Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Guaranteed electrical insulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble soldering flux dedicated for lead-free solder

InactiveCN1836825AImprove solderabilityImprove performanceWelding/cutting media/materialsSoldering mediaOrganic acidWater soluble

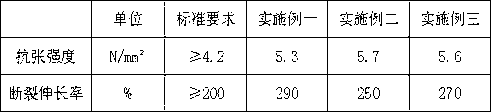

The water soluble soldering flux specially for lead-free soldering material consists of boric acid and organic acid activator 5.0-10.0 wt%, non-ionic surfactant or cationic surfactant 0.1-1.0 wt%, co-solvent 8.0-20.0 wt%, filming agent 0.1-1.0 wt%, corrosion retardant 0.1-0.5 wt%, except deionized water. The compounding process includes the following steps: mixing co-solvent and partial deionized water, adding filming agent under stirring, adding the rest deionized water, activator and surfactant after dissolving, adding corrosion retardant while stirring to dissolve, stilling, and filtering to obtain the filtrate as the soldering flux. The water soluble soldering flux has excellent soldering assisting performance on lead-free soldering material, environment friendship and other advantages.

Owner:BEIJING UNIV OF TECH

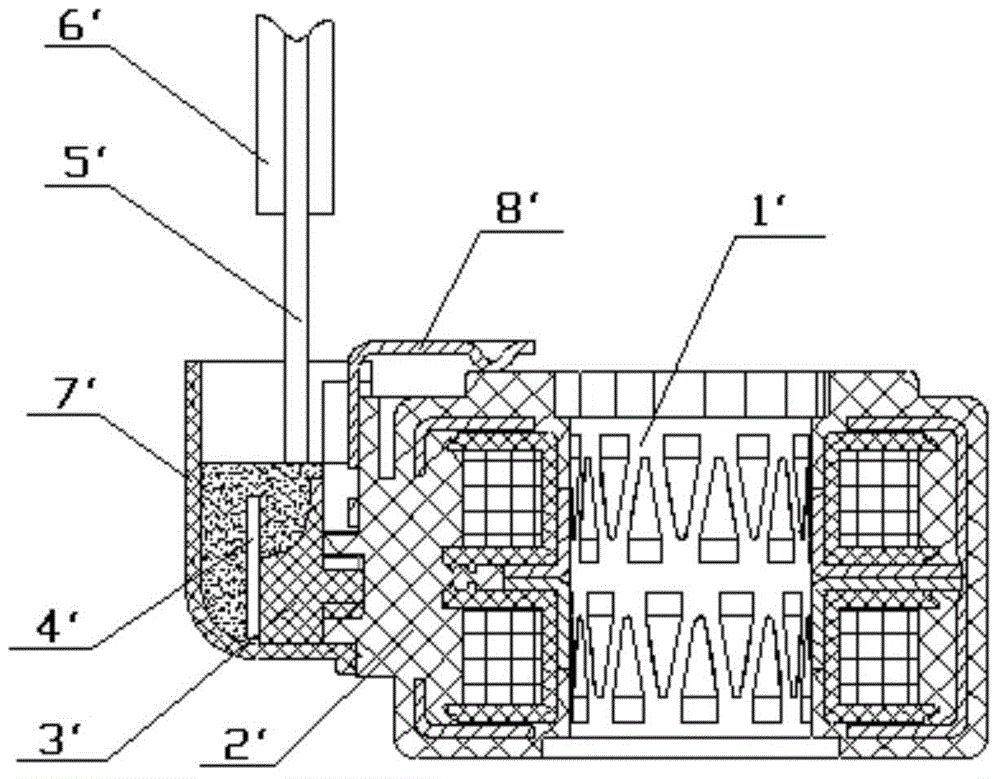

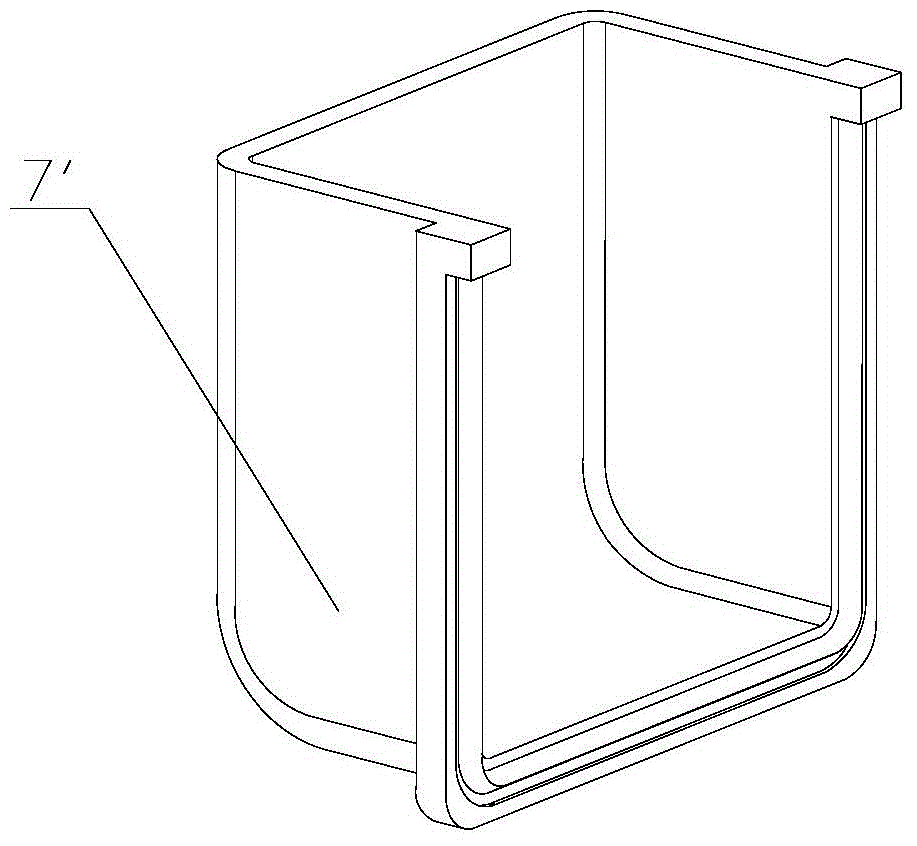

Explosion-proof coil, electronic expansion valve and machining method of explosion-proof coil

ActiveCN106151646AImprove explosion-proof performanceMeet certification requirementsOperating means/releasing devices for valvesEfficient regulation technologiesElectronic expansion valveMachining

