Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Structural process optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

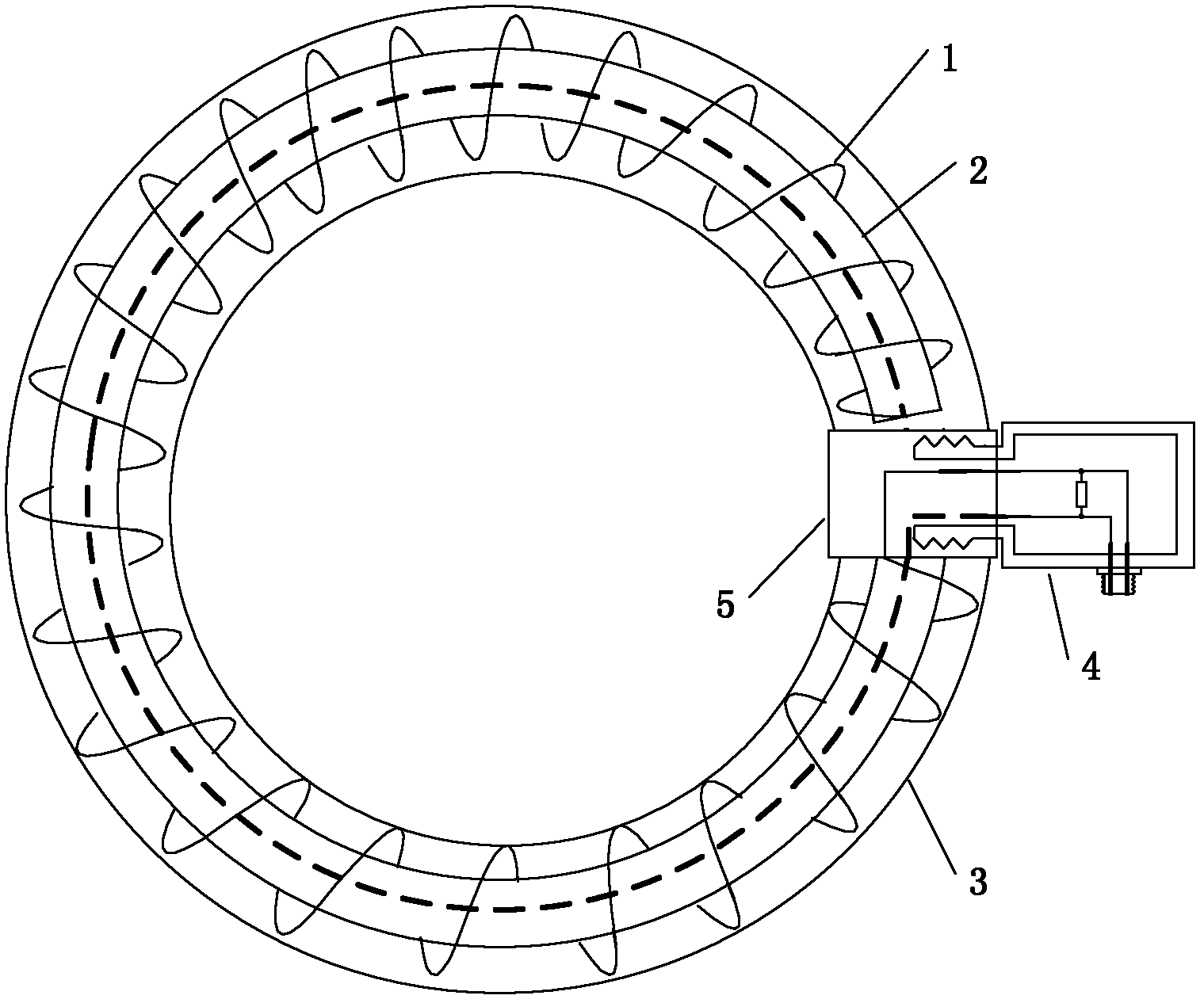

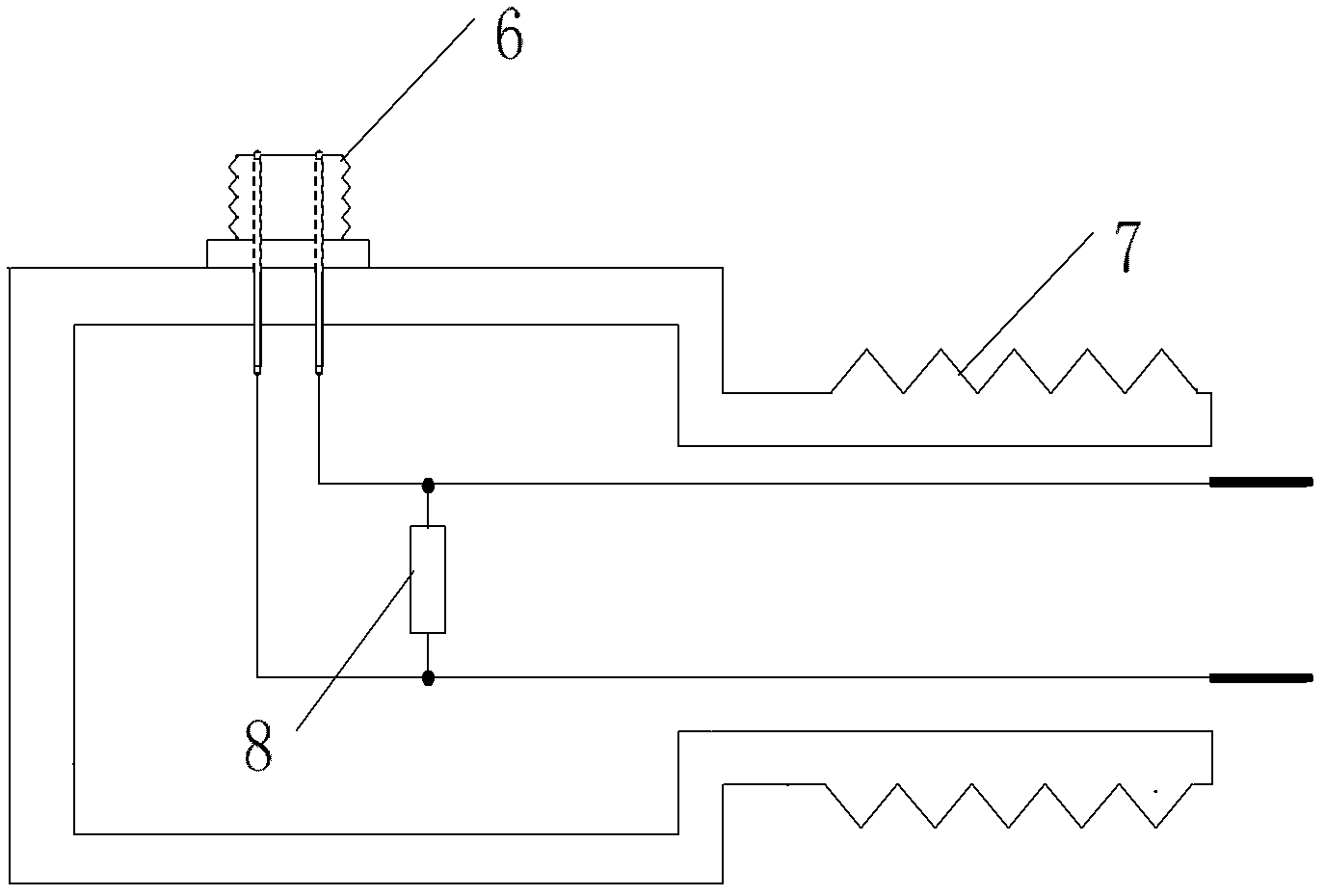

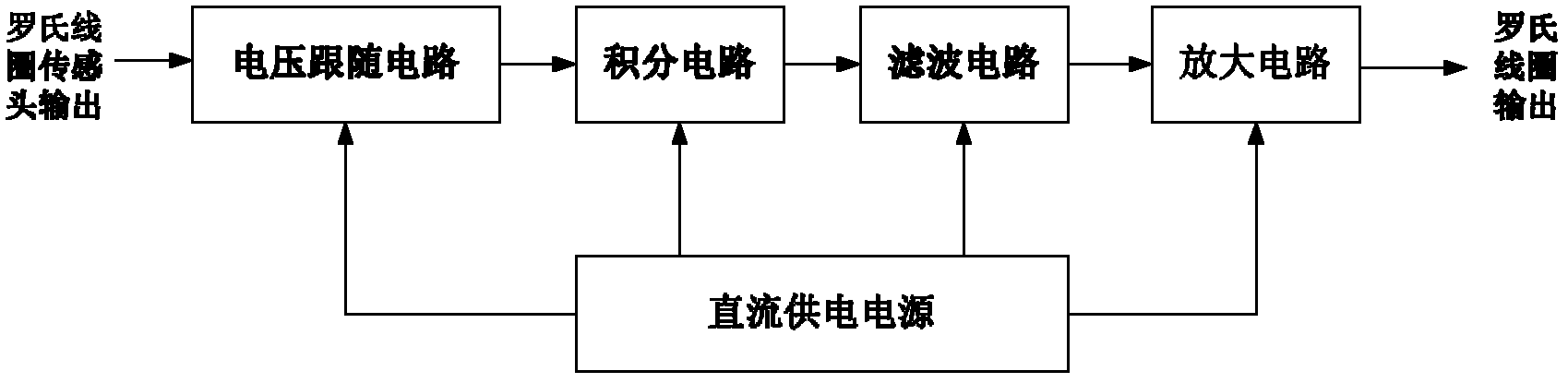

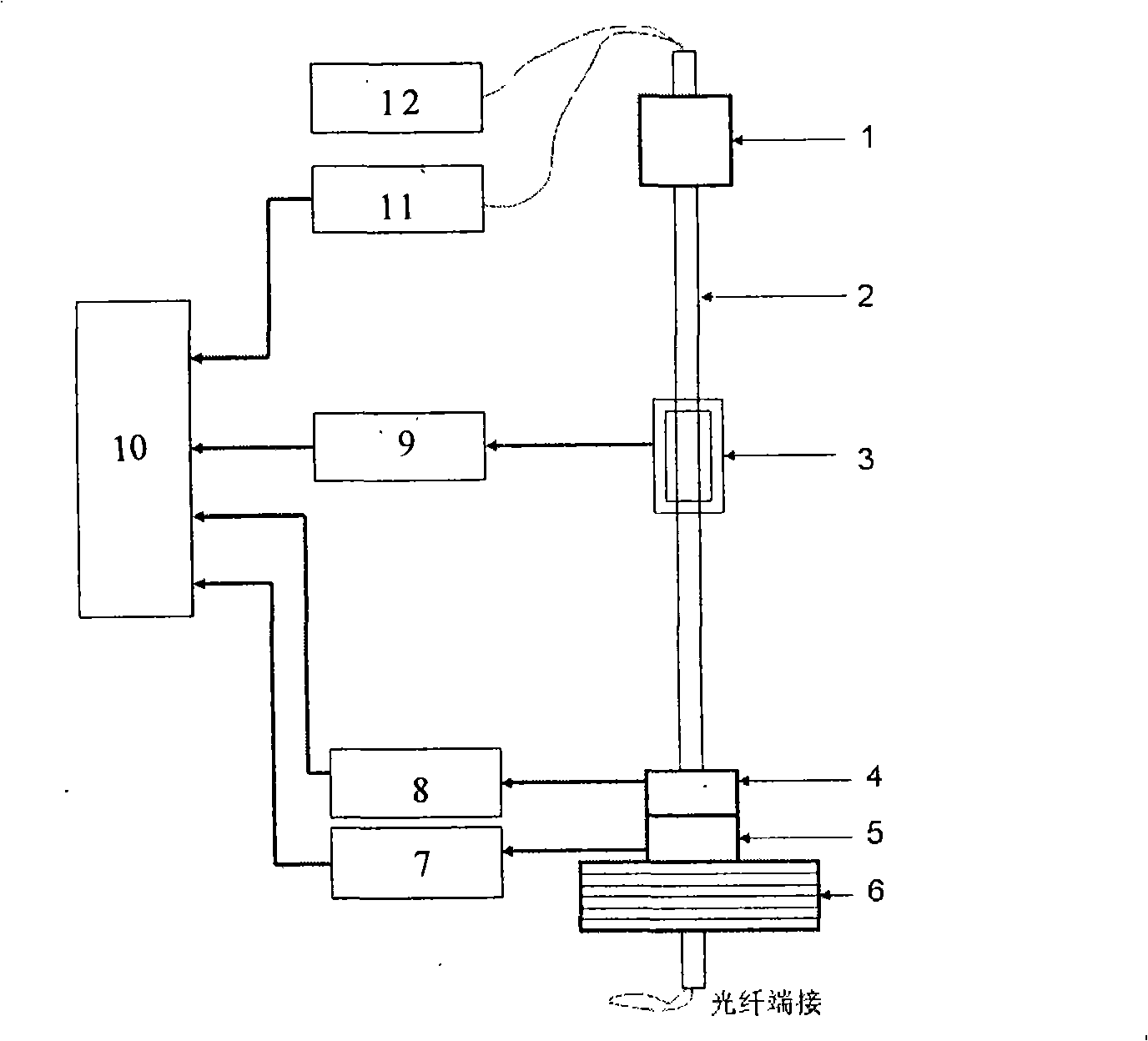

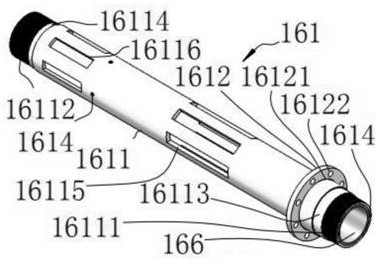

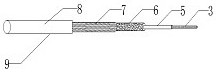

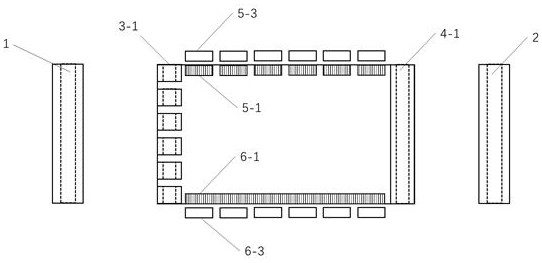

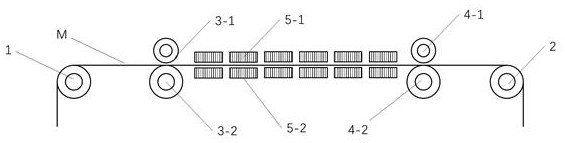

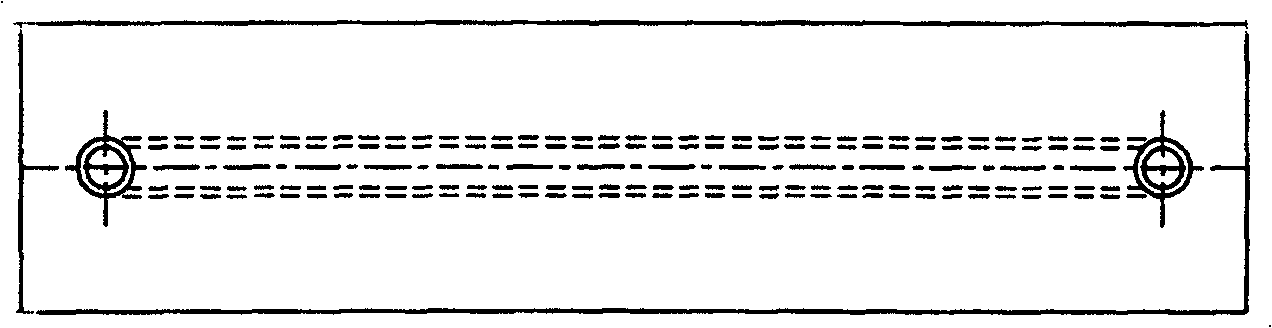

Flexible Rogowski coil used for detecting direct-current system short-circuit current and method for designing same

InactiveCN102436897AStructural process optimizationExtend mechanical lifeElectrical measurementsCoilsElectrical resistance and conductanceComputer module

The invention discloses a flexible Rogowski coil used for detecting the direct-current system short-circuit current and a method for designing the same, the coil comprises a coil and a loop uniformly wound around an annular flexible framework with an opening, an outer layer insulating bush is sleeved outside the coil and the loop, a plug-type interface attached to the coil and the loop is installed on the opening of the annular flexible framework, the coil outgoing line is connected with a sampling resistance module after being educed through the hole of the plug-type interface, the sampling resistance module educes a signal and is connected with a post-integrating circuit. In the Rogowski coil loop winding technique adopted in the invention, the return wire and the coil winding are constituted by one wire. The head end and the tip end of the Rogowski coil are connected by the plug-type interface, which can improve the mechanical life of the Rogowski coil to a great extent, has the advantages of high reliability and convenience for disassembly and installation; the method for designing the Rogowski coil used for detecting the direct-current system short-circuit current can combine the short circuit physical circumstances and the field working condition of the direct-current system.

