Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Guaranteed anti-corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

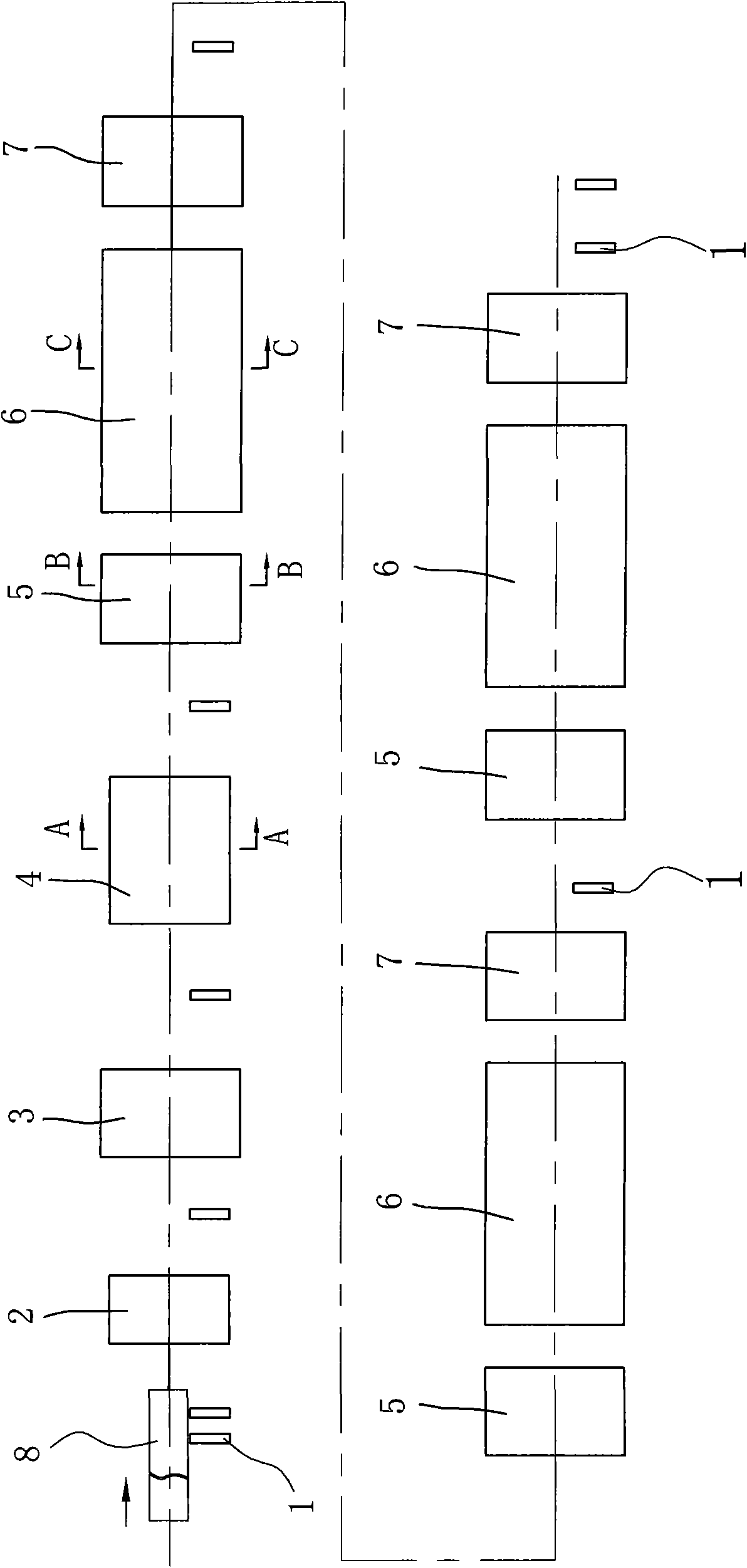

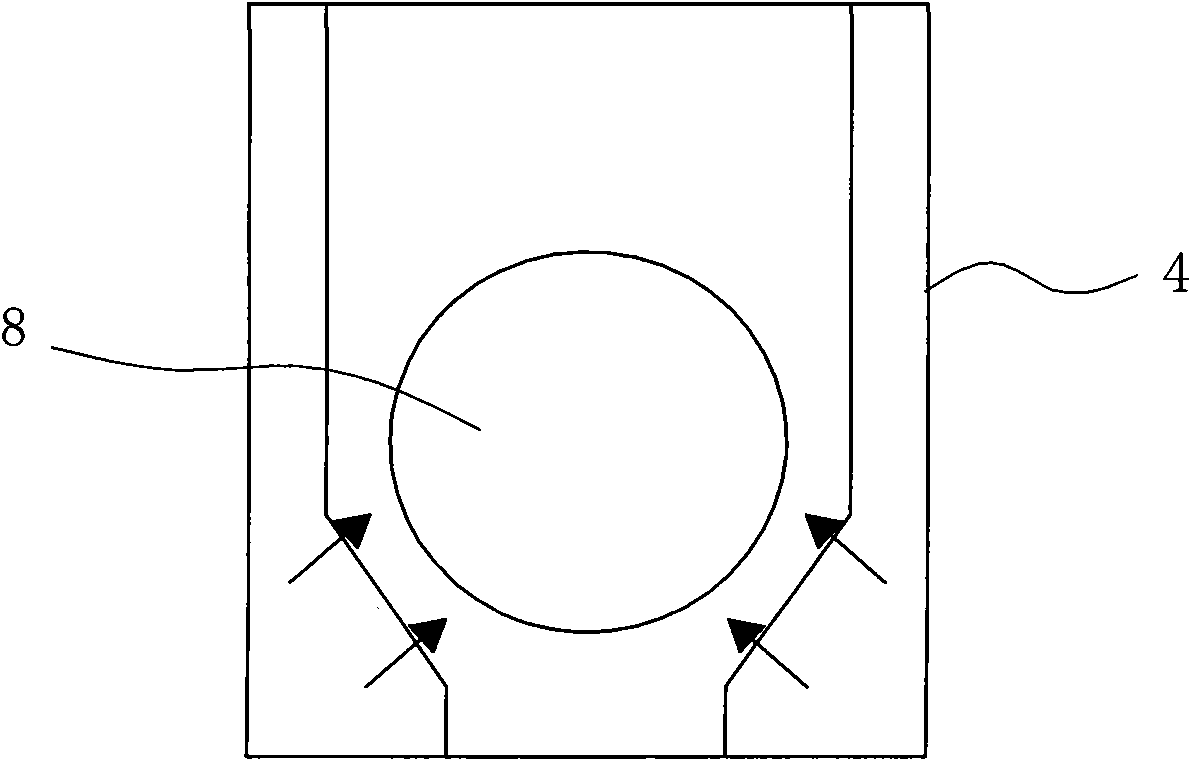

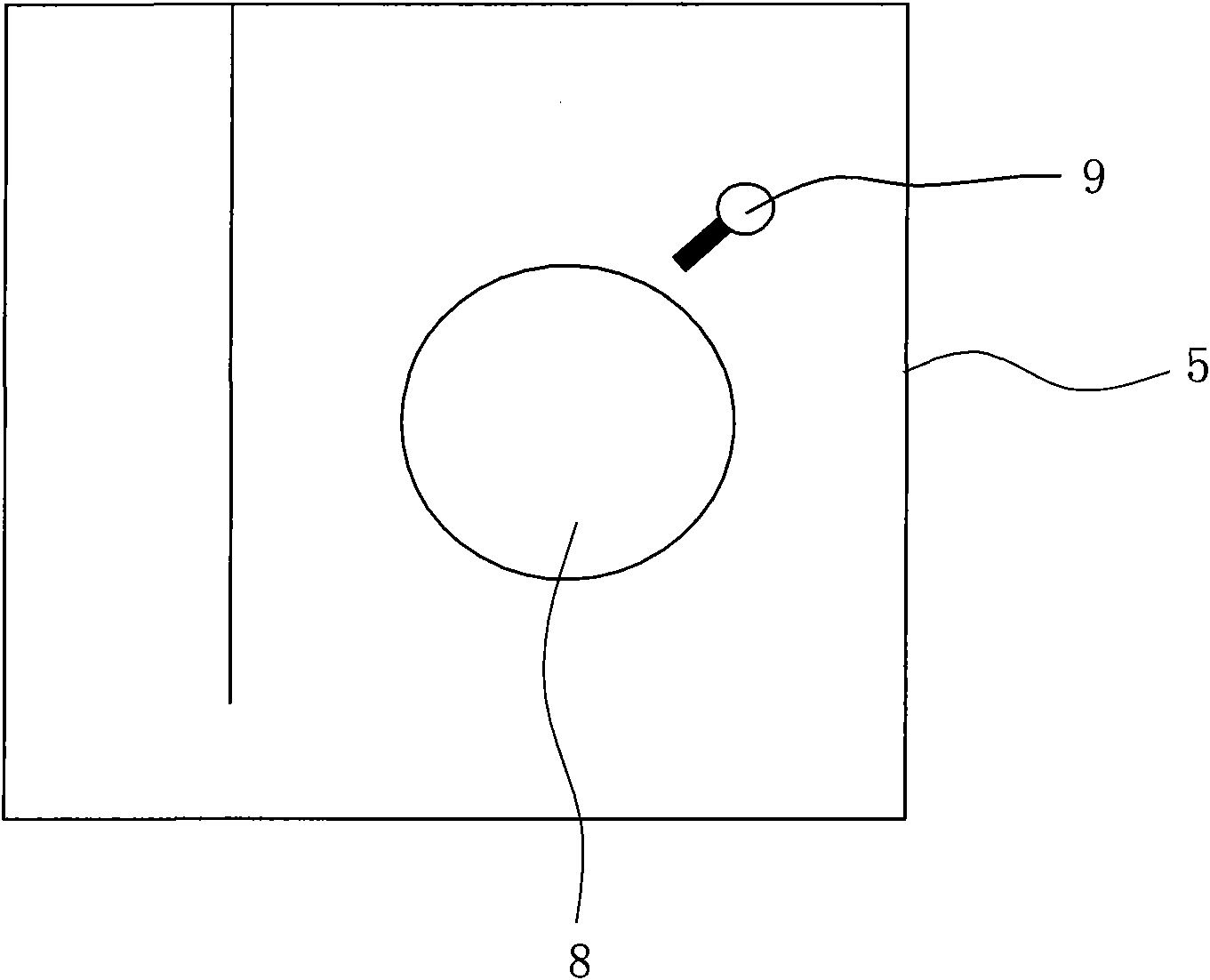

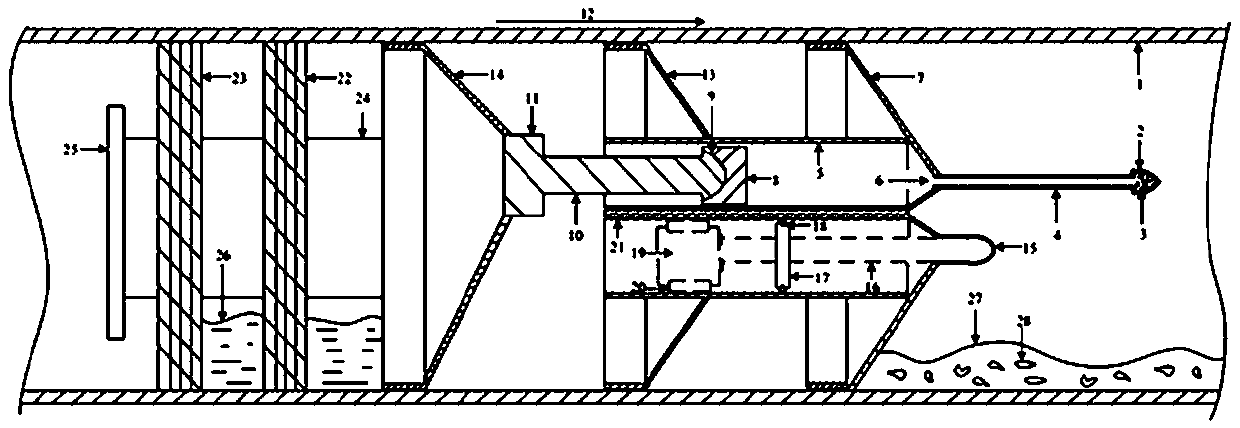

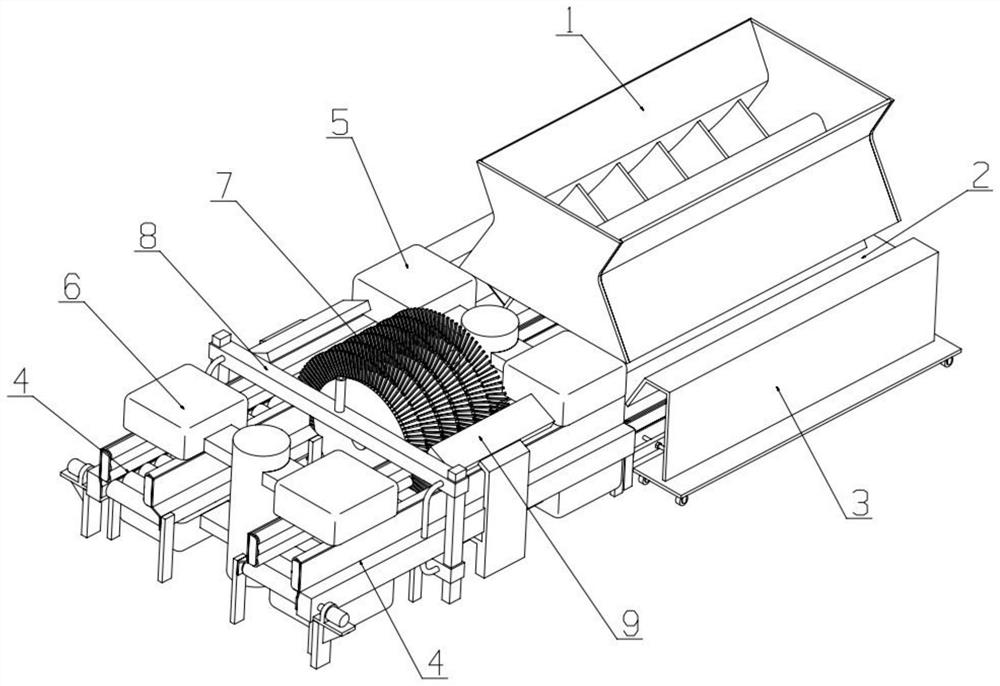

Automatic coating technology of large-scale steel pipe anticorrosion coating and production line thereof

ActiveCN101607247AHigh painting efficiencyShort curing timePretreated surfacesCorrosion preventionSteel tubeSurface finishing

The invention relates to an automatic coating technology of large-scale steel pipe anticorrosion coating and a production line thereof. The coating technology adopts the steps that steel pipes enter into a dehumidification cleaner, an automatic shot blasting machine, a preheating drying chamber, a spray chamber, a paint film solidifying chamber and a cooling chamber under the conveying of a steel pipe conveying mechanism, and after decontamination, dehumidification, surface treatment and preheating, the steel pipes enter into paint spraying, paint film solidifying and cooling processes; the production line comprises a steel pipe conveying mechanism, a dehumidification cleaner, an automatic shot blasting machine and a preheating drying chamber, wherein, the automatic shot blasting machine is arranged between the dehumidification cleaner and the preheating drying chamber; the automatic coating technology and the production line are characterized in that a paint spraying and solidifying unit is also arranged at the rear part of the preheating drying chamber; the paint spraying and solidifying unit comprises a spray chamber, a paint film solidifying chamber and a cooling chamber which are arranged in a line from the front part to the rear part in sequence, wherein, a coating machine for coating anticorrosion coat to the surfaces of the steel pipes is arranged in the spray chamber, and a hot air circulating system is arranged in the paint film solidifying chamber. The invention has the advantages that continuous and automated operation can be performed on a production line, the production efficiency is high, the coating quality is good, and environmental pollution is avoided.