The invention discloses an explosion-proof coil which comprises a winding (1) and a winding shell (2). A cable mounting part (3) and a circuit board (4) are arranged on the winding shell (2). A leading wire (5) is installed on the circuit board (4). A protection sleeve (6) is arranged outside the leading wire (5). A housing (7) is further fixedly connected outside the winding shell (2). The top end of the housing (7) is higher than the bottom end of the protection sleeve (6). The housing (7), the cable mounting part (3), the circuit board (4), the leading wire (5) and part of the protection sleeve (6) are formed into a whole through encapsulation. Compared with the prior art, encapsulation of the bottom end of the protection sleeve (6) is achieved through the explosion-proof coil, the electric insulation performance of the joint of the circuit board (4) is guaranteed, the explosion-proof performance of the explosion-proof coil is improved, the explosion-proof coil is made to meet the national certification requirements for explosion-proof coils, and meanwhile, market requirements for the explosion-proof coil of an electronic expansion valve can also be met. The invention further provides the electronic expansion valve with the explosion-proof coil applied and a machining method of the explosion-proof coil.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

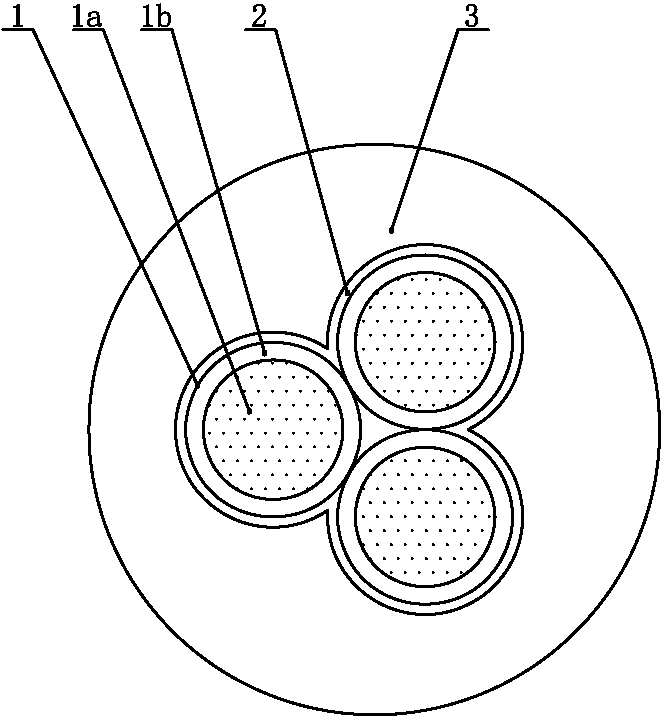

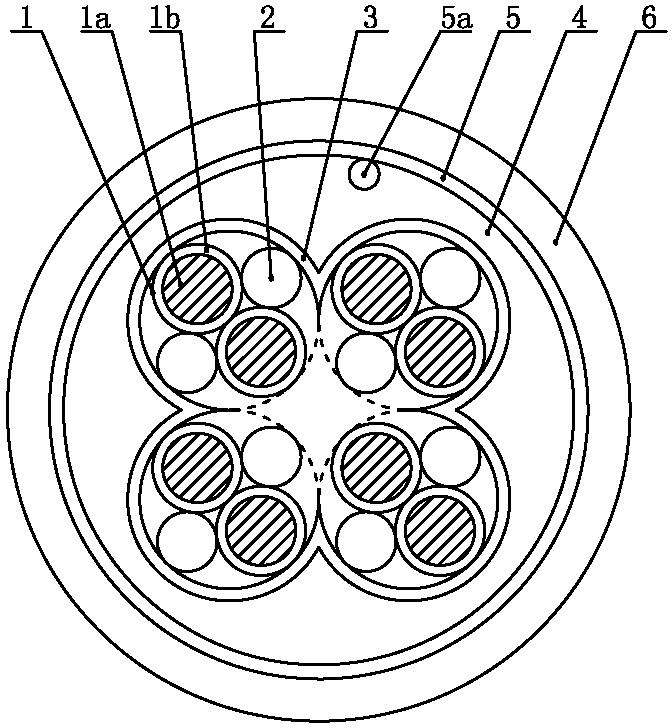

Salt corrosion resistant and twisting resistant power cable for ocean wind power and manufacturing method of power cable

ActiveCN103227008AReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

75kv low impedance coaxial cable

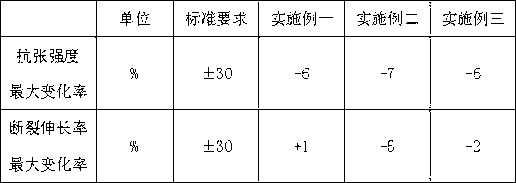

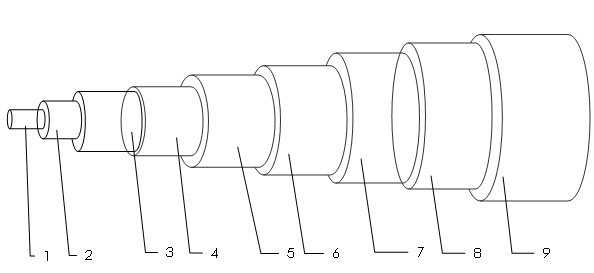

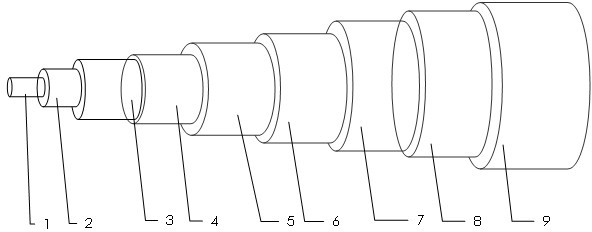

InactiveCN102280178AGuaranteed electrical insulation performanceGuaranteed electrical performanceBraided wire conductorsFlexible cablesCapacitanceElectrical conductor

The invention relates to a 75kV low-impedance coaxial cable used for connecting and wiring an accelerator control system and a linear pulse transformer for transmitting leading edge pulse signals. Braid multiple strands of tough copper wires outside the filler core as the inner conductor of the cable, and the inner conductor is provided with an isolation layer, a first layer of insulation, a second layer of insulation, a third layer of insulation, an isolation layer, an outer conductor and a sheath. The feature is: braiding multiple strands of tough copper wire on the filling core as the inner conductor of the cable, which not only reduces the weight of the cable, but also makes the whole cable soft and easy to bend. The isolation layer is a semi-conductive material to reduce the gap between the inner and outer conductors and the insulating layer, prevent the problem of partial discharge caused by the concentration of the electric field, and improve the withstand voltage of the cable. The first, second and third layers of insulation are respectively made of cross-linked polyethylene, polytetrafluoroethylene, and cross-linked polyethylene materials. The three layers of insulation together form a hierarchical composite insulation structure, which not only ensures the cable impedance, capacitance, inductance and the system. Matching design achieves low impedance of the cable.