Owner:XI AN JIAOTONG UNIV

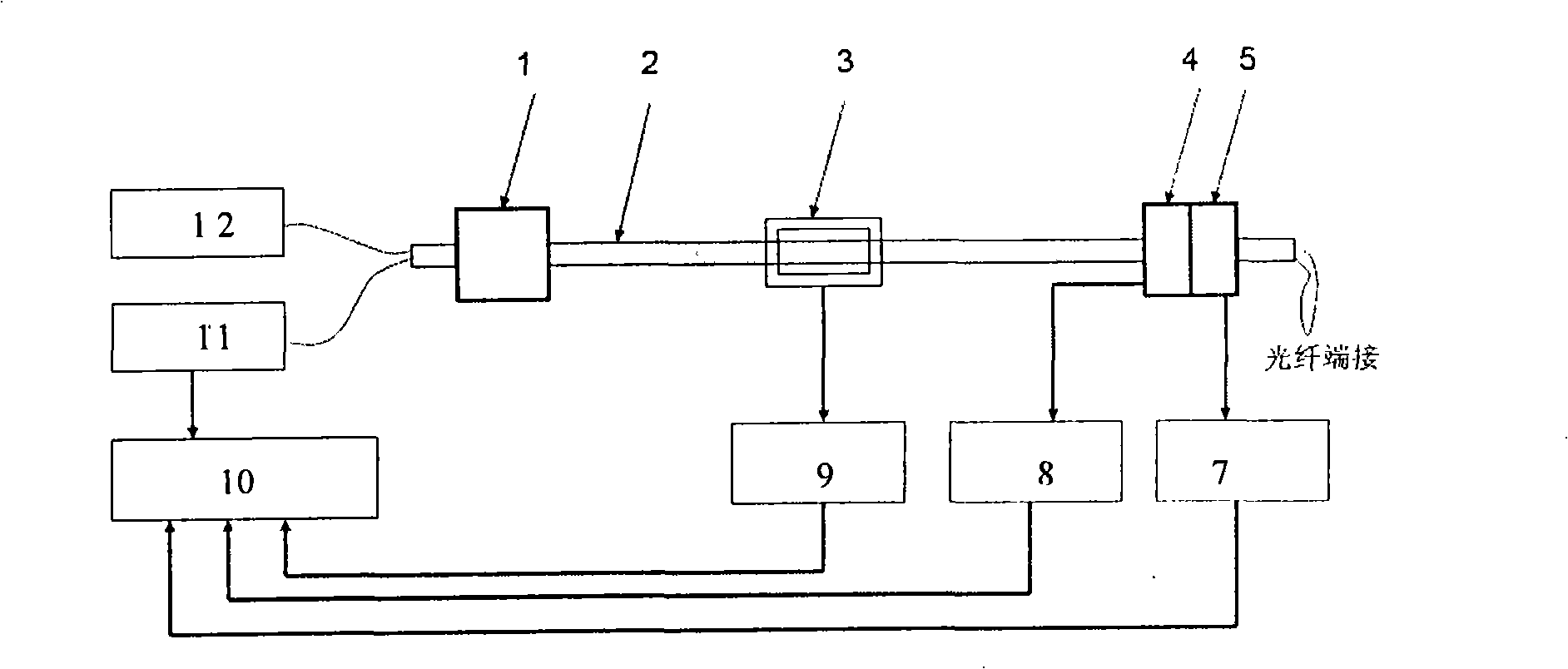

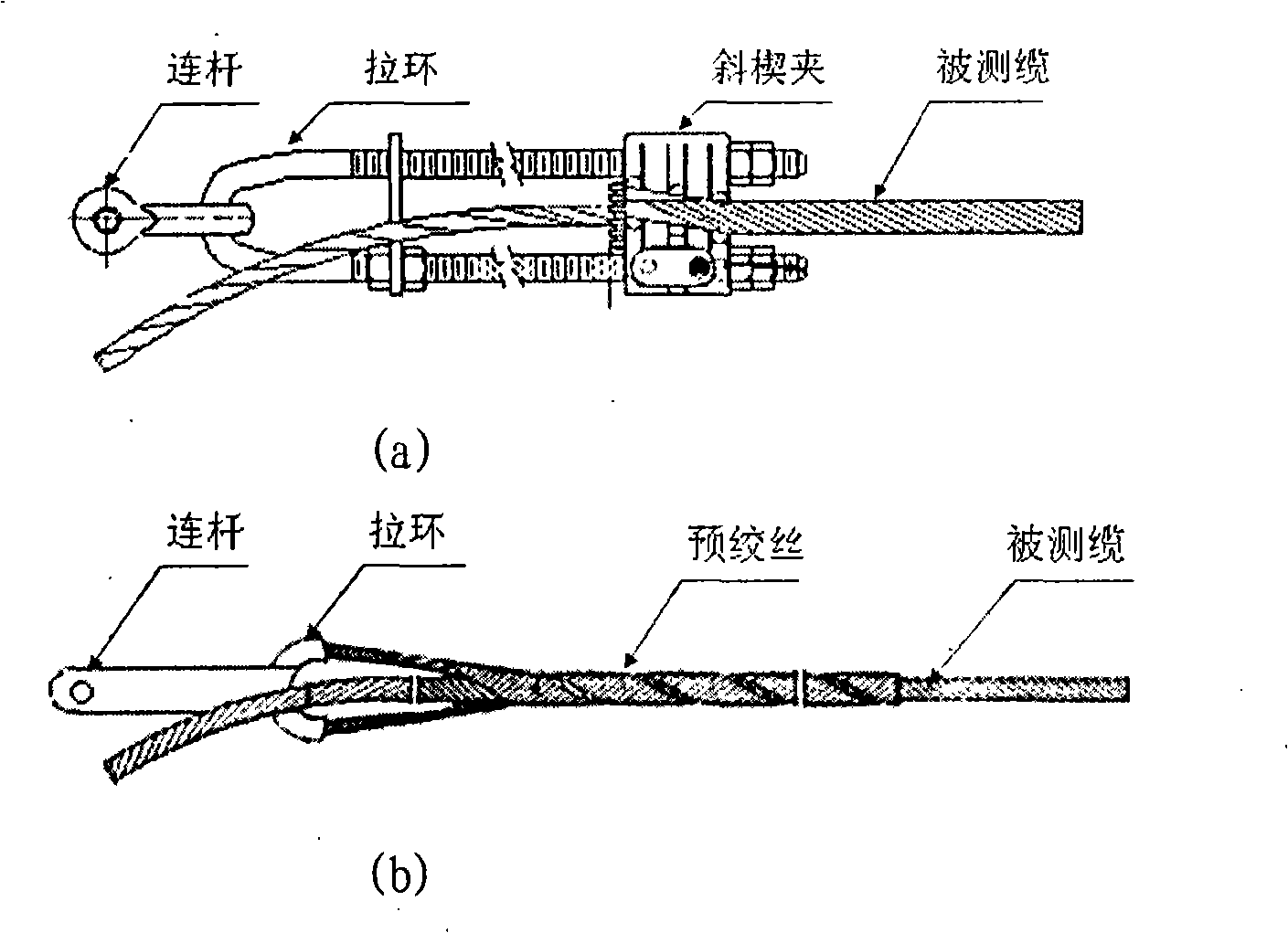

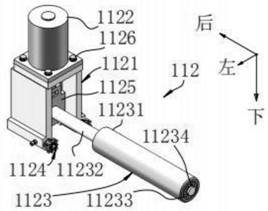

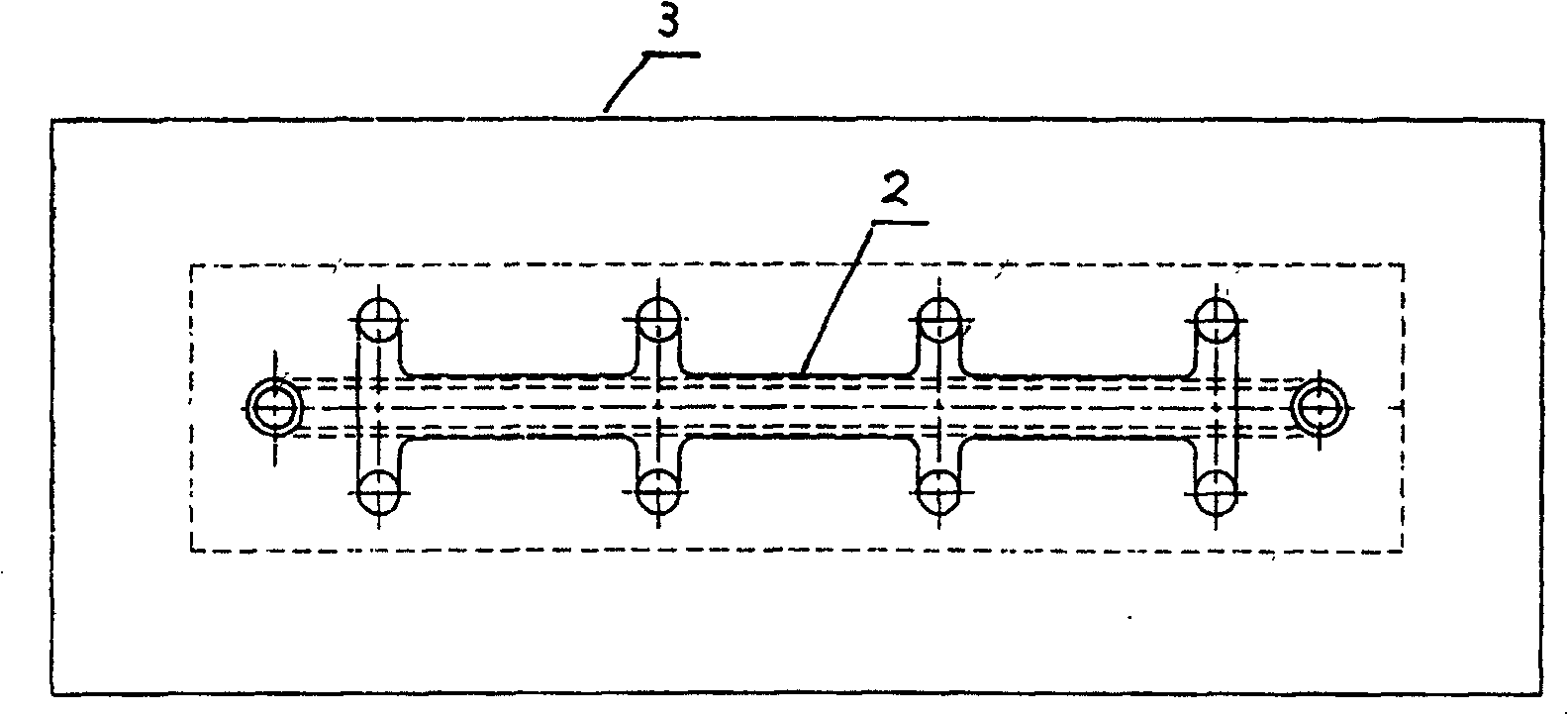

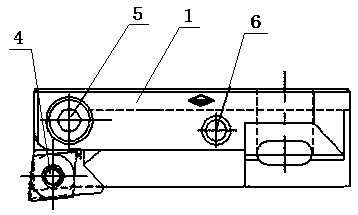

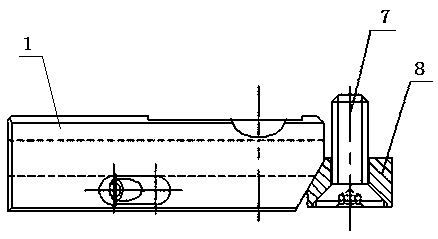

Seabed optical cable tension torque test method and device thereof

InactiveCN101275875AStructural process optimizationSimple technical processTension measurementMultiple fluid pressure valves simultaneous measurementOcean bottomMeasurement device

The invention discloses a test method and device for seabed cable tensility torque which can use horizontal and vertical ways, characterized in that the device comprises following components: (1) a fixed clamp for clamping the seabed cable, (2) an optical cable sample for the tested seabed, (3) a measuring device for displacement, (4) a rotatable clamp with an angle sensor, (5) a stretching sensor, (6) a counter poise and counter poise bracket, (7) a stretching converter, (8) an angle converter, (9) a displacement converter , (10) a centre processor, (11) a light power meter, (12) light source. After the method respectively processes optical connection and electrical connection for the test instruments and devices and forms the integral test devices, the method opens the light source and a stretching tester to observe and record the parameters of the light declining quantity, the tensility, the flexible strain capacity, the rotating direction of the cable and the angle of the seabed cable. The advantages of this invention is taking the parameters obtained by the test as import scientific foundation for research, design, production, technique and construction and maintenance of guide of the seabed cable for the leaders and scientific stuffs developing the relevant working decision.

Owner:JIANGSU TONGNENG INFORMATION

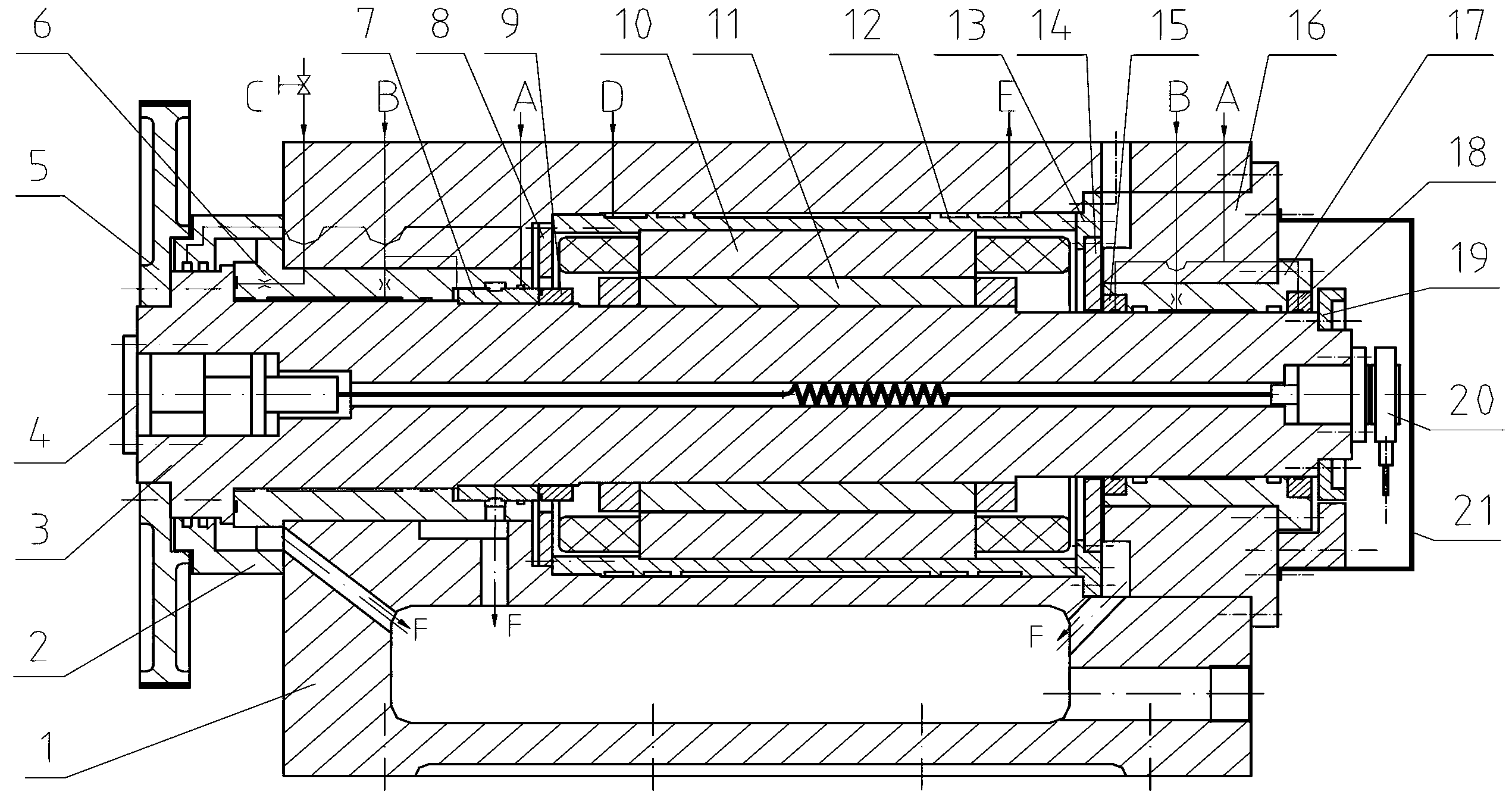

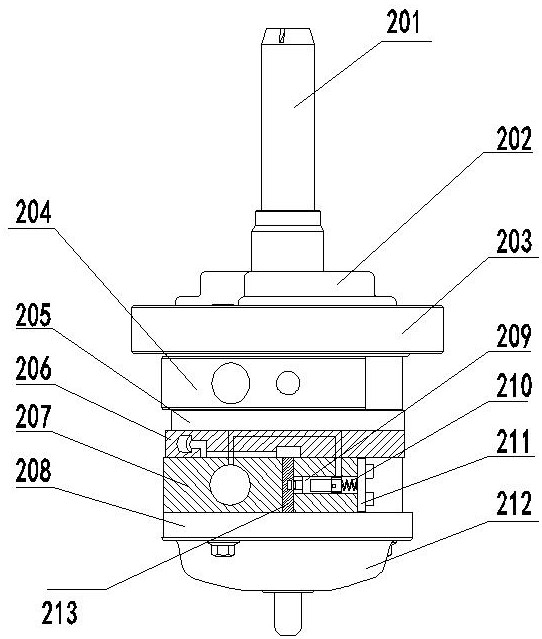

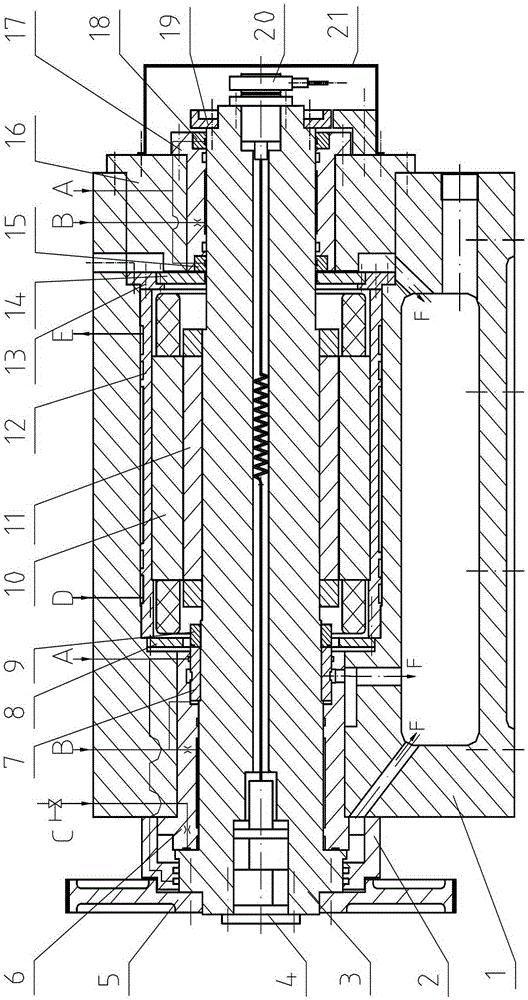

Multi-functional built-in dynamic-static-pressure motorized spindle for efficient high-speed precision machine

InactiveCN103286678AReduce radiationAvoid Limiting AppsGrinding machine componentsThrust bearingGrinding wheel

The invention relates to a multi-functional built-in dynamic-static-pressure motorized spindle for an efficient high-speed precision machine. The multi-functional built-in moving piezo spindle comprises a shell, a spindle body, a bearing, an oil sealing cover, a motor rotor and a stator. A front bearing is arranged at the right end of the shell and forms a static-pressure push bearing with the spindle. The inner surface of the front bearing is provided with a static-pressure oil cavity, and part of the large diameter of the inner surface matches with a pre-tightening piston. A rear bearing is mounted in a rear-bearing seat. The motor rotor is arranged between the front bearing and the rear bearing. The outer cylindrical face of the motor stator matches with a water sleeve tightly. The water sleeve matches with a hole in the middle of the shell and is connected to the shell. The rear bearing is sealed through a gas sealing ring, and the front bearing is sealed through the oil sealing cover and a gas sealing hole at the rear end. Heat shielding devices are arranged at two ends of the motor stator. The spindle can be mounted at different positions according to different using conditions. The multi-functional built-in dynamic-static-pressure motorized spindle can serve as a spindle of a grinding wheel of a precision machine, a milling center or a grinding machine or a spindle of a workpiece, and has the advantages of high precision, high rigidity, long service life, fine producing process, good sealing effect and the like.