Owner:宁波华恒防腐工程有限公司

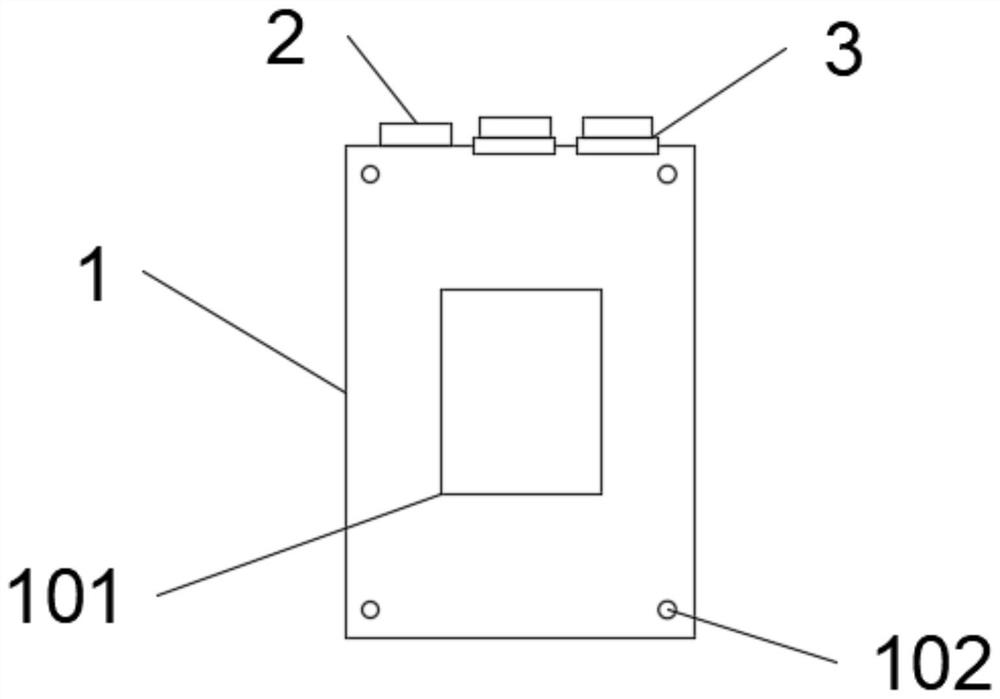

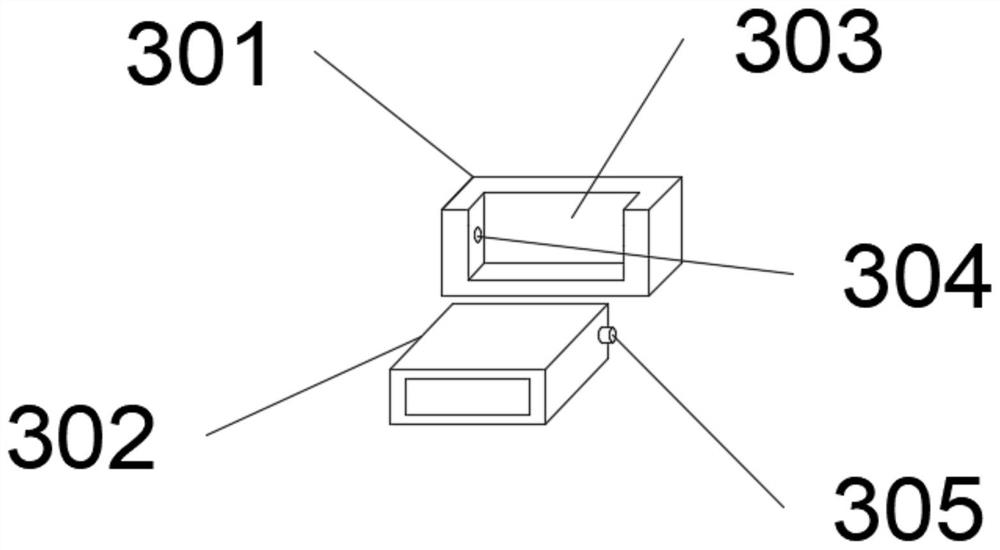

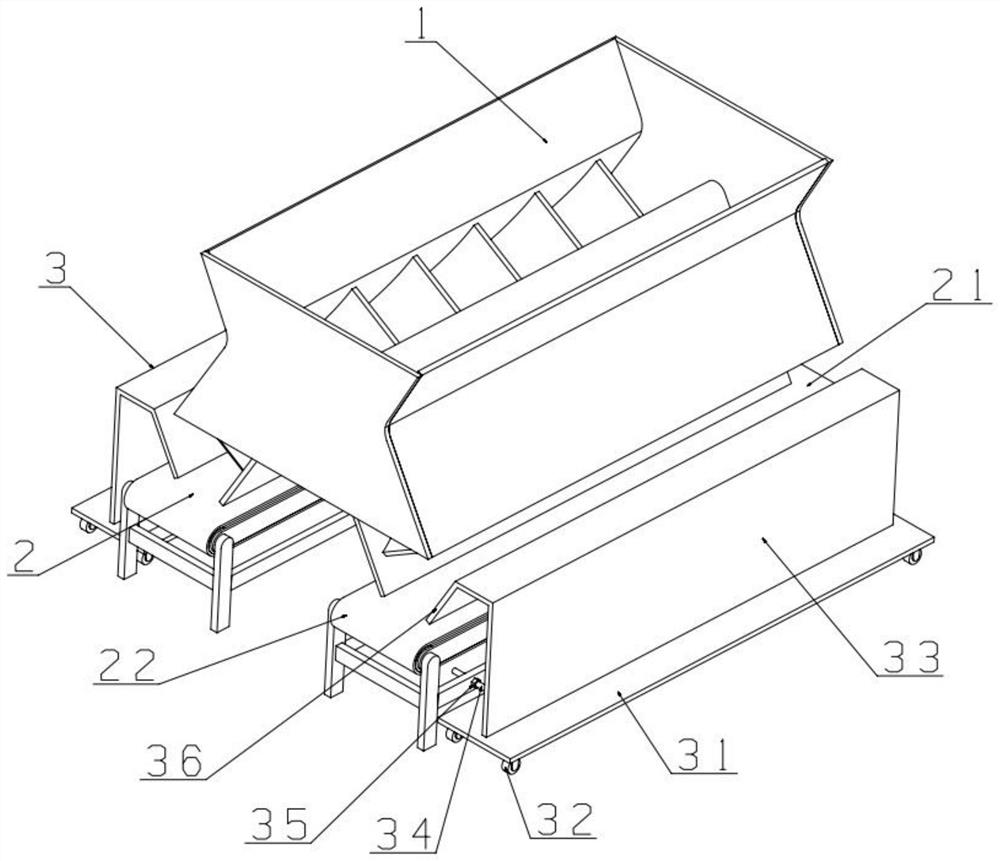

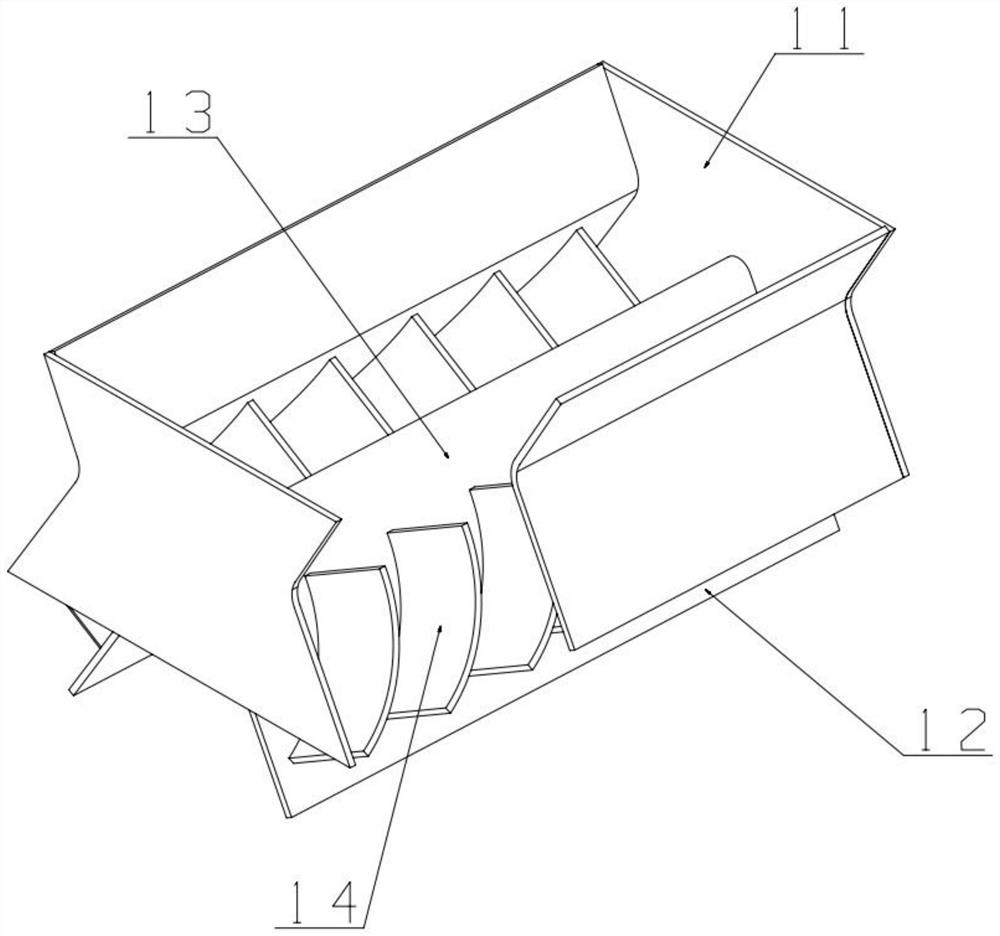

Intelligent spare part storing and taking device

PendingCN107777203AImprove storage efficiencyExtended service lifeStorage devicesControl engineeringElectric power

The invention relates to an intelligent spare part storing and taking device. The intelligent spare part storing and taking device comprises a controller, a vertically arranged support frame, a vertical rotation driver and a plurality of bin hoppers, wherein the vertical rotation driver is fixedly arranged on the support frame, is connected with the controller through a circuit and is capable of doing rotation motion around the support frame in a vertical direction under the control of the controller; spare parts are stored in the plurality of bin hoppers; all the bin hoppers are arranged on the vertical rotation driver and are capable of doing rotation motion in the vertical direction along with the vertical rotation driver; the controller is used for distributing and recording the type and the weight of the spare parts stored in each bin hopper. The intelligent spare part storing and taking device is capable of providing practical and effective storage manners for electricity repairing and testing staff when managing various types of small spare parts; the operation efficiency of storing and taking is improved; the storage environments of various types of spare parts can be improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

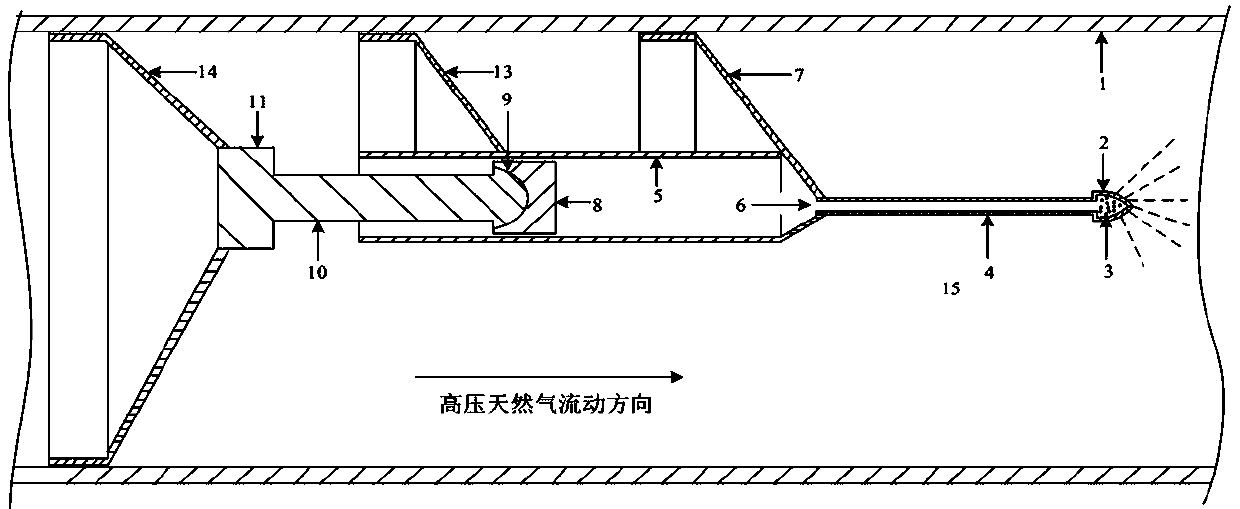

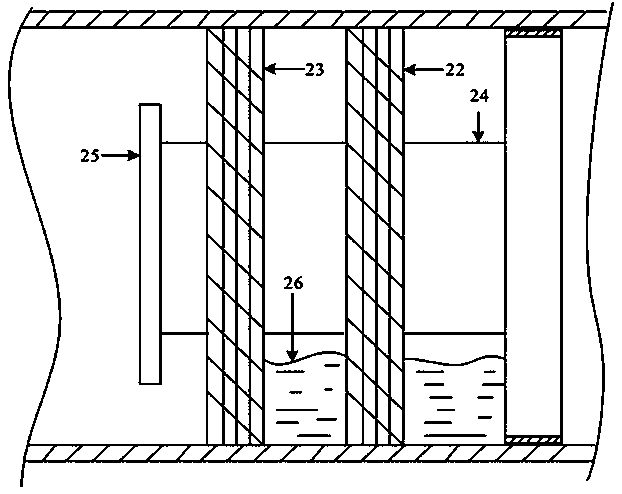

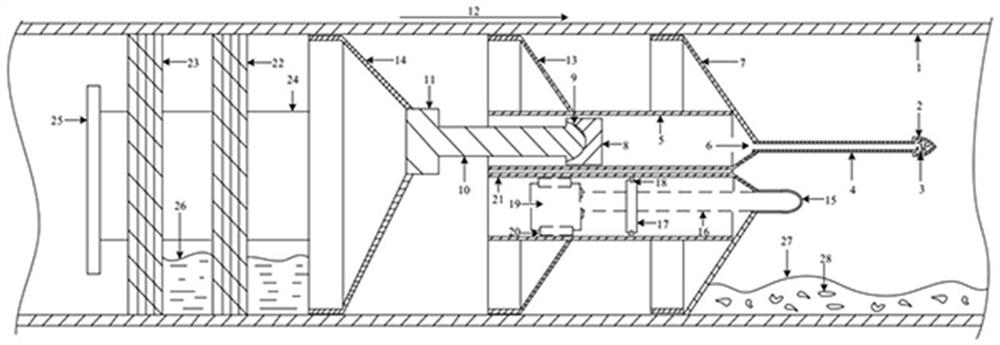

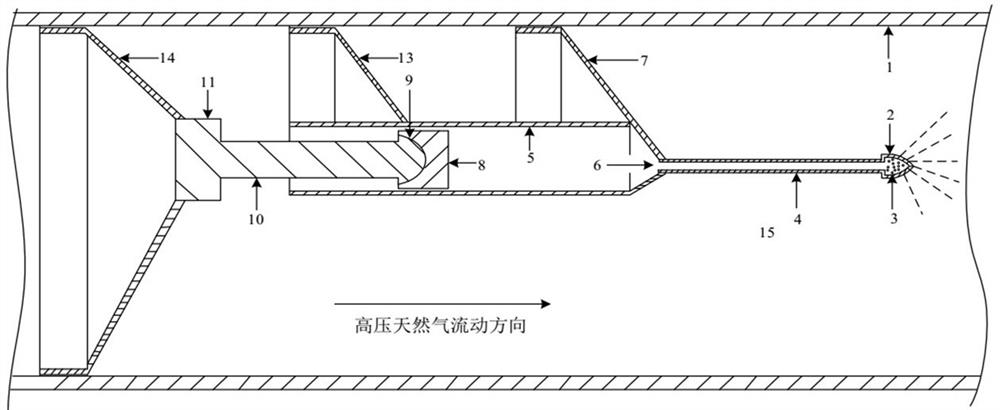

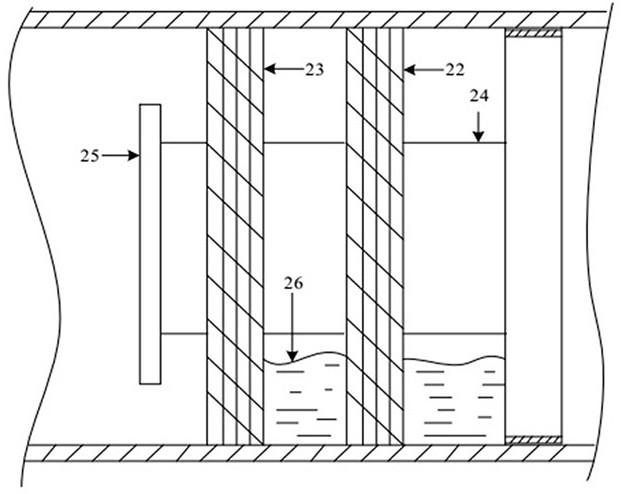

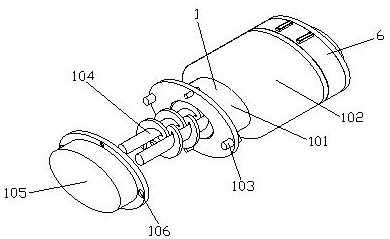

Corrosion inhibitor film coating pipe cleaning device for high-sulfur-containing moisture gathering and transportation pipeline

ActiveCN110252607ASolve the coating thicknessSolve the quality of coating filmLiquid surface applicatorsHollow article cleaningSpray coatingEngineering

The invention relates to a corrosion inhibitor film coating pipe cleaning device for a high-sulfur-containing moisture gathering and transportation pipeline. The pipe cleaning device mainly comprises a corrosion inhibitor storage and spray coating cavity, a chemical reagent storage and release cavity and circular corrosion inhibitor film coating brushes. The multiple functions of corrosion inhibitor atomization first-stage spray coating, circular brush rotating second-stage film coating, removal of solid impurities at the front end of the pipe cleaning device and the like are integrated, all-dimensional multi-angle corrosion inhibitor film coating of the inner wall of the pipe is achieved, and the film coating quality is improved. The corrosion inhibitor storage and spray coating cavity is designed, the high-pressure natural gas drives a piston to move, corrosion inhibitor in the cavity is extruded, is sprayed out of small holes in a mist mode and then adheres to the inner wall of the pipe, and therefore the first-stage corrosion inhibitor film coating is achieved. The circular corrosion inhibitor film coating brushes are designed, the high-pressure natural gas drives the circular brushes to rotate, and therefore the corrosion inhibitor which is deposited in the pipe can be uniformly dispersed on the inner wall of the pipeline, and the corrosion inhibitor second-stage film coating is achieved. The chemical reagent storage and release cavity is designed, the solid impurities at the front end of the pipe cleaning device are dissolved by a chemical reagent, and therefore the situation that the pipe cleaning ball collection operation is safe and stable is guaranteed.