Owner:TIANJIN 609 CABLE COMPANY

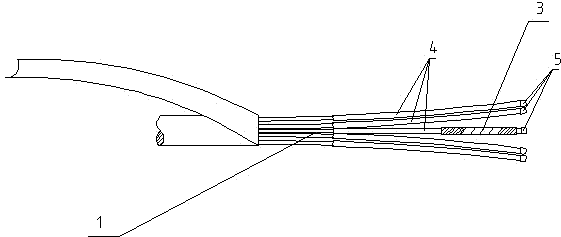

Method for manufacturing anti-disengaging pre-forking copper core cable

ActiveCN103489520AGuaranteed electrical conductivityEasy to buckleInsulated cablesMetal/alloy conductorsElectrical resistance and conductanceElectrical conductor

The invention discloses a method for manufacturing an anti-disengaging pre-forking copper core cable, and belongs to the field of cables, wherein the anti-disengaging pre-forking copper core cable is one of pre-forking cable terminals. According to the method, a conductor cable core of a main cable and a conductor cable core of a branch cable are formed in a pressing fit mode, after an insulation belt is wound and injection molding is conducted, the pre-forking copper core cable is obtained, then a net-shaped hanger is installed and a finished product is obtained. By the adoption of the method, the anti-disengaging pre-forking copper core cable has the advantages of being simple in end processing structure, safe, reliable, convenient to assemble and disassemble, firm in hoisting, good in sealing performance, resistant to high temperature and corrosion, and capable of preventing fire and explosion; insulation resistance cannot be lowered by moisture, and the anti-disengaging pre-forking copper core cable can be widely used in various industrial buildings and civil buildings.

Owner:四川新蓉电缆有限责任公司

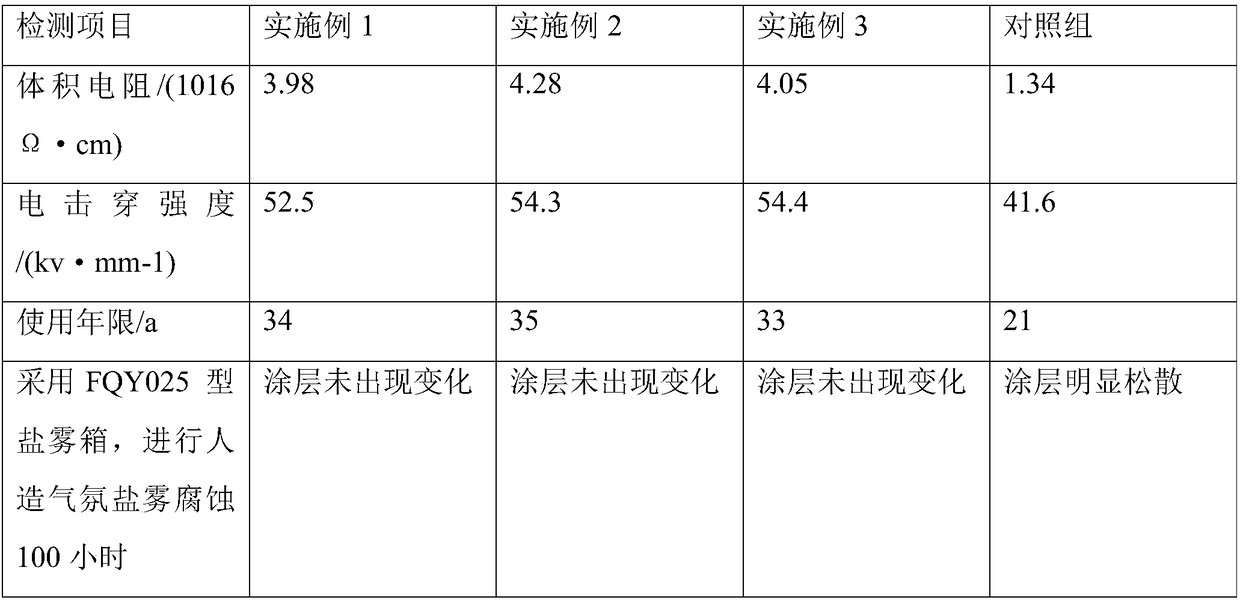

High-voltage insulation bus and coating process

InactiveCN109355008AGuaranteed anti-corrosionEnsure insulationPlastic/resin/waxes insulatorsInsulated cablesAlkali freeInsulation layer

The invention discloses a high-voltage insulation bus and a coating process. The high-voltage insulation bus comprises a bus body, the bus body is coated with an anticorrosive layer and an insulationlayer, the anticorrosive layer is positioned on the bottom layer of the bus body, the insulation layer is positioned on the outer layer of the bus body, the anticorrosive layer is coated with organicsilicon coatings, and the insulation layer comprises, by weight, 60-75 parts of organic silicon resin, 40-45 parts of polyacrylate rubber, 5-7 parts of titanate coupling agents, 3-4 parts of zirconiumoxide, 20-24 parts of silicon dioxide, 3-7 parts of naphthenic oil, 4-6 parts of calcium stearate, 3-4 parts of alunite, 5-7 parts of vinyl trimethoxysilane, 2-6 parts of alkali-free glass fibers and9-17 parts of ethylene-propylene-diene monomer glue. A coating structure of the bus can effectively decrease electrical short circuit of the bus body, and the insulating property and the anticorrosive property of the bus are greatly improved, so that the service life of the bus is prolonged.

Owner:镇江朝阳机电科技有限公司

MEMS gas sensor chip and sensor and preparation method of sensor

ActiveCN108844652AShort delivery pathFast balanceTemperatue controlThermometers using electric/magnetic elementsMOSFETTemperature control

The invention relates to an MEMS gas sensor chip and sensor and a preparation method of the sensor, belongs to the technical field of gas detection, and solves the problems of high technical cost, long response time and low environment stability in the prior art. The MEMS gas sensor chip comprises a gas sensitive unit, a temperature sensitive unit, a sensitive structure substrate and a temperaturecontrol unit. The MEMS gas sensor comprises the MEMS gas sensor chip and a control circuit, and the control circuit further comprises a microcontroller, an N type MOSFET, a P type MOSFET and a positive-negative power supply. The microcontroller compares a practical temperature collected by the temperature sensitive unit with a preset temperature, outputs a control signal according to a comparisonresult, controls ON / OFF of the N type MOSFET and the P type MOSFET, and further controls the direction and magnitude of a current through the temperature control unit and changes the surface temperature of the sensitive structure substrate. The MEMS gas sensor is simple in operation and high in versatility, can measure the concentration of different gases simultaneously, saves the cost, and is short in response time and high in environment stability.