Owner:上海原创精密机床主轴有限公司

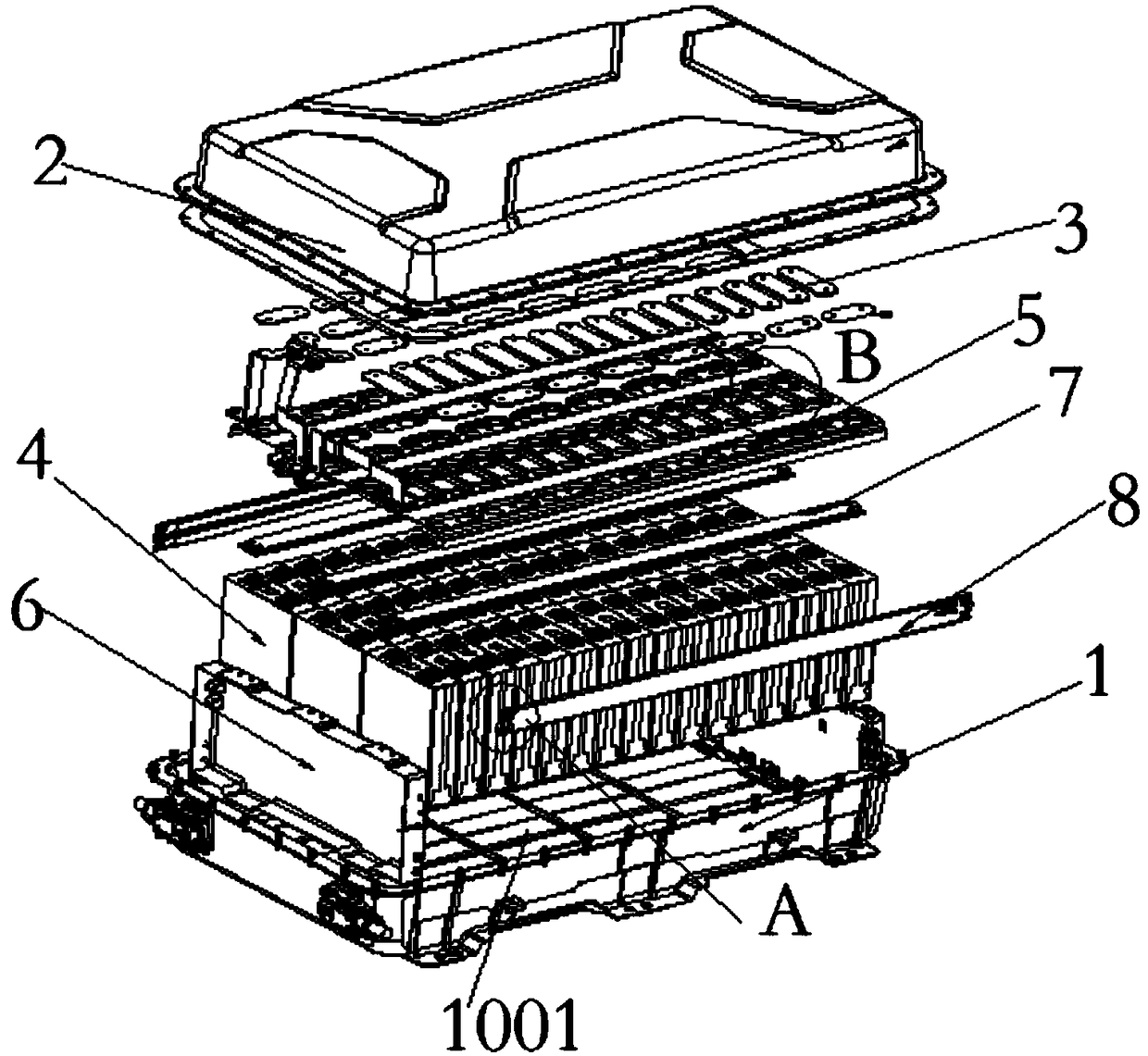

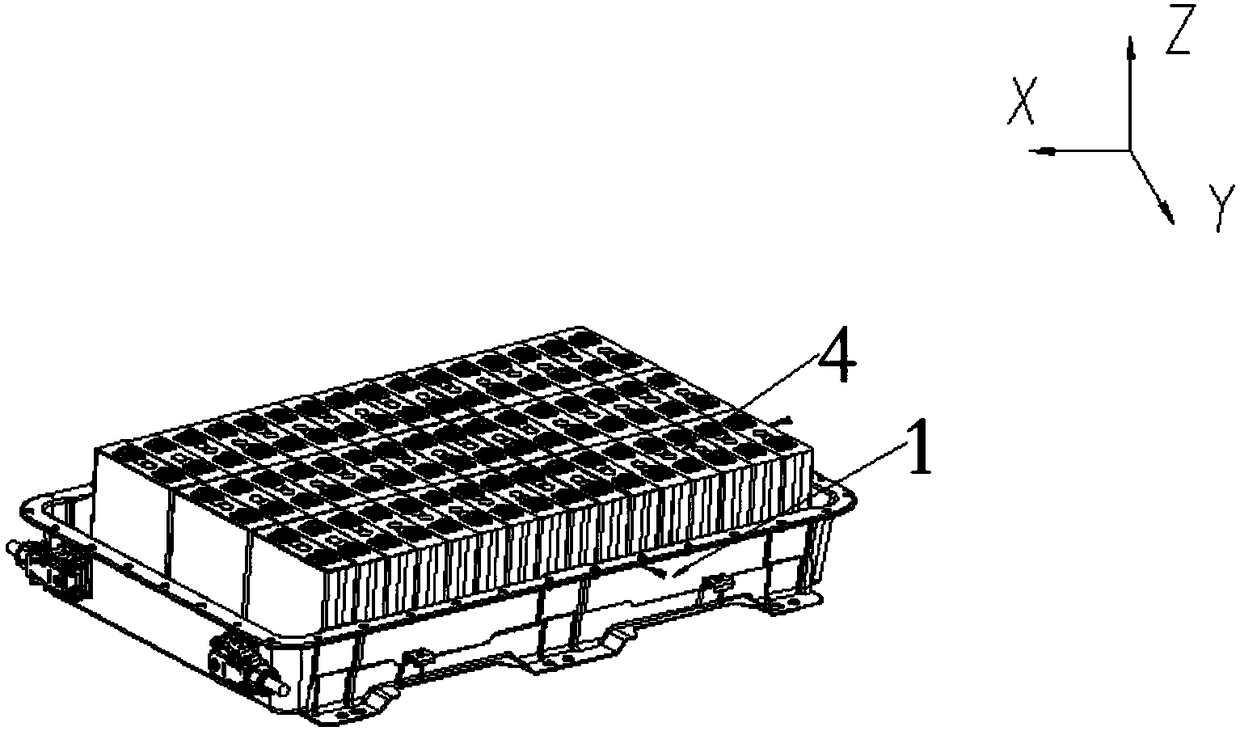

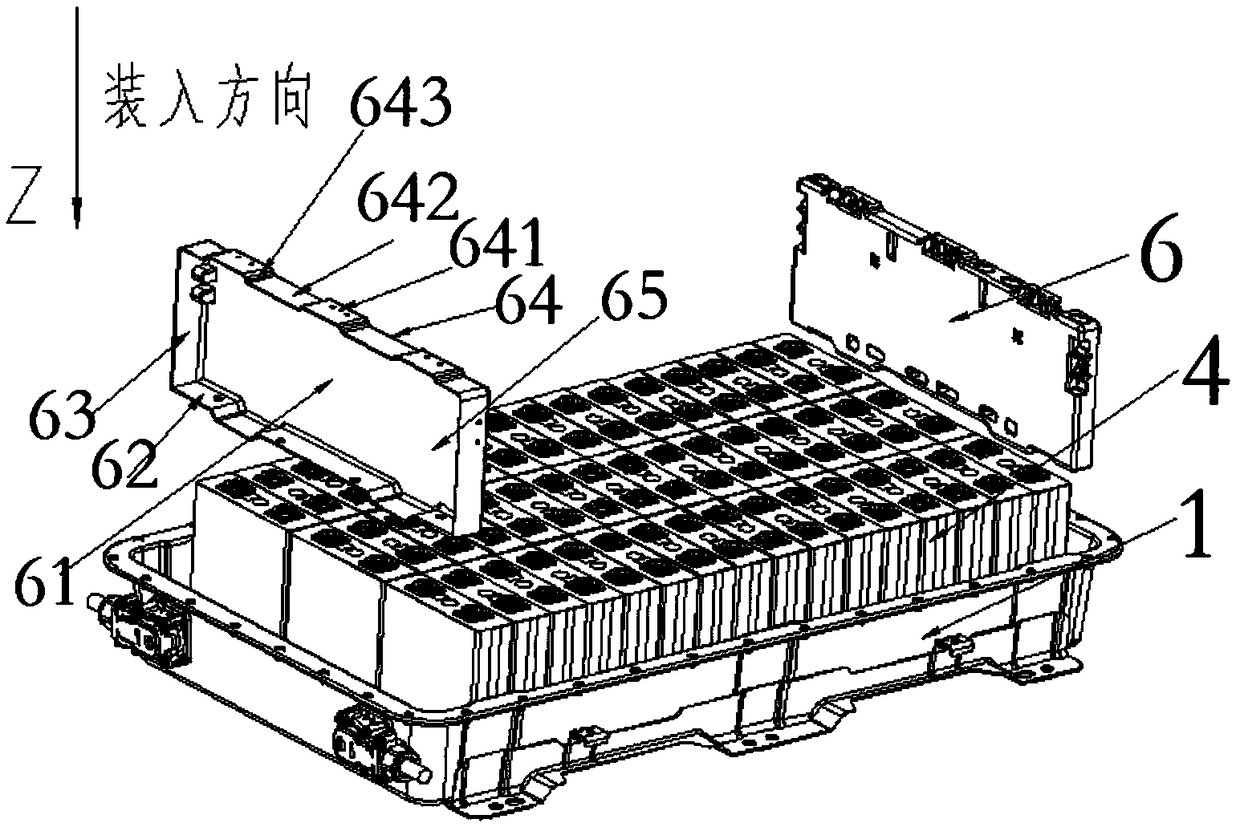

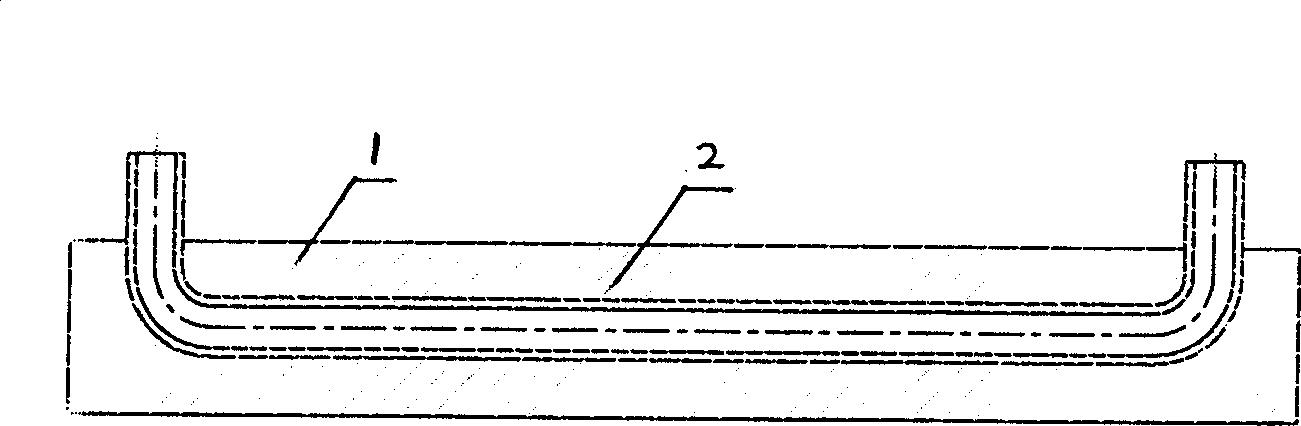

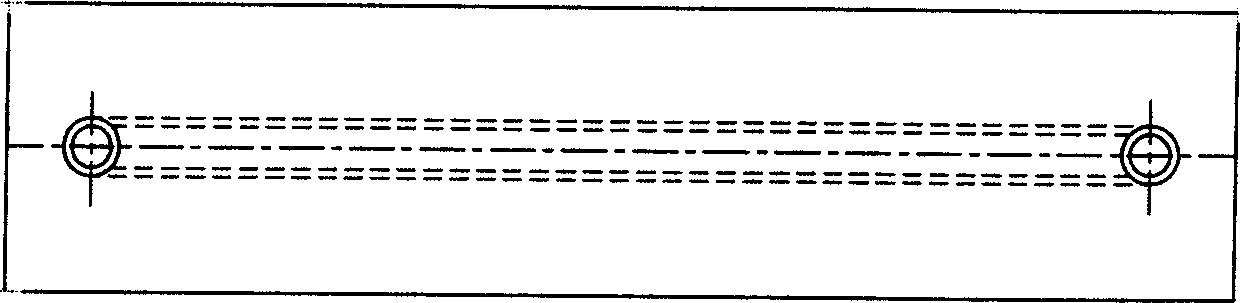

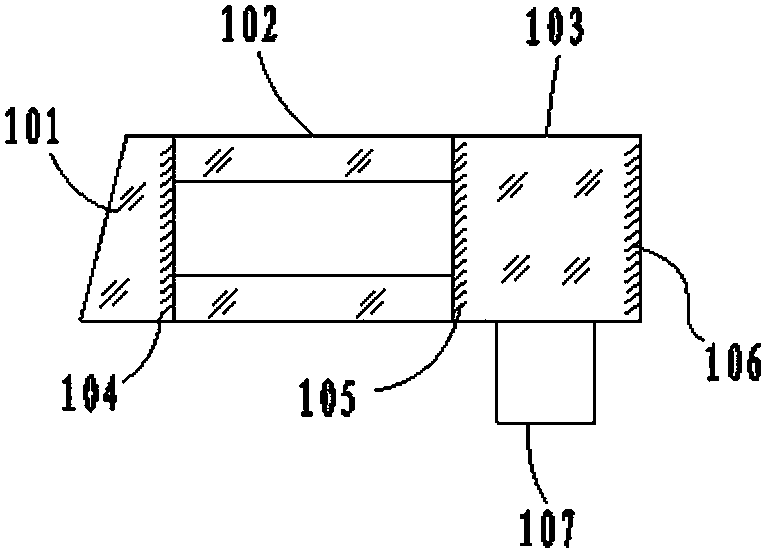

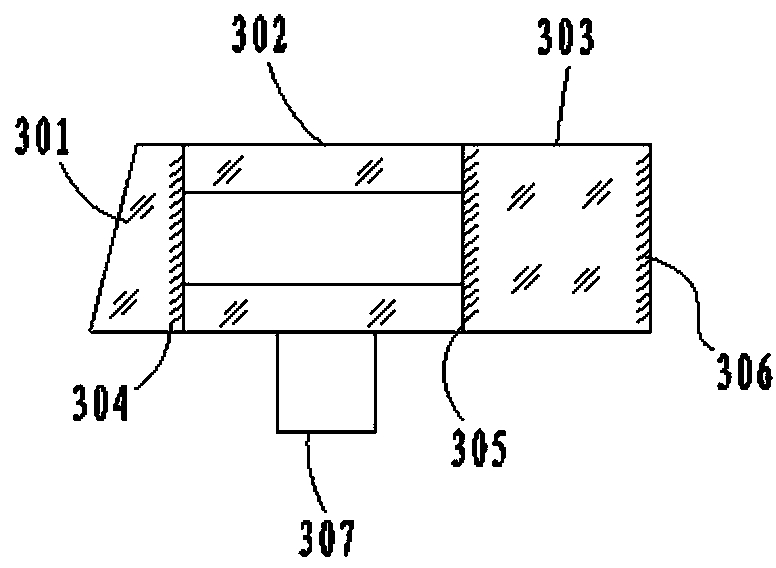

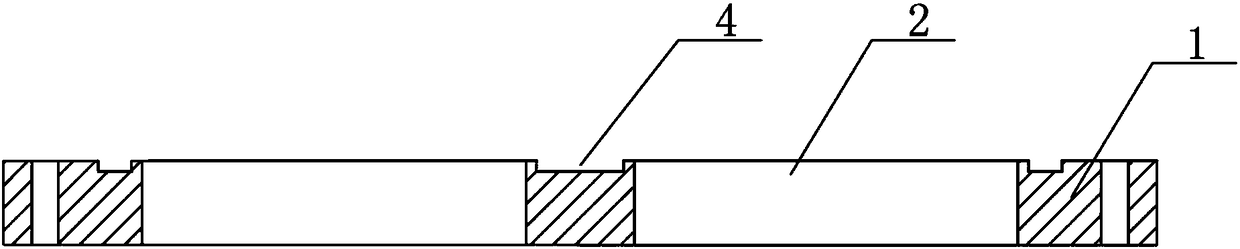

Novel power battery pack structure and assembly process thereof

InactiveCN108777268AStructural process optimizationSimple production processCurrent conducting connectionsBatteriesPower batteryElectrical battery

The invention relates to the field of power batteries, specifically to a novel power battery pack structure and an assembly process thereof. The battery pack structure comprises a box body used for placing battery cells, wherein the upper end of the box body is connected with a box cover used for protecting the battery cells arranged in the box body; a battery cell group is placed in the box bodyand comprises a plurality of battery cells; the lower end surface of each battery cell is connected with the bottom part of the box body through a structural adhesive; and the battery cells are connected through high-voltage connectors. According to a technical scheme of the invention, through improvement of traditional battery pack structures and production processes, the efficiency of group formation is high; in a traditional battery pack production process, the battery cells needs to be modularized and then assembled to form a required battery pack, while the assembly process provided by the invention omits the intermediate link of battery pack production, i.e., reduces the related production process of battery cell modularization, so the efficiency of group formation is improved; thus,the energy density of a product is improved, and the loss of energy conversion in the process of modularization is avoided.

Owner:芜湖天量电池系统有限公司

Low thermal resistance cast-iron cooling wall and manufacturing method thereof

InactiveCN1869568AImprove heat transfer efficiencyImprove thermal conductivityFurnace cooling arrangementsCarbon coatingDuctile iron

The invention relates to a new type low thermal resistance cast iron cooling wall. The feature is that the identity material of cooling wall is nodular cast iron or gray cast iron and the cooling water channel in cooling wall is made up from pure copper. The clearance between the cooling wall identity and the outer wall of pure copper pipeline is below 0.1mm. The manufacture method includes the following steps: fixing the molded pure copper pipeline into the sand box; casting by molten iron of nodular cast iron or gray cast iron, and taking inertia vapor cooling to copper pipeline to molding. The invention eliminates the thermal resistance caused by anti seepage carbon coating layer to make the heat exchange efficiency sharply increase and prolong the useful life of cooling wall.