Owner:SOUTHWEST PETROLEUM UNIV

Anti-corrosion treatment method of salix leucopithecia kimura

InactiveCN104441148AReduce crackingReduce intensityWood treatment detailsWood impregnation detailsUltravioletThermal treatment

The invention relates to an anti-corrosion treatment method of salix leucopithecia kimura. The method comprises the following steps: (1) thermal treatment; (2) ultraviolet treatment; and (3) treatment agent treatment. According to the salix leucopithecia kimura processed by adopting the method disclosed by the invention, the antiseptic property and the insect resistance of the salix leucopithecia kimura can be kept for over 10 years; and the service time of a salix leucopithecia kimura product is greatly prolonged.

Owner:阜南县宏泰工艺品有限公司

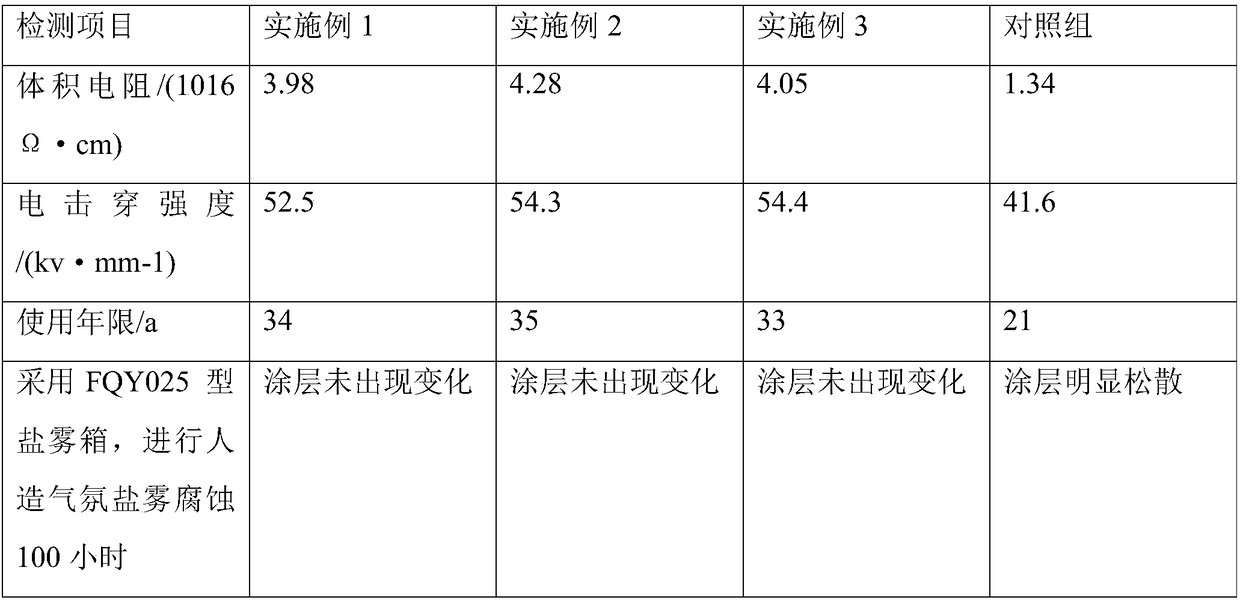

High-voltage insulation bus and coating process

InactiveCN109355008AGuaranteed anti-corrosionEnsure insulationPlastic/resin/waxes insulatorsInsulated cablesAlkali freeInsulation layer

The invention discloses a high-voltage insulation bus and a coating process. The high-voltage insulation bus comprises a bus body, the bus body is coated with an anticorrosive layer and an insulationlayer, the anticorrosive layer is positioned on the bottom layer of the bus body, the insulation layer is positioned on the outer layer of the bus body, the anticorrosive layer is coated with organicsilicon coatings, and the insulation layer comprises, by weight, 60-75 parts of organic silicon resin, 40-45 parts of polyacrylate rubber, 5-7 parts of titanate coupling agents, 3-4 parts of zirconiumoxide, 20-24 parts of silicon dioxide, 3-7 parts of naphthenic oil, 4-6 parts of calcium stearate, 3-4 parts of alunite, 5-7 parts of vinyl trimethoxysilane, 2-6 parts of alkali-free glass fibers and9-17 parts of ethylene-propylene-diene monomer glue. A coating structure of the bus can effectively decrease electrical short circuit of the bus body, and the insulating property and the anticorrosive property of the bus are greatly improved, so that the service life of the bus is prolonged.

Owner:镇江朝阳机电科技有限公司

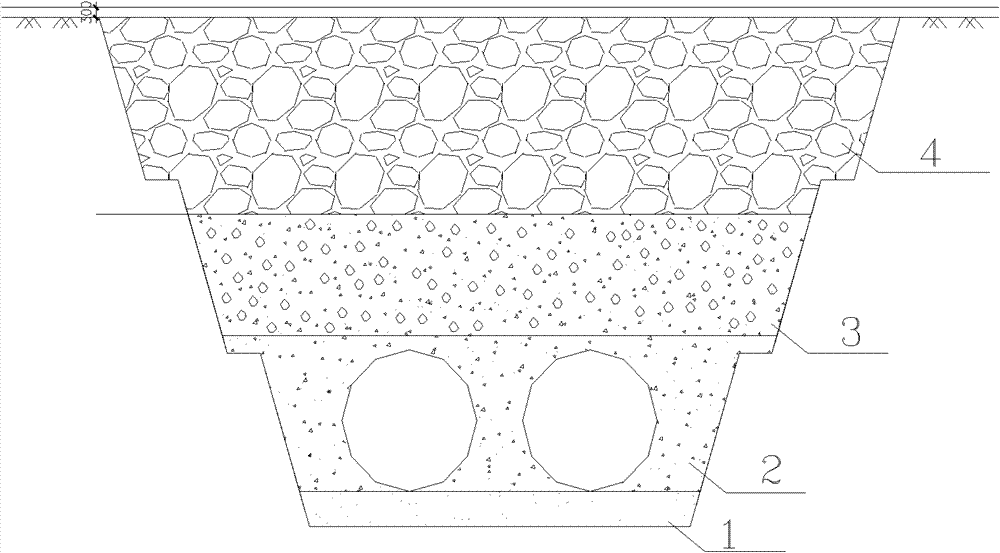

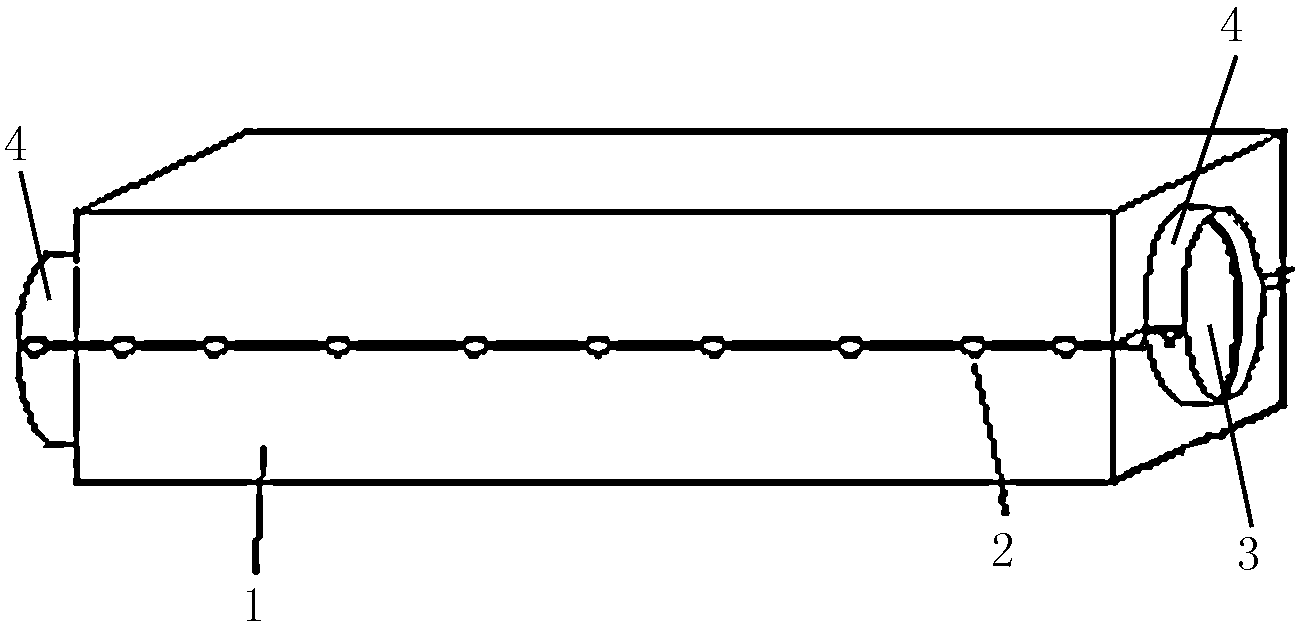

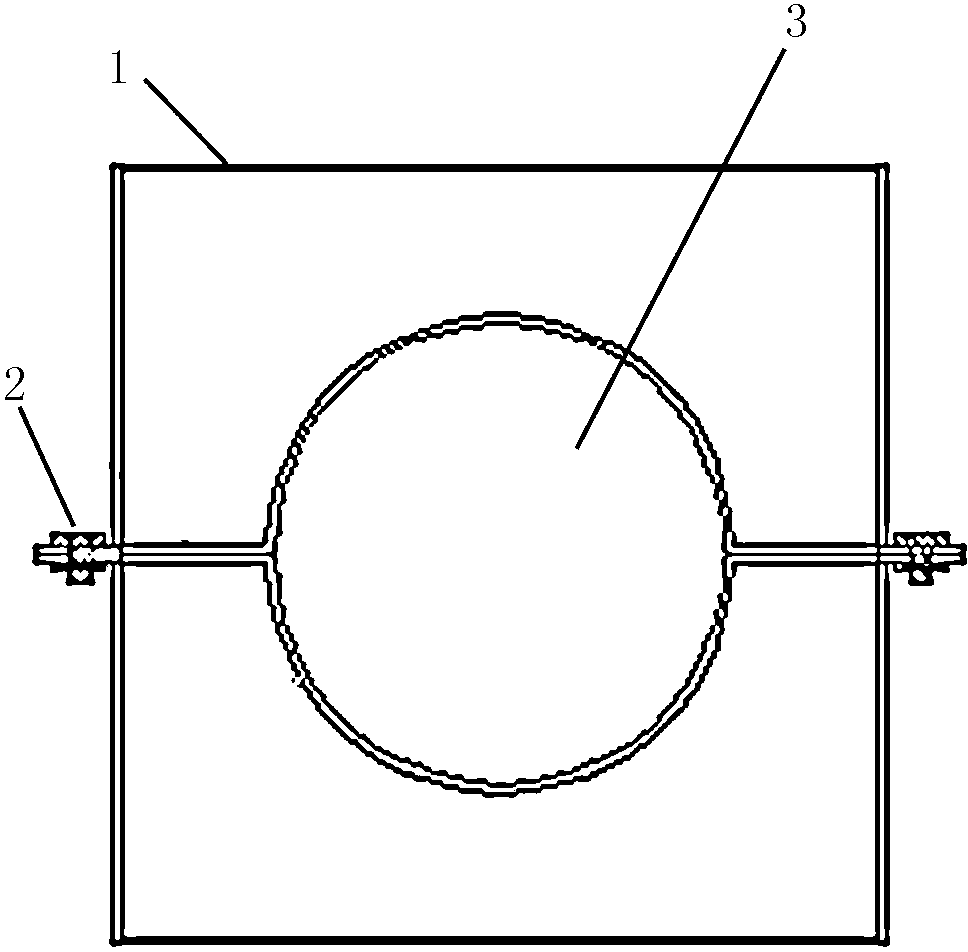

Steel frame reinforced type petroleum pipe

InactiveCN103292067AEnsure thermal insulationGuaranteed anti-corrosionThermal insulationCorrosion preventionGlass fiberSteel frame

The invention discloses a steel frame reinforced type petroleum pipe. A layer of glass fiber reinforced plastic protective shell is arranged on the outer surface of an outer pipe body, a steel ring is arranged in a cavity positioned between the outer pipe body and an inner pipe body, the distance between the outer surface of the steel ring and the inner wall surface of the outer pipe body is equal to that between the inner surface of the steel ring and the outer wall surface of the inner pipe body, and a plurality of trapezoidal steel frames are arranged in a cavity between the steel ring and the outer pipe body as well as a cavity between the steel ring and the inner pipe body uniformly. The steel frame reinforced type petroleum pipe has the advantages that an anticorrosive coating is arranged on the inner surface of the inner pipe body, a glass fiber reinforced plastic protective shell structure is arranged on the outer surface of the outer pipe body, and accordingly heat preservation and insulation performances and corrosion resistance of the inner pipe body and the outer pipe body are guaranteed; the double-layer steel frames are additionally arranged between the outer surface of the inner pipe body and the inner surface of the outer pipe body and combined with the steel ring, so that service lives of the inner and outer pipe bodies are prolonged beneficially, and maintenance cost is lowered greatly.