Owner:BEIJING MECHANICAL EQUIP INST

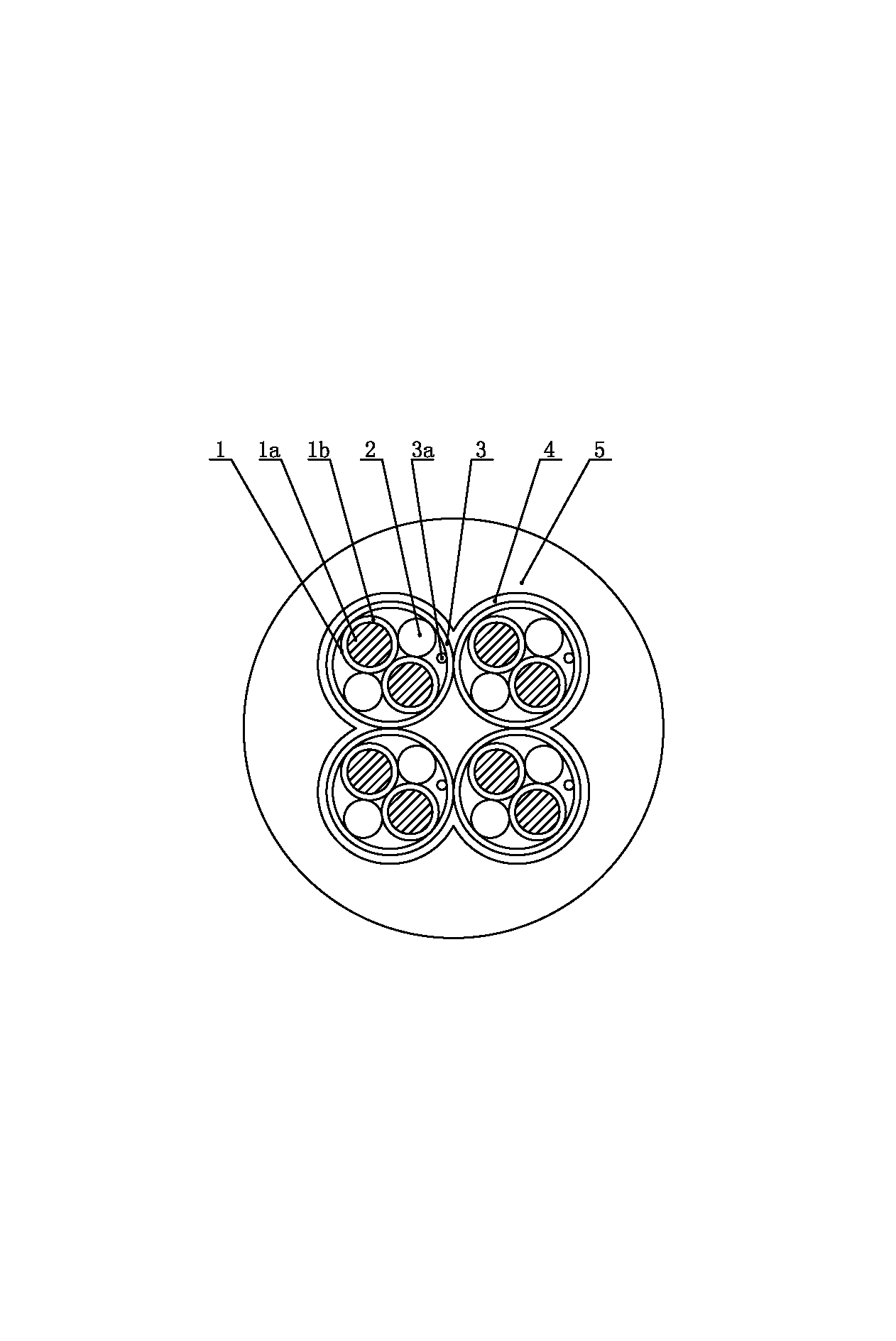

Salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and manufacturing method thereof

ActiveCN103187127AEliminate voidsExcellent impregnationRubber insulatorsInsulating conductors/cablesCopper conductorFiber

The invention relates to a salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and a manufacturing method thereof. A salt corrosion and torsion resisting type rubber insulating layer is uniformly extruded to wrap the peripheries of stranded copper conductors in order to form insulating wires, the insulating wires are stranded in pairs to form a stranded wire pair, the gap of the stranded wire pair is filled with a flame-retardant non-hygroscopic fiber filling core, the periphery of each group of stranded wire pair is wound with a copper foil polyester compounding belt shielding layer to form a stranded group, multiple stranded groups are mutually stranded to form a cable core, and the periphery of the cable core is wrapped with low strength non-woven fabrics, and is extruded with a protective sleeve. According to the salt corrosion and torsion resisting type shielding telecommunication cable, a longitudinal low strength non-woven fabric wrapping layer is adopted, and is completely matched with the insulating wire core in shape, so that the gap between the longitudinal low strength non-woven fabric wrapping layer and the insulating wire core is eliminated, a flame can be favorably prevented from being continuously transmitted to the inside under the combustion condition, and the humidity steeping resistance is improved. Meanwhile, the longitudinal low strength non-woven fabric wrapping layer can ensure that the protective sleeve does not adhere to the insulating wire core, and facilitates the stripping of the protective sleeve in the construction process without damages on the insulating wire core.