Owner:NANJING NANGANG IND DEV CO LTD

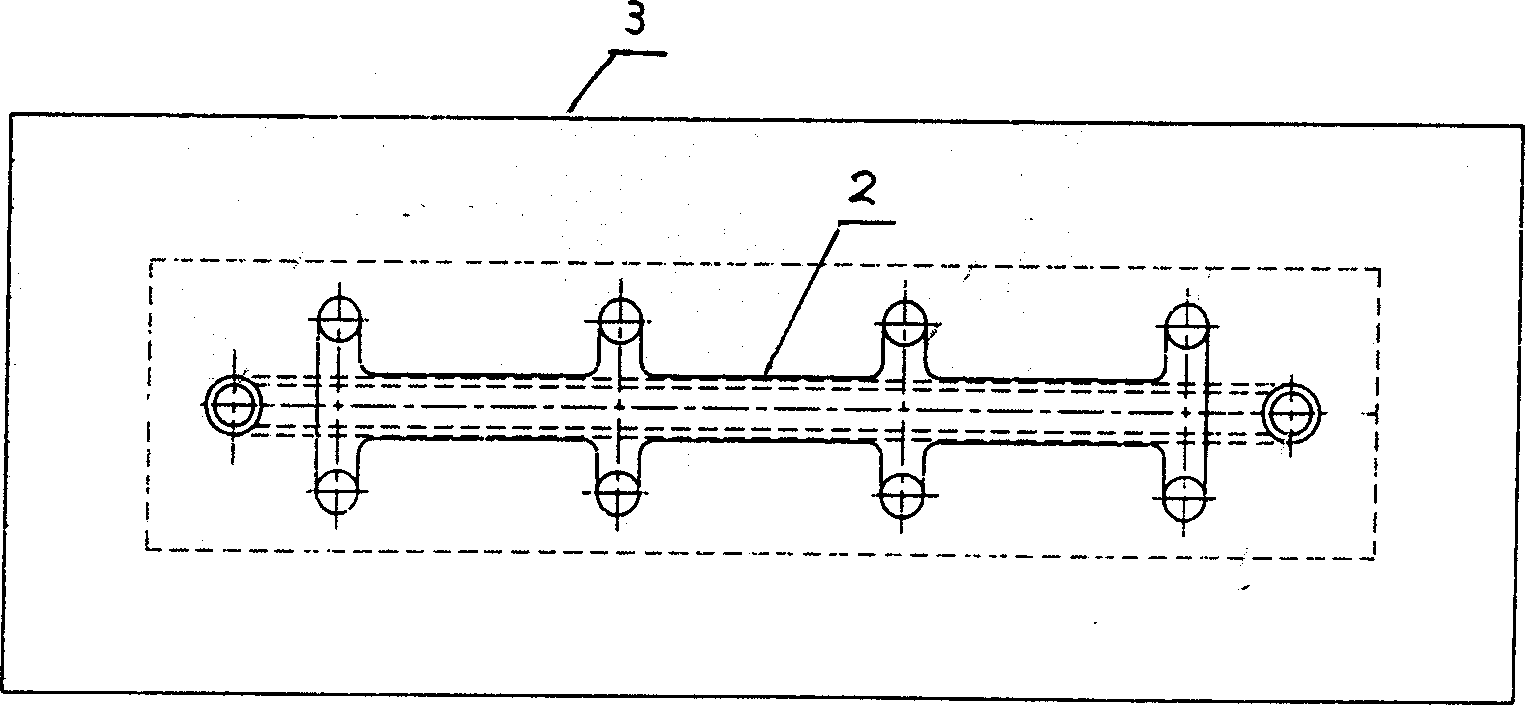

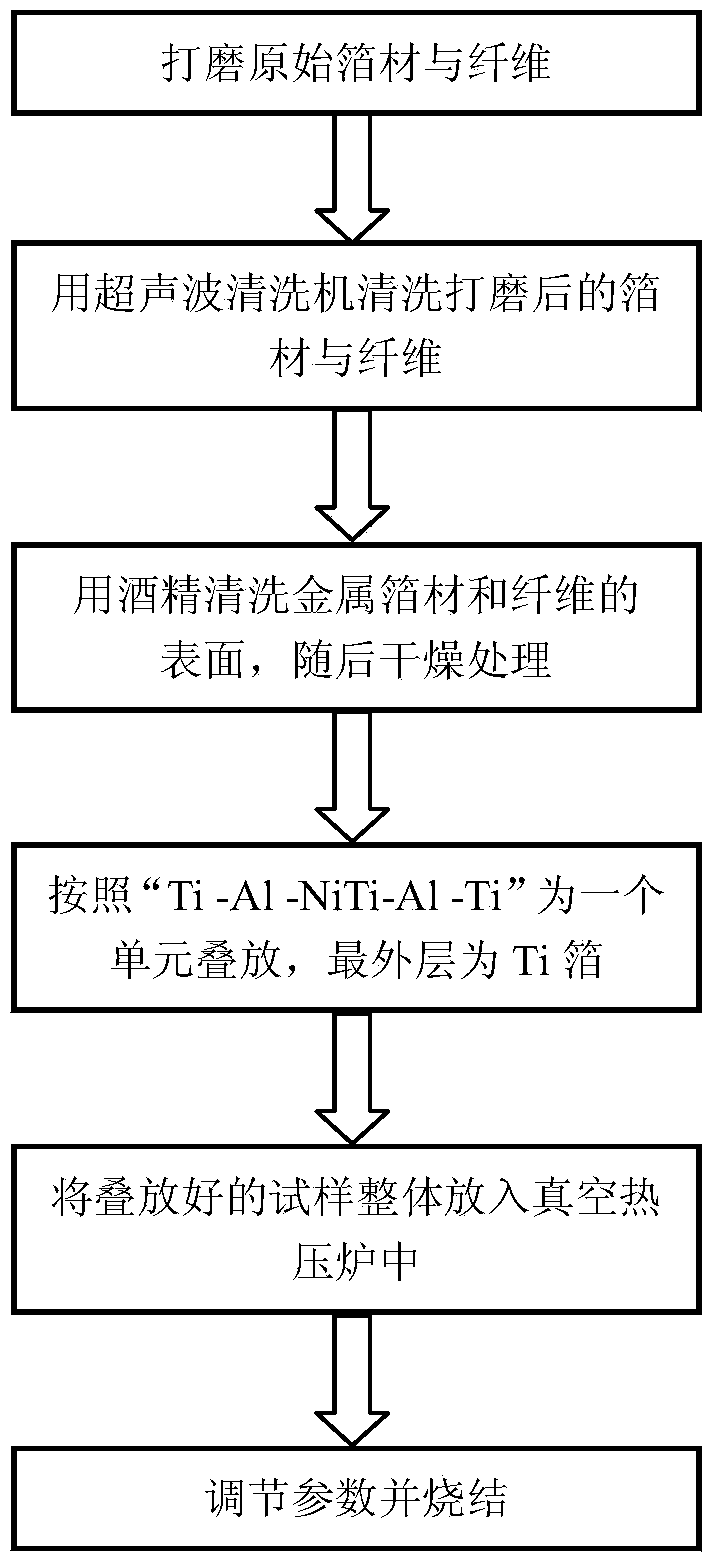

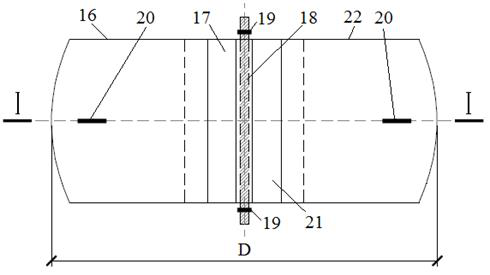

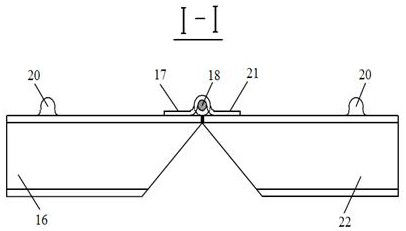

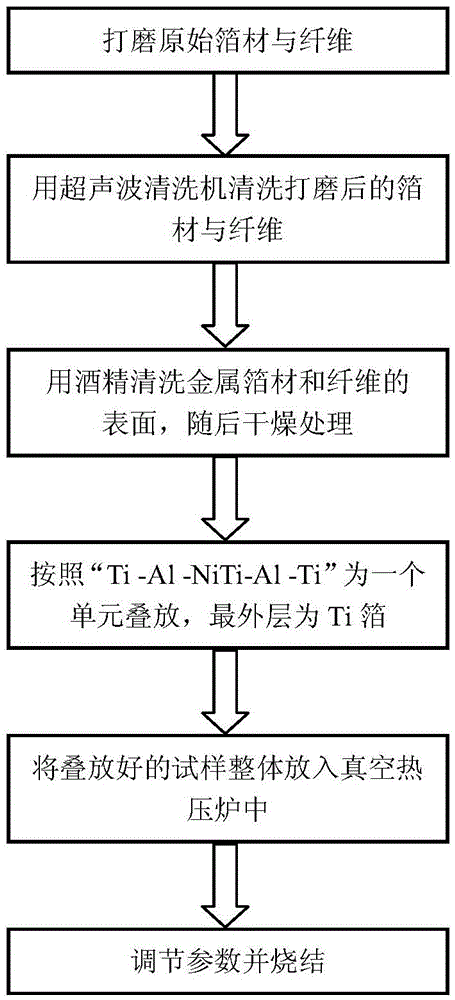

Preparation method of NiTi fiber reinforced intermetallic compound-based laminar composite material for vibration and noise reduction

ActiveCN104099540ASpecial high energy-absorbing laminated structureImprove performanceNiti alloyStructure function

The invention provides a preparation method of a NiTi fiber reinforced intermetallic compound-based laminar composite material for vibration and noise reduction. The preparation method comprises the steps of polishing Ti foils, Al foils and NiTi alloy fibers by use of abrasive paper to remove oxide layers, next, cleaning by use of an ultrasonic cleaner and then cleaning by use of alcohol, drying, stacking by the unit of Ti foil-Al foil-NiTi fibers-Al foil-Ti foil with the Ti foils as the outmost layers, and putting the entire stacked material in a vacuum hot pressing furnace for sintering. The prepared fiber reinforced laminar composite material is highly damped (the loss modulus can be 3500MPa under the conditions of a temperature ranging from a room temperature to 50 DEG C and 1Hz, and the loss modulus can be 4100MPa under the conditions of the same temperature range and 20Hz) and has high strength (the compressive strength can be 1400MPa), and therefore, the prepared fiber reinforced laminar composite material is a high-performance structure-function integrated composite material.

Owner:HARBIN ENG UNIV

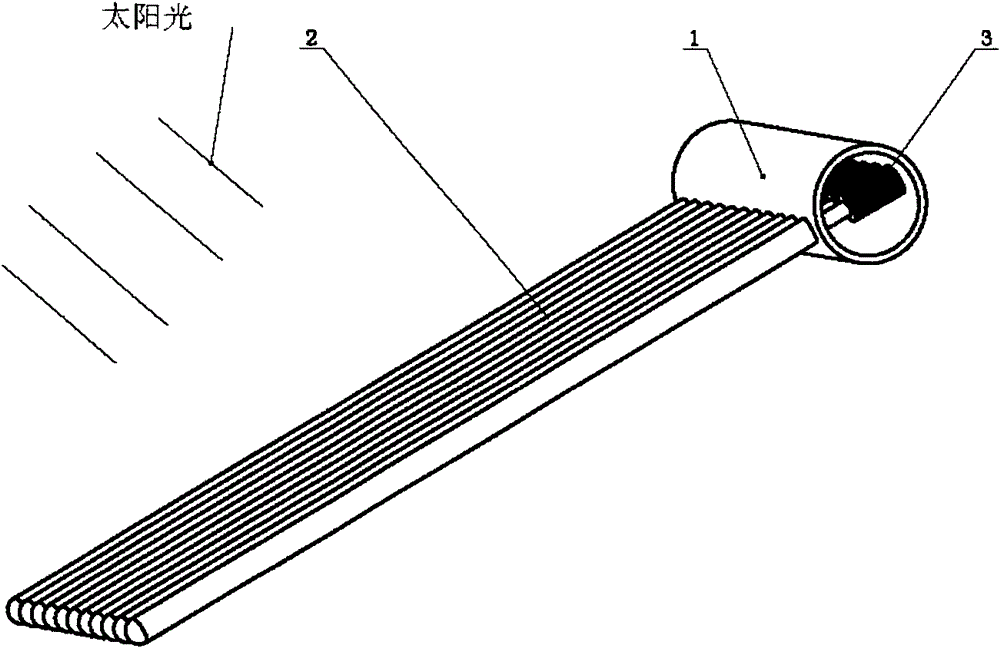

Vacuum-tube type solar air collector

InactiveCN102748873AImprove transmittanceHigh yieldSolar heating energySolar heat devicesSolar air collectorEngineering

The invention relates to a vacuum-tube type solar air collector. The vacuum-tube type solar air collector mainly comprises an all-glass vacuum tube, a heat collecting core and a case body, wherein the heat collecting core is installed inside the vacuum tube, a vane exposed out of the heat collecting core extends into the case body, and two ends of the case body are provided with openings for ventilation. In the working process, the sunlight penetrates through the vacuum tube, the heat collecting core is heated through the vacuum tube, the heat is transmitted to the radiating fin through the heat collecting core, the heat on the fin surface is taken away through the ventilation in the case body, and the air is heated. The solar air collector is simple in design and manufacturing process, mature and reliable in technology, low in cost and capable of being used in a large scale and in an integration mode. The contiguous integration of collectors can be achieved in accordance with requirements.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI +1

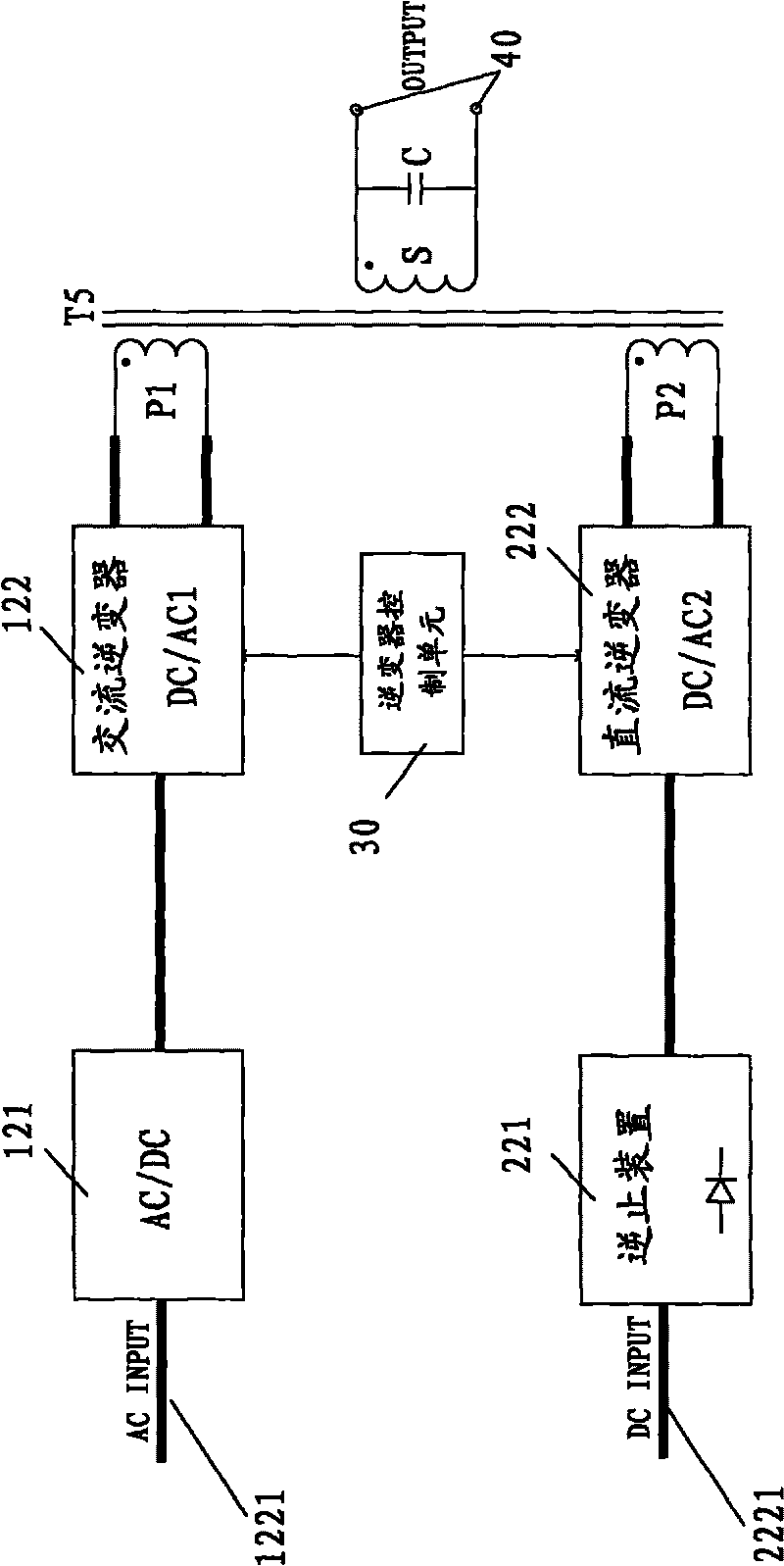

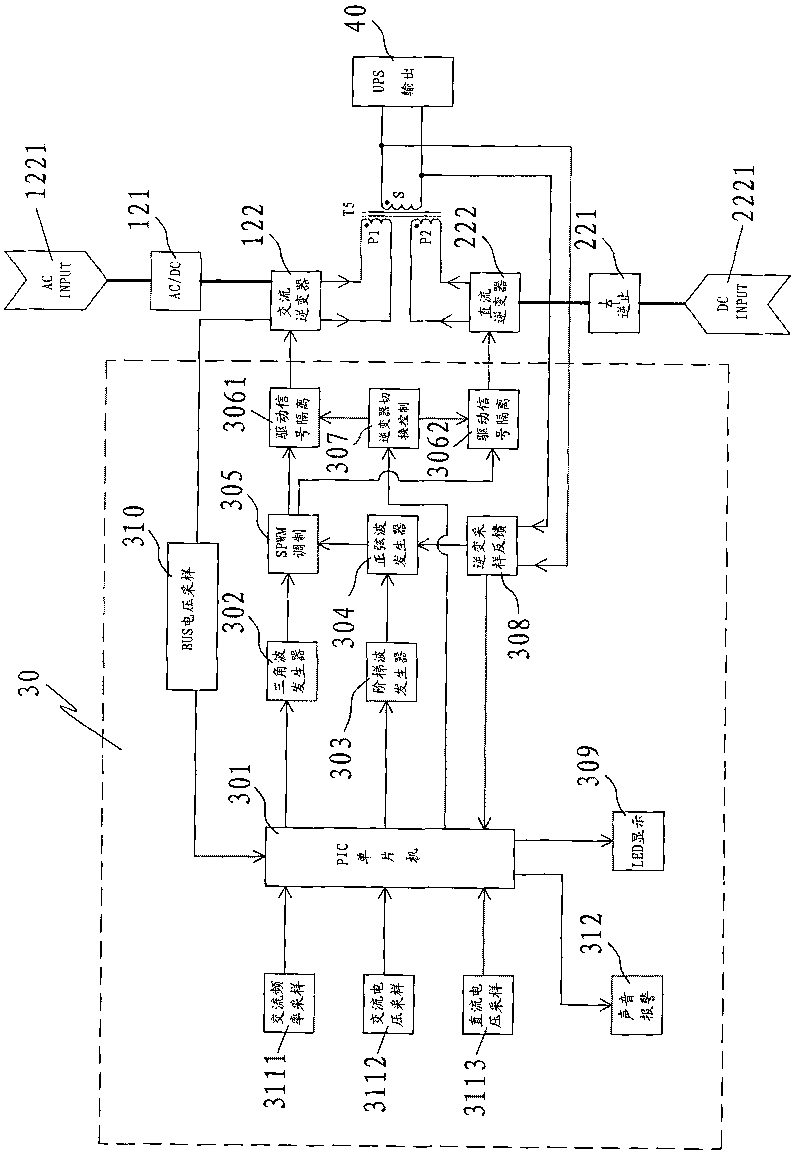

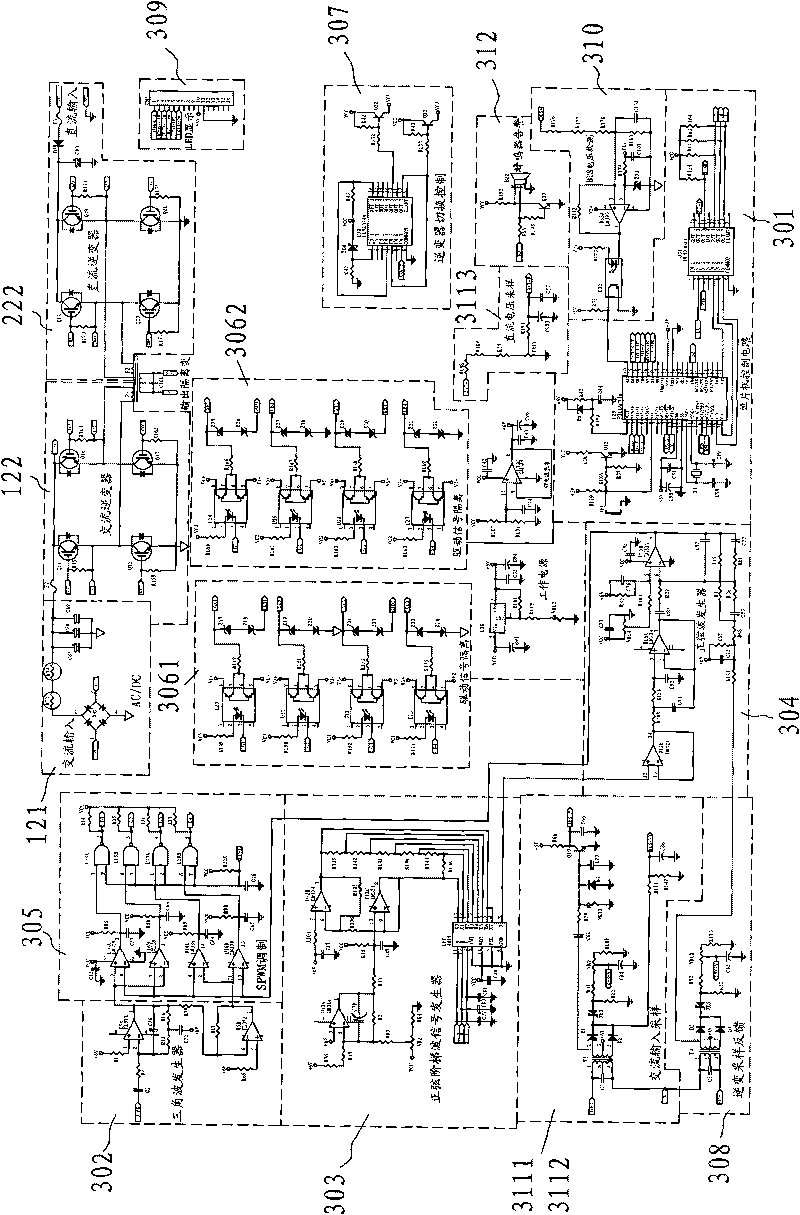

Method and circuit for realizing isolation of alternating current and direct current of double inverse uninterruptable power supply

ActiveCN101710790AReduce transformationReduce lossAc-dc conversionAc-ac conversionEngineeringGalvanic isolation

The invention relates to the field of an inverse uninterruptable power supply (UPS), in particular to the realization of the isolation technology of alternating current and direct current of the double inverse uninterruptable power supply. The method and circuit for realizing isolation of alternating current and direct current of the double inverse uninterruptable power supply is used for carrying out electrical isolation on the alternating inverse circuit with alternating current input and the direct inverse circuit with current circuit input, wherein the alternating input power supply (1221) passes through the rectifying circuit (121) and an alternating current inverter (122), is sent to the first primary winding (P1) of an output isolation transformer (T5) and is output via the secondary winding (S) of the output isolation transformer (T5) in a coupled manner to constitute an alternating inverse channel; the direct current input power supply (2221) passes through an inverted device (221) and a direct current inverter (222), is sent to the second winding (P2) of the output isolation transformer (T5) and is output via the secondary winding (S) of the output isolation transformer (T5) to constitute the direct current inverse channel.