Owner:WUXI JINDING OIL PIPE FITTINGS

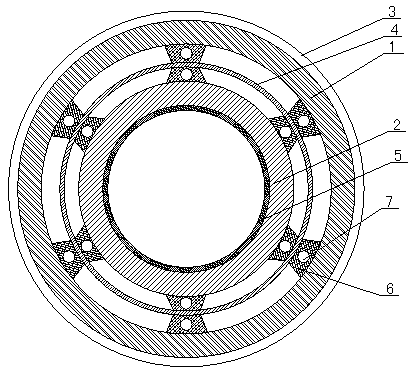

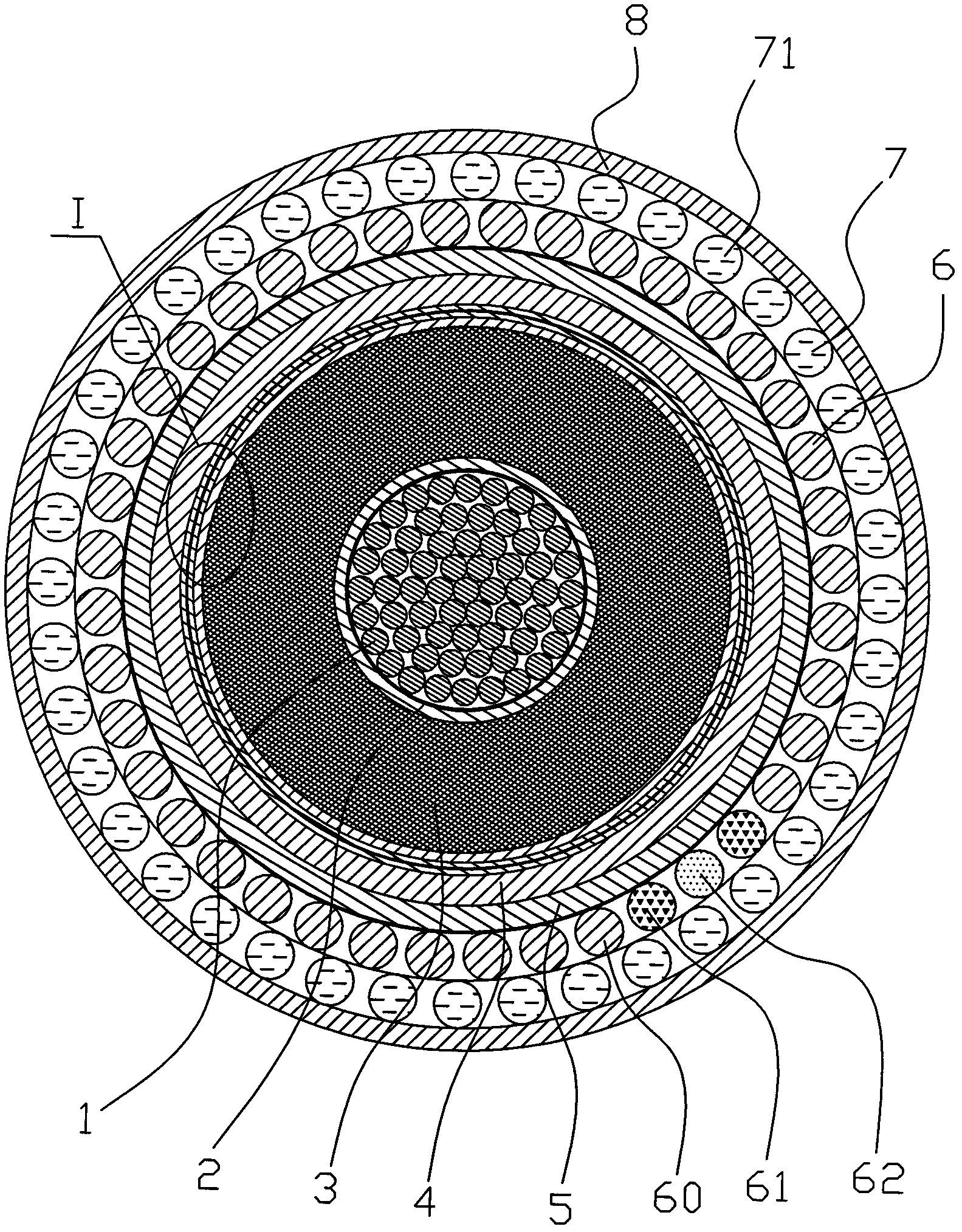

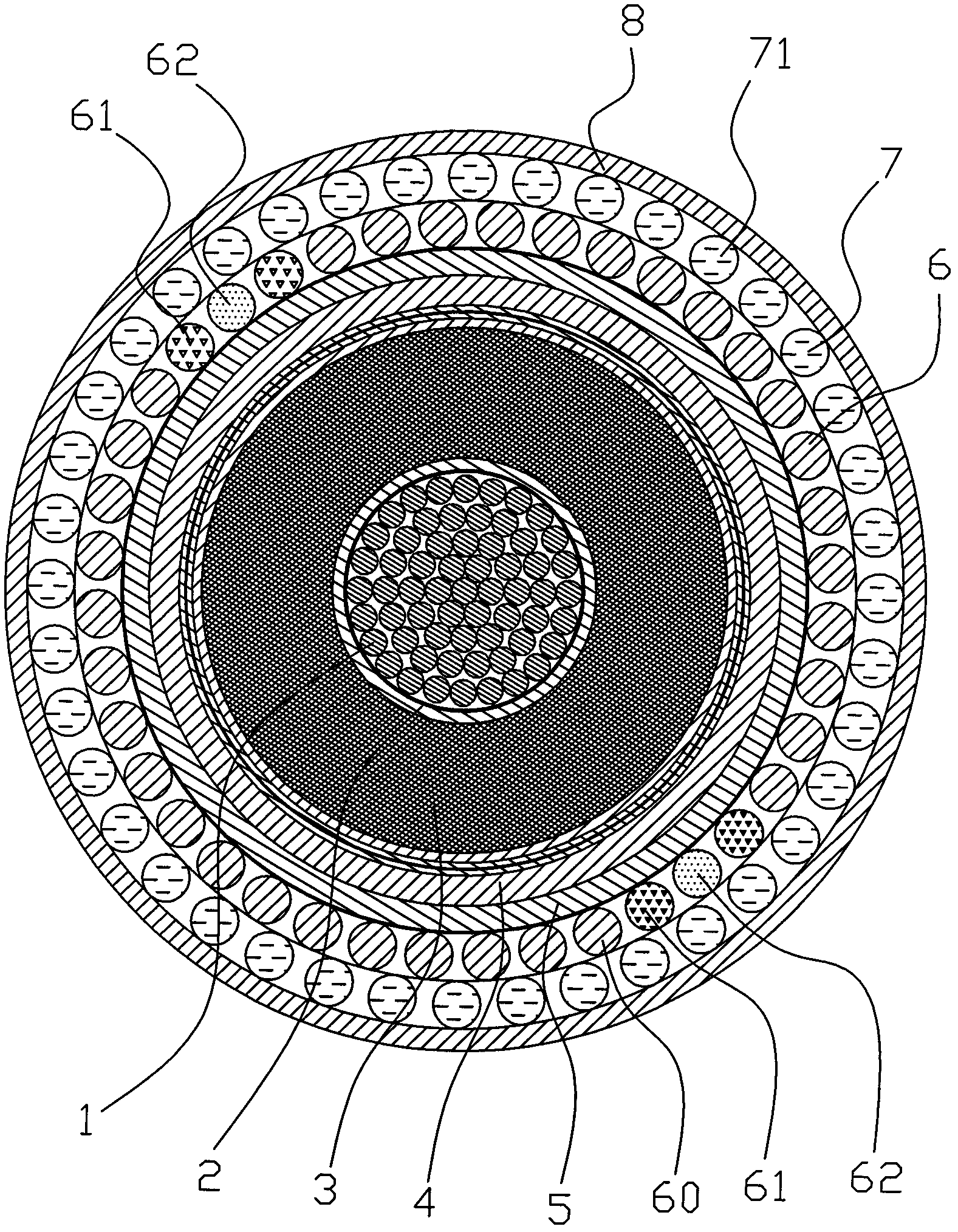

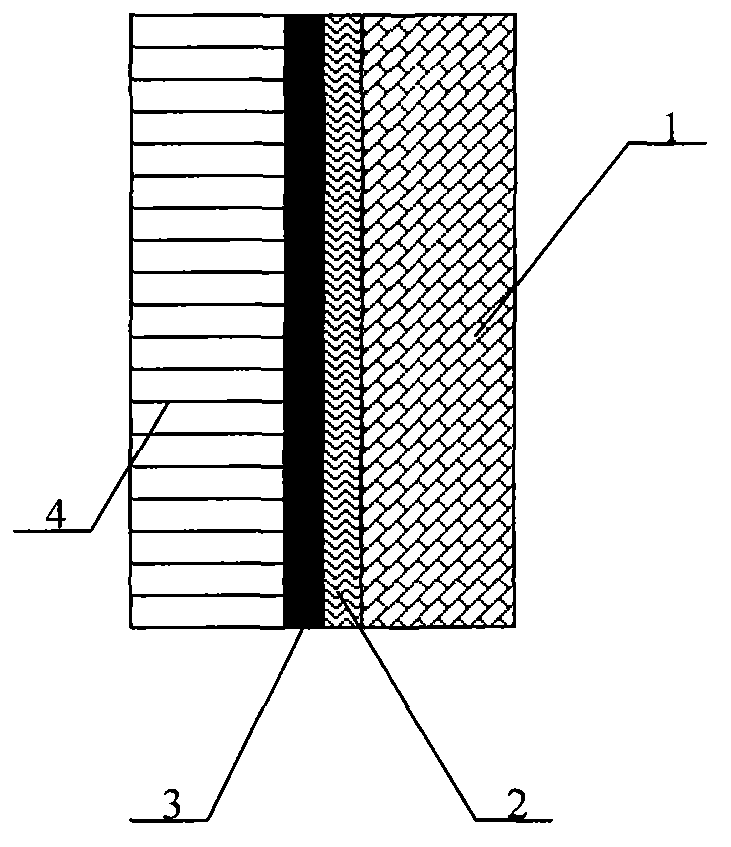

Anti-corrosion submarine cable with low armoring loss for communication monitoring

InactiveCN102222541AGuaranteed anti-corrosionGuaranteed tensile strengthSubmarine cablesInsulated conductorsEngineeringZinc

The invention relates to an anti-corrosion submarine cable with low armoring loss for communication monitoring, comprising a wire core (1), a shielding layer (2), an insulating layer (3), an insulator shielding layer, an inner protective layer (4), an armoring inner bedding layer (5), an armoring layer (7) and an armoring outer protective layer (8) which are sequentially arranged from inside to outside, wherein the armoring layer (7) consists of a plurality of non magnetic anti-corrosion metal wires (71), and an optical cable layer (6) is arranged between the armoring layer (7) and the armoring inner bedding layer (5). The anti-corrosion submarine cable has the advantages that serious eddy and magnetic hysteresis loss caused by a zinc-coated wire armoring structure can be eliminated, the allowed carry current of the cable is higher than that of the zinc-coated wire armoring cable by nearly 30 percent, the tensile strength of a submarine crosslinking power cable is ensured, and the armoring layer is formed by the non magnetic anti-corrosion metal wires, thereby having good anti-corrosion effect; besides, as a polyethylene protective layer is not needed to be coated outside the non magnetic anti-corrosion metal wires, good heat radiating effect is achieved, thereby meeting the communication and monitoring demands of the anti-corrosion submarine cable with low armoring loss for communication monitoring, reducing the armoring loss, being beneficial to heat radiation and ensuring anti-corrosion performance of armoring.

Owner:浙江省电力公司舟山电力局

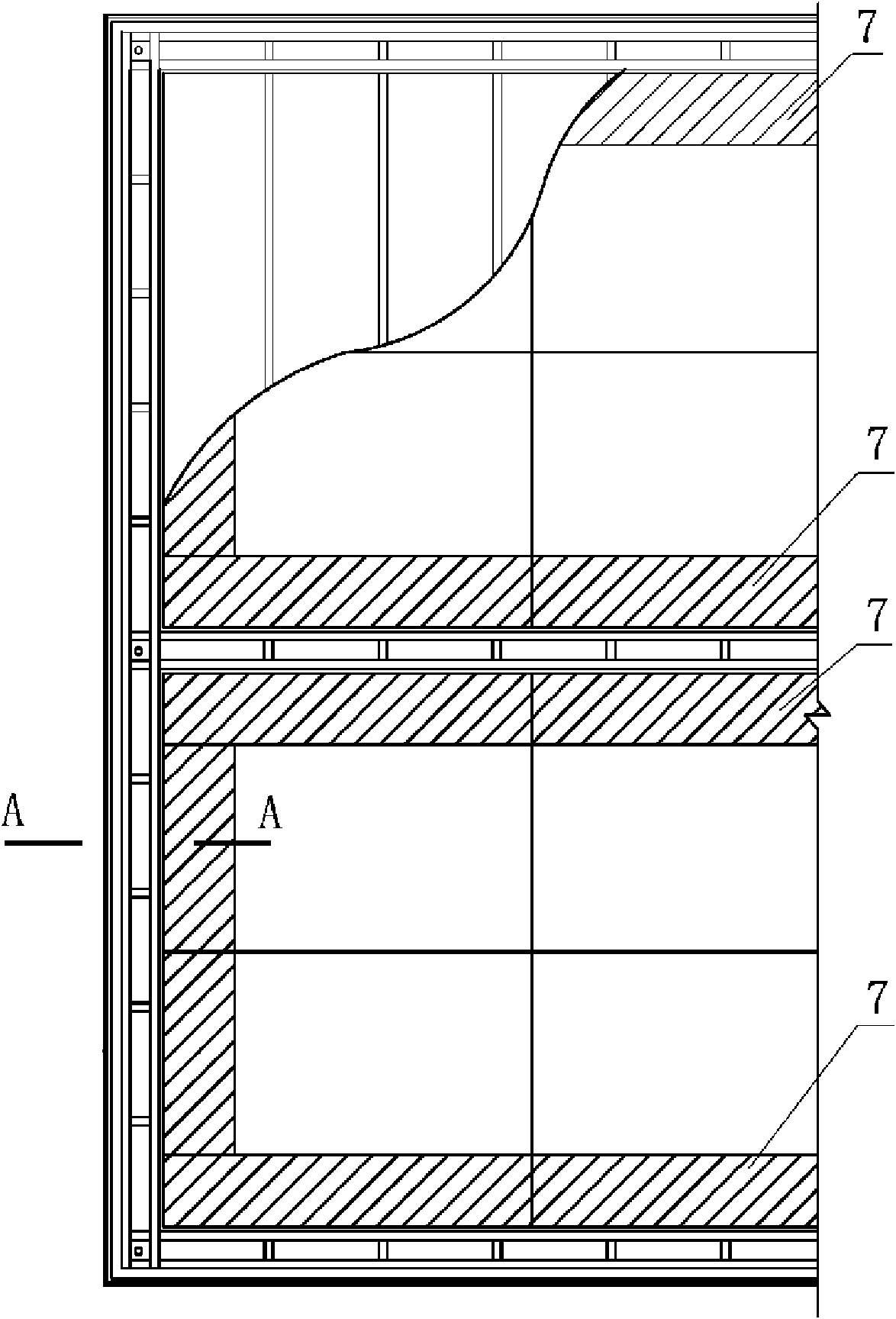

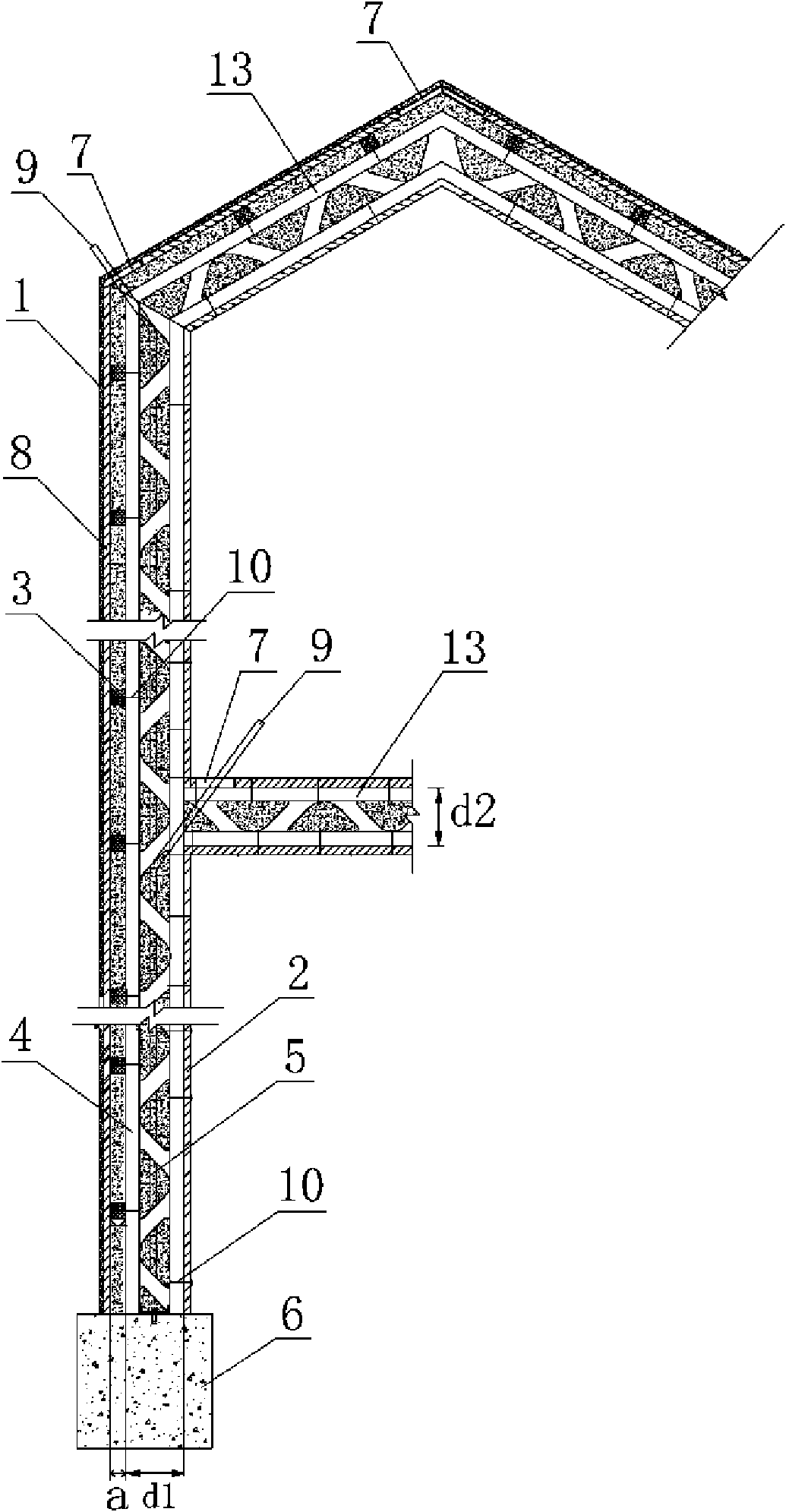

Cast-in-place light solid composite wall body of light steel truss structure and construction method thereof

InactiveCN101560798AOvercome heat retentionOvercome CorrosivityWallsBuilding material handlingFloor slabEngineering

The invention provides a cast-in-place light solid composite wall body of a light steel truss frame and a construction method thereof. The framework is a wall body light steel truss; the wall body light steel trusses are intermittently distributed in the composite wall body in the vertical direction; two chord rods are arranged at the internal side and the external side of the wall body respectively; the internal side of the light steel truss is covered by an internal side prefabricated plate; the external side of the light steel truss is fixedly connected with cushion blocks which are distributed in point shape; the external side of the cushion block is covered by an external side prefabricated plate; a heat-preservation filling material is filled between the internal side prefabricated plate and the external side prefabricated plate and in the clearance of the light steel trusses; the bottom of the light steel truss 4 is fixedly connected with the concrete foundation; and the top of the light steel truss is fixedly connected with the floor light steel truss. The wall body has the advantages of simple procedure, quick construction, high efficiency, low cost, and the like; simultaneously, the light steel composite structure also has the advantages of good sound insulation effect, good heat preservation performance, light load, and the like, and overcomes the hollow box characteristic of the traditional steel structure wall plate, and the filled foaming cement can lead the wall body to be solids.

Owner:周宏坤

Wood wax oil timber modifier and preparation method thereof

The invention discloses a wood wax oil timber modifier and a preparation method thereof. The modifier comprises the following components by mass percentage: 28-32% of tung oil, 8-12% of camphor wood oil, 17-22% of rosin-modified resin, 9-11% of orange oil, 4-6% of glass powder, and 22-27% of ethanol. The preparation method comprises the following steps: the tung oil, the camphor wood oil, rosin-modified resin, orange oil, and glass powder are placed in a reaction vessel, are subjected to a polymerization at the high temperature of 260-300 DEG C, then cooled to the temperature of 70-90 DEG C, ethyl alcohol is added for being stirred, and then the materials are cooled to the room temperature to obtain the product. The preparation method has simple process, the modifier does not contain toxic components such as triphenyl, formaldehyde and heavy metals, has no pungent smell, can keep original color when used on the timber, has the advantages of anticorrosion, insect resistance, non moisture absorption, non moistening, non deformation, and no influence on glues and paints.

Owner:董学明

Making method of environmentally-friendly thermoplastic composite material glove

InactiveCN105034248AGuaranteed heat resistanceGuaranteed gloves are heat resistantCoatingsEnvironmental resistanceCurrent technology

The invention relates to a making method of an environmentally-friendly glove, and concretely relates to a processing making method of an environmentally-friendly thermoplastic composite material glove. The external portion of a comfortable wearing glove processed through a current technology is provided with a thermoplastic composite material through using a plasticizing machine, so the obtained product has the characteristic of comfortable wearing of a common glove, has effectively guaranteed heat, water, irritation and corrosion resistance due to the adoption of the external environmentally-friendly thermoplastic composite material, and is suitable for the chemical engineering, the printing and dyeing industry, the automobile industry, the glass industry, the transportation industry and the electric power industry.