Owner:浙江华威设备制造有限公司

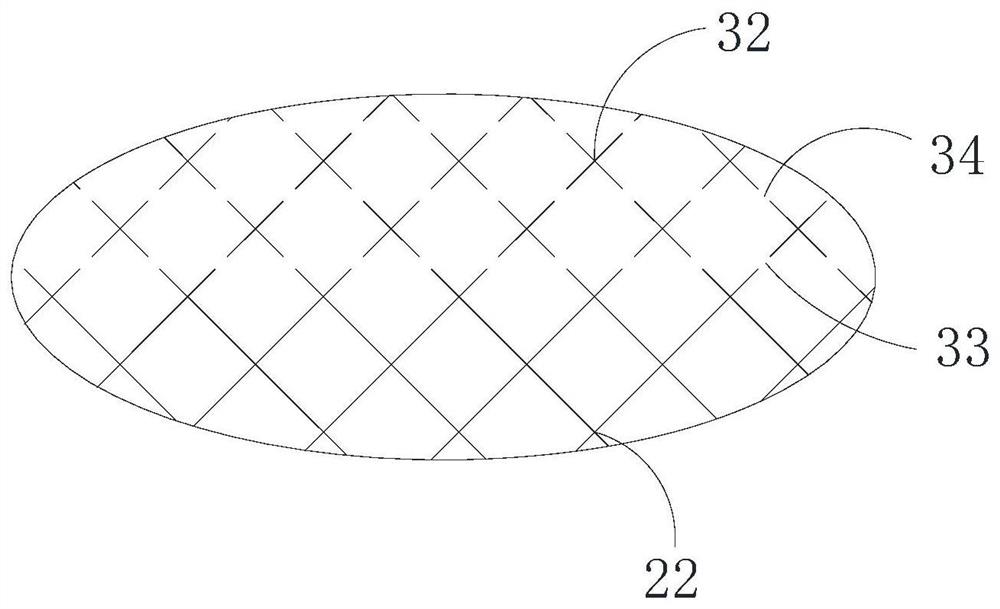

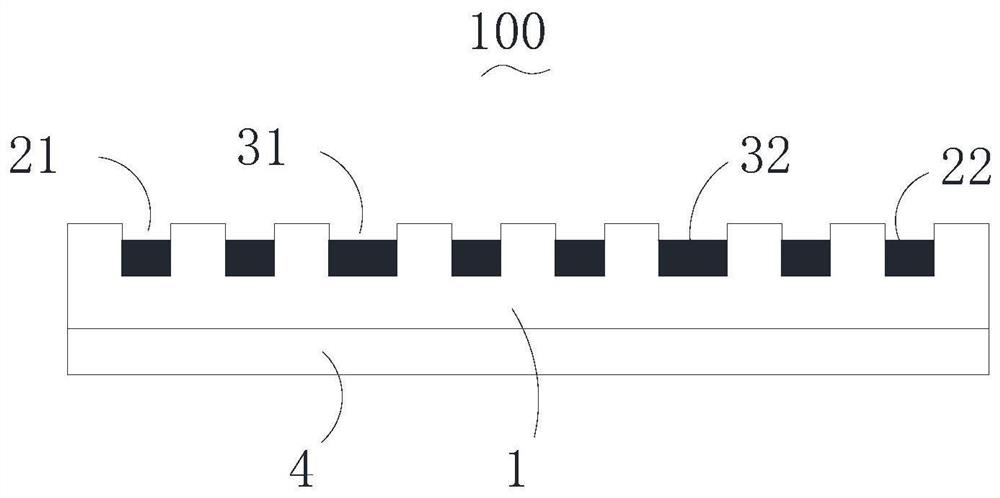

Transparent conductive film

ActiveCN110136864AImprove uniformityImprove light transmission uniformityConductive layers on insulating-supportsCable/conductor manufactureElectrically conductiveTransmittance

The invention discloses a transparent conductive film. The transparent conductive film comprises a transparent bearing layer and a plurality of conductive areas and a plurality of color matching areaswhich are alternately arranged on the transparent bearing layer, each conductive area comprises conductive grids which communicate with each other, each color matching area comprises color matching grids, and gaps are formed between the conductive grids and the color matching grids, and the conductive grids and the color matching grids are mutually insulated, wherein the widths of the grid linesof the color matching grids are larger than the widths of the grid lines of the conductive grids. Through arrangement of the widening of the grid lines of the color matching grids, the decreasing of the duty ratio of the color matching grids in the color matching area caused by gaps is compensated, the light transmittance of the conductive area and the color matching area is balanced, and the visual effect of the overall appearance of the transparent conductive film is guaranteed.

Owner:SHINE OPTOELECTRONICS KUNSHAN CO LTD

Stator of slewing electric machine

InactiveCN100490276CAvoid exposureImprove rigidityWindings insulation shape/form/constructionWindings conductor shape/form/constructionEpoxyElectrical conductor

To obtain a stator of a rotary electric machine wherein electromagnetic noise can be reduced and further electrical insulating properties can be secured.A stator winding is manufactured by inserting a U-shaped conductor segment into a slot from the first end face side of a stator core, and welding ends of the conductor segments to each other exposed to the second end face side of the stator core. Joints 6 between the ends of the conductor segments are disposed circumferentially and annularly in two rows on the second end face side of the stator core. Epoxy resin is applied so that the resin covers each joint 6 and the resin bridges two adjacent joints in the radial direction and forms a first insulating layer 8. Silicone resin is applied so that the resin covers the first insulating layer 8 and extends to the insulating coating 401 of the conductor segments 4, forming a second insulating layer 9.

Owner:MITSUBISHI ELECTRIC CORP

Flexible fine copper wire shielding drag chain power cable

InactiveCN105702332AResolution timeSolving Problems That Are Prone to FailurePower cables with screens/conductive layersFlexible cablesPolyesterPower cable

Provided is a flexible fine copper wire shielding drag chain power cable. The cable is formed by a conductor layer, a first separating layer, an insulating layer, a second separating layer, a shielding layer, a third separating layer, and an outer sheath layer in sequence from the inside to the outside, the conductor layer is a conductor layer formed by the twisting of type-6 ultra-soft structure conductors in IEC60228, the first separating layer is a layer of polyester tape wrapping the outside of the conductor layer in an overlapping manner, the insulating layer is an ethylene propylene rubber insulating layer, the second separating layer refers to two layers of polyester tapes wrapping the outside of the insulating layer in an overlapping manner, the shielding layer is a copper wire braided shielding layer, the third separating layer refers to two layers of polyester tapes wrapping the outside of the shielding layer in an overlapping manner, and the outer sheath layer is a neoprene outer sheath. According to the flexible fine copper wire shielding drag chain power cable, problems of short usage time and easy occurrence of faults of the conventional drag chain cables can be solved, and the mechanical property, flexibility, frequent bending resistance, and wear resistance are excellent.

