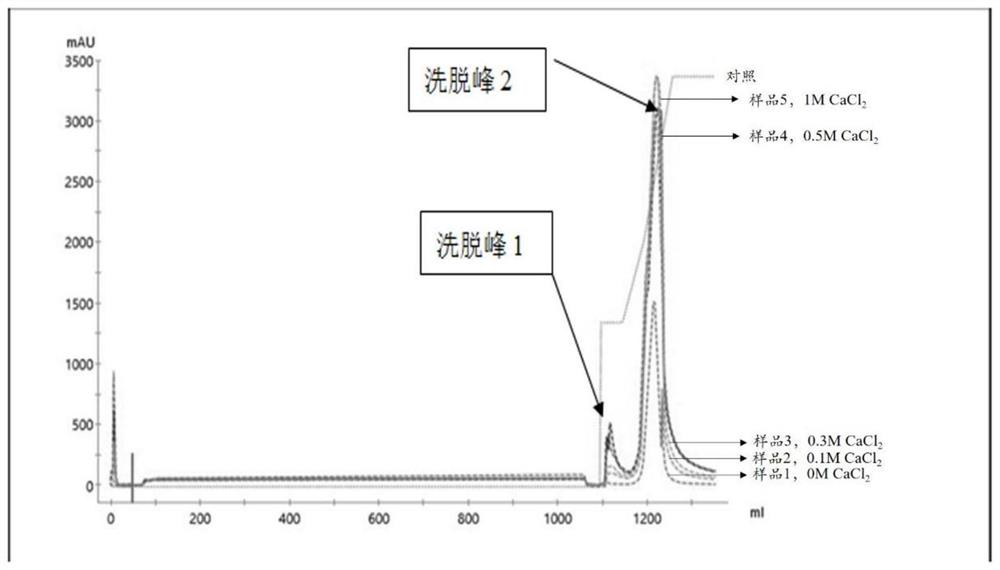

Method for purifying plasmids

The invention relates to a plasmid purification method for industrial production, which comprises the following steps: (1) splitting a bacterial culture containing plasmids to be purified to obtain a lysate; (2) adding a calcium chloride solution with the final concentration of 0.5-1M into the lysate to obtain a crude extract; (3) filtering the crude extract by using a membrane filter to obtain filtrate; and (4) carrying out chromatography on the filtrate by using an anion exchange column to obtain purified plasmids.

Owner:NANJING BIOHENG BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com