Owner:刘程秀

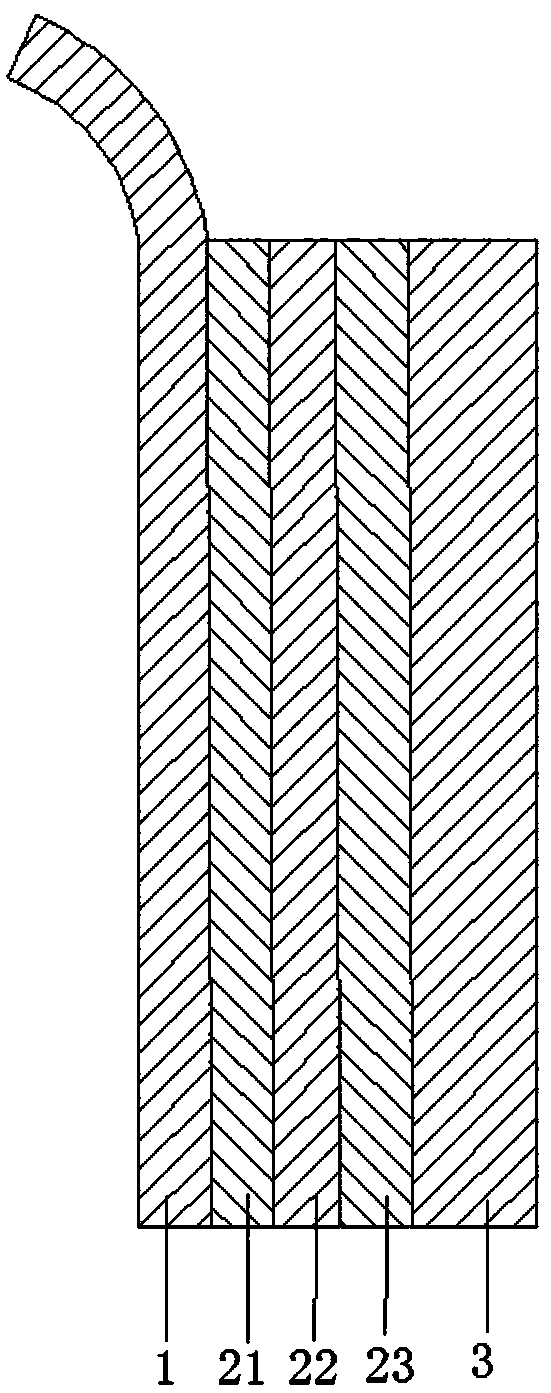

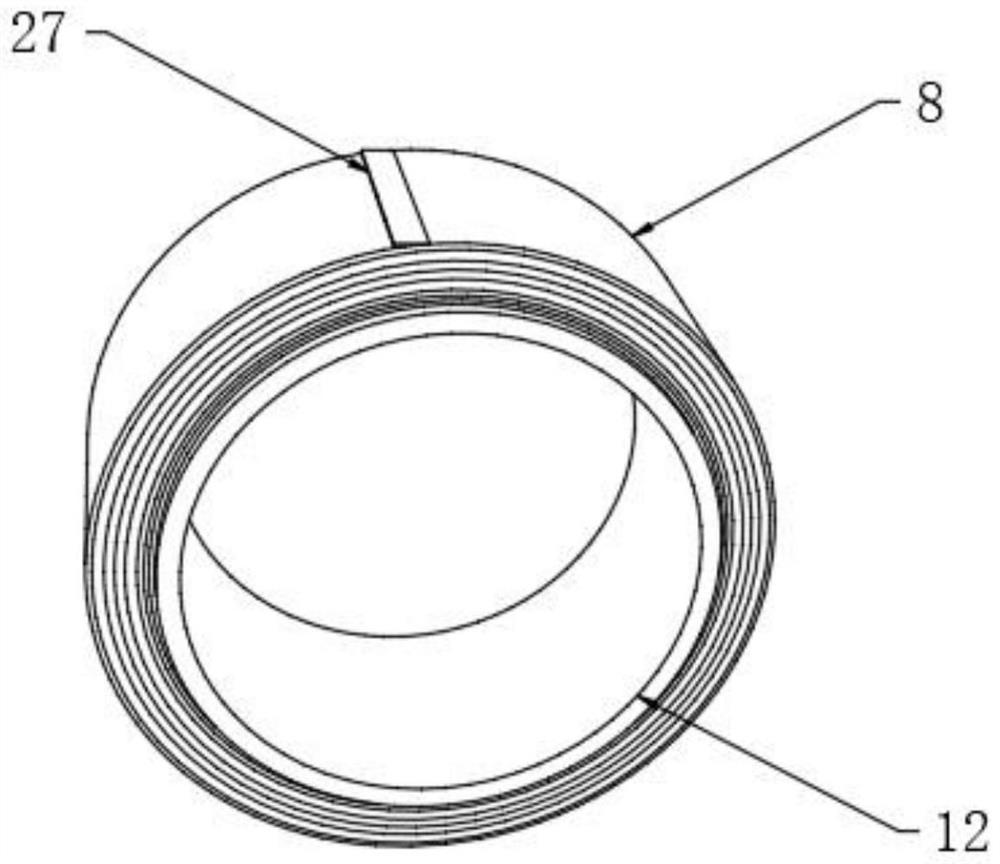

Strippable composite film for optical cable

InactiveCN108274848ASave stitching timeGuaranteed anti-corrosionSynthetic resin layered productsMetal layered productsEngineeringSteel belt

The invention discloses a strippable composite film for an optical cable. The strippable composite film for the optical cable comprises a chrome-plated steel belt arranged on the innermost layer, a co-extrusion film arranged on the intermediate layer as well as a PE sheath layer arranged on the outermost layer, wherein the co-extrusion film comprises a layer A arranged on the outer layer of the chrome-plated steel belt, a layer B arranged on the outer layer of the layer A, and a layer C arranged on the outer layer of the layer B; the layer adheres to the chrome-plated steel belt; the layer C adheres to the PE sheath layer. The co-extrusion film is divided into three layers, the three layers exist as a whole; the layer A adheres to the chrome-plated steel belt; the layer B is the intermediate layer; the layer C adheres to the outer PE sheath layer; a controllable stripping interlayer is arranged between the layer B and the layer C and has certain layering strength; the layering strengthis about 3 N / cm.

Owner:JIANGSU JIUTIAN PHOTOELECTRIC TECH CO LTD

Low-melting-point fiber-based thermoplastic type fiber-reinforced composite plate used for wood and preparation method

InactiveCN105172268AGood value for moneyIncrease productivitySynthetic resin layered productsLaminationFiber-reinforced compositeComposite plate

The invention discloses a low-melting-point fiber-based thermoplastic type fiber-reinforced composite plate used for wood and a preparation method. The preparation method comprises the following steps: successively winding bottom-layer mixed fabrics, intermediate-layer mixed fabrics and surface-layer mixed fabrics on a solid wood board, and carrying out hot-pressing and cooling shaping via a molding press so as to obtain the low-melting-point fiber-based thermoplastic type fiber-reinforced composite plate used for the wood, wherein the bottom-layer mixed fabrics are made of hemp fibers and low-melting-point fibers; the intermediate-layer mixed fabrics are made of high-strength and high-elasticity fibers and the low-melting-point fibers; and the surface-layer mixed fabrics are made of surface-modified inorganic fibers and the low-melting-point fibers. According to the invention, binding compound fastness between the composite plate and the wood is obtained; deformation energy generated by the wood due to changes with temperature and humidity is absorbed, so fatigue life of a wood composite material is improved; fire prevention, damp prevention, mildew prevention, corrosion prevention, pest prevention, and illumination aging prevention of a FRP plate substrate are guaranteed; stripping resistance and high processing efficiency are obtained; and a plurality of options of materials and structures are realized, so production cost is reduced.

Owner:TIANJIN POLYTECHNIC UNIV

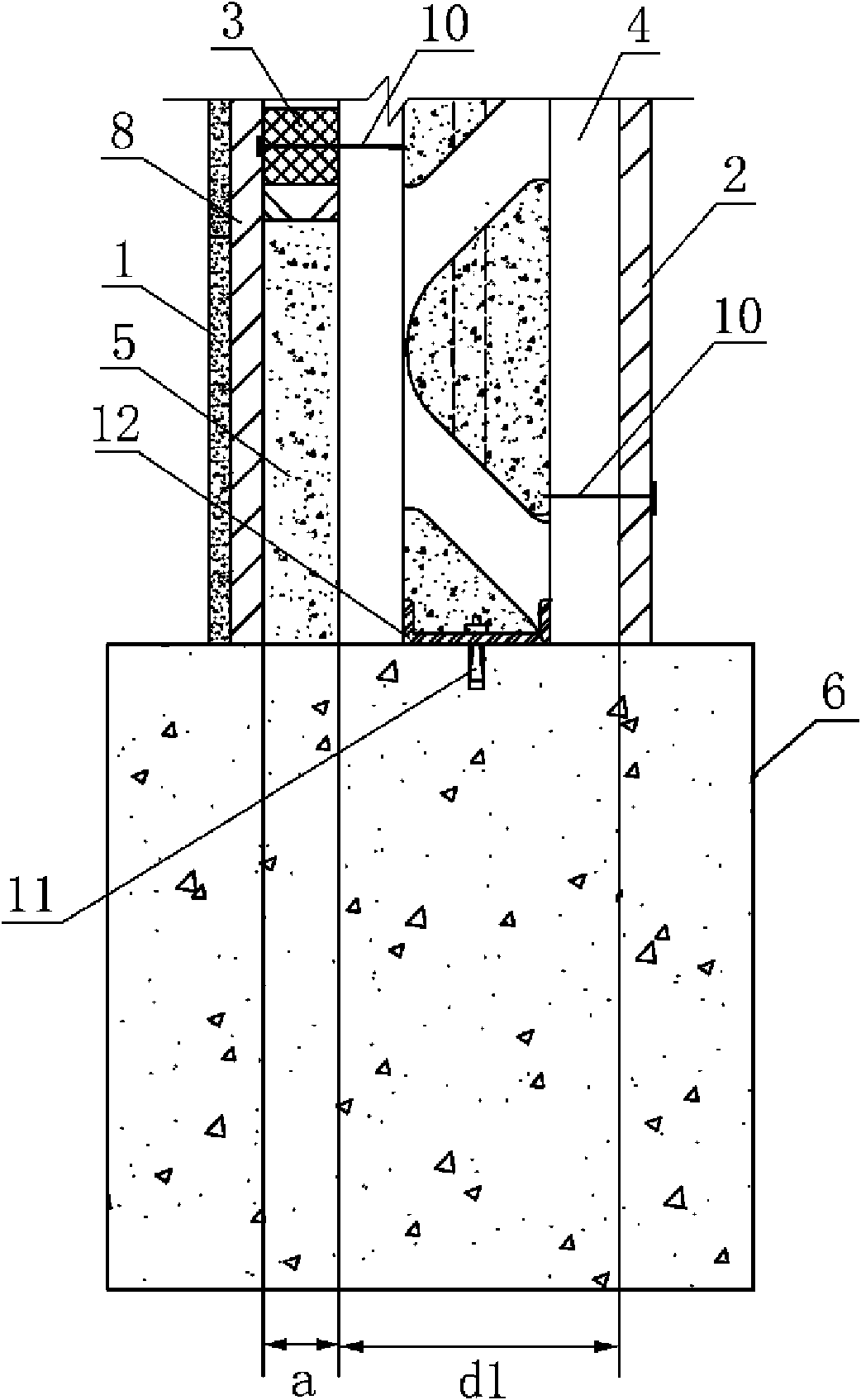

Backfilling process for large ultra-deep circulating water pipe

ActiveCN102182866BImprove anti-corrosion performanceGuaranteed anti-corrosionPipe laying and repairTotal thicknessWater pipe

Owner:ZHEJIANG THERMAL POWER CONSTR +1

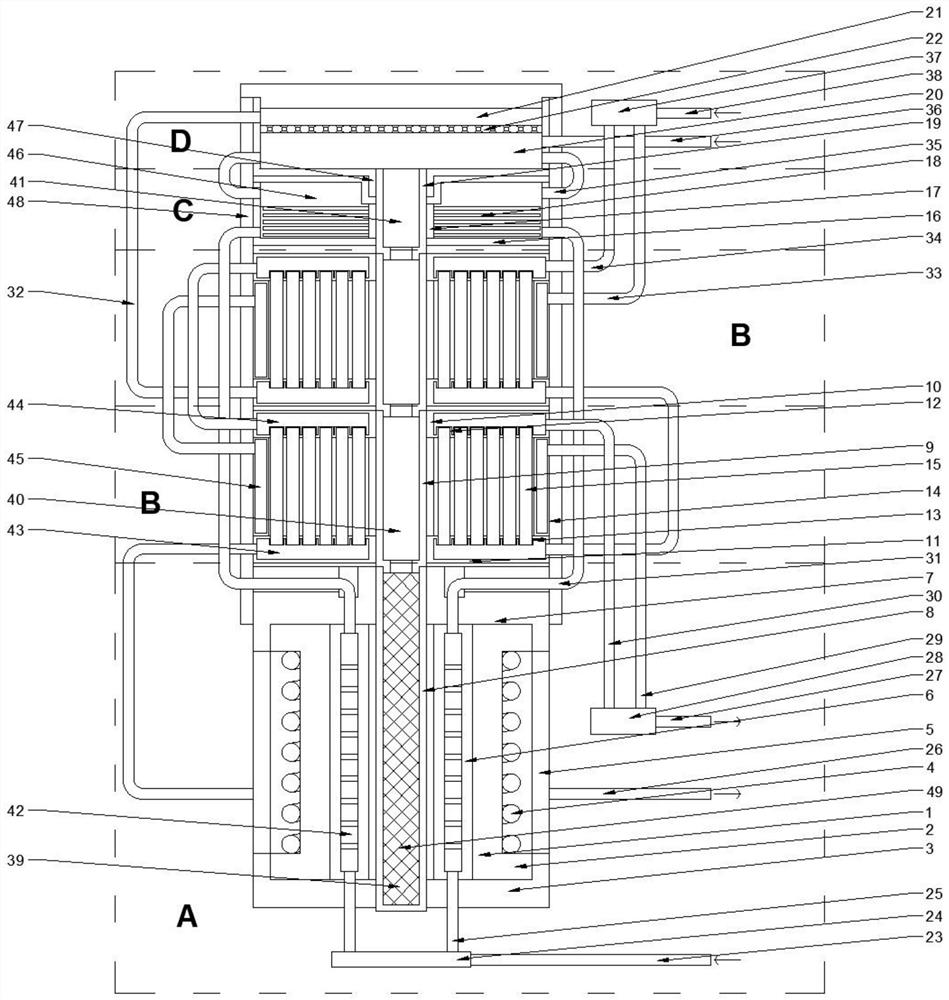

A 10kv superimposed heat storage boiler

ActiveCN110319583BAvoid overall overheatingImprove the heating effectStorage heatersWater storageEngineering

The invention relates to a 10 kV stacked heat storage boiler which comprises a vortex heating furnace, a heat accumulating type heat exchanger, a preheating water tank and a separation water tank frombottom to top. The vortex heating furnace, the heat accumulating type heat exchanger, the preheating water tank and the separation water tank realize heat conduction through heating pipes which are fixedly connected with each other; firstly, the vortex heating furnace heats the heating pipes, then heat storage on the heat accumulating type heat exchanger is carried out by the heating pipes, the preheating water tank is mainly used for storing water, and the separation water tank is mainly used for separating high-temperature water and high-temperature steam; high-temperature steam can performhigh-power heat storage on the heat accumulating type heat exchanger; the heat accumulating type heat exchanger can be used for supplying heat during heating; the heat conduction coil pipe structureof the traditional vortex electric boiler is improved into a vertical pipe structure, the heating of the heating pipes in the middle of the axis is realized by utilizing temperature difference and gravity driving, and the heating is more direct; the separation water tank at the top is used for preventing the heating pipes from being overheated and additionally generating high-temperature steam; and compared with the circulating heat pipe structure, the 10 kV stacked heat storage boiler has higher heating efficiency.

Owner:华电瑞源(北京)电气有限公司

A Steel Frame Reinforced Oil Pipe

InactiveCN103292067BGuaranteed anti-corrosionExtended service lifeThermal insulationCorrosion preventionGlass fiberSteel frame

The invention discloses a steel frame reinforced type petroleum pipe. A layer of glass fiber reinforced plastic protective shell is arranged on the outer surface of an outer pipe body, a steel ring is arranged in a cavity positioned between the outer pipe body and an inner pipe body, the distance between the outer surface of the steel ring and the inner wall surface of the outer pipe body is equal to that between the inner surface of the steel ring and the outer wall surface of the inner pipe body, and a plurality of trapezoidal steel frames are arranged in a cavity between the steel ring and the outer pipe body as well as a cavity between the steel ring and the inner pipe body uniformly. The steel frame reinforced type petroleum pipe has the advantages that an anticorrosive coating is arranged on the inner surface of the inner pipe body, a glass fiber reinforced plastic protective shell structure is arranged on the outer surface of the outer pipe body, and accordingly heat preservation and insulation performances and corrosion resistance of the inner pipe body and the outer pipe body are guaranteed; the double-layer steel frames are additionally arranged between the outer surface of the inner pipe body and the inner surface of the outer pipe body and combined with the steel ring, so that service lives of the inner and outer pipe bodies are prolonged beneficially, and maintenance cost is lowered greatly.