Owner:湖北龙腾红旗电缆(集团)有限公司

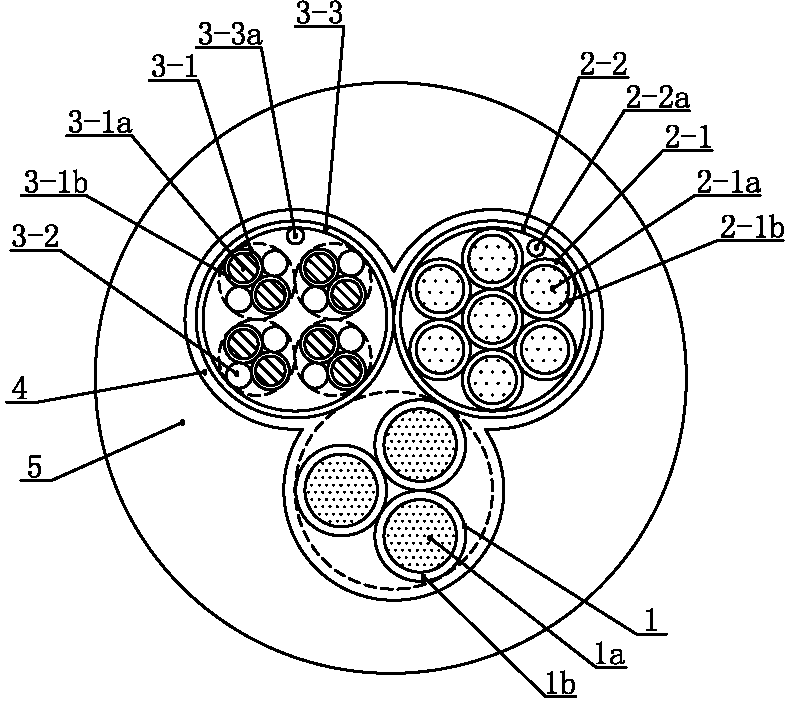

Salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and manufacturing method of integral shielding telecommunication cable

ActiveCN103227011AReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and a manufacturing method of the integral shielding telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; and the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer, an inner jacket, a copper foil polyester composite belt shielding layer and an outer jacket sequentially from the inside out. The integral shielding telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the inner jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

Salt corrosion resistant and twisting resistant control cable for ocean wind power and manufacturing method of control cable

ActiveCN103227000AReduce tensionEliminate voidsRubber insulatorsInsulated cablesCopper conductorInsulation layer

The invention relates to a salt corrosion resistant and twisting resistant control cable for ocean wind power and a manufacturing method of the control cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a control cable insulated core; a plurality of control cable insulated cores are mutually stranded to form a control cable core; the control cable core is wrapped in a low-strength non-woven fabric longitudinal wrap; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The control cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the control cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the control cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Aluminum shell PTC (positive temperature coefficient) brake resistor

PendingCN108447635ASolve positioning difficultiesProtection crackingResistor housing/enclosing/embeddingPositive temperature coefficient thermistorsState of artEngineering

The invention relates to an aluminum shell PTC (positive temperature coefficient) brake resistor which comprises a PTC core, an upper contact piece, a lower contact piece, a contact plate, a leading-out conductor, a positioning frame, an aluminum shell and an insulation sleeve. The upper surface and the lower surface of the PTC core are fitted with the upper contact piece and the lower contact piece and electrically connected with the outside through the leading-out conductor welded at one end of the contact plate, the vertically laminated PTC core and the contact pieces are positioned and fixed by the positioning frame, the insulation sleeve sleeves the outer side of the PTC core, and then the PTC core is embedded into the aluminum shell and fixed. Compared with the prior art, the brake resistor has the advantages of compact part structure, easiness in machining, good mechanical performance and the like.

Owner:上海克拉电子有限公司

High-temperature-resistant flexible fireproof cable intermediate joint

PendingCN110649559AWon't fall offWithout degrading its own performanceCable junctionsConnection insulationMulticore cableElectrical conductor

The invention discloses a high-temperature-resistant flexible fireproof cable intermediate joint. The intermediate joint comprises an intermediate joint body used for being connected with a multi-corecable insulation wire core. The intermediate joint body comprises a conductor connecting pipe. The conductor connecting pipe is sequentially wrapped by a silicone rubber self-adhesive tape, a ceramicfireproof mica tape and a silicone rubber insulating pipe from inside to outside. The gaps among the multi-core cable insulation wire cores are filled with ceramic oxygen isolation filling mud, and the periphery of the ceramic oxygen isolation filling mud is sequentially wrapped with a ceramic fire-resistant mica tape, a waterproof insulation composite tape, a sheath tube and a fireproof wrappingtape. The invention provides the high-temperature-resistant flexible fireproof cable intermediate joint. The fireproof performance of the intermediate joint is consistent with that of a connected fireproof cable. The intermediate joint is simple in structure, is smaller in size, is convenient to install, is high in insulating strength, is resistant to high temperature, is good in waterproof performance, is wide in application range, is bendable, is low in cost, and is good in fireproof performance.

Owner:江苏华侃核电器材科技有限公司

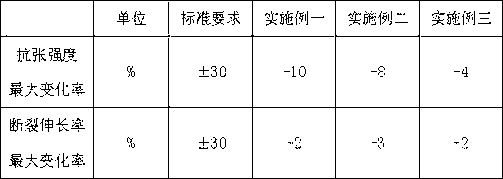

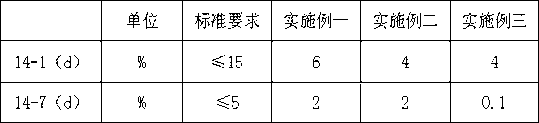

Super-hydrophobic fluorocarbon coating with high flame retardance and tracking resistance as well as preparation method and application of super-hydrophobic fluorocarbon coating

PendingCN112029345AResist high temperature damageHigh bond energyFireproof paintsAntifouling/underwater paintsCarbon coatingPolymer science

The invention relates to a super-hydrophobic fluorocarbon coating with high flame retardance and tracking resistance and a preparation method and an application thereof, and belongs to the field of fluorocarbon coating preparation and application, the super-hydrophobic fluorocarbon coating comprises a component A and a curing agent, the component A comprises the following raw materials by weight:100 parts of fluorocarbon resin; 100 parts of butyl acetate; 10 to 30 parts of a reinforcing filler; 50 to 100 parts of an inorganic flame retardant; 0.2-1 part of a dispersing agent; 0.1 to 0.5 partof an antifoaming agent; and 0.1-0.5 part of leveling agent. The problems of insufficient hydrophobicity, serious pollution accumulation, poor aging resistance and the like of the existing silicone rubber anti-pollution flashover coating are effectively solved, and compared with common silicone rubber coatings, the silicone rubber anti-pollution flashover coating has super hydrophobicity, can resist electric corrosion and high-temperature damage caused by the electric corrosion, and opens up the application of fluorocarbon coatings in the field of insulation in outdoor or harsh environments.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Salt corrosion resistant and twisting resistant composite cable for ocean wind power and manufacturing method of composite cable

ActiveCN103227007AReduce tensionEliminate voidsRubber insulatorsPower cables with screens/conductive layersElectricityCombustion