Owner:AVIC TECH XIAMEN ELECTRIC POWER TECH CO LTD

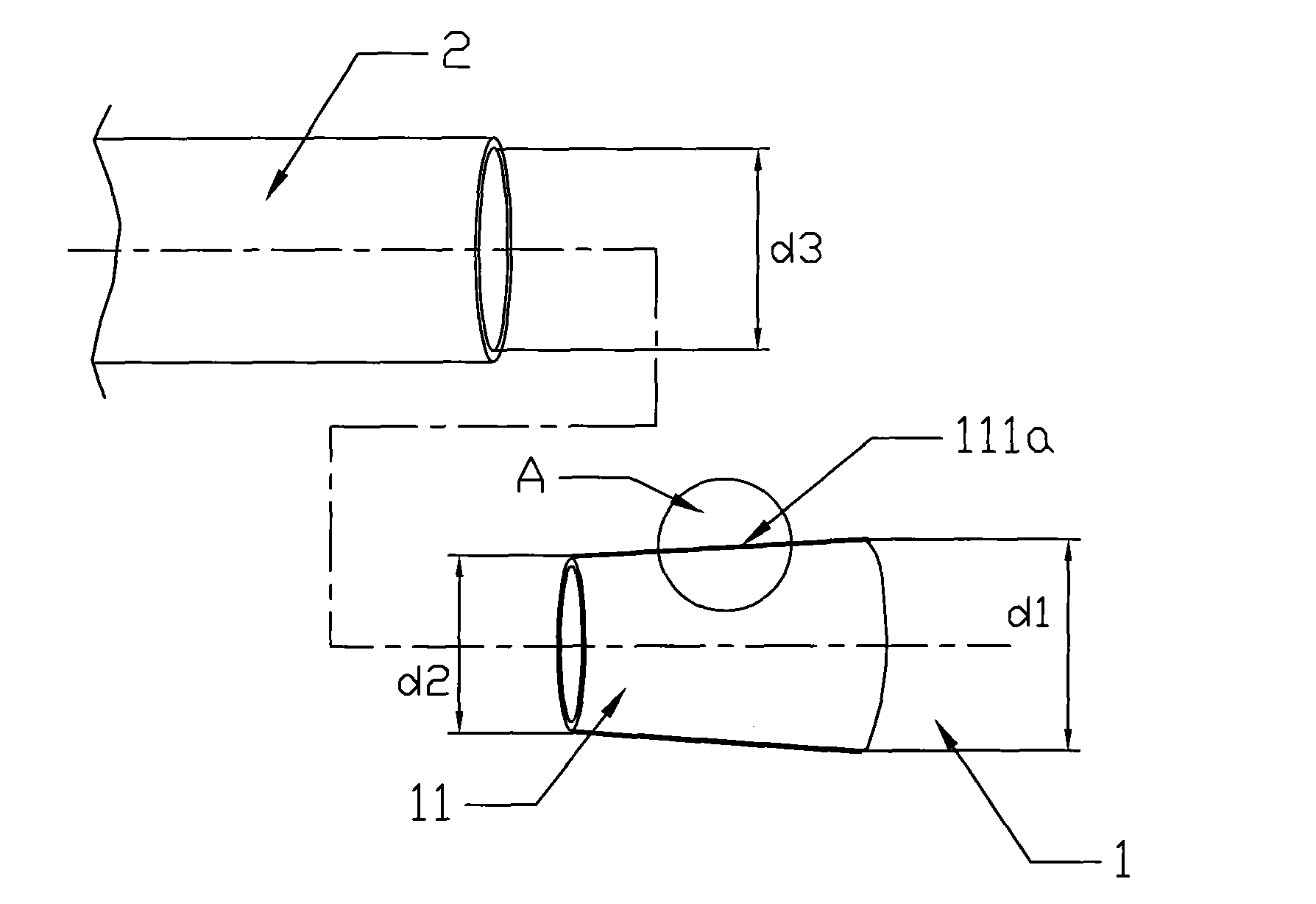

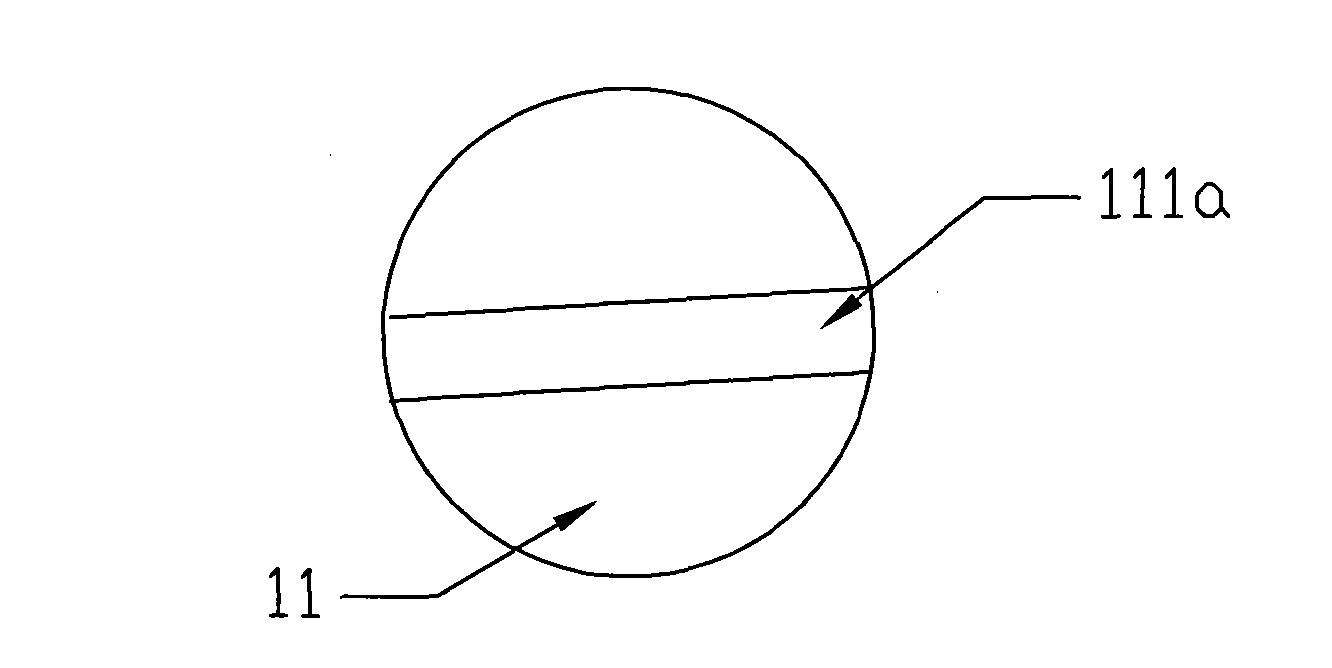

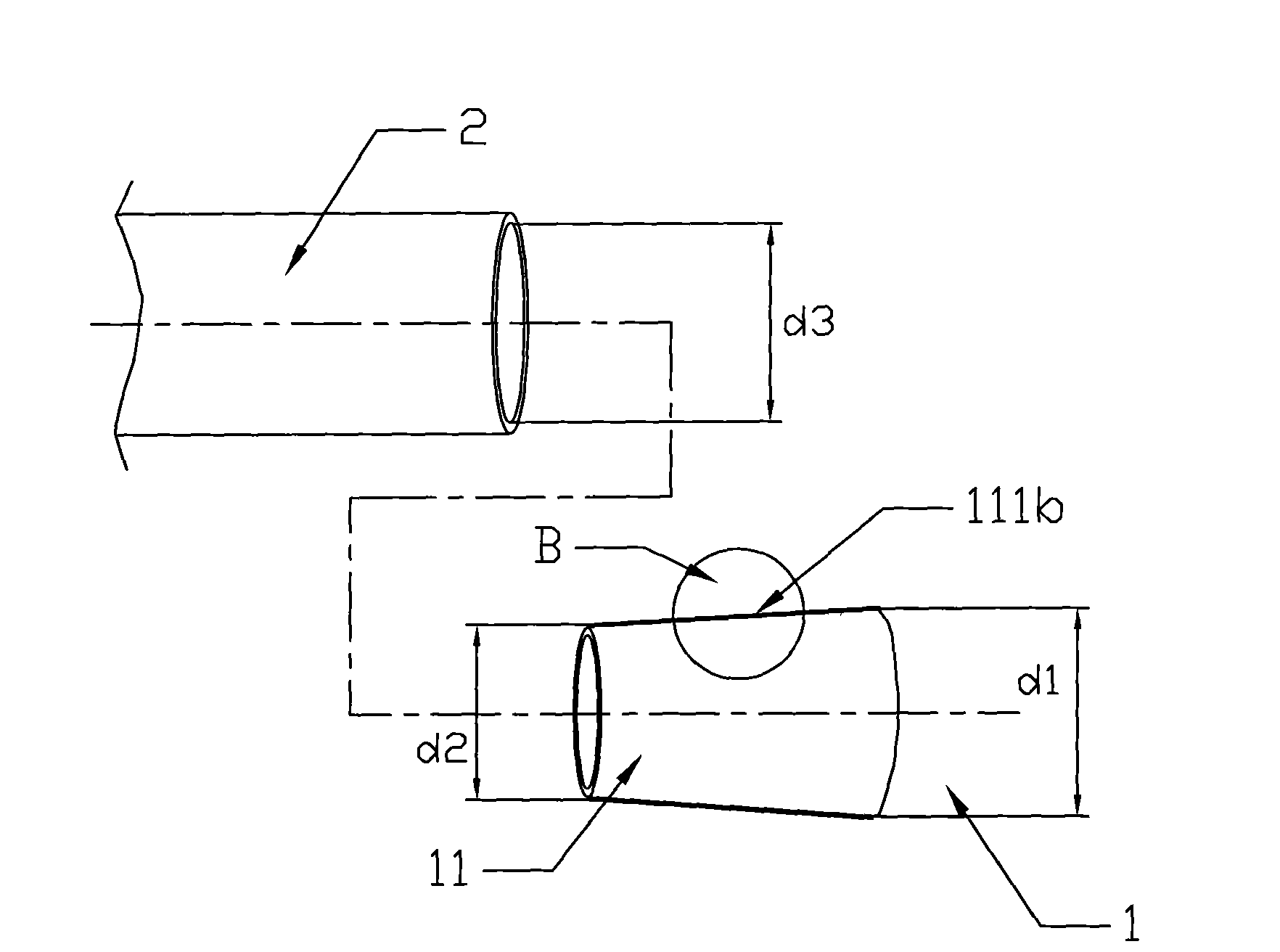

Blowing interface of blowing and sucking machine

InactiveCN101648196AStructural process optimizationSimple preparation processCleaning using gasesPolyesterButt joint

The invention discloses a blowing interface of a blowing and sucking machine in the field of mechanical interfaces, and the blowing interface is used for connecting an exhaust pipe of a blower and a pipe port of an extension pipe or a blowing and pressurizing nozzle. The invention is characterized in that the tail end of the exhaust pipe of the blower is in a taper pipe structure, and the inner diameter of the pipe port used for butt joint is ranged from the minimum outer diameter to the maximum outer diameter of the taper pipe; moreover, the outer surface of the taper pipe or the inner surface of the butt jointed pipe port at the tail end of the exhaust pipe is provided with a contact damping layer made of rubber or polyester. In the technical scheme of the invention, the pipe port at thetail end of the exhaust pipe is designed into a taper pipe, and is directly spliced and engaged with a pipe port of an external butt jointed component, so that the functions of the blowing and sucking machine can be conveniently and effectively switched, and the convenience of the use of the blowing and sucking machine is improved. In addition, the taper pipe structure and a preparation process thereof are simple and convenient, can effectively reduce the production cost and are beneficial to popularization and application.

Owner:王鸿智

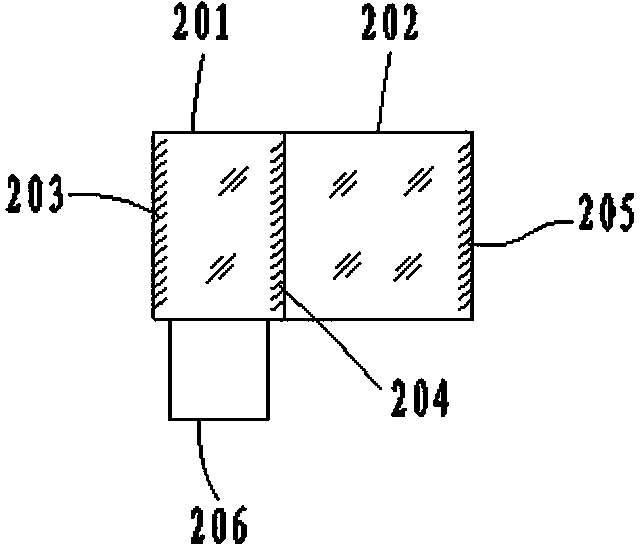

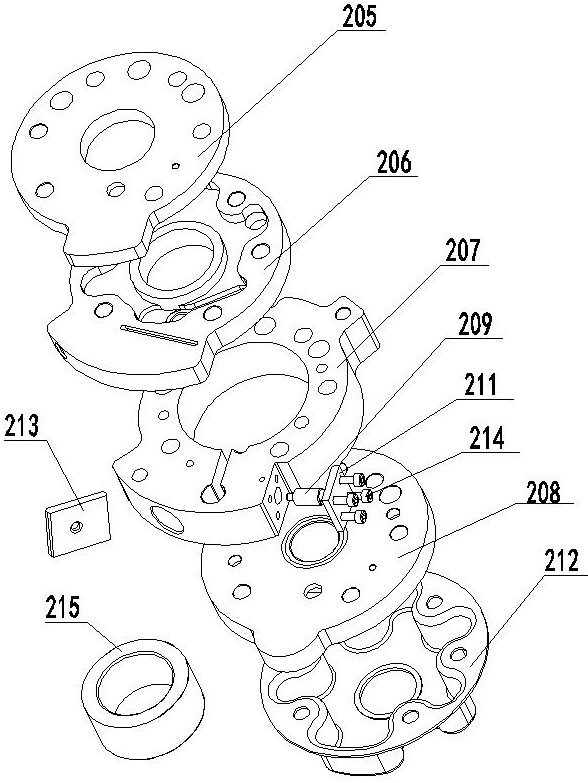

Double-cavity etalon

InactiveCN103676134AImprove finenessStructural process optimizationOptical elementsControl systemLength wave

The invention relates to the field of optics, and discloses a double-cavity etalon. The double-cavity etalon comprises a fixing cavity, a tuning cavity and a micro-control system, wherein the tuning cavity and the fixing cavity have consistent penetrated peaks, and the micro-control system is connected with the tuning cavity and slightly regulates the penetrated peak of the tuning cavity. According to the double-cavity etalon, the combination of the fixed cavity and the tuning cavity is adopted; through the slight tuning of the micro-control system, two single-cavity etalons forming the double-cavity etalon have the strictly consistent penetrated peaks, and the double-cavity etalon has flat top type penetrated peaks with high degree of finish so as to be suitable for wavelength locking in a laser. The structure is simple and convenient in process and is easy to achieve.

Owner:SHANGHAI BRANCH FUZHOU GAOYI COMM CO LTD

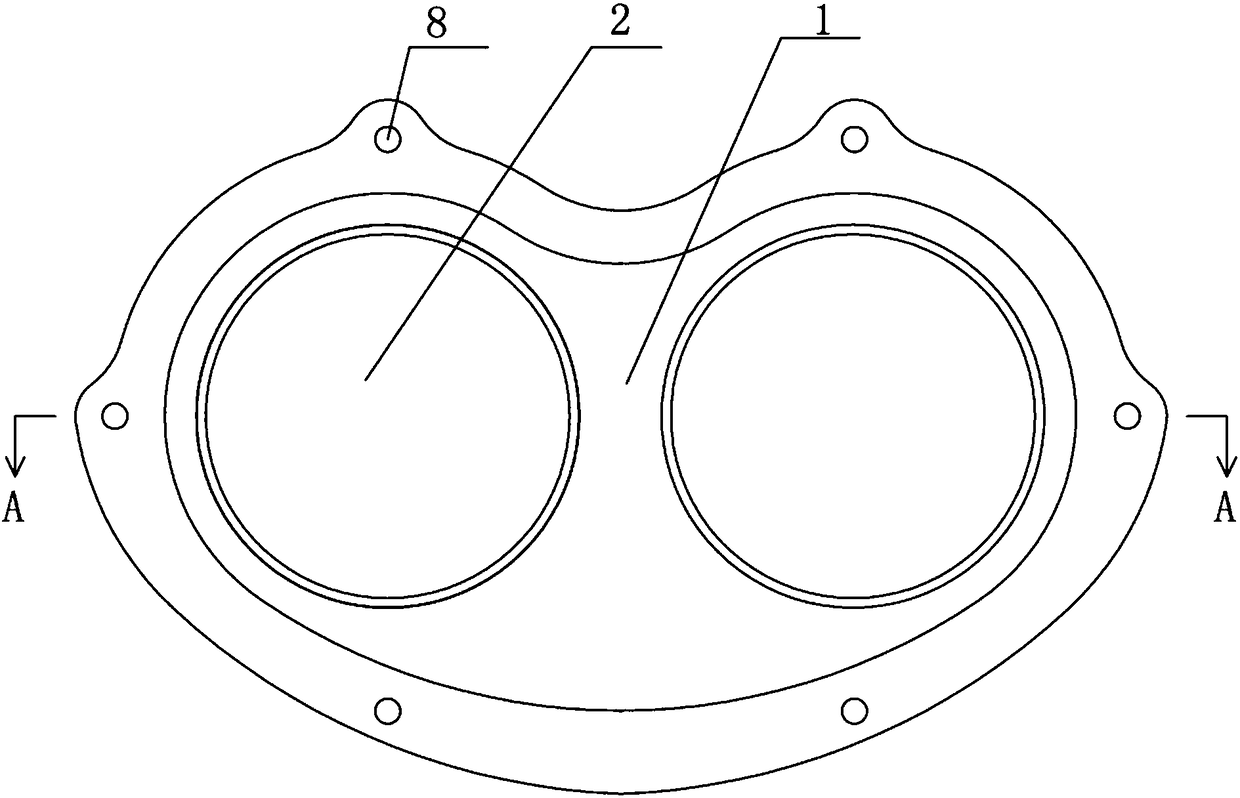

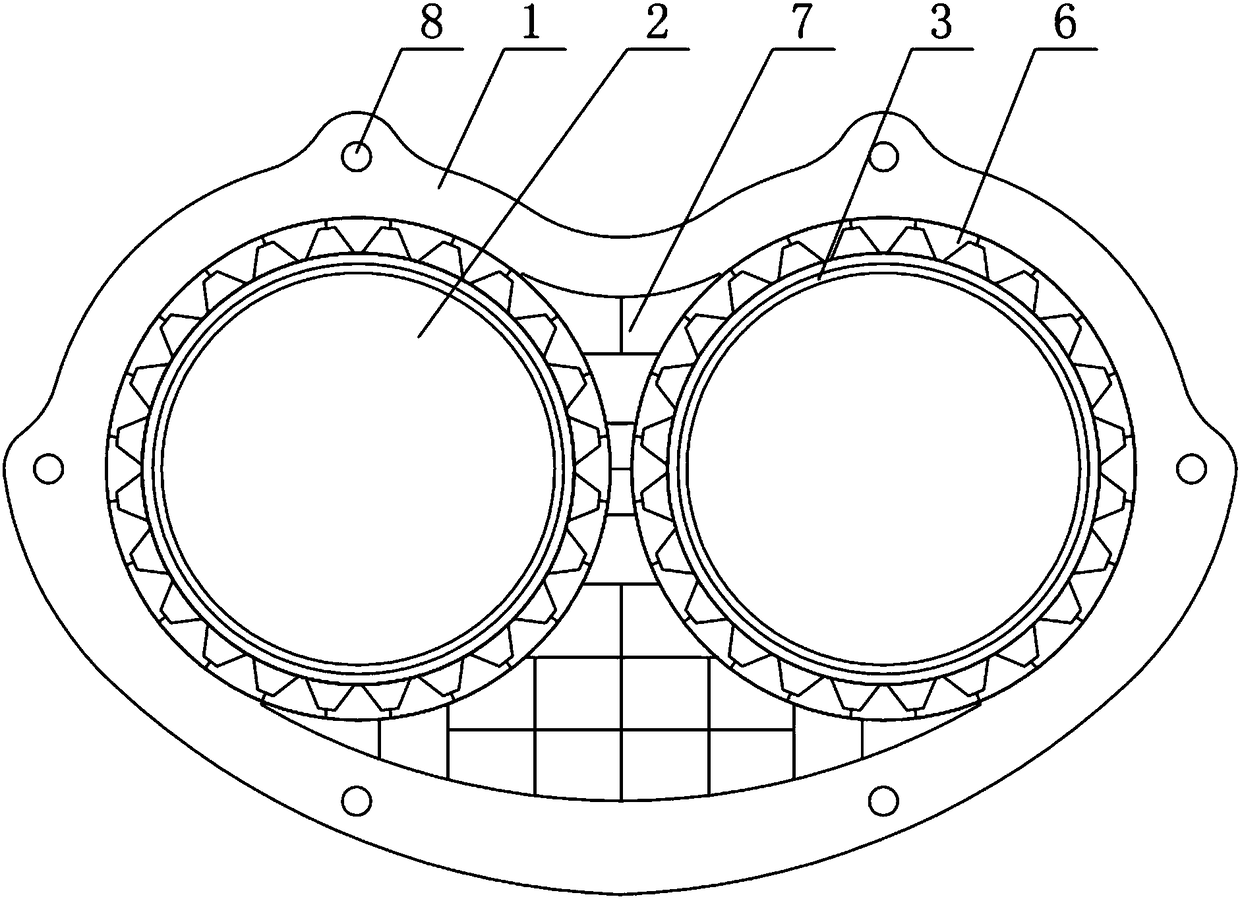

Impact resistant glasses plate and cutting ring for concrete pump

PendingCN108087261AReduce in quantityNo assembly errorsPositive displacement pump componentsPumpsMetallurgyAlloy

The invention discloses an impact resistant glasses plate and a cutting ring for a concrete pump. The impact resistant glasses plate comprises a body, wherein an opening is formed in the body, a groove is formed in one side of the body, a plurality of hard alloy blocks are brazed in the groove, at least one part of hard alloy blocks are spliced so as to form a hard alloy circular ring, the plurality of hard alloy blocks which are spliced so as to form the hard alloy circular ring include T-shaped hard alloy blocks which are located on the outer side of the hard alloy circular ring and are integrally in a T shape and trapezoidal hard alloy blocks which are located on the inner side of the hard alloy circular ring and are integrally in a trapezoidal shape, the T-shaped hard alloy blocks andthe trapezoidal hard alloy blocks are distributed in a staggered mode, the horizontal sides of the T-shaped hard alloy blocks are connected so as to form an outer ring of the hard alloy circular ring,the vertical sides of the T-shaped hard alloy blocks are in an inverted trapezoidal shape and are inserted between the waists of two adjacent trapezoidal hard alloy blocks, and the lower bottoms of the trapezoidal hard alloy blocks are connected with the upper bottoms of the vertical sides of the T-shaped hard alloy blocks so as to form an inner edge of the hard alloy circular ring. The impact resistant glasses plate has the advantages of good structural stability, impact resistance and easiness in manufacturing.