Owner:WUXI JINDING OIL PIPE FITTINGS

Intelligent electric energy meter with anti-corrosion performance

PendingCN113884725ASolve the problem of corrosionImprove hydrophobicityOptically investigating flaws/contaminationTime integral measurementDriving currentHemt circuits

The invention discloses an intelligent electric energy meter with anti-corrosion performance. The intelligent electric energy meter comprises a PCB, a driving circuit is arranged on the PCB, a first interface is fixedly connected to the side edge of the PCB, the first interface is connected with the driving circuit, the driving circuit inputs driving current and driving voltage to an installation circuit, the side edge of the first interface is fixedly connected with two second interfaces, the second interfaces are connected with the driving circuit, and the PCB is provided with nanometer waterproof paint. The proper nano waterproof paint is smeared on a component of the intelligent electric energy meter, so that a nano-scale coating film with a very good hydrophobic effect is formed on the surface of the PCB, a lotus leaf effect is formed; and a strong and powerful protective film can be formed on the surface of the electronic component through the ultrathin coating film, so that the component on the PCB of the electronic product are effectively prevented from meeting water, being affected with damp and being corroded by acid, alkali and salt.

Owner:BEIJING JINGYIBEIFANG INSTR

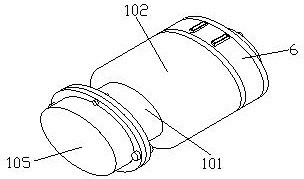

A corrosion inhibitor coating film pig for high sulfur-containing wet gas gathering and transportation pipeline

ActiveCN110252607BAchieve dischargeGuaranteed anti-corrosionLiquid surface applicatorsHollow article cleaningMetallurgySpray coating

The invention relates to a corrosion inhibitor film coating pipe cleaning device for a high-sulfur-containing moisture gathering and transportation pipeline. The pipe cleaning device mainly comprises a corrosion inhibitor storage and spray coating cavity, a chemical reagent storage and release cavity and circular corrosion inhibitor film coating brushes. The multiple functions of corrosion inhibitor atomization first-stage spray coating, circular brush rotating second-stage film coating, removal of solid impurities at the front end of the pipe cleaning device and the like are integrated, all-dimensional multi-angle corrosion inhibitor film coating of the inner wall of the pipe is achieved, and the film coating quality is improved. The corrosion inhibitor storage and spray coating cavity is designed, the high-pressure natural gas drives a piston to move, corrosion inhibitor in the cavity is extruded, is sprayed out of small holes in a mist mode and then adheres to the inner wall of the pipe, and therefore the first-stage corrosion inhibitor film coating is achieved. The circular corrosion inhibitor film coating brushes are designed, the high-pressure natural gas drives the circular brushes to rotate, and therefore the corrosion inhibitor which is deposited in the pipe can be uniformly dispersed on the inner wall of the pipeline, and the corrosion inhibitor second-stage film coating is achieved. The chemical reagent storage and release cavity is designed, the solid impurities at the front end of the pipe cleaning device are dissolved by a chemical reagent, and therefore the situation that the pipe cleaning ball collection operation is safe and stable is guaranteed.

Owner:SOUTHWEST PETROLEUM UNIV

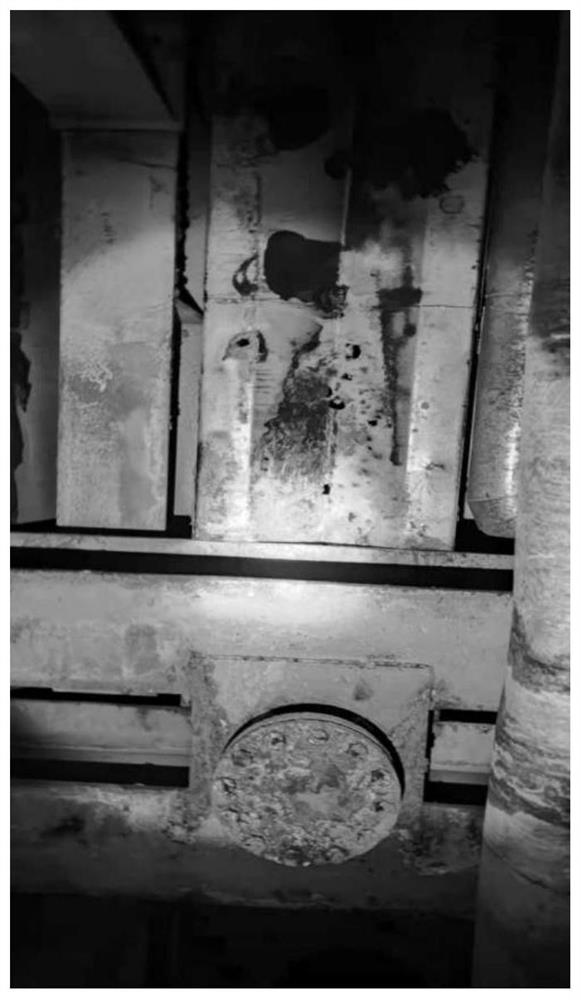

Repair method for solving water leakage of water seal tank of heating furnace

PendingCN113418395AGuaranteed StrengthGuaranteed anti-corrosionLiquid surface applicatorsFurnace componentsFiberCarbon fibers

The invention discloses a repair method for solving water leakage of a water seal tank of a heating furnace, and relates to the technical field of steel production. The repair method specifically comprises the following steps: S1, conducting surface treatment on the bottom surface of a heating furnace water tank; S2, conducting leakage point treatment conducted on the corrosion leakage points, and adopting a steel plate rapid attaching mode; S3, conducting primary prime coating on the bottom face of the heating furnace water tank, and adopting a brush coating or roll coating mode; S4, arranging a first reinforcing layer on the bottom face of the heating furnace water tank, and adopting a carbon fiber spreading mode; S5,conducting secondary prime coating on the bottom face of the heating furnace water tank, and adopting a brush coating or roll coating mode; S6, conducting primary floating coating on the surface of the pipeline, and adopting a blade coating mode; S7, arranging a second reinforcing layer on the surface of the pipeline, and adopting a macroporous fiberglass mesh winding and spreading mode; S8, conducting secondary floating coating on the surface of the pipeline, and adopting a blade coating mode; and S9, enabling the surface of the pipeline to be subjected to surface coating, and adopting a brush coating or roll coating mode. The phenomenon of water leakage of the water seal tank at the bottom of the heating furnace is avoided, and the hidden danger of gas leakage of a water seal tank due to low water level is effectively prevented.

Owner:NANJING IRON & STEEL CO LTD

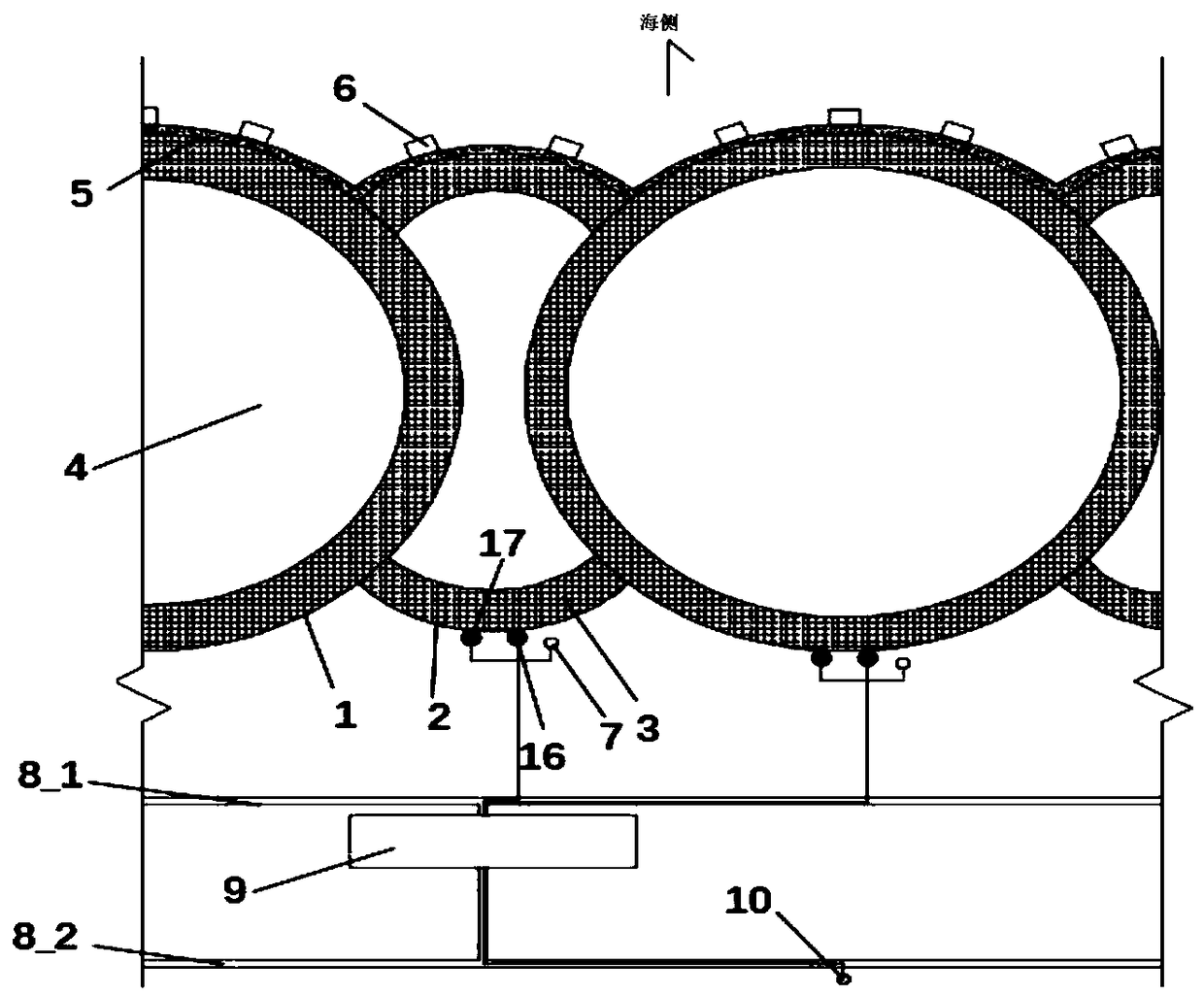

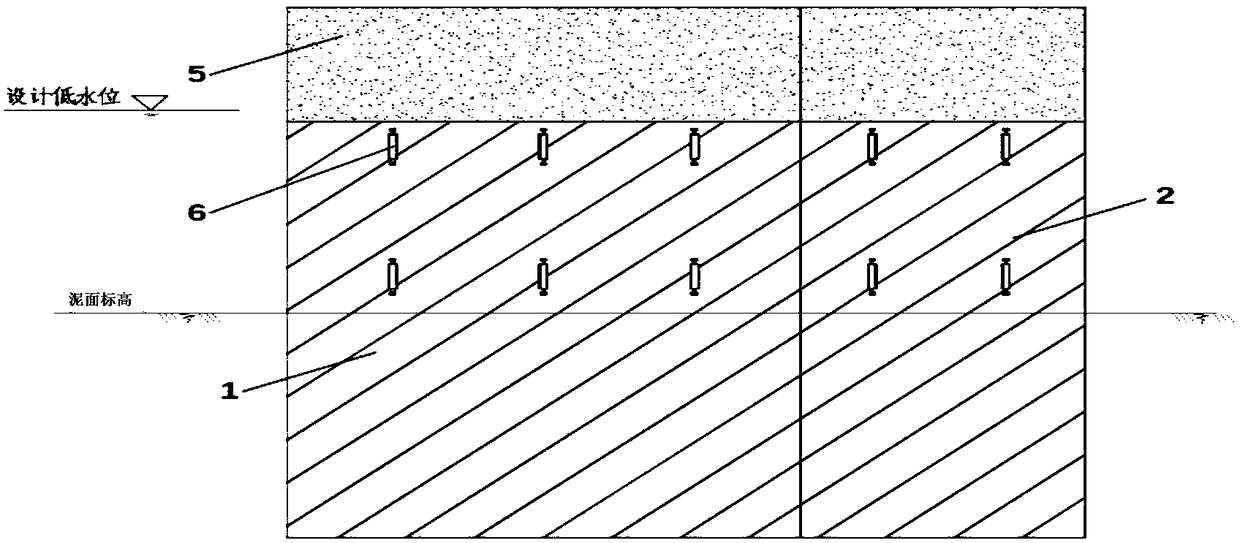

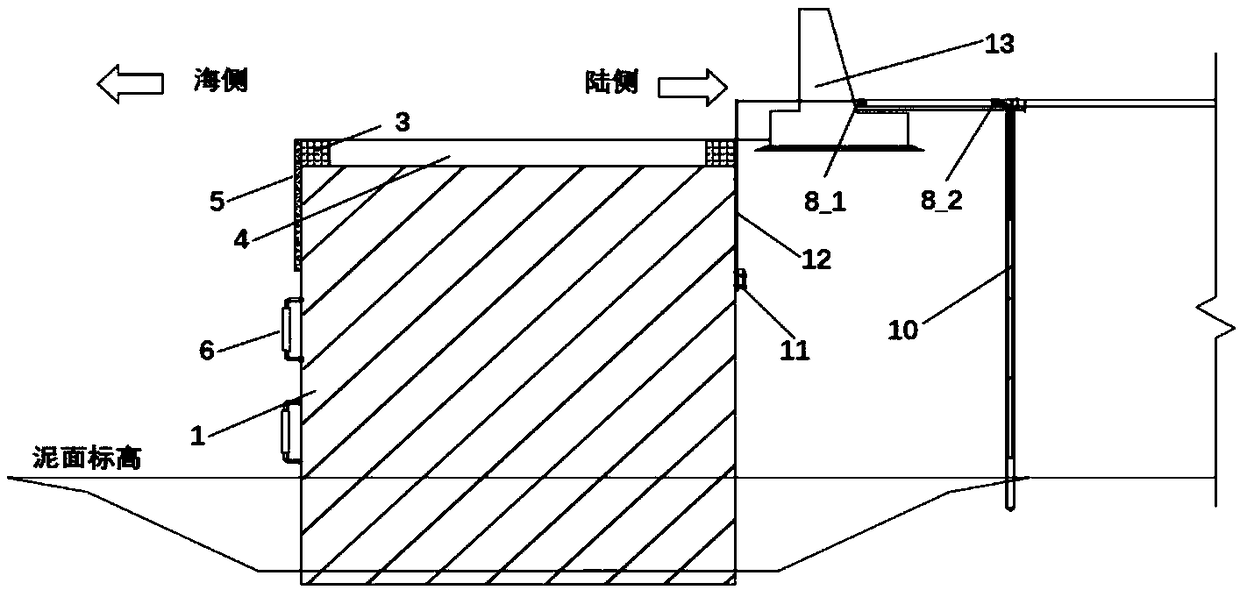

Construction method of multiple anti-corrosion protection for steel cylinder revetment structure in Haizhong

ActiveCN107119650BPlay a long-term anti-corrosion effectDesign Requirements for Achieving a 100-year Construction LifeArtificial islandsUnderwater structuresSoil scienceEngineering

The invention discloses a construction method for multiple anti-corrosion protection of a steel cylinder revetment structure in the sea. The auxiliary grid is connected as a whole at sea; fill each steel cylinder and steel auxiliary grid with medium-coarse sand to a certain distance from the steel cylinder and the upper edge of the steel auxiliary grid; pour capping concrete above the medium-coarse sand, Pouring sulfur mortar; pouring concrete on the coating of the steel cylinder and the outer wall of the steel auxiliary cell on the sea side above the design low water level and below the roof elevation; welding sacrificial anode blocks on the steel cylinder and the outer wall of the steel auxiliary cell on the sea side; The reference electrode, welding cathode welding spot and zero welding spot are respectively installed on the upper part of the steel cylinder on each land side and the outer wall of the steel auxiliary grid, and the lead wires of the reference electrode, zero welding spot and cathode welding spot are connected to the anode Well built-in pre-packaged anode body connections. Adopting the method can effectively play the long-term anticorrosion effect of the steel structure in the sea.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

Anti-corrosion screw vacuum pump

PendingCN114263608AClean up in timeEasy accessRotary piston pumpsRotary piston liquid enginesEngineeringVacuum pump

The invention discloses an anti-corrosion screw vacuum pump, and relates to the technical field of vacuum pumps. The anti-corrosion screw vacuum pump comprises a screw vacuum pump body, the screw vacuum pump body comprises a body pipe, the body pipe is in the shape of a hollow elliptic cylinder with two wide ends and a narrow middle, a low-temperature water-cooling spacer bush is fixedly connected to the front side of the rear end of the body pipe, and the low-temperature water-cooling spacer bush is connected to the rear half portion of the body pipe in a covering mode. A main body device is arranged behind the main body pipe and comprises a main body plate, the main body plate is in threaded connection with a threaded rod connected to the rear side of the main body pipe, a collecting pipe device is arranged in the main body plate and comprises two collecting pipes, and the two collecting pipes are both embedded and fixedly connected into the main body plate; the two ends of the collecting pipe extend out of the main body plate, the collecting pipe is of a tubular structure with the large inner diameter of the front end and the small inner diameter of the rear end, and collecting grooves are evenly formed in the inner side wall of the collecting pipe at equal intervals.