The invention relates to a salt corrosion resistant and twisting resistant composite cable for ocean wind power and a manufacturing method of the composite cable. Power cable insulation layers, control cable insulation layers and meter cable insulation layers are all salt corrosion resistant and twisting resistant rubber insulation layers and are mutually stranded to form a composite cable core; the composite cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The composite cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Miniature thermo-sensitive flexible probe

InactiveCN108036868AIncrease contact areaGuaranteed electrical insulation performanceThermometer detailsThermometers using electric/magnetic elementsElectrical resistance and conductanceResponse sensitivity

The invention belongs to the temperature-controlled sensing technological field and relates to a miniature thermo-sensitive flexible probe. The probe includes a metal probe, a thermistor, and a silicagel head; the silica gel head includes a hemispherical portion at the upper part of the silica gel head, a busing portion at the middle of the silica gel head, and an annular edge portion arranged atthe lower part of the silica gel head; the thermistor is arranged in the silica gel head in a manner that the thermistor passes through the silica gel head; the upper end of the thermistor abuts against the inner wall of the hemispherical portion; the wall thickness of the hemispherical portion is gradually increased from the periphery of the hemispherical portion to the center of the upper end of the hemispherical portion; a positioning mechanism of the thermistor and the silica gel head is arranged in the metal probe; and gaps in the inner cavities of the metal probe and the silica gel headare filled with a sealant. The miniature thermo-sensitive flexible probe is reasonable in structure. The elastic variable of the hemispherical portion can increase the contact area of the sensor, theheat of the thermistor is mainly transmitted by the silica gel head, and therefore, thermal response sensitivity can be improved, the difference of conduction rate stability is small, and the accuracy of temperature sensing can be improved; and the inner end of the thermistor is fixed and limited to a center position by a limiting ring, and pins, leads and solder joints are wrapped with an insulated bushing, and therefore, the electrical insulation of the sensor can be ensured.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY +1

Salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and manufacturing method of telecommunication cable

ActiveCN103227009AEliminate voidsEase of transmissionRubber insulatorsInsulating conductors/cablesEngineeringElectrical conductor

The invention relates to a salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and a manufacturing method of the telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; pair-twist wire pairs adopt different stranding pitches, a plurality of groups of pair-twist wire pairs are stranded to form a cable core; the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; and a jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way. The telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the jacket is stripped during construction.

Owner:嘉兴君宏光学有限公司

Salt corrosion-resistant and torsion-resistant composite cable and manufacturing method thereof

InactiveCN106653152AReduce tensionEliminate voidsRubber insulatorsPower cables including communication wiresInsulation layerCombustion

The invention relates to a salt corrosion-resistant and torsion-resistant composite cable and a manufacturing method thereof. A power cable insulation layer, a control cable insulation layer and an instrument cable insulation layer are salt corrosion-resistant and torsion-resistant rubber insulation layers. A power cable core, a control cable core and an instrument cable core are twisted into a composite core. The periphery of the composite core is coated with a low-intensity non-woven longitudinal cladding. A sheath is arranged at the periphery of the low-intensity non-woven longitudinal cladding by means of extrusion. The low-intensity non-woven longitudinal cladding which has a shape completely consistent with the appearance of an insulated wire core is adopted, and the gap between the low-intensity non-woven longitudinal cladding and the insulated wire core is eliminated, so that flame can be prevented from spreading to the inside under the condition of combustion, and the resistance to moisture impregnation can be enhanced. Moreover, the low-intensity non-woven longitudinal cladding can ensure that the sheath and the insulated wire core are not adhered together, and the insulated wire core is not damaged when the sheath is tripped in the process of construction.

Owner:重庆三峡电线电缆科技股份有限公司

Mems gas sensor chip, sensor and preparation method of sensor

ActiveCN108844652BShort delivery pathFast balanceTemperatue controlThermometers using electric/magnetic elementsMicrocontrollerMOSFET

The invention relates to an MEMS gas sensor chip and sensor and a preparation method of the sensor, belongs to the technical field of gas detection, and solves the problems of high technical cost, long response time and low environment stability in the prior art. The MEMS gas sensor chip comprises a gas sensitive unit, a temperature sensitive unit, a sensitive structure substrate and a temperaturecontrol unit. The MEMS gas sensor comprises the MEMS gas sensor chip and a control circuit, and the control circuit further comprises a microcontroller, an N type MOSFET, a P type MOSFET and a positive-negative power supply. The microcontroller compares a practical temperature collected by the temperature sensitive unit with a preset temperature, outputs a control signal according to a comparisonresult, controls ON / OFF of the N type MOSFET and the P type MOSFET, and further controls the direction and magnitude of a current through the temperature control unit and changes the surface temperature of the sensitive structure substrate. The MEMS gas sensor is simple in operation and high in versatility, can measure the concentration of different gases simultaneously, saves the cost, and is short in response time and high in environment stability.

Owner:BEIJING MECHANICAL EQUIP INST

A way to utilize nano-tio 2 Preparation of Insulating Oil Against Charge Accumulation from Modified Sunflower Oil

ActiveCN113528216BImproved resistance to charge buildupPromote accumulationAdditivesBiotechnologyAnhydrous ethanol

The invention discloses a kind of nanometer TiO 2 To prepare the anti-charge accumulation insulating oil from modified sunflower seed oil, the sunflower seed insulating oil is vacuum-dried, heated to 40-60°C, stirred for 30-60min, and modified by adding 1-4% of its mass to the sunflower seed insulating oil. Nano TiO 2 , ultrasonic oscillation is uniform, and modified sunflower oil is obtained; the modified nano-TiO 2 The preparation method is as follows: the nano-TiO 2 The particles are fully ground in a grinder, then anhydrous ethanol is added to mix, and a modifier composed of oleic acid, acrylic rosin polyoxyethylene sucrose ester and polyethylene glycol is added to the mixture for surface modification, and ethanol is washed. Drying to obtain modified nano-TiO 2 . The method of the present invention adopts nanometer titanium dioxide (TiO 2 ) Particle-modified sunflower seed insulating oil, which improves the anti-charge accumulation ability of sunflower seed insulating oil, makes the electric charge easy to dissipate and difficult to accumulate under the premise of ensuring its electrical insulation performance, and reduces the electric field distortion caused by the electric charge accumulation. , make the transformer run more safely.