Owner:株洲方玺机械有限公司 +1

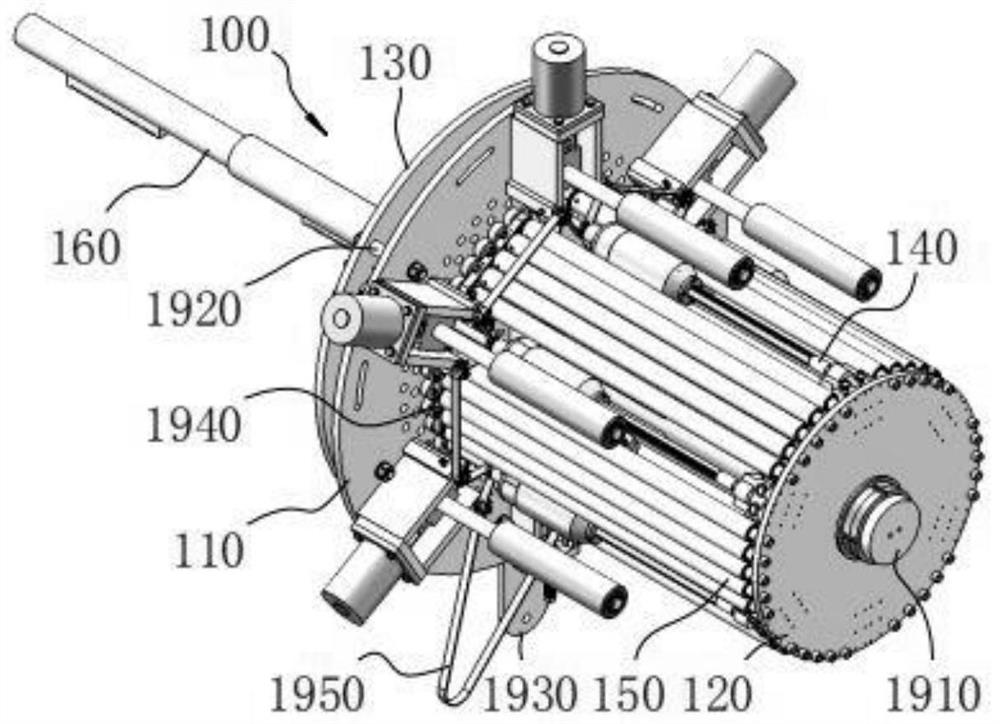

Equipment for manufacturing large-caliber bellmouth and flaring plastic pipe

PendingCN111634035AStructural process optimizationIncrease productivityTubular articlesProcess engineeringDigital control

The invention discloses equipment for manufacturing a large-caliber bellmouth and flaring plastic pipe. Pipe winding and bellmouth and flaring manufacturing are integrated, the structure and process design are optimized according to the functions and characteristics of different mechanisms of the equipment, according to the requirements of different pipe specifications for the structure wall thickness and according to the quality requirements of sustainable industrialized production and different work conditions, and overall running of the equipment is achieved through digital control; and energy saving and consumption reduction are achieved, the production efficiency and the speed are high, and the manufacturing requirement within the range that the pipe diameter ranges from 200 mm to 300mm and the ring rigidity ranges from SN 4 to SN 16 can be met.

Owner:济南寻龙机械科技有限公司

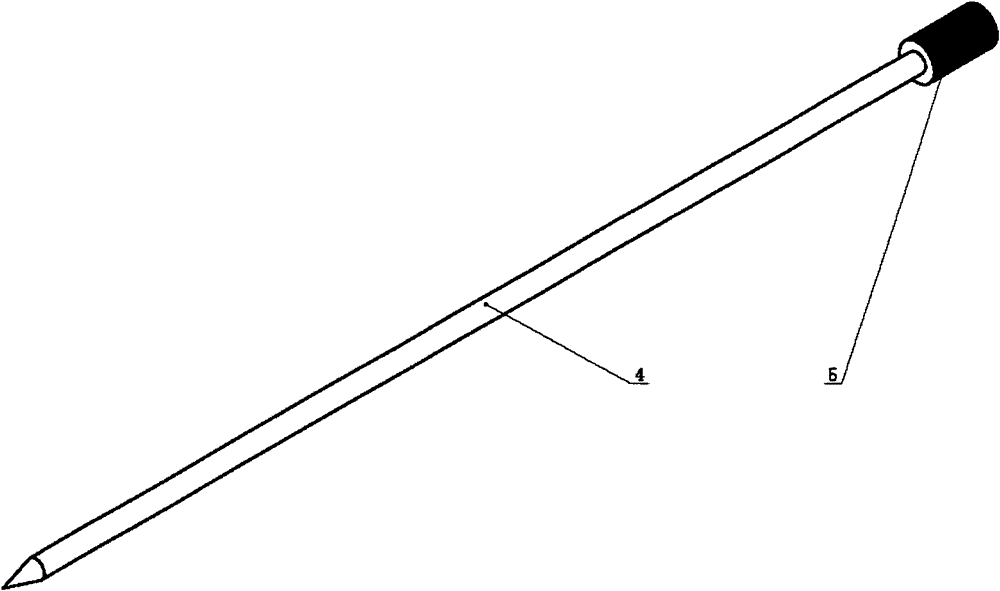

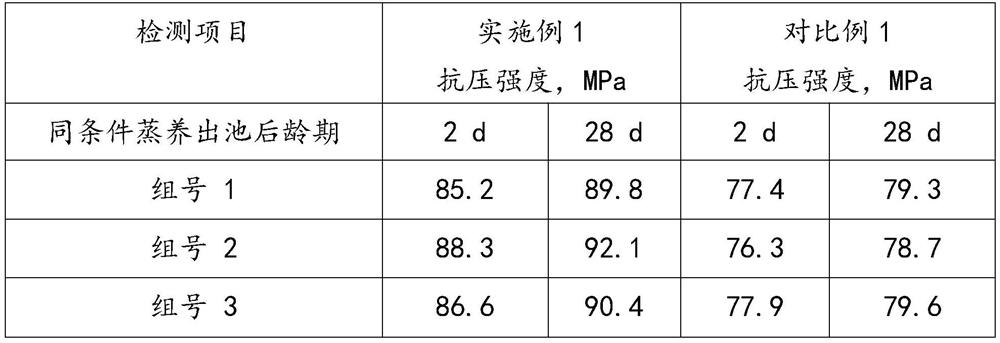

Preparation method of non-autoclaved high-performance prefabricated pipe pile

InactiveCN112776166AImprove performanceImprove bearing capacitySolid waste managementShaping reinforcementsArchitectural engineeringPipe

The invention provides a preparation method of a non-autoclaved high-performance prefabricated pipe pile. The method adopts the following steps including taking special cement for the pipe pile, an S115-grade composite admixture, a high-performance water reducing agent, machine-made sand and gravel as raw materials, preparing concrete, uniformly stirring, preparing a reinforcement cage, distributing and tensioning, centrifugally forming, carrying out normal-pressure steam curing, demolding, carrying out quality inspection, putting into a product storage yard and the like to obtain the finished non-autoclaved high-performance prefabricated pipe pile. The method is simple in process and low in cost, the prepared finished non-autoclaved high-performance prefabricated pipe pile has good stability, hitting (pressing) resistance, permeability resistance and corrosion resistance, the product design life is prolonged, durability is remarkably improved, conversion from common high-strength concrete to high-performance concrete of the pipe pile is achieved, and the concepts of ecological priority, green development and high-quality development in the new era are realized.

Owner:沧兴管桩有限公司

Multifunctional electrocardio lead special wire and manufacturing method thereof

InactiveCN111933328ATo resist bendingTensileNon-insulated conductorsCoupling contact membersElectrical conductorHemt circuits

The invention discloses a multifunctional electrocardio lead special wire and a manufacturing method thereof. The multifunctional electrocardio lead special wire comprises an electrocardio conductor formed by twisting a tin-copper foil wire conductor and a silver-plated copper foil wire conductor, and an FEP insulating layer is arranged on the outer surface of the electrocardio conductor to form an electrocardio inductor. The outer surface of the electrocardio inductor is sequentially coated with a conductive layer of an ethylene carbon resin component, a braided shielding layer of a tinned copper component and an outer sheath of an FEP component. One end of the five-core shielding lead wire is crimped with a human body connecting terminal, the other end of the five-core shielding lead wire is connected with the tail end of one core wire of the five-core shielding lead wire through the chip circuit board, and a series circuit of a gas discharger and a chip resistor in the chip circuitboard is insulated and shielded. The other end of the five-core shielding lead wire is connected with a plug used for electrocardiogram equipment, and magnetic ring anti-interference processing is adopted. The special wire has the advantages of bending resistance, tension resistance, high temperature resistance, good defibrillation effect, strong electrostatic protection, good shielding effect andthe like, is not interfered by the outside when transmitting physiological signals of a patient, and is accurate in signal transmission.

Owner:深圳市金瑞龙特种线材有限公司

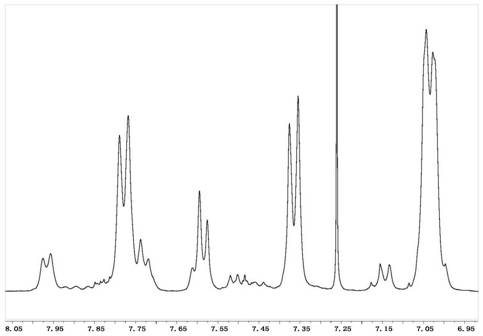

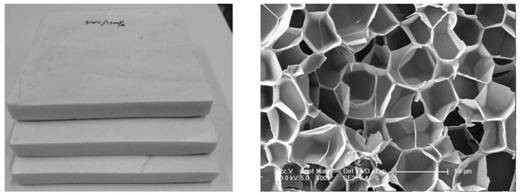

Branched polymer, preparation thereof and foam material

ActiveCN114249887AStructural process optimizationThe synthesis process is simplePolymer scienceStructural formula

The invention provides a branched polymer and a preparation method thereof, solves the problem of crosslinking in the existing branched polyaryletherketone (sulfone) preparation process, and realizes unification of high branching degree and high molecular weight of branched polyaryletherketone (sulfone). The structural formula of the polymer is shown as a formula (I) or a formula (II). The invention also provides a foam material prepared by taking the polymer as matrix resin, and the foaming mode is supercritical carbon dioxide foaming.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

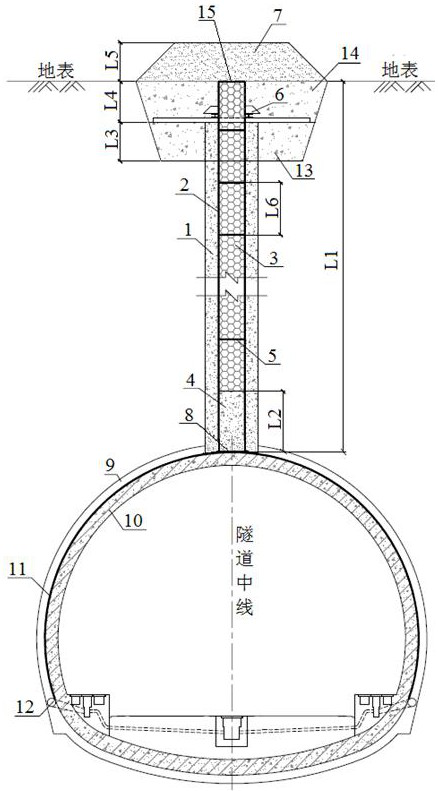

Large-buried-depth tunnel top vertical shaft backfilling load-reducing structure and construction method thereof

ActiveCN112627885AImprove deformation abilitySelf-weight pressure is smallUnderground chambersHydro energy generationStructural engineeringPipe

The invention discloses a large-buried-depth tunnel top vertical shaft backfilling load-reducing structure and a construction method thereof. The structure comprises a protection pipe which is arranged in a vertical shaft, wherein the top end of the protection pipe extends out of the vertical shaft, and a bottom sealing layer and a plurality of filling layers are arranged in the protection pipe; foldable supports are arranged between the adjacent filling layers, a base, a locking opening supporting beam and an outer wrapping layer are arranged outside the vertical shaft, and the parts, extending out of the vertical shaft, of the locking opening supporting beam and the protection pipe are located in the outer wrapping layer; and a soil sealing layer is arranged on the outer wrapping layer. A plurality of sections of steel protection cylinders are hoisted into the vertical shaft to form the protection pipe, the base is poured, the locking opening supporting beam is erected, the outer wrapping layer is poured, drainage blind pipes are densely arranged, and a secondary lining is poured; concrete is pumped into the protection pipe, the bottom sealing layer is formed through vibration and compaction, the bottom sealing layer is alternately provided with the filling layers and the foldable supports until the top surfaces of the finally-formed filling layers are flush with the top surface of the protection pipe, and a well top sealing plate is welded to the top surface of the protection pipe; and the soil sealing layer is piled on the outer wrapping layer, and the large-buried-depth tunnel top vertical shaft backfilling load-reducing structure is built. The load-reducing structure can effectively protect the safety of an underlying tunnel, and the technical blank is filled up.

Owner:LANZHOU RAILWAY SURVEY & DESIGN INST

Preparation method of niti fiber reinforced intermetallic compound-based matrix composite material for vibration and noise reduction

ActiveCN104099540BStructural process optimizationSimple preparation processNiti alloyStructure function

Owner:HARBIN ENG UNIV

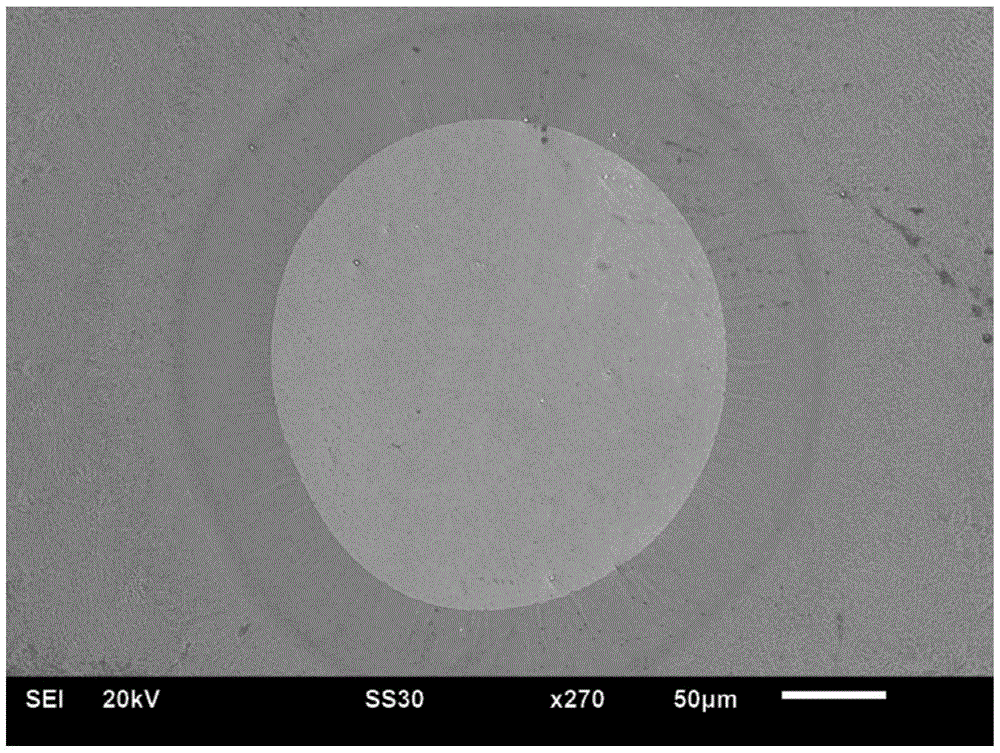

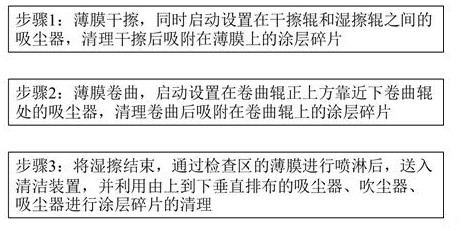

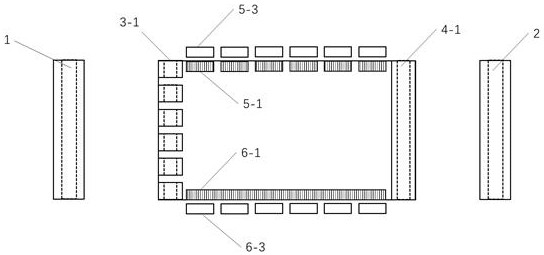

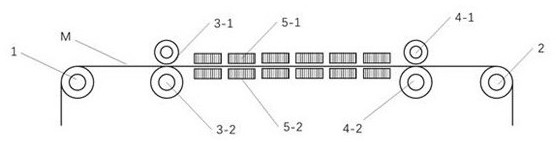

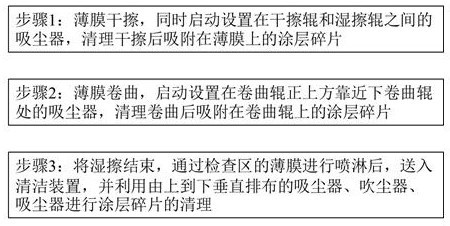

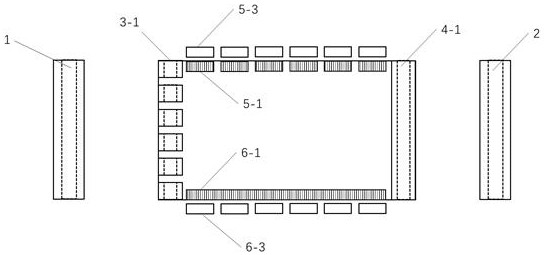

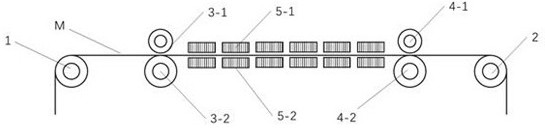

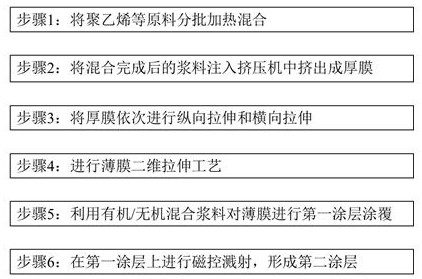

A kind of polyethylene film without coating debris and its preparation method

ActiveCN111978580BStructural process optimizationSimple preparation processVacuum evaporation coatingSputtering coatingPolymer scienceThin membrane

The invention discloses a preparation method of a polyethylene film without coating fragments. The preparation method comprises the following steps: preparing a polyethylene film; carrying out two-dimensional stretching after carrying out conventional stretching; coating the film with a first coating, sputtering the film with a second coating, and cleaning residual coating fragments by using multiple processes after coating shedding inspection, thereby ensuring that no coating fragment remains on the film, and enhancing the safety of a lithium battery film.