Owner:山东凯恩真空技术有限公司

Novel spiral bevel gear tooth dry cutting method

PendingCN112935737AGuaranteed aestheticsGuaranteed anti-corrosionSolid state diffusion coatingFurnace typesGear grindingGear wheel

The invention relates to the technical field of spiral bevel gears, and discloses a novel spiral bevel gear tooth dry cutting method. The method comprises the following steps of S1, manufacturing of a gear blank; S2, heat treatment of the gear blank; S3, tooth cutting; S4, strengthening of a gear workpiece, specifically, the bevel gear workpiece is subjected to low-temperature nitrocarburizing in the atmosphere containing active nitrogen and carbon atoms, and the active nitrogen and carbon atoms are absorbed by the surface of the workpiece; S5, finish machining of mounting and connecting parts; and S6, gear lapping and phosphating of the workpiece, specifically, gear lapping is conducted on the workpiece, gear grinding is not adopted as a tooth shape machining means, and phosphating treatment is conducted on the workpiece after gear lapping is accomplished. According to the novel spiral bevel gear tooth dry cutting method, the bevel gear workpiece is subjected to low-temperature nitrocarburizing in the atmosphere containing the active nitrogen and carbon atoms, and therefore the hardness, the abrasion resistance, the fatigue strength and the seizure resistance of workpiece steel are improved; and the workpiece is subjected to gear lapping, and therefore the situation that gear lapping can improve the meshing quality and reduce the tooth surface roughness and the meshing noise is guaranteed.

Owner:JIANGSUSNGCHI GROUP

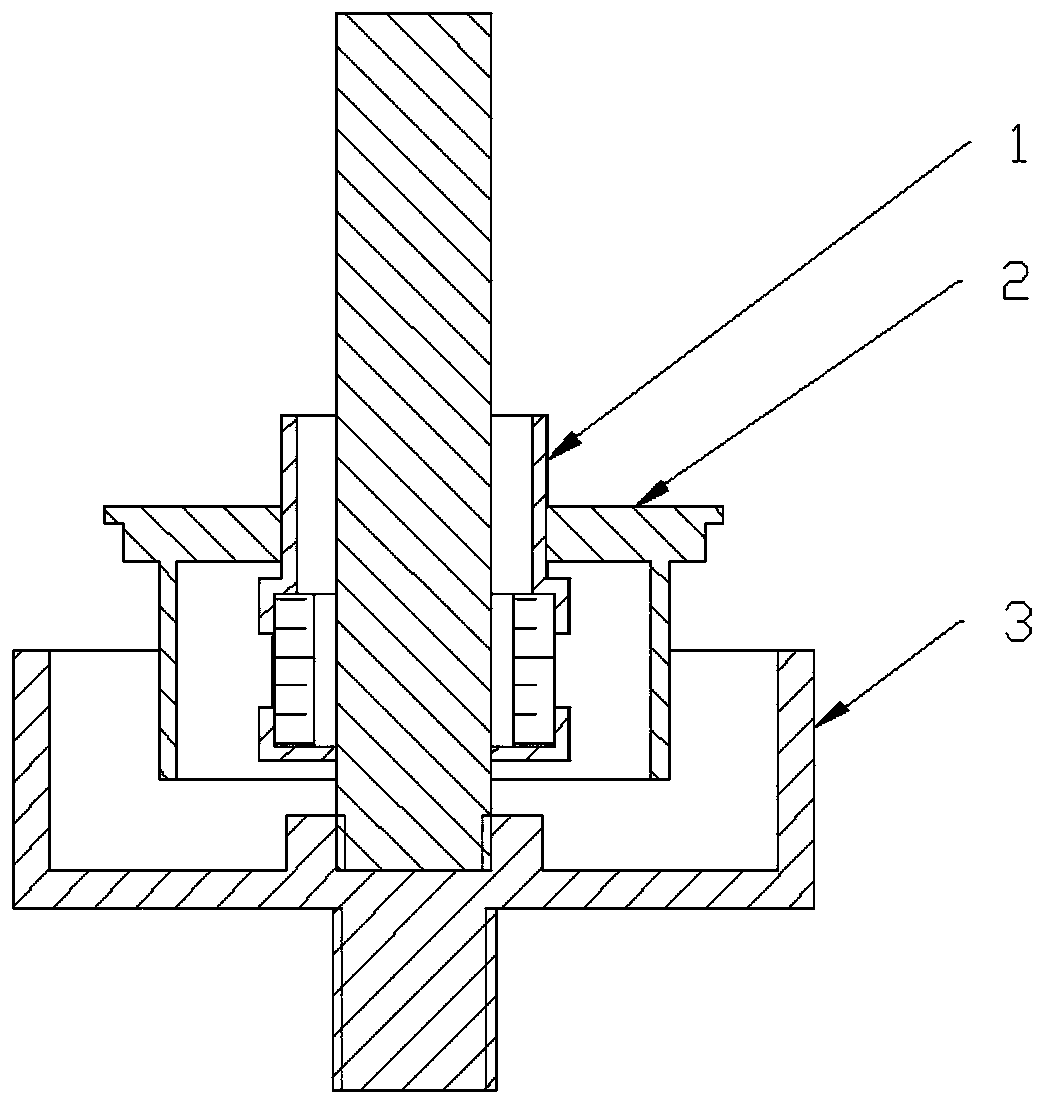

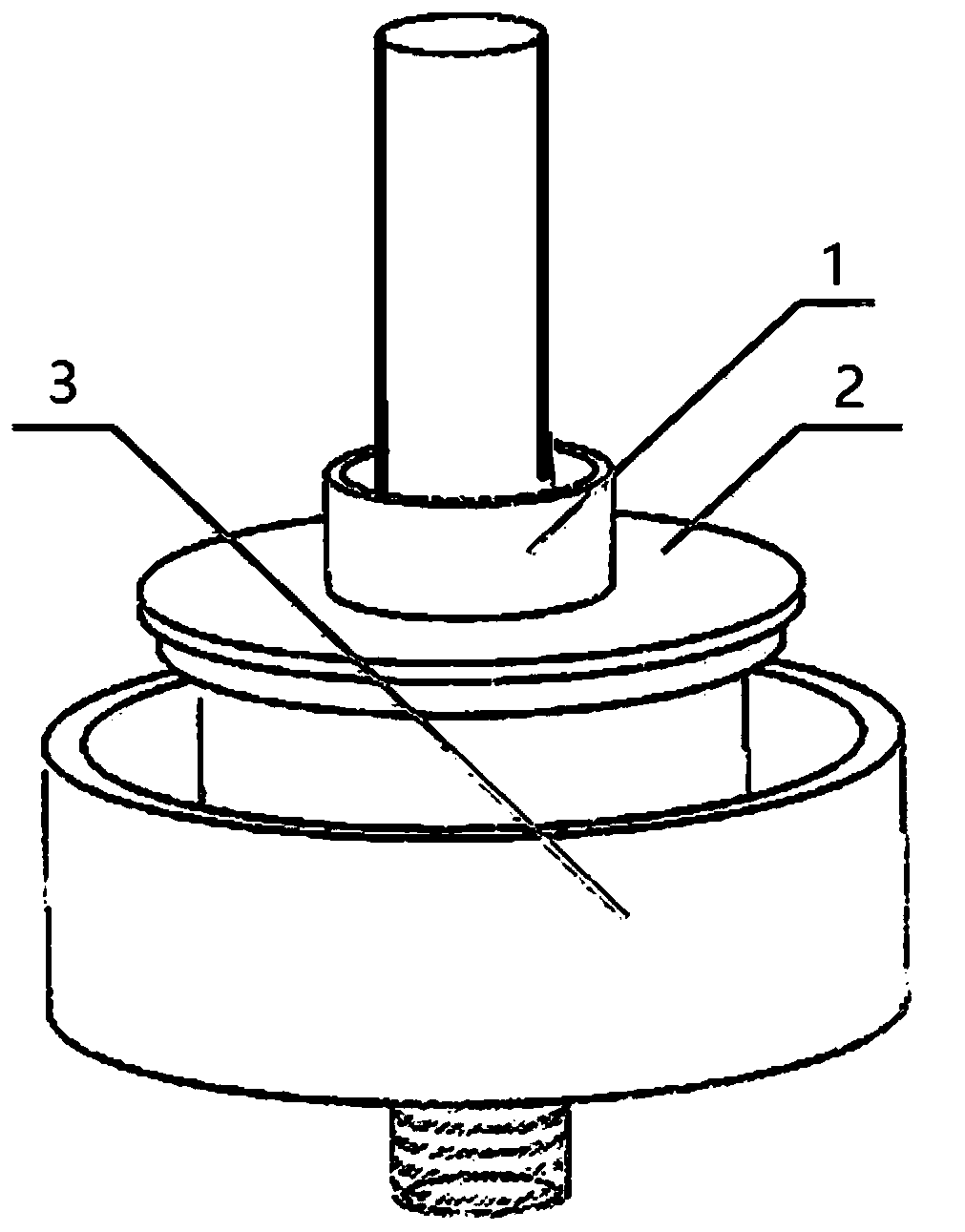

A liquid metal battery anti-corrosion sealing structure and assembly method thereof

ActiveCN107785623BSolve corrosionSolve the sealing problemFinal product manufactureSecondary cellsLiquid stateLiquid metal

Owner:CHINA XD ELECTRIC CO LTD

Airtight box for intermediate head of cable

InactiveCN103825240AShorten the repair periodGuaranteed to dry wellCable junctionsEngineeringMechanical engineering

The invention relates to an airtight box for an intermediate head of a cable. The structure of the airtight box is characterized in that a through hole is formed along the axial direction inside a box body; the through hole is provided with outer edges at the two ends of the box body, and sealing strips are arranged between the outer edges and the cable. The airtight box disclosed by the invention is used for replacing a cable well to protect the intermediate head of the cable, which not only eliminates the cost for building the cable well but also greatly shortens the repair period; the airtight box is convenient to carry, simple to operate, capable of retaining sealing and corrosion resistances and mechanical strength for a long time under the ground, stable in test data and firm in structure, and the materials and manufacturing process satisfy the standards; therefore, the airtight box is worth of popularization and application.

Owner:STATE GRID CORP OF CHINA +1

A production method of a bright stainless steel pot and its special mold

ActiveCN106881432BDeepen the drawing depthGuaranteed anti-corrosionHollow articlesCooking vessel constructionsHearthWork in process

Owner:LINKCO ELECTRICAL LNDUSTRIES LTD

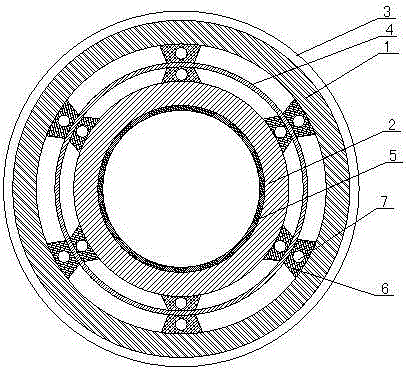

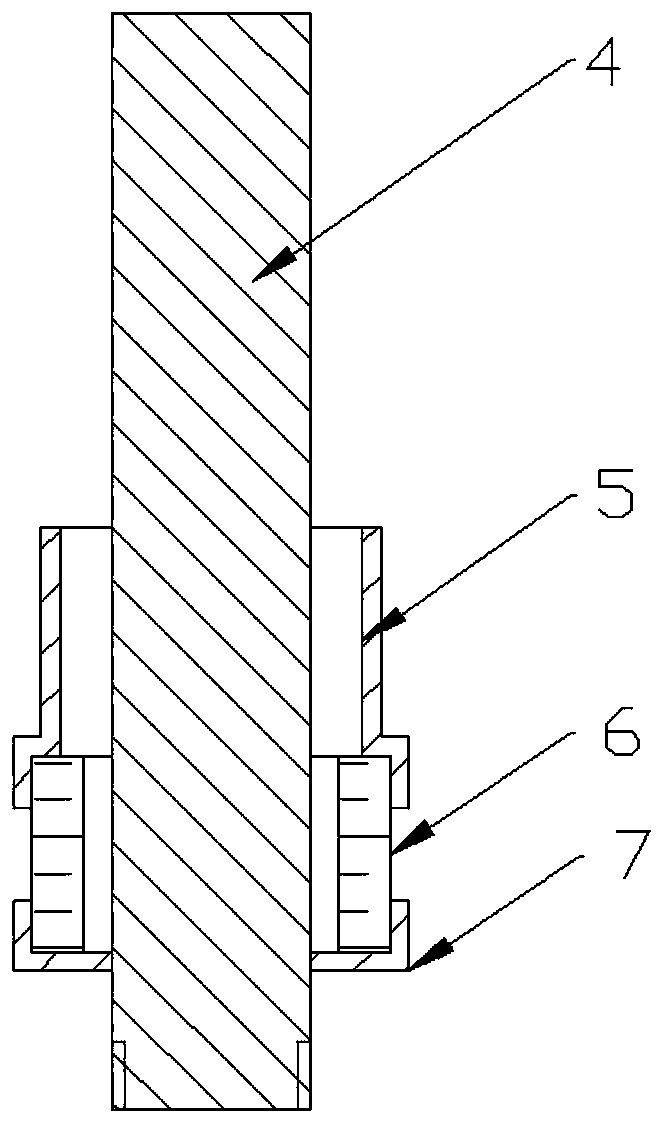

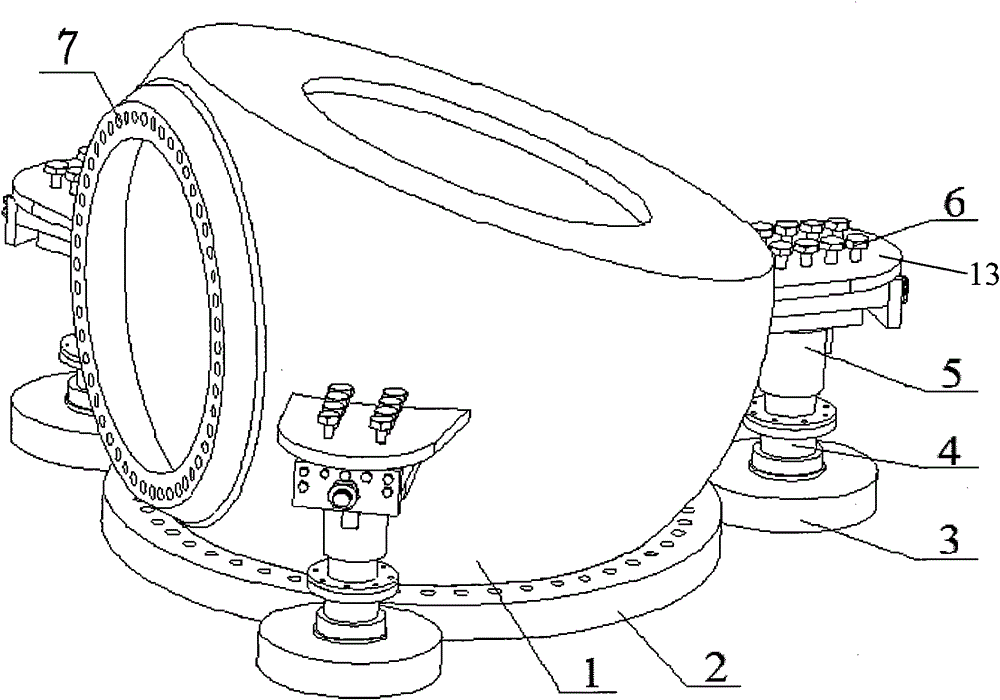

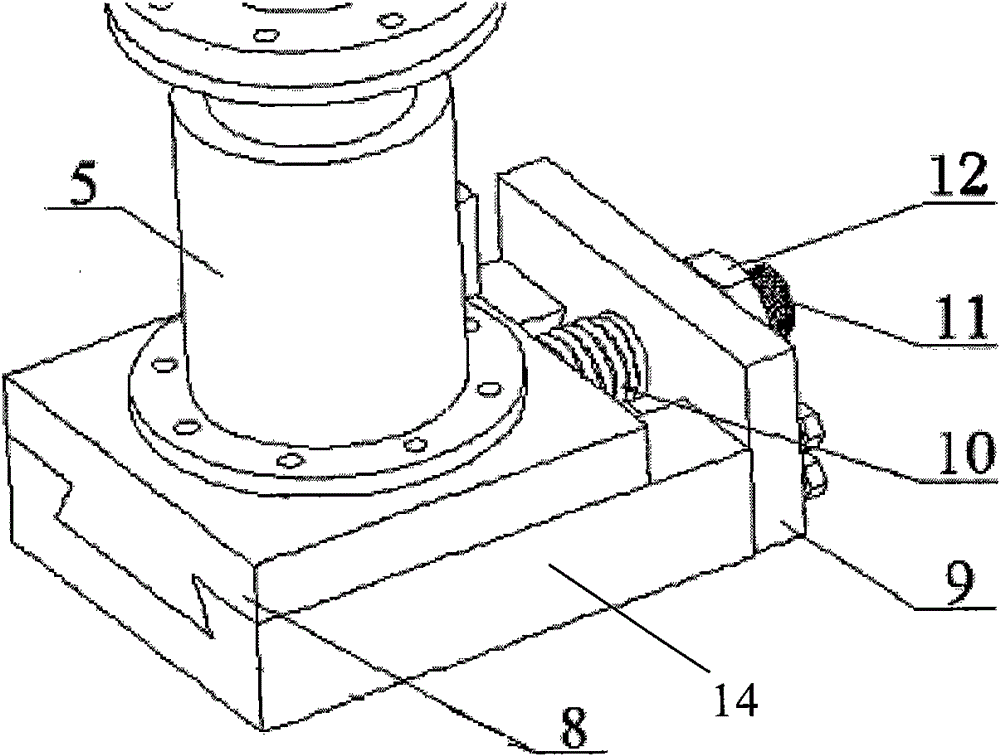

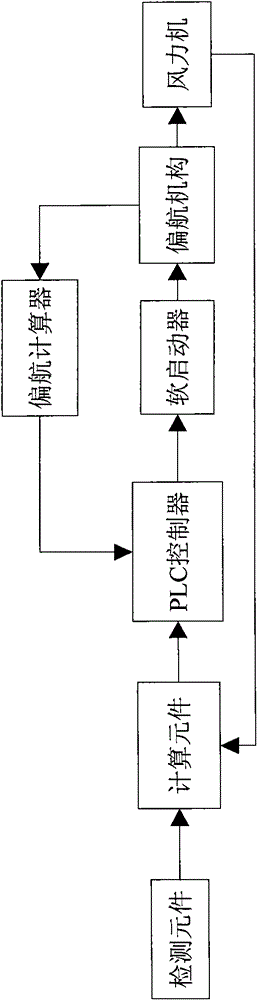

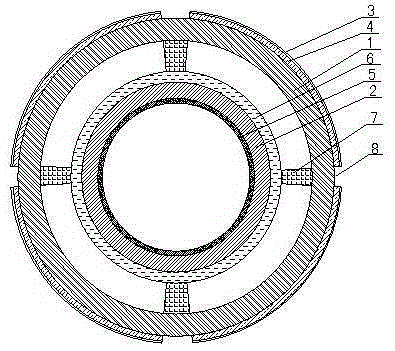

Yawing mechanism for wind driven generator, yawing control system and control method

InactiveCN101963131BStable weightReduce weightWind motor controlMachines/enginesBall bearingReduction drive

The invention relates to a yawing mechanism for a wind driven generator, a yawing control system adopting the yawing mechanism and a control method of the yawing mechanism, wherein the yawing mechanism of the wind driven generator comprises a pedestal and a four-point-contact ball bearing, wherein the pedestal is connected with a generator assembly, and three bulged lateral plates are arranged onthe outer lateral wall of the pedestal; a pretightening-pressure regulating device is fixed below each lateral plate; the other end of a yawing motor is fixed to a speed reducer, and the output shaftof the speed reducer is connected with a friction wheel; and the bottom end surface of the pedestal is fixed to the inner ring of the four-point-contact ball bearing, the outer ring of the four-point-contact ball bearing is connected with the top of a tower frame, and the friction wheel contacts the outer ring of the four-point-contact ball bearing. Compared with the prior art, relative to the common gear driving form of the yawing mechanism, because a friction-wheel driving form is adopted, the invention has the advantages of simple structural shape and convenient processing and has the characteristics of steady working process and small impact.