Owner:GUANGXI UNIV

Salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and manufacturing method of communication cable

ActiveCN103227012AReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorInsulation layer

The invention relates to a salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and a manufacturing method of the communication cable. Each stranded copper conductor is wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form an insulated core; each two insulated cores are stranded to form a twisted pair of which the gaps are filled with fillers; each twisted pair is wrapped in a twisted pair copper foil shielding layer to form a twisted-pair group; the twisted-pair groups are mutually stranded to form a cable core; and the cable core is wrapped in a low-strength non-woven fabric longitudinal wrap, an inner sheath, a cable core copper foil shielding layer and an outer sheath in sequence from inside to outside. The communication cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheaths are not stuck to the insulated cores, and provides convenience for stripping the sheathes in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Passive electronic voltage sensor and manufacturing method thereof

PendingCN111856111AReduce widthIncreased end faceVoltage measurements onlyPolyphase network asymmetry measurementsEngineeringVoltage transducers

The invention discloses a passive electronic voltage sensor and a manufacturing method thereof. The sensor comprises a casting body and a thin-film capacitor arranged in the casting body; the thin-film capacitor comprises a first electrode layer, a second electrode layer opposite to the first electrode layer, and an insulating layer filled between the first electrode layer and the second electrodelayer; the first electrode layer comprises a first base film and at least two first metal layers arranged on the first base film, and a gap is reserved between every two adjacent first metal layers;the second electrode layer comprises a second base film and a second metal layer arranged on the second base film, wherein the second metal layer and the first metal layers can form capacitors respectively, and the capacitors can be connected in series. The passive electronic voltage sensor is small in size and convenient to install, and the partial discharge performance of the voltage sensor is improved through an epoxy pouring process.

Owner:SHANGHAI ZHIXIN INTELLIGENT ELECTRIC CO LTD +2

Salt-corrosion-resistant torsion-resistant double-shielded communication cable for marine wind power and manufacturing method thereof

ActiveCN103227012BEasy not to hurtEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and a manufacturing method of the communication cable. Each stranded copper conductor is wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form an insulated core; each two insulated cores are stranded to form a twisted pair of which the gaps are filled with fillers; each twisted pair is wrapped in a twisted pair copper foil shielding layer to form a twisted-pair group; the twisted-pair groups are mutually stranded to form a cable core; and the cable core is wrapped in a low-strength non-woven fabric longitudinal wrap, an inner sheath, a cable core copper foil shielding layer and an outer sheath in sequence from inside to outside. The communication cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheaths are not stuck to the insulated cores, and provides convenience for stripping the sheathes in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Salt-corrosion-resistant torsion-resistant overall shielded communication cable for marine wind power and manufacturing method thereof

ActiveCN103227011BReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and a manufacturing method of the integral shielding telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; and the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer, an inner jacket, a copper foil polyester composite belt shielding layer and an outer jacket sequentially from the inside out. The integral shielding telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the inner jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

Salt-corrosion-resistant torsion-resistant communication cable for offshore wind power and method for manufacturing the same

ActiveCN103227009BReduce tensionEliminate voidsRubber insulatorsInsulating conductors/cablesCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and a manufacturing method of the telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; pair-twist wire pairs adopt different stranding pitches, a plurality of groups of pair-twist wire pairs are stranded to form a cable core; the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; and a jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way. The telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

Production technology of low-density flexible paper used for molded insulators of extra/ultra high voltage transformers

InactiveCN107476118AGuaranteed electrical insulation performanceImprove electrical performancePlastic/resin/waxes insulatorsNon-woody plant/crop pulpForeign matterUltra high voltage

The invention discloses a production technology of low-density flexible paper used for molded insulators of extra / ultra high voltage transformers. The production technology comprises the following steps: 1) performing mixing and beating on cotton fibers and wood fibers to obtain a pulp; 2) diluting the concentration of the pulp to 0.2-0.6%, removing impurities and foreign matters from the pulp, and performing dehydration on the clean pulp, so as to improve the concentration of the pulp to 2-5%; 3) making the prepared wet paper blank fibers arranged in a vertical state by utilizing a vacuum negative pressure method; and 4) adding a pressure to wet paper blanks in a thickness direction, so as to enable the wet paper blank fibers to be pressed and twisted to form a dead lock state, and further to enable the prepared low density flexible wet paper to be used for the production of the molded insulators of the extra / ultra high voltage transformers. According to the production technology, a formula of raw materials is optimized, so that the final product has good flexibility and also has very high strength, the production technology is simplified, and the insulation property of the final product is improved. The vacuum negative pressure method is utilized to make the fibers arranged vertically in the same direction, so that the fibers can twist to be locked deadly after subjected to pressure, and the strength and flexibility of the final product are further improved.

Owner:常州市英中电气有限公司

transparent conductive film

ActiveCN110136864BImprove the uniformity of light transmittance distributionImprove light transmission uniformityConductive layers on insulating-supportsCable/conductor manufactureTransparent conducting filmMaterials science

The invention discloses a transparent conductive film, which includes a transparent carrying layer and several conductive regions and several color matching regions arranged alternately on the transparent carrying layer, the conductive regions include interconnected conductive grids, and the color matching regions include In the color matching grid, there is a gap between the conductive grid and the color matching grid to insulate each other, and the grid line width of the color matching grid is larger than the grid line width of the conductive grid. The grid line widening setting of the color matching grid compensates for the decrease in the duty ratio of the color matching grid in the color matching area caused by the gap, balances the light transmittance of the conductive area and the color matching area, and ensures the visual effect of the overall appearance of the transparent conductive film .

Owner:SHINE OPTOELECTRONICS KUNSHAN CO LTD

A support structure for insulating and encapsulating a temperature sensing head

ActiveCN108007598BGuaranteed spacingGuaranteed electrical insulation performanceThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermistor

The invention relates to the technical field of thermosensitive sensing devices, and specifically relates to a temperature sensing head insulation package support structure. The temperature sensing head insulation package support structure comprises a body with a certain length, wherein the body is provided with N partition plates, N is an even number which is greater than 3, the N partition plates are arranged at equal angles in a spacing mode along the periphery of the body, the outer end of each partition plate is provided with two support pieces, and the two support pieces symmetrically extend towards two sides of the partition plate and thus form a Y-shaped integrated structure with the corresponding partition plate. The temperature sensing head insulation package support structure isreasonable in structure, welding spots of a thermistor are arranged between the partition plates, and the snowflake-shaped distributed partition plates and the support pieces perform clamping and positioning on the welding spots, so that the distance between the welding spots and a sensing head is effectively guaranteed, and the symmetric support structure enables the thermistor and the welding spots to be arranged at the middle of the sensor, thereby ensuring the electrical insulation of the sensor, being convenient for subsequent injection of a sealant, and also being capable of reducing the consumption of the sealant and improving the curing efficiency.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com