Owner:河南银金达新材料股份有限公司

Polyethylene film without coating fragments and preparation method of polyethylene film

ActiveCN111978580AAvoid breakingEnsure safetyVacuum evaporation coatingSputtering coatingThin membranePolyethylene membrane

The invention discloses a preparation method of a polyethylene film without coating fragments. The preparation method comprises the following steps: preparing a polyethylene film; carrying out two-dimensional stretching after carrying out conventional stretching; coating the film with a first coating, sputtering the film with a second coating, and cleaning residual coating fragments by using multiple processes after coating shedding inspection, thereby ensuring that no coating fragment remains on the film, and enhancing the safety of a lithium battery film.

Owner:河南银金达新材料股份有限公司

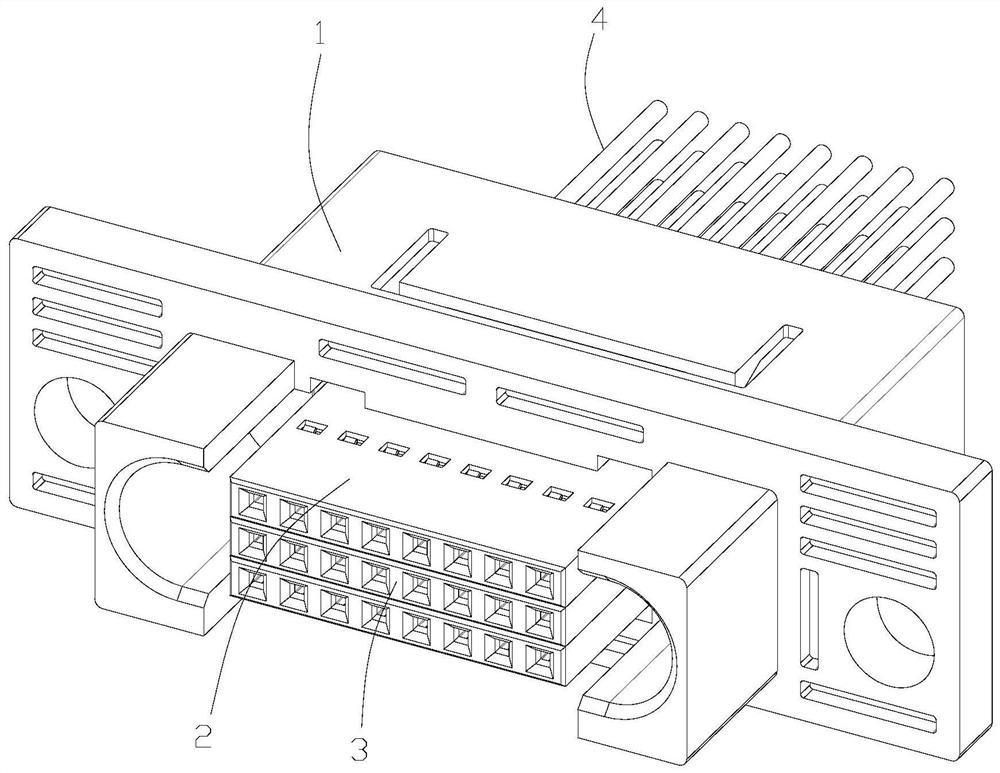

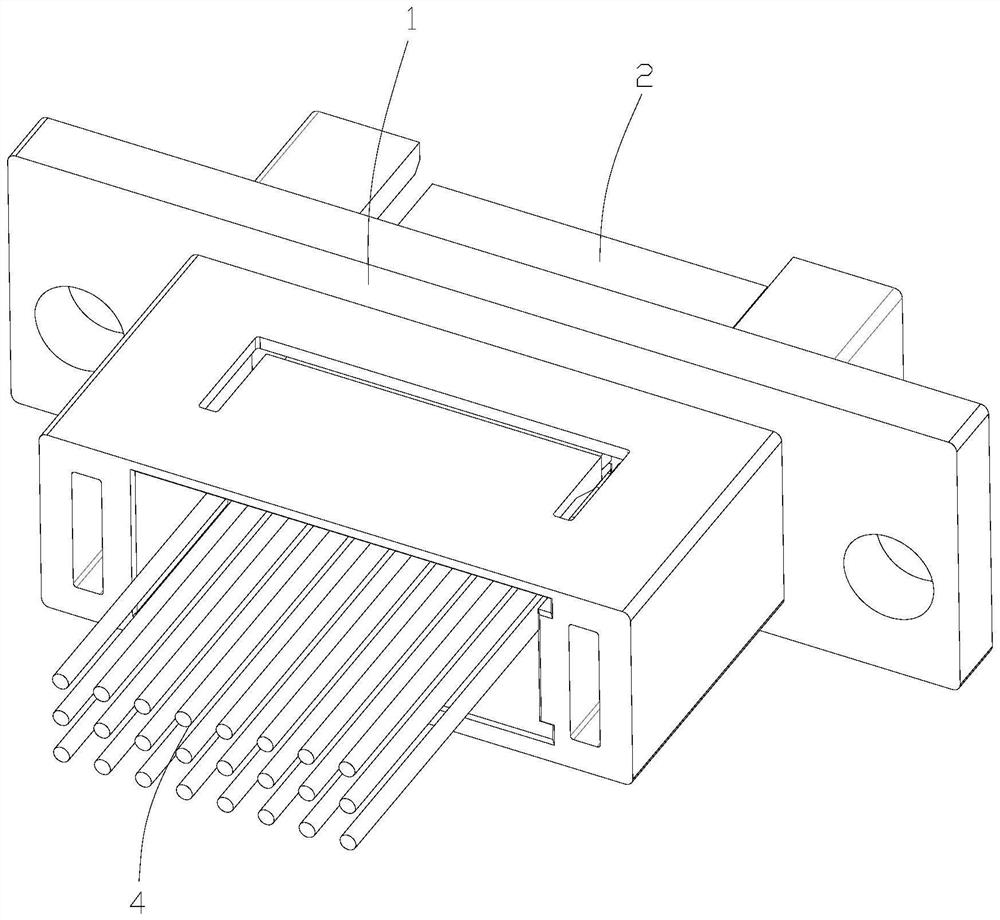

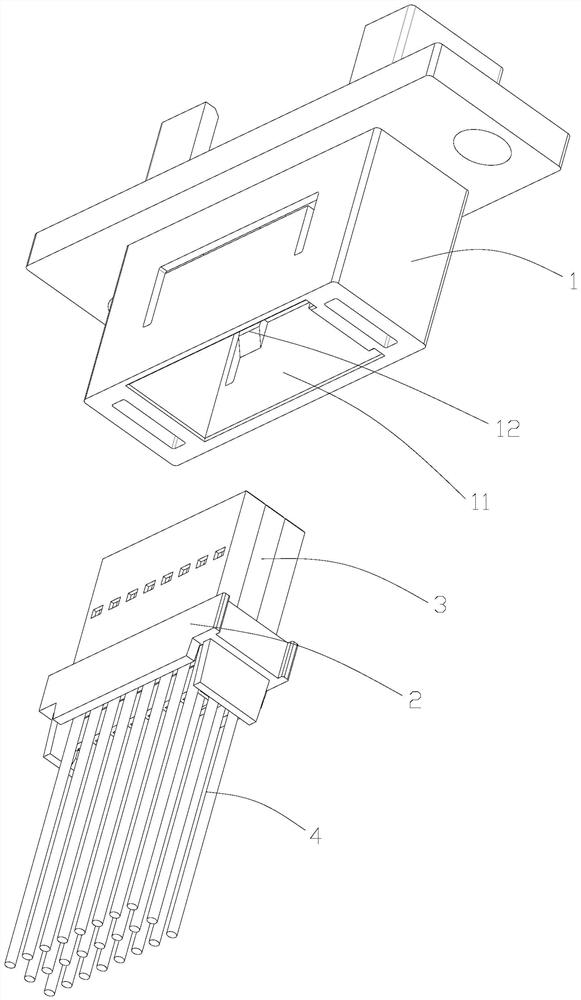

Connector

PendingCN114389089AOptimization of structure and assembly processLow implementation costSecuring/insulating coupling contact membersPhysicsEngineering

A connector disclosed by the present invention comprises a socket and a tongue piece assembly inserted in the socket, the tongue piece assembly comprises a main tongue piece and an auxiliary tongue piece inserted in the main tongue piece, the socket is internally provided with a socket inner slot, the main tongue piece is detachably inserted in the socket inner slot, and the auxiliary tongue piece is detachably inserted in the socket inner slot. The inner wall of the socket inner slot is provided with an elastic lock catch, and the elastic lock catch is used for locking the tongue piece assembly in the socket inner slot. The connector has the advantages of simple structure, few assembly steps, simple assembly process and the like, the assembly time can be effectively saved, the assembly efficiency can be improved, the labor cost and the labor intensity can be reduced during actual implementation, the structural stability and reliability of the product are higher, and the service life of the product is longer.

Owner:BIZCONN INT CORP (SHEN ZHEN)

High-adsorptivity automatic exhausting type protective film

InactiveCN109232814AStructural process optimizationSimple production processTectorial membraneTripropylene glycol

The invention discloses a high-adsorptivity automatic exhausting type protective film which is prepared from the following raw materials: 20%-30% of hexylene glycol dimethacrylate, 10%-25% of tripropylene glycol butyl diacrylate, 15%-25% of hydroxyethyl methylacrylate, 20%-30% of methacrylamide, 5%-12% of 2-ethylhexyl acrylate, 15%-25% of diluent, 2%-4% of additive and 3%-5% of coalescing agent. The high-adsorptivity automatic exhausting type protective film provided by the invention is prepared from macromolecule components and the additive is adopted for inhibiting reaction rate, so that gelling is avoided, and meanwhile, crosslinking density is increased, cohesion is enhanced, structure stability is guaranteed, base structure and production process of the protective film can be effectively improved and safety and stability in production and use can be promoted.

Owner:江苏创客新材料科技有限公司

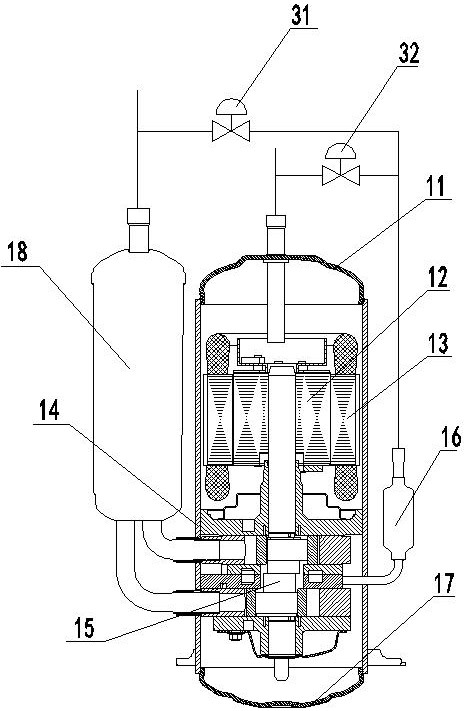

Pump body components and variable capacity compressor

ActiveCN111075721BSimple structure and processSimplify the assembly processRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsEngineeringCylinder block

The present invention relates to the technical field of compressors, in particular to a pump body device and a variable capacity compressor. The pump body assembly is applied to a variable capacity compressor and includes a cylinder part, a slide plate and a pin part. The cylinder part is provided with A plurality of pin holes are opened on the cylinder part, the pin part is arranged in the pin hole and can move along the axis direction of the pin hole, and a slide slot is also opened on the cylinder part, the The sliding vane is set in the sliding vane groove, and the pin hole and the sliding vane groove are connected with each other. This pump body assembly solves the problem of the complex structure of the lower flange of the conventional variable capacity compressor due to the setting of the pin hole. , making the structure and assembly process of the pump body components simpler.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

A kind of flexible membrane with composite coating and preparation method thereof

ActiveCN111933872BStructural process optimizationSimple preparation processLi-accumulatorsCell component detailsSputteringPolymer science

A method for preparing a flexible film with a composite coating, comprising preparing a polyethylene film; carrying out conventional stretching followed by two-dimensional stretching; coating the film with a first layer of coating, and then coating the film with a second layer of coating Sputtering, after softness inspection and preparation process control treatment of polyethylene film with composite coating, film formation to produce a film with suitable softness. Utilizing such a thin film as a lithium battery separator can prevent the coating from falling off during transportation, installation, and use, and has high safety and good mechanical and electrical properties.

Owner:河南功能高分子膜材料创新中心有限公司

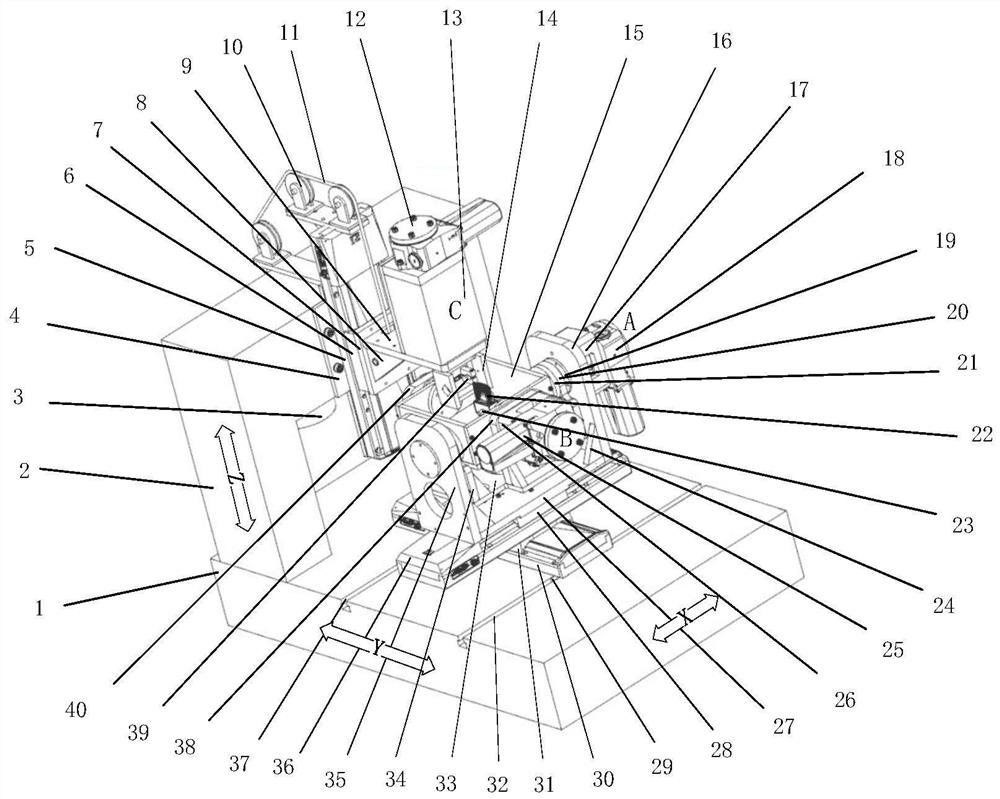

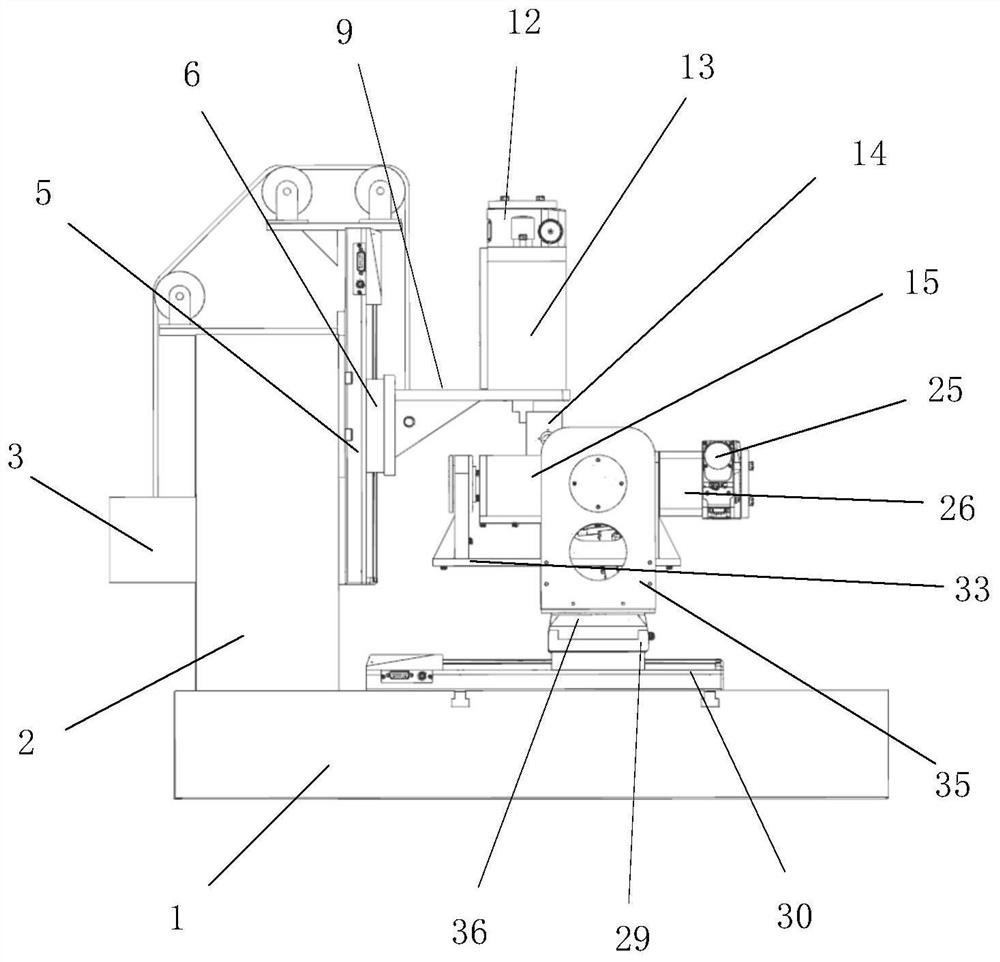

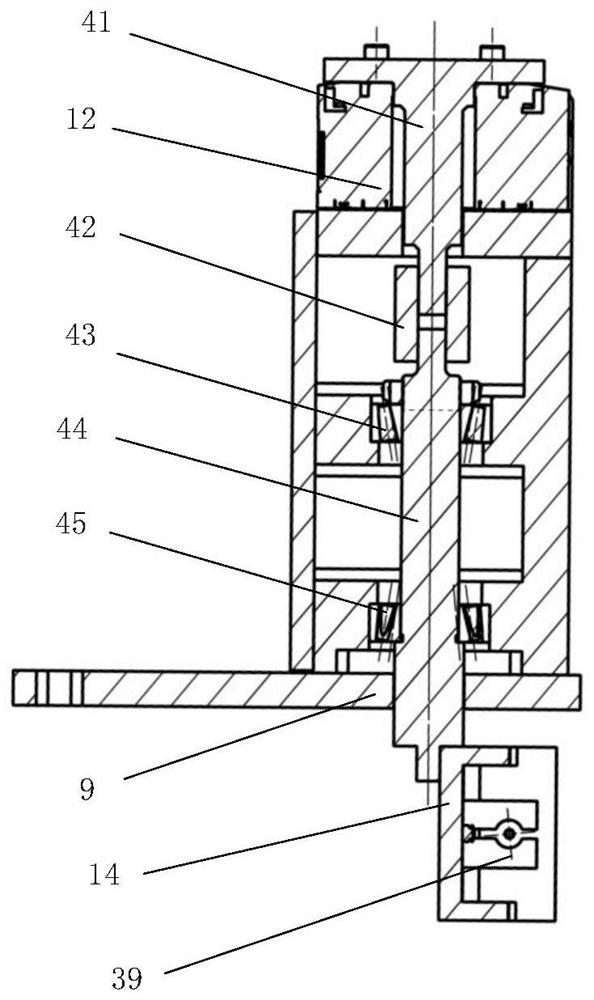

Blade intake and exhaust edge six-axis EDM machine

ActiveCN113231701BSimple structureEasy to disassembleElectrical-based auxillary apparatusRotational axisMachine

The invention provides a six-axis EDM machine tool for blade inlet and exhaust sides. The special machine tool bed is fixed with two positioning grooves on the horizontal plane of the Y-direction linear moving axis; Linear movement axis; two cradle mechanisms are connected to the X-direction linear movement axis, the first cradle is connected to the B rotation axis, the second cradle is connected to the A rotation axis, the second cradle is connected to the blade clamp, the left end of the bed There is a Z-axis support plate on the surface to fix the Z-direction linear moving axis. The Z-direction linear moving axis fixes the C-rotation rotation axis through the slider, horizontal plate, bearing box and other accessories; the C-rotation rotation axis is connected to the electrode fixture through the shaft. There are holes on the inside of the fixture to connect the actuator to provide vibration during machining. The invention has compact structure and simple assembly, can realize complex movement in space with six degrees of freedom, improve the machining efficiency of the blade edge circular arc, and can stably and reliably perform multi-degree-of-freedom EDM machining on the edges of the intake and exhaust of the blade.

