Underwater anticorrosion adhesive tape for maritime work

A kind of adhesive tape and marine engineering technology, applied in adhesives, thin material processing, climate change adaptation, etc., can solve the problems that the anti-corrosion function of the product cannot be realized, the tape structure is simple, etc., to ensure anti-corrosion, improve work efficiency, and enhance viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

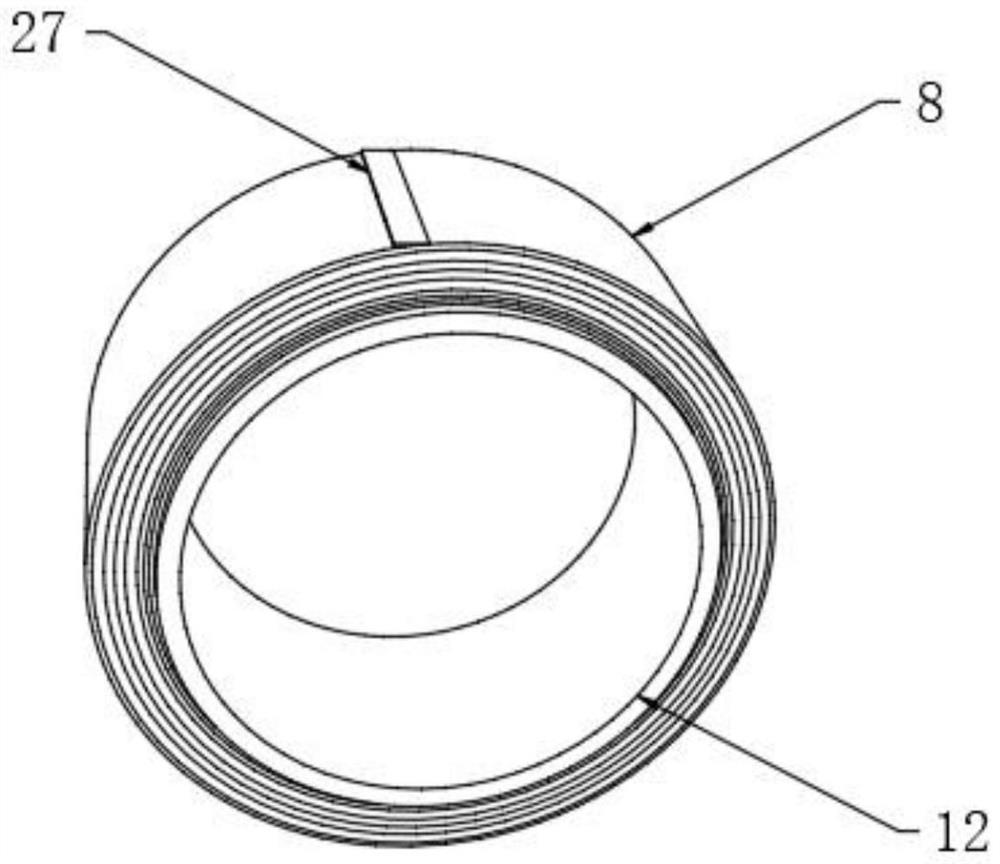

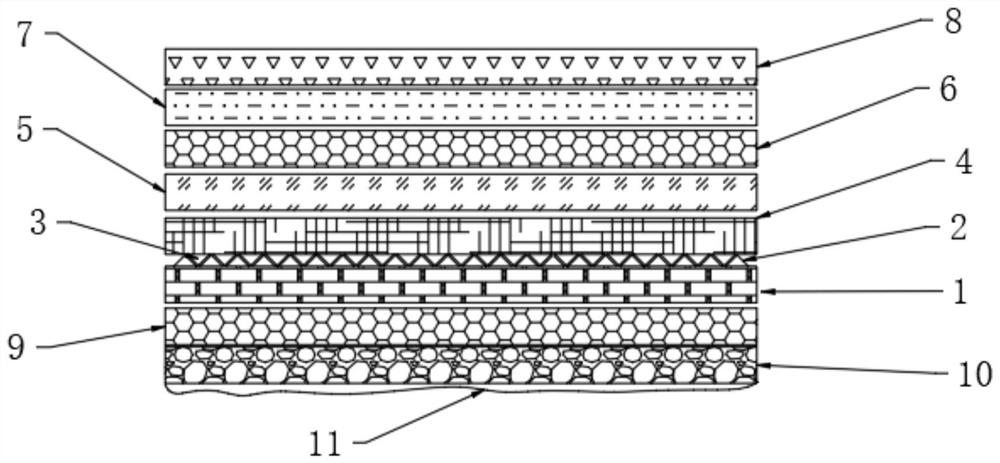

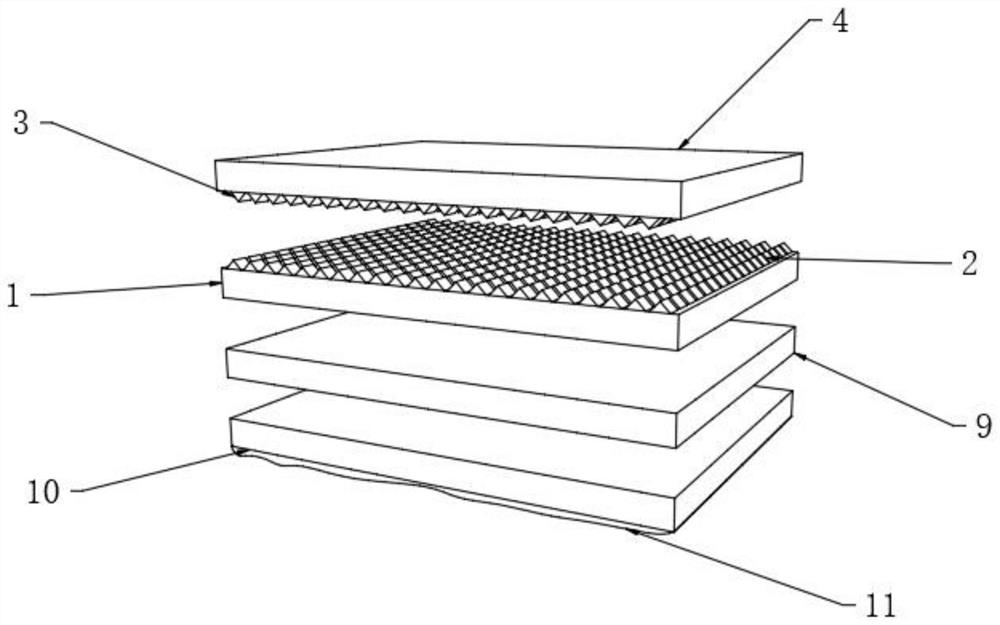

[0028] see Figure 1-6 , the present invention provides the following technical solutions: marine underwater anti-corrosion tape, including polyethylene base material 1, the upper surface of the polyethylene base material 1 is fixedly connected with a lower adhesion layer 2, and the upper surface of the lower adhesion layer 2 is fixedly connected with an upper adhesion layer Layer 3, the upper surface of the upper adhesion layer 3 is fixedly connected with a glass fiber cloth 4, the upper surface of the glass fiber cloth 4 is fixedly connected with an anti-corrosion primer 5, and the upper surface of the anti-corrosion primer 5 is fixedly connected with a first waterproof layer 6. An anti-corrosion film 7 is fixedly connected to the upper surface of a waterproof layer 6 , and an anti-scratch layer 8 is fixedly connected to the upper surface of the anti-corrosion film 7 .

[0029] In the specific embodiment of the present invention, the polyethylene substrate 1 is used as the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com