Owner:张舜德

A thermal insulation pipe for oil transportation

InactiveCN103292066BGuaranteed anti-corrosionExtended service lifeThermal insulationCorrosion preventionArchitectural engineeringAluminum foil

The invention discloses a novel oil delivery insulating pipe comprising an outer pipe and an inner pipe. The inner pipe is disposed in the center of an inner cavity of the outer pipe, while an anticorrosion layer is arranged on the inner surface of the inner pipe and a glass wool insulating layer structure is arranged on the outer surface of the inner pipe. Four cambered outer projections are evenly arranged on the outer wall of the outer pipe, and the outer periphery of each outer protrusion is wrapped with an aluminum foil reflecting layer. The inner pipe and the outer pipe are fixedly connected through stainless steel fastening tapes, and the outer end of each stainless steel fastening tape is fixed on the inner wall of the outer pipe. The novel oil delivery insulating pipe has the advantages that insulating performance and corrosion resistance of the inner pipe can be ensured; the aluminum foil reflecting layer in a projection form is arranged on the outer side of the outer pipe, the service life of the outer pipe can be prolonged, and maintenance cost is reduced greatly.

Owner:WUXI JINDING OIL PIPE FITTINGS

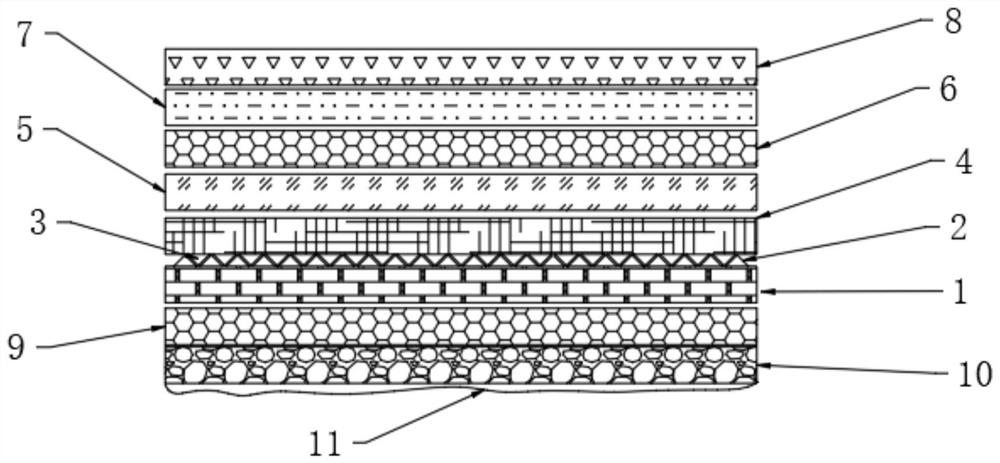

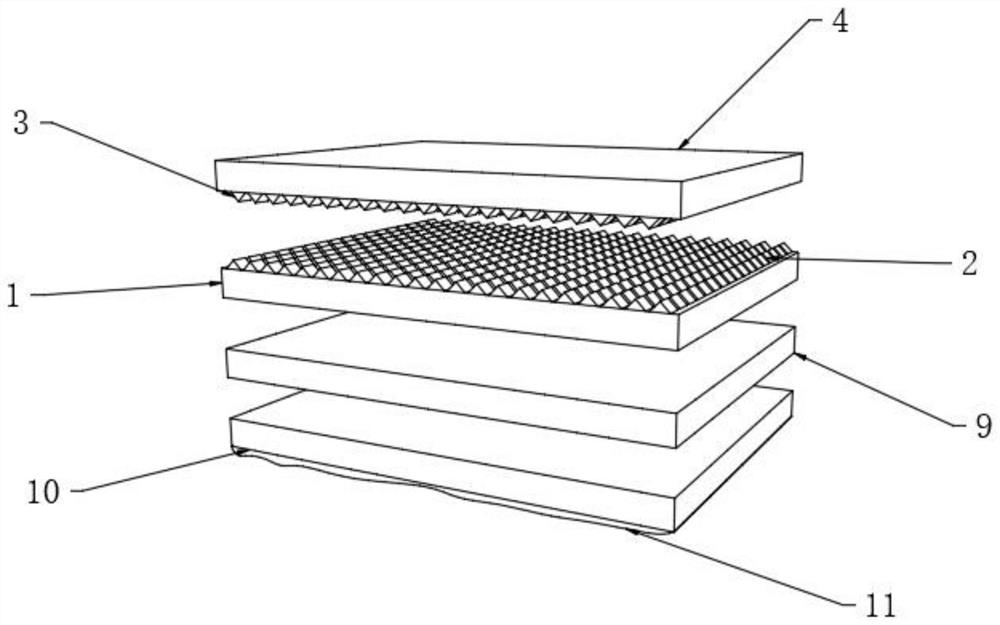

Underwater anticorrosion adhesive tape for maritime work

PendingCN114716936AAvoid scratches and damageIncrease contact areaFilm/foil adhesivesClimate change adaptationGlass fiberSilicone tape

The invention provides a maritime work underwater anti-corrosion adhesive tape, and belongs to the technical field of adhesive tapes, the maritime work underwater anti-corrosion adhesive tape comprises a polyethylene base material, the upper surface of the polyethylene base material is fixedly connected with a lower adhesion layer, the upper surface of the lower adhesion layer is fixedly connected with an upper adhesion layer, the upper surface of the upper adhesion layer is fixedly connected with glass fiber cloth, and the glass fiber cloth is fixedly connected with the polyethylene base material. The upper surface of the glass fiber cloth is fixedly connected with anti-corrosion primer. According to the maritime work underwater anti-corrosion adhesive tape, through the arrangement of the polyethylene base material, the lower adhesion layer, the upper adhesion layer, the glass fiber cloth, the anti-corrosion primer, the first waterproof layer, the anti-corrosion film and the anti-scraping layer, the polyethylene base material serves as a base material, the contact area between the lower adhesion layer and the upper adhesion layer is increased through the form arrangement of the lower adhesion layer and the upper adhesion layer, and the viscosity is enhanced; the glass fiber cloth reinforces the supporting performance of the adhesive tape and helps to resist corrosion, the anticorrosive primer helps to resist corrosion and helps to determine the color of the adhesive tape, the first waterproof layer is waterproof, the anticorrosive film helps to resist corrosion of the surface layer, and the scratch-resistant layer prevents the outer surface of the adhesive tape from being scratched and damaged.

Owner:济宁迅大管道防腐材料有限公司

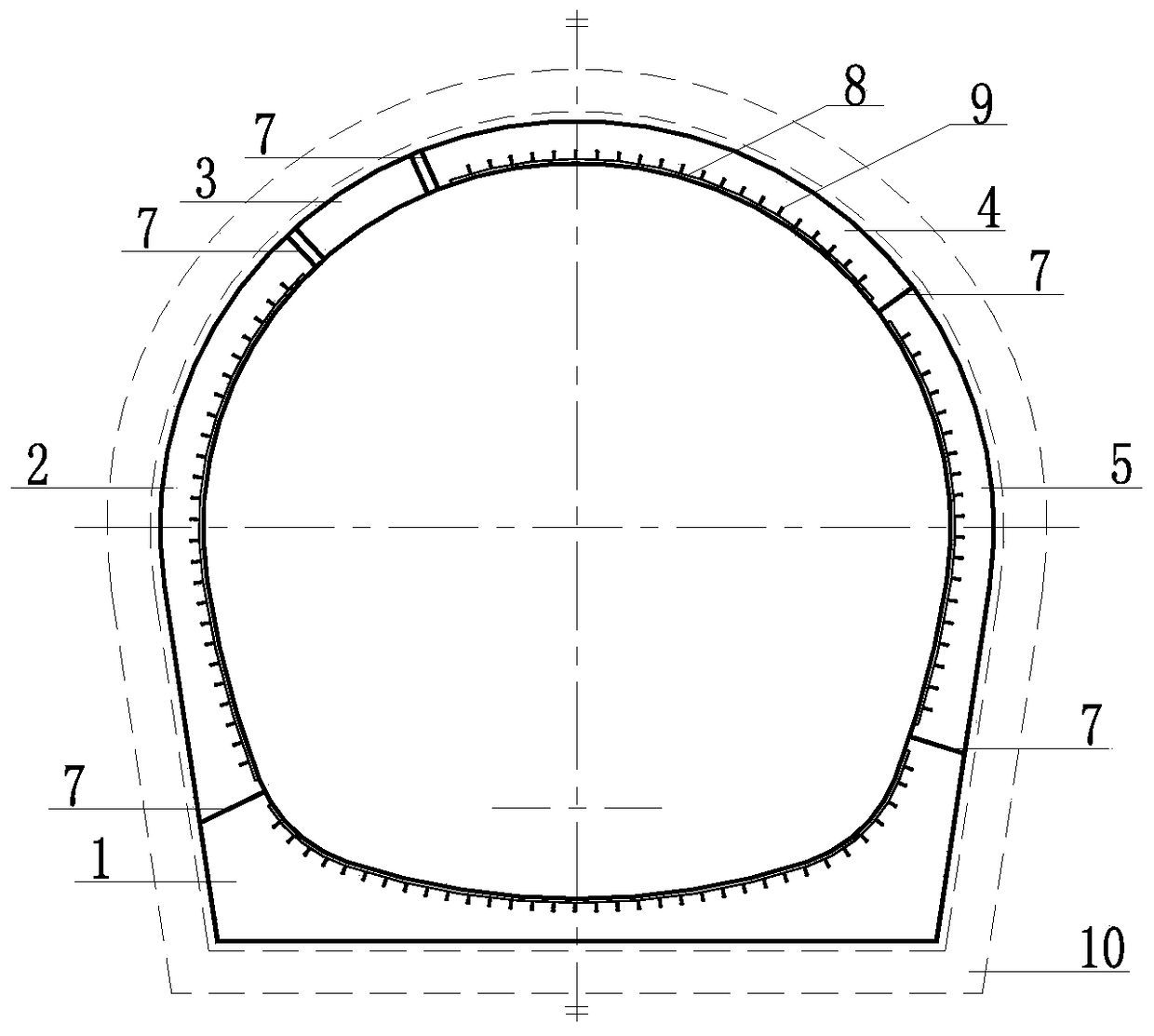

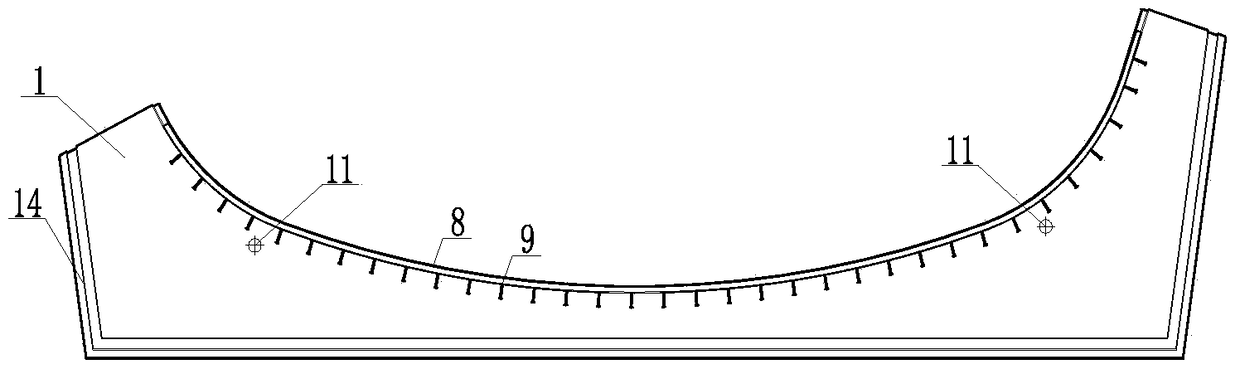

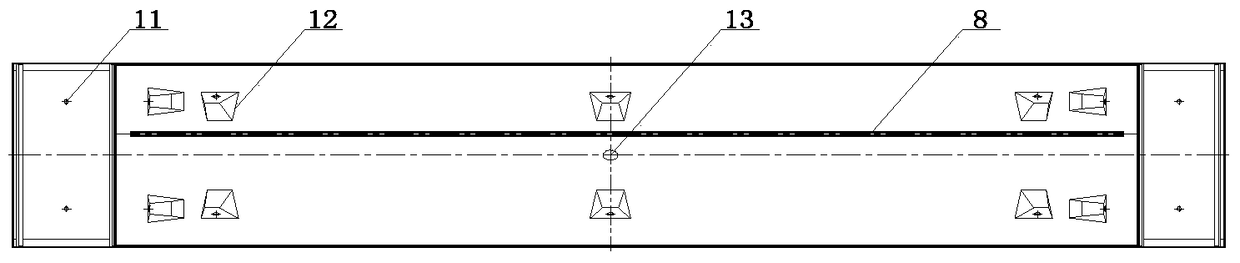

A prefabricated secondary lining structure for underground excavation tunnel and its construction method

ActiveCN105484765BRealize green constructionReduce occupancyUnderground chambersTunnel liningUnderground tunnelMechanization

The invention discloses a fabricated secondary lining structure of a bored tunnel and a construction method of the fabricated secondary lining structure. The fabricated secondary lining structure of the bored tunnel comprises a plurality of circles of splicing structures sequentially arranged in the extending direction of the tunnel. Each circle of splicing structure comprises a plurality of splicing blocks. The adjacent splicing blocks in the same circle of splicing structure are connected through a plurality of connecting devices arranged on the edges of the splicing blocks in the circumferential direction. The adjacent splicing blocks in the different circles of splicing structures are connected through connecting devices arranged on the edges of the splicing blocks in the extending direction of the tunnel. According to the fabricated secondary lining structure of the bored tunnel and the construction method of the fabricated secondary lining structure, working conditions can be improved, labor can be saved, and a large number of temporary materials can be saved. Standardization, mechanization and industrialization of the secondary structure of the bored tunnel are achieved, and the construction efficiency and industrialization level of the secondary lining structure are improved.

Owner:BEIJING RAIL & TRANSIT DESIGN & RES INST

Composite anti-corrosion structure

InactiveCN104626667AAvoid corrosion quality defectsGuaranteed anti-corrosionSynthetic resin layered productsGlass/slag layered productsGlass fiberInsulation layer

The invention discloses a composite anti-corrosion structure comprising a board brick masonry layer, an anti-corrosive insulation layer, an adhesion layer and an equipment substrate. The composite anti-corrosion structure disclosed by the invention is particularly suitable for connecting the anti-corrosive insulation layer (rubber or glass fiber reinforced plastics) with the equipment substrate, the anti-corrosive insulation layer (the rubber or the glass fiber reinforced plastics) and the equipment substrate are adhered with the maximum intensity by virtue of a resin rubber paste to form a whole, and a quasi-viscous and non-viscous mode is formed. The composite anti-corrosion structure disclosed by the invention is taken as an independent corrosion-resistant structure layer to ensure that the anti-corrosion quality defects caused by heat expansion and cold contraction of different materials can be avoided, and the effects of anti-leakage, anti-corrosion and corrosion resistance of the composite anti-corrosion structure can be ensured.

Owner:李向才

Corn fresh-keeping equipment and processing method thereof

ActiveCN114600956AEnsure packing conditionExcessive dosageSeed preservation by irradiation/electric treatmentCleaning using toolsAgricultural scienceAntioxidant

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com