Owner:DALIAN UNIV OF TECH

A multifunctional built-in dynamic and static piezoelectric spindle for high-efficiency high-speed precision machine tools

InactiveCN103286678BImprove axial movement accuracyHigh precisionGrinding machine componentsThrust bearingGrinding wheel

The invention relates to a multi-functional built-in dynamic-static-pressure motorized spindle for an efficient high-speed precision machine. The multi-functional built-in moving piezo spindle comprises a shell, a spindle body, a bearing, an oil sealing cover, a motor rotor and a stator. A front bearing is arranged at the right end of the shell and forms a static-pressure push bearing with the spindle. The inner surface of the front bearing is provided with a static-pressure oil cavity, and part of the large diameter of the inner surface matches with a pre-tightening piston. A rear bearing is mounted in a rear-bearing seat. The motor rotor is arranged between the front bearing and the rear bearing. The outer cylindrical face of the motor stator matches with a water sleeve tightly. The water sleeve matches with a hole in the middle of the shell and is connected to the shell. The rear bearing is sealed through a gas sealing ring, and the front bearing is sealed through the oil sealing cover and a gas sealing hole at the rear end. Heat shielding devices are arranged at two ends of the motor stator. The spindle can be mounted at different positions according to different using conditions. The multi-functional built-in dynamic-static-pressure motorized spindle can serve as a spindle of a grinding wheel of a precision machine, a milling center or a grinding machine or a spindle of a workpiece, and has the advantages of high precision, high rigidity, long service life, fine producing process, good sealing effect and the like.

Owner:上海原创精密机床主轴有限公司

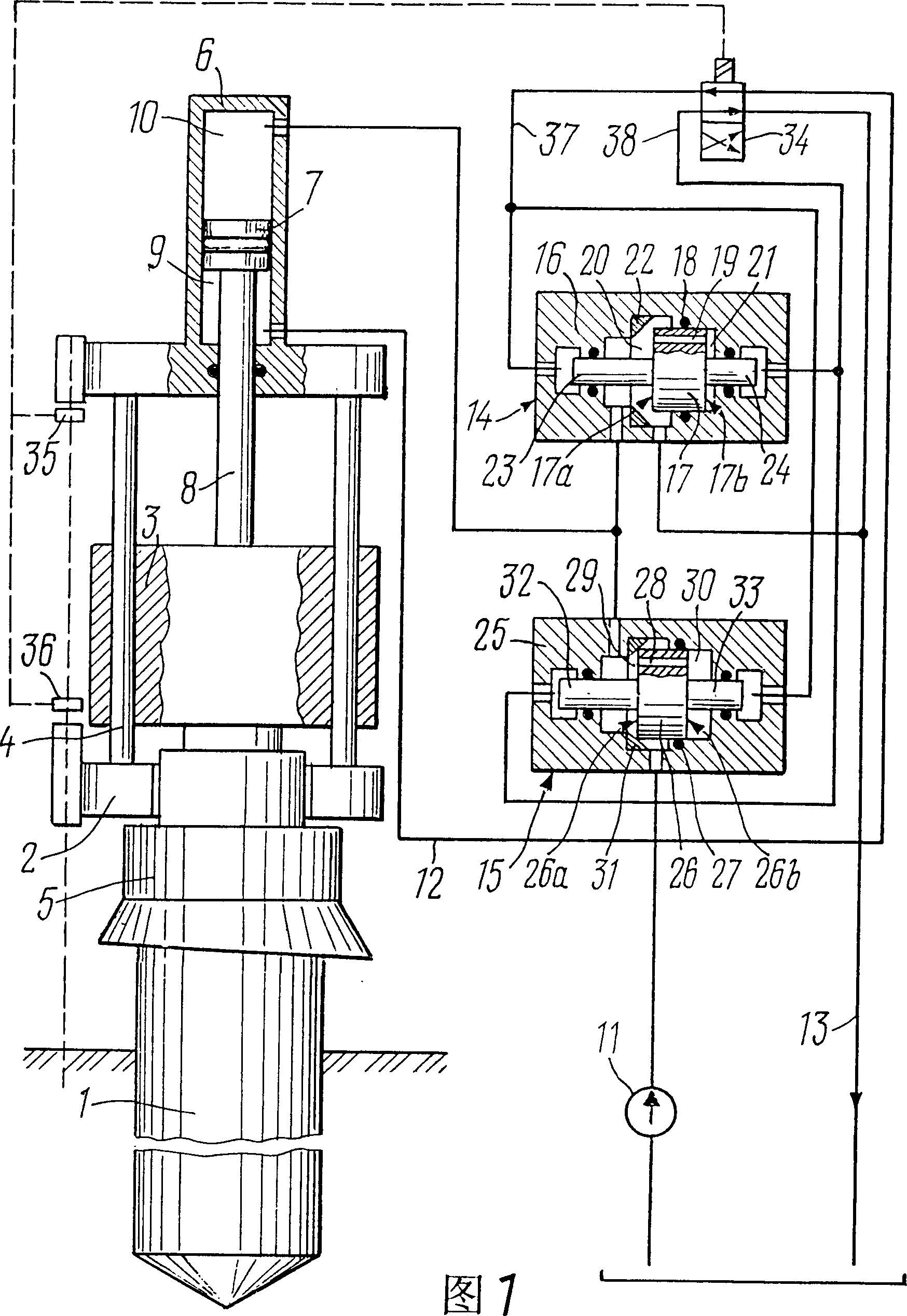

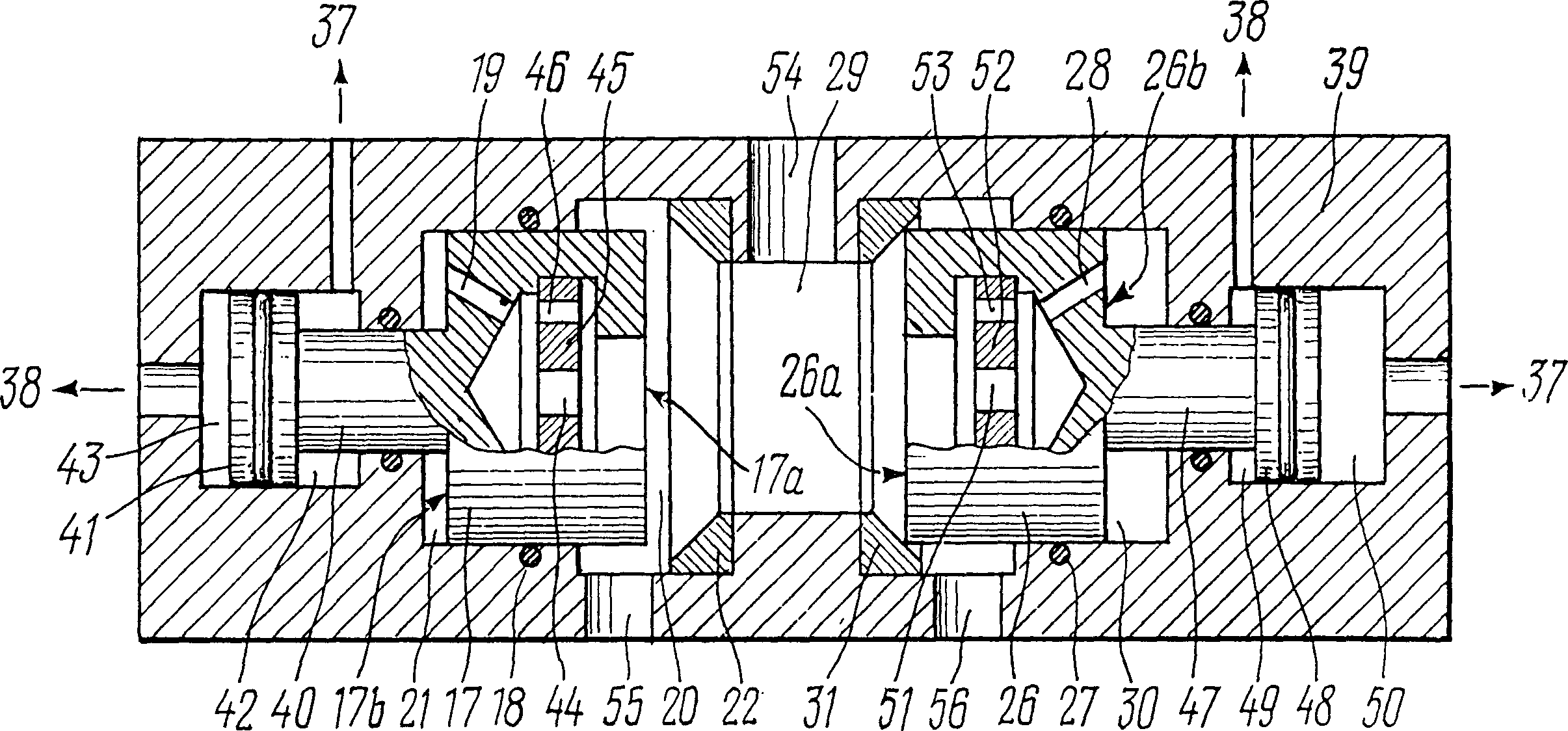

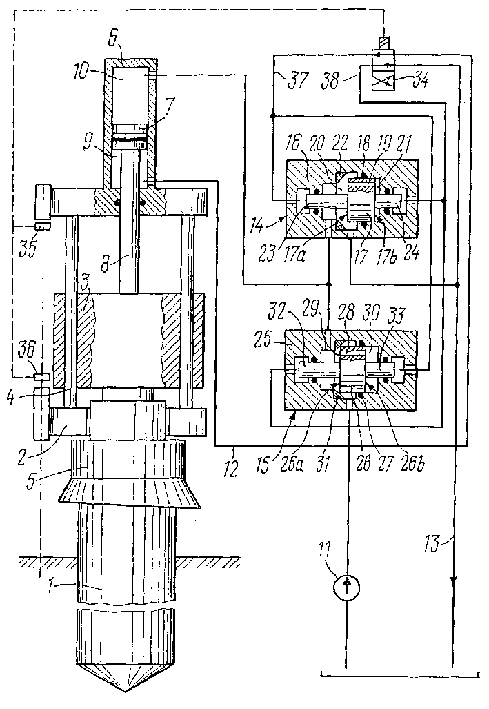

Hydraulic hammer

InactiveCN1125211CReliable reverse movementMovement Speed AdjustmentBulkheads/pilesEngineeringPiston

A hydraulic hammer, comprising a housing (2); an impact mass (3) equipped with a guide rod (4) reciprocatingly moving; a hydraulic cylinder (6) for moving the impact mass (3), which is fixed on the housing ( In 2), the piston (7) with the connecting rod (8) forms a connecting rod cavity (9) in the direction of the pile (1) in the hydraulic cylinder (6), and the other side forms a piston cavity (10). The connecting rod (8) is connected with the impact mass (3), the pump (11) with the overflow pipe (13) and the pressurizing pipe (12) which is connected with the connecting rod cavity ( 9) are connected, and also include two double-position valves (14, 15), which are used to connect with the piston chamber (10) of the hydraulic hammer (6) through the pressurizing pipe (12) or overflow pipe (13); each Valve parts (17, 26) are made into an oil cylinder form, arranged and sealed in the housing of the valve, and its outer diameter is close to the diameter of the contact surface of the valve. Wherein the chamber at the front end of the valve part communicates with the chamber at the rear end of the valve part facing the valve seat.

Owner:"罗帕特普琉斯"有限责任公司

Cast-iron cooling wall and manufacturing method thereof

InactiveCN100457923CImprove heat transfer efficiencyImprove thermal conductivityCooling devicesFurnace cooling arrangementsCarbon coatingDuctile iron

The invention relates to a new type low thermal resistance cast iron cooling wall. The feature is that the identity material of cooling wall is nodular cast iron or gray cast iron and the cooling water channel in cooling wall is made up from pure copper. The clearance between the cooling wall identity and the outer wall of pure copper pipeline is below 0.1mm. The manufacture method includes the following steps: fixing the molded pure copper pipeline into the sand box; casting by molten iron of nodular cast iron or gray cast iron, and taking inertia vapor cooling to copper pipeline to molding. The invention eliminates the thermal resistance caused by anti seepage carbon coating layer to make the heat exchange efficiency sharply increase and prolong the useful life of cooling wall.

Owner:NANJING NANGANG IND DEV CO LTD

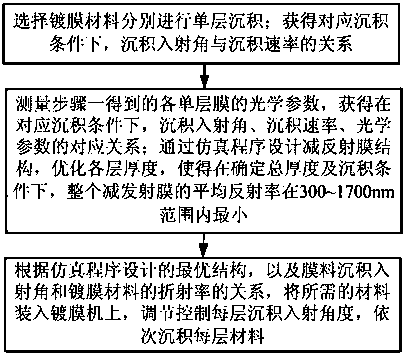

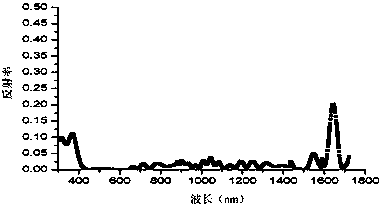

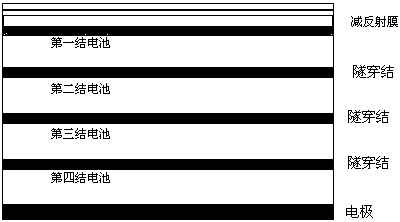

A kind of multi-junction solar cell anti-reflection film and preparation method thereof

ActiveCN106684205BStructural process optimizationSimple preparation processFinal product manufacturePhotovoltaic energy generationTotal thicknessMono layer

The invention provides an anti-reflection coating for a multi-junction solar cell and a preparation method thereof. The preparation method of the anti-reflection coating for the multi-junction solar cell provided by the invention comprises the following steps: I, selecting materials to perform single-layer deposition, and acquiring relations between a deposition incidence angle and a deposition rate under corresponding deposition conditions; and II, measuring optical parameters of single-layer coatings obtained in the step I, acquiring corresponding relations among the deposition incidence angle, the deposition rate and the optical parameters under corresponding deposition conditions, designing an anti-reflection coating structure through a simulation program, and optimizing the thicknesses of the layers, so that the average reflectivity of the whole anti-reflection coating is minimum within the range of 300 to 1,700nm under a determined total thickness and deposition conditions. The reflectivity of the anti-reflection coating for the multi-junction solar cell provided by the invention is less than 0.25 percent within the range of 300 to 1,700nm.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

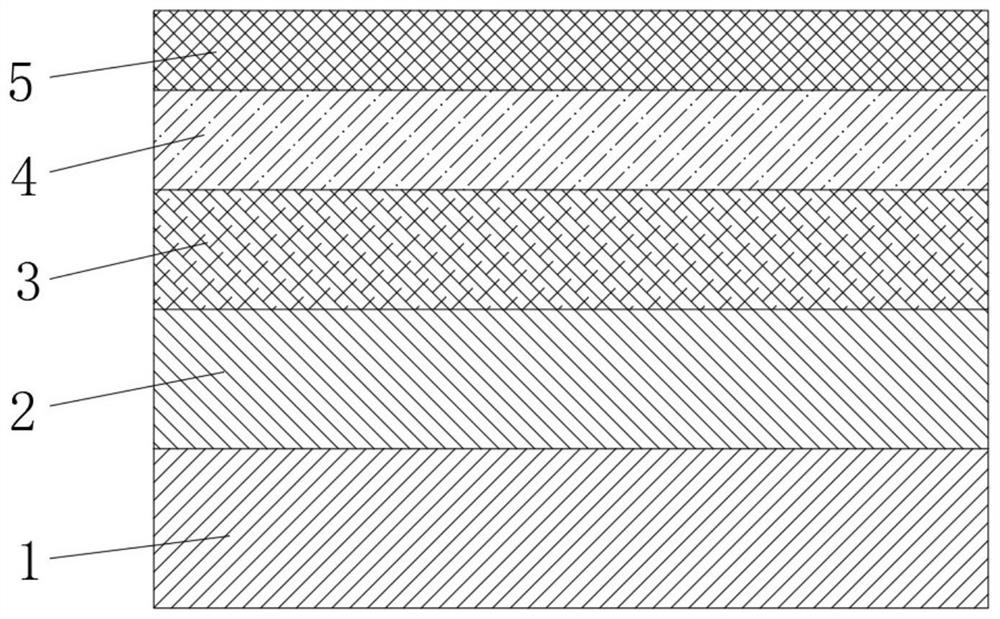

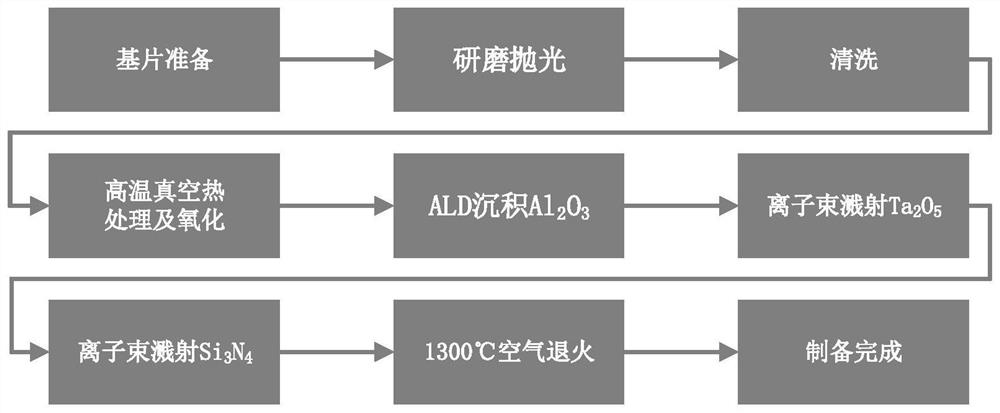

High-temperature insulating layer for engine blade film sensor and preparation method of high-temperature insulating layer

PendingCN113862673AGuaranteed electrical insulation performanceReduce stressVacuum evaporation coatingSputtering coatingThin membraneMechanical engineering

The invention discloses a high-temperature insulating layer for an engine blade film sensor and a preparation method of the high-temperature insulating layer. The high-temperature insulating layer comprises a blade substrate layer, a high-temperature oxide layer, an Al2O3 film layer, a Ta2O5 film layer and a Si3N4 film layer which are sequentially arranged from bottom to top. The preparation method comprises the steps of vacuum heat treatment and high-temperature oxidation, preparation of the Al2O3 film layer, preparation of the Ta2O5 film layer, preparation of the Si3N4 film layer and high-temperature heat treatment. The high-temperature insulating layer is compact in film, few in defect and capable of reducing leakage current caused by film defects at high temperature, and the preparation method is simple, easy to implement and low in cost.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

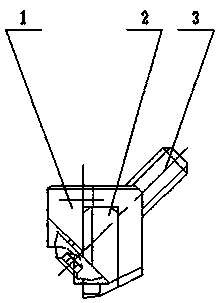

Fine-tuning fine boring tool holder and its adjustment method

ActiveCN105328226BReduce manufacturing costGuarantee quality requirementsTool holdersEngineeringScrew thread

The invention relates to a fine adjustment fine boring tool apron and an adjustment method. Currently, most boring toolholders produced in China do not have the function of displaying numerical value type fine adjustment, only can perform simple axial and radial adjustment, utilizes thread transmission mechanisms to perform rough adjustment of mechanisms through the screw stretching length, and are lower in adjustment accuracy. The fine adjustment fine boring tool apron comprises a tool apron body (1), wherein a blade bearing (2) is arranged in the tool apron body and is a slip mass provided with a rectangular groove; a fine adjustment bolt (5), a straight pin (6) and a sunk screw (4) are mounted on the front end face of the tool apron body respectively; an oblique plane is arranged on one side of the tool apron body; a hexagon socket button head screw (3) is mounted on the oblique plane; an adjustment block (8) is matched with the oblique plane on the other side of the tool apron body; a hexagon sunk screw (7) is mounted on the lower surface of the adjustment block. The invention is applicable to fine adjustment fine boring tool aprons.

Owner:HARBIN MEASURING & CUTTING TOOL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com