Branched polymer, preparation thereof and foam material

A technology of branched polymers and polymers, applied in the field of branched polymers, preparation methods and foam materials, which can solve the problem of the reduction of polymer molecular weight and mechanical properties, affecting the performance of polymer foams, polymer post-treatment and processing Difficulties and other problems, to achieve the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

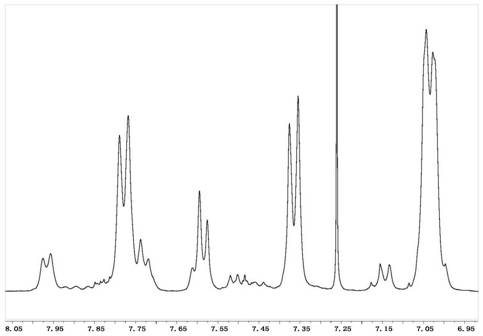

[0042] Add phenolphthalein (100mmol), 4,4-difluorobenzophenone (127mmol), 1,1,1-tris(4-hydroxyphenyl)ethane (8mmol), K 2 CO 3 (125mmol), TMS (130ml), toluene (50ml), under the condition of nitrogen protection, heat the above mixture to 150°C to azeotropically remove water, keep the temperature for 2h, remove toluene and produced water, continue to heat to 220°C for 2h, cool down To 150°C, add (4-fluorobenzene)-(4-hydroxy-3phenylbenzene)methanone (150mmol) and toluene (50ml) to react for 2h, remove the toluene, then raise the temperature to 220°C for 2h, end the reaction, add Dilute with 250ml DMAc, precipitate in ethanol-water (50:50) mixed solution, filter and pulverize the precipitate, and repeatedly boil and wash with deionized water for 5 times, 60min each time, remove inorganic salt and residual solvent, dry, That is, the long-chain branched polyaryletherketone having the structure of formula (III) is obtained. (10<m+p<15,5<m<10,5<p<10,20<n<30,10<y<20)

[0043]

[0...

Embodiment 2

[0052] Add phenolphthalein (100mmol), 4,4-difluorodiphenyl sulfone (125mmol), phloroglucinol (8mmol), K 2 CO 3 (125mmol), TMS (130ml), toluene (50ml), under the condition of nitrogen protection, heat the above mixture to 150°C to azeotropically remove water, keep the temperature for 2h, remove toluene, continue to heat to 220°C for 2h, cool to 150°C, Add 4-fluoro-4'-hydroxydiphenyl sulfone (150mmol) and toluene (50ml) to react for 2h, remove the toluene and the water produced, then raise the temperature to 220°C for 2h, and finish the reaction. Precipitate in water (50:50), filter and pulverize the precipitate, and repeatedly boil and wash with deionized water 5 times, each time for 60 minutes, remove inorganic salt and residual solvent, and dry to obtain the compound with the structure of formula (V) Polyaryl ether sulfone with long-chain branched structure. (10<m+p<15,5<m<10,5<p<10,20<n<30,10<y<20)

[0053]

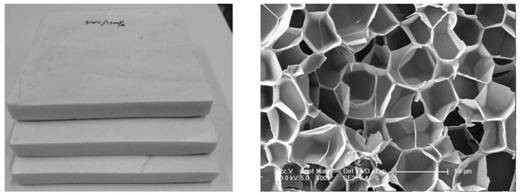

[0054] Mold the pulverized and dried powder sample in a hot ...

Embodiment 3

[0060] Add phenolphthalein (100mmol), 4,4-difluorodiphenylsulfone (127mmol), 1,3,5-tris(4-hydroxyphenyl)benzene (3mmol), K 2 CO 3 (125mmol), TMS (130ml), toluene (50ml), under the condition of nitrogen protection, heat the above mixture to 150°C to azeotropically remove water, keep the temperature for 2h, remove toluene and produced water, continue to heat to 220°C for 2h, cool down To 150°C, add 4-fluoro-4'-hydroxydiphenyl sulfone (150mmol) and toluene (50ml) to react for 2h, remove the toluene, then raise the temperature to 220°C for 2h, end the reaction, add 250ml of DMAc to dilute, then add Precipitate in water (50:50), filter and pulverize the precipitate, and repeatedly boil and wash with deionized water for 5 times, each time for 60 minutes, remove inorganic salt and residual solvent, and dry to obtain the compound with the structure of formula (VI). Long-chain branched polyarylethersulfone. (15<m+p<20,5<m<10,5<p<10,20<n<30,10<y<20)

[0061]

[0062] Mold the pulv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com